Page 1

[ CARE AND USE MANUAL ]

DYE QUALITY CONTROL REFERENCE MATERIAL KIT

CONTENTS

I. INTRODUCTION

a. MS-Directed Purification

b. The Purpose of a QCRM

c. What Affects Your QCRM Results

II. STORAGE AND STABILITY

III. RECOMMENDED USAGE OF THE DYE QCRM

a. Testing System Performance

b. Performing the Delay Timing Test Manually

c. Performing a Chromatography Test

IV. TROUBLESHOOTING

V. ORDERING INFORMATION

I. INTRODUCTION

The Quality Control Reference Materials (QCRM) portfolio is a unique

collection of standards and mixtures. These products allow users

to evaluate and benchmark the chromatography system before

analysis of critical material. The products in the portfolio are all

precisely formulated based on the expertise of Waters scientist.

The AutoPurification™ Dye QCRM contains 3 compounds including

Thionin, Thioflavin T, and Crystal Violet.

This standard mix is used to confirm the benchmark performance

of a Preparative/Purification System through fraction collection.

This particular QCRM is precisely formulated to allow the user to

verify correct fraction collection. This test is highly valuable to

perform upon first use/installation, and any time the system

has not been used or has had any changes. T hese compounds were

vigorously tested and evaluated and chosen because they provide

the following advantages:

• Well-separated

• Easily visually identified

515 makeup pump

(not s hown)

PC with MassLynx and

FractionLynx software

2767 sample

manager

Bottle

tray

2545 binary

gradient module

System fluidics

organizer

2998 PDA

detector

SQD2

detector

Dye Quality Control Reference Material Kit 1

a. MS-Directed Purification

The Waters MS-directed autopurification system uses the Waters

SQD2 Mass Detector as its primary detector.

UV-Directed SystemMS-Directed System

PC with MassLynx and

FractionLynx software

2767 sample

manager

Bottle

tray

2545 binary

gradient module

System fluidics

organizer

2489 UV

detector

Page 2

[ CARE AND USE MANUAL ]

b. The Purpose of a Quality Control Reference Material

Waters recommends to benchmark a purification chromatographic

system with a QCRM prior to system usage when there is confidence

that the system is in good working order. It is recommended to run

and save the initial results and to continue to compare new QCRM

results to the previous benchmark before any critical assay is run,

and after any hardware, column, or mobile phase changes.

The QCRM standard benchmark result will be specific to the

performance of the system it is run on. All chromatographic systems

have some minor level of variability from run-to-run. Trending of

results over time is useful for defining variability on a single system,

multiple systems or on systems in different locations.

Setting specification for QCRM results should not be done without

sufficient data trending. Once variability is understood, QCRM

results will help determine the capability of the system to provide

reliable results.

c. What Affects Your Quality Control Reference

Material Results

The goal of the QCRM specifications and criteria will be to indicate

that the system is functioning as expected. The system is comprised

of many interdependent components working together to produce

results within an expected specification. An issue in any one of

the components can affect your QCRM result. Variability can

be attributed to hardware, software or chemical changes. All

components performing correctly will produce results within an

expected variability.

Sources of the variability that may affect system results include:

• Mobilephasepreparation • Temperaturecontrol

• Columnperformance • Datacollectionrate

• Tubingsize • Integration

• System component performance

(pump, injector, detector)

II. STORAGE AND STABILITY

The AutoPurification™ Dye QCRM contains 3 compounds including

Thionin, Thioflavin T, and Crystal Violet. The compounds are stable

in their original packaging, through the expiration date listed as

provided in 10 mL amber ampule before opening. This is intended

to be a one time use product. T he integrity of the standard can

not be guaranteed if stored after first use.

III. RECOMMENDED USAGE OF THE DYE QCRM

a. Testing System Performance

After installing FractionLynx™, it is recommended to test the system

to confirm that the instruments are functioning correctly, and that the

system produces the expected chromatographic results.

Testing involves using the Dye Kit (part number 716000765) to inject

dyes and subsequently collect them. A passing result for this system-

level test means that the system instruments function properly. If the

test results differ from those in the examples provided, ensure that

collection parameters are set appropriately.

The conditions defined in each of the following tests are designed

to help rapidly determine whether all the components function as a

system. Actual system performance (column load per run) depends

greatly on conditions such as the HPLC solvents or modifiers, and the

dimension of the columns.

For the MS-directed system test and the UV-directed system test,

many FractionLynx method parameters are identical, including the

gradient and UV detector parameters. The chromatogram examples

represent results that can be expected, although they can differ

somewhat from system to system.

b. Performing the Delay Timing Test Manually

Determine the delay time manually by injecting the dye standard

from the dye kit. The following test is conducted using a Waters

19 mm x 50 mm XTerra® column.

Differences in any of the components mentioned can result in system

to system variability of results even when each system’s components

are functioning correctly.

