Page 1

Waters 996

PD A Detector

Operator’s Guide

34 Maple Street

Milford, MA 01757

053021TP, Revision 0

Page 2

NOTICE

The information in this document is subject to change without notice and should not be

construed as a commitment by Waters Corporation. Waters Corporation assumes no

responsibility for any errors that may appear in this document. This manual is believed to

be complete and accurate at the time of publication. In no event shall Waters Corporation

be liable for incidental or consequential damages in connection with, or arising from, the

use of this manual.

© 1997, 1993 WATERS CORPORAT ION. PRINTE D IN THE UNITED STATES OF

AMERICA. ALL RIG H TS RESERVED. THIS BO OK OR PARTS THERE OF MAY NOT BE

REPRODUCED IN ANY FORM WITHOUT THE WRITTEN PERMISSION OF THE

PUBLISHER.

Millennium, PowerStation, and Waters are registered trademarks and busLAC/E is a

trademark of Waters Corporation.

All other trademarks are the sole property of their respective owners.

The quality management system of Waters’ chromatography applications software design

and manufacturing facility, Milford, Massachusetts, complies with the International

Standard ISO 9001 Quality Managemen t and Quality Assurance Stand ards. Waters’

quality management system is periodically audited by the registering body to ensure

compliance.

Page 3

STOP

Attention:

instrument.

When you use the instrument, follow generally accepted procedures for quality control and

methods development.

If you observe a change in the retention of a particular compound, in the resolution

between two compounds, or in peak shape, immediately take steps to determine the

reason for the changes. Until you determine the cause of a change, do not rely upon the

results of the separations.

This is a highly sensitive instrument. Read this user's manual before using the

STOP

STOP

Caution:

same type and rating.

Attention:

responsible for compliance could void the user’s authority to operate the equipment.

Attention:

A digital device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio

frequency energy, and, if not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case you must correct the

interference at your own expense.

Shielded cables must be used with this unit to ensure compliance with Class A FCC limits.

Note:

Level II category pertains to equipment that receives its electrical power from a local level,

such as an electrical wall outlet.

For continued protection against fire hazard, replace fuses with those of the

Changes or modifications to this unit not expressly approved by the party

This equipment has been tested and found to comply with the limits for a Class

The Installation Category (Overvoltage Category) for t his instrument is Level II. The

Page 4

Canadian Emissions Notice

This digital apparatus does not exceed the Class A limits for radio noise emissions from

digital apparatus set forth in the Radio Interference Regulations of the Canadian

Departme nt of Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques de la classe A prescrites dans les règlements sur le

brouillage radioélectrique édictés par le Ministère des Communications du Canada.

Symbols Used on the Waters 996 Photodiode Array Detector

Direct current

Alternating current

Protective conductor

terminal

Frame or chassis terminal

Caution, risk of electric

shock (high voltage)

Caution or refer to

manual

Caution, hot surface

UV

Ultraviolet light

Page 5

Table of Contents

How to Use This Guide..................................................................... 10

Chapter 1

Installation ....................................................................................... 14

1.1 Installation Site Requirements .............................................. 14

1.2 Po wer Connections............................................................... 15

1.3 Millennium

1.3.1 Connecting the IEEE-488 Cable................................ 16

1.3.2 Setting the IEEE- 48 8 Addre ss............... ..... ..... .... ..... . 18

1.4 Non-IEEE-488 Communication Connections........................ 19

1.4.1 Connecting Analog Output Cables ............................ 19

1.4.2 Connecting Event Cables .......................................... 20

1.5 Fluidic Connections............................................................... 22

32

Workstation Connections................................. 16

1.6 Startup/Shutdown ................................................................. 24

Chapter 2

Diagnostics and Calibration ............................................................. 27

2.1 Startup Diagnostics............................................................... 27

2.2 User-Initiated Diagnostics..................................................... 30

2.3 PDA Calibration..................................................................... 31

Table of Content s 5

Page 6

Chapter 3

Maintenance .................................................................................... 33

3.1 Flow Cell Maintenance.......................................................... 33

3.1.1 Flushing the Flow Cell ............................................... 33

3.1.2 Removing the Flow Cell........... .... .............................. 34

3.1.3 Disassembling and Cleanin g the Flow Cell. ..... .... ..... . 36

3.1.4 Installing the Flow Cell Assembly .............................. 38

3.2 Replacing the Lamp.............................................................. 39

3.2.1 Checking Lamp Usage .. ..... ..... .... ..... ......................... 39

3.2.2 Removing the Lamp....... ..... ..... .... ..... ..... ..... ..... .......... 41

3.3 Replacing the Fuses............................................................. 43

Chapter 4

Principles of the 996 PDA Detector Optics ...................................... 44

4.1 996 Detector Optics .............................................................. 44

4.2 Resolving Spectral Data ....................................................... 46

4.3 Measuring Light at the Photodiode ....................................... 47

4.4 Computing Absorbance Data Points..................................... 50

4.4.1 Calculatin g Absor ban ce........... .... ..... ..... .................... 50

4.4.2 Resolution.............................................. .................... 52

4.4.3 Filterin g Data ................. ..... ....................................... 53

Chapter 5

Spectral Contrast Theory ................................................................. 54

5.1 Comparing Absorbance Spectra........................................... 54

5.2 Representing Spectra as Vectors.......................................... 55

5.2.1 Vectors Derived from Two Wavelengths..................... 56

5.2.2 Vectors Derived from Multiple Wavelengths .............. 56

6 Table of Contents

Page 7

5.3 Spectral Contrast Angles ...................................................... 57

5.4 Nonidealities ......................................................................... 60

5.4.1 Detector Noise............... ..... ..... .... ..... ..... ..... ..... .......... 60

5.4.2 Photom etric Error ..... .................................. ............... 61

5.4.3 Solvent Changes ...... ..... ............................................ 61

5.4.4 Thresho ld Angl e ... ..... ..... ..... ..... .... ..... ......................... 61

Appendix A

Detector S pecif icatio ns.. ..... ..... ...... ..... ..... ...... .. ...... ..... ..... ...... ..... 63

Appendix B

Spare Par ts ..... ...... ..... ..... ...... ..... ... ..... ..... ...... ..... ..... ...... ..... ..... ... 64

Appendix C

Warranty Informati on ..... ..... ..... ...... ..... ... ..... ..... ...... ..... ..... ...... ..... 65

C.1 Limited Express Warranty..................................................... 65

C.2 Shipments, Damages, Claims, and Returns......................... 69

Appendix D

Mobile P ha se A b so rb a nc e..... .. ... ... .. ................................... ........ 70

Index ................................................................................................ 74

Table of Contents 7

Page 8

List of Figures

1-1 Waters 996 PDA Detector Dimensions..........................................15

1-2 Detector Rear Panel......................................................................16

1-3 Example of IEEE-488 Cable Connections.....................................17

1-4 Locating the IEEE-488 Address Switches.....................................18

1-5 Analog Output Terminals ...............................................................20

1-6 Event Input/Output Terminal Strip..................................................22

1-7 Compression Screw Assembly......................................................24

1-8 996 Detector Indicator Lights.........................................................25

2-1 996 PDA Detector Indicator Lights ................................................28

3-1 Flow Cell Access Door...................................................................35

3-2 Removing the Flow Cell Assembly ................................................35

3-3 Flow Cell and Fluidic Connections Assemblies.............................36

3-4 Disassembling the Flow Cell..........................................................37

3-5 Lamp Access Door........................................................................40

3-6 Lamp Usage Indicator....................................................................40

3-7 Lamp Power Cord and Mounting Screws.......................................42

3-8 Fuse Block.....................................................................................43

4-1 Optics Assembly Light Path...........................................................45

4-2 Benzene Spectrum at 1.2 nm Resolution......................................47

4-3 Photodiodes Discharged by Light..................................................48

4-4 Absorbance as a Function of Concentration..................................51

5-1 Comparing Spectra of Two Compounds........................................55

5-2 Plotting Vectors for Two Spectra....................................................56

5-3 Spectra with a Large Spectral Contrast Angle...............................58

5-4 Spectra with a Small Spectral Contrast Angle...............................59

5-5 Absorbance Spectra of a Compound at Two Concentrations........ 60

5-6 Effects of pH and Solvent Concentration on the Absorbance

Spectrum of p-Aminobenzoic Acid.................................................62

Table of Contents 8

Page 9

List of Tables

1-1 Site Requirements ........................................................................14

1-2 Event In (Inject Start) Terminal Specifications on TTL

or Switch Closure.................................................................... 21

1-3 Event Out Terminal Specifications on Contact Closure............ 21

2-1 996 Detector Troubleshooting .......................................................28

4-1 Optics Assembly Components................................................. 45

A-1 996 Detector Specifications..................................................... 63

B-1 Spare Parts............................................................................. 64

C-1 Warranty Periods..................................................................... 68

D-1 Mobile Phase Absorbance Measured Against Air or Water...... 70

Table of Contents 9

Page 10

How to Use This Guide

Purpose of This Guide

The

Waters 996 PDA Detector Operator’s Guide

maintaining, and troubleshooting the Waters

optics and the principles of Spectral Contrast used in the Millennium

analyzing the data from the PDA detector. Also included is information on vector analysis,

mobile phase absorbance, specifications, and the warranty.

