Page 1

[ CARE AND USE MANUAL ]

Enzymate BEH Pepsin Column

CONTENTS

I. INTRODUCTION

II. HOW WATERS HDX TECHNOLOGY WORKS

III. GETTING STARTED

a. Column Connection

b. Column Installation and Equilibration

c. Digesting/Trapping Flow Rate

d. Quenc hing

e. Protein Injection

f. Trapping Time

g. pH and Solvent Compatibility

h. Temperature

i. Column Washing/Cleaning

j. Column Storage

IV. CHECKING FOR ENZYMATIC ACTIVITY

V. REFERENCES

I. INTRODUCTION

Thank you for choosing the Waters Enzymate™ BEH Pepsin Column.

Pepsin is immobilized onto rugged 5 μm BEH (Ethylene Bridged

Hybrid) particles which are packed into low dispersion 2.1 x 30 mm

stainless steel column hardware containing 0.5 μm porosity inlet

and outlet frits. This is the same column hardware used in our

eX tended P erformance [XP] Column line. This online, flow-through

digestion column reproducibly digests intact proteins into peptides

after incubating with H2O/D2O during HDX experiments. Benefits

of online protein digestion include reduced sample preparation

time, reproducible digests, minimized back-exchange, and limited

enzyme in solution.

The Enzymate BEH Pepsin Column is housed in a temperature-

controlled compartment to ensure optimal performance and

reproducibility. Once the peptic peptides elute from the pepsin

column, they are focused on a trap column. The peptides are then

separated at 0 ˚C on an ACQUITY UPLC® BEH C18 Column and

detected by high resolution mass spectrometry.

The Enzymate BEH Pepsin Column was designed and tested

specifically for use on the ACQUITY UPLC M-Class System with

HDX Technology and the nanoACQUITY UPLC® System with HDX

Technology. Waters cannot support the use of the Enzymate BEH

Pepsin Column on any other LC system.

Page 2

[ CARE AND USE MANUAL ]

