Page 1

[ CARE AND USE MANUAL ]

ACQUITY UPLC M-Class Columns

TABLE OF CONTENTS

I. PREPARING ELUENTS

II. SAMPLE PREPARATION

III. PREPARING AND CONNECTING 75, 100, AND

150 µM I.D. ACQUITY UPLC M-CLASS COLUMNS

IV. PREPARING AND CONNECTING 300 µM I.D.

ACQUITY UPLC M-CLASS COLUMNS

V. CARE WHEN STOPPING FLOW

VI. HOW TO DIAGNOSE AND ADDRESS ABNORMALLY

HIGH BACKPRESSURE AND LEAKS

VII. CHECKING AND CLEANING A FOULED EMITTER

VIII. LONG TERM COLUMN STORAGE

IX. ORDERING INFORMATION

Note: Gloves should be worn for ALL operations

detailed in this document.

INTRODUCTION

Waters® ACQUITY UPLC® M-Class Columns are manufactured

to exacting specifications and are designed for use at pressures

up to 15000 psi. In order to achieve maximum performance, it is

important to ensure that proper connections are made to minimize

peak tailing and poor efficiency.

Each ACQUITY UPLC M-Class Column is individually tested to

ensure that it passes stringent quality control. Compared to

standard flow chromatography, successful day-to-day performance

of capillary-flow systems can require extra attention to detail.

This document provides several essential recommendations for

the successful use of ACQUITY UPLC M-Class Columns.

ACQUITY UPLC M-Class System.

ACQUITY UPLC M-Class Columns are available in 75, 100, 150, and 300 μm I.D.s.

Page 2

[ CARE AND USE MANUAL ]

