Page 1

Waters 432 Conductivity

t

Detector

Operator’s Guide

34 Maple Stree

Milford, MA 01757

71500043202, Revision A

Page 2

NOTICE

The information in this document is subject to change without notice and should not be

construed as a commitment by Waters Corporation. Waters Corporation assumes no

responsibility for any errors that may appear in this document. This document is believed

to be complete and a c cu rate at th e time o f p u blication. In no event shall Water s

Corporation be liable for incidental or consequential damages in connection with or arising

from the use of this document.

1994–2003 WATERS CORPORATION. PRINTED IN THE UNITED STATES OF

AMERICA. ALL RIGHTS RESERVED. THIS DOCUMEBNT OR PARTS THEREOF MAY

NOT BE REPRODUCED IN ANY FORM WITHOUT THE WRITTEN PERMISSION OF

THE PUBLISHER.

Alliance, Millennium, and Waters are registered trademarks, and Empower, LAC/E,

PowerLine, SAT/IN, Sep-Pak, UltraWISP, and WISP are trademarks of Waters

Corporation.

All other trademarks or registered trademarks are the sole property of their respective

owners.

Page 3

When you use the instrument, follow generally accepted procedures for quality

P

Note:

control and methods development.

If you observe a change in the retention of a particular compound, in the resolution

between two compounds, or in peak shape, immediately determine the reason for the

changes. Until you determine the cause of a change, do not rely on the separation results.

The Installation Category (Overvoltage Category) for this instrument is Level II. The

Note:

Level II Category pertains to equipment that receives its electrical power from a local level,

such as an electrical wall outlet.

STO

Atención:

responsible for compliance could void the user’s authority to operate the equipment.

Importan t :

par l’autorité responsable de la conformité à la réglementation peut annuler le droit de

l’utilisateur à exploiter l’équipement.

Achtun g :

ausdrückliche Genehmigung der für die ordnungsgemäße Fun ktion stüchtigkeit

verantwortlichen Personen kann zum Entzug der Bedienungsbefugnis des Systems

führen.

Avvertenza:

espressamente approvate da un ente responsabile per la conformità annulleranno

l’autorità dell’utente ad operare l’apparecchiatura.

Atención:

expresamente aprobado por la parte responsable del cumplimiento puede anular la

autorización del usuario para utilizar el equip o .

Changes or modifications to this unit not expressly approved by the party

Toute modification sur cette unité n’ayant pas été expressément approuvée

Jedwede Änderungen oder Modifikationen an dem Gerät ohne die

eventuali modifiche o alterazioni apportate a questa unità e non

cualquier cambio o modificación efectuado en esta unidad que no haya sido

Page 4

Caution:

Use caution when working with any polymer tubing under pressure:

• Always wear ey e protection when near pressurized polymer tubing.

• Extinguish all nearby flames.

• Do not use Tefzel tubing that has been severely stressed or kinked.

• Do not use Tefzel tubing with tetrahydrofuran (THF) or concentrated nitric or

sulfuric ac id s.

• Be aware that methylene chlor ide and dimethyl sulfoxide cause Tefzel tubing to

swell, which greatly reduces the rupture pressure of the tubing.

Attention :

Soyez très prudent en travaillant avec des tuyaux de polymères sous

pression :

• Portez toujours des lunettes de protection quand vous vous trouvez à proximité de

tuyaux de polymères.

• Eteignez toutes les flammes se trouvant à proximité.

• N'utilisez pas de tuyau de Tefzel fortement abîmé ou déformé.

• N'utilisez pas de tuyau de Tefzel avec de l'acide sulfurique ou nitrique, ou du

tétrahydrofurane (THF).

• Sachez que le chlorure de méthylène et le sulfoxyde de diméthyle peuvent

provoquer le gonflement des tuyaux de Tefzel, diminuant ainsi for tem ent leur

pression de rupture.

Vorsicht:

Bei der Arbeit mit Polymerschläuchen unter Druck ist besondere Vorsicht

angebracht:

• In der Nähe von unter Druck stehenden Polymerschläuchen stets Schutzbrille

tragen.

• Alle offenen Flammen in der Nähe löschen.

• Keine Tefzel-Schläuche verwenden, die stark geknickt oder überbeansprucht sind.

• Tefzel-Schläuche nicht für Tetrahydrofuran (THF) oder konzentrierte Salpeter- oder

Schwefelsäure verwenden.

• Durch Methylenchlorid und Dimethylsulfoxid können Tefzel-Schläuche quel len;

dadurch wird der Berstdruck des Schlauches erheblich reduziert.

Page 5

Precauzio ne :

prestare attenzione durante le operazioni con i tubi di polimero sotto

pressione:

• Indossare sempre occhiali da lavoro protettivi nei pressi di tubi di polimero

pressurizzati.

• Estinguere ogni fonte di ignizione circostante.

• Non utilizzare tubi Tefzel soggetti a sollecitazioni eccessive o incurvati.

• Non utilizzare tubi Tefzel contenenti tetraidrofurano (THF) o acido solforico o nitrico

concentrato.

• Tenere presente che il cloruro di metilene e il dimetilsolfossido provocano

rigonfiamento nei tubi Tefzel, che riducono not evolmente il limite di pressione di

rottura dei tubi stessi.

Advertencia:

manipular con precaución los tubos de polímero bajo presión:

• Protegerse siempre los ojos en las proximidades de tubos de polímero bajo

presión.

• Apagar todas las llamas que estén a proximidad.

• No utilizar tubos Tefzel que hayan sufrido tensiones extremas o hayan sido

doblados.

• No utilizar tubos Tefzel con tetrahidrofurano (THF) o ácidos nítrico o sulfúrico

concentrados.

• No olvidar que el cloruro de metileno y el óxido de azufre dimetilo dilatan los tubos

Tefzel, lo que reduce en gran medida la presión de ruptura de los tubos.

Page 6

Page 7

Caution:

The user shall be made aware that if the equipment is used in a manner not

specified by the manufacturer, the protection provided by the equipment may be impaired.

Attention :

L’utilisateur doit être inform é que si le mat ériel est utilisé d’une façon non

spécifiée par le fabricant, la protection assurée par le matériel risque d’être défectueuses.

Vorsicht:

Der Benutzer wird darauf aufmerksam gemacht, dass bei unsachgemäßer

Verwenddung des Gerätes unter Umständen nicht ordnungs gem äß funktionieren.

Precau zion e :

l’utente deve essere al corrente del fatto che, se l’apparecchiatura viene

usta in un modo specificato dal produttore, la protezione fornita dall’apparecchiatura

potrà essere invalidata.

Adver tenc ia:

el usuario deberá saber que si el equipo se utiliza de forma distinta a la

especificada por el fabricante, las medidas de protección del equipo podrían ser

insuficientes.

Page 8

Caution:

rating.

To protect against fire hazard, replace fuses with those of the same type and

Attention :

Remplacez toujours les fusibles par d’autres du même type et de la même

puissance afin d’éviter tout risque d’incendie.

Vorsicht:

Zum Schutz gegen Feuergefahr die Sicherungen nur mit Sicherungen des

gleichen Typs und Nennwertes ersetzen.

Precauzio ne :

per una buona protezione contro i rischi di incendio, sostituire i fusibili con

altri dello stesso tipo e amperaggio.

Advertencia:

sustituy a l o s fusibles por o tros del mismo tipo y características para evitar

el riesgo de incendio.

Page 9

Caution:

To avoid possible electrical shock, disconnect the power cord before servicing

the instrument.

Attent i on :

Afin d’éviter toute possibilité de commotion électrique, débranchez le cordon

d’alimentation de la prise avant d’effectuer la maintenance de l’instrument.

Vorsicht:

Zur V ermeidung von Stromschlägen sollte das Gerät vor der Wartung vom

Netz getrennt werden.

Precauzio ne :

per evitare il rischio di scossa elettrica, scollegare il cavo di alimentazione

prima di svolgere la manutenzione dello strumento.

Precaució n:

para evitar descargas eléctricas, desenchufe el cable de alimentación del

instrumento antes de realizar cualquier reparación.

