Page 1

CORTECS Columns

CONTENTS

I. GETTING STARTED

a. Column Connectors

b. Column Installation

c. Column Equilibration

d. eCord Installation

e. Initial Column Efficiency Determination

f. VanGuard Pre-Columns

II. COLUMN USE

a. Sample Preparation

b. pH Range

c. Solvents

d. Pressure

e. Temperature

III. COLUMN CLEANING, REGENERATING

AND STORAGE

a. Cleaning and Regeneration

b. Storage

Thank you for choosing a Waters CORTECS™ Column. The

CORTECS packing materials were designed specifically for use

with the Waters ACQUITY UPLC® System and are manufactured

in a cGMP, ISO 9001 certified plant using ultra pure reagents.

Each batch of CORTECS material is tested chromatographically with

acidic, basic and neutral analytes and the results are held to narrow

specification ranges to assure excellent, reproducible performance.

Every column is individually tested and a Performance

Chromatogram and Certificate of Batch Analysis are provided on

™

the eCord

CORTECS Columns were designed and tested specifically for use on

the ACQUITY UPLC System. CORTECS Columns will exhibit maximum

chromatographic performance and benefits when used on the

holistically-designed ACQUITY UPLC System since they were created

and designed to operate with it.

Intelligent Chip.

IV. INTRODUCING eCORD INTELLIGENT

CHIP TECHNOLOGY

a. Introduction

b. Installation

c. Manufacturing Information

d. Column Use Information

V. ADDITIONAL INFORMATION

a. Tips for Maximizing CORTECS Column Lifetimes

b. Getting Started with CORTECS HILIC Columns

Page 2

I. GETTING STARTED

Each CORTECS Column comes with a Certificate of Analysis and

a Performance Test Chromatogram embedded within the eCord

intelligent chip. The Certificate of Analysis is specific to each batch

of packing material contained in the CORTECS Column and includes

the gel batch number, analysis of unbonded particles, analysis of

bonded particles, and chromatographic results and conditions. T he

Performance Test Chromatogram is specific to each individual

column and contains such information as: gel batch number,

column serial number, USP plate count, USP tailing factor,

capacity factor, and chromatographic conditions. These data

should be stored for future reference.

Note: If mobile-phase additives are present in low concentrations

(e.g., ion-pairing reagents), 100 to 200 column volumes may be

required for complete equilibration. In addition, mobile phases that

contain formate (e.g., ammonium formate, formic acid, etc.) may

also require longer initial column equilibration times.

c. Column Equilibration

CORTECS Columns are shipped in 100% acetonitrile. It is important

to ensure mobile-phase compatibility before changing to a different

mobile-phase system. Equilibrate the column with a minimum of 10

column volumes of the mobile phase to be used (refer to Table 1 for

a list of column volumes). The column may be considered thermally

equilibrated once a constant backpressure is achieved.

a. Column Connectors

The ACQUITY UPLC System utilizes tubing and gold plated

compression screws which have been designed to meet stringent

tolerance levels and to minimize extra column volumes.

Optimized column inlet tubing (Part Number 430001084) is supplied

with the ACQUITY UPLC System. The inject valve end of the tubing is

clearly marked with a blue shrink tube marker. Insert the opposite end

of the tubing into the CORTECS Column and tighten the compression

fitting using two 5/16-inch wrenches.

For information on the correct column outlet tubing, please refer

to the relevant detector section in the ACQUITY UPLC System

Operator’s Guide (Part Number 71500082502).

b. Column Installation

Note: The flow rates given in the procedure below are for a typical

1.6 µm, 2.1 mm ID by 50 mm length column. Scale the flow rate

up or down accordingly based upon the column pressure and

system limits.

1. Purge the pumping system of any buffer-containing mobile phases

and connect the inlet end of the column to the injector outlet.

2. Flush column with 100% organic mobile phase (methanol or

acetonitrile) by setting the pump flow rate to 0.1 mL/min and

increase the flow rate to 0.5 mL/min over 5 minutes.

3. When the mobile phase is flowing freely from the column

outlet, stop the flow and attach the column outlet to the

detector. This prevents entry of air into the detection system

and gives more rapid baseline equilibration.