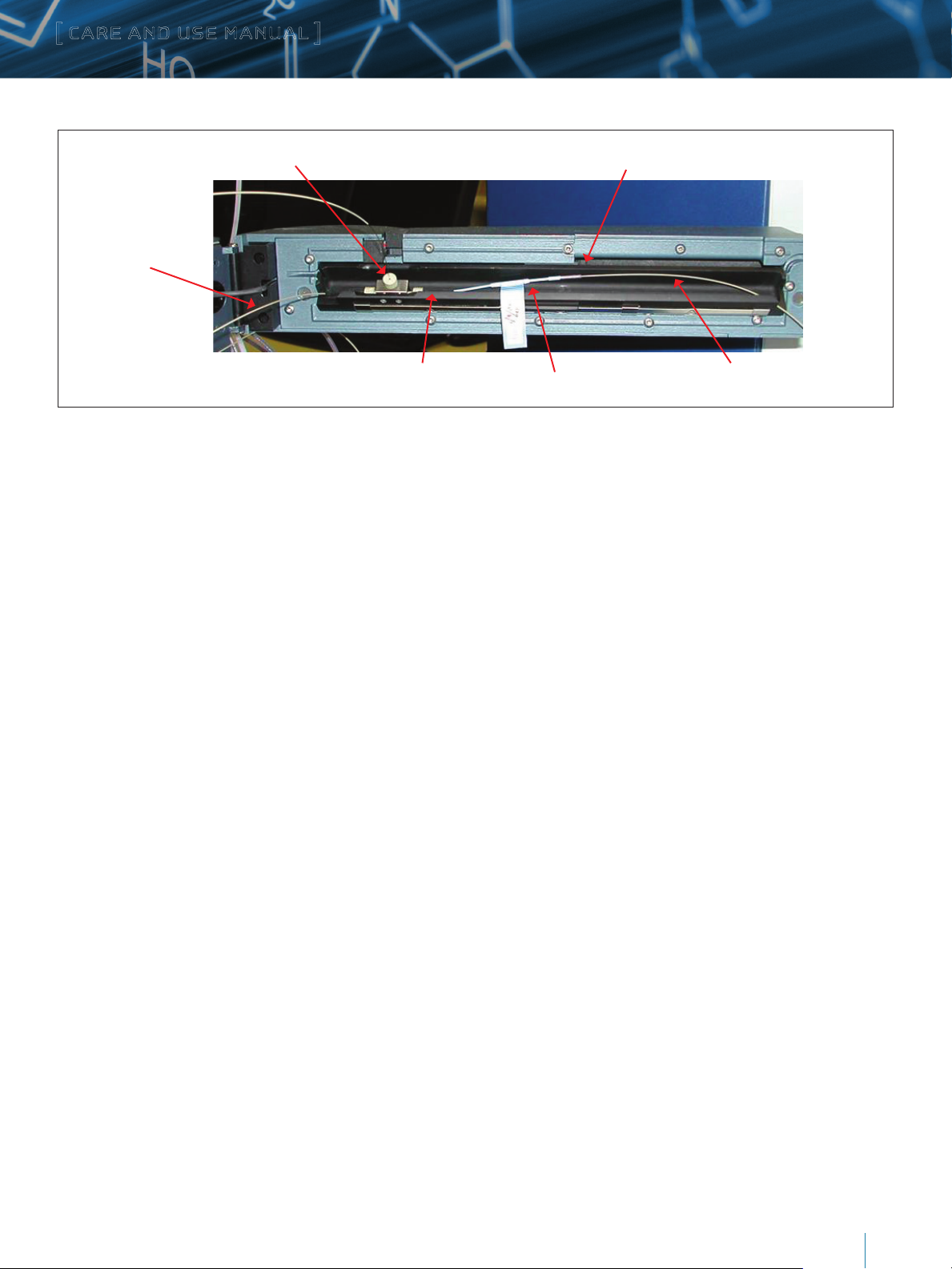

Nano-Tee with magnetic mount

Tubing to

HTM valve

outlet tubing

I. PREPARING ELUENTS

Do not filter organic solvents. Use MS grade solvents directly

from the bottle.

A solvent: 100% water with 0.1% formic acid.

B solvent: 100% acetonitrile or methanol with 0.1% formic acid.

Seal wash solvent: water, may contain small amount of

organic (no acid).

Inner compartment (swiveled open)

Analytical column

Tubing to MS sourceTrapping column

II. SAMPLE PREPARATION

Samples for expression analysis must contain tryptic peptides

derived from proteins of interest at suitable concentrations.

Samples may contain buffers and residual reagents from

approved digestion procedure.

The sample must not contain other reagents, denaturants,

detergents, lipids, and must be free of particulates.

Weak needle wash for peptides: 3% acetonitrile with 0.1%

formic acid.

Note:

Good lab practices: no solvent bottles to go through the

dishwasher!

Wear gloves when handling solvent lines and hardware.

If system is contaminated with poor quality solvents,

flush with appropriate solvent.

Many report successful use of solution containing 25% water,

25% acetonitrile, 25% methanol, 25% IPA and 0.1% formic acid.

For PEG contamination, flush system with IPA.

DO NOT USE strong bases, as they can strip fused silica.

Where to source solvents:

In North America: Fisher Optima or Burdick & Jackson.

In Europe: Biosolve (Netherlands) provide very good solvents.

They offer smaller bottles (0.5 L) as well as “UPLC”

grade solvents.

III. PREPARING AND CONNECTING 75, 100 OR

150 µM I.D. ACQUIT Y UPLC M-CLASS COLUMNS

a) Preparation

Carefully remove your column from bag.

The gold ferrule on the inlet of the column is placed snugly on the

tubing at the factory. The ferrule is lightly secured to reduce the

risk of it being lost as the column is removed from the packaging.

The ferrule is purposely set high on the tubing but will properly

seat itself in the correct position upon tightening.

A small piece of Teflon® tubing is present on the outlet end of the

column for those who want to connect the device to a UV or PDA

detector rather than a mass spectrometer.

Note: The column is attached to a transfer tube with the use of a

zero dead volume union. This is hidden beneath the heat shrink

tubing. Care must be taken NOT to apply excessive force on the

ends of the nano column (e.g., when removing teflon tubing at

column outlet) that could cause this joint to separate.

