Page 1

[ Care and Use ManUal ]

analytICal Columns and CartrIdges

I. IntroduCtIon

Waters offers a large selection of analytical columns and cartridges

packed with silica-based packing materials. Follow this instruction

sheet to obtain the best performance, reproducibility, and longevity

from your analytical columns and cartridges. Waters silica-based

materials are packed in:

TM

• Steel and PEEK

analytical columns are durable and highly efficient. PEEK

columns are used with nonmetallic systems.

• Steel Cartridge Columns — The cartridge columns feature reus-

able end fittings that permit you to replace the cartridge quickly

and easily without tools.

• Polyethylene Radial-Pak™ Column Segments — The Radial-Pak

column segments (also referred to as Radial-Pak cartridges)

employ Waters patented technology to improve efficiency

by eliminating the wall effect and voiding common to rigid

columns.

(polyetheretherketone) Columns — The steel

Contents

I. IntroduCtIon

II. start-up test proCedure

a. Measuring Intrument Band Spreading

b. Installing the Cartridge or Column

c. Equilibrating the Column

d. Testing the Column Efficiency and Calculating Column Backpressure

III. narrow-bore Columns

IV. Column maIntenanCe

a. Caring for the Column

b. Cleaning and Regenerating the Column

c. Storing the Column

V. troubleshootIng

Analytical Columns and Cartridges 1

VI. orderIng and addItIonal InformatIon

Page 2

[ Care and Use ManUal ]

