Page 1

[ Care and Use ManUal ]

Waters AccellPlus QMA and CM Bulk Media

I. calculatIng bulk medIa needs

II. packed column use

a. Slurry Column Packing

b. Dry Column Packing

c. Column Equilibration

d. Packed Column Testing

III. bulk medIa use

IV. addItIonal InformatIon

a. Chemical Compatibility

b. Sanitization

c. Regeneration

d. Short-Term Storage (less than 72 hours)

e. Long-Term Storage (more than 72 hours)

f. Troubleshooting

Waters AccellPlus™ QMA anion exchange and Waters AccellPlus CM

cation exchange packing materials are polymer-coated, silica-based

media of 37-55 µm particles with a 300Å pore size. AccellPlus

media is prepared by a patented copolymerization process that

encapsulates the rigid silica base with a hydrophilic bonding layer

and a highly stable cross-linked functional layer. AccellPlus media

provides excellent recovery and high resolution of bio-molecules. The

rigid and non-compressible structure of AccellPlus media makes it

well suited for the purification and isolation of proteins, enzymes and

immunoglobulins, particularly when preparative or process scale-up is

intended.

AccellPlus ion exchange media is available in 100 gm and 500 gm

bottles (Table 1). Larger quantities are available on request. The

media is shipped as a dry white finely divided powder and can be

stored dry.