Table 1. Column Volumes (mL)

Column Length (mm)

30 0.1 0.2

50 0.2 0.4

75 0.3 0.5

100 0.4 0.8

150 0.5 1.0

Internal Diameter

2.1 mm 3.0 mm

To avoid precipitating mobile-phase buffers on your column or

in your system, flush the column with five column volumes of a

water/organic solvent mixture, using the same or lower solvent

content as in the desired buffered mobile phase. (For example,

flush the column and system with 60% methanol in water prior to

introducing 60% methanol/40% buffer mobile phase).

For CORTECS HILIC Columns, flush with 50 column volumes of

50:50 acetonitrile/water with 10 mM final buffer concentration.

Prior to the first injection, equilibrate with 20 column volumes of

initial mobile-phase conditions (refer to Table 1 for a list of column

volumes). See “Getting Started with CORTECS HILIC Columns” for

additional information.

d. eCord Installation

The eCord button should be attached to the side of the column heater

module. The eCord button is magnetized and does not require specific

orientation.

4. Gradually increase the flow rate as described in step 2.

5. Once a steady backpressure and baseline have been achieved,

proceed to the next section.

2

CORT ECS Columns

Page 3

e. Initial Column Efficiency Determination

1. Perform an efficiency test on the column before using it. This

test may consist of:

a. An analyte test mixture that is commonly used in your

laboratory, and/or

b. An analyte mixture as found on the “Performance Test

Chromatogram” which accompanied your column.

Note: If b. is performed, the isocratic efficiencies measured in

your laboratory may be less than those given on the Waters

“Performance Test Chromatogram”. This is normal. CORTECS

Columns are QC tested on ACQUITY UPLC I-Class Systems

which have extremely low system volumes. This presents a

more challenging test of how well the column was packed and

guarantees the highest quality packed column.

2. Determine the number of theoretical plates (N) and use this

value for periodic comparisons.

3. Repeat the test at predetermined intervals to track column

performance over time. Slight variations may be obtained

on two different UPLC® Systems due to the quality of the

connections, operating environment, system electronics,

reagent quality, column condition and operator technique.

