Page 1

ACQUITY APC Columns

CONTENTS

I. INTRODUCTION

II. GETTING STARTED

a. Preparing the System

b. Column Connections

c. Column Installations

d. eCord Installation

e. Column Equilibration

III. COLUMN USE

a. Guidelines

b. Calibration

c. Useable Flow-Rate Ranges

d. Minimizing Band Spread

IV. TROUBLESHOOTING

V. COLUMN CLEANING, REGENERATION

AND STORAGE

a. Cleaning and Regeneration

b. Storage

VI. eCORD INTELLIGENT CHIP TECHNOLOGY

a. Introduction

b. Installation

c. Column Use Information

I. INTRODUCTION

Thank you for choosing an ACQUITY APC™ Column. The ACQUITY APC

Columns are designed to achieve maximum separation performance

when used with the ACQUITY® Advanced Polymer Chromatography®

(APC™) System. Please take a few moments to read this manual carefully.

Following the recommendations in this manual will prolong column life

and enhance chromatographic reproducibility.

ACQUITY APC Columns are packed with sub-3-µm ethylene bridged

hybrid (BEH) particles that provide mechanical strength, packedbed stability and high separation efficiency. They deliver superior

chromatographic performance for all polymer classes, including low

molecular weight aqueous and organic soluble polymers, up to a

molecular weight of 2,000,000 g/mole (Table 1).

To maximize separation selectivity and performance ACQUITY APC

Columns are available in two bonding technologies optimized for each

solvent class:

ACQUITY APC XT: Packed with a high-coverage trimethyl silane bonded to

a BEH substrate. These columns are recommended for extended temperature

(< 90 °C) separations in organic solvents.

ACQUITY APC AQ: Feature unbonded BEH substrate. Recommended for

room temperature (< 45 °C) separations in aqueous solvents.

ACQUITY APC Columns are manufactured in an ISO 9001 facility and are

held to narrow specification ranges to ensure reproducible performance.

Every column is individually tested and a Certificate of Batch Analysis is

provided on the attached eCord™ Intelligent Chip.

Page 2

Table 1. Physical Characteristics

Recommended

Separation Solvent

ACQUITY APC XT 45 Organic 90 1-11 45 1.7 200-5,000

ACQUITY APC XT 125 Organic 90 1-11 125 2.5 1,000-30,000

ACQUITY APC XT 200 Organic 90 1-11 200 2.5 3,000-70,000

ACQUITY APC XT 450 Organic 90 1-11 450 2.5 20,000-400,000

ACQUITY APC XT 900 Organic 90 1-11 900 2.5 300,000-2,000,000

ACQUITY APC AQ 45 Aqueous 45 1-9 45 1.7 200-5,000

ACQUITY APC AQ 125 Aqueous 45 1-9 125 2.5 1,000-30,000

ACQUITY APC AQ 200 Aqueous 45 1-9 200 2.5 3,000-70,000

ACQUITY APC AQ 450 Aqueous 45 1-9 450 2.5 20,000-400,000

*Linear range based on polystyrene standards

Temperature Limit

(°C)

pH Range

Pore Size

(Å)

dp

(µm)

Linear Range

(g/mol e)*

II. GET TING STARTED

a. Preparing the System

Before attaching the column, the system must be prepared as follows:

1. Remove the old columns and connect the tubing ends with a

zero-dead-volume connector.

2. Convert the system to the solvent required for the separation by

flushing the system and injector pathway to remove old solvents.

For additional information, refer to the ACQUITY APC System’s

operator guide.

b. Column Connections

The ACQUITY APC System uses tubing and connectors that have

been designed to meet stringent tolerances to minimize extracolumn volume within the system. It is highly recommended that

you use the column connection hardware that is supplied with the

system, and, when needed, replace with original manufacturer’s

hardware. For applications that require a bank of columns connected

in series, a u-shaped column-joining tube (which has been optimized

to fit within the column heater compartment) is available separately.

c. Column Installations

Generally, analytical results are independent of the sequence in

which a column bank is arranged. However, to improve resolution

and column life, arrange the columns in order of decreasing

pore size, with the largest pore size closest to the injector. This

is recommended because the species with the highest molecular

weight in the sample contributes the most to the viscosity of the

sample. If the largest species are separated first, the viscosity of

the sample plug decreases more quickly, placing less strain on

the column bank. In the case of higher molecular weight polymers,

there is less chance of shear degradation of the polymer sample.