Audience

This guide is intended for individuals who need to install, operate, maintain, and

troubleshoot the Waters 996 PDA Detector. It is also intended for users who need to

understand the Spectral Contrast principles underlying the processi ng of PDA detector

data by Millennium

32

soft wa r e .

Structure of This Guide

The

Waters 996 PDA Detector Operator’s Guide

Each chapter and appendix page is marked with a tab and a footer to help you quickly

access information.

The following table describes the mater ial covered in each chapter and appendix of this

guide.

describes the procedures for installing,

®

996 PDA Detector . It also describes detector

is divided into chapters and appendixes.

32

software for

Chapter/Appendix Description

Chapter 1, Installation De scr ibes how to install and set up the 996 detector.

Chapter 2, Diagnostics

and Calibration

Chapter 3,

Maintenance

Chapter 4, Princi pl e s of

the 996 PDA Detector

Optics

Chapter 5, Spectral

Contrast Theory

10 How to Use This Guide

Describes how to troubleshoot the 996 detector.

Describes how to replace the flow cell, the lamp, and the fuse.

Explains the principles involved in resolving spectral data,

measuring light at the photodiode, verifying wavelengths, and

computing absorbance data.

Describes the calculations used for Spectral Contrast.

Page 11

Chapter/Appendix Description

Appendix A, Detector

Provides the specifications of the Waters 996 PDA detector.

Specifications

Appendix B, Spare

Provides a list of recommended and optional spare par ts.

Parts

Appendix C, Warranty

Includes warranty and service information.

Information

Appendix D, Mobile

Phase Absorbance

Provides a table of absorbances at several wavelengths for

common mobile phases.

Related Documentation

The table below lists other guides related to the

.

Guide

Title Description

Millennium32 Online

Help

Describes all Millennium32 windows, menus, menu selections,

and dialog boxes. Also includes reference information and

procedures for performing all tasks required to use the

Millenn iu m

32

software. Included as part of the Millennium32

software.

Waters 996 PDA Detector Operator’s

Millennium32 Software

Getting Started Guide

Millennium32 PDA

Software Getting

Started Guide

Provides an introduction to the Millennium32 System.

Describes the basics of how to use Millennium

32

software to

acquire data, develop a processing method, review results,

and print a report. Also covers basics for managing projects

and configuring systems.

Describes the basics of how to use Millennium32 PDA soft ware

to develop a PDA processing method and to review PDA

results

How To Use This Guide 11

Page 12

Title Description

Millennium32 System

Insta l latio n /

Configuration Guide

Describes Millen niu m32 software inst a llat io n, includin g the

stand-alone workstation, PowerStation

system, and

™

client/server system. Discusses how to configure the

computer and chromatographic instruments as part of the

Millenn iu m

32

system. Also covers the installa ti o n ,

configuration, and use of the busLAC/E card and LAC/E

Acquisition Server.

Wa te r s 9 9 6 PDA

Describes qualification procedures for the PDA detector.

Detector Qualification

workbook

Related Adobe™ Acrobat Reader Documentation

For detailed information about using the Adobe Acrobat Reader, refer to the

Acrobat Reader Online Guide

. This Online Guide covers procedures such as viewing,

navigating and printing electronic documentation from Adobe Acrobat Reader.

Adobe

Printing From This Electronic Document

Adobe Acrobat Reader lets you easily print pages, pages ranges, or the entire electronic

document by selecting

recommends that you specify a Postscript printer driver for your printer. Ideally, use a

printer that supports 600 dpi print resolution.

Print

from the File menu. For optimum print quantity, Waters

32

Conventions Used in This Guide

This guide uses the following conventions to make text easier to understand.

Purple Text

•

Press 0, then press

•

Italic

text denotes new or important words, and is also used for emphasis. For

example:

An

12 How to Use This Guide

indicates user action. For example:

instrument method

Enter

for the remaining fields.

tells the software how to acquire data.

Page 13

• Underlined, Blue Color text indicates hypertext cross-references to a specific

chapter, section, subsection, or sidehead. Clicking this topic using the hand symbol

automatically brings you to this topic within the electronic document. Right-clicking

and selecting

originating topic. For example:

Before you replace the detector lamp, check the lamp usage indicator located to

the front of the lamp retainer, as described in Section 3.2.1,

Usage.

Notes, Attentions, and Cautions

• Notes call out information that is important to the operator. For example:

Record your results before you proceed to the next step.

Note:

• Attentions provide information about preventing possible damage to the system or

equipment. For example:

Go Back

from the popup context menu brings you back to the

Checking Lamp

STOP

Attention:

To avoid damaging the detector flow cell, do not touch the flow cell

window.

• Cautions provide information essential to the safety of the operator. For example:

Caution:

To avoid chemical or electrical hazards, always observe safe laboratory

practices when operating the system.

How To Use This Guide 13

Page 14

1

1

Installation

The Waters® 996 Photodiode Array (PDA) Detector operates in any standard laboratory

environment. The detector requires electrical power, sample and waste fluidic lines, and

the Millennium®

communication with chart recorders, data integrators, and other instruments that are not

compatible with Millennium software control.

1.1 Instal lation Site Requirements

Install the Waters 996 PDA Detector (Figure 1-1) at a site that meets the specifications

listed in Table 1-1

Table 1-1 Site Requirements

Ambient temperature 4 to 40° C (39 to 104° F)

Relativ e hum idi ty 20 to 80 percent,

32

Workstation. Optional connections on the detector rear panel allow

.

Factor Specification

noncondensing

Bench space Width: 11.5 in. (29 cm)

Bench support Capable of supporting

Clearance At least 4 in. (10 cm) on

14 Installation

Depth: 24 in. (61 cm)

Height: 8.125 in. (22

cm)

31.5 pounds (14.3 kg)

the back and left sides

for ventilation

Page 15

11.5 in. (29 c m )

WATERS 996

Photodiode Array

8.5 in.

(22 cm)

24 in.

(61 cm)

Figure 1-1 Waters 996 PDA Detector Dimensions

1.2 Power Connections

Ensure that power connections for the 996 PDA Detector are made according to the

procedures that follow.

1

LAMP

Sample Inlet

Sam ple Out let

Drain Line

Operating Voltage

The 996 PDA Detector has a universal input power supply that requires no voltage

adjustment. The electrical power requirements for the Waters 996 PDA Detector are:

Voltage range:

•

Frequency range:

•

95 to 240 Vac (±10%)

50 to 60 Hz (±3 Hz)

Fuses

The Waters 996 PDA Detector is shipped with fuses rated for North American operation. If

you operate the Waters 996 PDA Detector in another location, install the IEC-rated fuses

(supplied in the Waters 996 Detector Startup Kit) in the fuse holder in the rear of the

detector (refer to Section 3.3,

Replacing the Fuses).

Power Connections 15

Page 16

1

Connecting the Power Cord

Connect one end of the 996 detector power cord to the rear panel power receptacle

(Figure 1-2

) and the other end to a power outlet.

Power Cord

Receptacle

TP01452

Figure 1-2 Detector Rear Panel

1.3 Millennium32 Workstation Connections

The 996 detector requires signal connections to the Millennium32 Workstation over the

IEEE-488 bus. All detector control and data acquisition communications take place over

the IEEE-488 bus.

If an inject start signal is not available over the IEEE-488 bus, you must provide a

Note:

signal at the Event In terminals on the 996 detector rear panel (see Section 1.4.2,

Connecting Event Cables).

1.3.1 Connecting the IEEE-488 Cable

If the 996 detector is to be rack-mounted or stacked on other instruments, use the

Note:

right-angle adaptor included in the Star t up Kit when you make the IEEE-488 connection.

