Page 1

[ Care and Use ManUal ]

BIosuIte columns

I. IntroductIon

Thank you for choosing a Waters BioSuite™ column. Every column is individually tested to assure maximum product quality. Waters BioSuite high

performance chemistries are dedicated to the isolation, analysis, and characterization of proteins and peptides. For the latest list on ion-exchange, size

exclusion, hydrophobic interaction and reversed-phase go to www.waters.

com/lifesciences

contents

I. IntroductIon

a. Mobile Phase

b. Flow Direction

II. connectIng your column to the hPlc system

III. Waters BIosuIte Pc

and PPhenyl rPc columns

18

IV. Waters BIosuIte Phenyl hIc columns

V. Waters BIosuIte ultra hIgh resolutIon (uhr), hIgh

resolutIon (hr), and sIze exclusIon (sec) columns

VI. Waters BIosuIte Q-PeeK and sP-PeeK columns

VII. Waters BIosuIte deae and sP nP columns

VIII. Waters BIosuIte Q, deae, sP, and cm columns

BioSuite Columns 1

Page 2

[ Care and Use ManUal ]

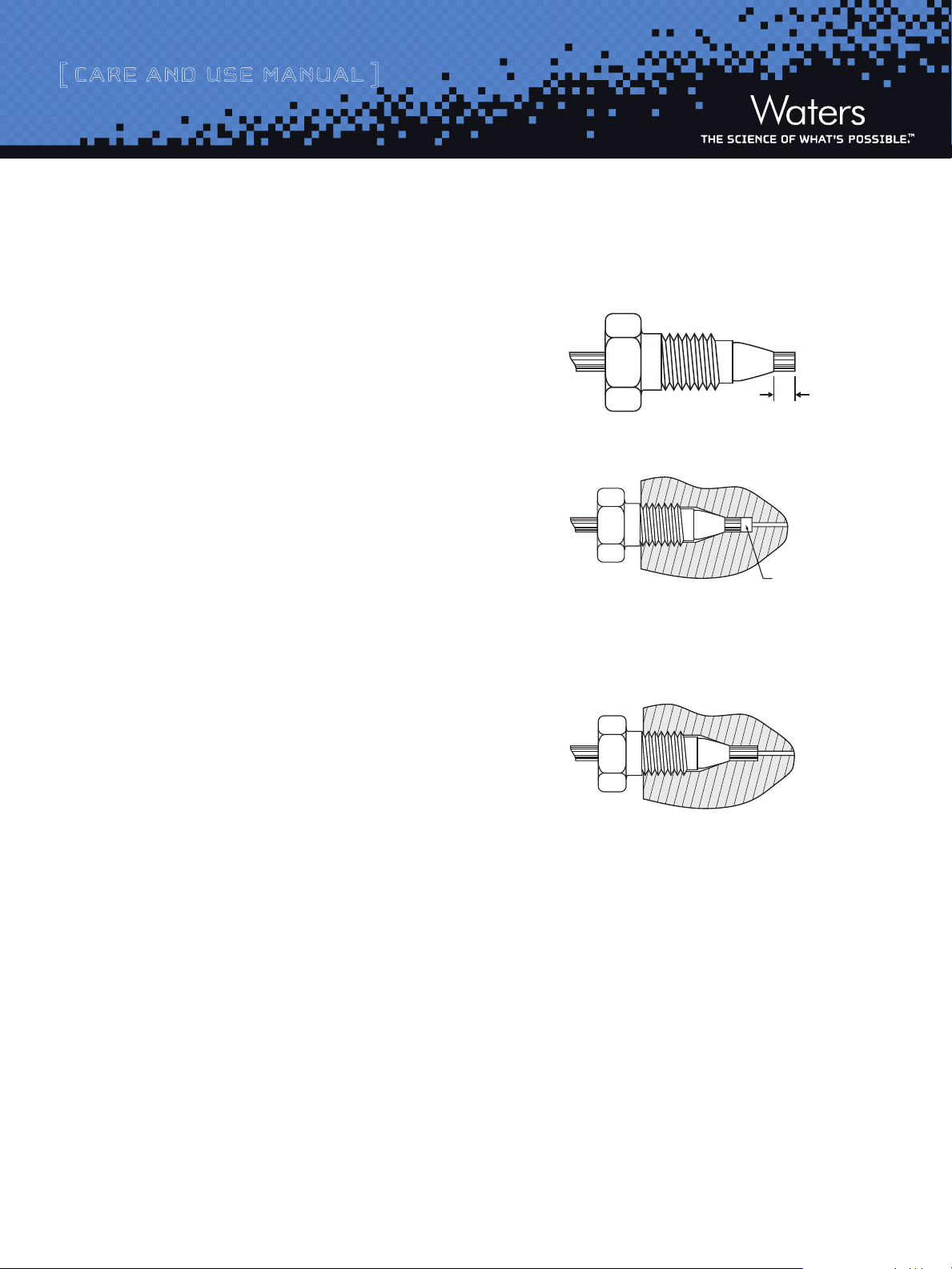

0.175 inches

Void

a. Mobile Phase

Prevent air bubbles from entering the column during its installation, use,

and storage since this may cause degradation of column performance

through the formation of channels in the packed bed. Mobile phases must be

thoroughly degassed before use. This can be accomplished by vacuum filtra-

tion, helium sparging or by in-line vacuum degassing. In addition to degas-

sing the solvent, vacuum filtration of the solvent will also prevent small

particles from plugging the column frit. You can use 0.20 or 0.45 µm mem-

brane to filter aqueous and aqueous/organic mobile phases. (Note: Consult

with filtration membrane manufacturer for details on solvent compatibility.)

Note: Use high quality reagents, HPLC grade water, and HPLC grade solvents

for preparing buffers to maximize column efficiency especially when using

Waters BioSuite Non-Porous (NP) columns.

The useful column lifetime is a function of numerous factors including: the

cleanliness and composition of the mobile phase and the sample; the flow

rate and pressure used; and the temperature. Refer to the section below

about “Cleaning” for information on extending column life.

Note: Cleaning, however, is not effective when the column is damaged by

irreversible sample adsorption, channeling, or exposure of the packing mate-

rial to excessive heat or shock.

tubing and the column that will result in undesired peak broadening (Figure

B). To correct this problem, Cut the tubing, place a new ferrule on it and re-

make the connection (i.e., 0.175” depth) to the Waters BioSuite column.

Figure A

Figure B