Page 10

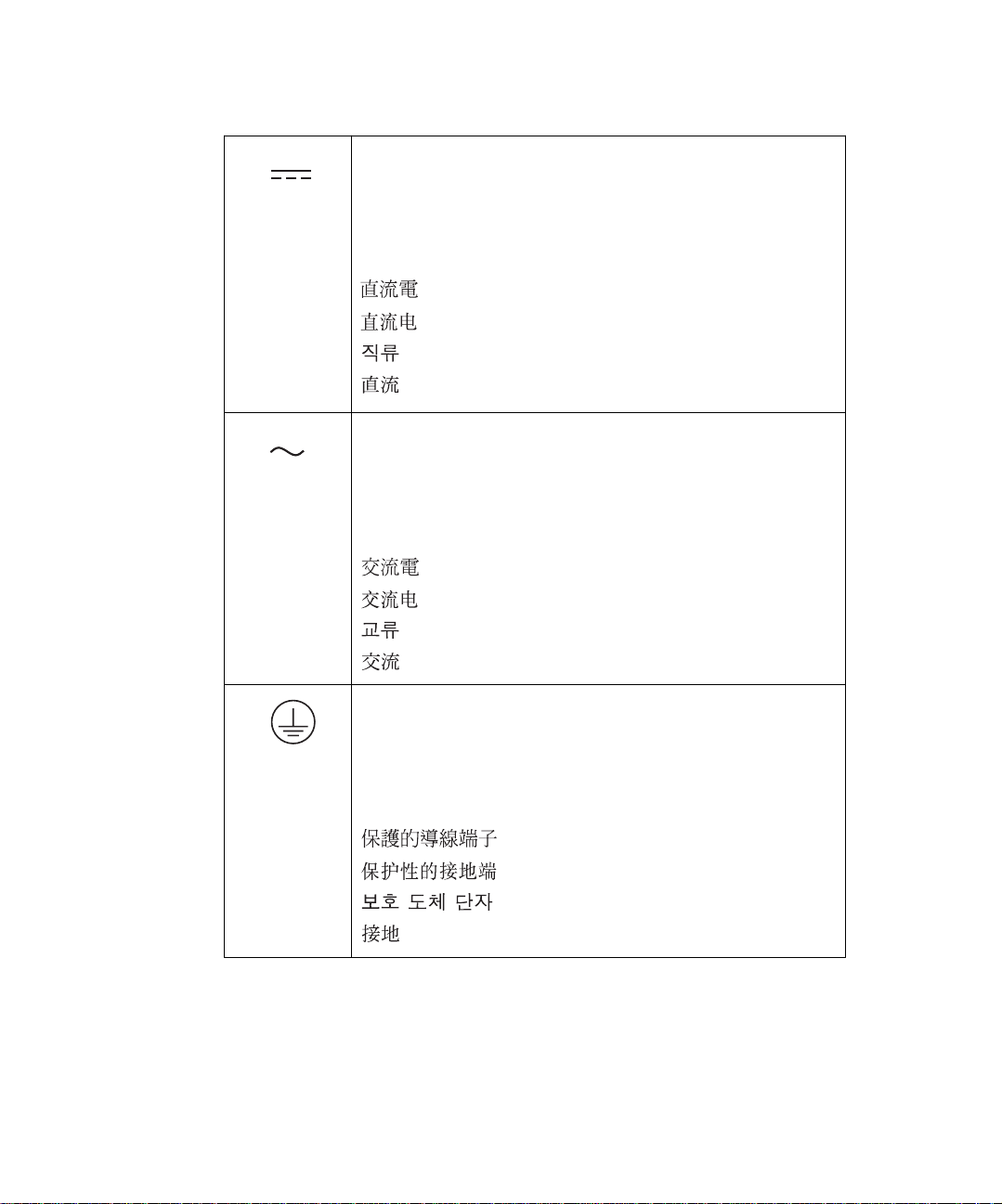

Commonly Used Symbols

Direct current

Courant continu

Gleichstrom

Corrente continua

Corriente continua

Alternating current

Courant alternatif

Wechselstrom

Corrente alternata

Corriente alterna

Protective conductor terminal

Borne du conducteur de protection

Schutzleiteranschluss

Ter m ina le di conduttore con protezione

Borne del conductor de tierra

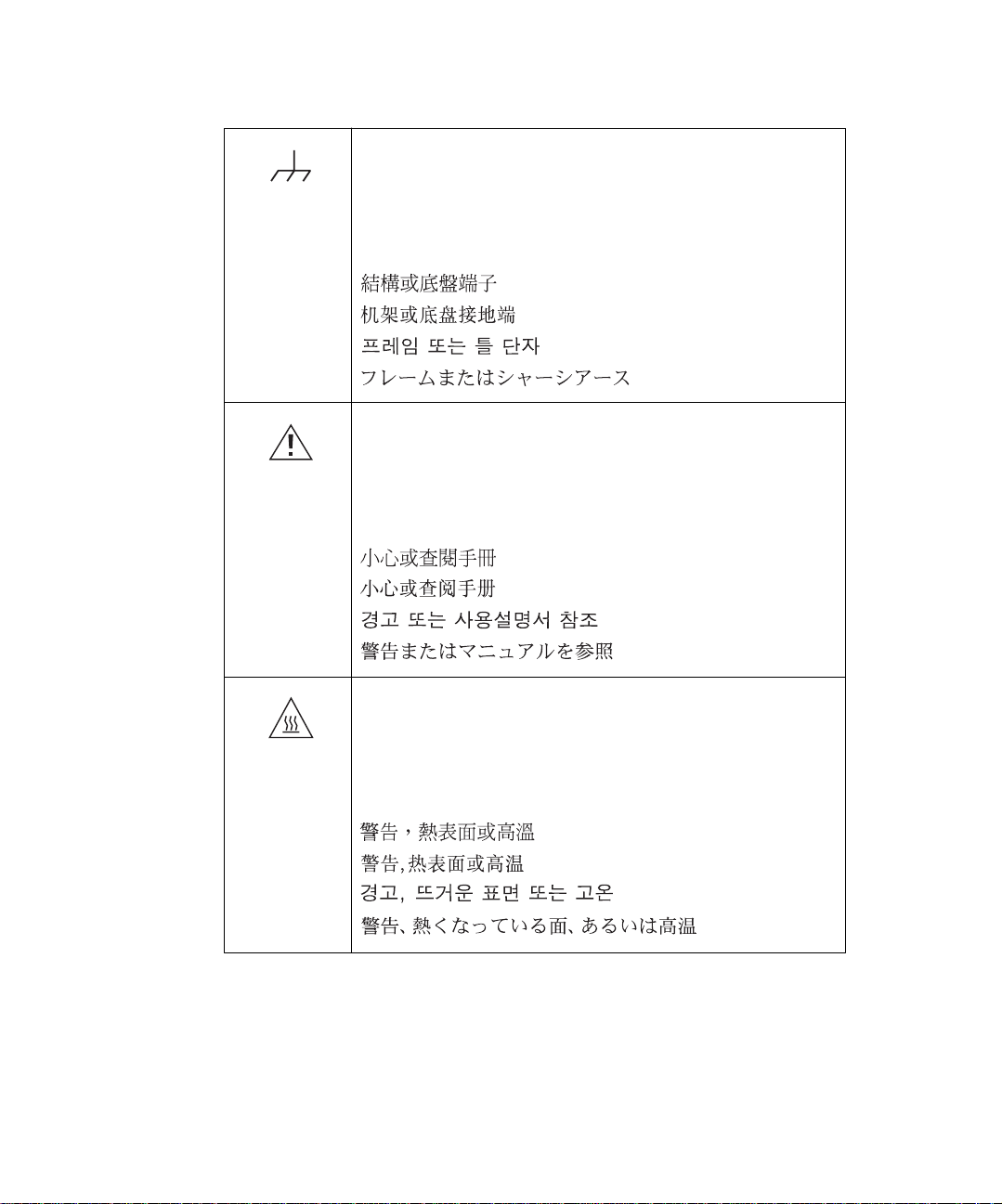

Page 11

Commonly Used Symbols (Continued )

Frame or chassis terminal

Borne du cadre ou du châssis

Rahmen- oder Chassisanschluss

Ter m ina le di str uttura o telaio

Borne de la estructura o del chasis

Caution or refer to manual

Attention ou reportez-vous au guide

Vorsicht, oder lesen Sie das Handbuch

Prestare attenzione o fare riferimento alla guida

Actúe con precaución o consulte la guía

Caution, hot surface or high temperature

Attention, surface chaude ou température élevée

Vorsicht, heiße Oberfläche oder hohe Temperatur

Precauzione, superficie calda o elevata temperatura

Precaución, superficie caliente o temperatura elevada

Page 12

Commonly Used Symbols (Continued )

Caution, risk of electric shock (high voltage)

Attention, risque de commot ion électri que (haut e tension )

Vorsicht, Elektroschockgefahr (Hochspannung)

Precauzione, rischio di scossa elettrica (alta tensione)

Precaución, peligro de descarga eléctrica (alta tensión)

Caution, risk of needle-stick puncture

Attention, risques de perforation de la taille d’une aiguille

Vorsicht, Gefahr einer Spritzenpunktierung

Precauzione, rischio di puntura con ago

Precaución, riesgo de punción con aguja

Caution, ultraviolet light

UV

Attention, rayonnement ultrviolet

Vorsicht, Ultr a violettes Licht

Precauzione, luce ultravioletta

Precaución, emisiones de luz ultravioleta

Page 13

Commonly Used Symbols (Continued )

1

0

Fuse

Fusible

Sicherung

Fusibile

Fusible

Electrical power on

Sous tension

Netzschalter ein

Alimentazione elettrica attivata

Alimentación eléctrica conectada

Electrical power off

Hors tension

Netzschalter aus

Alimentazione elettrica disat tivata

Alimentación eléctrica desconectada

Page 14

432 Conductivity Detector Information

Intended Use

The Waters® 432 Conductivity Detector can be used for in-vitro diagnostic testing to

analyze many compounds, including diagnostic indicators and therapeutically monitored

compounds. When you de velop methods, follow the “Protocol for the Adoption of

Analytical Methods in the Clinical Chemistry Laborator y,” American Journal of Medical

Tech nol ogy, 44, 1, pages 30–37 (1978). This protocol covers good operating procedures

and techniques necessary to validate system and method performance.

Biological Hazard

When you analyze physiological fluids, take all necessary precaut ions and treat all

specimens as potentially infectious. Precautions are outlined in “CDC Guidelines on

Specimen Handling,” CDC – NIH Manual, 1984.

Calibration

Follow acceptable methods of calibration with pure standards to calibrate methods. Use a

minimum of five standards to generate a standard curve. The concentration range should

cover the entire range of quality-control samples, typical specimens, and atypical

specimens.

Quality Control

Routinely run three quality-control samples. Quality-control samples should represent

subnormal, nor m al, and above-norm al levels of a compound. Ensure that quality-control

sample results are within an acceptable range, and ev aluate precision from day to day and

run to run. Data collected when quality-control samples are out of range may not be valid.