To install the columns:

1. Remove the end plugs from each column and save them.

2. Connect the first column to the injector outlet tubing. Note the

direction of flow. A flow direction arrow is etched on the inlet

side end nut of the column.

3. Finger-tighten the fitting, then tighten with a wrench by

another turn using the flats machined into the column end nut.

Do not use a wrench on the column tubing. Figure 1 shows a

proper tubing-to-column connection.

2

ACQUITY APC Columns

4. Connect the next column to the previous column using

u-shaped tube connectors. Ensure that the solvent flow

continues in the direction shown on the column end fittings.

Thread the inlet and outlet fittings of the u-shaped tube until

finger tight, then tighten with a wrench.

5. Repeat Step 4 until all columns in the bank are connected.

6. Connect the last column to the detector inlet tubing.

Page 3

In a proper tubing/column connection (Figure 1), the tubing touches

the bottom of the column endfitting, with no void between them.

Figure 1. Proper Tubing Column Connection.

The presence of a void in the flow stream reduces column

performance. This can occur if a Parker ferrule is connected

to a Waters style endfitting (Figure 2).

Table 2. Empty Column Volumes in mL

Column Length

(mm)

30 4.6 0.50

50 4.6 0.83

75 4.6 1.25

150 4.6 2.50

Column Internal Diameter

(mm)

Volume

(mL)

The rigid hybrid particle bed used for the ACQUIT Y APC Columns

allows the user to rapidly switch solvents without damaging the

column packing material. Changing solvents works best between

compatible solvents. For example, when changing between two

immiscible solvents, an intermediate solvent/co-solvent that is

miscible in both initial and final conditions should be used. For highly

viscous solvents, reduce the flow rate to avoid over pressuring the

system. Once the exchange is complete, equilibrate the column using

the final solvent conditions with a minimum of 20-column empty

volumes, or until a stable detector baseline is achieved.

III. COLUMN USE

Figure 2. Parker Ferrule in a Waters Style Endfitting.

d. eCord Installation

Attach the eCord button for each column to the side of the column

heater module noting their sequence. Up to four columns can

be installed at one time. The eCord button is magnetized and

does not require specific orientation. Once connected, column

identification and usage will be available though the instrument’s

control software.

e. Column Equilibration

ACQUITY APC Columns are shipped dry giving the user full

option of the solvent needed for the separation. Equilibrate the

column with a minimum of 20-column volumes, or until a stable

detector baseline is achieved. For a column bank, use the sum of

the column volumes in series to determine the total equilibration

volume. Refer to Table 2 for a listing of column volumes.

a. Guidelines

ACQUITY APC Columns have a finite lifetime directly related to

their care and use. Column lifetime is reduced by contamination

from samples and eluents; improper handling and storage; and

exceeding operational conditions. To maximize ACQUITY APC

Column lifetime, pay attention to these guidelines:

For best resolution and maximum column life, do not exceed

the flow rate recommendations found in Section III c.

Protect the column from vibration and mechanical shock.

Avoid precipitation by dissolving samples in the mobile

phase. If the sample is not dissolved in the mobile phase,

ensure that the sample, solvent and mobile phase are

miscible to avoid precipitation.

Always use high-quality, particle-free, HPLC-grade solvents.

Dedicate, whenever possible, the column to specific

applications. Frequent switching of samples and solvents

accelerates column deterioration and loss of resolution.

Exceeding the upper temperature limit of the column.

3

ACQUITY APC Columns

For aqueous mobile phases, take steps to avoid bacterial

contamination. For additional information refer to "Controlling

Contamination in UPLC®/MS and HPLC/MS Systems", Waters

part number 715001307.