In a proper tubing/column connection, the tubing touches the bottom of the

column end fitting with no void between them. (Figure C)

b. Flow Direction

The recommended flow direction through the column is indicated by the

arrow on the tag. Operating the column with the flow in the reverse direc-

tion is only recommended as part of a cleaning procedure when removing

particulates from a clogged frit.

II. connectIng your column to the hPlc system

Due to the absence of an industry standard, various column manufacturers

have employed different styles of chromatographic column connectors. The

chromatographic performance of your separation can be negatively affected

if the style of column end fitting does not match the existing instrumenta-

tion tubing ferrule setting. Waters BioSuite columns require end fittings

that have a 0.175” depth between the ferrule and the end of the extending

stainless steel tubing (Figure A) that must perfectly seat to the end of the

BioSuite column. Connecting a non-BioSuite style connector to a Waters

BioSuite column will leave a gap between the end of the stainless steel

BioSuite Columns 2

Figure C

After manufacturing and quality control, the column has been flushed with

storage solvent and closed with caps to prevent solvent evaporation. When

installing the column to the Liquid Chromatograph, it is important to prevent

air from entering the column. The following steps can be used to minimize

this potential problem:

• Remove the cap from the column’s inlet side. Solvent should be visible at

the inlet fitting (if not, see below).

• StartsolventflowthroughtheliquidchromatographBEFOREconnecting

the Waters BioSuite column to the system. Turn off the pump after a

steady flow of solvent from the system is observed. You can now connect

the waters BioSuite column to the liquid chromatograph and slowly begin

delivering solvent to the column (Note: If the Waters BioSuite column

inlet fitting appears dry, we recommend that you first disconnect the

bottom cap and hook up the column exit to the injector. Then slowly start

Page 3

[ Care and Use ManUal ]

the flow in this reversed flow direction until a few drops of mobile phase

exit from the column. Turn off the flow, let the pressure go to zero, and

disconnect the column from the system. Turn the column around and hook

it up so that the flow is now in the direction of the arrow. Start the flow

at a low setting and stop it as soon as the mobile phase exits from the

bottom fitting. Now you can hook up the column to the detector inlet and

increase the flow to the desired setting.)

• Besuretosettheflowwithintherecommendedrangeshowninthe

following tables.