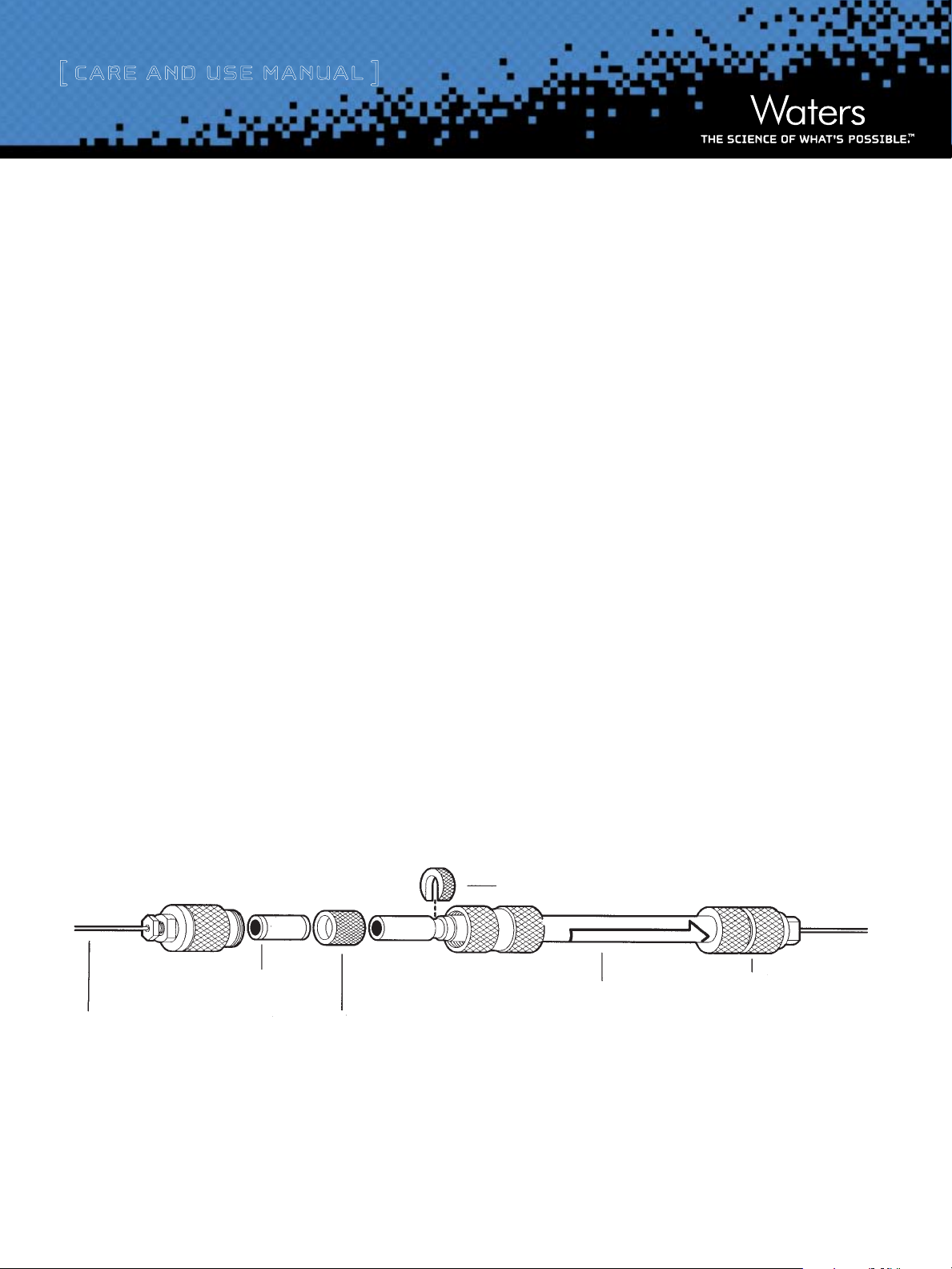

Spacer

0.25 mm (0.009 inch) Tubing

Sentry Guard

Column

C-Clip

Cartridge Column

End Connector

II. start-up test proCedure

Follow the four step start-up procedure for successful operation of

your Waters column or cartridge: A. The pH range for the mobile

phase is pH 2 to 8. However, phosphate buffer at pH 8 in combination

with high temperatures can lead to shorter column life. For high

temperature work, this buffer at neutral pH is preferred.

a. Measuring Instrument Band Spreading

Poor column performance can sometimes be attributed to excessive

instrument band spreading. Test the band spreading of your HPLC

system before you install your column or cartridge. Band spreading

of a properly operating analytical system should be less than

100 μL and <40 μL for 2.1 mm i.d. microbore columns.

Test the instrument band spreading using the procedure below.

1. Remove the column or cartridge from the system. Connect the

inlet and outlet tubing with a low-dead-volume union.

2. Inject the test sample used for a plate count determination (see

Section II. d.) using a fast chart speed or sampling rate. You may

need to adjust the detector sensitivity or dilute the sample to

keep the peak on scale.

Determine the width of the peak at 4.4% of the peak maximum.

Determine how many microliters per minute your eluent is flowing.

Multiply the two terms to yield the band spread of your instrument.

If the band spreading is excessive, check all tubing and fittings. If it

is necessary to repair fittings, refer to the procedure below. If you

have a 2.1 mm i.d. microbore column, you may need to modify your

HPLC system. Refer to the System Modifications Guidelines outlined

in Section III.

Repair a damaged compression screw or a worn ferrule assembly

using the procedure below.

1. Scribe the circumference of the tubing at the desired break point

using a tube cutter or a file with a cutting edge.

2. Grasp the tubing on both sides of the scribe mark with cloth

covered pliers. Gently work the tube back and forth until it sepa-

rates at the scribe mark. Ensure that the tubing end is straight,

open and free of burrs.

3. Slide the compression screw, followed by the ferrule (large end

of the taper first), over the tube. Seat the tubing in the fitting. If

the tubing is not completely seated, the resulting dead volume

can lead to poor chromatographic results.

3. Use the 5-Sigma method shown in Figure 2 to obtain the band

spreading value in μL.

Figure 1: Installing a Cartridge Column with a SentryTM Guard Column

Analytical Columns and Cartridges 2

Page 3

[ Care and Use ManUal ]

2.1 • L • f

∆p =

dp • D

2

System Volume

4.4% h

b. Installing the Cartridge or Column

For Column Installation: Connect the column with the direction of

flow arrow pointing toward the detector. You will need a 5/16-inch

open-end wrench.

For Steel Cartridge Column Installation: Refer to Figure 1. Unscrew

the end connectors from the old cartridge column, leaving them

connected to the inlet and outlet lines of the instrument. Attach the

new cartridge column between the connectors so that the flow is in

the direction of the arrow on the label. Finger tighten all fittings.

For Radial-Pak Column Segments: The column segments are

installed in a Waters 8 x 10 Cartridge Holder. Please refer to the

RCM 8 x 10 Cartridges Holder Manual for installation and operation

instructions. Tighten the piston until the pressure gauge needle

is in the correct compression zone, referring to the table below.

Radial-Pak column segments are shipped dry. They should be

prewetted with 100% organic solvent before equilibration with the

mobile phase.

Column Segment Pressure Zone Approximate Pressure

®

, Resolve™ middle of green 18 MPa (2500 psi)

Nova-Pak

μPorasil™, μBondapak™ beginning of yellow 7 MPa (1000 psi) and

Delta-Pak™

d. Testing the Column Efficiency and Calculating Column

Back pressure

Perform an efficiency test on your column before you use it. Prepare

the test sample and test the column using the conditions for your

particular column configuration. Test sample preparation and column

test conditions are enclosed in a separate sheet. Repeat the efficiency

test periodically to track column performance aver time.