Dye Quality Control Reference Material Kit 2

Page 3

[ CARE AND USE MANUAL ]

Note: When using a different size and type of column than the one

described here, the flow and injection volumes must be adjusted

accordingly. Pressure balancing and flow to the mass spectrometer

need to be performed at the purification flow rate. When using the

column isocratically, the retention time is approximately 90 to

120 seconds, based on the column size and flow rate.

Required materials:

• Stopwatch

• Mobile phases:

– A Water/TFA, 0.1% (v:v)

– B Acetonitrile/TFA, 0.1% (v:v)

• Sample dye kit, part number 716000765

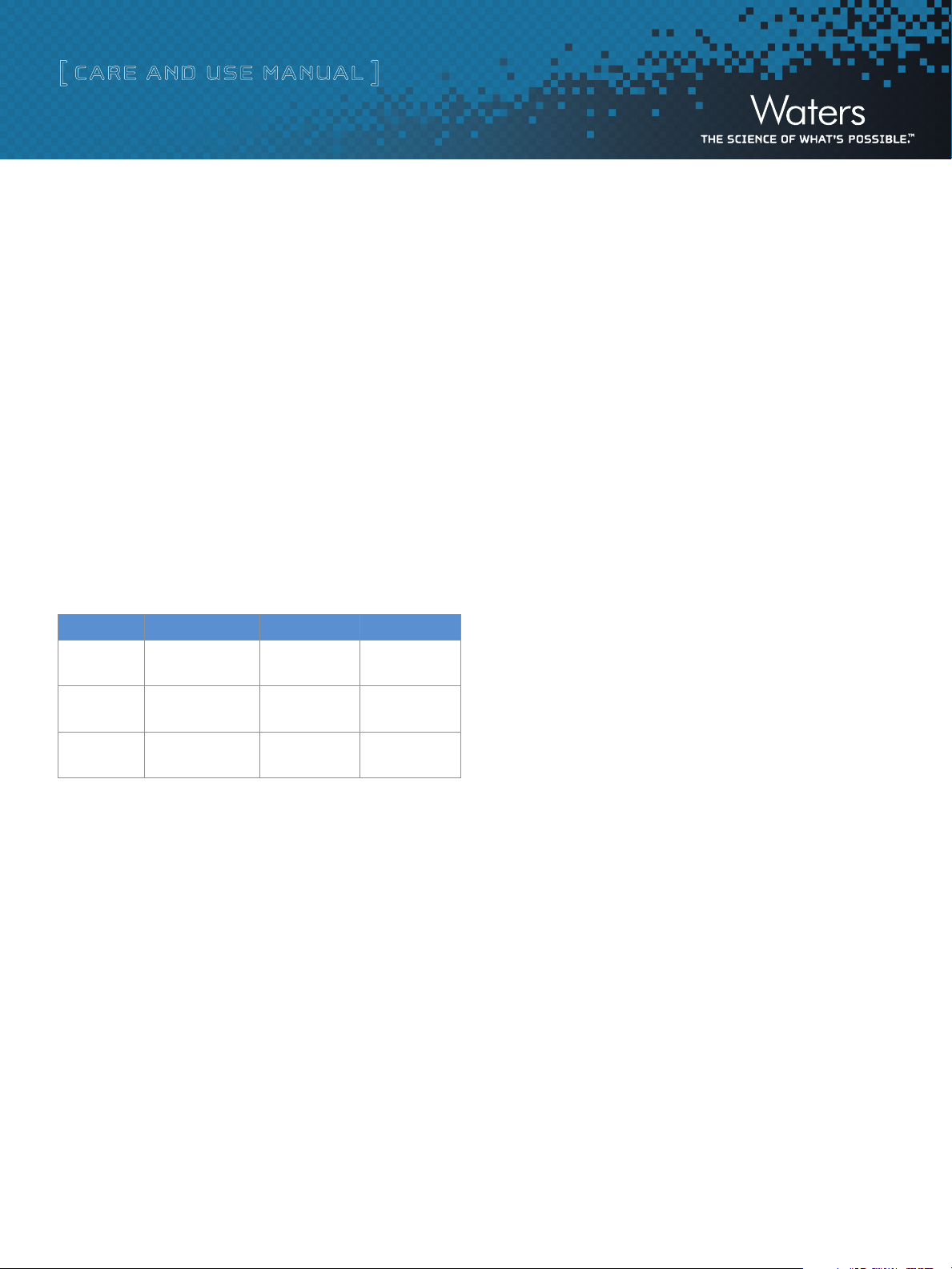

Table 1. Test Dye Compounds Information

Item Thionin Acetate Thioflavin T Crystal Violet

m/z 227.1 282.1 371.2

UV

max

Formula C12H9N3SC2H4O

590 nm 418 nm 590 nm

C17H19CIN2S C25H30CIN

2

3

3. For MS-directed systems, create an MS method for a 3 minute scan

acquisition with electrospray + ve, and specify these parameters:

– Centroid = 150 to 550 amu scan for 0.5 seconds

– Inter-scan delay = 0.1 seconds

– Cone Voltage = 35 V.