Sample

If possible, always dissolve your sample in mobile phase or the starting

mobile phase when operating under gradient conditions. Alternatively, try

to match the pH, salt concentration and organic solvent of the sample with

those of the mobile phase and run a test to ensure that no precipitate, sus-

pension or flocculate is formed. Finally, before making an injection, filter the

sample through a 0.20-0.45 µm porosity membrane.

III. Waters BIosuIte Pc18 and PPhenyl rPc columns

This section contains recommended operating conditions and specifications

for the Waters polymer-based, C

and phenyl reversed-phase columns.

18

Operating Conditions

1. Shipping Solvent: 70% Methanol - 30% Water

Note: When using a high viscosity buffer and ambient temperature, the maximum flow rate may have to be reduced to avoid exceeding the maximum

recommended operating pressure for the column. When changing solvents,

use 50% of the maximum flow rate (20% for the 21.5 mm i.d. preparative

column).

3. Recommended pH Range: 2 - 12 (Avoid extended operation at pH >

10 to maximize column life.)

4. Recommended Organic Concentration Range: 0 - 100% (Note:

Reduced organic concentrations may be required if buffers are present

in the eluent in order to avoid salt precipitation.)

5. Recommended Temperature Range: 5 - 50 °C (Note: Reduce flow rate

when operating at low temperatures (e.g.. 5 C) to avoid excessive

column pressure.)

6. Recommended Cleaning Solvents/Procedures:

A) Acetonitrile or Methanol, or

B) Aqueous buffer in organic solvent, or

C) 0.1 - 0.2M NaOH, or

D) 20 - 40% acetic acid in HPLC grade water.

Clean the column regularly with any of the listed solvents. Cleaning

solvents (C) and (D) can be injected onto the column in 250 µl incre-

ments for a total of one column volume. Use proportionally larger

volumes for the 21.5 mm i.d. prep column. Following use of cleaning

solvent, rinse the column with 3 to 5 column volumes of HPLC grade

water before storage.

