Page 1

[ Care and Use ManUal ]

Waters envirogel gPC CleanuP Column

The Waters GPC Cleanup System uses two Envirogel™ GPC Cleanup

Columns to perform routine cleanup of environmental samples

as specified by EPA Method 3640A, GPC Cleanup. T he columns,

19 x 150 mm and 19 x 300 mm, are connected in series.

A 4.6 x 30 mm Guard Column is available for customers interested in

using a guard column in front of the column set.

The Envirogel columns:

• are packed with high-performance, fully-porous, highly

cross-linked, styrene divinylbenzene copolymer particles.

• contain 100 Å pore size material, with a nominal particle size

of 15 μm.

• are shipped with methylene chloride as the mobile phase.

• the same three columns packed in 50/50 ethyl acetate/

cyclohexane are also available.

Contents

I. Installing the Columns

a. Connecting the Column

b. Equilibrating the Columns

II. Calibrating the Columns

a. Preparing the Calibration Solution

b. Procedure

c. Injecting the Calibration Solution

d. Calculating Peak Resolution

e. Requirements

III. Column Care and Use Guidelines

IV. Column Storage

a. Short-term

b. Long-term

V. Care and Maintenance

VI. Ordering Information

Waters Envirogel GPC Cleanup Column

VII. Warrenty/Service Information

Page 2

[ Care and Use ManUal ]

i. installing tHe Columns

When installing the Waters GPC Cleanup System for the first time,

refer to Chapter 2 “Preparing the System” for instructions on

connecting the fluid lines and purging the system. This section

describes:

• Connecting columns to the system

• Equilibrating the columns

Do not connect the columns to the injector or detector until the GPC

Cleanup System is purged with methylene chloride. Refer to the

Waters GPC Cleanup System Operator’s Guide for more information.

a. Connecting Columns

To connect the columns to the system:

1. Remove the end plugs from the columns and save them for use

when storing the columns.

