Page 1

[ Care and Use ManUal ]

CeRtIFIeD seP-PAK CARtRIDGes

Contents

I. IntRoDUCtIon

II. UsInG CeRtIFIeD seP-PAK CARtIDGes

III. stRAteGIes FoR soLID-PHAse eXtRACtIon

IV. FACtoRs AFFeCtInG sePARAtIon eFFICIenCY

V. stoRAGe AnD DIsPosAL oF UseD CARtRIDGes

VI. oRDeRInG InFoRmAtIon

VII. ADDItIonAL InFoRmAtIon

VII. LIteRAtURe ReFeRenCes

I. IntRoDUCtIon

Waters Certified Sep-Pak® cartridges are convenient, reproducible,

disposable solid-phase extraction (SPE) devices for sample

preparation. Certified Sep-Pak cartridges are manufactured in a

Waters ISO 13485 and ISO 9002-registered facility in compliance

with cGMP guidelines for the U.S. Food and Drug Administration for

Class 1 Medical Devices.

Certified Sep-Pak cartridges are available in many styles to

accommodate manual and automated solid-phase extraction and are

available in 3 cc and 6 cc formats in the following chemistries:

Reversed-Phase: C

Normal-Phase: Silica, Alumina A, Alumina B, Alumina N, Florisil

18

®

Certified Sep-Pak Cartridges 1

Page 2

[ Care and Use ManUal ]

