Page 1

[ Care and Use ManUal ]

CarbaMate analysIs ColuMn

I. IntroduCtIon

The Waters Carbamate Analysis Column (3.9 x 150 mm) is packed

with a durable, high efficiency, 4μ spherical silica-based stationary

phase ideally suited for the reversed-phase separation of carbamate

pesticides and related compounds.

Waters exclusive sequential bonding and packing processes coupled

with stringent quality control procedures ensure precise surface

chemistry, reproducibility, and stability. When used as a component

of Waters Carbamate Analysis System with the Waters Carbamate

Analysis Method, this column is guaranteed to provide the resolution

and sensitivity needed for successful analysis of the analytes listed

in Figure 1.

Contents

I. IntroduCtIon

II. InstallatIon

a. Attaching the Column

b. Equilibration

III. MobIle phase and saMple guIdelIne

a. Solvent Preparation and Filtration

b. Sample Preparation and Filtration

IV. operatIon

a. Chromatography Guidelines

b. Efficiency Testing

V. Care and MaIntenanCe

a. Troubleshooting

b. Shutdown and Storage

VI. ColuMn and supplIes orderIng and InforMatIon

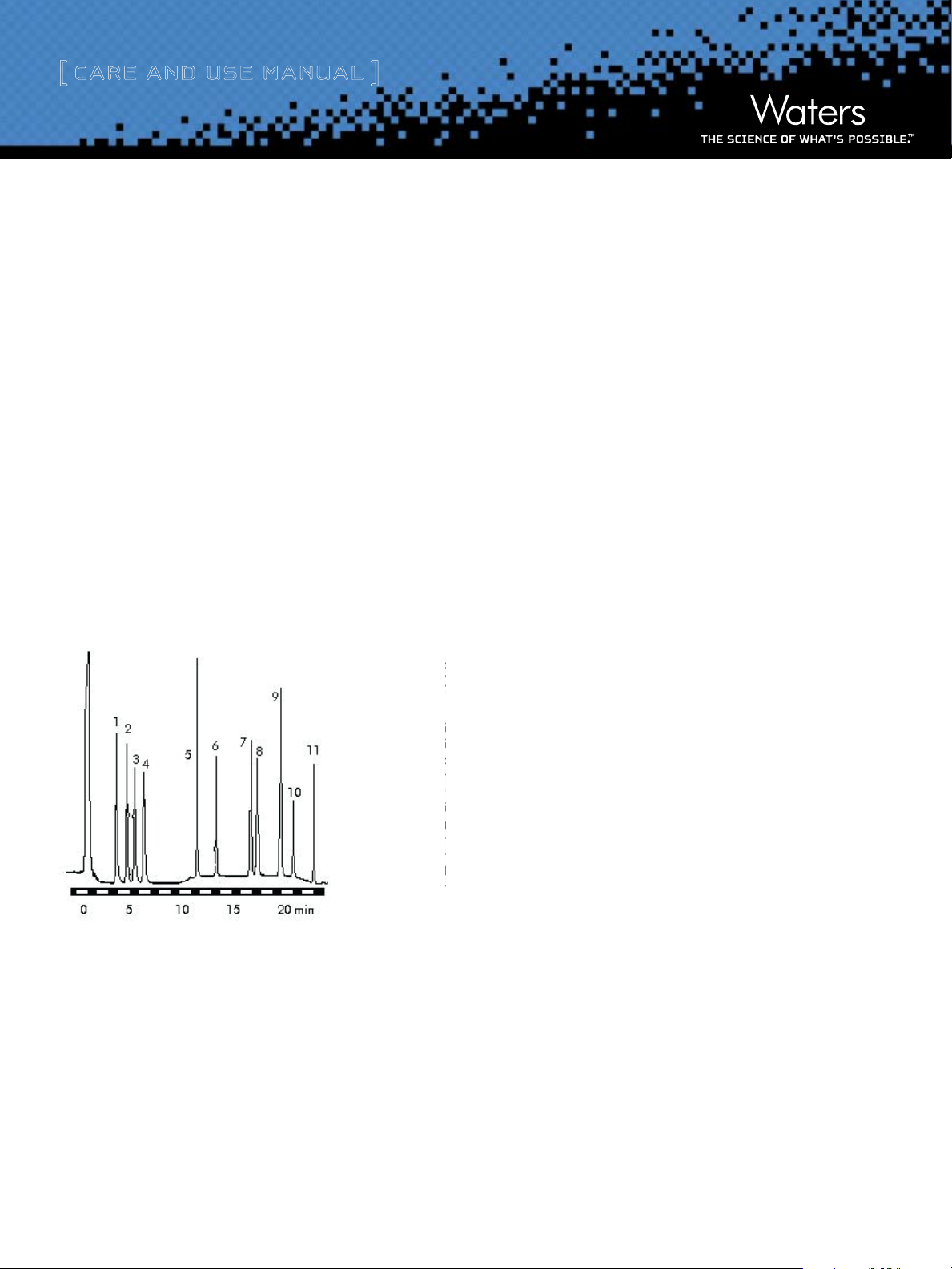

Figure 1: A Typical Separation of Carbamate Pesticides & Related

Compounds using Waters Carbamate Analysis System*

Please take a few moments to read this manual carefully. Use the

information it contains to ensure that you obtain quality results and

take full advantage of the features your Waters column offers.

Note: Liquid chromatography columns have a finite life, which is

directly related to the care and use they receive. Column life is

affected by contamination from samples and solvents, frequent

solvent changeovers, and improper handling and storage.

* For additional information on the complete method, please refer to Waters Carbamate

Analysis System Manual.

Carbamate Analysis Column 1

VII. Warranty/serVICe InforMatIon

Page 2

[ Care and Use ManUal ]

Compression Screw or Nut

Ferrule

End must be straight

and smooth to achieve

maximum column efficiency

Tu be

Critical Distance to be determined by

the union or column fitting, etc.

Follow generally accepted procedures for quality control and methods

development when using this column.

If you observe a change in peak shape, retention of a particular

compound, or resolution between two compounds, take immediate

steps to determine the reason for the changes. Until the cause of the

change is determined, do not rely on the results of the analyses.