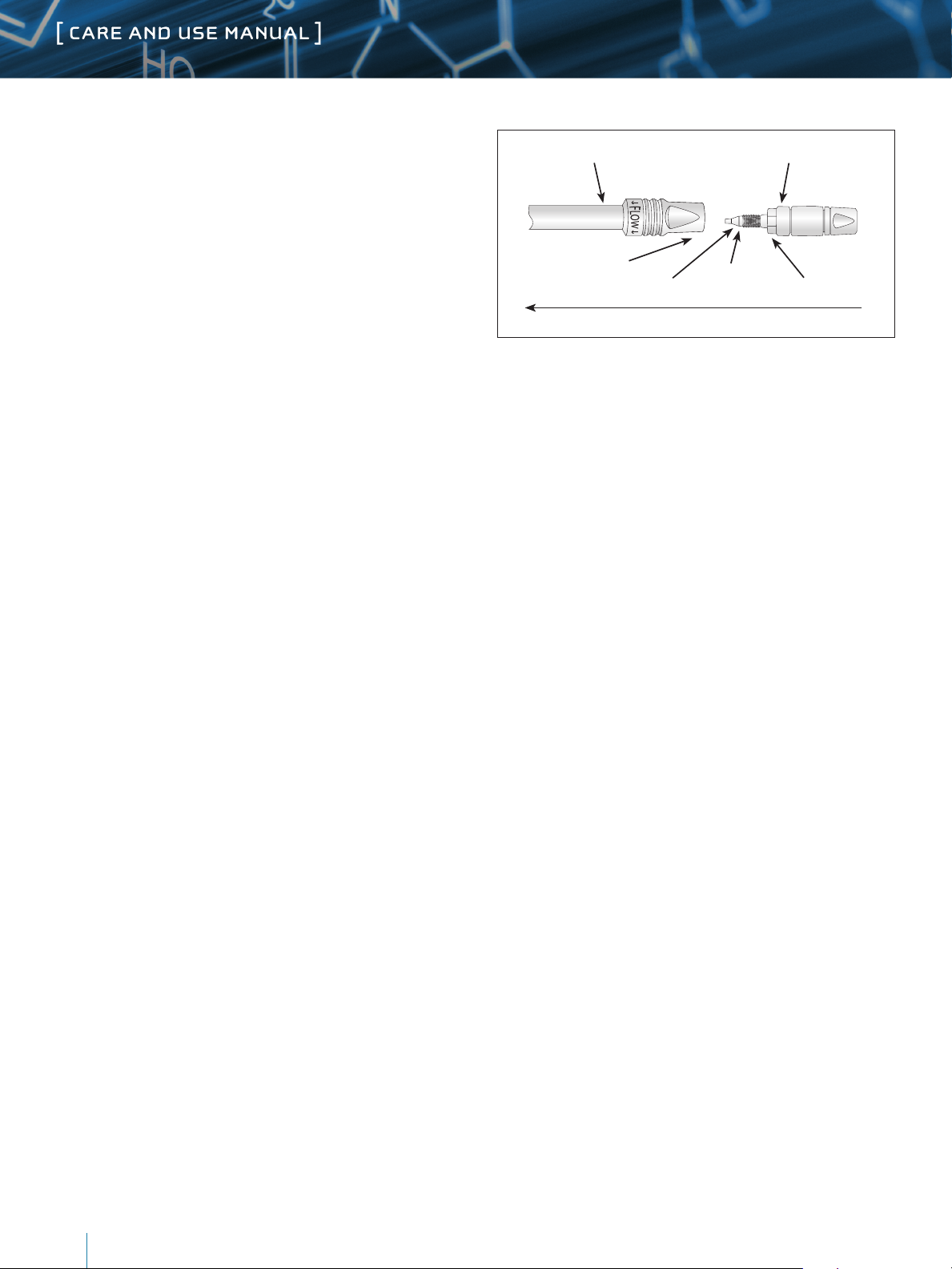

f. VanGuard Pre-Columns

VanGuard™ Pre-columns are 2.1 mm ID x 5 mm length guard

column devices designed specifically for use in the ACQUITY

UPLC System. VanGuard Pre-columns are packed with the same

CORTECS chemistries and frits as our 2.1 mm ID CORTECS

Columns. VanGuard Pre-columns are designed to be attached

directly to the inlet side of a CORTECS Column.

Note: In order to ensure void-free and leak-free connections, the

VanGuard Pre-column is shipped with the collet and ferrule NOT

permanently attached. Care must be taken when removing the

O-ring that holds these two pieces on the pre-column tubing.

CORT ECS Column

Place wrench here

Ferrule

Flow

VanGuard Pre-Column

Collet

Place wrench here

Installation Instructions

1. Remove the VanGuard Pre-column from its box and shipping

tube and remove plastic plug.

2. Orient the pre-column so that male end is facing up and

carefully remove rubber O-ring that holds collet and ferrule

in place during shipping (collet and ferrule are not yet

permanently attached).

3. Orient the CORTECS Column perpendicular to the work surface

so that column inlet is on the bottom (column outlet on top).

4. From below, insert the VanGuard Pre-column into the CORTECS

Column inlet and hand-tighten (collet and ferrule are not yet

permanently attached).

5. While pushing the VanGuard Pre-Column into the column

inlet, turn assembled column and pre-column 180˚ so that

pre-column is now on top.

6. Tighten with two 5/16” wrenches placed onto the CORTECS

Column flats and the VanGuard Pre-column hex nut (male end)

as shown above.

7. Tighten 1/4 turn to set collet and ferrule.

8. Check that the ferrule is set by loosening the connection and

inspecting the ferrule depth. A properly set ferrule depth will

resemble other connections in the ACQUITY UPLC System.

3

9. Reattach pre-column, apply mobile-phase flow and inspect

for leaks.

CORT ECS Columns

Page 4

Table 2: Buffer Recommendations for Using CORTECS Columns

Additive/Buffer pKa

TFA 0.30 Volatile Yes

Acetic Acid 4.76 Volatile Yes

Formic Acid 3.75 Volatile Yes

Acetate

(NH

COOH)

4CH2

Formate

(NH

COOH)

4

Phosphate 1 2.15 1.15 – 3.15 Non-volatile No Traditional low pH buffer, good UV transparency.