16 Installation

Page 17

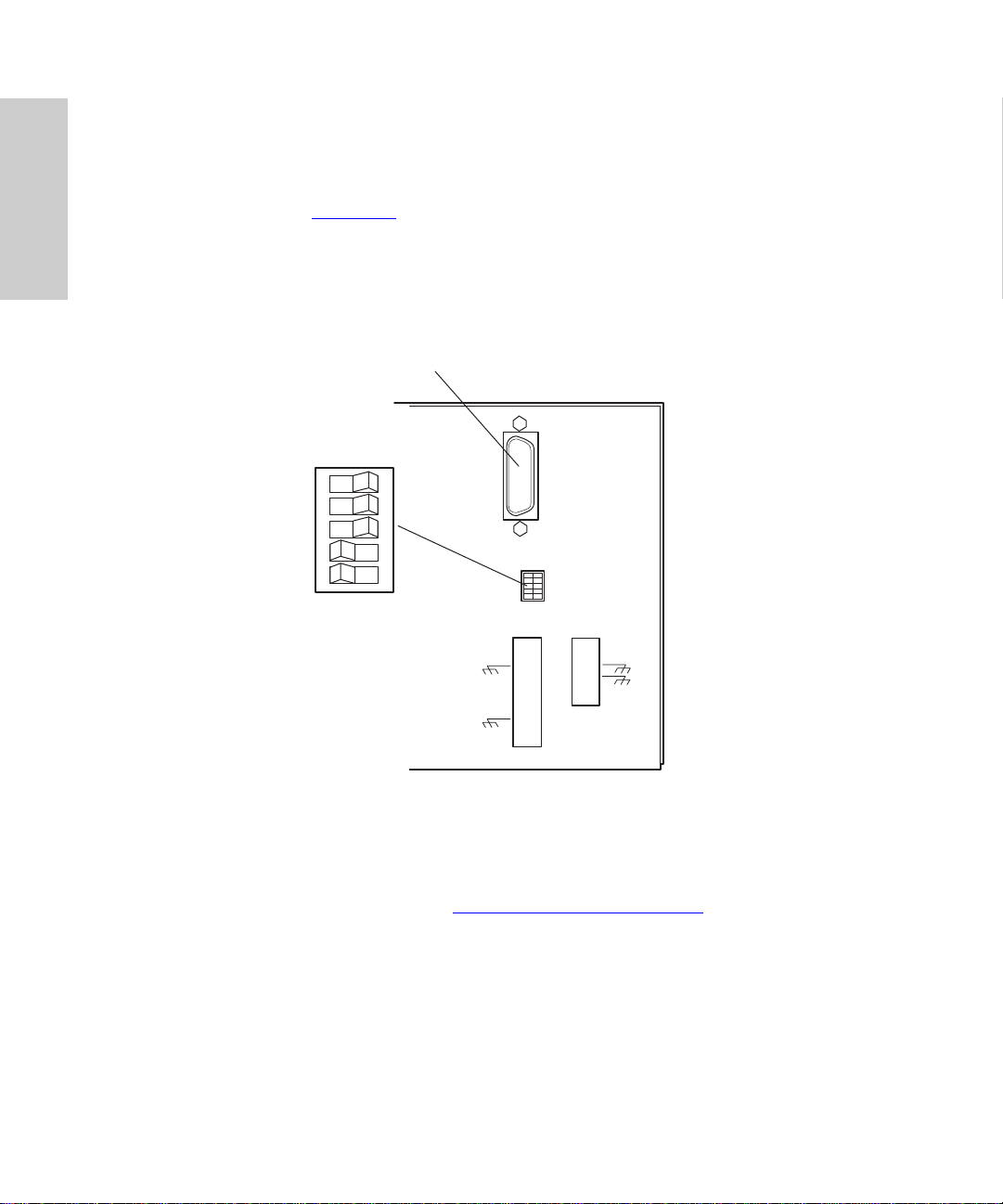

To connect the 996 detector to a Millennium32 Workstation:

1. Con nect one end of the IEEE-488 cable to the IEEE-488 receptacle on the rear

panel of the 996 detector. Connect the other end of the cable (stackable

connector for daisy-chaining additional instruments) to the IEEE-488 connector

on any of the other instruments in your chromatographic system (Figure 1-3

Waters

IEEE-488

Cable

).

1

2690

32

IEEE-488 Cabl e

Wate r s 996

Detector

TP01544

IEEE-488

Connector

Millennium

busLAC/E Card

(on Workstati on)

Wate rs

Separations Module

Figure 1-3 Example of IEEE-488 Cable Connections

The order in which you connect IEEE-488 devices to the busLAC/E card on

Note:

the workstation is not important. For example, you can connect the 2690

separations module before or after the 996 detector.

2. Use another IEEE-488 cable to connect to the stackable connector on the first

instrument and the IEEE-488 connector on another instrument.

3. Repeat step 2 for each IEEE-488 i nst rument in your chromatographic system, up

to a maximum of 14 IEEE-488 instruments.

Keep in mind cable-length limitations when you set up your system. For a list

Note:

of IEEE-488 interface guidelines, refer to the Millennium

32

System

Installation/Configuration Guide, Section 2.3.1, Connecting IEEE-488 Devices.

4. Ensure that all IEEE-488 cable screws are fastened finger-tight.

Millennium32 Workstation Connections 17

Page 18

1.3.2 Setting the IEEE-488 Address

To set the IEEE-488 address for the 996 detector:

1

1. Use a small screwdriver (or similar device) to set the DIP switches on the detector

rear panel (Figure 1-4

) to the IEEE-488 address of the 996 detector. The address

must be a number from 2 to 29 and must be unique within your network.

Refer to the

Millennium32 System Installation/Configuration Guide,

Section 2.3.1,

Connecting IEEE-488 Devices, for the correct IEEE-488 DIP switch settings.

IEEE-488 Cable

Connection

12345

IEEE-488

Address

Switches

– OPEN –

IEE 488 ADDRESS

2. To instruct the 996 detector to accept the new IEEE-488 address, power off, then

power on the detector (see Section 1.6,

18 Installation

TP01457

Figure 1-4 Locating the IEEE-488 Address Switches

Startup/S hutdown).

Page 19

1.4 Non-IEEE-488 Communication Connections

Non-IEEE-488 communication connections on the 996 detector include:

Analog Ou t pu ts

STOP

•

absorbance-unit analog output channels to integrators, chart recorders, or other

components.

Event Inputs and Outputs

•

signals to and from other instruments.

You make all non-IEEE-488 communication cable connections to the 996 detector at the

rear panel (see Figure 1-2

Attention:

disturbances that may affect the performance of this instrument, do not use cables longer

than 9.8 feet (3 meters) when you make connections to the screw-type barrier terminal

strips. In addition, ensure that you always connect the shield of each cable to chassis

ground at one instrument only.

To me et the regulator y requirem ents of immunity from external electrical

– The 996 detector provides two, unattenuated, 1 volt-per

– The 996 detector sends and receives contact closure

).

1.4.1 Connecting Analog Output Cables

The values of the analog output signals generated by the 996 detector are specified

by parameter valu es set from the Millen niu m

“Waters 996 Detector Properties” topic in the

Required Materials

• One small, flat-blade screwdriver

32

Workstation. For details, refer to the

Millennium32 Online Help

Find tab.

1

• One electrical insulation stripping tool

• Analog signal cables (from Startup Kit)

Procedure

To connect the Waters 996 detector to a device that receives analog output signals from

the 996 detector

1. Pull off the Analog output term inal str ip from the 996 detector rear panel

(Figure 1-5

). This step simplifies the following steps.

Non-IEEE-488 Communication Connections 19

Page 20

1

Removable An a l og O utput

Term inal Strip

+

Analog Ou t 1

–

IEE 488 ADDRESS

123456

+

Analog Out 2

–

Figure 1-5 Analog Output Terminals

2. Insert the bare wires at one end of an analog signal cable into the positive (+)

and negative (–) terminals of Analog Out 1 (see Fi gure 1-5

screws to secure the + and – wires.

3. Connect the other end of the analog signal cable to the appropriate analog input

terminal on the external device, being sure to maintain negative-to-negative and

positive-to-positive continuity.

4. Reinstall the Analog Output strip.

1.4.2 Connecting Event Cables

The 996 detector has four terminal strip connections for contact closure signals:

TP01456

). Tighten the two

• Two input (inject start) signal terminals

• Two output (programmable event table) signal terminals

If an inject start signal is not avail a ble over the IEEE-488 bus, you must provide a signal at

an Event In terminal on the 996 detector rear panel. Manual injectors such as the

Rheodyne 7725i provide a cable that connects the injector to an Event In terminal on the

996 detector rear panel.