To run the delay timing test

1. In the MassLynx sample list, specify these values:

• Specify the Injection Volume as 100 μL.

• Enter these values depending upon the detectors configured

in the system:

– For an MS-directed system, enter 227.1 in the Mass A column,

282.1 in the Mass B column, and 371.2 in the Mass C

column. In the Fraction Trigger 1 column, enter Mass A. In

the Fraction Trigger 2 column, enter Mass B. In the Fraction

Trigger 3 column, enter Mass C.

– For a UV-directed system, enter 418 in the Wavelength

A column and 590 in the Wavelength B Column. In the

Fraction Trigger 1 column, enter Wavelength A for a PDA

detector or UV1 for a UV detector, such as a Waters 2489.

In the Fraction Trigger 2 column, enter Wavelength B for a

PDA detector or UV2 for a UV detector.

To set up the delay timing test:

1. In the FractionLynx method, set the split collector delay to

30 seconds.

2. In MassLynx™, create an inlet method with the following settings:

• Run at the required flow rate for 3 minutes with 10% A

and 90% B.

For UV-directed systems, set the UV detector to the following

parameters, and ensure that the connections on the UV Fraction

Manager correspond to the flow rate used for this test:

– Waters 2998 PDA Detector to scan from 200 to 600 nm

– Waters 2489 UV Detector to monitor 418 nm and 590 nm.

Dye Quality Control Reference Material Kit 3

Tip: UV1 and UV2 correspond to Channel A and Channel B wave-

lengths in the Inlet method. The setting in the Wavelength column is

for reporting purposes only; it does not control the 2489 detector. The

software uses the value set in the Fraction Trigger column, UV 1, UV 2,

against the value set in the Inlet Editor.

2. When the injection occurs, monitor the waste line from the

fraction collector valve. As soon as the dye appears in the

waste line of the fraction collector valve, start the stopwatch.

When you hear the fraction collector valve click to the dispense

position, stop the stopwatch. The dye should have eluted before

the collection valve opened.

4. Calculate the actual Splitter/Collector delay as follows:

The actual delay is equal to original Splitter/Collector delay

specified in the FractionLynx method (e.g., 30 seconds) minus

the time recorded on the stopwatch.

Page 4

[ CARE AND USE MANUAL ]

Example: If the dye is seen in the waste line 15 seconds before

the valve clicks to the collection position, the delay time is

calculated as follows:

Actual splitter collector delay = 30 – 15 = 15 seconds.

5. In the Timing tab of the FractionLynx method, change the Splitter/

Collector delay to the value just calculated, and rerun the

ex periment to ensure that the delay time is correct.

6. Repeat the procedure for all flow rates, such as 10, 15, 20,

or 25 mL/min.

7. For the MS-based system, complete the procedure for APCI and

ESI if you are using both probes.

8. Perform a chromatography test of the entire system, as

described below.

c. Performing a Chromatography Test

To perform the chromatography test, an inlet method using the

parameters provided in this procedure needs to be created. The

XTerra 19 mm x 50 mm column is used to perform the tests in the

manual. Scale the method appropriately for different flow rates and/

or differently-sized columns. Use the flow rate that will be used for

purification.