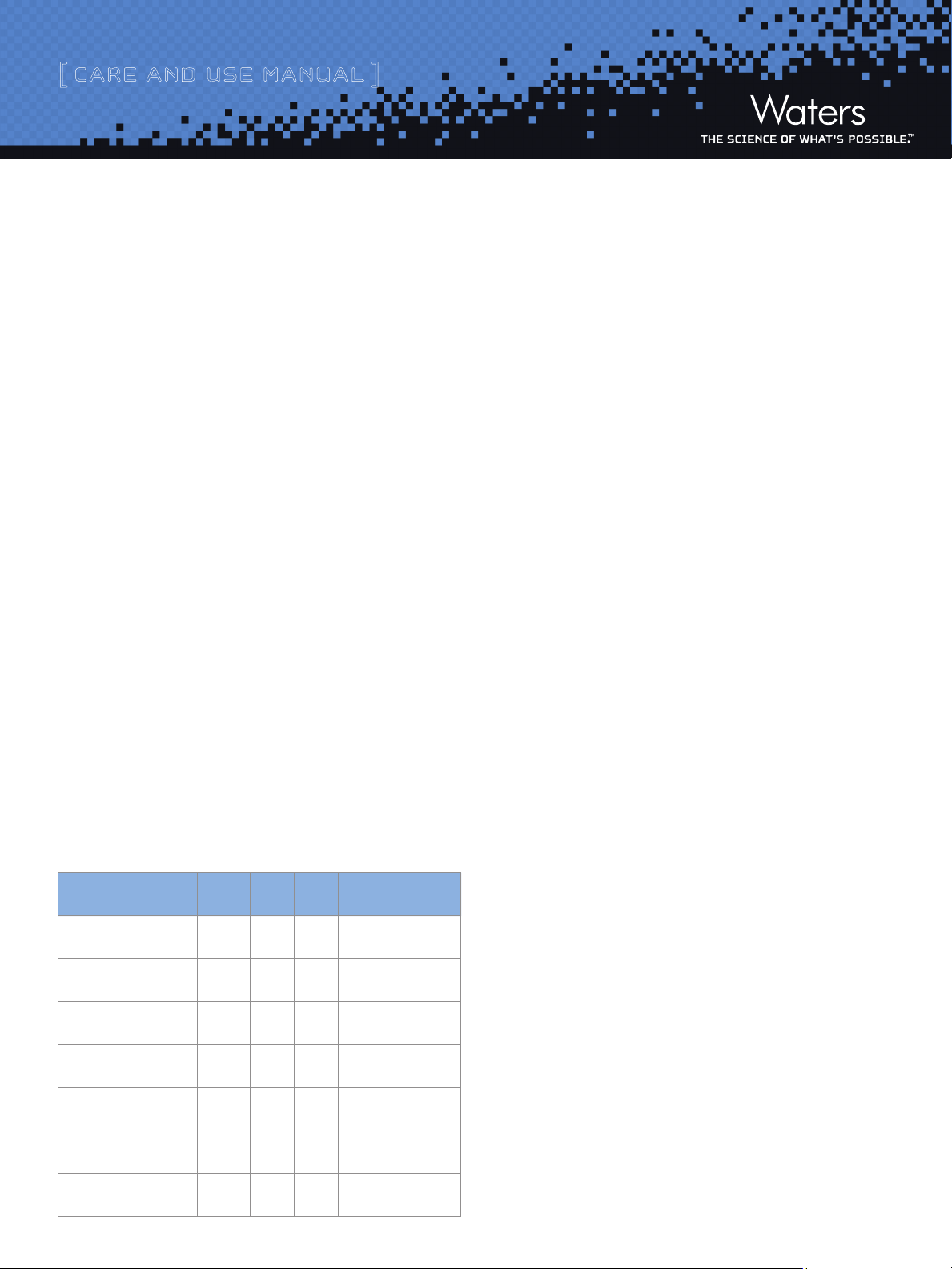

2. Recommended Operating Flow Rates/Max Pressure:

Description Matrix i.d.

(mm)L (mm)

BioSuite pC

NP RPC

BioSuite pC

7 µm RPC

BioSuite pC

7 µm RPC

BioSuite pC

13 µm RPC

BioSuite pPhenyl, 1000,

10 µm RPC

BioSuite pPhenyl, 1000,

10 µm RPC

BioSuite pPhenyl, 1000,

13 µm RPC

BioSuite Columns 3

, 2.5 µm

18

, 500,

18

, 500,

18

, 500,

18

polymer 4.6 35 1.0 - 1.6 mL/min /

polymer 4.6 150 0.08 - 0.22 mL/min

polymer 4.6 150 0.5 - 1.2 mL/min /

polymer 21.5 150 3.0 - 8.0 mL/min /

polymer 2.0 75 0.05 – 0.12 mL/min

polymer 4.6 75 0.5 - 1.2 mL/min /

polymer 21.5 150 6.0 - 8.0 mL/min /

Flow Rates / Max

Pressure

3000 PSI

/ 1500 PSI

1750 PSI

500 PSI

/ 150 PSI

450 PSI

450 PSI

7. Recommended Storage: For overnight storage, continuously flush the

column with the mobile phase at 10 - 20% of the maximum recom-

mended flow rate. Store the column in the shipping solvent when the

column will not be used within 48 hours.

Page 4

[ Care and Use ManUal ]

IV. Waters BIosuIte Phenyl hIc columns

This section contains recommended operating conditions and specifica-

tions for the Waters polymer-based, Phenyl Hydrophobic-interaction

Chromatography columns.

Operating Conditions

1. Shipping Solvent: HPLC grade Water

2. Recommended Operating Flow Rates/Max Pressure:

Description Matrix i.d.

(mm)L (mm)

BioSuite Phenyl, 1000,

10 µm HIC

BioSuite Phenyl, 1000,

13 µm HIC

polymer 7.5 75 0.5 - 1.2 mL/min /

polymer 21.5 150 4.0 - 8.0 mL/min /

Note: When using a high viscosity buffer and ambient temperature, the maxi-

mum flow rate may have to be reduced to avoid exceeding the maximum

recommended operating pressure for the column. When changing solvents,

use 50% of the maximum flow rate (20% for the 21.5 mm i.d. preparative

column).

3. Recommended pH Range: 2 - 12 (Avoid extended operation at pH > 10

to maximize column life.)

4. Recommended Organic Conc.: less than 50% (Note: Reduced organic

concentrations may be required if buffers are present in the eluent in

order to avoid salt precipitation.)

5. Recommended Salt Conc.: Less than or equal to 4.0 Molar

Flow Rates /

Max Pressure

300 PSI

300 PSI

mended flow rate. Store the column in the HPLC grade water

when it will be used within 24 hrs or in either 20% ethanol or metha-

nol for long term storage. (Caution: Rinse column in HPLC

grade water before switching to 20% organic solvent to avoid salt

precipitation in column.)