II. InstallatIon

a. Attaching the Column

1. If this column is to be used with an LC system previously used

for a purpose other than carbamate analysis, then before

installing the column in the flow path connect the column

inlet and outlet lines to each other with a union and flush the

lines, as well as the sample injector and injector loops, free of

previous solvents. Make certain that the final flushing solvent

is miscible with water. Remove the union.

2. Remove the end plugs from your column with a 5/16-inch

wrench.

5. Grasp the tubing on both sides of the scribe mark with cloth-

covered pliers (to prevent marring the tube surface) and gently

work the tub back and forth until it breaks cleanly. Check that

the end is straight and smooth with no burrs. Flush the tube

from the opposite end with mobile phase to remove any metal

particles that may have lodged in the interior of the tube.

6. Slide the compression screw head first followed by the ferrule

(large end of the taper first) over the tube. Insert the end of

the tube into the fitting seat to which it will be connected.

Tighten the compression screw in the fitting seat as in Step 3.

Assembly details are shown in Figure 2.

CAUTION: Properly bottom the tubing in the fitting seat

while tightening the compression screw to the column.

Tubing not completely seated will result in dead volume

which could cause excessive sample band spreading.

NOTE: Be sure to replace and tighten the end plugs when the

column is removed from the system for storage.

3. The column outlet is indicated by an arrow on the label

showing the direction solvent should flow. Thread the inlet and

outlet tubing fittings into the column until finger tight and then

tighten the fittings with a wrench turning each - turn.

CAUTION: Do not over-tighten. Over-tightening will damage

the connection. Follow the next three steps of this procedure

if you must remove a damaged compression screw or worn

ferrule.

4. Using a miniature tubing cutter, scribe deeply the

circumference of the tubing at the desired break point. Or,

alternatively, using a three-cornered file with a cutting edge,

cut 1/3 of the way through the tubing at the desired break

point.

Carbamate Analysis Column 2

Figure 2: Ferrule and Compression Screw Assembly

b. Equilibration

The Waters Carbamate Analysis Column is shipped in the mobile

phase used for column storage: 50/50 v/v methanol/acetonitrile.