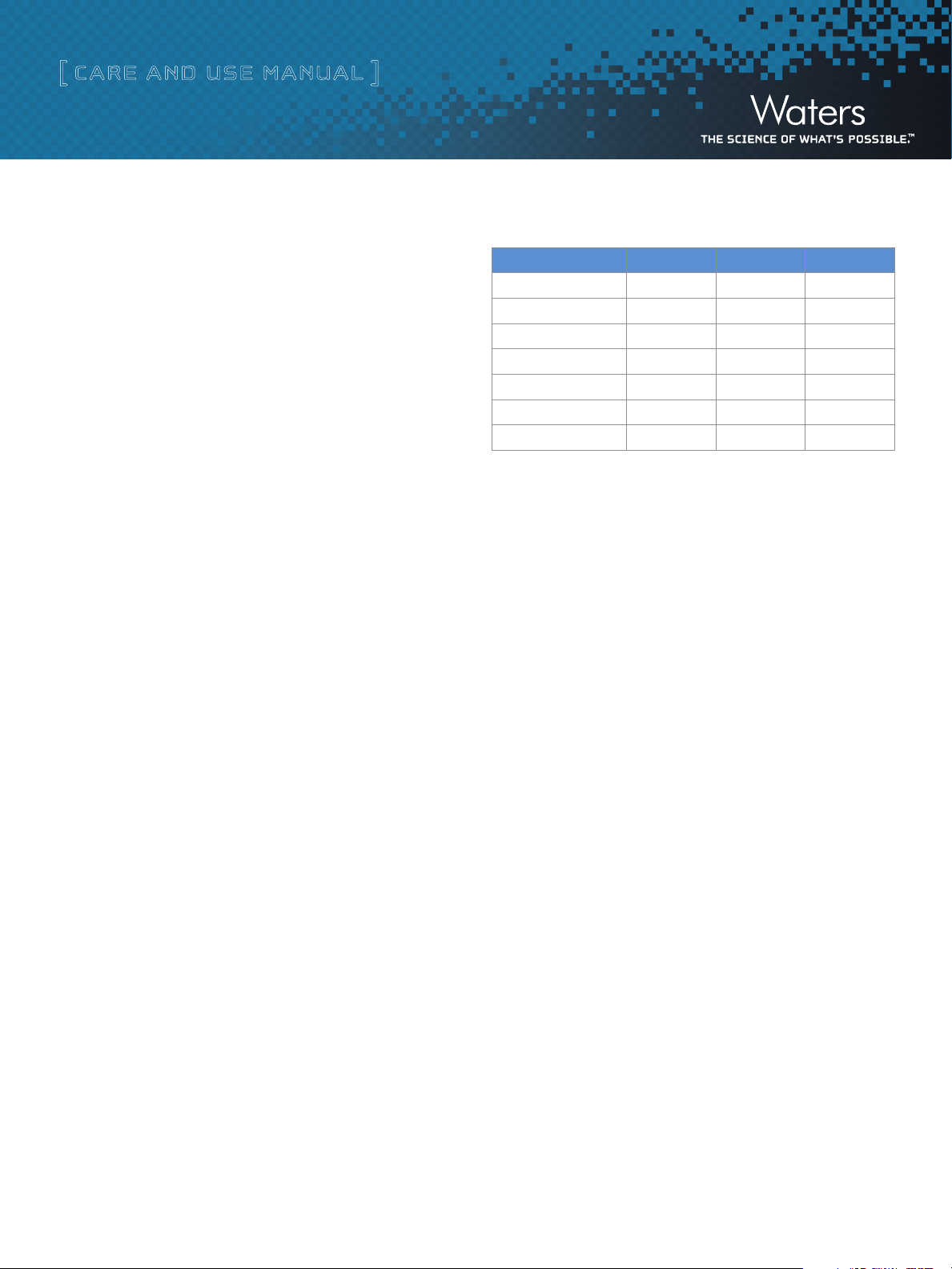

Table 2. Gradient Conditions for the System Test

Time A% B% Curve Number

T = 0 minutes 95 5 6

T = 1 minutes 95 5 6

T = 7 minutes 30 70 6

T = 7.5 minutes 5 95 6

T = 8.5 minutes 5 95 6

T = 9 minutes 95 5 6

T = 10 minutes 95 5 6

3. In the Inlet Editor, set the wavelength range you want to

acquire, based on your detector type:

• For a Waters 2998 PDA Detector, in the Inlet Editor, set the

wavelength range to 210 nm to 650 nm.

• For a Waters 2489 dual wavelength absorbance detector,

in the Inlet Editor, set the single channel wavelength to

418. Set the dual channel wavelength to 590.

4. For an MS-directed system, create a mass spectrometer method

with these parameters, and then set it to run for 10 minutes:

• Set up a Scan Function: 150 to 500 amu

To create an inlet method for the system test:

1. Set up the Inlet Editor to run a 10 minute method labeled “Dye.”

2. Set up the Waters 2545 binary gradient module to use

these parameters:

• Mobile Phase A: Water with 0.1% TFA or 0.2% formic acid

• Mobile Phase B: Acetonitrile with 0.1% TFA or 0.2%

formic acid

• Flow Rate: specify the same rate that you used in the delay

timing test.

• Run Time: 10 minutes

• Gradient conditions as specified in Table 2

Dye Quality Control Reference Material Kit 4

• ES+

• Centroid Data

• 0.5 second scan time with a 0.1 second Inter Scan Delay

• Cone Voltage = 35 V

5. In the MassLynx sample list, perform these tasks:

• Specify an injection volume of 100 μL.

• For an MS-directed system, enter 227.1 in the Mass A col-

umn, 282.1 in the Mass B column, and 371.2 in the Mass C

column. In the Fraction Trigger 1 column, enter Mass A. In

the Fraction Trigger 2 column, enter Mass B. In the Fraction

Trigger 3 column, enter Mass C.

Page 5

[ CARE AND USE MANUAL ]

• For a UV-directed system, enter 418 in the Wavelength A

column and 590 in the Wavelength B column. In the Fraction

Trigger 1 column, enter Wavelength A for a PDA detector

or UV1 for a UV detector, such as the Waters 2489 dual

wavelength absorbance detector. In the Fraction Trigger 2

column, enter Wavelength B for a PDA detector, or UV2 for

an UV detector.

Tip: The Mass and Wavelength columns are for information only,

unless the corresponding fraction information is entered in the

Fraction Trigger column.