Do not report this data until you ensure that chromatographic system performance is

acceptable.

Page 15

Table of Contents

Preface ....................................................................................... 23

Chapter 1

Introduction .................. ............................. ............................. .......... 26

Chapter 2

Installing the Detector ...................................................................... 30

2.1 Selecting the Installation Site................................................ 30

2.2 Unpacking and Inspection..................................................... 31

2.3 AC Power Connection ........................................................... 32

2.4 I/O Signal Connections......................................................... 35

2.4.1 I/O Signal Desc ri pt ions ....... ..... .... ..... ................... ..... . 35

2.4.2 Powe rLine Controller Connections ............................ 37

2.4.3 Empower and Millennium

32

Connections .................. 39

2.4.4 Data Module Connections ......................................... 44

2.4.5 Chart Recorder Connections..................................... 45

2.4.6 Chart Marker Input Connections................................ 45

2.4.7 Auto Zero Input Connections..................................... 46

2.4.8 Alliance Separatio ns Mo dule Connec tion s ............... . 46

2.5 Making Fluidic Connections.................................................. 48

2.6 Passivating the System......................................................... 53

2.7 Verifying the Detector............................................................ 54

Table of Contents 15

Page 16

Chapter 3

Operating the Detector .................................................................... 56

3.1 Controls and Indicators......................................................... 56

3.2 Startup and Shutdown .......................................................... 61

3.3 Operating Recommendations ............................................... 62

Chapter 4

Performing Ion Analysis ................................................................... 64

4.1 Fundamental Considerations................................................ 64

4.2 Configuring the System......................................................... 68

4.3 Eluents for Ion Analysis......................................................... 69

4.3.1 Preparing Anion Eluent....... ................... ..... ..... .... ...... 70

4.3.2 Preparing Cation Eluent .......... .... ..... ..... ..... ..... .......... 70

4.4 Standards for Ion Analysis .................................................... 70

4.4.1 Preparing Anion Standa rds ......... ..... ................... ..... . 71

4.4.2 Injecting Anion Standards.......................................... 72

4.4.3 Preparing Cation Standard s ............. ..... ................... . 74

4.4.4 Injecting Cati on Stan dar ds........... ..... ..... ..... ..... .......... 76

Chapter 5

Maintenance .................................................................................... 78

5.1 Routine Maintenance............................................................ 78

5.1.1 Replacing the Fuse.................................................... 78

5.1.2 Maintaining the Flow Cell........................................... 79

5.2 Cleaning the Detector Exterior.............................................. 82

5.3 Troubleshooting..................................................................... 82

Table of Contents 16

Page 17

Appendix A

Specifications ................................................................................... 87

Appendix B

Spare Parts......... ..... ..... ..... ..... .... ..... ................... ..... ..... ..... ..... .......... 90

Appendix C

Ion Chromatography Methods .......................................................... 91

C.1 General-Purpose Anion Analysis Using Conductivity

and UV Detection ................................................................ 91

C.1.1 Prepa rin g Eluent ...... ..... ..... ..... .... .................... .... ..... . 93

C.1.2 Prepa rin g Stand ard s .......... ..... ................... ..... .... ..... . 93

C.1.3 Preparing a Sample .................................................. 93

C.1.4 Empower Data Processing Method........................... 94

C.1.5 Method Valid atio n .............. ..... .... ..... ..... ..... ............... 95

C.1.6 Method Linea rity.. ..... ..... ..... ................... ..... ..... .... ..... . 95

C.1.7 Quantita tion Prec ision... ..... ..... .... ..... ..... ..... ............... 97

C.1.8 Method Detection Limits............................................ 97

C.1.9 Quantita tion Accu racy... ..... ..... .... ..... ................... ..... . 98

C.1.10 Analyte Recovery.................................................... 99

C.1.11 Example of Use..................................................... 100

C.1.12 Using Direct UV Detection .................................... 100

C.1.13 Preparing Lithium Borate/Gluconate 50X

Stock Concentrate................................................... 102

C.1.14 Preparing Lithium Borate/Gluconate Eluent.......... 102

Table of Contents 17

Page 18

C.2 Alkali and Alkaline Earth Cations, Ammonium,

and Amines........................................................................ 103

C.2.1 Prepa rin g Elu ent .................... .... ..... ................... .... 104

C.2.2 Prepa rin g Stand ard s .......... ..... ................... ..... .... .... 104

C.2.3 Preparing a Sample ................................................ 105

C.2.4 Empower Data Processing Method......................... 105

C.2.5 Method Detection Limits.......................................... 106

C.2.6 Examples of Use..................................................... 107

C.2.7 Preparing Stock Reagent........................................ 108

Appendix D

Validation Support .......................................................................... 109

Index ..................................................................................... 111

Table of Contents 18

Page 19

List of Figures

1-1 Waters 432 Conductivity Detector.................................................26

1-2 Flow Cell Schematic ......................................................................28

2-1 Rear Panel..................................................................................... 33

2-2 Changing the Voltage Setting........................................................34

2-3 I/O Terminal Strip...........................................................................36

2-4 IEEE-488 Address Switch..............................................................38

2-5 Bus SAT/IN Module (Front Panel).................................................. 40

2-6 Bus SAT/IN to Bus LAC/E Connections.........................................42

2-7 Bus SAT/IN to 432 Detector Connections...................................... 43

2-8 Alliance Separations Module Connections to the 432

Detector Auto-Zero on Inject..........................................................47

2-9 Alliance Separations Module Connections to the 432

Detector Chart Mark on Inject........................................................48

2-10 Fluid Connections.......................................................................... 49

2-11 Cutting Po lymeric Tubing...............................................................50

2-12 Ferrule and Compression Screw Assembly...................................51

2-13 Pulse Dampener............................................................................ 53

3-1 Front Panel ....................................................................................56

4-1 Soda Lime Tube.............................................................................67

4-2 System Configuration for Ion Analysis...........................................68

4-3 Chromatogram of a 7-Anion Standard........................................... 74

4-4 Chromatogram of an 8-Cation Standard........................................77

5-1 Installing Operating Voltage Fuses................................................79

5-2 Flow Cell Assembly....................................................................... 81

C-1 Common Anion Standards ............................................................92

List of Figures 19

Page 20

C-2 Calibration Curves for Chloride, Fluoride, and Bromide ............... 95

C-3 Calibration Curves for Nitrite and Nitrate ...................................... 96

C-4 Calibration Curves for Sulfate and Phosphate ..............................96

C-5 100-mL Injection ...........................................................................97

C-6 Typical Drinking Water, No Dilution Required ............................100

C-7 Direct UV Detection ....................................................................101

C-8 100-ppb Anion Standard .............................................................101

C-9 1-ppm Standard .......................................................................... 103

C-10 25-ppb Cation Standard ..............................................................106

C-11 Typical Drinking Water, No Dilution Required ............................107

C-12 Typical Municipal Wastewater, Diluted 1:50, Overlay

of Duplicate Injections.................................................................. 107

List of Figures 20

Page 21

List of Tables

1-1 Limiting Equivalent Conductance of Ions in Water at 25 °C .........29

2-1 Power Cord Wire Identification .....................................................33

2-2 Nominal Operating Voltage...................................................... 34

2-3 I/O Signal Descriptions ........................................................... 36

2-4 IEEE-488 DIP Switch Setting.................................................. 38

2-5 Bus SAT/IN Cable Connections............................................... 44

2-6 Data Module Signal Cable Connections .................................. 44

2-7 Data Module Chart Mark Cable Connections........................... 45

2-8 Chart Recorder Cable Connections......................................... 45

2-9 Autosampler Chart Mark Cable Connections........................... 46

2-10 Autosampler Auto Zero Cable Connections............................. 46

2-11 Connections for Generating Auto-Zero on Inject...................... 47

2-12 Connections for Generating Chart Mark on Inject.................... 48

3-1 Key Descriptions ...........................................................................58

3-2 Setting the Beep Function....................................................... 60

4-1 Shelf-Life of Standards .................................................................71

4-2 Salts for Anion Standard Concentrates.................................... 72

4-3 Anion Concentrate Dilutions.................................................... 72

4-4 Salts for Cation Standard Concentrates .................................. 75

4-5 Cation Concentrate Dilutions ................................................... 75

5-1 Troubleshooting Guide ..................................................................85

A-1 Operational Specifications ............................................................87

A-2 Mechanical Specifications............................................................ 87

A-4 Electrical Specifications................................................................ 88

A-3 Environmental Specifications........................................................ 88

List of Tables 21

Page 22

A-5 Communications........................................................................... 89

B-1 Spare Parts ...................................................................................90

C-1 Required Instru ment ation ...................................................... .......91

C-1 Analysis Conditions ......................................................................92

C-2 IC Processing Method Using Peak Apex for Retention Time....... 94

C-3 Method Validation......................................................................... 95

C-4 Quantitation Precision................................................................... 97

C-5 Quantitation Accuracy................................................................... 98

C-6 Analyte Recovery.......................................................................... 99

C-1 Required Instru ment ation ...................................................... .....103

C-2 Analysis Conditions.................................................................... 104

C-3 IC Processing Method Using Peak Apex for Retention Time..... 105

List of Tables 22

Page 23

Preface

The Waters 432 Conductivity Detector Operator’s Guide details the procedures for

unpacking, installing, operating, maint ain ing, and troubleshooting the 432 Conductivity

Detector. It also includes appendixes listing specifications and spare parts and describing

validation support.

This guide is intended for use by personnel who need to install, operate, maintain, or

troubleshoot the 432 Detector. This guide assum es an understandi ng of the princip les of

chromatography.