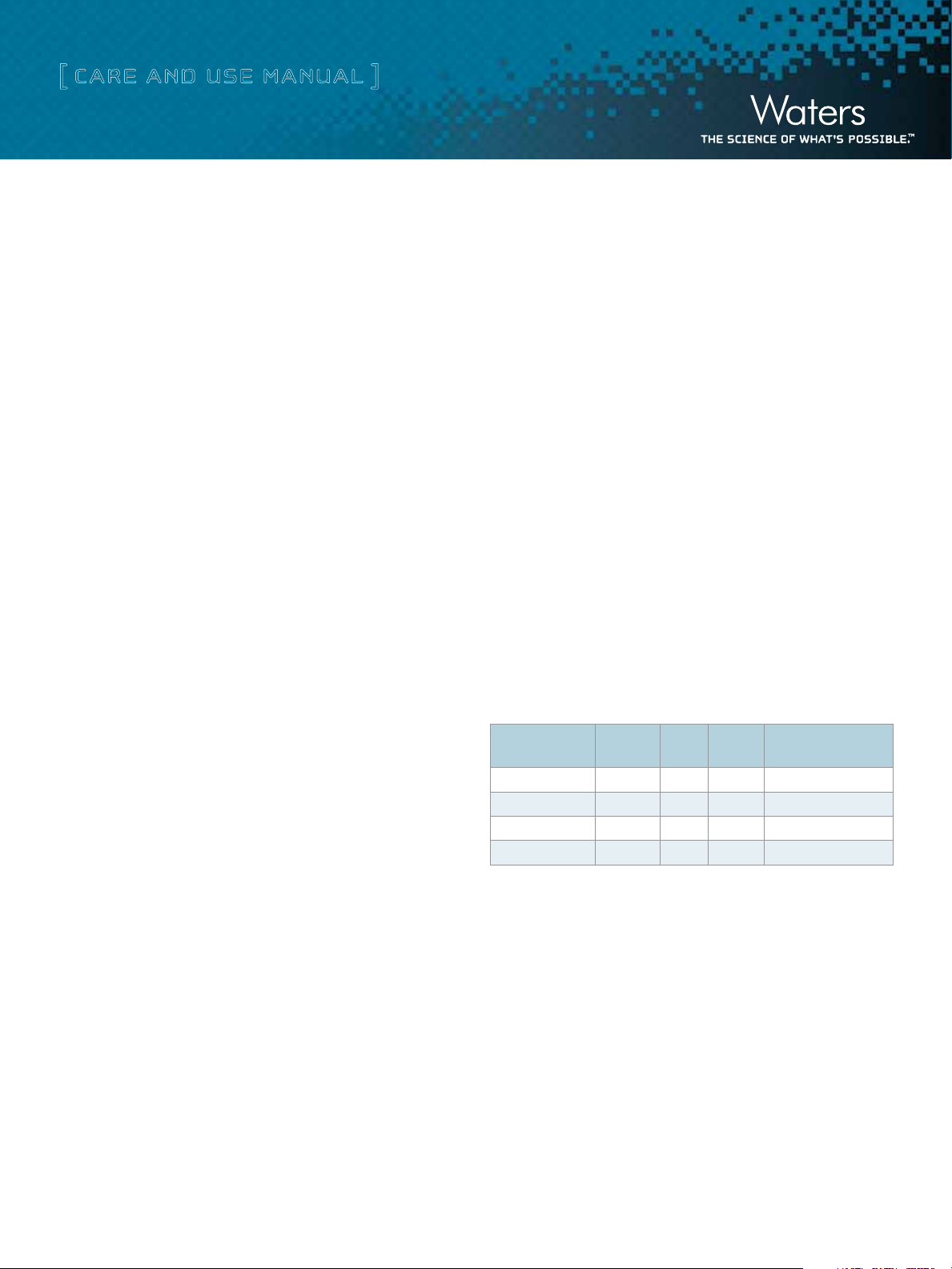

Table 1. AccellPlus Ion-Exchange Bulk Packings

Particle

Description

AccellPlus QMA

Anion Exchanger

AccellPlus CM

Cation Exchanger

Particle

Size

40

µm 300Å

40

µm 300Å

40

µm 300Å

40

µm 300Å

Pore

Size

Qty. Part No.

100 g WAT010742

500 g WAT010741

100 g WAT010740

500 g WAT010739

Waters AccellPlus QMA and CM Bulk Media 1

Page 2

[ Care and Use ManUal ]

Required column volume (mL)

I. calculatIng bulk medIa needs

AccellPlus ion exchange media can be used for batch processes or can

be packed into columns. Columns may be dry- or slurry-packed using

AccellPlus media.

The amount of ion exchange medium and the column size to be used

depends on the amount of sample to be purified. Typically, optimum

performance is achieved when the total sample amount represents

less than 20% of the protein capacity of the AccellPlus medium used

(Tables 2 and 3). Samples exceeding 20% of the column’s maximum

protein binding capacity can be applied with somewhat lower than

optimal resolution of the components contained in the mixture. The

demands of the separation will determine the sample load for amount

of AccellPlus medium used.