2

Protein in HO, pH 7.0, 20 °C

Protein Labeling

Labeling Quenched

Enzymate BEH Pepsin Column

UPLC Separation

Add excess D2O

Reduce pH to 2.5

ESI MS Analysis

Global analysisLocal analysis

Maintained at

10–20 ˚C

HDX Manager

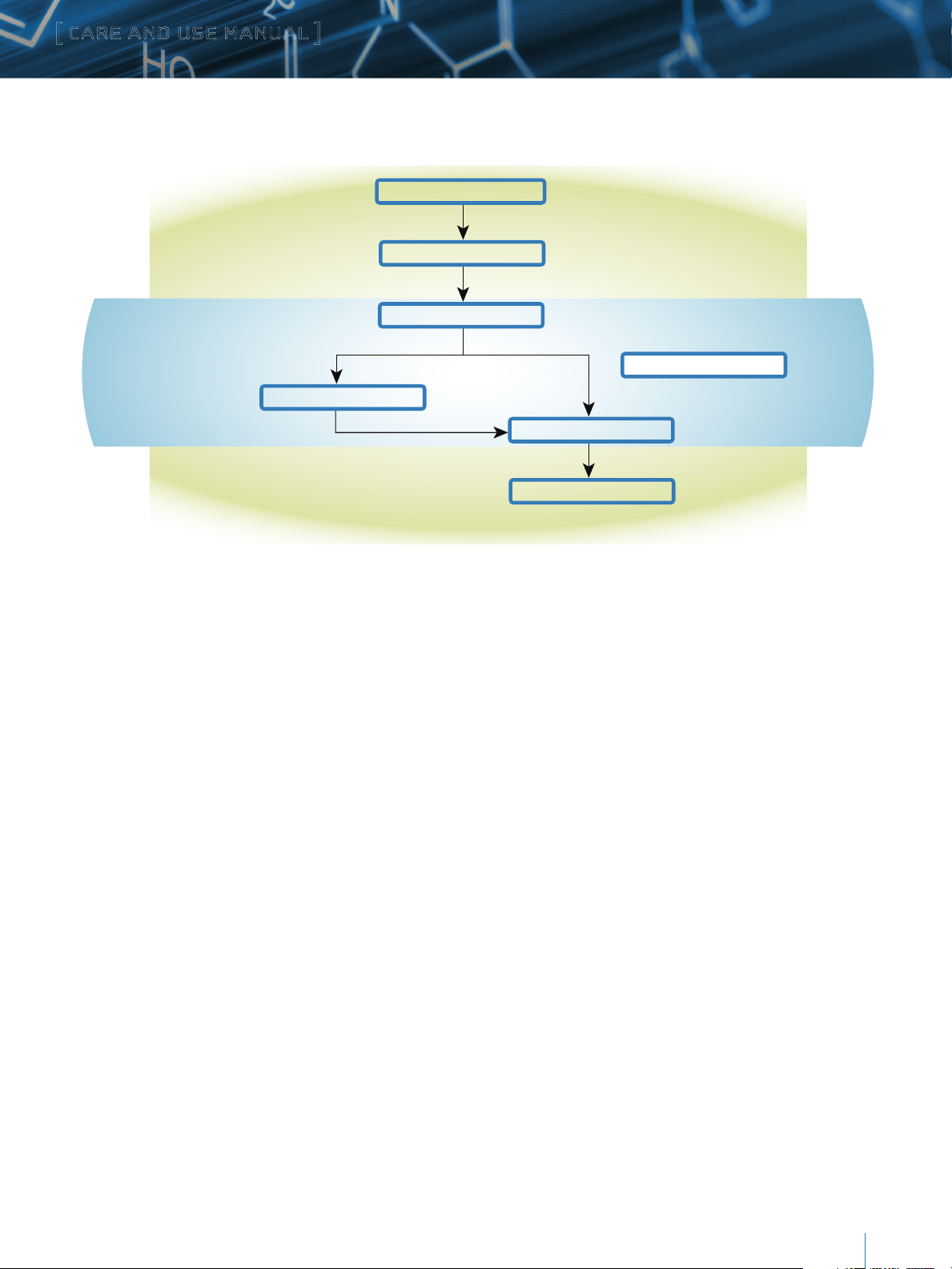

II. HOW WATERS HDX TECHNOLOGY WORKS

Figure 1. How Hydrogen Deuterium Exchange (HDX) works in the ACQUITY UPLC M-Class System with HDX Technology.

Waters offers a complete HDX MS system for protein higher-order

structure analysis, such as protein conformational dynamics,

protein-drug binding, protein-protein interactions including

6. The peptides are then trapped on a VanGuard™ Pre-Column.

7. The trapped peptides are then eluted from the trap column,

and separated on an ACQUITY UPLC Column at 0 °C.

epitope mapping, and protein aggregation. This integrated system

includes automated sample preparation with a LEAP system,

on-line pepsin digestion using the Enzymate BEH Pepsin Column,

III. GETTING STARTED

UPLC, and QTof MS instrumentations for peptide separation

and characterization with automated data processing and

interpretation by DynamX.

a. Column Connection

The Enzymate BEH Pepsin Column uses eXtended Performance

[XP] or ACQUITY UPLC Column-style hardware. Therefore, the

ACQUIT Y UPLC M-Class with HDX Technology workflow:

1. Deuterium oxide (D2O) is added to the protein sample which is

solubilized in a physiological buffer (e.g., 100 mM phosphate

buffer, pH 7.0).

2. The exchange reaction proceeds until a defined end point or

multiple time points for rate determinations.

3. The exchange reaction is stopped by reducing the pH to 2.5

and decreasing the temperature to 0 °C.