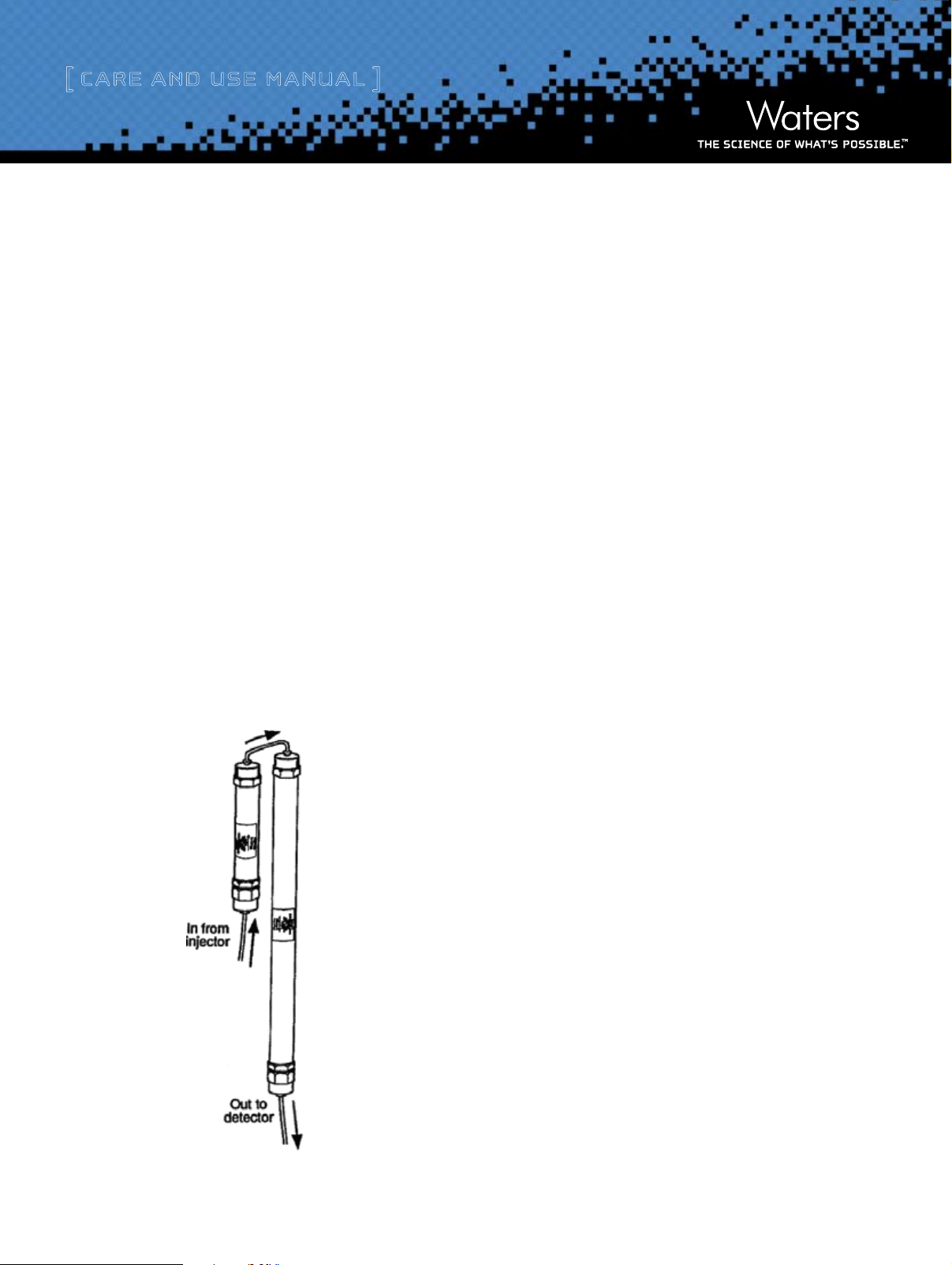

2. Place a ring stand or other column mounting device between the

injector and detector. Mount the columns so that sample flows

through the columns as shown in Figure 1.

3. Connect the tubing from the injector outlet to the column inlet

on the small column. Using a wrench, tighten the connection

1/4 to 1/2 turn beyond hand-tight. Do not over-tighten the

fittings; over-tightening damages the connection.

4. Connect the outlet of the smaller column to the inlet of the

larger column, using the 0.009-inch i.d., U-shaped, and column

joining tube.

5. Connect the column outlet tubing (supplied separately with

the detector) to the outlet of the larger column. Place a waste

collection flask at the outlet tubing from the last column.

6. Set the pump flow rate to 1 mL/min, and collect column effluent

for 1 minute.

7. Increase the flow rate 1 mL/min, and collect column effluent for

1 minute. Repeat until the flow rate is 5 mL/min.

8. Allow solvent to flow at 5 mL/min, until approximately 100 mL

of solvent is collected.

9. Set the pump flow rate to 0.0 mL/min. Allow the system pres

sureto return to 0 psi (approximately 30 seconds).

10. Connect the column outlet tubing to the sample inlet connection

on the detector.

Figure 1. Column Installation.

Waters Envirogel GPC Cleanup Column

b. Equilibrating the Columns

To equilibrate the columns:

1. Resume flow as in steps 6 and 7 above, until the flow rate is

5 mL/min.

2. Adjust the absorbance level to zero on the detector.

3. Monitor the UV absorbance on the detector to ensure that the

column is fully equilibrated. At a flow rate of 5 mL/min, full

column equilibration can take up to 20 minutes.

During this time you should observe no large fluctuations in pump

pressure (as indicated by the pump pressure transducer). Typical

pump pressures are approximately 200 psi at flow rates of 5 mL/min.

2

Page 3

[ Care and Use ManUal ]

4. Continue the flow until a stable absorbance reading is obtained.

The columns are equilibrated when the change in the absorbance

reading is ≤ 0.002 AU from zero after 500 mL of solvent passes

through the column.

5. Read just the absorbance level to zero, if necessary

ii. CaliBrating tHe Columns

The Envirogel GPC Cleanup columns are calibrated using a

calibration solution.

Calibrating the columns involves:

• Preparing the calibration solution

• Injecting the calibration solution

• Calculating peak resolution

If you are using an injector with a 5 mL sample loop, use the calibra-

tion method listed in the EPA method.

If you are using the Waters GPC Cleanup System, use the calibration

method described in this section.