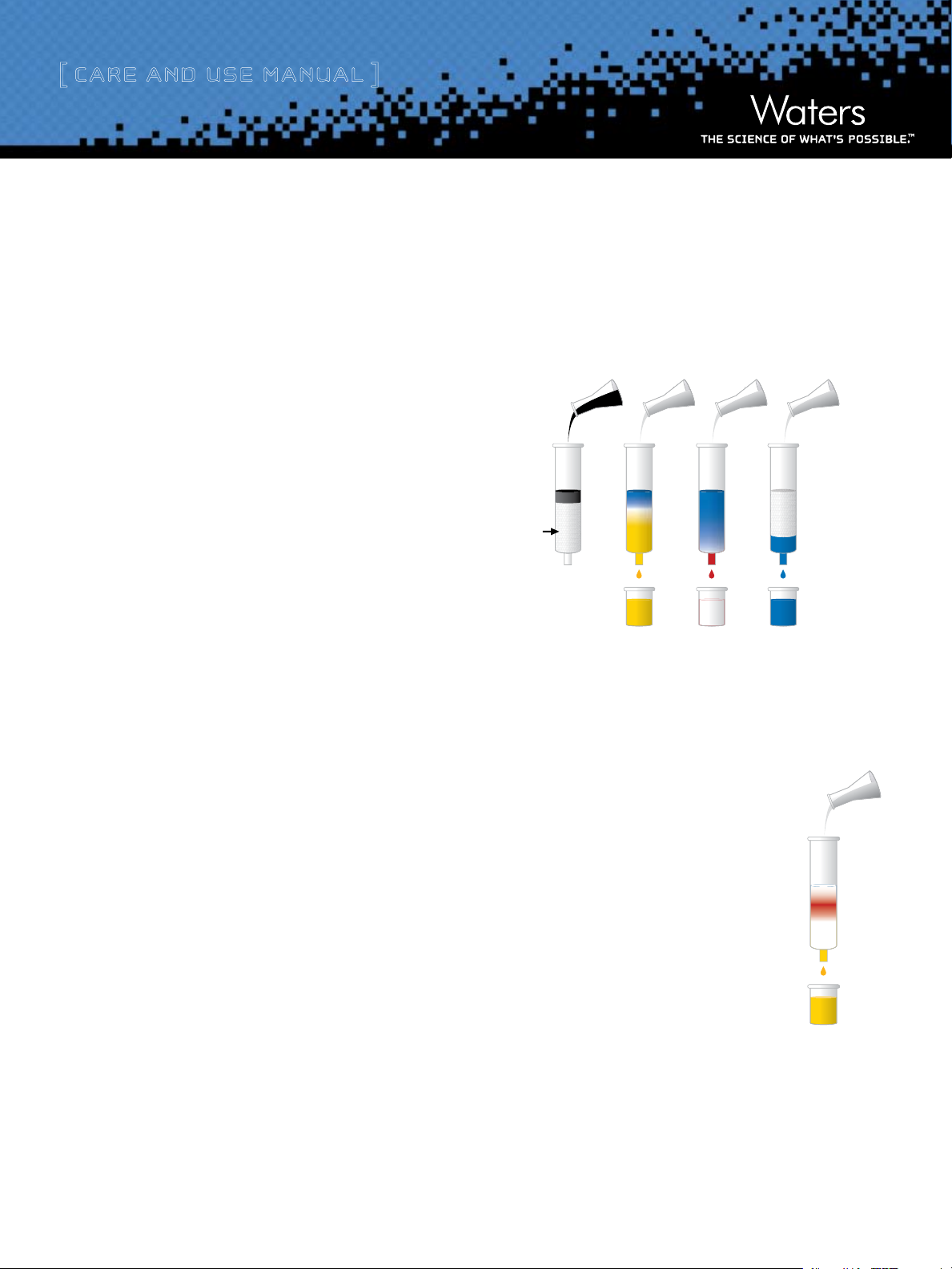

Load Sample

(Black)

Step

Elute 1

Step

Elute 2

One cartridge can separate all three dyes

Step

Elute 3

NOTE: Different

strength solvents

can be used to

separate the dyes.

Stationary

Phase

Particles

II. UsInG CeRtIFIeD seP-PAK CARtRIDGes

Below is a five step guideline for using Certified Sep-Pak cartridges.

Each separation is different and not all steps may be required for

your application.

1. Prepare sample: T he sample can be applied to the Certified Sep-Pak

cartridge in either liquid or a gas phase. If the sample is a solid, it must

be dissolved or extracted prior to loading.

2. Condition/equilibrate cartridge: A conditioning step is required for

reversed-phase sorbents (e.g., C

). Use a strong solvent to wet the

18

stationary phase. Conditioning is followed by an equilibration step

using a weak solvent.

3. Load sample: T he sample is loaded onto the cartridge.

4. Wash: The wash step removes interferences while retaining the analyte.

If weakly retained interferences are present in the sample matrix, wash

with an appropriate weak solvent.

5. Elute: Use an appropriate stronger solvent to elute the analyte while

retaining more strongly bound interferences.

III. stRAteGIes FoR soLID-PHAse eXtRACtIon

a. Retention-Cleanup-Elution Strategy

As the sample is loaded onto the cartridge, the analytes of interest are

retained by the sorbent. If needed, an optimized series of washes are

used to remove matrix interference from the cartridge. A strong solvent

is used to elute the analytes from the cartridge. Sample enrichment

results when the final elution volume is smaller than the load volume.

b. Pass-Through Cleanup Strategy

Pass-through cleanup methods optimize matrix retention while the

analytes of interest pass-through the cartridge unretained. No sample

enrichment occurs during the solid-phase extraction (SPE) step.

Purification: Use as a “chemical filter” to retain the component

of interest while interferences elute, or to retain the interferences

while the analyte passes through unretained.

Trace enrichment or concentration: Use to concentrate an analyte

from a dilute solution. This is done when the analyte concentration is

below the detection limit of the analytical method.

Fractionation: Use with a step gradient of increasing solvent

strength to selectivity elute and isolate analytes based on differences

in polarity.

Solvent exchange: Use to adsorb the analyte and elute with a desir-

able solvent. This is helpful of the sample is dissolved in a solvent

that is incompatible with the analytical method.

Certified Sep-Pak Cartridges 2

1. Sample is passed through sorbent and collected

• No sample enrichment

2. Matrix interferences are retained on sorbent

Pass-Through

Page 3

[ Care and Use ManUal ]

c. SPE Procedure Steps

The following section describes the steps involved in a complete

solid-phase extraction procedure:

1. Pretreatment

Solid samples (soil, tissue, etc.)