4. Sample is injected into the injection port of the HDX Manager

which is maintained at 0 °C.

internal geometry of the Enzymate BEH Pepsin Column end nuts

is the same as eX tended Performance [XP] or ACQUITY UPLC

Columns. This geometry is very similar to “Parker-style” depths

which is the LC industry standard. It is important, however, to

reset the fitting every time a new Enzymate BEH Pepsin Column is

installed to ensure no voids or leaks occur.

Use 1/16” PEEK tubing (0.005” internal diameter) for the

Enzymate BEH Pepsin Column inlet and outlet tubing, hand cut

to the appropriate lengths (e.g., part number WAT022995).

Alternatively, 1/16” steel tubing of similar dimensions and

lengths may also be used.

5. Proteins are digested into peptides on the Enzymate BEH

Pepsin column maintained at 10–20 °C.

Enzymate BEH Pepsin Column

2

Page 3

[ CARE AND USE MANUAL ]

W

W

b. Column Installation and Equilibration

Install the Enzymate BEH Pepsin Column in the temperature controlled compartment located on the left side of the HDX Manager

(maintained between 10 and 20 °C). Connect it between port 6 of the Injection Valve and port 3 of the Trap Valve as indicated in Figures 2a

and 2b.

Trap ValveInjection Valve

Sample

aste

2

3

4

1

6

5

Enzymate BEH

Pepsin Column

Waste

Auxiliary Solvent

Manager (ASM)

Figure 2a. Protein digestion in trapping mode (sample already injected and is in loop).

Sample

2

3

1

6

Enzymate BEH

Pepsin Column

Waste

3

4

Binary Solvent

Manager (BSM)

Trap ValveInjection Valve

3

Trap

Trap

12

ACQUITY UPLC® Column

6

5

12

To MS

ACQUITY UPLC® Column

6

To MS

aste

4

5

Auxiliary Solvent

Manager (ASM)

Figure 2b. After proteins are digested on the Enzymate BEH Pepsin Column, the valve is switched and the peptic peptides are separated using reversed-phase UPLC.

The trap column used is a VanGuard 2.1 x 5 mm Pre-Column containing 1.7 μm ACQUITY UPLC BEH C

reversed-phase separation occurs on an ACQUITY UPLC Column containing 1.7 μm ACQUITY UPLC BEH C

or 1.0 x 50 mm, part number 1860 02344).

4

5

Binary Solvent

Manager (BSM)

packing material (part number 186003975). The analytical

18

packing material (1.0 x 100 mm, part number 1860 02346

18

1. Set the temperature of the Enzymate BEH Pepsin Column to between 10–20 °C. Higher temperatures aid digestion and lower

temperatures minimize back-exchange.

2. Equilibrate the Enzymate BEH Pepsin Column using 0.1% formic acid in water, pH 2.5 for at least twenty minutes (20 column volumes) at

a flow rate of 100 μL/min before performing protein digestions.

Enzymate BEH Pepsin Column

3

Page 4

[ CARE AND USE MANUAL ]

c. Digesting/Trapping Flow Rate

The recommended starting digestion flow rate is at 100 μL/min

using 0.1% formic acid (pH 2.5) in water. Decreasing the digestion

flow rate increases the contact time between the proteins and

the immobilized pepsin enzyme. This can increase digestion

efficiency but will result in longer digestion times. Increasing

the flow rate decreases the contact time between the proteins

and the immobilized pepsin enzyme and can decrease digestion

efficiency.

d. Quenching

A recommended quenching solution is 100 mM potassium

phosphate, pH 2.50 dissolved in water (50 mM K2HPO4 and 50 mM

in KH2PO4 adjusted to exactly pH 2.50 with concentrated HCl).

e. Protein Injection

Typical protein buffers include Tris (tris(hydroxymethyl)

aminomethane), HEPES (4-(2-hydroxyethyl)-1-piperazineethanesulfonic

acid), or PBS (phosphate buffered saline). Between 10 and 50 pmol

of protein can be injected on column.