For equilibration, flush the column with the initial mobile phase

used for the gradient analysis. This can be conveniently done while

the post-column reaction system, column oven, and detector are

warming up to stable operating conditions (about 30 minutes at 1.5

mL/min). Refer to the Waters Carbamate Analysis System Manual

for details.

Page 3

[ Care and Use ManUal ]

III. MobIle phase and saMple guIdelIne

a. Solvent Preparation and Filtration

1. Use only HPLC Grade or better solvents suitable for high sensitivity

fluorescence analysis, filtered to remove micro-particulate matter

about 0.45 µm.

NOTE: All glassware used for solvent and sample preparation must

be scrupulously clean. Detergent, fingerprint, cigarette smoke, breath

residues, etc., may contain amines which can cause interference with the

analysis.

Acetonitrile and methanol, even HPLC grade, may contain traces of

amines or ammonia, which will react with OPA/mercaptoethanol to

form highly fluorescent impurities. These derivatives may cause base-

line shifts or increased baseline noise. If this becomes a problem, clean

the reservoirs and use fresh solvent. If necessary, switch to a different

lot of solvent or to a different solvent vendor until a suitable grade is

found.

Distill or HPLC grade water. De-ionized water is not acceptable because

it contains organic compounds which may alter column selectivity.

2. Use vacuum filtration, sonication, and/or helium sparging to remove

dissolved gases, which could affect your solvent delivery system.

Waters Solvent Clarification Kit is designed to assist in the degassing

and preparation of mobile phases. Waters Carbamate Analysis System

has provision for continuous sparging of each mobile phase component.

3. Use a Waters In-Line Pre column Filter to capture system particulates

and extend column life. Note: a Waters In-Line Pre column Filter is

supplied with the Waters Carbamate Analysis System.

IV. o pe rat Io n

a. Chromatography Guidelines

Liquid chromatography columns have a finite life which, is directly

related to the care and use they receive. Column life is affected

by contamination from; samples and solvents, frequent solvent

changeovers, and improper handling and storage.

If you observe a change in peak shape, retention of a particular

compound, or resolution between two compounds, take immediate

steps to determine the reason for the changes. Until the cause of the

change is determined, do not rely on the results of the analyses.

Follow generally accepted procedures for quality control and

methods development when using this column

NOTE: Before running the first analysis on your new column, perform

the test sample separation given in Section IV. b., Efficiency Testing

PRECAUTIONS

a. Pressure

Maximum pressure should not exceed: 28 Mpa (4000 psi or 275

bars). Typical operating pressure in the Waters Carbamate Analysis

System: 10-20 Mpa (1500-3000 psi or 100-200 bars).

b. Temperature

Recommended column operating temperature range: 20 °C - 40

°C. Typical operating pressure in the Waters Carbamate Analysis

System: 30 °C.

c. Flow Rate

b. Sample Preparation and Filtration

1. Use a Waters Sample Clarification Kit or 0.45 μ Membrane Filter

Units to filter samples and prevent excessive pressure buildup.

2. Do not inject a sample that is dissolved in a solvent, which is not

miscible with the mobile phase.

3. If samples contain contaminants which become irreversibly bound

to the column packing under normal operating conditions, it may be

®

desirable to use Waters Sep-Pak

column module and Guard-Pak Cartridges to remove the contaminants

off-line or on-line, respectively.

Carbamate Analysis Column 3

Cartridges or Waters Guard-Pak™ Pre

There are not flow rate restrictions as long as the recommended

pressure limits are not exceeded. Typical operating flow rate is

1.5mL/min. Flow rate should be increased gradually (in 0.5 mL/min

increments) to reach operating flow rate and decreased gradually to

zero upon system shutdown.

d. pH Range

Maintain pH of mobile phase and samples between 3 and 8. Avoid

using concentrated acids or bases.

Page 4

[ Care and Use ManUal ]

INJ ECT

W

V

R

= Column efficency (plates)

= Volume to peak apex (mL)

= Volume at 4.40% of peak height (mL)

N25

=

()

2

V

R

W

e. Particular Contamination

Filter all mobile phases. Never use turbid or cloudy solvents or

solutions.

f. Shock

Protect column from vibration, mechanical shock, and rapid changes in

operating pressure. Any thermal, physical, or chemical shock (such as

changing solvent composition rapidly) may cause the particles to shift and

may result in void and a loss of efficiency.