• Shake, sonicate, or use soxhlet extraction.

- Extract sample with polar organic solvent (methanol,

acetonitrile) for polar analytes.

- Extract sample with organic solvent and drying agent

(dichloromethane, acetone) for non-polar analytes and

multi-residue extraction.

Non-Aqueous liquid

• If the sample is soluble in water, dilute it with water for

reversed-phase SPE.

• If the sample is soluble in hexane, dilute it with (or exchange to)

hexane for SPE.

Wastewater

• Filter or centrifuge as necessary.

2. Condition

For reversed-phase sorbents, preconditioning of the sorbent with

an organic solvent, such as methanol, acetonitrile, isopropanol, or

tetrahydrofuran, is usually necessary to obtain reproducible results.

Without this step, a highly aqueous solvent cannot penetrate the

hydrophobic surface and wet the sorbent. Thus, only a small fraction

of the sorbent surface area would be available for interaction with the

analyte. For the same reason, it is important not to let silica-based

SPE cartridges dry out between the solvation step and the addition of

the sample. A complete preconditioning of a reversed-phase cartridge

includes the solvation step and an equilibration with a low-strength

solvent such as water or buffer.

3. Load

When the analytes of interest are not retained by the sorbent,

this is called analyte breakthrough. For some methods, such as

pass-through cleanup, analyte breakthrough is desirable and is

maximized for those specific methods. However, in all other cases,

analyte breakthrough is unwanted and contributes to poor recovery

and method reproducibility. Breakthrough occurs when:

• T here is too high an organic concentration in the load solution for very

polar analytes. Dilute sample at least 1:1 with water or buffer prior to

loading.

• T he analytes are bound to proteins, they may pass through

the sorbent. Ensure that analytes are not bound to proteins by

acidifying or basifying the sample.

• Sorbent is overloaded by the matrix component. Therefore, it is

important to choose the correct sorbent mass (see table 1).

• T he flow rate of the load step is too fast. T here is not enough

contact time between the analytes and the sorbent. Look at the drops

and adjust the vacuum so that you see discrete droplets, not a stream

of liquid.

Table 1. Choice of Cartridges Based on Sample Size

Sample Size Cartridge

10-100 mL 3 cc/200 mg or 6 cc/500 mg

100-500 mL 3 cc/200 mg or 6 cc/500 mg

500-1000 mL 6 cc/500 mg (LP) or 6 cc/1 g

4. Wash

The wash steps are designed to remove unwanted matrix components

that remain from the loading step. The ideal wash solvent removes

only the matrix while keeping the analytes bound to the sorbent. For

complex samples this is impossible, so the wash steps are optimized

using pH, solvent strength, and solvent polarity to remove as much

matrix as possible while maintaining acceptable analyte recovery.

Certified Sep-Pak Cartridges 3

Page 4

[ Care and Use ManUal ]

5. Elute

Once the interferences are washed off the cartridge, a strong solvent is introduced to elute the analytes of interest. T he volume and flow rate

of the eluting solvents should be precisely controlled as in the load step to ensure reproducible results.

Table 2. Guidelines on the Various Types of Separation Mechanisms

Reversed Phase Normal Phase Ion Exchange

Analyte

Matrix Aqueous Non-polar organic solvent Aqueous/low ionic strength

Low to moderate polarity/

hydrophobic

Moderate to highly polar/uncharged Charged or ionized

Condition/Equilibrate

Wash Aqueous/buffer Non-polar Low ionic strength buffer

Elute

IV. FACtoRs AFFeCtInG sePARAtIon eFFICIenCY

Separation efficiency varies with flow rate and sample load. Here

are some guidelines to consider when optimizing your separation.

a. Flow Rate

If the sample flow rate is too high, components may not interact

sufficiently with he sorbent. The result is loss of resolution, analyte

breakthrough, and poor recovery. To condition the cartridge, use a

flow rate of 5-10 mL/min. To load and elute Certified Sep-Pak Vac 3

cc 200 mg, and 500 mg cartridges, use a flow rate or 0.2-1 mL/min.