f. Trapping Time

The digested peptides can be trapped and desalted on the trap

column for several minutes (and for as little as thirty seconds)

depending on the buffer concentration before eluting to the

ACQUITY UPLC Column. Increasing the trapping time by decreasing

the flow rate can increase digestion efficiency but may cause

back-exchange (i.e., deuterium for hydrogen).

g. pH and Solvent Compatibility

The Enzymate BEH Pepsin Column is NOT

compatible with organic solvents, detergents, or

high pH. Therefore, DO NOT expose the Enzymate

BEH Pepsin Column to high concentrations of

organic solvents, detergents, or high pH solvents (pH > 4.5).

The Enzymate BEH Pepsin Column can tolerate a very low

concentration of organic solvent (≤ 5%) which can be injected

during a column cleaning procedure as described in section i.

h. Temperature

The Enzymate BEH Pepsin Column is maintained at a digestion

temperature of between 10–20 °C. Increasing digestion

temperature may increase digestion efficiency but may also

promote back-exchange (i.e., deuterium for hydrogen).

i. Column Washing/Cleaning

Under normal operating conditions, the digestion buffer (0.1%

formic acid in water, pH 2.5) should be sufficient to remove

residual proteins and/or peptides from the Enzymate BEH Pepsin

Column and the trap column, thereby reducing injection-to-

injection carryover. However, if carryover is observed, prepare

a column cleaning solution of 1.5 M guanidine hydrochloride/

acetonitrile/formic acid (95.2/4/0.8). Inject 100 μL of this

cleaning solution and allow it to flow through the Enzymate

BEH Pepsin Column and the trap column. Inject a blank solution

to ensure no injection-to-injection carryover is observed. If

carryover is observed, repeat the cleaning solution injection

protocol until no injection-to-injection carryover is observed,

j. Column Storage

Store the Enzymate BEH Pepsin Column at 4 °C in 0.1% formic

acid in water when not in use. Make certain that the column end

caps are secured tightly in place to ensure that the Enzymate BEH

Pepsin Column does not dry out.

IV. CHECKING FOR ENZYMATIC ACTIVITY

The Enzymate BEH Pepsin Column should be checked periodically

to ensure acceptable enzymatic activity. Waters recommends

checking the enzymatic activity by injecting a standard

protein (e.g., Waters HDX Phosphorylase B Check Standard, PN

1860 06930) onto the Enzymate BEH Pepsin Column, followed

by LC-MS analysis to detect the peptides from the on-column

proteolysis. Acceptable performance criteria for the Enzymate

BEH Pepsin Column activity can be subjective. In general, if the

Phosphorylase B sequence coverage from the LC-MS analysis

is ≥ 75%, the Enzymate BEH Pepsin Column has maintained its

optimum enzymatic activity.

Enzymate BEH Pepsin Column

4

Page 5

[ CARE AND USE MANUAL ]

V. REFERENCES

1. Zhang, Z., and Smith, D. L., Determination of amide hydrogen exchange by mass spectrometry: a new tool for

protein structure elucidation, Protein Science, 1993, 2, 522-531.

2. Wales, T. E., and Engen, J. R., Hydrogen exchange mass spectrometry for the analysis of protein dynamics,

Mass Spectrometry Reviews, 2006, 25, 158-170.

3. Jacob, R.E., and Engen, J.R., Are we out of the quicksand?, American Society of Mass Spectrometry, 2012,

23, 1003 -1010.

To learn more about Hydrogen Deuterium Exchange with Mass Spectrometry,

please visit www.waters.com/HDX

Waters, The Science of W hat’s Possible, ACQUITY U PLC, nanoACQUITY UPLC, and UPLC are registered trademarks of Waters Corporation.

Enzymate and VanGuard are trademarks of Waters Corporation.

©2014 Waters Corporation. Produced in the U.S.A. April 2014 720005019EN KP-P DF

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...