Since the Waters GPC Cleanup System performs 2 mL sample injec-

tions, you must use a calibration solution that is 2.5 times more

concentrated than the calibration solution listed in the EPA method.

A 2 mL injection of the concentrated calibration solution achieves

mass loading equal to a 5 mL injection of the EPA method calibration

solution.

a. Preparing the Calibration Solution

Mix the calibration compounds into low acid methylene chloride (pesticide quality or equivalent). Refer to the Waters GPC Cleanup System

Operator’s Guide, Chapter 2 “Preparing the System” for the procedure

to determine the acid level of methylene chloride.

One liter of calibration solution requires the following quantities of

compounds:

Compound mg/L

Corn oil 62,500

Bis(2-ethylhexyl)phthalate 2,500

Methoxychlor 500

Perylene 50

Sulfur 200

Reduce the quantities for smaller volumes of solution.

b. Procedure

To prepare the calibration solution:

1. Weigh the Corn oil into a beaker. Since the sulfur is more soluble

in warm com oil than methylene chloride, add the sulfur to the

corn oil. Warm the mixture until the sulfur dissolves.

2. Add the remaining compounds listed in the table above to a

volumetric flask.

3. Add the warm corn oil-sulfur mixture to the volumetric flask.

4. Add methylene chloride to bring the volume of solution to one

liter.

5. Store the calibration solution away from light, at 4 ˚C, in an

®

amber bottle with a Teflon

stored up to 6 months. After storage, allow the solution to stand

at room temperature until components redissolve.

A small amount of sulfur may precipitate from the solution when the

methylene chloride is added or after the solution is stored. Remove

this precipitate by filtering the calibration solution through a GHP

®

Acrodisc

0.45 μm filter before injection.

lined screw-cap. The solution can be

Waters Envirogel GPC Cleanup Column

3

Page 4

[ Care and Use ManUal ]

c. Injecting the Calibration Solution

To inject the calibration solution:

1. Filter approximately 10 mL of calibration solution through a GHP

Acrodisc 0.45 μm filter.

2. For 717 autosamplers, fill a WISP sample vial with 3 to 4 mL

of calibration solution, and place the vial in the carriage at

position 1.

3. For manual injectors with 2 mL sample loop, fill a 10 mL syringe

with calibration solution. Inject 2 mL of solution into the sample

loop.

4. Inject the calibration solution by either:

• Pressing the RUN/STOP key on the autosampler, or

• Switching the injector to INJECT

The initial peak for corn oil appears approximately 10 to 12 minutes

after injection. The final peak for sulfur appears approximately

25 minutes after injection. Figure 2 shows a sample calibration

chromatogram.

d. Calculating Peak Resolution

To calculate the resolution between the peaks, measure the

resolution height of the valley between the peaks, and the height of

the smaller peak (Figure 3).

Figure 3. Peak Resolution.

Calculate the resolution by:

%R = 100 (1 - A/B)

Where:

R = resolution in percent

Figure 2. Sample Chromatogram

A = height of the valley

B = height of smaller peak

e. Requirements

EPA Method 3640A requires that:

• All peaks are observed and symmetrical.

• The observed resolution between the following peaks is greater

than 85%:

• Corn oil and phthalate peaks

• Phthalate and methoxychlor peaks

• Methoxychlor and perylene peaks

• The observed resolution between the perylene and sulfur peaks

is greater than 90%.

Waters Envirogel GPC Cleanup Column

4

Page 5

[ Care and Use ManUal ]

Due to variations in detector sensitivities and cell volumes, you

may need to dilute the calibration solution to achieve the specified

resolution.

Refer to the Waters GPC Cleanup System Operator’s Guide,

Chapter 3 “Calibrating the System” for information on setting frac-

tion collection times.

iii. Column Care anD use guiDelines

Gel permeation chromatography columns have a finite lifetime

directly related to their care and use. Column life is reduced

by contamination from samples and eluents, frequent solvent

changeover, and improper handling and storage.

For best results, observe the following guidelines:

• Protect the column from vibration and mechanical shock.