Phosphate 2 7.20 6.20– 8.20 Non-volatile No

4.76 3.76 – 5.76 Volatile Yes

3.75 2.75 – 4.75 Volatile Yes

Buffer

Range

Volatility

(±1 pH unit)

Used for

Mass Spec

Comments

Ion pair additive, can suppress MS signal, used in the

0.02-0.10% range.

Maximum buffering obtained when used with ammonium acetate

salt. Used in 0.1-1.0% range.

Maximum buffering obtained when used with ammonium formate

salt. Used in 0.1-1.0% range.

Used in the 1-10 mM range. Note that sodium or potassium salts

are not volatile.

Used in the 1-10 mM range. Note that sodium or potassium salts

are not volatile.

Above pH 7, reduce temperature/concentration and use a guard

column to maximize lifetime.

II. COLUMN USE

To ensure the continued high performance of CORTECS Columns, follow these guidelines:

a. Sample Preparation

1. Sample impurities often contribute to column contamination. One option to avoid this is to use Waters Oasis® Solid-Phase Extraction

Cartridges/Columns or Sep-Pak® Cartridges of the appropriate chemistry to cleanup the sample before analysis. For more information,

visit www.waters.com/sampleprep

2. It is preferable to prepare the sample in the operating mobile phase or a mobile phase that is weaker than the mobile phase for the

best peak shape and sensitivity.

3. If the sample is not dissolved in the mobile phase, ensure that the sample, solvent and mobile phases are miscible in order to avoid

sample and/or buffer precipitation.

4. Filter sample with 0.2 µm membranes to remove particulates. If the sample is dissolved in a solvent that contains an organic modifier

(e.g., acetonitrile, methanol, etc.) ensure that the membrane material does not dissolve in the solvent. Contact the membrane

manufacturer with solvent compatibility questions. Alternatively, centrifugation for 20 minutes at 8000 rpm, followed by the

transfer of the supernatant liquid to an appropriate vial, could be considered.

5. For Hydrophilic Interaction Chromatography (HILIC) separations, the samples must be prepared in a high percentage of organic

solvents (e.g., 95% acetonitrile). See “Getting Started with CORTECS HILIC Columns”.

b. pH Range

The recommended operating pH range for CORTECS Columns is 2 to 8 for the C

See Table 2 for more characteristic details of CORTECS chemistries.

+

and C18 chemistries, and 1 to 5 for the HILIC chemistry.

18

4

CORT ECS Columns

Page 5

A listing of commonly used buffers and additives is given in Table 2. Additionally, the column lifetime will vary

OSi

O

O

OSi

O

O

depending upon the operating temperature, the type and concentration of buffer used.

Note: Working at the extremes of pH, temperature and/or pressure will result in shorter column lifetimes.

Table 3: CORTECS Chemistry Characteristics

C

18

C18+ HILIC

Chemistry

General purpose, high-efficiency,

Intended Use

reversed-phase column. Balanced

retention of acids, bases and

neutrals at low and mid-range pH.

Ligand Type Trifunctional C

General purpose, high-efficiency,

reversed-phase column. A positively

charged surface delivers excellent

peak shape for basic compounds

at low pH.

18

Trifunctional C

18

High-efficiency column designed

for retention of extremely polar

analytes. Offers ort hogonal

selectivity vs. C

None

Surface Charge Modification None + None

Endcap Style Proprietary Proprietary None

Carbon Load 6.6% 5.7% Unbonded

Ligand Density 2.7 µmol/m

2

2.4 µmol/m

2

N/A

pH Range 2-8 2-8 1-5

Temperature Limits

1

Low pH = 45 °C

High pH = 45 °C

Low pH = 45 °C

High pH = 45 °C

Low pH = 45 °C

High pH = 45 °C

columns.

18

c. Solvents

To maintain maximum column performance, use high quality chromatography grade solvents. Filter all

aqueous buffers prior to use through a 0.2 µm filter. Solvents containing suspended particulate materials

will generally clog the outside surface of the inlet distribution frit of the column. This will result in higher

operating pressure and poorer performance. See Section V for more information.

d. Pressure

CORTECS Columns can tolerate operating pressures up to 18000 psi (1241 bar or 124 MPa).