20 Installation

Page 21

The values of the event output signals generated by the 996 detector are specified by

parameter values set from the Millennium

996 Detector Properties” topic in the

32

Workstation. For details, refer to the “Waters

Millenn iu m32 Online Help

Find tab.

Electrical Specifications

Before you connect an external device to an event input or output terminal, refer to the

electrical specifications in Table 1-2

Table 1-2 Event In (Inject Start) Ter m in al Specifications on TTL or Switch Closure

Parameter Specification

Low trigger <1.8 V

High trigger >3.0 V

Protected to ±30 V

Minimum pulse width 30 msec

Maximum current 5 mA

Table 1-3 Event Out Ter minal Spec ifications on Contact Closure

Parameter Specification

and Table 1-3.

1

Maximum power 10 W

Maximum current 0.5 A at 20 V

Maximum voltage 24 V RMS

Attention:

STOP

electrical connections as outlined in this section.

Required Materials

• Small flat-blade screwdriver

• One electrical insulation stripping tool

• Event signal cables (in Startup Kit)

To avoid damage to the 996 detector electronics, be sure you make the proper

Non-IEEE-488 Communication Connections 21

Page 22

Making Event Input/Output Connections

To connect the 996 detector to an external event input or output device:

1

1. Pull off the Event Input/Output terminal strip from the rear panel (Figure 1-6

simplifies the following steps.

Removable Event

Input/Output

Terminal Strip

Event

Out 2

Event

Out 1

Event

–

In 2

+

1234567890

–

Event

+

In 1

IEE 488 ADDRESS

TP01455

Figure 1-6 Event Input/Output Terminal Strip

). This

2. Insert the bare wires at one end of the event signal cable into the positive (+)

and negative (–) slots of the appropriate event input or output terminal (see

Figure 1-6

). Tighten the two screws to secure the +and – wires.

3. Connect the other end of the event signal cable to the appropriate event input or

event output terminal on the external device.

4. Reinstall the Event Input/Output strip.

1.5 Fluidic Connections

Caution:

handing solvents. Refer to the Material Safety Data Sheets for the solvents in use.

22 Installation

To avoid chemical hazards, always observe safe laboratory practices when

Page 23

Required Materials

• 5/16-inch open-end wrench

• 0.009-inch (0.23 mm) I.D. stainless steel tubing (in Startup Kit)

• Stainless steel tubing cutter or scribing file

• Pliers, plastic-covered, or with cloth

• Compression screw assembles, three

Procedure

To make fluidic connections to the 996 detector:

1. Measure the lengths of tubing needed to connect:

• The column outlet to the 996 detector inlet.

Be sure that you keep the length of this tubing as short as possible to

Note:

prevent band broadening.

• The 996 detector outlet to a waste collection bottle.

Ensure the length of this tubing is at least 1 to 2 feet (30 to 60 cm) to

Note:

prevent air bubbles from forming in the flow cell.

2. Cut the two lengths of tubing as follows:

• Use a Waters 1/16-inch stainless steel tubing cutter or a file with a cutting edge

to scribe the circumference of the tubing at the desired break point.

1

• Grasp the tubing on both sides of the scribed mark with cloth- or

plastic-covered pliers (to prevent marring the surface), then gently work the

tubing back and forth until it separates.

• File the tubing ends smooth and straight to minimize dead volume and band

broadening.

3. Assemble a compression fitting (as shown in Figure 1-7

column outlet line and at one end of the detector outlet line.

) at both ends of the

Fluidic Connec tions 23

Page 24

1

Tubing

Compression

Screw

Ferrule

End Must Be Straight

and Smoot h to Prevent

Dead Volume

TP01139

Figure 1-7 Compression Screw Assembly

4. Bottom one end of the column outlet tubing in the fitting seat of the column

outlet, then tighten the compress ion screw about 3/4-turn past finger-tight ( using

the 5/16-inch open-end wrench).

5. Bottom the other end of the tubing in the fitting seat of the detector inlet, then

tighten the compression screw as in step 4.

6. Bottom one end of the detector outlet tubing with the compression fitting in the

fitting seat of the detector outlet, then tighten the compression screw about

3/4-turn past finger-tight. Insert the other end of the tubing in t he waste

container.

To avoid damage to the flow cell, avoid pressures approaching the maximum

STOP

Attention:

pressure for the analytical flow cell, 1000 psi (70 kg/cm

1.6 Startup/Shutdown

Follow the procedures in this section to ensure reliable detector performance.

Distan ce D etermi n e d by

the Union or Column Fitting

2

).

Startup

To star t up the 996 detecto r :

1. In your instrument method, set the solvent delivery system or pump to deliver 1

mL/min of degassed mobile phase. For details, refer to the “Waters 2690

Separations Module Proper ties” or the “Waters 600 Properties” topic in the

Millennium32 Online Help

24 Installation

Find tab.

Page 25

Use only thoroughly degassed HPLC-grade solvents. Gas in the mobile

Note:

phase may form bubbl es in the fl ow cell and cause the detector to fail the Ref erence

Energy diagnostic.

2. Flush the detector for 10 minutes or until no bubbles appear in the outlet line.

3. Press the 0/1 (Off/On) switch on the front panel of the detector (Figure 1-8

1

(On) position.

) to the

4. Observe the Lamp and Status indicator lights on the front panel of the detector

(Figure 1-8

).

• If both lights remain illu mi nated , the detector pas sed the internal diagnostic s.

• If either indicator light blinks or is off, refer to the troubleshooting tables in

Chapter 2,

Diagnostics and Calibration.

WATERS 996

Photodiode Array

Detector

On/Off

Switch

LAMP

1

Status

Indicator

Lamp

Indicator

TP01460

Figure 1-8 996 Detector Indicator Lights

5. Wait 1 hour for the deuterium lamp to stabilize before you attempt to acquire

data at low absorbances.

Startup/Shutdown 25

Page 26

Shutdown

To shut down the 996 detector:

1

1. If the mobile phase contains buffers, set the solvent delivery system or pump to

deliver 1 mL/min of HPLC-grade water for 10 minutes. Otherwise, set the solvent

delivery system or pump to deliver 1 mL/min of degassed methanol for 10 minutes.

2. Press the 0/1 (Off/On) Switch on the front panel of the detector to the 0 (Off)

position.

26 Installation

Page 27

2

Diagnostics and Calibration

The Waters 996 Photodiode Array Detector automatically runs a series of internal

diagnostics upon start up. The indicator lights on the front of the detector and messages at

the Millennium

(Figure 2-1

32

Workstation show the results of the start up internal diagnosti cs

).

If you need to determine the cause of a problem during operation of the detector, you can

run the same internal diagnostics from the Millennium

information about the performance of the detector is also available through the PDA

Calibration window, accessed from QuickSet in the Millennium

If you encounter a problem that you cannot troubleshoot (see Section 2.1,

Diagnostics), contact Waters Technical Service at (800) 252-4752,

customers only

Technical Service Representative, or call Wat ers c orporate headquarters for assistance at

1-508-478-2000 (U.S.).

. Other customers, call your local Waters subsidiary or your local Waters

2.1 Startup Diagnostics

Refer to Table 2-1 to troubleshoot problems encountered during startup diagnostics and

during detector operation.

32

Workstation. Additional

32

software .

Startup

U.S. and Canadian

2

Startup Diagnostics 27

Page 28

2

WATERS 996

Photodiode Array

Detector

Figure 2-1 996 PDA Detector Indicator Lights

Table 2-1 996 Detector Troubleshooting

Symptom Possible Cause Corrective Action

On/Off

Switch

LAMP

Status

Indicator

Lamp

Indicator

TP01460

Status light off No power. 1. Check line cord connections.

Status light blinks and

lamp light off

28 Diagnostics and Calibration

2. Check outlet for power.

Blown fuse. Replace fuse (see Section 3.3,

Replacing the Fuses).

Detector is st ill

Wait for diagnostics to end.

performing

diagnostics

Fail ed startup

diagnostics.

1. Check that lamp door is secure.

2. Replace lamp. If replacing the lamp

fails to correct the problem, contact

Waters Technical Service.

Page 29

Table 2-1 996 Detector Troubleshooting (Continued)

Symptom Possible Cause Corrective Action

Status light blinks and

lamp light on

Shutter failure

message.