V. Waters BIosuIte ultra-hIgh resolutIon (uhr), hIgh

resolutIon (hr), and sIze-exclusIon (sec) columns

This section contains recommended operating conditions and specifications

for the Waters silica-based, ultra-high Resolution (UHR), high-resolution (HR),

and standard size-exclusion (SEC) columns.

Operating Conditions

1. Shipping Solvent: 0.05% Sodium Azide or 0.1M Sodium Sulphate in

0.1M phosphate buffer, pH 6.7

2. Recommended Operating Flow Rate/Max Pressure:

Description Matrix i.d.

(mm)L (mm)

BioSuite 125, 4 µm

UHR SEC

BioSuite 250, 4 µm

UHR SEC

BioSuite UHR Guard SEC silica 4.6 35 0.1 - 0.4 mL/min /

silica 4.6 300 0.1 - 0.4 mL/min /

silica 4.6 300 0.1 - 0.4 mL/min /

Flow Rates /

Max Pressure

1800 PSI

1800 PSI

1800 PSI

6. Recommended Temperature: 10-50 °C. Reduce flow rate when

operating at low temperatures (e.g. 10 °C) to avoid excessive column

pressure.

7. Recommended Cleaning Solvents/Procedures:

A) 0.1 - 0.2M NaOH, and, if not successful,

B) 20 - 40% acetic acid in HPLC grade water.

Clean the column regularly by injecting up to one column volume 0.1

- 0.2M NaOH in 250 µl increments. Use proportionally larger volumes

for the 21.5 mm i.d. preparative column. Following use of cleaning

solvent, rinse the column with 3 to 5 column volumes of HPLC grade

water before storage.

8. Recommended Storage: For overnight storage, continuously flush the

column with the mobile phase at 10 - 20% of the maximum recom-

BioSuite Columns 4

BioSuite 125, 5 µm

HR SEC

BioSuite 250, 5 µm

HR SEC

BioSuite 450, 8 µm

HR SEC

BioSuite HR Guard SEC silica 6 40 0.5 - 1.2 mL/min /

BioSuite 125, 10 µm

SEC

BioSuite 125, 13 µm

SEC

BioSuite 250, 10 µm

SEC

silica 7.8 300 0.5 - 1.2 mL/min /

1050 PSI

silica 7.8 300 0.5 - 1.2 mL/min /

1050 PSI

silica 7.8 300 0.5 - 1.2 mL/min /

525 PSI

1050 PSI

silica 7.5 300 0.5 - 1.2 mL/min /

300 PSI

silica 21.5 300 3.0 - 8.0 mL/min /

150 PSI

silica 7.5 300 0.5 - 1.2 mL/min /

375 PSI

Page 5

[ Care and Use ManUal ]

Description Matrix i.d.

(mm)L (mm)

BioSuite 250, 13 µm

SEC

BioSuite 450, 13 µm

SEC

BioSuite 450., 17 µm

SEC

BioSuite Guard SEC silica 7.5 75 0.5 - 1.2 mL/min /

BioSuite Guard SEC silica 21.5 75 3.0 - 8.0 mL/min /

silica 21.5 300 3.0 - 8.0 mL/min /

silica 7.5 300 0.5 - 1.2 mL/min /

silica 21.5 300 3.0 - 8.0 mL/min /

Flow Rates /

Max Pressure

225 PSI

225 PSI

300 PSI

600 PSI

450 PSI

Note: When using a high viscosity buffer and ambient temperature, the maxi-

mum flow rate may have to be reduced to avoid exceeding the maximum

recommended operating pressure for the column. When changing solvents,

use 50% of the maximum flow rate.

3. Recommended pH Range: 2.5 - 7.5

4. Recommended Salt Conc.: Less than or equal to 0.5 Molar

5. Recommended Organic Conc.: 0 - 100% (Caution: Many proteins and

peptides are insoluble at elevated organic concentrations. Prior to

chromatography, test to ensure the sample does not precipitate at the

organic concentration to be used for the chromatography.)

before switching to 20% organic solvent to avoid salt precipitation in

column.)

9. Recommended Column Protection: Use of guard columns is recom-

mended to prolong the life of the analytical column life. Guard column

life depends greatly on sample cleanliness. As a general rule, guard

columns should be replaced after every 30-40 sample injections,

when the peaks become excessively wide, or when the peaks show

splitting.

