Page 1

[ Care and Use ManUal ]

delta-Pak HIGH-Pressure Inert HPlc coluMn

I. IntroductIon

a. Overview

Waters High Pressure Inert (HPI) HPLC columns are a metal free alternative

for both bio-chromatographic and ion-chromatographic applications. In this

®

advanced design, the sample contacts only polyetherether ketone (PEEK

and ultrahigh molecular weight polyethylene (UHMWPE), two materials

which are widely accepted for their biocompatibility and inertness. The

chromatographic performance of these columns is essentially identical

to their metal counterparts with the added advantage of greater chemical

inertness.

b. Delta-Pak Columns

TM

The Delta-Pak

phase. It is synthesized from 5 µm spherical silica particles having an average pore diameter of 100 Å or 300 Å. Delta-Pak

analysis and purification of peptides and proteins.

column packing material is an endcapped C18 or C4 bonded

columns are ideal for the

)

contents

I. IntroductIon

a. Overview

b. Delta-Pak Columns

II. InstallatIon

a. Installing the Column

b. Equilibration

III. MoBIle PHase and saMPle GuIdelInes

a. Solvent Compatibility

b. Mobile Phase Requirements

c. Sample Preparation and Filtration

IV. oPeratIon

a. Chromatography Guidelines

b. Efficiency Testing

c. Typical Column Backpressure and Eluent Viscosity

d. Column Temperature Limits

V. care and MaIntenance

a. Troubleshooting

b. Cleaning the Column

c. Storing the Column

VI. orderInG InforMatIon

1

Page 2

[ Care and Use ManUal ]