6. For systems that include a ZMD mass detector, set the

instrument’s multiplier voltage to 550 V. For systems that

include a ZQ™ mass detector, set the multiplier voltage to

500 V. For systems that include a 3100 or SQD2 mass

detector, retain the default gain setting of 0.1.

7. From the shortcut bar, click FractionLynx > Collection

Control, and verify that your system is activated.

To set the FractionLynx method parameters for a system test

1. In the FractionLynx main window, click Edit FractionLynx method.

2. In the FractionLynx method, click each tab to set the parameters

you want to define for this fraction collection method.

Exception: The FractionLynx method parameters for the UV-based

system test apply to Waters UV detectors. When using the detectors

of other manufacturers, the threshold values can differ slightly. They

might also differ from system to system. Use the values specified in

the Table 3 as guidelines.

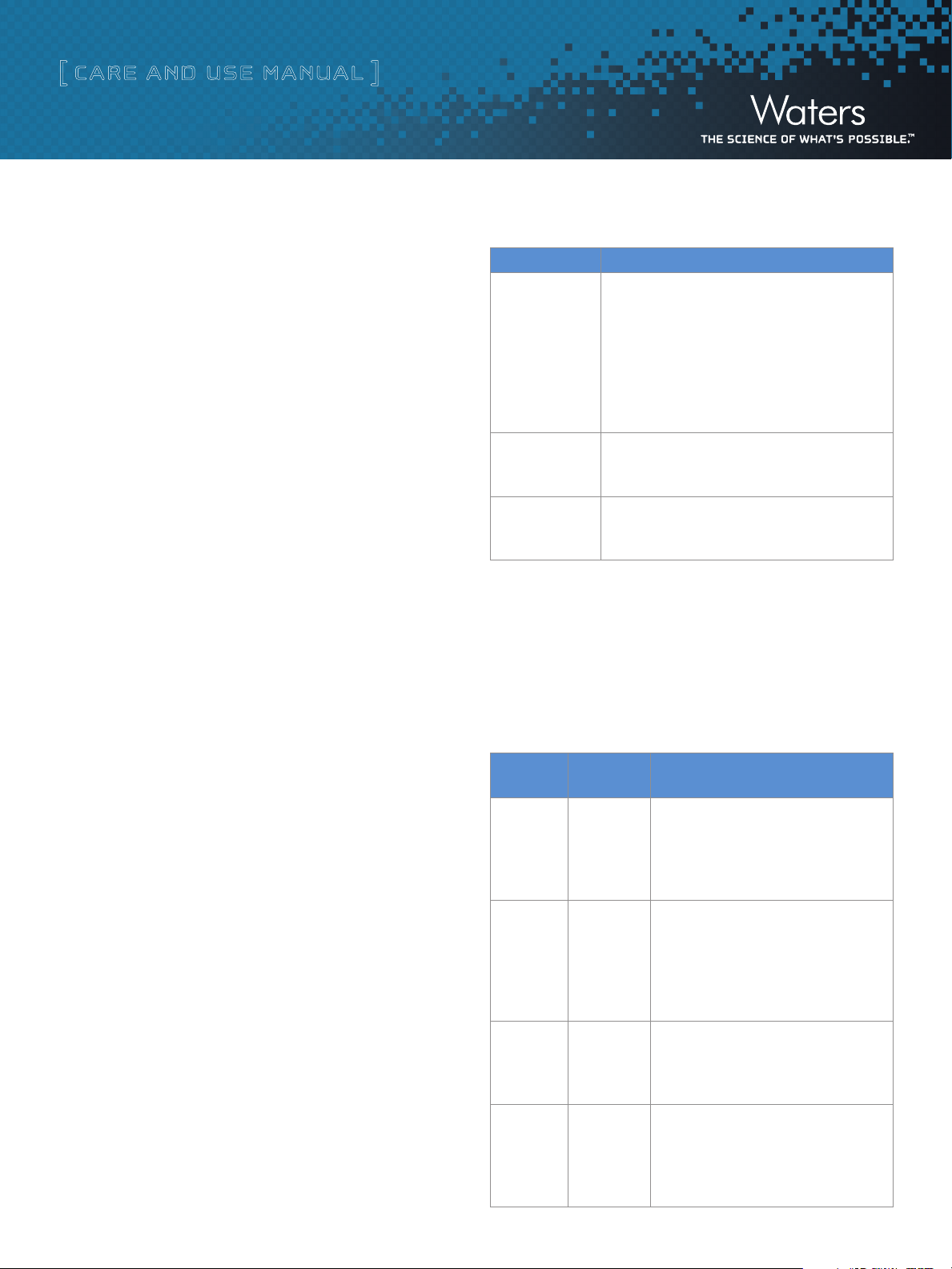

Table 3. FractionLynx Method Settings

Parameter Tab Settings You Can Specify

General • Set Fraction Collection to On and Peak Type to

Preparative

• Select the Max Fractions per injection check box,

and specify a value of 10

• Select the Max Tubes per injection check box, and

specify a value of 10

• Rinse time = 0

• Span = 0.5 amu

Timing • Solvent Front Delay = 0 seconds

• Split/Collector Delay = seconds, where x = the

split collector delay determined earlier

Volume • Minimum Fraction Width = 3 seconds

• Maximum Fraction Width = 120 seconds

• Maximum Tube Fill = 90 percent

3. Based on your detector, enter the values specified in the

table below.