Organization

This guide contains the following:

Chapter 1

Chapter 2

electrical connections.

Chapter 3

general operating instructions.

Chapter 4

for anion and cation analysis.

Chapter 5

tables to aid in problem diagnosis.

Appendix A

Detector.

Appendix B

Appendix C

Appendix D

support .

describes the features and method of operation of the 432 Detector.

describes the procedures for installing the 432 Detector and making fluid and

describes the controls and indicators of the 432 Detector, and provides

describes the system configuration, eluents, and standards recommended

describes simple maintenance procedures and provides troubleshooting

describes the operational specifications and requirements of the 432

lists the recommended spare parts for the 432 Detector.

describes ion chromatography methods.

describes the recommended validation protocols and Waters® validation

Related Documentation

Waters Licenses, Warranties, and Support: Provides software license and warranty

information, describes training and extended support, and tells how Waters handles

shipments, damages, claims, and returns.

23

Page 24

Documentation on the Web

Related product information and documentation can be found on the W orld Wide Web .

Our address is http://www.waters.com

.

Related Adobe Acrobat Reader Documentation

For detailed infor mation about using Adobe® Acrobat® Reader, see the Adobe Acrobat

Reader Online Guide. This guide covers procedures such as viewing, navigating, and

printing electronic documentation from Adobe Acro bat Reader.

Printing This Electronic Docu men t

Adobe Acrobat Reader lets you easily print pages, page ranges, or the entire document by

selecting File > Print. For optimum print quant ity, Waters recommends that you specify a

PostScript

resolution.

®

printer driver for your printer. Ideally, use a printer that supports 600 dpi print

Documentation Conventions

The following conventions can be used in this guide:

Convention Usage

Purple

Italic Italic indicates information that you supply such as variables. It also

Courier

Courier Bold

Underlined Blue I ndi cates hypert ext cross-references to a specific chapter, section,

Keys T he word key refers to a computer key on the keypad or keyboard.

Purple text indicates user action such as keys to press, menu selections, and commands. For example, “Click Next to go to the next

page.”

indicates emphasis and document titles. For example, “Replace

file_name with the actual name of your file.”

Courier indicates examples of source code and system output. For

example, “The SVRMGR> prompt appears.”

Courier bold indicates characters that you type or ke ys you press in

examples of source code. For example, “At the LSNRCTL> prompt,

enter set password oracle to access Oracle.”

subsection, or sidehead. Clicking this topic using the hand symbol

brings you to this topic within the document. Right-clicking and

selecting Go Back from the short c ut menu returns you to the origi-

nating topic. For example, “The detector’s I/O signals are described

in Section 2.4,

Screen keys ref er to the ke ys on the instrument located immediately

below the screen. For example, “The A/B screen key on the 2414

Detector displays the selected channel.”

I/O Signal Connections.”

24

Page 25

P

Convention Usage

… Three periods indicate that more of the same type of item can

optionally follow. For example, “You can store filename1, filename2,

… in each folder.”

>

Notes

Notes call out information that is helpful to the operator. For example:

Record your result before you proceed to the next step.

Note:

Attentions

Attentions provide information about preventing damage to the system or equipment. For

example:

A right arrow between menu options indicates you should choose

each option in sequence. For example, “Select File > Exit” means

you should select File from the menu bar, then select Exit from the

File menu.

Attention:

STO

Cautions

window.

Cautions provide information essential to the safety of the operator. For example:

Caution:

replacement or adjustment.

Caution:

performing maintenance procedures.

Caution:

when operating the system.

To avoid damaging the detector flow cell, do not touch the flow cell

To avoid burns, turn off the lamp at least 30 minutes before removing it for

To avoid electrical shock and injury , unplug the power cord before

To avoid chemical or electrical hazards, observe safe laboratory practices

25

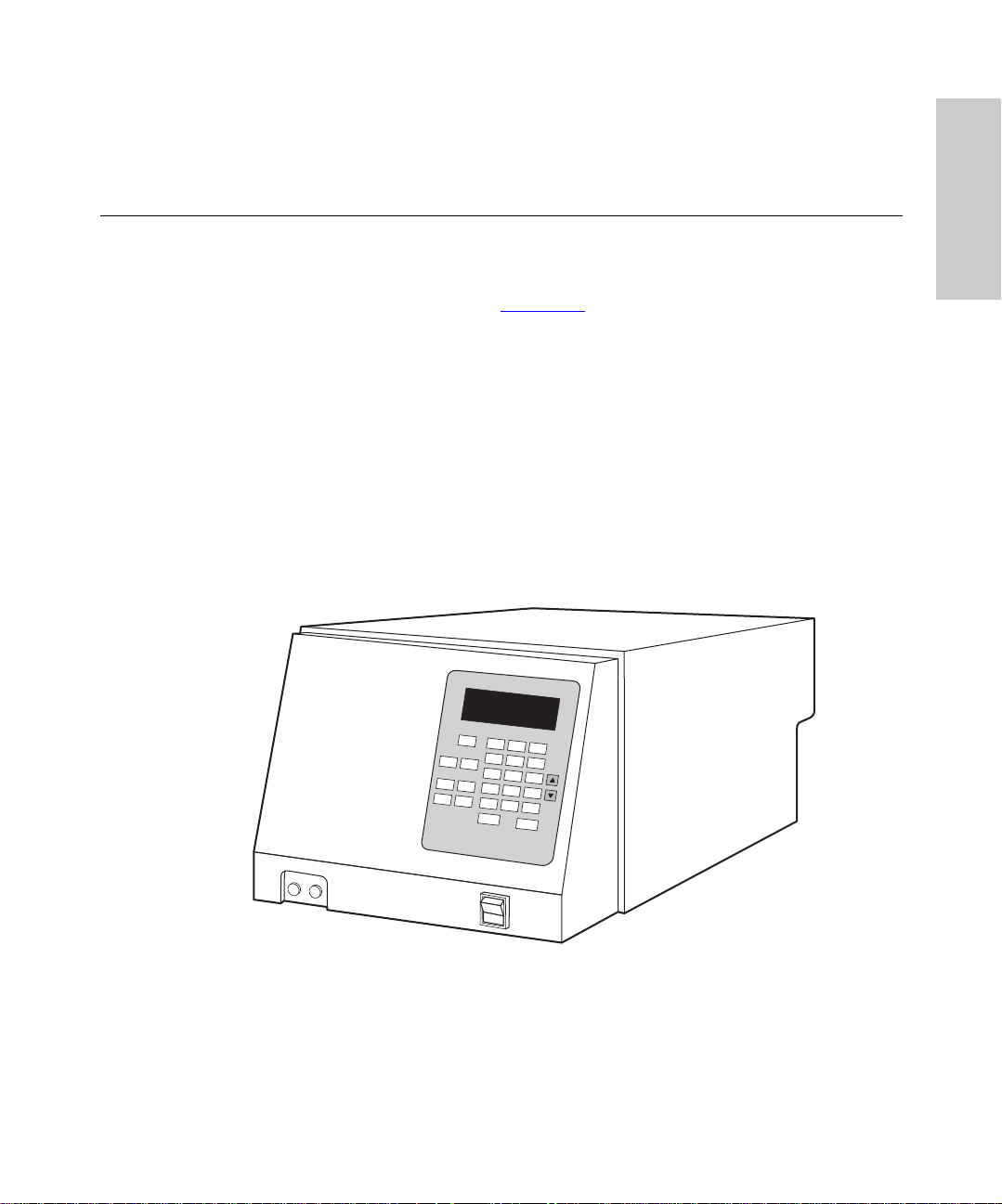

Page 26

Chapter 1 Introduction

Features

The Waters® 432 Conductivity Detector (Figure 1-1) is specifically designed to be

integrated into chromatographic systems. The following features contribute to its

performance in measuring the conductivity of column eluents:

• Unique 5-electrode flow cell design

• Heat exchanger and a built-in automatic temperature control system for stable

operation

• Auto baseline/auto zero

• External recorder/integrator and chart mark connections

• Three time constant selections

• “Leak-detected” alarm signal

W

aters 432

Conductivity Detector

1

TP01268

IN

OUT

Figure 1-1 Waters 432 Conductivity Detector

26

Page 27

Method of Operation

This section discusses the method of operation of the 432 Detector. Additional descriptive

information appears in these sections:

• Section 2.4.1,

• Section 3.1, Controls and Indicators

• Appendix A, Specifications

Measurement Technique

The 432 Detector responds to all ions present in the flow cell, since all ions in solution

conduct electricity. This allows the 432 Detector to detect a wide variety of sample ions.

The 432 Detector eliminates the eluent’s contribution to conductivity with an electronic

technique called baseline suppression. The detector measures the eluent conductivity and

assigns it a value of zero. Thus, any sample ions appear as positive or negative

measurements, relative to the baseline.

The temperature of an ionic solution affects the conductivity of the ions. Generally, a

solution’s conductivity rises about 2% for every degree Celsius of temperature increase.

The special flow cell heater in the 432 Detector minimizes the effect of ambient

temperature fluctuations on measurement accuracy .

Flow Cell Design

The flow cell in the 432 Detector contains five electrodes connected in a measuring circuit:

two reference electrodes, two detection electrodes, and a guard electrode that provides a

local electrical “ground” (Figure 1-2

set temperature, and then flows through the cell, directly contacting the electrodes. The

5-electrode design permits measurem ent of conduct ivity to be made with a very low

current at the detection electrodes. The low current employed eliminates impedance and

other problems associated with simpler designs, and results in a stable baseline and an

extended range of linearity .