Note: Working at the extremes of pressure, pH and/or temperature will result in shorter column lifetimes.

e. Temperature

Temperatures between 20–45 °C are recommended for operating CORTECS Columns in order to enhance

selectivity, lower solvent viscosity and increase mass transfer rates. When operating at high pH, lower operating

temperatures are recommended for longer column lifetime. Working at high temperatures (e.g. > 40 ˚C) may also

result in shorter column lifetimes.

Note: Working at the extremes of temperature, pressure and/or pH will result in shorter column lifetimes.

5

CORT ECS Columns

Page 6

III. COLUMN CLEANING, REGENERATING

AND STORAGE

a. Cleaning and Regeneration

Changes in peak shape, peak splitting, shoulders on the

peak, shifts in retention, change in resolution or increasing

backpressure may indicate contamination of the column. Flushing

with a neat organic solvent, taking care not to precipitate buffers,

is usually sufficient to remove the contaminant. If the flushing

procedure does not solve the problem, purge the column using the

following cleaning and regeneration procedures.

Use the cleaning routine that matches the properties of the

samples and/or what you believe is contaminating the column

(see Table 4). Flush columns with 20 column volumes of solvent.

Increasing column temperature increases cleaning efficiency. If

the column performance is poor after regenerating and cleaning,

call your local Waters office for additional support.

Flush CORTECS HILIC Columns with 50:50 acetonitrile/water to

remove polar contaminants. If this flushing procedure does not

solve the problem, purge the column with 5:95 acetonitrile/water.

Table 4. Reversed-Phase Column Cleaning Sequence

Polar Samples

1. water

2. methanol

3. tetrahydrofuran

(THF)

4. methanol 4. hexane

5. water

6. mobile phase 6. mobile phase

Non-polar

Samples**

1. isoproanol (or

an appropriate

isopropanol/water

mixture*)

2. tetrahydrofuran

(THF)

3. dichloromethane

5. isopropanol (followed by an appropriate isopropanol/

water mixture*)

Proteinaceous Samples

Option 1: Inject

repeated aliquots of

dimethylsulfoxide

(DMSO)

Option 2: gradient of

10% to 90% B where:

A = 0.1% trifluoroacetic

acid (T FA) in water

B = 0.1% trifluoroacetic

acid (T FA) in acetonitrile

CN)

(CH

3

Option 3: Flush column

with 7M guanidine

hydrochloride, or 7M

urea

b. Storage

For periods longer than four days at room temperature,

store reversed-phase and CORTECS HILIC Columns in 100%

acetonitrile. For elevated temperature applications, store

immediately after use in 100% acetonitrile for the best column

lifetime. Do not store columns in buffered eluents. If the mobile

phase contained a buffer salt, flush the column with 10 column

volumes of HPLC grade water (see Table 1 for common column

volumes) and replace with 100% acetonitrile for storage. Failure

to perform this intermediate step could result in precipitation

of the buffer salt in the column when 100% acetonitrile is

introduced. Completely seal column to avoid evaporation and

drying out of the bed.

For periods longer than four days, store CORTECS HILIC Columns

in 95:5 acetonitrile/water. Do not store in buffered solvent. If

the mobile phase contained a buffered salt, flush the column with

10 column volumes of 95:5 acetonitrile/water (see Table 1 for

common column volumes).

Note: If a column has been run with a mobile phase that contains

formate (e.g., ammonium formate, formic acid, etc.) and is then

flushed with 100% acetonitrile, slightly longer equilibration times

may be necessary when the column is re-installed and run again

with a formate-containing mobile phase.

* Use low organic solvent content to avoid precipitating buffers.

** Unless a Hexane Tetrahydrofuran Compatibility Kit (P/N 205000464) has been

installed, running solvents such as THF or hexane should only be considered when

the column cannot be cleaning by running neat, reversed-phase organic solvents

such as acetonitrile. Reduce flow rate, lower operating temperatures and limit

system exposure to THF and/or hexane.