Detector not

responding to

Millennium

Workstation

32

Fail ed startup

diagnostics.

Insufficient energy

reaching photodiode

array because of air

bubble or dirty flow

cell can cause shutter

diagnostic to fail.

Weak lamp. Replace lamp (see Section 3.2,

Shutter failure. Run the Shutter diagnostic. For

Detector not

connected to

busLAC/E or to

32

LAC/E

server in the

Millennium

Workstation

acquisition

32

Flush the flow cell (see Section 3.1.1,

Flushing the Flow Cell).

Flush the flow cell (see S ec tion 3.1.1,

Flushing the Flow Cell).

To prevent air bubbles from forming,

check that there is a 1- to 2-f oot (30- to

60-cm) length of 0.009-inch (0.23-mm)

I.D. tubing connected to the detector

waste outlet.

Replacing the Lamp).

details, refer to the “PDA Diagnostics

Window” topic in the

Online Help

Check IEEE-488 cable connections,

tighten connectors.

Find tab.

Millennium32

2

Incorrect IEEE-488

address.

1. Ensure that the 996 detector

IEEE-488 addre ss is unique and

within the range 2 to 29 (see the

Millennium

32

System

Insta l latio n /Confi gurat i o n Guide

2. Rescan the IEEE-488 bus. For

details, see the “Scanning the

bus/LAC/E Card for Serial

Instruments” topi c in the

Millennium32 Online H elp

Startup Diagnostics 29

Find tab.

).

Page 30

Table 2-1 996 Detector Troubleshooting (Continued)

Symptom Possible Cause Corrective Action

2

Change in reference

spectrum

Solvent in drain line Leak from flow cell

Mobile phase

contains gas or is

contaminated.

Air bubbles trapped in

flow cell.

gasket.

Leak from flow cell

fittings.

2.2 User-Initiated Diagnostics

Prepare fresh mobile phase and

degas thoroughly.

Flush the flow cell, or apply slight

backpressure on the detector waste

outlet.

To prevent air bubbles, check that

there is a 1- to 2-foot (30- to 60-cm)

length of 0.009-inch (0.23-mm) I.D.

tubing connected to the detector

waste outlet.

Rebuild flow cell with a new gasket

(see Section 3.1.3,

Cleaning the Flow Cell).

Check fittings for overtightening or

undertightening , and replace fittings if

necessary.

Disassembling and

There are two types of user-initiated PDA diagnostic tests:

Internal Tests

•

source of a malfunction. These tests do not require connections to external devices.

Interactive Tests

•

communications between the detector and connected external devices. These tests

require connections to pump flow and/or test equipment.

You cannot perform diagnostics on a 996 detector while it is acquiring data.

Note:

The system administrator can restrict access to the 996 detector diagnostics by

Note:

disabling user access to Quick Set. For details, refer to the “User Type Properties Dialog

Box” topic in the Millennium

30 Diagnostics and Calibration

– Tests run by the instrument firm ware that help you determine the

– Tests that check analog output and event input/output signal

32

Online Help Find tab.

Page 31

You can run all user-initiated dia gnos tics from Qui ckSet in the Millen nium32 software. For

more information on QuickSet and PDA diagnostics, refer to the “PDA Diagnostics

Window” topic in the

Millennium32 Online Help

Find tab.

If you encounter a problem that you cannot troubleshoot (see Section 2.1,

Diagnostics), contact Waters Technical Service at (800) 252-4752,

customers only

Technical Service Representative, or call Wat ers c orporate headquarters for assistance at

1-508-478-2000 (U.S.).

. Other customers, call your local Waters subsidiary or your local Waters

2.3 PDA Calibration

You can adjust, or calibrate, the 996 detector to ensure that wavelength readings are

accurate. Recalibrate the 996 detector

Internal Diagnostics tests) fails.

You calibrate the 996 detector using the PDA Calibration window, which you access from

QuickSet and which allows you to:

• View the effects of exposure time on photodiode saturation for a given wavelength

range.

• Verify the wavelength location of the deuterium spectrum Balmer lines (486.0 nm

and

656.1 nm).

• Recalibrate to set the 486-nm peak at the proper wavelength.

• Ensure precise data for library matching.

Startup

U.S. and Canadian

only

if the Wavelength Accuracy diagnostic (in the

2

The system administrator can restrict access to the PDA Calibration window.

Note:

Recalibrating the wavelength requires that spectral libraries be reentered.

Required Materials

• HPLC-grade methanol

• HPLC-grade water

Preparing for Calibration

Ensure that the flow cell is clean before you check calibration. (See Section 3.1.1,

Note:

Flushing th e F low Cell .)

PDA Calibration 31

Page 32

2

To prepare for calibration:

1. Set the pump to deliver 1 mL/min of degassed methanol for 10 minutes. If methanol

is not miscible with the previous solvent, flush with a miscible sovent before

switching to methanol.

2. If you have been using buffers, flush with HPLC-quality water at 1 mL/min for 10

minutes, then switch to methanol for 10 minutes.

Ensure that the solvent is miscible with the previous mobile phase.

Note:

For information on performing calibration, refer to the “PDA Calibration Window” topic in

Millennium32 Online Help

the

Find tab.

32 Diagnostics and Calibration

Page 33

3

Maintenance

This chapter covers maintenance of the Waters 996 Photodiode Array Detector flow cell,

lamp, and fuse.

Caution:

supply covers. The power supply does not contain user-serviceable component s.

To avoid the po ssibility of elec tric shock, do no t rem ove the 996 de tec t or power

3.1 Fl ow Cell Maintenance

The flow cell requires maintenance when:

• The reference spectrum changes.

• The Lamp diagnostic (in the Millennium

lamp status light i s on (see Table 2-1

• The 996 detector causes high backpressure.

Conditions other than a dirty flow cell may cause decreased lamp intensity . F or

Note:

more information, refer to Chapter 2,

Flow cell maintenance consists of:

• Flushing the flow cell

• Removing the flow cell

• Cleaning the flow cell

• Installing the flow cell a ssembly

Diagnostics and Calibration.

32

PDA Diagnostics window) fails, and the

).

3

3.1.1 Flushing the Flow Cell

Required Materials

• HPLC grade water

• HPLC grade methanol

If the flow cell requires cleaning, the first cleaning method to try is flushing the flow cell

with solvent.

Flow Cell Maintenance 33

Page 34

To flush the flow cell:

1. Select a solvent compatible with the samples and mobile phases that you have been

using. If you have been using buffers, flush with HPLC-grade water f or 10 minutes at

1 mL/min, then switch to a low-surface-tension solvent such as methanol.

3

STOP

Attention:

2. Set p ump flow to 1 mL/min, then run the pump 10 minutes.

3. Test the lamp energy by performing the Lamp diagnostic tes t. For details, refer to

the “PDA Diagnostics Window” topic in the

If the lamp diagnostic fails and the lamp has not been used more than 1000

hours, disassemble the flow cell and clean the flow cell components using the

procedure described in Section 3.1.2,

Ensure that the solvent is miscible with the previous mobile phase.

3.1.2 Removing the Flow Cell

You do not need to shut down the 996 detector to remove and replace the flow cell.

Note:

Required Materials

• 5/16-inch open-end wrench

• Phillips screwdriver

Procedure

To remove the 996 detector flow cell:

1. Set the flow to

2. Power off the solvent delivery system or pump.

0.0

mL/min.

Millennium

Removing the Flow Cell.

32

Online Help

Find tab.

Caution:

inlet or outlet fluidic lines while there is pressure in the chromatographic system.

Always vent your system before disconnecting fluidic lines.

3. Use the 5/16-inch wrench to disconnect the fluidic lines at the front of the

detector.

4. Lift up the 996 detector front cover and pull the front cover from the detector

chassis.

5. Open the flow cell access door by pulling the black thumbtab, then pull the door

gently toward you (Figure 3-1

34 Maintenance

To avoid the possibility of leaking mobile phase, do not disconnect the

).

Page 35

Flow C ell Access

Door

Thumbtabs

LAMP

STATUS

TP01461

Figure 3-1 Flow Cell Access Door

6. Use th e P h illips s crewd river to lo osen the two thu m b scr ews tha t ho ld t h e f low

cell assembly to the optics bench and the thumbscrew that secures the bracket

holding the fluidic connections, then detach the bracket (Figure 3-2

).