VI. Waters BIosuIte Q-PeeK and sP-PeeK columns

This section contains recommended operating conditions and specifications

for the Waters polymer-based, anion and cation-exchange materials con-

™

tained in PEEK

columns.

Note: Compared to use of stainless-steel columns, connect the PEEK column

to the HPLC or Liquid Chromatographic System with a 10-32 polymer nut

and ferrule.

Operating Conditions:

1. Shipping Solvent: 20% Ethanol containing 20 mM Tris-HCl buffer

(pH 8.0)

6. Recommended Temperature: 10-30 °C. Reduce flow rate when

operating at low temperatures (e.g., 10 °C) to avoid excessive column

pressure.

7. Recommended Cleaning Solvents/Procedures:

A) A concentrated salt solution at low pH, e.g. 0.5M Na

2SO4

,

pH 2.7

B) A low concentration of methanol or acetonitrile (e.g., 20%) in

HPLC grade water

C) A buffered solution of SDS, urea, or guanidine

Note: Choose a cleaning solvent based on sample properties, e.g. use (A) to

remove basic proteins, and (B) to remove hydrophobic proteins. Chaotrophic

agents can solvate strongly adsorbed proteins via hydrogen bond disruption.

8. Recommended Storage: For overnight storage, continuously flush the

column with the mobile phase at 10 - 20% of the maximum recom-

mended flow rate. Store the column in the HPLC grade water when

it will be used within 24 hrs or in either 20% ethanol or methanol

for long term storage. (Caution: Rinse column in HPLC grade water

2. Recommended Operating Flow Rates/Max. Pressure:

Description Matrix i.d.

(mm)L (mm)

BioSuite Q-PEEK 10 µm

AXC

BioSuite SP-PEEK 7 µm

CXC

polymer 4.6 50 0.3 - 1.2 mL/min /

polymer 4.6 50 0.3 - 1.0 mL/min /

Flow Rates /

Max Pressure

375 PSI

375 PSI

Note: When using a high viscosity buffer and ambient temperature, the maxi-

mum flow rate may have to be reduced to avoid exceeding the maximum

recommended operating pressure for the column. When changing solvents,

use 50% of the maximum flow rate.

3. Recommended pH Range: 2 - 12 (Avoid extended operation at pH

values less than 3 or greater than 10 to maximize column life.)

4. Recommended Salt Conc.: Less than or equal to 2.5 Molar

5. Recommended Organic Conc.: 0 - 30%. (Caution: Some large

molecular weight proteins may be insoluble at elevated organic

BioSuite Columns 5

Page 6

[ Care and Use ManUal ]

concentrations. Prior to chromatography, test to ensure the sample

does not precipitate at the organic concentration to be used for the

chromatography.)

6. Recommended Temperature: 4 - 60 °C. Reduce flow rate when

operating at low temperatures (e.g., 4 °C) to avoid excessive column

pressure.

7. Recommended Cleaning Solvents/Procedures:

A) 0.1 - 0.5M NaOH in HPLC grade water and if not successful,

B) 20 - 40% acetic acid in HPLC grade water or,

C) 30% acetonitrile or 30% methanol in HPLC grade water or,

D) 30% ethanol containing 0.5M NaOH or,

E) 8M Urea, 6M Guanidine or other nonionic surfactant HPLC

grade water

Clean the column regularly by injecting up to one column volume of

solution (A) (i.e., 0.1 - 0.5M NaOH in HPLC grade water) in 100 to

250 microliter increments. To maximize cleaning effect, reverse the

direction of eluent flow through the column and reduce the flow rate by

25%.

If desired, the HPLC column can also be cleaned by delivering, in

reverse eluent flow direction and at a 25 % standard flow rate, one of

the alternative cleaning solvents (i.e., 20 - 40% acetic acid in HPLC

grade water, or 30% acetonitrile or methanol in HPLC grade water, or

30% ethanol containing 0.5M NaOH, or either 8M Urea, 6M Guanidine

or other nonionic surfactant in HPLC grade water).

8. Recommended Storage: For overnight storage, continuously flush the

column with the mobile phase at 10 - 20% of the maximum recom-

mended flow rate. Store the column in the HPLC grade water when

it will be used within 24 hrs or in 20% ethanol containing 20mM

Tris-HCl buffer, pH 8 for long term storage.