ACQUITY UPLC M-Class Column Care & Use

2

Page 3

[ CARE AND USE MANUAL ]

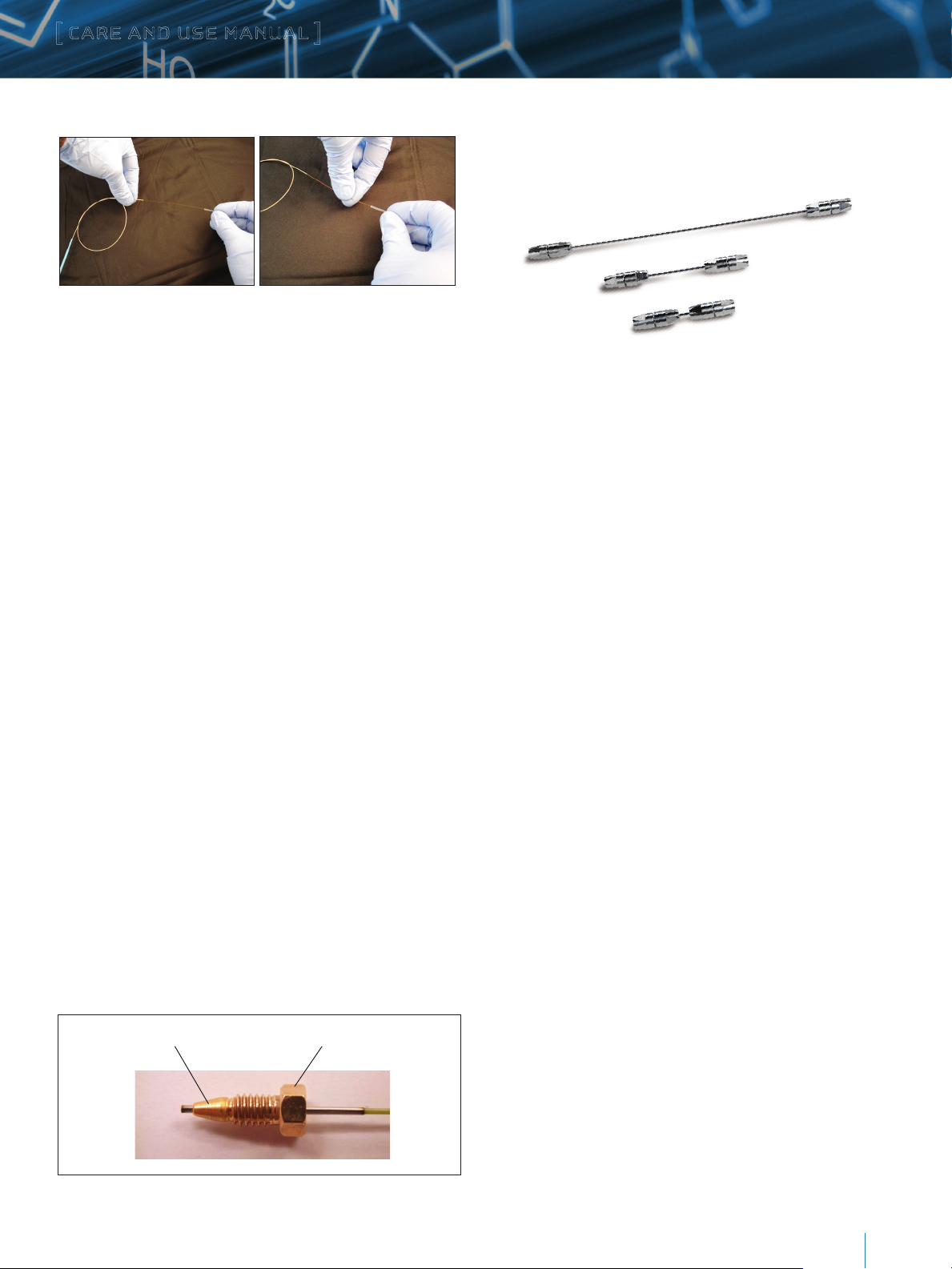

Wrong Correct

Carefully grab the teflon tubing with one hand and the BARE FUSED

SILICA capillary, not the PEEK tubing, with the other hand, to remove

the Teflon sleeve. Again, be careful NOT to apply unnecessary force

when removing the teflon tubing which could cause the fragile joint

between transfer tube and packed capillary to separate.

b) Connection

Connecting and proper tightening of 75, 100, or 150 µm I.D.,

ACQUITY UPLC M-Class Columns to 15 K ACQUITY UPLC system.