6

CORT ECS Columns

Page 7

IV. INTRODUCING eCORD INTELLIGENT CHIP

TECHNOLOGY

a. Introduction

The eCord Intelligent Chip provides the history of a column’s performance

throughout its lifetime. The eCord will be permanently attached to the

Figure 1. Waters eCord Intelligent Chip

column to assure that the column’s performance history is maintained in

the event that the column is moved from one instrument to another.

At the time of manufacture, tracking and quality control information

will be downloaded to the eCord. Storing this information on the chip

will eliminate the need for a paper Certificate of Analysis. Once the

user installs the column, the software will automatically download key

parameters into a column history file stored on the chip. In this manual,

we explain how the eCord will provide a solution for easily tracking the

eCord inserted into

side of column heater

history of the columns, reduce the frustration of paperwork trails, and give

customers the reassurance that a well-performing column is installed onto

Figure 2. eCord Inserted into Side of Column Heater

their instruments.

b. Installation

Install the column into the column heater. Plug the eCord into the side of the column heater. Once the eCord

is inserted into the column heater the identification and overall column usage information will be available

allowing the user to access column information on their desktop.

Waters eCord -

intelligent chip

c. Manufacturing Information

The eCord chip provides the user with an overview of the bulk material QC test results.

d. Column Use Information

The eCord chip provides the customer with column use data. The top of the

screen identifies the column including chemistry type, column dimensions and

serial number. The overall column usage information includes the total number

of samples, total number of injections, total sample sets, date of first injection,

date of last injection, maximum pressure and temperature. The information

also details the column history by sample set including date started, sample

set name, user name, system name, number of injections in the sample set,

number of samples in the sample set, maximum pressure and temperature in

the sample set and the column.

The eCord chip provides QC test

conditions and results on the

column run by the manufacturer.

The information includes mobile

phases, running conditions

and analytes used to test the

columns. In addition the QC

results and acceptance is placed

onto the column.

7

CORT ECS Columns

Page 8

V. ADDITIONAL INFORMATION

a. Tips for Maximizing CORTECS Column Lifetimes

1. To maximize CORTECS Column lifetime, pay close attention to:

Water quality (including water purification system)

Solvent quality

Mobile-phase preparation, storage and age

Sample, buffer and mobile-phase solubilities

Sample quality and preparation.

2. W hen problems arise, often only one improper practice must

be changed.

3. Always remember to:

Use in-line filter unit or, preferably, a VanGuard

Pre-column.

Discourage bacterial growth by minimizing the use of

100% aqueous mobile phases where possible.

Change aqueous mobile phase every 24 – 48 hours

(if 100% aqueous mobile phase use is required).

Discard old 100% aqueous mobile phases every 24-48

hours to discourage bacterial growth.

Add 5% -10% organic modifier to mobile phase A and

adjust gradient profile.

Filter aqueous portions of mobile phase through

0.2 µm filter.

Maintain your water purification system so that it is in

good working order.

Only use ultra pure water (18 megohm-cm) water and

highest quality solvents possible. HPLC grade water is not

UPLC grade water.

Consider sample preparation (e.g., solid-phase extraction,

filtration, etc).

4. Avoid (where possible):

100% aqueous mobile phases (if possible)

HPLC-grade bottled water

“Topping off” your mobile phases

Old aqueous mobile phases. Remember to rinse bottles

thoroughly and prepare fresh every 24 to 48 hrs

Using phosphate salt buffer in combination with high

ACN concentrations (e.g., > 70%) due to precipitation.

5. Don’t: assume a “bad” column is the culprit when high

backpressure or split peaks are observed:

Investigate cause of column failure

• Backpressure

Mobile phase(s), bacteria, precipitation and/or samples

Peak splitting

Sample quality

Injection solvent strength.

8

CORT ECS Columns

6. Remember: the diameter of CORTECS Column (2.1 and 3.0 mm

ID) are often lower than that of a conventional HPLC column and

therefore, mobile phases last much longer. To reduce the chances of

mobile-phase contamination or degradation, only prepare what you

need for analysis or store excess bulk quantities in a refrigerated

environment.

7. Mobile-phase related questions to ask:

Am I using 100% aqueous mobile phases? Am I able to

add a small amount of organic modifier to my mobile

phase A?