Tip: Where values are not specified in Table 4, retain FractionLynx

method’s defaults.

Table 4. FractionLynx Method Settings Based on Detector Type

Detector

Type

2489 UV • MIT = 1000

PDA PDA • Span = 3 nm

Mass Spec ES+ • ES+ Ion Adducts = 1

Analog Analog • MIT = 5,000

FractionLynx

Method Tab

Settings You Can Specify

• Peak Start = Leading Edge Gradient %

with a value of 30

• Terminate Peak = Below Gradient %

with a value of 60

• MIT = 5,000

• Peak Start = Leading Edge Gradient %

with a value of 30

• Terminate Peak = Below Gradient %

with a value of 60

• MIT = 5,000,000

• Peak Start = Use MIT only

• Terminate Peak = Use MIT only

• Peak Start = Leading Edge Gradient %

with a value of 30

• Terminate Peak = Below Gradient %

with a value of 60

Dye Quality Control Reference Material Kit 5

Page 6

[ CARE AND USE MANUAL ]

1. From the shortcut bar, click FractionLynx > Collection

Control, and verify that your system is activated.

2. From the MassLynx toolbar, click Start.

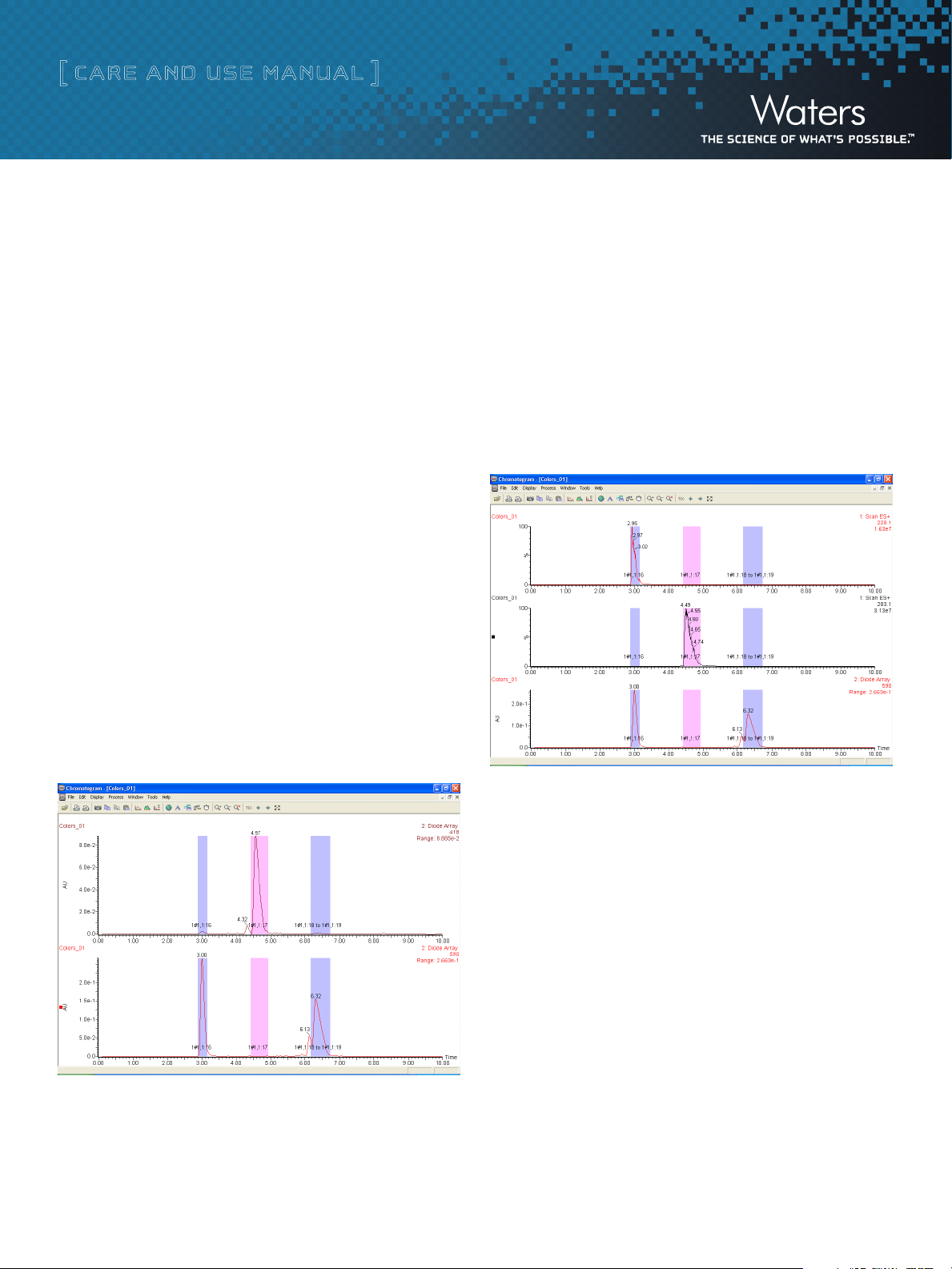

UV Chromatography Dye Test Results

These chromatograms represent typical results of the dye test. The

chromatograms show three separate color samples of blue, yellow,

and violet collected into separate vials labeled 1:16, 1:17, and 1:18

to 1:19.

Requirements: Sample dye kit, which contains three compounds for

testing the ability of the AutoPurification System to perform high-flow-

rate targeting and fractionation of specified masses and wavelengths.

The compounds elute in this order:

•Thioninacetatelosestheacetatesalt(C2H4O2) to give this [M+H] ion:

Thionin ([M+H] = 228.1), lambda max. = 590 nm