I/O Signal Descriptions

). Column eluent flows through the heater to attain the

1

Introduction 27

Page 28

1

k

G

TP01271

Ion Detection Theory

1= Reference Electrodes

2= Detection Electrodes

3

Figure 1-2 Flow Cell Schematic

2

3= Guard Electrode

Flow Cell Bloc

(heated)

Fluid Outlet

1

The conductance of a solution of known concentration can be calculated using the

following equation:

λC

----------

=

G = measured conductance of the solution, in Siemens

(1 S = ohm

C = concentration in equivalents per 1000 cm

K = length/area of cell (the cell constant)

λ = equivalent conductance in S cm

Table 1-1 lists the equivalent conductances of some common ions.1 Concentrations above

−5

10

to 10−3 N, generally exhibit decreased equivalent conductance due to interionic

effects.

−1

)

10

3–

3

equiv

−1

2

28

Page 29

Table 1-1 Limiting Equivalent Conductance of Ions in Water at 25 °C

Cations

+

H

+

Li

+

Na

+

K

+

Rb

+

Ag

+

NH

4

(CH3)2NH

2+

Hg

2+

Mg

2+

Ca

2+

Ba

2+

Cu

2+

Zn

3+

La

3+

Ce

l

+

349.8 OH

38.6 F

50.1 Cl

73.5 Br

77.8 I

61.9 NO3

73.3 ClO

+

2

51.8 ClO

53.0 IO

−

−

−

−

4

Anions

−

−

−

3

−

4

−

198.6

55.4

76.4

78.1

76.8

71.5

64.6

67.4

54.5

λ

—

1

53.1 Formate 54.6

59.5 Acetate 40.9

63.6 Benzoate 32.4

2

53.6 SO

52.8 CO

69.7 Fe(CN)

−

4

2

−

3

4

−

6

80.0

69.3

111.0

69.8

1. Henry H. Bauer et al., eds. “Instrumental Analysis,” Allyn and Bacon, Boston (1978), p. 115. Reprinted

with permission from the publisher.

Introduction 29

Page 30

Chapter 2 Installing the Detector

This chapter guides you through the following steps in preparing the 432 Detector for

operation in a chromatographic system:

• Selecting an installation site that satisfies the detector’ s power and environmental

requirements

• Unpacking and inspecting the 432 Detector and accompanying items

• Connecting the detector to your AC power supply

• Connecting the detector electrically to the other components of your chromatographic

system

• Connecting the detector inlet to the column and the detector outlet to a waste

receptacle (and, if required, installing the pulse dampener)

• Passivating the detector and other post-column fluid path componen ts

After you have successfully completed this chapter, familiarize yourself with the

information in Section 3.1,

detector, perform the startup procedure described in Section 3.2,

Controls and Indicators. When you are ready to operate the

2.1 Selecting the Installation Site

Operating Environment

The 432 Detector operates in any standard laboratory environment that provides suitable

electrical power and remains within the following ranges:

• Temperatu re: 5 to 35 °C (40 to 95 °F)

• Humidity: 20 to 80%, noncondensing

Install the instrument in a clean area that is free from exposure to:

2

Startup and Shutdown.

• Temperature or humidity extremes, which can be found near direct sunlight, heat

registers, and air conditioning vents

• Strong electromagnetic radiation, such as from large motors or arcing contacts

• Appreciable shock or vibration

Selecting the Installation Site 30

Page 31

Required Space

P

The 432 Detector requires bench space that measures approximately:

• 10 inches (25 cm) high

• 14 inches (34 cm) wide

• 24 inches (60 cm) deep

Make sure that air can circulate freely through the ventilation slots on both

STO

Attention:

side panels.

Power Requirements

The 432 Detector requires:

• One properly grounded AC voltage outlet.

• Correct voltage and fuse selections as shown in Table 2-2

2.2 Unpacking and Inspection

Unpacking

The 432 Detector is shipped in one carton that contains the following items:

• Waters 432 Conductivity Detector

• Startup Kit

• Validation certificate

• Waters 432 Conductivity Detector Operator’s Gui de

• Packing list

• Declaration of conformity

2

.

If you purchased the 432 Detector as part of an ion/liquid chromatograph system, a

Note:

Waters representative will perform the installation and startup.

To unpack the 432 Detector :

1. Locate the packing list.

2. Unp ack the contents of the shipping carton and check the contents against the

packing list to make sure that you received all items.

3. Check the contents of the Startup Kit against the Waters 432 Conductivity Detector

Star tup Kit List.

4. Save the shipping carton for future transport or shipment.

Installing the Detector 31

Page 32

Inspection

Inspect all items. If you find any damage or discrepancy , immediately contact the shipping

agent and Waters. For more information about the instrument warranty, refer to Waters

Licenses, Warranties, and Support.

If the shipment is complete and undamaged, record the installation date and serial number

of the 432 Detector in the spaces provided in Appendix B,

2.3 AC Power Connection

Spare Parts.

Caution:

the voltage selector in the power connector is set correctly to match the available AC

power source, and that the correct fuses are installed before you apply AC power.

To avoid a potential fire hazard and damage to the 432 Detector, make sure that

Power Cord

The power connector is located on the lower-r ight co rner of the rear panel, as shown in

Figure 2-1

Table 2-1

. If a power pl ug other than the one supplied is needed for your location, consult

and observe the existing applicable regulations.

2

AC Power Connection 32

Page 33

IEEE DIP

Switch Cover

Figure 2-1 Rear Panel

Table 2-1 Power Cord Wire Identification

Wire (USA) Wire (International) Connection

Black Brown Hot

White Blue Neutral

Green Green/Yellow Ground (Earth)

2

The 432 Detector can be adapted to operate within two voltage ranges at 50 or 60 Hz.

Table 2-2

describes these voltage ranges and the fuse value that is appropriate to each.

Installing the Detector 33

Page 34

Table 2-2 Nominal Operating V oltage

Nominal Voltage (VAC) Fuse

100/120 T 2A

220/240 T 1A

Required Material

You need a flat-blade screwdriver to perform this procedure.

Procedure

Caution:

and unplug the power cord.

To change the operating voltage setting:

1. Remove the power cord from its connector on the rear panel of the controller and

2. Remove the voltage selection barrel and locate the correct voltage setting

3. Reinstall the voltage selection barrel so the desired voltage setting appears through

To avoid the possibility of electrical shock, turn off the front panel power switch

pry open the power connector cover with a flat-blade screwdriver.

(Figure 2-2

the window when you close the power connector cover (Figure 2-2

).

).

2

Voltage Settings

Figure 2-2 Changing the Voltage Setting

4. Determine if you need to change the fuses (see Table 2-2

with two 2-A fuses installed for 100/120 volt operation. If you operate the unit on

220/240 volt power, change the fuse as outlined in Section 5.1.1, Replacing Fuses.

5. Reins tall the power connector cover and the power cord.

). All units are supplied

AC Power Connection 34

Page 35

2.4 I/O Signal Connections

P

The 432 Detector is usually installed as an integral part of a data collection system. You

can control the 432 Detector either locally from the keypad on the front panel or remotely

from a PowerLine™ controller, such as the Waters 600S.

This section describes the detector’s I/O signals and how they connect to the following

devices:

• PowerLine controller

• Empower™ or Millennium®

• Data module

• SAT/IN™ module

• Chart recorder

• Device signalling the Chart Marker input

• Device signalling the Auto Zero input

32

soft wa r e

2

To meet the regulatory requirements of immunity from external electrical

STO

Attention:

disturbances that may affect the performance of this instrument, do not use cables longer

than 9.8 feet (3 meters) when connecting to the screw-type barrier termi nal strips. In

addition, ensure you always connect the shield of the cable to chassis ground at one

instrument only.

2.4.1 I/O Signal Descriptions

The 432 Detector rear panel has an IEEE-488 connector for communication with a

PowerLine controller, and a terminal strip (Figure 2-3

signals are described in Table 2-3.

) for the input/output signals. These

Installing the Detector 35

Page 36

+

+

–

+

–

+

–

+

–

t

INT

Int

–

+

REC

Rec

–

LEAK

Leak

+

MARKER

Marker In

IN

–

MARKER

Marker Ou

OUT

+

AUTO ZERO

Auto Zero

–

Figure 2-3 I/O Terminal Strip

Table 2-3 I/O Signal Descriptions

Terminal Pairs Function

2

Rec (+ and –)

Recorder output – A 10-mV full-scale analog output signal appears

on these terminals. The measurement range is deter mined by the

product of the Base Range and Sensitivity settings: for example,

500 µS (base range) x 0.005 (sensitivity) = 2.5 µS full sca le.

Int (+ and –)

Integrat or ou tp ut – A 1-V fu ll-scale analo g output signal appears on

these terminals. The measurement range is selectable:

10, 50, or 100 µS full scale.

Marker Ou t

Marker output – A 1-second contact closure signal appears on these

terminals when either of the following events occurs:

Leak

Auto Zero

(+ and –)

• The Char t Mark key on the keypad is pressed

• A contact closure signal occurs between the Marker In terminals

Leak Alert output – A contact closure signal appears on these termi-

nals if a leak is detected inside the detector.

Auto Zero input – The voltage at the Recorder and Integrator output

terminals is set to the user-selected balance offset level when a

contact closure occurs between these terminals.

Marker I n

(+ and –)

Marker input – A chart mark (~0.5 mV for 3 seconds) is added to the

Recorder output signal when a contact closure signal appears

between these terminals.

I/O Signal Connections 36

Page 37

Required Material

To connect cables to the I/O terminals, use a small flat-blade screwdriver.

