Page 1

[ Care and Use ManUal ]

gUaRD-pak hOlDeR aND INseRTs

I. INTRODUCTION

The Waters Guard-Pak™ protects your HPLC column from particulate and

chemical contamination in the mobile phase stream. The Waters Guard-Pak

assembly consists of a holder and a disposable insert.

CONTeNTs

I. INT RODUCTION

a. Sorbents

b. Precautions

II. INsTallINg The gUaRD-pak

a. Conditioning the Insert

b. Assembling the Guard-Pak

c. Installing the Assembled Guard-Pak

III. ReplaCINg The INseRT

Iv. speCIfICaTIONs

v. ORDeRINg INfORmaTION

vI. WaRRaNTy/seRvICe INfORmaTION

Guard-Pak Holder and Inserts

Guard-Pak Holder and Inserts 1

Page 2

[ Care and Use ManUal ]

a. Sorbents

The sorbents used in Guard-Pak inserts are identical to the sorbents used in

Waters HPLC columns and cartridges. Select an insert with the same sorbent

as your column or cartridges. Use the Nova-Pak® Silica insert when using a

μPorasil™ column or cartridge.

a. Precautions

When using a Guard-Pak insert with high performance/low volume columns,

some loss of efficiency may result. When using the Guard-Pak holder and

insert, observe the same precautions that you follow with an analytical column. To prevent precipitation inside the insert, use only miscible eluents in

series.

II. INsTallINg The gUaRD-pak

To install the Guard-Pak on your HPLC system:

• If necessary, condition the insert

• Assemble the Guard-Pak

• Install the assembled Guard-Pak holder

a. Conditioning the Insert

1. Use 0.009-inch (0.23 mm) i.d. tubing to connect the Guard-Pak

assembly to your system. Use the fittings included in the kit to

make the extra connections.

2. Connect the Guard-Pak inlet to the injector and the outlet unit to

the column or cartridge.