II. InstallatIon

a. Installing the column

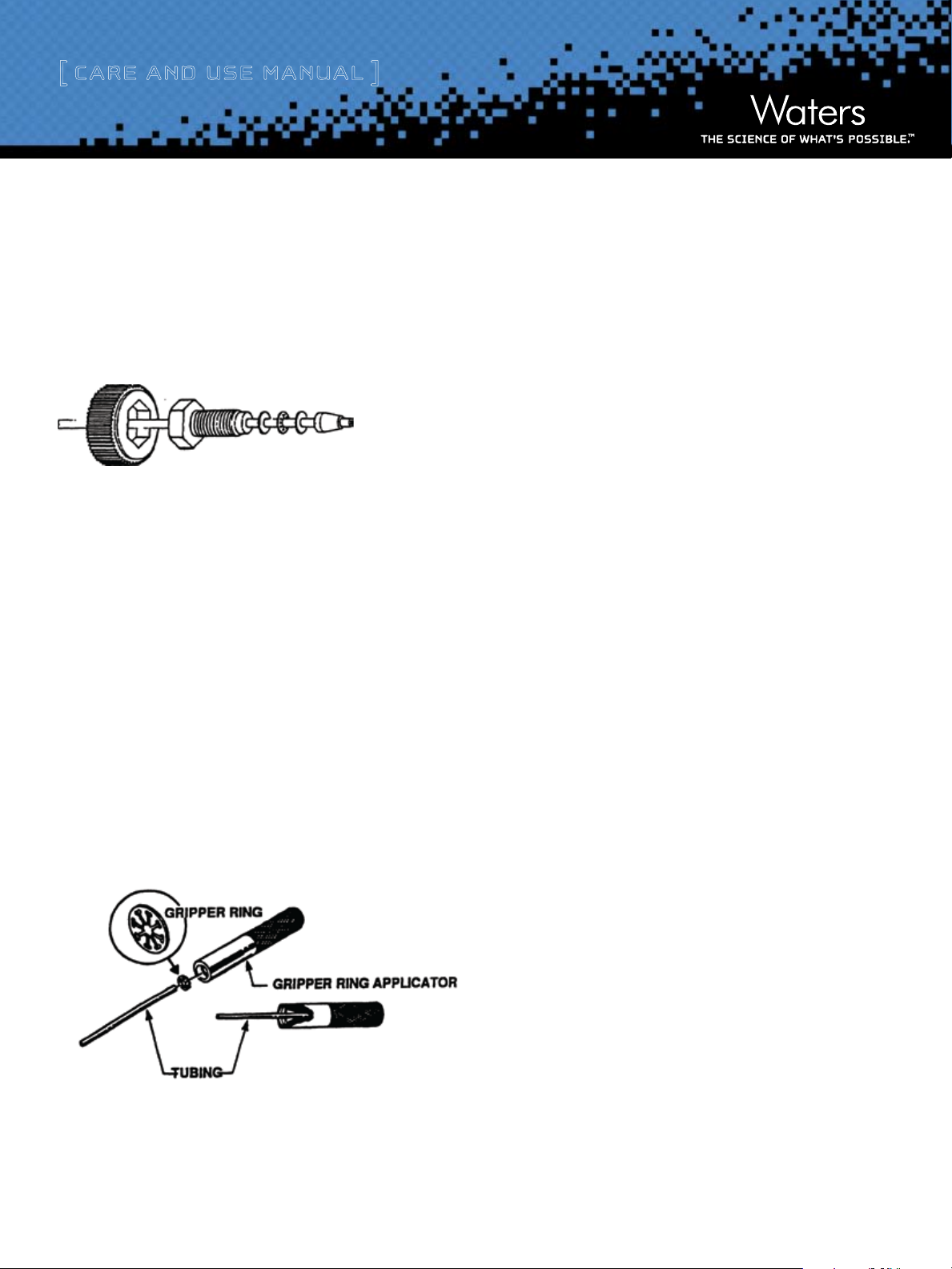

Use only plastic tubing and plastic finger-tight endfittings with the HighPressure Inert column. The Waters endfitting design is shown in Figure 1.

Over-tightening the endfittings can cause irreversible damage to the filter

housing.

Figure 1: Finger-tight Endtting

To install a new fitting or replace a worn fitting:

1) Using a single-edge razor, make a straight and square cut on the

plastic tubing. Make this cut in front of the compression screw on the

worn endfitting.

2) Slide a compression screw fitting and a washer over the end of the cut

tubing.

3) Place the gripper ring in the top depression of the tool (see Figure 2).

Insert the end of the tubing into the gripper ring tool as far as it will

go. This seats the gripper ring at the proper length of the tubing.

4) Remove the tubing from the tool and slide the other washer and ferrule

over the end of the tubing. Insert a union over the endfitting assembly

and tighten. This seats the assembly.

Make sure that any mobile phase used for startup is miscible with the shipping solvent. Before placing the column in the flow path:

1) Attach a union between the column inlet and outlet lines.

2) Flush the lines to remove any microparticulates and old solvents. Flush

the injector loop if applicable.

3) Remove the union.

Remove the finger-tight end plugs from our column and save them to store

the column when it is removed from the system. Attach the column so that

flow follows the direction of the arrow on the column label. To install the

column, read the inlet and outlet fittings into the column until finger-tight.

b. Equilibration

The column is delivered in the mobile phase indicated in Table 1. Prior to

use, the column should be equilibrated with the mobile phase that will be

used in a analysis. Check mobile phase/shipping solvent miscibility.

Delta-Pak material is highly hydrophobic. If mobile phases with high concentrations of water are to be used, it is necessary to thoroughly solvate the

packing with the non-aqueous component before starting. To do so, pure the

column with 5 to 10 column volumes of the non-aqueous solvent to be used

in the mobile phase prior to equilibrating the column with the mobile phase.

Should the mobile phase contain a buffer salt, flush the column with 30

mL of water prior to equilibrating the column with the buffer. With PIC

ion- pairing reagents, whose concentration in the mobile phase is very

low (typically 5 mmol/l), 100 to 300 mL of mobile phase is required for

equilibration.

®

Figure 2: Gripper Ring Installation

III. MoBIle PHase and saMPle GuIdelInes

Liquid chromatography columns have a finite lifetime directly related to the

care and use they receive. Column life is reduced by:

• contamination from the mobile phase or sample

• improper storage and handling

• frequent solvent switching

• exposure to high or low pH eluents (for example, less than

2.0, greater than 8.0)

2

Page 3

[ Care and Use ManUal ]

a. Solvent Compatibility

The HPI column is constructed from non-metallic components which

have been chosen on the basis of their chemical inertness. While the

materials of construction are resistant to a wide spectrum of organic

and inorganic chemicals, the following list of chemicals attack the

surface and cause irreparable damage.

