Page 1

Waters 2996

et

7

C

PDA Detector

Operator’s Guide

34 Maple Stre

Milford, MA 01 75

71500023202, Revision

Page 2

NOTICE

The information in this document is subject to change without notice and should not be

construed as a commitment by Waters Corporation. Waters Corporation assumes no

responsibility for any errors that may appear in this document. This document is believed

to be complete and accurate at the time of publication. In no event shall Waters

Corporation be liable for incidental or consequential damages in connection with, or

arising from, the use of this docum ent.

© 2001 WATERS CORPORATION. PRINTED IN THE UNITED STATES OF

AMERICA. ALL RIGHTS RESERVED. THIS DOCUMENT OR PARTS THEREOF

MAY NOT BE REPRODUCED IN ANY FORM WITHOUT THE WRITTEN

PERMISSION OF THE PUBLISHER.

Millennium, PIC, and Waters are register ed t rad emar ks, and busLAC/E and PowerStation

are trademarks of Waters Corporation.

Micromass is a registered trademark, and MassLynx is a trademark of Micromass Ltd.

All other trademarks or registered trademarks are the sole property of their respective

owners.

Page 3

STOP

Note: When you use the instrument, follow generally accepted procedures for quality

control and methods development.

If you observe a change in the retention of a particular compound, in the resolution

between two compounds, or in peak shape, immediately determine the reason for the

changes. Until you determine the cause of a change, do not rely on the separation results.

Note: The Installation Category (Overvoltage Category) for this instrument is Level II. The

Level II Category pertains to equipment that receives its electrical power from a local level,

such as an electrical wall outlet.

Attention: Changes or modifications to this unit not expressly approved by the party

responsible for compliance could void the user’s authority to operate the equipment.

Important : Toute modification sur cette unité n’ayant pas été expressément approuvée

par l’autorité responsable de la conformité à la réglementation peut annuler le droit de

l’utilisateur à exploiter l’équipement.

Achtung: Jedwede Änderungen oder Modifikationen an dem Gerät ohne die

ausdrückliche Genehmigung der für die ordnungsgemäße Funktionstüchtigkeit

verantwortlichen Personen kann zum Entzug der Bedienungsbefugnis des Systems

führen.

Avvertenza: eventuali modifiche o alterazioni apportate a questa unità e non

espressamente approvate da un ente responsabile per la conformità annulleranno

l’autorità dell’utente ad operare l’apparecchiatura.

Atención: cualquier cambio o modificación realizado a esta unidad que no haya sido

expresamente aprobado por la parte responsable del cumplimiento puede anular la

autorización de la que goza el usuario para utilizar el equipo.

Page 4

Caution: Use caution when working with any polymer tubing under pressure:

• Always wear eye protection when near pressurized polymer tubing.

• Extinguish all nearby flames.

• Do not use Tefzel tubing that has been severely stressed or kinked.

• Do not use Tefzel tubing with tetrahydrofuran (THF) or concentrated nitric

or sulfuric acids.

• Be aware that methylene chloride and dimethyl sulfoxide cause Tefzel

tubing to swell, which greatly reduces the rupture pressure of the tubing.

Attention : soyez très prudent en travaillant avec des tuyaux de polymères sous

pression :

• Portez toujours des lunettes de protection quand vous vous trouvez à

proximité de tuyaux de polymères.

• Eteignez toutes les flammes se trouvant à proximité.

• N'utilisez pas de tuyau de Tefzel fortement abîmé ou déformé.

• N'utilisez pas de tuyau de Tefzel avec de l'acide sulfurique ou nitrique, ou

du tétrahydrofurane (THT).

• Sachez que le chlorure de méthylène et le sulfoxyde de diméthyle

peuvent provoquer le gonflement des tuyaux de Tefzel, diminuant ainsi

fortement leur pression de rupture.

Vorsicht: Bei der Arbeit mit Polymerschläuchen unter Druck ist besondere Vorsicht

angebracht:

• In der Nähe von unter Druck stehenden Polymerschläuchen stets

Schutzbrille tragen.

• Alle offenen Flammen in der Nähe löschen.