Other Rear Panel Connections and DIP Switch

In addition to the I/O terminal strip, the rear panel also contains the following items:

• IEEE-488 connector – Communication bus for use with a Waters PowerLine system

controller, such as the Waters 600S.

• DIP switch – Sets the IEEE-488 address seen by the system controller.

• Ground lugs – Used to connect the 432 Detector to an earth ground connection and

also used as a chassis ground connection to other system instruments.

2.4.2 PowerLine Controller Connections

The 432 Detector can be programmed remotely by a PowerLine controller (such as the

Waters 600S) via the IEEE-488 data communications bus.

Required Material

You need a 2.5-mm Allen wrench to connect to the 432 Detector.

Procedure

To connect the 432 Detector to a PowerLine controller:

2

1. Turn off the PowerLine controller and the 432 Detector.

2. Plug one end of the IEEE-488 cable (included in the Start up K it) into the bus

connector on the rear panel of the 432 Detector (Figure 2-1

the cable into the bus connector on the PowerLine controller.

3. Remove the DIP switch cov er (Figure 2-1

4. R efer to Table 2-4 to set the DIP switches on the rear panel of the 432 Detector

(Figure 2-4

5. Afte r you set th e DIP swi tc hes, re in stall the DIP switch cover.

To operate the 432 Detector in local mode, press the front panel

Note:

illuminated light above the key will go out.

) to a unique IEEE-488 address between 2 and 29.

) using a 2.5-mm Allen wrench.

) and the other end of

Remote

Installing the Detector 37

key. The

Page 38

4

2

1

1 2 3 4 5

OFF

(Address 8 Shown)

Figure 2-4 IEEE-488 Address Switch

The IEEE-488 address DIP switch employs positive logic to determi ne the addre ss of the

432 Detector from the switch settings. Table 2-4

Table 2-4 IEEE-488 DIP Switch Setting

IEEE-488

Address

2 OFF ON OFF OFF OFF

3 ON ON OFF OFF OFF

4 OFF OFF ON OFF OFF

5 ON OFF ON OFF OFF

6 OFF ON ON OFF OFF

7 ON ON ON OFF OFF

8 OFF OFF OFF ON OFF

9 ON OFF OFF ON OFF

10 OFF ON OFF ON OFF

11 ON ON OFF ON OFF

12 OFF OFF ON ON OFF

13 ON OFF ON ON OFF

14 OFF ON ON ON OFF

15 ON ON ON ON OFF

16 OFF OFF OFF OFF ON

17 ON OFF OFF OFF ON

18 OFF ON OFF OFF ON

19 ON ON OFF OFF ON

1 2 3 4 5

DIP Switch Set t ings

8

16

Switch 5Switch 1

shows the settings for valid addresses.

2

I/O Signal Connections 38

Page 39

Table 2-4 IEEE-488 DIP Switch Setting (Continued)

IEEE-488

Address

20 OFF OFF ON OFF ON

21 ON OFF ON OFF ON

22 OFF ON ON OFF ON

23 ON ON ON OFF ON

24 OFF OFF OFF ON ON

25 ON OFF OFF ON ON

26 OFF ON OFF ON ON

27 ON ON OFF ON ON

28 OFF OFF ON ON ON

29 ON OFF ON ON ON

1 2 3 4 5

DIP Switch Set t ings

PowerLine Operation

Under PowerLine control, the 432 Detector is recognized as a 431 Detector and it retains

the functionality of the 431 Detector with the following differences:

• The Balance field on the detector setup page of the PowerLine controller affects the

Integrator Balance and the Integrator Output only.

• When you press the Setup key on the controller, t he selected Balance value is sent to

the 432 Detector from the PowerLi ne controller. However, the 432 Detector output

does not change to the selected balance until the detector is autozeroed by a contact

closure at the Auto Zero input terminals on the rear panel (remote or local mode) or

when you press the Auto Zero key on the front panel (local mode only).

2

Under PowerLine control, the 432 Detector retains the full functionality of local mode

operation, except for the following differences:

• The Recorder Sensitivity ranges of 0.0002 and 0.0001 are not accessible.

• The Integrator Sensitivity ranges are not accessible.

• The 432 Detector does not automatically perform an Auto Zero after an Auto Base

routine has occurred.

2.4.3 Empower and Mille nn ium32 Connections

Empower and Millennium32 software perform data acquisition, processing, and

management of chromatographic information. This software requires the detector’ s analog

signal to be converted to a digital form.

Installing the Detector 39

Page 40

Empower and Millennium32 are menu-driven applications specifically designed by Waters

for chromatographers. Use the software to:

• Acquire data

• Process d a ta

• Generate and print reports

• Store information (or data) in a central area and share this information with users who

have pr oper se cu rity acce ss

To connect the 432 Detector to an Empower or Millennium

32

computer, be sure to:

• Connect the Bus Satellite Interface (SAT/IN) module to the Bus Laboratory

Acquisition and Control/Environment (LAC/E™) card in the Empower computer,

32

Millennium

computer, acquisition client, or LAC/E32.

• Connect the 432 Detector to the Bus SAT/IN module (Channel 1 or 2).

• Remove the IEEE-488 cable from the rear panel of the 432 Detector, if it is

connected.

The 432 Detector is in local m ode when it is connec t ed to an Empower and Mille nnium

computer.

Bus S AT/IN Module

The Waters Bus SAT/IN module, shown in Figure 2-5, translates analog signals into digital

form. It then transmits these digital signals to the Bus LAC/E card inside the workstation,

acquisition client, or LAC/E

32

.

2

32

Waters SAT/IN Module

CHANNEL 1 CHANNEL 2

EVENTS

CH1

IN INOUT OUT

+ –

1 2 3 4 5 6 7 8

CH2

+ –

Figure 2-5 Bus SAT/IN Module (Front P anel)

CH1CH

OK

2

I/O Signal Connections 40

Page 41

To prevent damage to the unit, always disconnect the power cord at either the wall

Note:

outlet or the power supply before you attach or remove the power connection to the Bus

SAT/IN module. The Bus SAT/IN module does not have a power switch.

Connecting the Bus SAT/IN Module to the Bus LAC/E Card

The Bus SAT/IN module connects to the Bus LAC/E through an I/O distribution box, as

shown in Figure 2-6

To connect the Bus SAT/IN module to the Bus LAC/E card:

.

1. Use the I/O distr ibution cable to connect the I/O distribution box to the 9-pin I/O

distr ibut ion po rt on the Bus L AC/E car d a t the b ack of the Millennium

2. Use a serial cable to connect the data terminal on the back of the Bus SAT/IN to a

port of the I/O distribution box.

3. Configure the serial port for the Bus SAT/IN module as described in the Empower or

Millennium

32

installation and configuration guides.

32

computer.

2

Installing the Detector 41

Page 42

I/O Distribution

Cable

I/O Distribution Port (9-pin)

of Bus LAC/E Card

SAT/IN Module

Rear Panel

I/O Distribution Box

BCD

DATA

PWR

Serial Cable

AC to DC Converter

Modified Modular

Jack Connections

Connect SAT/IN

to Port 1 on the

I/O Distribution Box

2

Figure 2-6 Bus SAT/IN to Bus LAC/E Connections

I/O Signal Connections 42

Page 43

Connecting the Bus SAT/IN Module to the 432 Detector

P

te

Black

The Bus SAT/IN module connects to the 432 Detector as shown in Figure 2-7. Refer to the

procedure following the figure and Table 2-5

for complete details.

STO

Waters SAT/IN Module

Attention:

To prevent damage to the unit, do not plug in the power cord of the Bus

SAT/IN module until you perform all of the procedures described in the Waters B u s

SAT /IN Mo dule Installation Guide.

Waters 432 Detector

Whi

Red

Black

+

INT

–

+

REC

–

LEAK

+

MARKER

IN

–

EVENTS

CH1

CHANNEL 1 CHANNEL 2

IN INOUT OU T

+ –

1 2 3 4 5 6 7 8

CH2

+ –

CH1CH

OK

2

MARKER

OUT

+

AUTO ZERO

–

2

TP01264

Figure 2-7 Bus SAT/IN to 432 Detector Connections

To connect the 432 Detector to the Bus SAT/IN module:

1. Connect the white wire of the analog cable (included with the Bus SAT/IN module) to

the Int + terminal on the rear panel of the 432 Detector. Connect the black wire to

the Int – terminal.

2. Con nect the other end of the cable to either the Channel 1 or Channel 2 connector

on the front panel of the Bus SAT/IN module.

Installing the Detector 43

Page 44

3. Connect the Event In terminals of the channel you chose in the previous step to the

P

Inject St a rt output signal of the Waters Alliance

Waters 717plus (or equivalent) Autosampler.

4. Remove the IEEE-488 cable from the rear panel of the 432 Detector, if it is

connected.

The connections from the 432 Detector to the Bus SAT/IN are summarized in Table 2-5.

Table 2-5 Bus SAT/IN Cable Connections

®

solvent delivery system or the

432 Detector I/O

Connector Terminal

Int (+ ) White wire

Int (–) Black wire Channel 1 or 2

Bus SAT/IN

Cable

2.4.4 Data Module Connections

This section describes how to connect the analog output signal from the 432 Detector to

the Waters 746 Data Module.

Attention:

STO

electrical disturbances that may affect the performan ce of this instrument, do not use

cables longer than 9.8 feet (3 meters) when connecting to the screw-type barrier terminal

strips. In addition, ensure you always connect the shield of the cable to chassis ground.