Flow mobile phase only in the direction indicated by the arrow

on the column label. Connect the column with the direction of

the flow arrow on the label pointing to the detector or Mass

Spectrometer.

1. For a column never installed on an ACQUITY UPLC

M-Class System.

Turn nut until hand tight then an additional 1/2 turn

IV. PREPARING AND CONNECTING

300 µM I.D. ACQUITY UPLC M-CLASS COLUMNS

Carefully remove column from box.

Connect the column inlet to the injector utilizing a Valco style

compression screw.

Connect the column outlet to the detector or Mass Spectrometer

using a Valco style compression screw.

V. CARE WHEN STOPPING FLOW

Do not stop the flow to your ACQUITY UPLC M-Class Column

suddenly. It is critical that the flow be slowly lowered via

the ACQUITY UPLC M-Class System controller to prevent

column damage.

2. For a previously installed and removed column from

ACQUITY UPLC M-Class System.

Hand tight plus 1/8 turn

“Hand Tight” is when the ferrule bottoms in the M-detail fitting.

The ferrule is pre-staked higher than necessary on the tube, so

the ferrule must be seated by hand (hand tight) or lightly with

a wrench, then an additional turn. Note: In virtually every case,

gentle wrenching is required to get to the “hand tight” state

before the final half turn. Taking “hand tight” or “finger tight” too

literally can result in under tightening/leaks.

Note: DO NOT over tighten, leaking may occur and/or the ferrule

may become stuck in the port.

Ferrule Nut

VI. HOW TO DIAGNOSE AND ADDRESS

ABNORMALLY HIGH BACKPRESSURE AND LEAKS

The inlet or the head of a chromatography column experiences

the largest amount of pressure in a LC system. The

ACQUITY UPLC M-Class Column inlet is designed to

operate at pressures up to 15 K psi.

The fluidic pressure drops across the column at the outlet of the

column should only experience atmospheric pressure. The outlet

connection which connects the column to the transfer capillary is

designed to handle a maximum pressure of 800 psi.

With a higher than normal system pressure, a small leak might be

detected at the outlet of an ACQUITY UPLC M-Class Column.

ACQUITY UPLC M-Class Column Care & Use

3

Page 4

[ CARE AND USE MANUAL ]

Problem

If a clog or a blockage is created after the ACQUIT Y UPLC

M-Class Column (e.g., at emitter) the pressure at the outlet

of the column may rise.

The increase in pressure at the column outlet may create a

temporary leak between the column and the transfer tubing.

The most common source of post column clogs is a blocked

nanospray emitter.

Note: Set high pressure limit on the ACQUITY UPLC M-Class

System to approximatively 1000 psi above maximum normal

operating pressure.

Diagnosis 1

The pressure traces in the console window show an increase in

pressure during the analytical gradient (red arrows) between two

injections (highlighted by the red squares).

Diagnosis 2

This shows the increase in system pressure must originate after the

trap column.

Notice the pressure during the trapping portions of the analysis did

not increase between injections (red arrows).

Representative diagram of ACQUITY UPLC M-Class System with attached trap and

ACQUITY UPLC M-Class Column.

ACQUITY UPLC M-Class Column Care & Use

4

Page 5

[ CARE AND USE MANUAL ]

Diagnosis 3

A clogged emitter may still produce an ion signal.

The charged emitter may act as an APCI needle and ionize the gas

in the source producing ions for the mass spectrometer (below).

Test for a clogged emitter

If the system pressure drops more than 200 psi the emitter

is clogged.

Remove the column transfer tubing from the universal sprayer

(or other nanospray source).

Note: In normal use, stop the flow and wait for the pressure to drop

to zero before breaking the connection at the union to minimize

the chance of dislodging potential particulates in the union and

having them be swept into (and clog) the emitter. If one needs to

disconnect to relieve pressure, it is much better to disconnect the

outlet end, as shown here, rather than the inlet.