Page 4

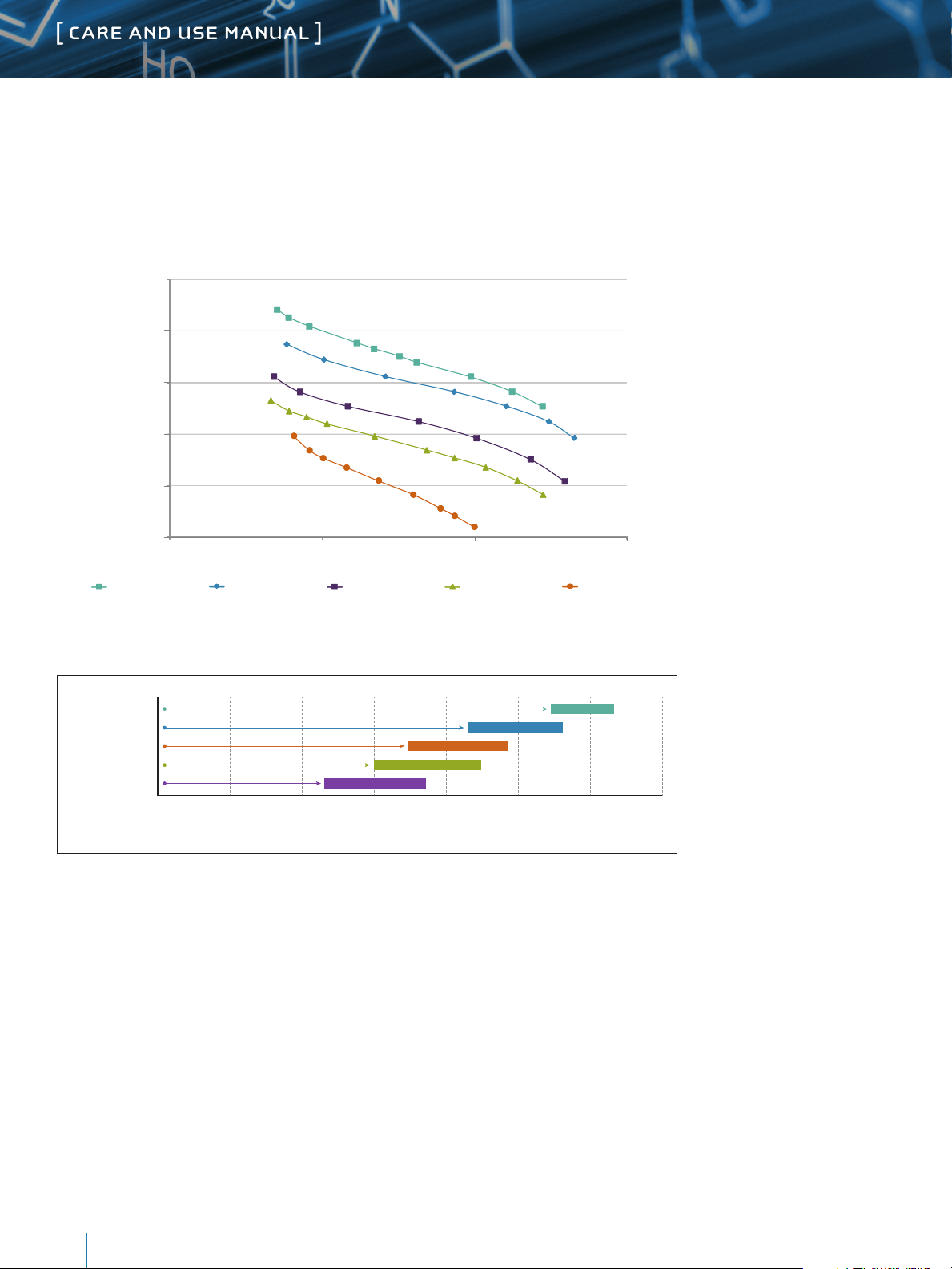

b. Calibration

Whenever replacing a single column of a complete column bank, generate a new calibration curve to

ensure the reproducibility of the application. Figure 3 shows typical calibration curves for each column.

The calibration curves were obtained with polystyrene standards. Figure 4 shows the expected linear

range based on the calibration data.