••ThioflavinTlosesaCltogivethis[M+H]ion:

Thioflavin T ([M+H] = 283.1), lambda max. = 418 nm

••CrystalvioletlosesHCltogivethis[M+H]ion:

• T he extracted wavelength shows the correct picture of what

was actually collected.

• Click Display > Wavelength to input the wavelengths of

choice, and then click OK to get the extracted wavelengths.

• To extract the spectrum, double-click the peak in the Total

Absorbance Chromatogram (TAC).

Actual results can vary if different column sizes, flow rates, and

injection volumes are used.

MS Chromatography Dye Test Results

([M+H] = 372.2), lambda max. = 590 nm

Tip: Report masses to one decimal place.

This sample was collected using the Waters 2998 PDA Detector. The wavelength values

were put in the sample list, and the fraction triggers were set to Wavelength A and B.

The chromatograms above represent typical results of the dye test. The three

components of the dye mix have been separated and collected into separate vials

labeled 1:16, 1:17, and 1:18 to 1:19.

The extracted ion shows the correct picture of what was actually

collected into each vial. Double-click the peak in the Total Ion

Chromatogram (TIC) to extract the spectrum, and double-click the

spectrum of the mass of interest to extract the mass chromatograms.

Always consider the extracted ion or wavelength when trouble-

shooting as it will give the correct representation of what was

actually collected.

IV. TROUBLESHOOTING

For specific troubleshooting of the system and settings refer to the

AutoPurification System Guide 71500135202ra.

Dye Quality Control Reference Material Kit 6

Page 7

[ CARE AND USE MANUAL ]