The sprayer should be retracted to shut off the high voltage before

touching the sprayer.

Should your ACQUITY UPLC M-Class Column be replaced?

Excessive pressure at the column outlet may create a small leak.

If the column outlet only experiences excess pressure for a short

period of time the column should still be acceptable for use since

the union between packed column and transfer tube can “recover.”

If the column outlet experiences pressure over an extended period

of time (e.g., overnight) the union between the column and the

transfer tubing may be permanently compromised. Any nonreversible open space created between the column and transfer

line may lead to band broadening (wider peaks).

VII. CHECKING AND CLEANING A FOULED EMITTER

Examine the emitter

Examining a clogged nanospray emitter under a microscope may

allow the user to determine the source of the clog.

Fused silica particles: These particles will be transparent and have

sharp, fractured edges. Fused silica particles can be created when

a column and an emitter are joined with too much force (over

tightened union).

Organic material: The material will appear brown in color (bottom).

Organic material can derive from a dirty sample or solvents.

GLOVES MUST BE WORN to prevent contamination with

undesired biological material.

Clean emitter

Emitter clogged with organic residue

Examining the Union (Part Number 700002843, available on waters.com).

ACQUITY UPLC M-Class Column Care & Use

5

Page 6

[ CARE AND USE MANUAL ]

1. Remove the clogged emitter and the column from the union on

the universal sprayer.

2. Remove the PEEK nuts on either end.

3. Loosen the screw on the sliding portion of the sprayer and

remove the union.

5. Even if the union does not appear to be clogged it should be

cleaned to remove any small particulates.

Cleaning the Union (Method #1)

As the union is 100% stainless steel, 20% nitric acid in water

can be used to clean it. This aggressive procedure helps ensure

that the union becomes free of even the strongest contaminations.

In addition, it provides excellent electric contact for

electrospray ionization.

Wash the outside of the outlet capillary and fitting with

water/acetronitrile (50/50) before reconnecting to union.

Note: Again for demonstration purposes only, these photos show

fittings and tubing being handled with bare fingers, which is

known to introduce contamination in the system. It is therefore

critical that customers ALWAYS wear clean, powder-free gloves

when changing tubing or handling fittings.

4. Hold the union up to a light (above). Light should shine through

an unclogged union. If the union is completely clogged the

obstruction must be removed.

Note: Do not mix nitric acid with organic acids, as they will react

and produce high volumes of CO2.

To order the Union: Waters PN 700002843

To order Peek Fitting: Waters PN 700002842

Cleaning the Union (Method #2)

The union can be cleaned by sonication in a solution of IPA/water

for at least 15 minutes.

After sonication, remove any residual solvent by flushing the

union with air or nitrogen.

After cleaning, examine the union with a microscope and ensure

that any particulate matter has been removed. While looking at

the union be sure the internal threads and opening have not been

scored or damaged in any way.

If the obstruction within the union cannot be removed or it

appears damaged please replace the union.

Note: In many cases it is best to simply REPLACE the union

whenever a new emitter is used.

ACQUITY UPLC M-Class Column Care & Use

6

Page 7

[ CARE AND USE MANUAL ]

Replace the Emitter

Place the pin plug at the back side of the union. This will mark the

center of the union (right).

Thread the replacement emitter (back end first) through the front

of the sprayer and into the union.

Tighten the PEEK nut around the union carefully (do not

over-tighten).

Remove the pin plug and replace it with the transfer line from the

ACQUITY UPLC M-Class Column (again, do not over-tighten

the fitting).

To reduce the occurrence of clogging

Make sure the union between the column and emitter is clean.

Do not over tighten the fittings on the union (finger tight only).

Make sure the UPLC solvents are clean.

Keep a flow on the tip even when the instrument is not in use

(as low as 200 nL/min).

Try using a TaperTip instead of a Pulled Tip Emitter if

clogging persists.

TaperTip Emitter

A TaperTip (P/N 186003932) is offered as an alternative to a

PicoTip and is the default emitter in the universal sprayer kit.