3

Thumbs c rews

Holding Flow

Cell Assembly

and Bracket

Fluidic Connec ti ons

(Inside Bracket)

TP01462

Figure 3-2 Removing the Flow Cell Assembly

Flow Cell Maintenance 35

Page 36

7. Pull the flow cell assembly and fluidic connection bracket gently toward you to

remove it from the detector (Figure 3-3

).

Flow Cell Body

Lens Holder

Assembly

3

Fluidic

Connections

Figure 3-3 Flow Cell and Fluidic Connections Assemblies

3.1.3 Disassembling and Cleaning the Flow Cell

The lens surface finish and the alignment of the lenses are critical to the performance of

the 996 detector. Be careful not to touch or damage the lenses and the lens holders.

STOP

STOP

Attention:

inspecting, cleaning, or replacing parts within the flow cell or when removing or replacing

the flow cell within its assembly.

Attention:

inspecting, cleaning, or replacing parts within the flow cell or when removing or replacing

parts within the flow cell or when removing or replacing the flow cell within its

subassembly.

To prevent contamination, use powder-free gloves when disassembling,

To prevent contamination, use powder-free gloves when disassembling,

Bracket

TP01463

36 Maintenance

Page 37

Required Materials

• TORX T10 screwdriver

• Small, flat-blade screwdriver

• Lens tissue or nonparticulating swab

• HPLC-grade methanol

• Belleville spring washer

• Flow cell gas ket

Procedure

To disassemble and clean the flow cell (and lenses):

1. Use the TORX T10 screwdriver to remove the three screws that secure one of the

lens holder assemblies (Figure 3-4

).

Screws

Flow Cell Disk

Lens Assembl y

Flow Cell

Body

Spring

Washer

Gasket

Slot for

Removing

Lens

Assembly

Lens Assembly

Flow Cell Disk

Belleville

Spring

Washer

TP01464

Figure 3-4 Disassembling the Flow Cell

2. Use the small, flat-blade screwdriver to gently pry the lens assembly from the

flow cell body at the slots.

3

Flow Cell Maintenance 37

Page 38

3

Attention:

STOP

norma l use, the gasket protects the lens holder from solvents.

3. Use a lens tissue or a nonpar ticulating swab to wipe the lens with methanol.

4. Remove and discard the gasket.

5. Repeat steps 1 through 4 to remove, disassemble, and clean the other lens

holder assembly.

6. Use methanol and a nonparticulating swab to clean the flow cell body.

Solvents other than methanol may damage a disassembled flow cell. In

Reassembling the Flow Cell

To reassemble the flow cell (see Figure 3-4):

1. Insert a replacement gasket into one side of the flow cell body.

2. Align the screw holes of the lens assembly with the holes in the flow cell body.

3. Place the new Belleville spring washers (wit h t h e c o ncave side facing out) onto

the lens assembly.

4. Place the flow cell disk over the lens assembly.

5. Insert the three screws using the TORX T10 driver to gradually tighten each

screw, alternating between the screws in a clockwise pattern. Tighten until the

screws meet the flow cell disk, then tighten each screw 1/4-turn. If a torque

screwdriver is available, tighten the screws to 16 in-oz (0.113 N-m).

STOP

Attention:

6. Repeat steps 1 through 5 to reassemble the other side of the flow cell.

Be careful not to overtighten the screws.

3.1.4 Installing the Flow Cell Assembly

Attention:

STOP

38 Maintenance

operation. Be careful not to damage the flow cell body.

To install the flow cell assembly:

1. While you hold the flow cell assembly in a vertical orientation (see Figure 3-3

2. Gently push the front of the assembly until it seats on the front alignment pins.

3. Hand-tighten the thumbscrews.

4. Secure the fluidic connection bracket.

5. Reconnect the fluidic lines.

The alignment of the flow cell in the optics bench is critical to detector

the assembly into the optics bench. Note that the flow cell is self-aligning and uses

the guide pins on the optics bench.

), insert

Page 39

6. Replace the front cover.

7. Flush the flow cell (refer to Section 3.1.1,

3.2 Replacing the Lamp

Replace the lamp in the 996 detector when either of the following conditions exists:

• Intensity is low enough that sensitivity is not sufficient for your method.

• The sampling rate requires an exposure time shorter than the minimum exposure

time you can set with the current lamp.

Before you replace the detector lamp, check the lamp usage indicator located to the front

of the lamp retainer, as described in Section 3.2.1,

3.2.1 Checking Lamp Usage

The Waters 996 detector lamp is designed to provide adequate energy for more than 1000

hours of operation. You can monitor lamp usage by checking the lamp usage indicator, a

mercury column with a scale of 0 to 10, where 10 represents 1000 hours. As the lamp

ages, the bubble in the mercury column moves toward the 10.

Caution:

disconnect the power cord before you begin this procedure. Note that the lamp and

housing are extremely hot. To avoid the possibility of contacting hot surfaces, allow the

lamp to cool for 15 minutes before you handle the lamp assembly or surfaces close to the

lamp.

To avoid electrical hazards and exposure to UV light, turn off the power and

Flushing the Flow Cell).

Checking Lamp Usage.

3

Procedure

To inspect the lamp usage indicator:

1. Power off the 996 detector, remove the pow er cord, and allow the lamp to cool for at

least 15 minutes.

2. Lift up the front panel cover and pull it away from the chassis.

3. Open the lamp access door by pulling t he t humbtab, then pulling the door toward

you (Figure 3-5

).

Replacing the Lamp 39

Page 40

Thumbtabs

LAMP

STATUS

Figure 3-5 Lamp Access Door

Lamp

Access Door

TP01461

3

4. Examine the lamp usage indicator (Figure 3-6

Figure 3-6 Lamp Usage Indicator

).

Lamp Us age

Indicator

TP01466

40 Maintenance

Page 41

If lamp intensity is low , but the lamp has not been used for 1000 hours, you

S

Note:

may be able to increase lamp intensity by cleaning the flow cell (see Section 3.1,

Flow Cell Maintenance).

Absorbance by the mobile phase also affects the apparent lamp intensity. For

example, acetonitrile is more transparent than methanol at wavelengths under 220

nm.

3.2.2 Removing the Lamp

Attention:

STOP

lamp glass damages the lamp and reduces life expectancy.

Attention:

TOP

the lamp.

Required Materials

TORX T20 screwdriver

Caution:

the 99 6 d etect or and disc onne ct the power cord.

Procedure

To replace the lamp in the 996 detector:

1. Power off the 996 detector, remove the power cord, and allow the lamp to cool for

at least 15 minutes.

Caution:

15 minutes after powering off the detector before you handle the lamp.

2. Lift up the front panel cover and pull it away from the chassis.

3. Open the lamp access door by pulling the thumbtab, then pull the door toward

you (see Figure 3-5

Do not touch the lamp glass while unpacking or inserting the lamp. Touching

To prevent contamination, use powder-free gloves when removing or replacing

To avoid electrical hazards when you perform the following procedure, power off

3

To avoid the possibility of contacting hot surfaces, wait at least

).

4. Disconnect the lamp power connector (Figure 3-7

).

Replacing the Lamp 41

Page 42

Lamp Alignment Notch

3

Lamp Mounting

Screws

Figure 3-7 Lamp Power Cord and Mounting Screws

5. Use the TORX T20 screwdriver to unscrew the two T20 lamp mounting screws.

6. Grip the metal base of the lamp, pull the lamp out, and set it aside.

7. Carefully unpack the replacement lamp.

8. While wearing powder-free gloves and holding the lamp by its base, orient the

lamp so that the notch in the base aligns with the positioning pin in the optics

bench.

Lamp Power

Connector

TP01467

9. Insert the lamp and secure it with the two T20 screws. Make sure that the lamp

base is flush against the lamp housing.

10. Reconnect the lamp power connector (see Figure 3-7

11. Close the lamp door and secure it with the thumbtab.

12. Install the front panel cover.

13. Reconnect the power cord and power on the 996 detector.

42 Maintenance

).

Page 43

3.3 Replacing the Fuses

Replace the fuses under the conditions indicated in the troubleshooting table (see Section

2.1, Start up Diagnostics). The 996 detector requires two 4 A, 250 V fuses (5 mm ×20

mm).

Caution:

cord before you perform the following procedure.

To avoid electrical hazards, power off the 996 detector and disconnect the power

Procedure

To replace the two fuses in the 996 detector:

1. Power off the 996 detector and remove the power cord.

2. Locate the fuse block above the power cord plug (Figure 3-8

Squeeze Side C li p s

to Access Fuses

Figure 3-8 Fuse Block

3. Squeeze the two side clips on the fuse block while you pull out the block.

4. Remove the fuses from the block, then install the new fuses.

) on the rear panel.