10,000,000

1,000,000

100,000

10,000

Polystyrene Molecular Weight (Da)

1,000

100

0.50 1.00 1.50 2.00

Elution volume (mL)

ACQUITY APC

XT 900

ACQUITY APC

XT 450

ACQUITY APC

XT 200

ACQUITY APC

XT 125

ACQUITY APC

XT 45

Figure 3. Calibration Curves for ACQUITY APC XT and ACQUITY APC AQ Columns (4.6 x 150 mm) Using Polystyrene Standards.

ACQUITY APC (XT) 900

ACQUITY APC (AQ/XT) 450

ACQUITY APC (AQ/XT) 200

ACQUITY APC (AQ/XT) 125

ACQUITY APC (AQ/XT) 45

10 10

1

2

10

Effective Molecular Weight Range

3

10

4

10

5

10

6

10

7

10

Figure 4. Effective Molecular Weight Range for ACQUITY APC Columns.

c. Useable Flow-Rate Ranges

Excessive mobile-flow rates can create backpressure that can damage the column packing material.

For any given particle size, as the pore volume increases, the base particle loses mechanical strength

due to the reduction in particle wall thickness surrounding the open pore. Table 3 shows the maximum

flow rate recommendation for a single column for each pore size, independent of column length. When

connecting multiple columns in series, the column that specifies the lowest flow rate will dictate the

maximum flow rate for the column bank. Higher viscosity solvents will limit the flow rate due to flow

restriction. Table 4 provides viscosity data for common solvents.

4

ACQUITY APC Columns

Page 5

Diluted/Distor ted Sample Band

0.005 inches

0.020 inches

0.040 inches

For example, if you were to select a three-column bank using

45Å, 200Å and 450Å columns and require that DMF to be used

as the mobile-phase solvent, you would be limited to a maximum

flow rate of 1.0 mL/min. In this case, DMF has a solvent viscosity

of 0.92 cP at 25 °C. Under these conditions the 450Å column

limits the flow to 1.0 mL/min, even though the other columns

can support a higher flow.

Note: When connecting multiple columns in series, the maximum flow rate may

not be achievable due to pressure limitations of the instrumentation. Please

refer to the system's owner manual for more information.

Table 3. Recommended Mobile Phase

Flow Rate for a Single ACQUITY APC Column

Pore Size

(Å)

45 1.8 m L/min 1.1 m L/min

125 2.0 mL/min 1.6 mL/min

200 2.0 mL/min 1.4 mL /min

450

900 0.90 mL/min 0.60 mL/min

Maximum Flow

Rate at Solvent

Viscosity < 0.6 cP

1.7 m L/min 1.0 mL/min

Maximum Flow

Rate at Solvent

Viscosity > 0.6 cP

Table 4. Viscosity of Common Solvents at

Different Temperatures **

Solvent

Acetone 0.32 0.26

Chloroform 0.57 0.45

Dimethyl formamide (DMF) 0.92 0.68

Dimethyl sulfoxide (DMSO) 2.00 1.50

Ethyl Acetate 0.44 0.36

Hexane 0.33 0.26

Methanol 0.60 0.44

Methylene chloride 0.44 N/A

N-Methylpyrrolidone (NMP) 1.70 1.30

Tetrahydrofuran (THF) 0.55 0.39

Toluene 0.59 0.46

Water 1.00 0.67

**References:

1. Reid, R.C., Prausnitz, J.M., Poling, B.E. The Properties of Gases and Liquids,

4th Edition, McGraw Hill, 1987, Table 9-8.

2. http://www.wolframalpha.com

3. Yang, J. Chem Eng Data (2008), 53, 1639 -1642.

Vi scosity (cP)

20 °C 40 °C

d. Minimizing Band Spread

The ACQUITY APC System was designed to minimize band

spreading. Deviation from Waters specified tubing could result

in deterioration of chromatographic performance. Figure 5

shows the influence of tubing inner diameter. Using larger

tubing causes excessive peak broadening, lower sensitivity,

and loss in resolution.

Figure 5. Effect of Connecting Tubing on System.