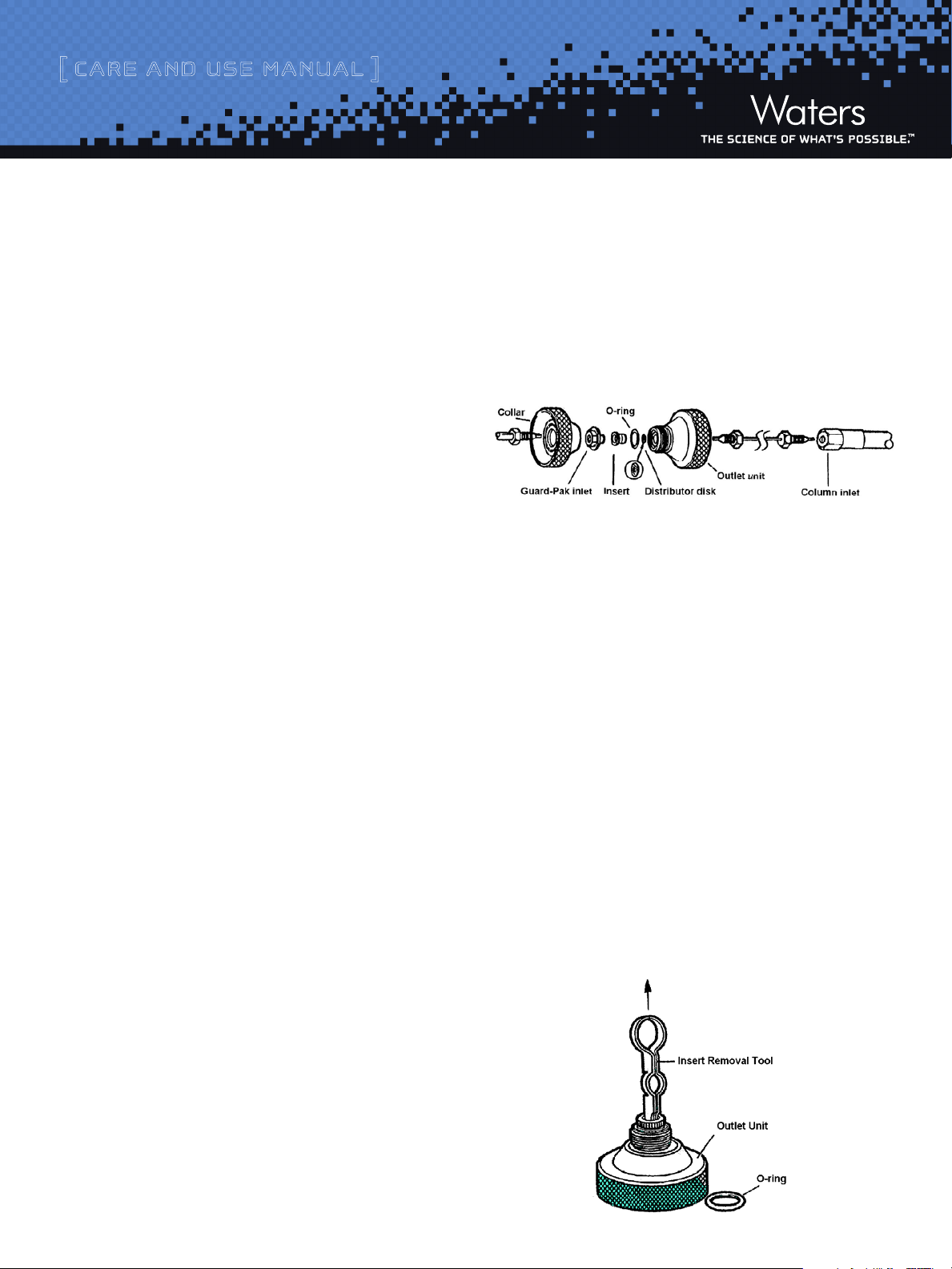

Figure 1: System with Guard-Pak Holder and Insert (Exploded View)

Keep the tubing between the holder and the column as short as possible.

Ensure that the tubing is seated in the bottom of the fitting before tightening

the compression screw.

III. ReplaCINg The INseRT

Replace Guard-Pak inserts before contaminants appear in the chromatogram.

For best results, replace the insert:

Before use, condition dry-packed inserts (Nova-Pak®, Resolve™, μBondapak®,

and Delta-Pak™). Polymer-based Guard-Pak inserts are shipped wet and does

not require conditioning.

Remove and discard the polyethylene foam shipping plug.

To condition the insert, either:

• Soak the insert for 2 minutes in 5 mL of the organic component of

the mobile phase.

• Assemble the Guard-Pak. Run 5 mL of the organic component of the

mobile phase through the assembled Guard-Pak and out to waste.

b. Assembling the Guard-Pak

Place the Guard-Pak insert on the outlet unit and place the Guard-Pak holder

inlet and collar on top. Hand-tighten only.

c. Installing the Assembled Guard-Pak

This procedure requires a 5/16-inch wrench. To install:

Ensure that the spiral-cut distributor disk in the outlet unit was not dislodged

during shipping.

• After completion of a set of analyses

• After running 50 to 100 samples

• When the initial backpressure increases significantly

Procedure:

To replace the Guard-Pak insert:

1. Unscrew the inlet unit from the outlet unit. Hold the outlet unit to

prevent the injector tubing from twisting.

2. Use the insert removal tool to remove the old insert.

Figure 2: Using the Insert Removal Tool

Guard-Pak Holder and Inserts 2

Page 3

[ Care and Use ManUal ]

Be careful not to damage the O-ring or metal seat. Insert the tool into

the cavity of the insert only; do not pry from between the insert and

metal flange of the outlet unit.

3. Condition the new insert, if necessary.

4. Install the new Guard-Pak insert on the insert mount. Inspect the

O-ring when you replace the insert.

5. Reassemble the holder. Hand-tighten only. Check the assembled

holder for leaks while it is under pressure.

Iv. speCIfICaTIONs

Table 1 shows the specifications for a Waters Guard-Pak assembly.

Table 1: Waters Guard-Pak Specifications

Adsorption 1 mg to 10 mg, depending on contaminants

Pressure Limit 40 Mpa (400 Atm, 6000 psi)

Amount of Packing 50-100 mg, depending on the density of the

packing material

Dead Volume 60 μL to 75 μL

Table 2 lists shipping solvents for Guard-Pak inserts packed with

polymer-based sorbents. Flush the assembled Guard-Pak with a

miscible solvent before use.