(July, 2007). The TaperTip has an I.D. of 20 µm but unlike the

PicoTip the I.D. remains unchanged throughout the emitter. This

allows the emitter to be implemented for higher flow rates.

Furthermore, the TaperTip may experience a lower frequency

of particle clogging.

About poorly cut fittings

DO NOT cut or modify the emitter or column tubing.

All tubing and columns supplied by Waters are pre-cut and polished.

Improperly cut tubing can lead to "shedding" and introduction of

fused silica particles downstream of ACQUITY M-Class 75, 100,

or 150 µm I.D. Columns. This consequently can cause undesired

system backpressure increases.

Note: Compared to the PicoTip Emitter, Waters TaperTip Emitter does

not produce as stable a spray at 250-400 nL/min, which is the flow

rate range most customers use with 75 μm or 100 μm I.D. columns.

As indicated above, use of the TaperTip Emitter is the suggested

when a more robust device is preferred.

Column I.D. Optimal Flow Rate (nL/min) Emitter Type

75 µm 300 PicoTip

100 µm 400-500 PicoTip/TaperTip

150 µm 1000 TaperTip

300 µm 4000 ESI Source required

ACQUITY UPLC M-Class Column Care & Use

7

Page 8

[ CARE AND USE MANUAL ]

What flow rate can I use with each type of emitter?

The flow rate of an LC method should be determined by the

optimal flow rate for the particular column. The optimal flow rate

is directly related to the column I.D.

A PicoTip is ideally suited for nanospray applications while the

TaperTip is suited for microspray applications (>1 µL/min).

Waters currently does not recommend the use of a nanospray

source for the 300 µm column format.

VIII. LONG TERM ACQUITY UPLC M-CLASS

COLUMN STORAGE

When not in use, it is recommended to maintain flow through

the ACQUITY UPLC M-Class Column using 100% eluent B to

maximize bed stability and minimize potential bed drying.

If prolonged column storage is required or if the column needs

to be removed from the system, it is recommended that the

ACQUITY UPLC M-Class Column be flushed with 100% organic

solvent containing no TFA or FA (e.g., simply store in

100% acetonitrile).