Caution: Use of any of these solvents with the column will result in a

void of the warranty:

• Chlorinated hydrocarbons

• Concentrated sulfuric acid

• Tetrahydrofuran (THF)

• Concentrated nitric acid

b. Mobile Phase Requirements

The following precautions are recommended for the preparation

of eluents:

• Use LC-grade solvents which have been filtered to remove

microparticulate matter above 0.45 µm. Ultrapure water

(18 megohm) is recommended.

• Use Gelman Sciences Aerodisc

to filter samples and prevent the high backpressure that results

from a blocked column inlet filer.

®

syringe filters from Waters

IV. oPeratIon

Simple procedures such as those outlined in this and the previous

chapter can significantly extend the column lifetime.

Should a change in peak shape, retention of a particular compound,

or resolution between two compounds be observed, take immediate

steps to determine a reason for the changes (see Section V. a.,

Troubleshooting). Until the cause of the change is determined, do not

rely on the results of the analyses.

Note: Before running the first analyses on your new column, perform

the test sample separation given in Efficiency Testing, Section IV, b.

a. Chromatography Guidelines

The following operating guidelines will help you obtain the best

performance from your Waters analytical HPIC column.

• Do not exceed an operating pressure of 40 Mpa (400 atm or

6,000 psi).

• Use vacuum filtration and/or sonification to remove dissolved

gases which could affect your pump. Care should be exercised

when vacuum filtering or sparging mixtures of solvents, because

the composition of the mixture could change. The best way to

degas the mobile phase is to place it into an ultrasonic bath and

apply vacuum and ultrasonic power simultaneously for about

30 seconds.

• Use ultrapure water as an intermediate solvent when changing

from aqueous salt solutions to organic solvents. Perform this

changeover gradually. Use care when adding organic solvents to

aqueous buffer solutions, as salt precipitation may occur.

c. Sample Preparation and Filtration

If the sample contains dissolved contaminants or particulates that

may bind irreversibly to the column, the following procedure is

recommended:

®

• Use Sep-Pak

sample that may be adsorbed onto the packing material surface

causing changes in performance and reduced column lifetime.

cartridges to remove contaminants from the

• Avoid using concentrated acids and bases. T he use of mobile

phases whose pH is below 2.0 or above 8.0 results in significantly reduced column lifetime due to the hydrolysis of the

bonded phase.

• Filter all aqueous buffers through a 0.45 µm filter prior to use.

Never use turbid or cloudy mobile phases.

• Protect the column from vibration, mechanical shock, and rapid

changes in pressure which can result from rapidly changing the

composition of the eluent.

• Use ultrapure water (18 megohn). Deionized water is not accept

able because it contains organic compounds that may alter

column selectivity.

b. Efficiency Testing

Waters’ columns are tested for compliance with our specifications. It

is possible that columns may be damaged during shipment. Test the

column before using it. The results of the efficiency test may be used

as a benchmark or future references.

3

Page 4

[ Care and Use ManUal ]

INJECT

N = 25

2

(

)

To perform an efficiency test, prepare the test sample as follows:

1) Prepare an acetone/acenaphthene sample by dissolving 0.05 g

acenaphthene and 600 µl acetone in 100 mLs of mobile phase.

While acenaphthene is the recommended sample, you can

substitute the following simple aromatic hydrocarbons:

Figure 3: 5 Sigma Test Method

• naphthalene

• p-cymene

• xylene

• dibutyl-, dipropyl-, or diethylphthalate

• propylbenzene

• toluene

• ethylbenzene

Toluene and diethylphthalate are the least desirable substitutes

since they have the lowest k.

2) Equilibrate the column employing the conditions summarized

below. Note: Incomplete equilibration results in tailing, fronting

or split peaks.