• Do not exceed flow rates of 9 mL/min or pressures greater than

1000 psi.

iv. Column storage

Refer to the Waters GPC Cleanup System Operator’s Guide for

system shutdown and storage procedures.

a. Short-term

During short-term column storage (storage overnight or a weekend),

ensure that columns do not dry out. Leave the system power ON, and

reduce the flow rate to the column to 0.5 mL/min. Divert the detector

output to waste. Recalibrate the system upon startup.

b. Long-term

Follow the long-term shutdown procedure in the Waters GPC

Cleanup System Operator’s Guide. Return the column to its box with

the end plugs firmly in place. Store the column at room temperature.

• Do not use mobile phases which include water, ketones, alkanes,

or alcohols (except hexafluoroisopropanol).

• Protect the column from rapid changes in pressure, which can

result from rapidly changing the flow rate of the solvent. Change

flow rates in increments no more than 11 mL/min each minute.

• Dedicate columns to a specific application. Frequently switching

samples and solvents accelerates column deterioration and loss

of resolution.

• Be sure that columns do not dry out. Replace the end plugs when

storing the columns.

Waters Envirogel GPC Cleanup Column

5

Page 6

[ Care and Use ManUal ]

v. Care anD maintenanCe

General care and maintenance procedures are addressed in the Waters GPC Cleanup System Operator’s Guide. Additional symptoms that you

may observe are listed in Table 1. Recalibrate columns after any cleaning procedure.