Protect the column from rapid changes in solvent composition which may

alter the mobile phase viscosity, and thereby, the system back pressure

drastically.

g. Efficiency Testing

Waters columns are tested in our quality control laboratories for

adherence to our specifications. Slight variations in your results will

occur depending on:

• EquipmentUsed

Save the chromatogram from this test. With the calculated column

efficiency, record the retention times, system settings, and all

experimental conditions so that they can be reproduced exactly in

the future. If problems occur during normal operation of the column,

repeat the initial efficiency test under the original conditions and

compare the results.

Differences in the results may indicate the source of the problem.

Refer to Table 1 and also the Waters Carbamate Analysis System

Manual for troubleshooting guidelines.

• TestSystemmakeup

• Equipmentsettingsandexperimentalconditions

Each new column’s performance should be checked on your system to

provide an initial efficiency standard for future comparison. After the

column has been installed and equilibrated, run the test sample as

described in the Waters Carbamate Analysis System Manual.

Choose a peak for one of the following analytes: aldicarb sulfoxide,

aldicarb sulfone, oxamyl, or methomyl. Measure the column effi-

ciency as shown in Figure 3.

NOTE: For convenience, VR and W can be expressed in units of length

rather than volume as measure with a scale from the chromatogram.

The “5-Sigma” method shown in Figure 3 is a more stringent way

to calculate plate count, N, than “half-peak height” and “tangent”

methods. It takes into account naturally occurring peak asymmetry

which can significantly reduce the resolution between adjacent peaks.

Figure 3: 5-Sigma Method for Measuring Column Efciency

V. Care and MaIntenanCe

a. Troubleshooting

Table 1 provides the corrective action for some typical column

problems that may occur with the Carbamate Analysis Column.

Refer also to the Waters Carbamate Analysis System Manual for

more detailed information on troubleshooting Waters Carbamate

Analysis Method.

NOTE: Eventually, column performance will degrade over time below

an acceptable level as determined by periodic efficiency testing.

When this happens, replace the old column with a new Waters

Carbamate Analysis Column. See Section VI. for reorder information.

Carbamate Analysis Column 4

Page 5

[ Care and Use ManUal ]

Table 1: Troubleshooting the Carbamate Analysis Column

Symptom Conditions Corrective Action

Excess pressure

buildup

Loss of resolution,

broad peaks, or

low plate counts

Filters plugged with

particulates.

Sample precipitates on

column (sample not

soluble in mobile

phase).

Clogged tubing. Replace tubing.

Mass overload Dilute sample and run it again.

Incorrect tubing size

(0.040” or 0.020”

i.d.)

Contaminated column. Slowly flush with a 50-100

Insufficient equilibrium Continue equilibration

Filters partially plugged Replace or clean (inlet and

Failing Injector Repair Injector.

Replace filter element or clean

in an ultrasonic bath. Always

filter solvents and samples

Slowly purge with a solvent

appropriate to dissolve the

precipitate.

Install correct 0.009” ID stainless steel tubing to column

inlet & outlet.

mL of 50/50 v/v acetonitrile/

MeOH; then equilibrate with

initial mobile phase and run

sample again.

outlet) the Filter Retainer Disc

and the Filter.

Long-term Storage (more than 72 hours)

Flush the column with 15-30 mL of 50/ v/v acetonitrile/methanol.

Then turn the pump off. Allow the column to cool to ambient

temperature. Disconnect the inlet and outlet tubes from the column

and join them with a union. Install the end plugs in the column inlet

and outlet fittings. Tighten the end plugs firmly in place with 5/16”

open end wrench.