Analog Signal

To send the analog output signal from the 432 Detector to a Waters data module, connect

the signal cable in the 432 Detector Startup Kit as described in Table 2-6

Table 2-6 Data Module Signal Cable Connections

Wire

Remember to meet the regulatory requirement s of immunity from external

432 Detector I/O

Connec tor Terminal

Bus SAT/IN

Connector

2

.

746

Terminal

Red Int (+) (+)

Black Int (– ) (–)

Shield Ground lug None

Marker Out Signal

The Marker Out terminals of the 432 Detector provide a contact closure output signal

when either of the following events occurs:

• Chart Mark key is pressed

• Marker In terminals are shorted to gether

I/O Signal Connections 44

Page 45

Use the signal to start a Waters 746 Data Module by connecting a signal cable to the

module’s data cable (Table 2-7

Table 2-7 Data Module Chart Mark Cable Connections

).

432 Detector I/O

Wire

Either wire Marker Out Join to both Remote Start

Other wire Marker Out Green wire

Connector

Terminal

2.4.5 Chart Recorder Connections

To connect the 432 Detector to a chart recorder:

1. Attach the Recorder cable (see Appendix B,

output terminals, as indicated in Table 2-8

2. Con nect the cable shield to the ground lug on the 432 Detector rear panel.

3. Con nect the other end of the cable to the 10-mV input terminals on the chart

recorder, as indicated in Table 2-8

Table 2-8 Chart Recorder Cable Connections

Wire

Red Rec (+) Pen (+)

Black Rec (–) Pen (–)

432 Detector I/O

Connector Terminal

746

Cable

wires (white and red)

2

Spare Parts) to the 432 Detector REC

.

.

Chart Recorder

Terminal

2.4. 6 Chart Marker Input Connections

The 432 Detector accepts a chart mark (start inject) signal from the following devices:

• Waters 717plus Autosampler

• Any other device that provides a compatible switch closure

Waters 717plus Autosampler

To connect the 432 Detector to a Waters 717/717plus Autosampler , connect a signal cable

as indicated in Table 2-9

.

Installing the Detector 45

Page 46

Table 2-9 Autosampler Chart Mark Cable Connections

432 Detector I/O

Connector Terminal

Marker In (+) Either Inject Start ter m inal of a pair

Marker In (–) Other Inject Start terminal of the same pair

2.4.7 Auto Zero Input Connections

The voltage at the Recorder and Integrator outputs is set to the user-selected balance

offset level when a contact closure occurs between the Auto Zero terminals. This section

describes how to connect the 432 Detector to the following devices (so that an auto zero

occurs at the injection point):

• Waters 717plus Autosampler

• Any other device that provides a compatible switch closure

Waters 717plus Autosampler

To connect the 432 Detector to a Waters 717plus Autosampler, connect a signal cable as

indicated in Table 2-10

Table 2-10 Autosampler Auto Zero Cable Connections

432 Detector I/O

Connector Terminal

.

Autosampler

Terminal

2

Autosampler

Terminal

Auto Zero (+) Either Inject Start ter m inal of a pair

Auto Zero (–) Other Inject Start terminal of the same pair

2.4.8 Alliance Separations Module Connections

Connect the detector to Waters Alliance Separations Modules, when it is not under the

control of the Millennium

• Auto-Zero on inject

• Chart mark on inject

• Method start

Generating Auto-Zero on Inject

To generate the Auto-Zero function on the 432 Detector at the start of an injection, make

the connections summarized in Table 2-11

32

softwa re, to per fo rm the foll o w i n g tasks:

and illustrated in Figure 2-8.

I/O Signal Connections 46

Page 47

Table 2-11 Connections for Generating Auto-Zero on Inject

+

–

+

–

+

–

+

–

INT

REC

LEAK

MARKER

IN

MARKER

OUT

AUTO ZERO

+

–

+

–

+

–

+

–

t

Alliance Separations Modules

(B Inputs and Outputs)

432 Detector (A Inputs)

Pin 1 Inject Start Auto-Zero (+)

Pin 2 Inject Start Auto-Zero (–)

Before you can generate an Auto-Zero from an Alliance Separations Module, you must

configure the Auto-Zero signal at the 432 Detector front panel. The default Auto-Zero

signal is Low.

Waters All iance

B (Inputs and Outputs)

Inject Start +

Inject Start –

Ground

Stop Flow

Stop Flow –

Hold Inje c t 1+

Hold Inject 1

Hold Inject 2 +

Hold Inje c t 2

Ground

Chart Ou t

Chart Out

+

+

–

–

–

Waters 432 Detector

A (Inputs)

1 Inject Start +

2 Inject Start -

3 Ground

4 Lamp On/Off +

5 Lamp On/Off -

6 Chart M a rk +

7 Char t M ark -

8 Ground

9 Auto-Zero +

10 Auto-Zero -

Int

Rec

Leak

Marker In

Marker Ou

Auto Zero

2

Figure 2-8 Alliance Separations Module Connections to the 432 Detector

Generating Char t Mark on Inject

To generate the chart mark function at the start of an injection, make the connections

summarized in Table 2-12

Auto-Zero on Inject

and illustrated in Figure 2-9.

Installing the Detector 47

Page 48

Table 2-12 Connections for Generating Chart Mark on Inject

+

–

+

–

+

–

+

–

INT

REC

LEAK

MARKER

IN

MARKER

OUT

AUTO ZERO

+

–

+

–

+

–

+

–

t

Alliance Separations Modules

(B Inputs and Outputs)

432 Detector (A Inputs)

Pin 1 Inject Start Marker In (+)

Pin 2 Inject Start Marker I n (–)

Before you can generate a chart mark from an Alliance Separations Module, you must

configure the chart mar k signa l at the front panel. The default chart mark signal is Low.

Waters All iance

B (Inputs and Outputs)

Inject Start +

Inject Start –

Ground

Stop Flow

Stop Flow –

Hold Inje c t 1+

Hold Inject 1

Hold Inject 2 +

Hold Inje c t 2

Ground

Chart Ou t

Chart Out

+

+

–

–

–

Waters 432 Detector

A (Inputs)

1 Inject Start +

2 Inject Start -

3 Ground

4 Lamp On/Off +

5 Lamp On/Off -

6 Chart M a rk +

7 Char t M ark -

8 Ground

9 Auto-Zero +

10 Auto-Zero -

Int

Rec

Leak

Marker In

Marker Ou

Auto Zero

2

Figure 2-9 Alliance Separations Module Connections to the 432 Detector

Chart Mark on Inject

2.5 Making Fluidic Connections

Fluid lines to a column and waste container connect to the front of the 432 Detector, as

shown in Figure 2-10

. To make these connections:

• Cut the tubing.

• Assemble compression fittings and ferrules.

• Connect the tubing to the detector.

Making Fluidic Connections 48

Page 49

This section will guid e you through each of these pr ocedures.

P

STO

Attention:

Conductivity detection is sensitive to flow rate fluctuations. If you use a

non-Waters pump or a Waters pump without the SILK microflow compensation algorithm,

you must install the pulse dampener kit supplied in the Startup Kit for optimum

performance. Refer to the installation procedure in this section.

W

aters 4

3

2

o

n

ductivity Dete

O

Out to Waste (18 inches,

0.009-inch I.D.)

U

T

0.009-inch ID)

c

to

r

In from Column

In From Column

C

IN

Out To Waste (18 inches.

Figure 2-10 Fluid Connections

2

Cutting Stainless Steel Tubing

You need the following tools to cut stainless steel tubing:

• A file with cutting edge

• Two cloth- or plastic-covered pliers

To cut the tubing:

1. Meas ure the length of 1/16-inch OD, 0.009-inch ID, stainless steel tubing you need

to make the following connections:

• Column to the detector inlet

• Detector outlet to a suitable waste container

2. Use a file with a cutting edge to scribe the circumference of the tubing at the desired

length.

3. G rasp the tubing on both sides of the scribe mar k with cloth-covered pliers. Gently

work the tubing back and forth until it separates.

4. File the ends smooth.

Installing the Detector 49

Page 50

Cutting Polymeric Tubing

Waters chromatography systems are supplied with a tubing cutter (similar to the one in

Figure 2-11

procedure for using the tubing cutter.

Note:

cuts leave unswept dead volumes at the connection junction due to the poor fit of the

tubing against the connector or port.

To cut a length of polymeric tubing:

1. Estima te the length of tubing required to connect the componen ts. Allow slack so

2. Insert the tubing into the cutter so that the tubing extending from the metal side is

) to facilitate cutting polymeric tubing. This section presents the recommended

To avoid bandspreading caused by angled cuts, always use a tubing cutter. Angled

that the tubing is not pulled tightly around sharp corn ers.

the length required. Use the proper hole to have a snug enough fit so that the tubing

is not flexed by the blade when you cut it.

2

Figure 2-11 Cutting Polymeric Tubing

3. Pres s down on the razor blade to cut the tubing (Figure 2-11

tubing that extends from the clear side of the cutter.

4. Inspec t the cut for burrs or scratches and for the perpendiculari ty of the cut.

). Discard the excess

Assembling Compression Fittings

To assemble each compression fitting:

1. Slide the com pression screw over the tubing end, followed by the ferrule

(Figure 2-12

2. Mount the ferrule with its taper end facing the end of the tubing (Figure 2-12

).

Making Fluidic Connections 50

).

Page 51

Compression

Compression

Screw

Screw

0.009-inch I D Tubing

0.009-inch I.D. Tubing

(0.23 mm)

(0.23 mm)

Figure 2-12 Ferrule and Compression Screw Assembly

Ferrule

Ferrule

Connecting to the 432 Detector

To make connections at the column outlet and detector inlet, and at the detector outlet:

1. Insta ll a compression screw and then a ferrule on the length of 0.009-inch tubing

from the column outlet. Use stainless steel fittings on stainless steel tubing and

PEEK fittings on PEEK tubing.