VII. Waters BIosuIte deae and sP nP columns

This section contains recommended operating conditions and specifications

for the Waters non-porous, polymer-based, anion-and cation-exchange col-

umns.

Operating Conditions:

1. Shipping Solvent: The columns are shipped in HPLC grade water. Upon

receiving, flush the column with 30% acetonitrile/70% HPLC grade

water for 15 minutes at 1 mL/min. This is followed by equilibrating the

columns with the starting buffer.

Use high quality reagents, HPLC grade water, and HPLC grade solvents

for preparing buffers to maximize Waters BioSuite non-porous (NP)

column efficiency and life. Filter all eluents through a 0.20 or 0.45

µm membrane before use (Consult the with filtration membrane

manufacturer for details on solvent compatibility.) Fouling of the

non-porous resin, leading to a loss in retention and/or efficiency,

occurs faster compared to use of porous packing materials due to the

small surface area of non-porous resin particles. The useful column

lifetime is a function of numerous factors including the cleanliness and

composition of the mobile phase and the sample, the flow

rate and operating temperature, and the operating pressure. While

column cleaning is possible (see below), cleaning is not effective when

the column is damaged by irreversible sample

adsorption, channeling, or exposure of the packing material to exces-

sive heat of shock.

2. Recommended Operating Flow Rates/Max Pressure:

Description Matrix i.d.

(mm)L (mm)

BioSuite DEAE 2.5 µm

NP AXC

BioSuite SP 2.5 µm NP

CXC

Note: When using a high viscosity buffer and ambient temperature, the maxi-

mum flow rate may have to be reduced to avoid exceeding the maximum

recommended operating pressure for the column. When changing solvents,

use 50% of the maximum flow rate.

polymer 4.6 35 1.0 - 1.6 mL/min /

polymer 4.6 35 1.0 - 1.6 mL/min /

Flow Rates /

Max Pressure

3000 PSI

3000 PSI

BioSuite Columns 6

3. Recommended pH Range: 2 - 12 (Avoid extended operation at pH

values less than 3 or greater than 10 to maximize column life.)

4. Recommended Salt Conc.: Less than or equal to 1.0 Molar

5. Recommended Organic Conc.: 0 - 20%.

Page 7

[ Care and Use ManUal ]

6. Recommended Temperature: 4 - 60 °C. Reduce flow rate when

operating at low temperatures (e.g., 4 °C) to avoid excessive column

pressure.

7. Recommended Cleaning Solvents/Procedures:

A) 0.1 - 0.2M NaOH in HPLC grade water and if not successful,

B) 20 - 40% acetic acid in HPLC grade water or,

C) 30% acetonitrile, 30% methanol, or 30% ethanol in HPLC

grade water or,

D) 8M Urea, 6M Guanidine or other nonionic surfactant HPLC

grade water

Clean the column regularly by injecting up to one column volume of

solution (A) (i.e., 0.1 - 0.2M NaOH in HPLC grade water) in 100 to

250 microliter increments. To maximize cleaning effect, reverse the

direction of eluent flow through the column and reduce the flow rate by

25%.

If desired, the HPLC column can also be cleaned by delivering, in

reverse eluent flow direction and at a 25% standard flow rate, one of

the alternative cleaning solvents (i.e., 20 - 40% acetic acid in HPLC

grade water, or 30% acetonitrile, 30% methanol, or 30% ethanol in

HPLC grade water, or either 8M Urea, 6M Guanidine or other nonionic

surfactant in HPLC grade water).

8. Recommended Storage: For overnight storage, continuously flush the

column with the mobilephase at 10 - 20% of the maximum recom-

mended flow rate. Store the column in the HPLC grade water when it

will be used within 24 hrs or in 20% acetonitrile in HPLC grade water

for long term storage.

VIII. Waters BIosuIte Q, deae, sP, and cm columns

This section contains recommended operating conditions and specifications

for the Waters polymer-based, anion- and cation-exchange columns.

Operating Conditions:

1. Shipping Solvent: HPLC grade Water

2. Recommended Operating Flow Rate/Max Pressure:

Description Matrix i.d.