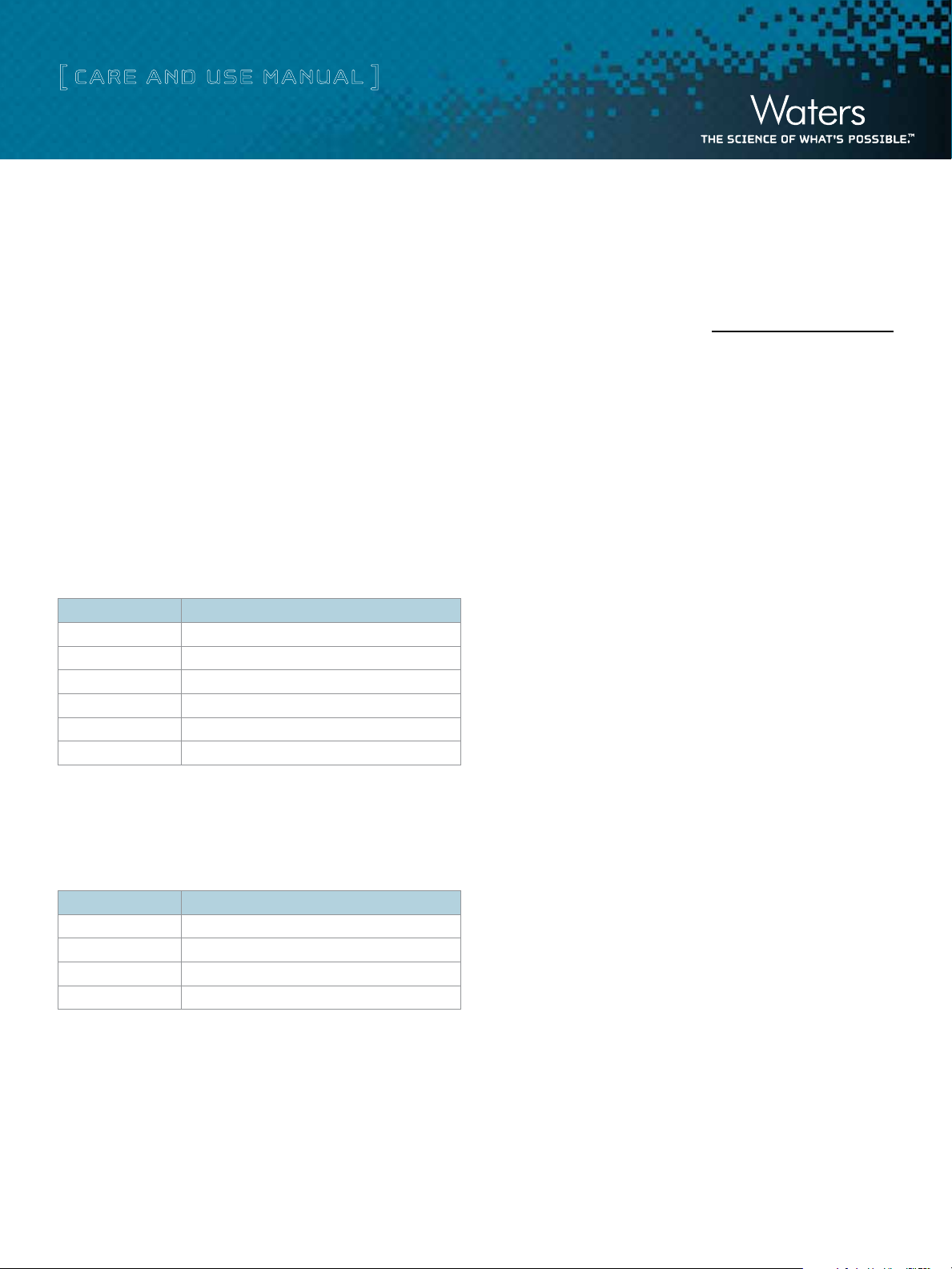

Table 2. AccellPlus QMA - Protein Binding Capacity

Measured using Bovine Serum Albumin in 0.02 M Tris/HCl buffer.

pH Mg BSA/gm Accell® (± 5%)

6.0 122

6.5 180

7.0 180

7.5 171

8.0 105

8.5 62

To pack a column with AccellPlus media:

The bulk density of AccellPlus is 0.5 g/mL. Thus, 1 gm of media will

produce 2 mLs of packed column bed.

AccellPlus media required (grams) =

2

a. Slurry Column Packing

Slurry packing using methanol solvent provides an efficient means

to column packing. We strongly recommend that columns greater

than 5 cm in diameter be slurry packed. Methanol slurry packing

produces more efficient columns providing better peak shapes than

slurry packing using dilute buffer or water eluents. Typically a

3-5:1 v/v methanol:AccellPlus slurry should be used. Pour slurry

directly into the column with the outlet attached to a water aspirator.

Alternatively, the columns can be packed using conventional HPLC

slurry packing techniques. AccellPlus media can withstand pressure of

up to 2000 psi without any problems.

b. Dry Column Packing

To dry pack AccellPlus media into any column follow these steps:

1. Pour the media slowly into the column while either tapping the

side or the base of the column. This will help the media settle

into a densely packed bed.