CAUTION: Do not overtighten – Overtightening will damage the

column fittings. Allowing columns to dry out may result in poor

chromatographic performance. Return the column to its box for

storage

VI. ColuMn and supplIes orderIng InforMatIon

Item Part Number

Carbamate Analysis Column, 3.9x150mm WAT035577

Filter Retainer WAT088084

Filter Retainer Disc WAT089567

In-Line Pre column Filter WAT084560

Solvent Clarification Kit with pump WAT085113

b. Shutdown and Storage

Between Analyses

During the course of a working day, between analyses, continue

to pump the initial mobile phase mixture through the column. This

will maintain the equilibrium in the column necessary for good

retention time reproducibility. If a few hours will pass before the

next injection, the flow rate may be slowed down in the interim to a

few tenths of a mL/min to conserve solvent.

Overnight

When shutting down overnight or over a weekend, first flush the

column with 15-30 mL of 50/50 v/v acetonitrile/methanol. Then

turn the flow rate to zero mL/min and leave the column connected

in the system. The oven temperature may be maintained at 30 °C,

if desired.

Carbamate Analysis Column 5

Solvent Clarification Kit without pump WAT085124

Aqueous Replacement Filters (HATF 04700),

pkg. of 100

Organic Replacement Filters (FHUP 04700),

pkg. of 100

Aqueous Sample Clarification Kit WAT026865

Guard-Pak Pre column Module: Kit WAT080040

®

Nova-Pak

Sep-Pak C

Sep-Pak C

Sep-Pak C

C18 Guard-Pak Cartridges (10/Pkg.) WAT015220

Cartridges (50/Box) WAT051910

18

Plus Cartridges (24/Box) WAT011191

18

Plus Cartridges (96/Box) WAT015402

18

WAT085147

WAT085118

Page 6

[ Care and Use ManUal ]

VII. Warrant y/serVICe InforMatIon

Waters Corporation staff of experienced specialists provides

maintenance assistance on both preventative and/or corrective

levels. For complete information and assistance, please call Waters

Service Department at 1-800-252-HPLC. For solutions to particular

applications questions, Waters team of technical support personnel

are available to help you with specialized support. They may be

contacted at 1-800-252-HPLC in Milford, MA, USA.

Wa r r a nt y

Waters Corporation warrants its high performance liquid

chromatography columns in accordance with the following terms

and conditions:

Waters will repack or replace (at our discretion) without cost any

steel column that fails to perform satisfactorily if notice within 90

days from your receipt. Any column returned mush have a Return

Authorization Number granted by the Waters Customer Service

Depart. Approval is subject to the following exclusions:

Sales Offices:

Austria and European Export

(Central South Eastern Europe,

CIS and Middle East) 431 877 18 07

Australia 2 9933 1777

Belgium 32 2 726 1000

Brazil 55 11 5094 3788

Canada 800 252 4752

China 8621 6495 6999

CIS/Russia +7 495 3367000

Czech Republic 42 02 617 11384

Denmark 45 46 59 8080

Finland +358 9 5659 6288

France (33) 1 30 48 72 00

Germany 49 6196 400600

Hong Kong 852 29 64 1800

Hungary 36 1 350 5086

India and India Subcontinent

91 80 2 837 1900

Ireland 353 1 448 1500

Italy 39 02 274 211

Japan (81) 3 3471 7191

Korea (82) 2 820 2700

Mexico 5255 5200 1860

The Netherlands +31 (0)76-50 87 200

Norway 47 63 84 60 50

Poland (48) 22 833 4400

Puerto Rico 787 747 8445

Singapore 65 6273 1221

Spain 34 93 600 93 00

Sweden 46 8 555 11500

Switzerland 41 62 889 2030

Taiwan 886 2 2543 1898

• Physicaldamagetothecolumnduetomisuseorabuse.

• Chemicaldamagetothepackingmaterialbecauseofusewithincom-

patible solvents or buffers, or at an incorrect pH.

• Physicaldamagetothepackingmaterialbecauseofoperationatincor-

rect temperatures or pressures.

• Particulatebuilduporprecipitationinthecolumnorendfittingscausing

high internal pressure which has occurred due to improper solvent or

sample filtration practices.

© 2007 Waters Corporation. Waters, The Science of W hat’s

Possible, Sep-Pak, Nova-Pak, and Guard-Pak are trademarks of

Waters Corporation.

November WAT035583 Rev 2 VW-PDF

Carbamate Analysis Column 6

United Kingdom 44 208 238 6100

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...