Table 1: Column Efciency Test Conditions

Column Mobile Phase Flow Rate Test Samples

Delta-Pak C

Delta-Pak C

18

4

and

50/50

acetonitrile/

0.7 ml/min Acenaphthene

water

Do not substitute methanol for acetonitrile in reversed-phase

column tests due to the much higher viscosity of methanol/water

mixtures.

If problems occur during normal operation of the column, repeat th

efficiency test and compare the results. This may help locate the

source of the problem.

c. Typical Column Backpressure and Eluent Viscosity

The column hardware has been designed to withstand operating

pressures as high as 50 Pa (500 atm or 7,000 psi). However, normal

operating backpressure should not exceed 40 Mpa (400 atm or

6,000 psi).

The normal operating backpressure of a column varies considerably

and is affected by column length, flow rate, mobile phase viscosity,

temperature, and particle size. The backpressure may rise significantly during the course of a gradient.

The following equation can be used to calculate the backpressure of

your column:

Pressure (atm) at 1 L/min in H

0 = 210 x l • v

2

dp2 x d2

Where:

L = column length, mm

dp = particle diameter, µm

d = column diameter, mm

v = mobile phase viscosity, centipose (see Table 2)

3) Set a UV detector at 254 nm with an attenuation of 0.05 AUFS.

The resulting detector deflection should be approximately 90

percent of full scale. The minimum deflection is 60%.

4) Inject about 2 µL of sample. Large amount may overload the

column.

5) Measure and record plate count, asymmetry, backpressure, and

instrument settings. Waters uses the 5 sigma method, shown

in Figure 3, to measure column efficiency. Unlike the tangent

method, this more stringent method takes peak asymmetry into

account

4

Page 5

[ Care and Use ManUal ]

Table 2: Viscosity

Mobile Phase Viscosity (20 °C),

Centipoise

n-Pentane 0.24

n-Hexane 0.33

wn-Heptane 0.42

Isoctane 0.50

Acetone 0.32

Dioxane 1.54

Nitromethane 0.65

Acetonitrile 0.37

n-Propanol 2.3

Ethanol 1.2

Methanol 0.6

Water 1.0

60/40 Methanol/Water 2.0

The typical operating backpressure for Waters® Delta-PakTM columns

is summarized below.

Table 3: Typical Operating Backpressure at 1 mL/min

Column Dimension Mpa Methanol

DeltaPak

DeltaPak

2.1 x 150

TM

mm

3.9 x 150

TM

mm

(Water)

17 (28) 170 (285) 2500 (4200)

6.0 (10.0) 60 (100) 900 (1500)

Atm Methanol (Water)

Psi Methanol

(Water)

A variation of plus or minus 10-15% is acceptable.

d. Column Temperature Limits

The column hardware has been designed to operate between 4 °C and

50 °C.

Note: Column failure due to operation outside of these temperature

limits voids the warranty.

V. care and MaIntenance

a. Troubleshooting

Table 4, on the following page, provides the corrective action for

specific problems that may occur with the Waters HPLC High Pressure

Inert columns.

b. Cleaning the Column

Flush reversed-phase columns with methanol or acetonitrile. It is

useful to monitor the UV absorbance during this procedure to see if

contaminants are being removed from the column.

If flushing does not resolve the problem, wash the column with solvents of decreasing polarity, always making sure the solvent in the

column and a washing solvent are miscible. Return the column to the

standard reversed-phase conditions by reversing the wash sequence.

If you suspect a particular contaminant is building up on the column,

use solvents or chemicals that are known to dissolve a material.

Be sure to remain within the limits of pH 2.0 to pH 8.0. Also,

ensure that no precipitate forms as a result of mixing the washing

solution with the solvent in the column. Proteinaceous material can

sometimes be removed by making repeated injections of 200 µL of

dimethylsulfoxide (DMSO).

c. Storing the Column

Leaving the column unused for less than 72 hours does not generally

require specialized storage procedures. However, never let columns

dry out. For longer storage:

• DO NOT store the column in water alone, as this may result

in bacterial growth in the column. Storing the column in a 10%

aqueous solution of isopropanol or methanol will hinder

bacterial growth.