IV. TROUBLESHOOTING

Changes in retention time, resolution or backpressure are

often due to column contamination. See the Column Cleaning,

Regeneration and Storage section of the care and use manual.

Information on column troubleshooting problems may be

found in HPLC Column Theory, Technology and Practice, U.D.

Neue, (Wiley-VCH, 1997); Waters HPLC Troubleshooting Guide

(Literature Code # 720000181EN); or by visiting www.waters.com

V. COLUMN CLEANING, REGENERATION

AND STORAGE

Assuming that there is no damage to the column bed, changes

in peak shape, peak splitting, shoulders on the peak, shifts in

retention, change in resolution or increasing backpressure

may indicate contamination of the column. Flushing with high

concentrations of organic solvent, taking care not to precipitate

buffers, is usually sufficient to remove the contaminant. If the

flushing procedure does not solve the problem, purge the column

using the following cleaning and regeneration procedures.

a. Cleaning and Regeneration

Use a cleaning routine that matches the properties of the samples

and/or what you believe is contaminating the column. The

columns are stable using a wide range of solvents to improve the

dissolution of the contaminant. Before beginning any cleaning

procedure it is best to isolate the column from downstream

5

ACQUITY APC Columns

Page 6

connections to protect further contamination post column.

Increasing column temperature increases cleaning efficiency. If

the column performance is poor after cleaning and regenerating,

call your local Waters office for additional support.

If the inlet for the first column in the column bank series is

plugged with precipitated material or sample, it is possible to

disconnect the column and reverse the flow to dislodge the

blockage. This must be done extremely carefully at a low flow rate

(not to exceed 0.1 mL/min) to prevent disruption of the packed

sorbent bed. Once the blockage is removed, the column must be

returned to its proper flow direction. If inlet plugging is a concern,

a column in-line filter unit is available (Waters part number

205000343).

Note: The addition of an in-line filter increases the likelihood of shear

degradation, especially for large molecular weight polymer species.

If the column performance is poor after cleaning and regenerating,

call your local Waters office for additional support.

VI. eCORD INTELLIGENT CHIP TECHNOLOGY

a. Introduction

The eCord Intelligent Chip will provide the history of a column’s

performance throughout its lifetime. The eCord is permanently

attached to the column to assure that the column’s performance

history is maintained in the event that the column is moved from

one instrument to another.

Figure 6. eCord Intelligent Chip.

b. Storage

If you will be using the column again within 24 hours, special

storage procedures are unnecessary. For longer storage periods,

return the column to its box with the end plugs firmly in place. Do

not leave a column at elevated temperature without solvent flow.

For maximum column life, avoid temperature cycling. Maintain

operating temperature and reduce the flow rate to 0.1 mL/min

when columns are not in use.

b. Installation

Install the column into the ACQUITY APC Column Manager. Plug

the eCord into the side of the column heater noting the order of

the attachment point. Once the eCord is inserted into the column

heater (see Figure 7) the identification and overall column usage

information will be available allowing the user to access column

information on their desktop. Up to four columns can be connected

at one time.

eCord Fob

Figure 7. Installing the eCord Intelligent Chip.

6

ACQUITY APC Columns

Page 7

c. Column Use Information

The eCord Chip provides the customer with column use data, column dimensions and serial number. The overall

column usage information includes the total number of samples, total number of injections, total sample sets,

date of first injection, date of last injection, maximum pressure and temperature. The information also details

the column history by sample set including date started, sample set name, user name, system name, number

of injections in the sample set, number of samples in the sample set, maximum pressure and temperature in

the sample set, and if the column met basic system suitability requirements. Up to 50 sample sets can be

stored on the eCord Chip. In addition, the eCord provides two-way communications between the eCord Chip and

Empower® Software.

Waters, The Science of W hat’s Possible, Empower, UPLC, Advanced Polymer Chromatography, and ACQUITY are registered

trademarks of Waters Corporation. ACQUITY APC, APC, and eCord are trademarks of Waters Corporation.

©2014 Waters Corporation. Produced in the U.S.A. July 2014 720004667EN Rev. B TC-PDF

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Loading...

Loading...