IX. ORDERING INFORMATION

ACQUITY UPLC M-Class Columns

Product Description Particle Size Dimensions Part Number

ACQUITY UPLC M-Class BEH C18, 130Å 5 µm 300 µm x 50 mm 186007471

ACQUITY UPLC M-Class HSS T3 1.8 µm 300 µm x 150 mm 186007472

ACQUITY UPLC M-Class HSS T3 1.8 µm 75 µm x 150 mm 186007473

ACQUITY UPLC M-Class HSS T3 1.8 µm 75 µm x 250 mm 186007474

ACQUITY UPLC M-Class CSH C

ACQUITY UPLC M-Class CSH C

ACQUITY UPLC M-Class CSH C18, 130Å 1.7 µm 75 µm x 200 mm 18 60 0747 7

ACQUITY UPLC M-Class CSH C18, 130Å 1.7 µm 75 µm x 250 mm 18 60 0747 8

ACQUITY UPLC M-Class CSH C18, 130Å 1.7 µm 100 µm x 100 mm 186007479

ACQUITY UPLC M-Class CSH C18, 130Å 1.7 µm 150 µm x 100 mm 186007480

ACQUITY UPLC M-Class CSH C

ACQUITY UPLC M-Class CSH C18, 130Å 1.7 µm 150 µm x 150 mm 186 007514

ACQUITY UPLC M-Class BEH C

ACQUITY UPLC M-Class BEH C18, 130Å 1.7 µ m 75 µm x 150 mm 186007482

ACQUITY UPLC M-Class BEH C18, 130Å 1.7 µ m 75 µm x 200 mm 186007483

ACQUITY UPLC M-Class BEH C18, 130Å 1.7 µ m 75 µm x 250 mm 186007484

ACQUITY UPLC M-Class BEH C18, 130Å 1.7 µ m 100 µm x 100 mm 18 60 07485

ACQUITY UPLC M-Class BEH C18, 130Å 1.7 µ m 150 µm x 100 mm 186007486

ACQUITY UPLC M-Class BEH C18, 300Å 1.7 µ m 75 µm x 100 mm 186007487

ACQUITY UPLC M-Class BEH C18, 300Å 1.7 µ m 100 µm x 100 mm 18 60 07488

ACQUITY UPLC M-Class BEH C18, 300Å 1.7 µ m 150 µm x 100 mm 186007489

ACQUITY UPLC M-Class BEH C18, 300Å 1.7 µ m 75 µm x 150 mm 18600749 0

ACQUITY UPLC M-Class BEH C18, 300Å 1.7 µ m 75 µm x 200 mm 186 007491

ACQUITY UPLC M-Class BEH C18, 300Å 1.7 µ m 75 µm x 250 mm 18600749 2

ACQUITY UPLC M-Class BEH C4, 300Å 1.7 µm 75 µm x 100 mm 1860074 93

ACQUITY UPLC M-Class BEH C4, 300Å 1.7 µm 100 µm x 100 mm 18 60 0749 4

ACQUITY UPLC M-Class BEH C4, 300Å 1.7 µm 150 µm x 100 mm 18 60 0749 5

ACQUITY UPLC M-Class Symmetry C18 Trap, 10 0Å 5 µm 180 µm x 20 mm 18600749 6

ACQUITY UPLC M-Class Symmetry C18 2D Trap, 100Å 5 µm 180 µm x 20 mm 18 6007497

ACQUITY UPLC M-Class Symmetry C18 Trap, 10 0Å 5 µm 300 µm x 50 mm 18600749 8

ACQUITY UPLC M-Class Symmetry C18 2D HCP Trap, 100Å 5 µm 300 µm x 25 mm 18600749 9

ACQUITY UPLC M-Class Symmetry C18 V/V Trap, 100Å 5 µm 180 µm x 20 mm 186007500

, 130Å 1.7 µm 75 µm x 100 mm 18 60 07475

18

, 130Å 1.7 µm 75 µm x 150 mm 18 60 07476

18

, 130Å 1.7 µm 150 µm x 50 mm 186007513

18

, 130Å 1.7 µ m 75 µm x 100 mm 186007481

18

1

2

1

2

1

1

Trap columns designed for 1D (low pH only) work. These 1D traps are reversible.

2

Trap columns designed for 2D (high pH/low pH) work. These 2D traps are not reversible.

ACQUITY UPLC M-Class Column Care & Use

8

Page 9

[ CARE AND USE MANUAL ]

SALES OFFICES

Austria 43 1 877 18 07

Australia 61 2 9933 1777

Belgium and Luxembourg 32 2 726 1000

Brazil 55 11 4134 3788

Canada 1 800 252 4752

China 86 21 6156 2666

Czech Republic 420 2 617 11384

Denmark 45 46 59 8080

Finland 358 9 5659 6288

France 33 1 30 48 72 00

Germany 49 6196 400 600

Hong Kong 852 2964 1800

Hungary 36 1 350 5086

India 080 49292200 03

Japan 81 3 3471 7191

Korea 82 2 6300 4800

Mexico 52 55 52 00 1860

The Netherlands 31 76 508 7200

Norway 47 6 384 6050

Poland 48 22 101 5900

Portugal 351 21 893 61 77

Puerto Rico 1 787 747 8445

Russia/CIS 7 495 727 4490 / 290 9737

Singapore 65 6593 7100

Spain 34 93 600 9300

Sweden 46 8 555 115 00

Switzerland 41 56 676 7000

Taiwan 886 2 2501 9928

Ireland 353 1 448 1500

Israel 9723 3731391

Italy 39 02 265 0983

UK 44 208 238 6100

US 1 800 252 4752

Waters, The Science of W hat’s Possible, ACQUITY UPLC, UPLC, and Symmetry are registered trademarks of Waters Corporation. CSH is a

trademark of Waters Corporation. All other trademarks are the property of their respective owners.

©2014 Waters Corporation. Produced in the U.S.A.

March 2014 720004944EN Rev A LM-PDF

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...