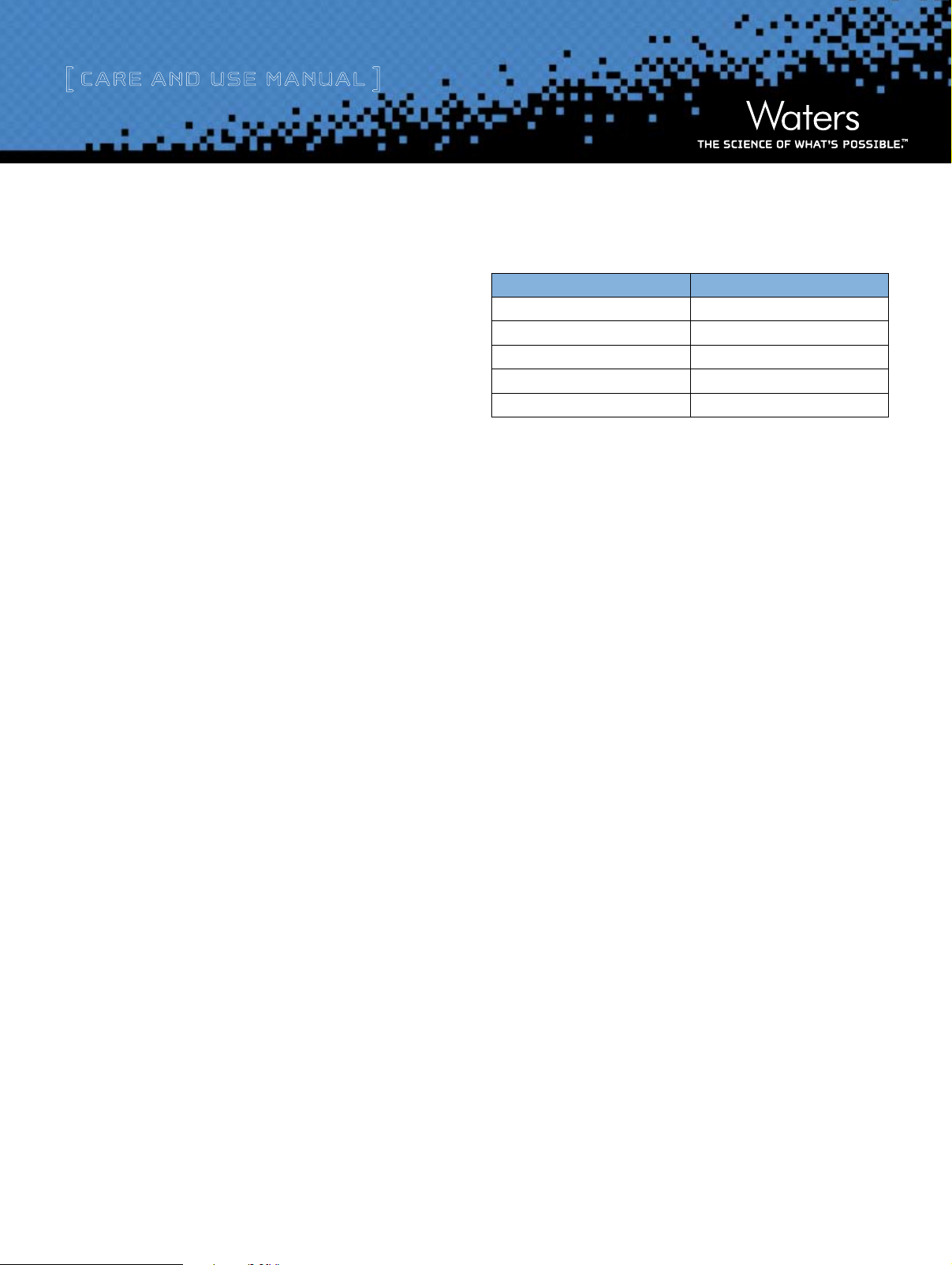

Table 1. Troubleshooting

Problem Possible Cause Corrective Action

High pressure shutdown Clogged fluid path Change all filters in fluid path. Filter all samples and

solvents before use. Replace all tubing.

Flush column at 2 m by reversing direction of flow through

column.

Replace column.

Low operating pressure Leaks Tighten all fluid connections.

Insufficient solvent Refill solvent reservoir.

Air in-line Purge system.

Retention times too long Pump flow rate set too low Check flow setting and verify output.

Leaks Tighten fluid connections.

Wrong columns Verify length and diameter.

Retention times too short Pump flow rate set too fast Check flow rate setting and verify output.

Data collection device improperly connected Ensure data collection starts at inject signal.

Wrong columns Verify length and diameter.

No peaks, poor recovery Solvent flow too low Verify pump pressure.

Injector blocked or leaking Check for leaks or blockage.

Detector malfunctioning Check wavelength, sensitivity, signal output cables.

Broad, smeared peaks, or peaks

appear as doublet

Rearrangement of packed bed or void in the

column packing

Blockage or leak in injector sample loop Check for leaks or excessive pressure drop across sample

Check system performance with each column separately.

Reverse flow through affected column using 2 mL injections

of toluene or xylene at 2 mL/min. If not corrected after 10

injections, replace column.

loop. Back flush loop.

In-line or inlet filter is partially clogged Reverse flow through column and inject 2 mL of

tetrahydrofuran, butylchloride, or a mixture of 1:1

cyclohexane:methylene chloride. Change the inlet filters.

Retention times shift more than 5%Change in flow rate Check flow rate.

Change in laboratory temperature Stabilize laboratory temperature or column temperature.

Waters Envirogel GPC Cleanup Column

6

Page 7

[ Care and Use ManUal ]

Sales Offices:

Austria and European Export

(Central South Eastern Europe,

CIS and Middle East) 431 877 18 07

Australia 2 9933 1777

Belgium 32 2 726 1000

Brazil 55 11 5094 3788

Canada 800 252 4752

China 8621 6495 6999

CIS/Russia +7 495 3367000

Czech Republic 42 02 617 11384

Denmark 45 46 59 8080

Finland +358 9 5659 6288

France (33) 1 30 48 72 00

Germany 49 6196 400600

Hong Kong 852 29 64 1800

Hungary 36 1 350 5086

India and India Subcontinent

91 80 2 837 1900

Ireland 353 1 448 1500

Italy 39 02 274 211

Japan (81) 3 3471 7191

Korea (82) 2 820 2700

Mexico 5255 5200 1860

The Netherlands +31 (0)76-50 87 200

Norway 47 63 84 60 50

Poland (48) 22 833 4400

Puerto Rico 787 747 8445

Singapore 65 6273 1221

Spain 34 93 600 93 00

Sweden 46 8 555 11500

Switzerland 41 62 889 2030

Taiwan 886 2 2543 1898

Waters Envirogel GPC Cleanup Column

United Kingdom 44 208 238 6100

©2007 Waters Corporation. Waters, The Science of W hat’s Possible

and Envirogel are trademarks of Waters Corporation. Acrodisc is a registered trademark of Pall Corporation. Teflon is a registered trademark

of the E.I. du Pont do Nemours Company. All rights reserved.

October 2007 WAT036556 Rev 4 VW-PDF

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...