3

5. Orient the fuse block with the small tab pointing down, then push in the block

until the side clips engage.

6. Connect the power cord, then power on the 996 detector.

Replacing the Fuses 43

Page 44

4 Pr incipl es of the 996 PDA Detector Optics

To use the Millennium32 PDA software effectively, you must be familiar with the principles

of operation of the optics and electronics of the Waters 996 PDA Detector.

4.1 996 Detector Optics

The 996 detector is an ultraviolet/visible light (UV/Vis) spectrophotometer with:

• 512 diodes

• Optical resolution of 1.2 nm per diode

• Operating wavelength range from 190 nm to 800 nm

4

The light path through the optics assembly of the 996 detector is shown in Figure 4-1

.

44 Principles of the 996 PDA Detector Optics

Page 45

Photodiode

Array

50-mm

Aperture

Assembly

Spectrographic

Mirror and Mask

Shutter

Flow Cell

Assembly

Lamp and

Lamp Optics

Figure 4-1 Optics Assembly Light Path

Grating

Beamsplitter

Assembly

Reference

Diode

Table 4-1

describes the optics assembly components in the 996 detector.

Table 4-1 Optics Assembly Components

Component Function

Lamp and lamp

optics

Beamsplitter and

reference diode

Focuses light from the deuterium source lamp through a

beamsplitter to the flow cell.

Reflects par t of the light back to a reference diode, which

measures the intensity of the light emitted by the lamp. The

detector uses this measurement to keep the lamp output constant.

4

996 Detector Optics 45

Page 46

Table 4-1 Optics Assembly Components (Continued)

Component Function

Flow cell

assembly

Spectrograph

mirror and mask

Aperture Controls wavelength resolution and intensity of light striking the

Shutter assembly Prevents light from reaching the photodiode array except during

Grating Disperses the light into bands of wavelengths and focuses those

Second-order

filter

Houses the segment of the flow path (containing eluent and

sample) through which the polychromatic light beam passes. This

arrangement of optical components, with the flow cell positioned

between the lamp and the grating, is commonly called reversed

optics.

The mirror focuses light transmitted through the flow cell onto the

aperture at the entrance to the spectrographic portion of the optics.

The mirror mask defines the beam of light focused on the

spectrograph mirror.

photodiodes. The width of the aperture is 50 µm.

sampling and calibration. For details on the dark current, see

Section 4.4.1,

wavelength bands onto the plane of the photodiode array.

Reduces the contribution of second-order reflection of UV light

(less than

350 nm) to the light intensity observed at visible wavelengths

(greater than 350 nm).

Calculating Absorbance.

4

Photodiode array An array of 512 diodes arranged linearly. The diode width and

spacing provide a single wavelength resolution of 1.2 nm.

4.2 Resolving Spectral Data

The ability to distinguish similar spectra depends on photodiode spacing and the

bandwidth of the light striking the photodiode. The bandwidth of the light striking the

photodiodes depends on the aperture width.

The aperture width determines:

• Attainable wavelength bandwidth at the photodiode array

• Intensity of the light reaching the photodiode array (optical throughput)

46 Principles of the 996 PDA Detector Optics

Page 47

The aperture creates a narrow beam that reflects from the grating to the photodiode array.

The wavelength that strikes a particular diode depends on the angle of reflection from the

grating.

Figure 4-2

using the standard 50-µm aper ture. In this spectrum, the wavelength resolution is

sufficient to resolve five principal benzene absorption peaks.

shows an absorbance spectrum of benzene obtained from the 996 detector

Absorbance

nm

Figure 4-2 Benzene Spectrum at 1.2 nm Resolution

4.3 Measuring Light at the Photodiode

The Waters 996 Photodiode Array Detector measures the amount of light striking the

photodiode array to determine the absorbance of the sample in the flow cell.

The array consists of 512 photodiodes arranged in a row. Each photodi ode acts as a

capacitor by holding a fixed amount of charge.

Light striking a photodiode discharges the diode (Figure 4-3

discharge depends on the amount of light striking the photodiode.

Measuring Light at the Photodiode 47

). The magnitude of the

4

Page 48

Light from gra ti ng

dispersed in to 1.2 nm

wav elength beams

continuously

discharges diodes.

Grating

Sample in flow cell

absorbs at spe cific

wav elengths

100%

Charge

0 %

Deuterium Lamp

Flow

Cell

Mirror

4

Figure 4-3 Photodiodes Discharged by Light

The 996 detector measures the amount of current required to recharge each photodiode.

The current is proportional to the amount of light transmitted through the flow cell over the

interval specified by the diode exposure time.

Exposure Time

The 996 detector recharges each diode and reads the recharging current one diode at a

time. The interval between two readings of an individual diode is the exposure time. The

996 detector requires 11 msec to sequentially read all of the diodes in the array. The

minimum exposure time is 11 msec. You can set exposure time from 11 to 500 msec.

For example, if an exposure time is set to 50 milliseconds, the Waters 996 detector:

1. Recharges diode 1 and reads the current required to recharge diode 1.

2. Recharges diode 2 and reads the current required to recharge diode 2.

3. Sequentially recharges and reads the current required to recharge all the

remaining 510 photodiodes.

48 Principles of the 996 PDA Detector Optics

Page 49

4. After all of the diodes have been recharged and read (11 msec), the detector

waits 39 msec before beginning the recharge-and-reading sequence with

diode 1.

You set the exposure time parameter in the General tab of the 996 PDA Instrument

Method Editor. You can specify either Auto Exposure or Exposure Time. For details, refer

to the “Waters 996 PDA Detector Properties” topic in the

tab.

Millennium32 Online Help

Using the Auto Exposure Parameter

The Auto Exposure time parameter allows the 996 detector optics to calculate the

optimum exposure time needed to recharge the diodes based on lamp energy, lamp

spectrum, mobile phase absorbance, and the chosen wavelength range. To minimize

detector noise, Auto Exposure adjusts the exposure time to 80 to 90 percent of full scale.

The Auto Exposure time setting ensures that the photodiodes are:

• Not saturating due to overexposure

• Operating above the range of normal, dark current discharge

With auto exposure enabled, the 996 detector:

• Calculates exposure time at the start of a run based on maximum light intensity

within the wavelength range

• Limits the exposure so that no diode within the given wavelength range is

discharged more than 80%

Find

• Provides proper settings for signal-to-noise and dynamic range for each run

The Auto Exposure time setting may not support certain sampling rates or wavelength

ranges required for your analysis. If this is the case, you can set the exposure time

manually to adjust the exposure time from experiment to experiment.

Using the Exposure Time Parameter

The Exposure Time parameter enables you to manually set the length of time the

photodiodes are exposed to light before they are read. The supported range is 11 to

500 msec.

Be aware that increasing the Exposure Time parameter has the potential to saturate the

photodiodes. A longer exposure time may cause the 996 detector to lose the signal at

certain wavelengths because of diode saturation. When specifying the Exposure Time,

select a value that provides settings for an optimum signal-to-noise ratio over the

wavelength range of your analysis (see “

Optimizing the Signal-to-Noise Ratio” below).

Measuring Light at the Photodiode 49

4

Page 50

Optimizing the Signal-to-Noise Ratio

To optimize signal-to-noise ratios, choose an acquisition wavelength range that includes

only the wavelengths of interest and over which the mobile phase absorbs minimally (see

Appendix D,

Mobile Phase Absorbance).

4.4 Computing Absorbance Data Points

4

The 996 detector calculates absorbance values before transmitting the data to the

Millenn iu m

32

database. To calculate absorbance, the 996 detector:

• Computes the absorbance at each diode using the dark current and reference

spectrum (see Section 4.4.1,

• Aver ages the absorbances at a particular wavelength as specified in the spectra per

second sample rate and repor ts the average as a single data point (see Section

4.4.2, Resolution).

• Can apply a filter that acts like an analog filter (see Section 4.4.3,

4.4.1 Calculating Absorbance

The 996 detector computes absorbance by subtracting the dark current and reference

spectrum from the acquired spectrum . Absorbanc e is based on the pr inciple s of Beer's

Law.

Beer’s Law

The relationship between the quantity of light of a particular wavelength arriving at the

photodiode and the concentration of the sample passing through the flow cell is described

by the Beer-Lambert Law (commonly called Beer’s Law). Beer’ s Law i s ex pressed as

ε

A

=

lc

Where:

Calculating Absorbance).