If you are using a column with 1/4–28 end fittings and there is a length of

Note:

tubing with 1/4–28 fittings on each end, use the 1/4–28 to Z-detail adapter (included

in the Startup Kit) to connect this tubing to the tubing that leads to the detector inlet.

The Waters IC-Pak C column comes supplied with a length of tubing that has a

1/4–28 fitting on one end (column outlet) and a Waters compression screw and

ferrule on the other end (detector inlet).

2

2. Push the free end of the tubing as far as it will go into the IN fitting on the 432

Detector. While you hold it there, use a 5/16-inch open-end wrench to tighten the

compression screw 3/4-turn past finger-tight.

The 432 Detector and IC-Pak series of columns have very deep ferrules.

Note:

3. Remove the compression screw and tubing from the connection and verify that fluid

can flow freely.

4. Reconnect the tubing to the IN fitting, making sure to push the tubing all the way into

the fitting.

5. Install a ferrule on an 18-inch length of 0.009-inch tubing and connect it to the OUT

connection on the 432 Detector. Use stainless steel fittings on stainless steel tubing

and PEEK fittings on PEEK tubing.

6. Place t he other end of the tube in a waste container. If you are using any Teflon

tubing, attach it after the stainless steel or PEEK tubing.

Installing the Detector 51

Page 52

Installing the Pulse Dampener

To achieve the best performance from the 432 Detector in a chromatographic system with

a non-Waters pump, Breeze™ software, or Waters HPLC 515 Pump, you must install the

pulse dampener kit supplied in the Startup Kit. The pulse dampe ner is not required if you

are using a Waters 2695 Separations Module.

To install the pulse dampener betwee n the pump and the injector:

1. Assemble the pulse dampener (Figure 2-13

dampener kit.

2. Con nect the large-ID (0. 020-inch) tubing to the pump outlet using a stainless steel

compression screw and ferrule.

3. Con nect the small-ID (0.009-inch) tubing to the injector inlet using a stainless steel

compression screw and ferrule.

4. Disconnect the tubing from the injector inlet.

5. Pum p AST M Type I reagent water at £ 2 mL/min through the pulse dampener

assembly until you see a constant stream exiting from the restrictor assembly outlet

line.

6. Reconnect the tubing to the injector inlet.

) using the instructions in the pulse

2

Making Fluidic Connections 52

Page 53

P

y

y

0.020-inch I.D.

i

r

0.009-inch I D

Tubing

F

Restrictor

Assembly

0.020-inch I D

Tubing

Tubing

0.009-

Tubing

nch I.D.

From Pum p

rom Pum p Union To Injector

Low Pressure

Low Pressure

Filter Assembly

Filter Assembl

Figure 2-13 Pulse Dampener

2.6 Passivating the System

Union

To Injecto

2

Restrictor

Assembl

STO

Passiv ating the system removes potential contamination from the wetted surfaces of all

system components. Perform pas sivation on a new system, and subsequently, whenever

you suspect that contamination may have occurred. See Section 5.3,

help diagnosing performance problems.

Use this procedure for Waters hardware only. For other equipment, check with the

manufacturer before you continue with this procedure.

Attention:

the pump seals before you passivate. Use the new pump seals supplied in the Startup Kit

and refer to the replacemen t procedure in the pump manual.

If you are installing the 432 Detector into an existing Waters system, replace

Installing the Detector 53

Troubleshooting, for

Page 54

To passivate the system:

1. Rep lace the column with a union fitting.

2. If the system is not new, flush it thoroughly with ASTM Type I reagent water to

remove any residual solvents or salts.

3. Con nect the power cord to the 432 Detector and plug the other end into an AC

power outlet. Push the 432 Detector power switch to tur n on the instrum ent .

Caution:

when you are using solvents.

4. Prime the pump with 6 N nitric acid (HNO

20 minutes to passivate all the wetted parts of the detector. Press the Clear key to

stop the overrange alarm.

5. St op the pump.

6. Remove the inlet line from the nitric acid and place it in ASTM Type I reagent water .

7. Flush the system using one of the following methods:

• Prime and start the pump, then flush it with ASTM Type I reagent water at

1.2 mL/min until you observe a consistent reading of less than 20 µS (base range

set to 50 µS).

• Flush the system overnight with 100% methanol at a reduced flow rate. By the

next morning the system will be passivated and ready for use.

If you are using a pump with seal-wash capability, skip step 8.

Note:

8. Use a syr inge to flush the back of the pump seals and pistons by slowly running

about 5 mL of water into the top hole in the baseplate of the pump heads. Place a

tissue under the baseplates to absorb the water .

9. Set the pump flow rate to 0.0 mL/mi n. It is not nec essary to turn off the 432 Dete ctor

unless it will be idle for an extended period (14 days).

To avoid chemical hazards, alwa ys wear safety glasses and gloves

) and run it at a flow rate of 1.2 mL/min for

3

2

For best results, alw ays leave the power on to main t a in c e ll temperature ; it takes a

minimum of 2 to 3 hours once the detector is turned on to equilibrate the flow cell at the

selected operating temperature.

2.7 Verifying the Detector

This procedure is a guideline for verifying that the detector works correctly within its

expected operational range. The detector is calibrated before shipping, and recalibration is

not normally required.

Verifying the Detector 54

Page 55

Verify the detector when any of these conditions apply:

• When you replace the flow cell

• To verify accuracy

• When you make adjustments

Calibration Procedure

You need solution of 1 mM potassium chloride (KCl) to calibrate the detector.

Note:

Waters suggests one of its Technical Service Representatives perform this

Note:

procedure.

1. Turn on the 432 Detector and set the temperature control to 35 °C. Allow 2 to 3

hours for the temperature in the flow cell to equilibrate.

2. Set the base range to 200 µS.

3. Set the Filter Time Response to Fast.

4. Pump 1 mM KCl solution through the detector (without a column in place).

5. Verify that the front panel output is 147 µS ± 5 µS.

2

Installing the Detector 55

Page 56

Chapter 3 Operating the Detector

This chapter contains:

• A description of front panel controls and displays

• Procedures for starting up, shutting down, and long-term storage

• Recommended operating practices

3.1 Controls and Indicators

Figure 3-1 illustrates the controls and indicators on the front panel of the 432 Detector.

Waters 432

Conductivity Detector

274 500 0.0005

CONDUCT

( S/cm)

BASE

( S/cm/FS)

3

SENS

IN OUT

Auto

Base

Base

Range

Resp.

Figure 3-1 Front Panel

Remote

Chart

Mark

89

56

23

.

Clear

EnterShift

Auto

Zero

Sens.

Range

Bal.

Temp. Pol.

7

4

1

0

ON

OFF

Controls and Indicators 56

Page 57

Power Switch

The power switch ( located in the lower-right corner of the front panel) controls power to the

432 Detector. Upon startup, an initialization routine verifies the data in ROM memory, tests

RAM memory function, and checks for any internal leakage or an eluent conductivity

over-range condition.

Display

The display shows instrument status and parameter values in two 20-character lines of

text. Upon startup, Waters 432 Self Check appears briefly. If any error conditions are

detected during start up or normal operation, the appropriate error message is displayed.

The main screen shows the measured conductivity, as well as the base range and

sensitivity settings. When you set an operating parameter, the display shows the selected

or entered value.

Error Messages

A corresponding error message is displayed if one of the following conditions occurs:

• ROM/RAM error (checked during startup only)

Error: ROM/RAM

• Leakage detected

Error: Leak

3

• Temperature control fail ure

Error: Temp

• Over-range (above base range setting)

Error: Over Range

• Overflow (above 10,000 µS)

Error: Over Flow

Press the Clear key to clear an error alarm and message. For a continuing error condition,

the error message remains after the audio alarm is cleared.

Keypad

Use the keypad to control the operation of the 432 Detector. Table 3-1 describes the

function of each key.

Operating the Detector 57

Page 58

Three keys (Balance, Sensitivity Range, and the numeral 1) perform an alternate

Note:

function when they are preceded by the Shift key.

Table 3-1 Key Descriptions

Key Function

Remote key: Toggles betwee n local and remote operating mode s. In

Remote

Pol.

Base Range

Sens.

Range

remote mode, the light above the key is on and all other front panel

controls are disabled.

Polarity key: Toggles the polarity of the signal to the external chart

recorder and integrator. When positive polarity is selected, the light

above the key is illuminated.

Base Range key: Sets the base sensitivity range of the 432 Detector to

the appropriate value for the eluent being used. The base sensitivity is

set to one of ten steps, from 10 µS (maximum gain) to 10,000 µS, using

the Up and Down keys or the numeric keypad.

Sensitivity Range key: Sets the sensitivity range multiplier of the 432

Detector. The sensitivity range has twelve steps, from 0.0001 (maximum

sensitivity) to 1.0 (avai lable onl y with 100µS multiplier setting), and is set

using the Up and Down keys or the numeric keypad. The 10-mV

full-scale recorder response is calculated by multiplying the Base Range

by the Sensitivity Range to obtain a value of “x” µS / 10 mV FS. The

recorder range is 1 to 0.0001 for the 100 µS setting and 0.1 to 0.0001 for

the two lower settings.

3

Bal.

Temp.

Shift key then Sensitivity Range key: Sets the sensitivity range multiplier of the integrator to 100, 50, or 10 µS using the Up and Down keys or