Table 2: Shipping Solvents for Polymer-Based Inserts

Sorbent Shipping Solvent

Fast Fruit Juice 10% Methanol/Water

IC-Pak™ Ion-Exclusion 10% Methanol/Water

FAM-Pak

Sugar-Pak™ II 0.1% calcium acetate

IC-Pak Anion Borate buffer with 60% Acetonitrile

Silica-based Guard-Pak inserts are shipped dry and require conditioning

with the organic component of the mobile phase before use.

™

10% Methanol/Water

10% Methanol/Water

v. ORDeRINg INfORmaTION

To order these and other parts and supplies, contact you Waters

Representative.

Table 3: Guard-Pak Inserts and Spare Parts

Guard-Pak Insert Part Number

Nova-Pak C

Delta-Pak C18, 100Å WAT036870

Nova-Pak C

Delta-Pak C18, 300Å WAT036875

Nova-Pak Phenyl WAT020795

Delta-Pak C4, 100Å WAT036860

Nova-Pak Silica WAT020790

Delta-Pak C4, 300Å WAT036865

Nova-Pak CN HP WAT020800

Resolve C

μBondapak C

Resolve C

μBondapak NH

Resolve CN WAT085826

μBondapak Phenyl WAT026745

Resolve Silica WAT085825

μBondapak CN WAT026750

IC-Pak Anion WAT010551

FAM-Pak WAT011818

IC-Pak Ion Exclusion WAT020770

Fast Fruit Juice WAT015207

IC-Pak C M/D WAT044250

Sugar-Pak WAT015209

Puresil

Guard-Pak Holder Kit WAT088141

Guard-Pak In-line Filters, 5/pkg. WAT032472

Guard-Pak O-ring, 1/pkg. WAT072917

Compression screw and Ferrule, 5/pkg. WAT025604

18

8

18

18

8

2

™

Refer to the Waters Chromatography Columns, SPE, Supplies and Waters

Quality Parts Catalog at www.waters.com/chemcat for a complete list of

column accessories and supplies.

WAT015220

WAT035880

WAT085824

WAT088070

WAT026755

WAT026760

WAT044347

Guard-Pak Holder and Inserts 3

Page 4

[ Care and Use ManUal ]

vI. WaRRaNTy/seRvICe INfORmaTION

Waters Corporation warrants its Guard-Pak products in accordance with the

following terms and conditions:

Waters will replace without cost any holder or insert that fails to perform satisfactorily, if notified within 90 days from your receipt. Any column returned

must have a Return Authorization Number granted by Waters Customer

Service Department. Approval is subject to the following exclusions:

• Physical damage to the holder or insert because of misuse or abuse

• Damage to the holder/insert assembly because of use with incom-

patible solvents or use at incorrect temperatures or pressures.

• Failure or decreased performance as a consequence of normal use

Sales Offices:

Austria and European Export

(Central South Eastern Europe,

CIS and Middle East) 431 877 18 07

Australia 2 9933 1777

Belgium 32 2 726 1000

Brazil 55 11 5094 3788

Canada 800 252 4752

China 8621 6495 6999

CIS/Russia +7 495 3367000

Czech Republic 42 02 617 11384

Denmark 45 46 59 8080

Finland +358 9 5659 6288

France (33) 1 30 48 72 00

Germany 49 6196 400600

Hong Kong 852 29 64 1800

Hungary 36 1 350 5086

India and India Subcontinent

91 80 2 837 1900

Ireland 353 1 448 1500

Italy 39 02 274 211

Japan (81) 3 3471 7191

Korea (82) 2 820 2700

Mexico 5255 5200 1860

The Netherlands +31 (0)76-50 87 200

Norway 47 63 84 60 50

Poland (48) 22 833 4400

Puerto Rico 787 747 8445

Singapore 65 6273 1221

Spain 34 93 600 93 00

Sweden 46 8 555 11500

Switzerland 41 62 889 2030

Taiwan 886 2 2543 1898

©2007 Waters Corporation. Waters, Nova-Pak, Delta-Pak,

FAM-Pak, Guard-Pak, IC-Pak, μBondapak, μPorasil, Resolve,

Sugar-Pak, and The Science of What’s Possible are trademarks of

Waters Corporation.

August 2007 WAT080048 Rev 11 EY-PDF

Guard-Pak Holder and Inserts 4

United Kingdom 44 208 238 6100

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...