Do I filter my aqueous mobile phases through 0.2 µm

filters?

How old is my mobile phase? Do I label the bottle with

preparation date?

Do I “top off” or do I prepare fresh mobile phases every

24 – 48 hrs?

What is the quality of my water? Has the quality recently?

changed? How is my water purification system working?

When was it last serviced?

Am I working with pH 7 phosphate buffer (which is

VERY susceptible to bacterial growth)?

8. Sample-related questions to ask:

If I inject neat standards prepared in mobile phase do I

observe these problems?

If I prepare my standards in water and prepare them

like samples (e.g. SPE, filtration, etc.) do I still observe

these problems?

Has the quality of my samples changed over time?

b. Getting Started with CORTECS HILIC Columns

1. Due the fact that CORTECS HILIC Columns do not possess a

bonded phase, the pH operating range is 1 to 5, and they can be

operated at temperatures up to 45 °C.

2. As with any LC column, operating at the extremes of pH,

pressures and temperatures will result in decreased column

lifetime.

Column Equilibration

1. When the column is first received, flush in 50% acetonitrile/

50% water with 10 mM final buffer concentration for

50 column volumes.

2. Equilibrate with 20 column volumes of initial mobile-phase

conditions before making first injection.

3. If gradient conditions are used, equilibrate with 8-10 column

volumes between injections.

4. Failure to appropriately equilibrate the column could result in

drifting retention times.

Page 9

Mobile-Phase Considerations

1. Always maintain at least 3% polar solvent in the mobile

phase or gradient (e.g., 3% aqueous/3% methanol or 2%

aqueous/1% methanol, etc.). This ensures that the CORTECS

particle is always hydrated.

2. Maintain at least 40% organic solvent (e.g., acetonitrile) in

your mobile phase or gradient.

Miscellaneous Tips

1. CORTECS HILIC Columns are designed to retain very polar

bases. Acidic, neutral and/or non-polar compounds will have

limited retention.

2. Optimal flow rates for small (<200 daltons) very polar bases

are in the 0.4 to 0.8 mL/min range with the CORTECS HILIC

Columns.

3. Avoid phosphate salt buffers to avoid precipitation in HILIC

mobile phases. Phosphoric acid is okay.

4. Buffers such as ammonium formate or ammonium acetate

will produce more reproducible results than additives such

as formic acid or acetic acid. If an additive (e.g., formic acid,

etc.) must be used instead of a buffer, use 0.2% (v:v) instead

of 0.1%.

5. For best peak shape, maintain a buffer concentration of 10 mM

in your mobile phase/gradient at all times.

Injection Solvents

1. If possible, injection solvents should be 95% acetonitrile.

The polar solvent (i.e., water, methanol, isopropanol) should

be minimized to 25% of the total volume.

2. A generic injection solvent is 75:25 acetonitrile/methanol.

This is a good compromise between analyte solubility and

peak shape.

3. Avoid water and dimethylsulfoxide (DMSO) as injection solvents. These solvents will produce very poor peak shapes.

4. Exchange water or DMSO with acetonitrile by using

reversed-phase solid-phase extraction (SPE). If this is not

possible, dilute the water or DMSO with organic solvent.

3. In HILIC, it is important to remember that water is the strongest

solvent. Therefore, it must be eliminated or minimized in the

injection solvent.

4. For initial scouting conditions, run a gradient from

95% acetonitrile to 50% acetonitrile. If no retention occurs, run

isocratically with 95:3:2 acetonitrile/methanol/aqueous buffer.

5. Alternate polar solvents such as methanol, acetone or isopropanol

can also be used in place of water to increase retention.

6. If using an ACQUITY UPLC System, the weak needle wash

should closely match the % organic present in the initial

mobile-phase conditions, otherwise, analyte peak shape or

retention may suffer.

©2013 Waters Corporation. Waters, ACQUITY UPLC, UPLC, Oasis and

SepPak are registered trademarks of Waters Corporation. CORT ECS,

VanGuard, eCord and The Science of What’s Possible are trademarks

of Waters Corporation. All ot her trademarks are the property of their

respective owners.

June 2013 720004750EN Rev. A VW-PDF

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...