To load and elute all other cartridges, use a flow rate or 2-10 mL/min.

b. Sample Load

1. Solvate polar organic

2. Water

Increase polar organic content

in steps

Non-polar organic Low ionic strength buffer

Increase moderate to high polarity

organic content in steps

Stronger buffers ionic strength or

pH to neutralize the charge

V. stoRAGe AnD DIsPosAL oF UseD CARtRIDGes

Cartridges stored in their original sealed pouch remain stable

for long periods. Once opened, special care must be taken to

ensure that the SPE cartridges are not exposed to the laboratory

environment for long periods. The highly active sorbents will readily

accumulate background contaminants from the environment and

will affect the quality of the device. Waters recommends that you

open and use only those cartridges that will be needed. If this is not

possible, store the exposed cartridges in clean contaminant free

container such as a desiccator.

Dispose of used cartridges safely in accordance with applicable

government or local regulations.

Cartridge capacity depends upon the mass of all components in the

sample, volume of solvent, solvent strength, sorbent type, sorbent

quality, and retention factor (k) of components. Overloading results in

sample breakthrough which leads to variability in sample recovery.

Certified Sep-Pak Cartridges 4

Page 5

[ Care and Use ManUal ]

VI. oRDeRInG InFoRmAtIon

Description Part Number

Alumina A

Certified Sep-Pak Vac, 3 cc, 500 mg, 50/box 186004602

Certified Sep-Pak Vac, 6 cc, 500 mg, 30/box 186004603

Certified Sep-Pak Vac, 6 cc, 1 g, 30/box 186004604

Alumina B

Certified Sep-Pak Vac, 3 cc, 500 mg, 50/box 186004605

Certified Sep-Pak Vac, 6 cc, 500 mg, 30/box 186004606

Certified Sep-Pak Vac, 6 cc, 1 g, 30/box 186004607

Alumina N

Certified Sep-Pak Vac, 3 cc, 500 mg, 50/box 186004608

Certified Sep-Pak Vac, 6 cc, 500 mg, 30/box 186004609

Certified Sep-Pak Vac, 6 cc, 1 g, 30/box 186004610

Florisil

Certified Sep-Pak Vac, 3 cc, 500 mg, 50/box 186004611

Certified Sep-Pak Vac, 6 cc, 500 mg, 30/box 186004612

Certified Sep-Pak Vac, 6 cc, 1 g, 30/box 186004613

Silica

Certified Sep-Pak Vac, 3 cc, 200 mg, 50/box 186004614

Certified Sep-Pak Vac, 3 cc, 500 mg, 50/box 186004615

Certified Sep-Pak Vac, 6 cc, 500 mg, 30/box 186004616

Certified Sep-Pak Vac, 6 cc, 1 g, 30/box 186004617

18

C

Certified Sep-Pak Vac, 3 cc, 200 mg, 50/box 18 60 04618

Certified Sep-Pak Vac, 3 cc, 500 mg, 50/box 186004619

Certified Sep-Pak Vac, 6 cc, 500 mg, 30/box 186004620

Certified Sep-Pak Vac, 6 cc, 1 g, 30/box 186004621

VII. ADDItIonAL InFoRmAtIon

Sep-Pak accessories are available to help with your solid-phase

extraction. Ordering information for these products is below.

Sep-Pak Cartridge Accessories

Description Qty. Part No.

30 cc Reservoir 48/pkg WAT011390

60 cc Reservoir 12/pkg WAT024659

Reservoir Adapters for 3, and 6 cc VAC 12/pkg WAT054260

Male-Male Adapter 100/pkg WAT024310

Male Luer Plugs WAT044395

Female Luer Plugs WAT044385

Extraction Manifolds

20 position extraction manifold without rack

20 position extraction manifold with 13 x 75 mm test tube rack

20 position extraction manifold with 13 x 100 mm test tube rack

WAT200677

WAT200606

WAT200607

Description Qty. Part No.