Protein binding capacity varies considerably based on selected

protein, buffer type, and pH.

Table 3. AccellPlus CM - Protein Binding Capacity

Measured using Cytochrome C in 0.02 M sodium phosphate.

pH Mg Cytochrome C/gm Accell (± 5%)

5.0 157

6.0 171

6.5 172

7.0 155

Note: For best results do no exceed 20% of protein binding capacity.

II. packed column use

Rigid AccellPlus particles greatly simplify column packing compared

to use of many traditional soft gel media. Columns can be easily

packed using either slurry- or dry-column packing techniques.

Waters AccellPlus QMA and CM Bulk Media 2

2. Once the column has been packed, flow mobile phase through

the column for 2-3 minutes at as high a flow rate as the pump

or column pressure limit will allow. This will settle the column

bed slightly. Voids should be filled by stirring the packing at the

column inlet and topping off with a thick slurry media.

3. Adjust the plunger or tap up with media to adjust voids. Repeat

this procedure until a stable column bed is obtained.

c. Column Equilibration

1. Wash the column with 5 column volumes of dilute buffer.

Note: If the column has been packed in methanol, flush with 5

column volumes HPLC-grade water prior to the dilute buffer wash.

2. After the dilute buffer wash, wash the column with 5 column

volumes of concentrated buffer.

3. Wash the column with starting buffer until the pH and ionic

strength of the column eluate match those of the solvent being

pumped onto the column.

Page 3

[ Care and Use ManUal ]

2

The AccellPlus column should now be tested (see Packed Column

Testing). Use methanol as the mobile phase to run the efficiency and

asymmetry test.

d. Packed Column Testing

Waters recommends that columns be tested prior to use. There are

many different ways of doing this, but one of the simplest is to inject

a small volume of a 500:1 buffer:acetone solution. This will absorb

effectively at 280 nm. The peak should be symmetrical. A typical

calculated plate count an AccellPlus IEX slurry packed, 1 x 10 cm

column should be greater than 500 plates. Lower observed values

would be normal for columns that are packed using the less efficient,

dry packing process.

N = 16

Rt

W

Rt = retention time in minutes

W = peak width at baseline in minutes

III. bulk medIa use

Determine the amount of bulk ion exchange media required for

application needs (see Section II, Table 2 or Table 3).

• 100% methanol

• 100% acetone

• 100% ethanol

• 0.1% sodium azide

• 70% ethanol

• 2 M sodium chloride

• 0.25 M hydrochloric acid (limited)

• 0.1 M sodium hydroxide (limited)

b. Sanitization

70% ethanol, 0.10% sodium azide or 0.5% Hibitane are effective

sanitizing agents.

c. Regeneration

Clean protein solutions, carefully filtering of buffers, and occasional

column regeneration will yield 100 or more runs. Occasionally, a

reduction in capacity is observed. When this happens, the column

should be regenerated by pumping 5 column volumes of 2 M sodium

chloride at pH 7.5 for the AccellPlus QMA media and pH 4 for the

AccellPlus CM media. More aggressive cleaning solutions may be

found in Table 4.

Slurry the media with 5 times the media’s volume of dilute buffer

for 2-3 minutes. The media should be allowed to settle and then the

excess buffer drained off. A similar volume of concentrated buffer

(0.1 M) should be added, slurried up 2-3 minutes, and then drained

off. The same procedure should be repeated with dilute buffer until pH

and salt concentration remain at the desired values.

IV. addItIonal InformatIon

a. Chemical Compatibility

AccellPlus is fully stable in aqueous buffers between pH 2-9. The

following reagents are compatible with AccellPlus media for use in

cleaning and as anti-microbials.