• DO NOT store the column in buffered solution or solutions

containing salts, as these may precipitate.

• Return the column to its box with the end plugs firmly in place

for storage. Allowing the column to dry out may result in poor

chromatographic performance.

• DO NOT leave a column at elevated temperatures with no mobile

phase flow.

5

Page 6

[ Care and Use ManUal ]

Table 4: Troubleshooting

Symptom Cause Corrective Action Prevention

Buildup in system operating

pressure.

Loss of resolution, low plate

count.

Inlet filter plugged with

particulates from dirty sample

or mobile phase. Injector seal or

pump seal shredding.

Sample precipitates on the

column (sample not soluble in

the mobile phase).

Clogged tubing Replace the tubing. Identify and eliminate the source

Sample solvent is incompatible

with or stronger than the mobile

phase.

Failing injector (measure system

band spreading periodically).

Contaminated column. Wash with strong solvent. Isolate the source of the con-

Insufficient equilibration. Continue equilibration.

Replace the filter. Install an in-line filter between

the pump and the injector. Filter

the sample and/or mobile phase.

Wash the column using a solvent

that will dissolve the sample.

Dissolve sample in another

solvent.

Repair the injector. Filter mobile phases and use an

Use a mobile phase in which the

sample is soluble.

of the material clogging the

tubing.

Dissolve sample in another

mobile phase. If not possible,

change mode of separation.

in-line filter.

tamination and use a Sep-Pak

cartridge to clean up the sample.

If this is not possible, use a

Guard-Pak™ holder and insert

to protect the column from

contaminants. Use HPLC grade

solvents.

®

Incorrect connecting tubing. Replace with 0.0009” internal

diameter tubing.

All tubing from injector to the

detector should be 0.0009”

internal diameter.

VI orderInG InforMatIon

Delta-Pak HPI (High Pressure Inert Analytical Columns (PEEK)

Column (non metallic) Particle Size Pore Size Dimensions Part No.

DeltaPak HPI C18 5 µm 100 Å 2.1 mm x 150 mm WAT052750

DeltaPak HPI C18 5 µm 300 Å 2.1 mm x 150 mm WAT052765

DeltaPak HPI C4 5µm 100 Å 2.1 mm x 150 mm WAT052760

DeltaPak HPI C4 5 µm 300 Å 2.1 mm x 150 mm WAT052755

DeltaPak HPI C18 5 µm 300 Å 3.9 mm x 150 mm WAT035571

6

Page 7

[ Care and Use ManUal ]

Sales Offices:

Austria and European Export

(Central South Eastern Europe,

CIS and Middle East) 431 877 18 07

Australia 2 9933 1777

Belgium 32 2 726 1000

Brazil 55 11 5094 3788

Canada 800 252 4752

China 8621 6495 6999

CIS/Russia +7 495 3367000

Czech Republic 42 02 617 11384

Denmark 45 46 59 8080

Finland +358 9 5659 6288

France (33) 1 30 48 72 00

Germany 49 6196 400600

Hong Kong 852 29 64 1800

Hungary 36 1 350 5086

India and India Subcontinent

91 80 2 837 1900

Ireland 353 1 448 1500

Italy 39 02 274 211

Japan (81) 3 3471 7191

Korea (82) 2 820 2700

Mexico 5255 5200 1860

The Netherlands +31 (0)76-50 87 200

Norway 47 63 84 60 50

Poland (48) 22 833 4400

Puerto Rico 787 747 8445

Singapore 65 6273 1221

Spain 34 93 600 93 00

Sweden 46 8 555 11500

Switzerland 41 62 889 2030

Taiwan 886 2 2543 1898

United Kingdom 44 208 238 6100

©2007 Waters Corporation, Waters, The Science of W hat’s Possible, Delta-Pak, Guard-Pak, PIC and Sep-Pak are trademarks of

Waters Corporation. Aerodisc is a trademark of Gelman Sciences.

PEEK is a trademark of Victrex plc.

October 2007 WAT035904 Rev 4 V W-PDF

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

7

Loading...

Loading...