Use the following equation to calculate the back pressure of your col-

umn or cartridge with water as a mobile phase at 1 mL/min flow rate.

Multiply the result by your mobile phase viscosity in (cP) and your

flow rate to obtain your operating back pressure. A viscosity table

for common solvents and a viscosity curve for aqueous mixtures is

enclosed on a separate sheet.

Where Δp (H2O, 1 mL/min) is the pressure (MPa); L is the column

length (mm); f is a constant, 20 for Radial-Pak™ column segments

or 10 for steel columns; dp is the particle diameter (μm) and D is the

column diameter.

III. narrow-bore Columns (2.1 mm I.d.)

c. Equilibrating the Column

1. Equilibrate your column when it is first installed and after

storage. Verify that your mobile phase is miscible in the

column shipping solvent.

2. When you change the mobile phase of your system, gradually

increase the flow rate of the new mobile phase from 0 mL/min

to 1.0 mL/min in 0.1mI/mm increments.

3. Purge the column with at least 10 column volumes of your

mobile phase until you achieve a stable baseline. If mobile

phase additives are present (such as ion-pairing reagents, at 5

to 10 mmol/L) 100 to 200 column volumes may be required

for complete equilibration.

Analytical Columns and Cartridges 3

This section describes how to measure extra column effects and

gives some guidelines on how to maximize the advantages of your

Waters narrow-bore column. Modifications to your HPLC system will

probably be required in order to avoid system band spreading.

Without proper system modifications, system band spreading causes

peak broadening and has a large impact on peak width as peak vol-

ume decreases. To measure the band spreading of your HPLC system,

refer to the procedure, Measuring Instrument Band Spreading, in

Section II. a. and refer to Figure 2.

Figure 2: Determination of System Bandspreading Using the 5-Sigma

Method

Page 4

[ Care and Use ManUal ]

1.0

0.8

0.6

Height

Volume (µL)

0.4

0.2

0.0

Dwell

Volume

A second effect, called dwell volume is observed with gradient analy-

sis. In this case, the lower flow rate causes the gradient front to take

longer to reach the head of the column. To measure the dwell volume

for your system, refer to the procedure, For Gradient Analysis, below

and refer to Figure 3.

Figure 3: Determination of Dwell Volume

For Gradient Analysis:

1. Replace the column with a zero dead volume union.

2. Determine the gradient-delay or dwell volume for your system by

performing a dwell volume test. Prepare eluent A (pure solvent), and

eluent B (solvent plus sample).

IV. Column maIntenanCe

This section describes routine column maintenance procedures that

should be followed to maximize the lifetime of your Waters column.

The procedures are described in detail below:

a. Caring for the Column

To ensure the continued high performance of your Waters column,

follow these guidelines:

• Protect steel columns, cartridge columns and column segments from

contaminants with a Waters Sentry Guard Column or a Waters Guard-

Pak™ Insert.

®

• Use Waters Sep-Pak

®

Cartridges to clean up your sample prior to analysis.

Oasis

• Make sure that solvents are miscible when changing mobile phases.

This will prevent phase separation or precipitation.

• Always degas and filter mobile phases through a 0.22 μm membrane

filter. Acrodisc

solid-phase extraction cartridges or Waters

®

filters by Gelman Sciences are recommended.

3. Equilibrate system with eluent A until a stable baseline is achieved.

Switch to 100% eluent B and record the time at half height of the step.

Refer to Figure 3 for an illustration.

4. Modify your HPLC system in order to minimize the dwell volume

according to the System Modifications Guidelines section. The dwell

volume should be less than 1 mL for small volume columns.

System Modification Guidelines:

1. Use 0.25 mm (0.009-inch) tubing between pump and injector.

2. Use a microbore detector flow cell, for example, Waters Tuneable

UV-VIS Absorbance Detector with a 2.6 μL volume) for the 2.1 mm

columns. Recall that due to the shorter path length, detector sensitivity

is reduced to achieve lower band spread.

3. Use 0.12 mm (0.005-inch) i.d. tubing for the 2.1 mm column to

minimize dead volume. With careful plumbing, standard 0.25 mm

(0.009-inch) i.d. tubing can be used with the 3.0 mm column.

4. Use a manual injector with a low dead volume, for example, Rheodyne

Model 7725.