• 10% acetic acid (pH 2.5)

• 2.5 M sodium acetate (pH 8) 20% aqueous propanol,

0.1% trifluoroacetic acid 5 M urea

• 0.5% Hibitane™ (chlorohexidine)

• 5 M urea

• 1% Triton™ X-100

• 0.1% sodium azide

Table 4. Suggested Cleaning Solutions

Agent Concentration Exposure

Sodium Hypochlorite 1000 ppm 2 hours

Hydrochloric Acid 0.25 M less than 30 minutes

Sodium Hydroxide 0.1 M

d. Short-Term Storage (less than 72 hours)

AccellPlus media does not require special storage or treatment for

periods less than 72 hours. We recommend, however, that the

columns be stored at 4 °C.

e. Long-Term Storage (more than 72 hours)

Although AccellPlus media is not susceptible to microbial attack, an

anti-microbial such as Hibitane, sodium azide or 70% ethanol can be

added (see Chemical Compatibility). If the medium is to be stored dry,

pump the medium out of the column, wash with 10 column volumes

of 1 M sodium chloride, 10 column volumes of HPLC-grade water, and

10 column volumes of methanol. Dry the media under vacuum at 80 °C.

3 column volumes pump through

in less than 20 minutes

Waters AccellPlus QMA and CM Bulk Media 3

Page 4

[ Care and Use ManUal ]

f. Trouble Shooting

Problem Cause Remedy

Poor Resolution Sample overload Reduce sample amount (see Bulk Media Packing).

Flow rate too high Reduce flow rate.

Media fouling Reverse flow direction. Flush with suitable cleaning agent (see Chemical Compatibility).

Column voiding Check efficiency, and if low, repack or fill column void.

Low Flow Rate Media fouling Reverse flow direction. Flush with suitable cleaning agent (see Chemical Compatibility).

Frits plugged

Low Capacity Salt concentration too high

pH too high (QMA)

pH too low (CM)

Inappropriate buffer salt

Reverse flow. Replace connector frits.

Reduce salt concentration.

Lower pH if protein stability is not affected.

Raise pH if protein stability is not affected.

Change buffer salt.

Waters AccellPlus QMA and CM Bulk Media 4

Page 5

[ Care and Use ManUal ]

Sales Offices

Austria and European Export

(Central South Eastern Europe, CIS

and Middle East) 43 1 877 18 07

Australia 61 2 9933 1777

Belgium 32 2 726 1000

Brazil 55 11 5094 3788

Canada 1 800 252 4752

China 86 10 5293 6688

Czech Republic 420 2 617 11384

Denmark 45 46 59 8080

Finland 358 9 5659 6288

France 33 1 30 48 72 00

Germany 49 6196 400 600

Hong Kong 852 2964 1800

Hungary 36 1 350 5086

Norway 47 6 384 6050

Poland 48 22 833 4400

Puerto Rico 1 787 747 8445

Russia/CIS 7 495 727 4490/ 290 9737

Singapore 65 6593 7100

Spain 34 93 600 9300

Sweden 46 8 555 115 00

Switzerland 41 56 676 7000

Taiwan 886 2 2501 9928

United Kingdom 44 208 238 6100

All other countries:

Waters Corporation U.S.A.

1 508 478 2000

1 800 252 4752

www.waters.com

India 91 80 2837 1900

Ireland 353 1 448 1500

Italy 39 02 265 0983

Japan 81 3 3471 7191

Korea 82 2 6300 4800

Mexico 52 55 52 00 1860

The Netherlands 31 76 508 7200

©2012 Waters Corporation. Waters, AccellPlus, Accell, and

The Science of What's Possible are trademarks of Waters

Corporation. Hibitane is a trademark of Ayerst Labs and

Imperial Chemical Industries, Ltd. Triton is a trademark of Rohm

and Haas Company.

December 2012 WAT010737 Rev D LS--KK-PDF

Waters Corporation

34 Maple Street

Milford, MA 01757 U.S.A.

T: 1 508 478 2000

F: 1 508 872 1990

www.waters.com

Waters AccellPlus QMA and CM Bulk Media 5

Loading...

Loading...