20 position extraction manifold with 16 x 75 mm test tube rack

20 position extraction manifold with 16 x 100 mm test tube rack

WAT200608

WAT200609

Accessories and Spare Parts for the Waters Extraction Manifolds

Needle valves, 20/pkg (required when using silicabased SPE cartridges)

Needle tips, 20/pkg WAT200691

Cover, 20 position without gauge assembly WAT200686

Gauge assembly, vacuum WAT200687

Reservoir, glass with outlet valve WAT200687

Outlet valve kit WAT200688

Gasket for cover WAT200689

Ejector tool WAT200690

Luer Plugs 25/pkg WAT058839

Rubber ball ring (for vacuum gauge assembly) WAT058851

Reversible Vial Rack for 1 mL or 4 mL

autosampler vials

13 x 75 mm test tube rack WAT058871

13 x 100 mm test tube rack WAT200678

16 x 75 mm test tube rack WAT200679

16 x 100 mm test tube rack WAT200680

Adapter (to attach reservoir to 1, 3, and 6 cc

Sep-Pak Vac cartridges)

Adapter (to attach reservoir to 12, 20, and 35 cc

Sep-Pak Vac cartridges)

Vacuum pump (110 V, 60 Hz) 10/pkg WAT048160

Vacuum pump (220 V, 50 Hz) WAT085114

Vacuum pump (220 V, 50 Hz) WAT085115

100/pkg WAT024310

12/pkg WAT054260

WAT200685

WAT058840

For more detailed information, consult the Chromatography Columns

and Supplies Catalog by visiting www.waters.com (literature code

720002419EN), or contact your Waters representative.

If you require technical assistance, or have any questions

regarding sample preparation, visit www.waters.com or call us at

1-800-252-4752.

VIII. LIteRAtURe ReFeRenCes

Description Literature Code

Certified Sep-Pak Brochure 720002806EN

Sorbent Selection Guide Wall Chart 720002007EN

A Sample Preparation Primer and Guide to Solid-Phase

Extraction Methods Development

Sample Preparation Solutions Brochure 720000848EN

Sep-Pak Sample Extraction Products Brochure 720000860EN

Food Safety Application Notebook 720002565EN

Environmental Chromatography Methods Guide 720002543EN

WA20300

Certified Sep-Pak Cartridges 5

Page 6

[ Care and Use ManUal ]

Sales Offices

Austria and European Export

(Central South Eastern Europe, CIS

and Middle East) 43 1 877 18 07

Australia 61 2 9933 1777

Belgium 32 2 726 1000

Brazil 55 11 5094-3788

Canada 1 800 252 4752 x2205

China 86 21 6879 5888

CIS/Russia +497 727 4490/290 9737

Czech Republic 420 2 617 1 1384

Denmark 45 46 59 8080

Finland 09 5659 6288

France 33 1 30 48 72 00

Germany 49 6196 400600

Hong Kong 852 29 64 1800

The Netherlands 31 76 508 7200

Norway 47 6 384 60 50

Poland 48 22 833 4400

Puerto Rico 1 787 747 8445

Singapore 65 6273 7997

Spain 34 93 600 9300

Sweden 46 8 555 11 500

Switzerland 41 56 676 70 00

Taiwan 886 2 2543 1898

United Kingdom 44 208 238 6100

All other countries:

Waters Corporation U.S.A.

1 508 478 2000

1 800 252 4752

www.waters.com

Hungary 36 1 350 5086

India and India Subcontinent

91 80 2837 1900

Ireland 353 1 448 1500

Italy 39 02 265 0983

Japan 81 3 3471 7191

Korea 82 2 6300 4800

Mexico 52 55 5524 7636

© 2009 Waters Corporation. Waters, The Science of W hat’s

Possible, and Sep-Pak are trademarks of Waters Corporation.

Florisil is a trademark of U.S. Silica.

Sep-Pak Cartridges are covered by U.S. Patents # 4,211,658

and/or # 4,250,035 and several foreign patents.

March 2009 720002966EN Rev A V W-PDF

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Certified Sep-Pak Cartridges 6

Loading...

Loading...