Filtering Data).

A

= absorbance

ε

= molar absorptivity

l

= path length (1.0 cm in the 996 detector normal flow cell)

c

= molar concentration

50 Principles of the 996 PDA Detector Optics

Page 51

Beer’s Law applies only to well-equilibrated dilute solutions. It assumes that the refractive

index of the sample remains constant, that the light is monochromatic, and that no stray

light reaches the detector element. As concentration increases, the chemical and

instrumental requirements of Beer's law may be violated, resulting in a deviation from

(absorbance versus concentration) linearity (Figure 4-4

can reduce the linear range by the amounts shown in Appendix D,

Absorbance.

Absorbance

). The absorbance of mobile phase

Mobile Phase

Ideal

Actual

Working Ran ge

AbsorbanceBackground

Concentrati on

Figure 4-4 Absorbance as a Function of Concentration

Dark Current

Photodiodes lose charge over time even when they are not exposed to light. The amount

of charge lost is called

At the start of a chromatographic run, the 996 detecto r closes the shutter to take a dark

current reading for each diode. The shutter closes after the exposure time is calculated

and stays closed for the same interval as the exposure time.

The detector subtracts the dark current values from the current values recorded during

absorbance measurements for both the sample and the reference spectra.

dark current

.

Computing Absorbance Data Points 51

4

Page 52

Refer ence Spectrum

Immediately after the dark current measurement and before any components are eluted,

the 996 detector records a reference spectrum. The reference spectrum is a measure of

lamp intensity and mobile phase absorbance over the interval specified in the exposure

time taken with the shutter open.

For best results, the reference spectrum should be representative of the initial

Note:

mobile phase.

For extremely long exposure times, the dark current and reference spectrum

Note:

readings may take several minutes to finish.

Absorbance

The 996 detector calculates the absorbance for each diode at the end of each exposure

time using the following equation:

Sn Dn

–()

Absorbance

where:

S

= Signal obtained during sample analysis

D

= Signal obtained during the dark test

R

= Signal obtained from the reference spectrum

n

= Diode number

log=

-------------------------

Rn Dn

–()

4

4.4.2 Resolution

The data reported by the 996 detector to the Millennium32 database can be the average of

a number of data points. After calculating absorbance, the detector averages absorbance

values based on:

• Spectral resolution

• Sample rate

Averaging Spectral Data Based on Resolution

Spectral resolution (or bandwidth) is the wavelength interval (in nanometers) between

data points in an acquired spectrum. The minimal resolution of the 996 detector is 1.2 nm.

Spectral resolution with the 996 detector is always a multiple of 1.2 nm. For example, the

996 detector averages three diodes for each reported wavelength when the spectral

resolution is set in the Millennium

52 Principles of the 996 PDA Detector Optics

32

software to 3.6 nm.

Page 53

Averaging Chromatographic Data Based On Sample Rate

Sample rate is the number of data points per second reported to the Millennium32

database. The number of times the photodiodes are read during the sample rate interval is

dependent on the exposure time.

For ex ample, if e xposure time is 25 msec, and sample rate is 1 second, then readings per

data point are

1000 msec

------------------------- 40=

25 msec

The readings are averaged and reported as a single data point.

Combining Spectral Resolution and Sample Rate

Spectral resolution and sample rate have opposite effects on noise and spectral detail.

Increasing the value of the spectral resolution parameter and decreasing the number of

spectra per second decrease the size of the data file.

The data storage rate is based on wavelength range, spectral resolution, and

Note:

sample rate, which are set in the General tab of the 996 PDA Instrument Method Editor.

For details, ref er to the “Waters 996 PDA Detector Properties” topic in the

Millennium

32

Online Help Find tab.

4.4.3 Filtering Data

Use the Channel 1 tab of the 996 PDA Instrument Method Editor (for details, refer to the

“Waters 996 Detector Properties” topic in the

an optional noise filter (the Filter Response parameter) to the dat a sent to the Mi llennium

software database. A noise filter of 1 second is the default value, which provides a good

signal-to-noise ratio for most chromatographic separations.

Note the following with regard to filtering data:

• The noise filter is similar in function to an analog RC filter.

• The filter calculates a data point that is a modified rolling average for a wavelength

over a number of readings.

• The filter values are comparable to the effects of a 1-, 2-, or 3-second RC filter.

Millennium32 Online Help

Computing Absorbance Data Points 53

Find tab) to apply

32

4

Page 54

5

Spectral Contrast Theory

This chapter explains the theory behind the Spectral Contrast technique, which is used to

compare UV/Vis absorbance spectra collected by the 996 detector. Spectral Contrast

makes use of the fact that different compounds have differently shaped absorbance

spectra. This chapter describes how Spectral Contrast represents absorbance spectra as

vectors. When applied to the UV/Vis absorbance data collected by the 996 detector, the

Spectral Contrast technique determines whether differences between spectra are due to

the presence of multiple compounds in the same peaks (coelution) or due to nonideal

conditions such as noise, photometric error, or solvent effects.

5.1 Comparing Absorbance Spec tra

The shape of an absorbance spectrum is determined by the relative absorbance at

different wavelengths. The shape of a compound’s absorbance spectrum is a

characteristic of that compound at the solvent and pH conditions under which the

absorbance spectrum is measured.

5

Figure 5-1

absorbance at 245 nm to the absorbance at 257 nm is approximately 2.2 for compound A

and 0.7 for compound B.

The absorbance ratios of two wavele ngth pairs is a limited spectral comparison. For more

information, you need to compare the absorbance ratios of multiple wavelength pairs.

54 Spectral Contrast Theory

shows the absorbance spectra for the two compounds, A and B. The ratio of the

Page 55

Compound A:

245 nm

257 nm

Compound A

Compound B:

Compound B

Figure 5-1 Comparing Spectra of Two Compounds

5.2 Representing Spectra as Vectors

Ab

245

-------------- 2.2=

Ab

257

Ab

245

-------------- 0.7=

Ab

257

The Spectral Contrast technique uses vectors to quantify differences in the shapes of

spectra. Spectral Contrast converts baseline-corrected spectra to vectors and then

compares the vectors. Spectral vectors have two properties:

Length

•

Direction

•

– Proportiona l to analyte concentration.

– Determined by the relative absorbance of the analyte at all wavelengths

(its absorbance spectrum). Direction is independent of concentration.

Vector direction contributes to the identification of a compound, since the direction is a

function of the absorbance spectrum of the compound. The ability of spectral vectors to

differentiate compounds depends on the resolution of spectral features. As both

wavelength range and spectral resolution increase, the precision of a spectral vector for

the resultant spectrum increases. A vector derived from the Waters 996 PDA Detector can

include absorbances in any range between 190 nm and 800 nm with a spectral resolution

of 1.2 nm.

Representing Spectra as Vectors 55

5

Page 56

5.2.1 Vectors Derived from Two Wavelengths

The Spectral Contrast algorithm uses vectors to characterize spectra (Figure 5-2). To

understand the vector principle, consider two vectors (Figure 5-2

depicted in Figure 5-1

AU at 257 nm

.

AU at 245 nm

Figure 5-2 Plotting Vectors for Two Spectra

) based on the spectra

5

The axes in Figure 5-2

the absorbance ratio shown in Figure 5-1

intersection of the absorbance values (for Compound A) at the two wavelengths

represented by each axis. The other vector is similarly derived for the spectrum of

Compound B.

The vector for Compound B points in a direction different from that of the vector for

Compound A. The difference in direction, which reflects the difference in the absorbance

ratios of the two compounds at wavelengths 245 nm and 257 nm, is called the Spectral

Contrast Angle. A Spectral Contrast angle (e.g., θ in Figure 5-2

indicates a shape difference between spectra (see Section 5.3,

The length of the vector is proportional to the concentration.

are in absorbance units at the two wavelengths used to calculate

. The head of the vector for Compound A is at the

5.2.2 Vectors Derived from Multiple W av elengths

When absorbance ratios are limited to two wavelengths, the chance that two different

spectra will have the same absorbance ratio is much greater than if comparison is made

using absorbance ratios at many wavelengths. Therefore, the Spectral Contrast technique

uses absorbances from multiple wavelengths to form a vector in an

n

space, where

56 Spectral Contrast Theory

is the number of wavelengths from the spectrum.

)

greater than zero

Spectral Contrast Angles).

n

-dimensional vector

Page 57

To compare two spectra, the Spectral Contrast technique forms a vector for each spectrum

n