(mm)L (mm)

BioSuite Q 10 µm AXC polymer

BioSuite Q 13 µm AXC polymer 21.5 150 4.0 - 8.0 mL/min /

BioSuite DEAE 10 µm

AXC

BioSuite DEAE 13 µm

AXC

BioSuite SP 10 µm CXC polymer 7.5 75 0.5 - 1.2 mL/min /

BioSuite SP 13 µm CXC polymer 21.5 150 40 - 8.0 mL/min /

BioSuite CM 10 µm CXC polymer 7.5 75 0.5 - 1.2 mL/min /

BioSuite CM 13 µm CXC polymer 21.5 150 4.0 - 8.0 mL/min /

polymer 7.5 75 0.5 - 1.2 mL/min /

polymer 21.5 150 4.0 - 8.0 mL/min /

7.5

75 0.5 - 1.2 mL/min /

Note: When using a high viscosity buffer and ambient temperature, the maxi-

mum flow rate may have to be reduced to avoid exceeding the maximum

recommended operating pressure for the column. When changing solvents,

use 50% of the maximum flow rate (20% for the 21.5 mm i.d. preparative

column).

Flow Rates /

Max Pressure

300 PSI

300 PSI

225 PSI

375 PSI

225 PSI

375 PSI

225 PSI

375 PSI

BioSuite Columns 7

3. Recommended pH Range: 2 - 12 (Avoid extended operation at pH

values less than 3 or greater than 10 to maximize column life.)

4. Recommended Salt Conc.: Less than or equal to 1.0 Molar

5. Recommended Organic Conc.: 0 - 20%.

6. Recommended Temperature: 4 - 40 °C. Reduce flow rate when

operating at low temperatures (e.g., 4 °C) to avoid excessive column

pressure.

7. Recommended Cleaning Solvents/Procedures:

A) 0.1 - 0.2M NaOH in HPLC grade water and if not successful,

B) 20 - 40% acetic acid in HPLC grade water, or

Page 8

[ Care and Use ManUal ]

C) 30% acetonitrile, 30% methanol, or 30% ethanol in HPLC

grade water, or

D) 8M Urea, 6M Guanidine or other nonionic surfactant HPLC

grade water

Clean the column regularly by injecting up to one column volume

of solution (A) (i.e., 0.1 - 0.2M NaOH in HPLC grade water) in 250

microliter to 2 mL increments. To maximize cleaning effect, reverse the

direction of eluent flow through the column and reduce the flow rate

by 25%.

If desired, the HPLC column can also be cleaned by delivering, in

reverse eluent flow direction and at a 25% standard flow rate, one of

the alternative cleaning solvents (i.e., 20 - 40% acetic acid in HPLC

grade water, or 30% acetonitrile, 30% methanol, or 30% ethanol in

HPLC grade water, or either 8M Urea, 6M Guanidine or other nonionic

surfactant in HPLC grade water).

8. Recommended Storage: For overnight storage, continuously flush the

column with the mobile phase at 10 - 20% of the maximum recom-

mended flow rate. Store the column in the HPLC grade water when it

will be used within 24 hrs or in 20% acetonitrile in HPLC grade water

for long term storage.

Austria and European Export (Central South Eastern Europe, CIS

and Middle East) 43 1 877 18 07

Australia 61 2 9933 1777

Belgium 32 2 726 1000

Brazil 55 11 4134 3788

Canada 1 800 252 4752 x2205

China 86 21 6879 5888

CIS/Russia +497 727 4490/290 9737

Czech Republic 420 2 617 1 1384

Denmark 45 46 59 8080

Finland 09 5659 6288

France 33 1 30 48 72 00

Germany 49 6196 400600

Hong Kong 852 29 64 1800

Hungary 36 1 350 5086

India and India Subcontinent 91 80 2837 1900

Ireland 353 1 448 1500

Italy 39 02 265 0983

Japan 81 3 3471 7191

Korea 82 2 6300 4800

Mexico 52 55 5524 7636

The Netherlands 31 76 508 7200

Norway 47 6 384 60 50

Poland 48 22 833 4400

Puerto Rico 1 787 747 8445

Singapore 65 6273 7997

Spain 34 93 600 9300

Sweden 46 8 555 11 500

Switzerland 41 56 676 70 00

Taiwan 886 2 2543 1898

United Kingdom 44 208 238 6100

All other countries:

Waters Corporation U.S.A.

1 508 478 2000

1 800 252 4752

www.waters.com

©2009 Waters Corporation, Waters, The Science of W hat’s

Possible, and BioSuite are trademarks of Waters Corporation.

PEEK is a trademark of Victrex plc.

March 2009 715000652 Rev C K K-PDF

BioSuite Columns 8

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...