• Do not exceed an operating pressure of 40 MPa (400 atm or 6000 psi)

for steel columns, or 13 MPa (130 atm or 2000 psi) for Radial-Pak™

column segments.

b. Cleaning and Regenerating the Column

A shift in retention or resolution may indicate contamination of

the column. Flushing with an organic solvent is usually sufficient to

remove the contaminant.

If system back pressure increases with usage, replace the guard col-

umn. If you are not using a guard column, replace the inlet frit. If the

problem continues, the column may be plugged with a contaminant

that needs to be dissolved with an appropriate solvent. For example,

proteinaceous material can be removed with repeated 200 μL

injections of dimethylsulfoxide.

If the flushing procedure does not solve the problem, wash the

column with a sequence of progressively more nonpolar solvents. For

example, switch from water to tetrahydrofuran (THF) to methylene

chloride. Return to the standard mobile phase conditions by reversing

the sequence.

Analytical Columns and Cartridges 4

Page 5

[ Care and Use ManUal ]

c. Storing the Column

For Column and Cartridge Columns: Leaving the column unused for

less than four days does not require special storage procedures.

For longer storage, store the column in shipping solvent which is

identical to the column test solvent with a few exceptions. Store

Nova-Pak CN HP and μBondapak CN columns in 0.1 M ammonium

sulfate. Store all μBondapak C18 columns in methanol and store

all μBondapak Phenyl columns in acetonitrile/water. If the mobile

phase contains a buffer salt, first flush the column with 10 column

volumes of 18 megohm water. Make sure that the end plugs are

firmly in place. Never let the column dry out.

For Radial-Pak Column Segments: Wash Radial-Pak column

segments with water to remove all buffer salts, then with the

organic component of the mobile phase. Use a miscible intermediate

if necessary. Remove the cartridges from the 8 x 10 holder and

replace the end caps.

V. troubleshootIng

VI. orderIng and addItIonal InformatIon

If you would like new product information or a copy of the Waters

Parts and Supplies Catalog, complete the reply card and mail. For

more detailed information about Waters columns and cartridges,

consult the Waters Chromatography Columns and Supplies Catalog

or contact your Waters representative. To obtain a copy of the

catalog, complete the enclosed reply card. The catalog is also

available on the Internet at www.waters.com.

Changes in retention time, resolution or back pressure are often

due to column contamination. This is discussed in Section IV. b.,

Cleaning and Regenerating the Column.

Poor chromatography is often the result of a system problem. For

information on troubleshooting your system refer to the Guide to

Successful Operation of your LC System, available from Waters. Ask

for part number WAT022378.

Our experienced team of chromatographic specialists provide

outstanding customer support for corrective, preventive, and quality

maintenance. Our technical support staff is always available to help

you with questions and provide solutions to your applications needs.

In the U.S., call us at 1-800-252-4752. If you are outside the U.S.,

contact your local Waters representative.

Analytical Columns and Cartridges 5

Page 6

[ Care and Use ManUal ]

Sales Offices:

Austria and European Export

(Central South Eastern Europe,

CIS and Middle East) 431 877 18 07

Australia 2 9933 1777

Belgium 32 2 726 1000

Brazil 55 11 5094 3788

Canada 800 252 4752

China 8621 6495 6999

CIS/Russia +7 495 3367000

Czech Republic 42 02 617 11384

Denmark 45 46 59 8080

Finland +358 9 5659 6288

France (33) 1 30 48 72 00

Germany 49 6196 400600

Hong Kong 852 29 64 1800

Hungary 36 1 350 5086

India and India Subcontinent

91 80 2 837 1900

Ireland 353 1 448 1500

Italy 39 02 274 211

Japan (81) 3 3471 7191

Korea (82) 2 820 2700

Mexico 5255 5200 1860

The Netherlands +31 (0)76-50 87 200

Norway 47 63 84 60 50

Poland (48) 22 833 4400

Puerto Rico 787 747 8445

Singapore 65 6273 1221

Spain 34 93 600 93 00

Sweden 46 8 555 11500

Switzerland 41 62 889 2030

Taiwan 886 2 2543 1898

United Kingdom 44 208 238 6100

©2007 Waters Corporation, Waters. The Science of W hat’s

Possible, μBondapak, Delta-Pak, Guard-Pak, Nova-Pak, μPorasil,

Radial-Pak, Resolve, Sentry, Sep-Pak, Symmetry, and Waters are

trademarks of the Waters Corporation. Acrodisc is a trademark of

Gelman Pall Laboratory.

November 2007 WAT035699 Rev 6 VW-PDF

Analytical Columns and Cartridges 6

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...