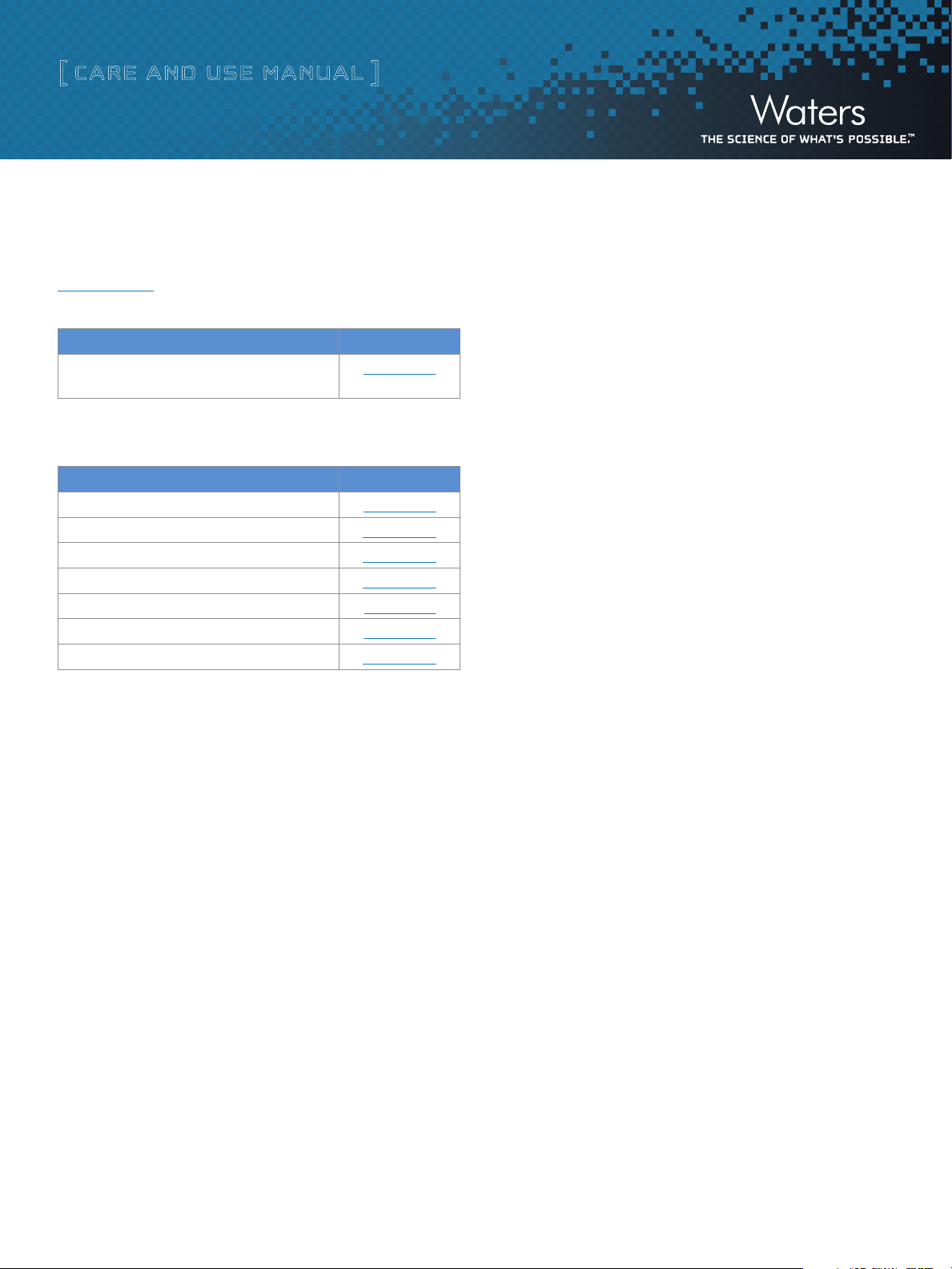

V. ORDERING INFORMATION

To order these products, contact your nearest subsidiary, or visit

www.waters.com and click on Order Center.

Description Part Number

Auto Purification Dye Quality Control

Reference Material Kit

716000765

Related Products

Description Part Number

XBridge™ C18, 5 µm, 19 x 50 mm

XSelect™ CSH C18, 5 µm, 19 x 50 mm

XSelect CSH Phenyl-Hexyl, 5 µm, 19 x 50 mm

XSelect CSH Fluoro-Phenyl, 5 µm, 19 x 50 mm

XTerra MS C18, 5 µm, OBD 19 x 50 mm

Symmetry® C18, 5 µm, OBD 19 x 50 mm

Atlantis® T3 C18, 5 µm, OBD 19 x 50 mm

186 0 02977

186005420

186005446

186005433

186 00193 0

186000210

186 0 03696

Thank you for choosing a Quality Control Reference Material (QCRM)

from Waters. T he standards are manufactured in our ISO 9001,

ISO 17025 facility. Each standard is manufactured to ensure optimal

reproducibility from lot-to-lot. A Waters QCRM can be depended

on for its’ accuracy. This removes one variable from your system

variability and provides you the most dependable starting point for

your testing. If the QCRM box shows significant damage, notify the

carrier and your supplier at once and retain evidence of shipping

damage so that a claim can be made.

Dye Quality Control Reference Material Kit 7

Page 8

[ CARE AND USE MANUAL ]

Austria and European Export

(Central South Eastern Europe, CIS

and Middle East) 43 1 877 18 07

Australia 61 2 9933 1777

Belgium 32 2 726 1000

Brazil 55 11 5094-3788

Canada 1 800 252 4752 x2205

China 86 21 6879 5888

CIS/Russia +497 727 4490/290 9737

Czech Republic 420 2 617 1 1384

Denmark 45 46 59 8080

Finland 09 5659 6288

France 33 1 30 48 72 00

Germany 49 6196 400600

Hong Kong 852 2964 1800

The Netherlands 31 76 508 7200

Norway 47 6 384 60 50

Poland 48 22 6393000

Puerto Rico 1 787 747 8445

Singapore 86 21 6879 5888

Spain 34 936 009 300

Sweden 46 8 555 11 500

Switzerland 41 56 676 70 00

Taiwan 886 2 2543 1898

United Kingdom 44 208 238 6100

All other countries:

Waters Corporation U.S.A.

1 508 478 2000

1 800 252 4752

www.waters.com

Hungary 36 1 350 5086

India and India Subcontinent

91 80 2837 1900

Ireland 353 1 448 1500

Italy 39 02 265 0983

Japan 81 3 3471 7191

Korea 82 2 6300 4800

Mexico 52 55 5524 7636

©2013 Waters Corporation. Waters, The Science of What's

Possible, AutoPurification, MassLynx, FractionLynx, XTerra,

ZQ, XBridge, S unFire, XSelect, Symmetry, and Atlantis are

trademarks of Waters Corporation.

March 2013 720004436EN Rev B IH-PDF

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

8

Loading...

Loading...