• Keine Tefzel-Schläuche verwenden, die stark geknickt oder

überbeansprucht sind.

• Tefzel-Schläuche nicht für Tetrahydrofuran (THF) oder konzentrierte

Salpeter- oder Schwefelsäure verwenden.

• Durch Methylenchlorid und Dimethylsulfoxid können Tefzel-Schläuche

quellen; dadurch wird der Berstdruck des Schlauches erheblich

reduziert.

Page 5

Precauzione: prestare attenzione durante le operazioni con i tubi di polimero sotto

pressione:

• Indossare sempre occhiali da lavoro protettivi nei pressi di tubi di

polimero pressurizzati.

• Estinguere ogni fonte di ignizione circostante.

• Non utilizzare tubi Tefzel soggetti a sollecitazioni eccessive o incurvati.

• Non utilizzare tubi Tefzel contenenti tetraidrofurano (THF) o acido

solforico o nitrico concentrato.

• Tenere presente che il cloruro di metilene e il dimetilsolfossido

provocano rigonfiamento nei tubi Tefzel, che riducono notevolmente il

limite di pressione di rottura dei tubi stessi.

Advertencia: manipular con precaución los tubos de polimero bajo presión:

• Protegerse siempre los ojos a proximidad de tubos de polimero bajo

presión.

• Apagar todas las llamas que estén a proximidad.

• No utilizar tubos Tefzel que hayan sufrido tensiones extremas o hayan

sido doblados.

• No utilizar tubos Tefzel con tetrahidrofurano o ácidos nítrico o sulfúrico

concentrados.

• No olvidar que el cloruro de metileno y el óxido de azufre dimetilo inflan

los tubos Tefzel lo que reduce en gran medida la presión de ruptura de

los tubos.

Page 6

Caution: The user shall be made aware that if the equipment is used in a manner not

specified by the manufacturer, the protection provided by the equipment may be impaired.

Attention : L’utilisateur doit être informé que si le matériel est utilisé d’une façon non

spécifiée par le fabricant, la protection assurée par le matériel risque d’être défectueuses.

Vorsicht: Der Benutzer wird darauf aufmerksam gemacht, dass bei unsachgemäßer

Verwenddung des Gerätes unter Umständen nicht ordnungsgemäß funktionieren.

Precauzione: l’utente deve essere al corrente del fatto che, se l’apparecchiatura viene

usta in un modo specificato dal produttore, la protezione fornita dall’apparecchiatura

potrà essere invalidata.

Advertencia: El usuario deberá saber que si el equipo se utiliza de forma distinta a la

especificada por el fabricante, las medidas de protección del equipo podrían ser

insuficientes.

Caution: To protect against fire hazard, replace fuses with those of the same type and

rating.

Attention : Remplacez toujours les fusibles par d’autres du même type et de la même

puissance afin d’éviter tout risque d’incendie.

Vorsicht: Zum Schutz gegen Feuergefahr die Sicherungen nur mit Sicherungen des

gleichen Typs und Nennwertes ersetzen.

Precauzione: per una buona protezione contro i rischi di incendio, sostituire i fusibili con

altri dello stesso tipo e amperaggio.

Precaución: sustituya los fusibles por otros del mismo tipo y características para evitar

el riesgo de incendio.

Page 7

Caution: To avoid possible electrical shock, power off the instrument and disconnect the

power cord before servicing the instrument.

Attention : Afin d’éviter toute possibilité de commotion électrique, mettez hors tension

l’instrument et débranchez le cordon d’alimentation de la prise avant d’effectuer la

maintenance de l’instrument.

Vorsicht: Zur Vermeidung von Stromschlägen sollte das Gerät vor der Wartung

abgeschaltet und vom Netz getrennt werden.

Precauzione: per evitare il rischio di scossa elettrica, spegnere lo strumento e

scollegare il cavo di alimentazione prima di svolgere la manutenzione dello strumento.

Precaución: para evitar choques eléctricos, apague el instrumento y desenchufe el

cable de alimentación antes de realizar cualquier reparación en el instrumento.

Page 8

Commonly Used Symbols

Direct current

Courant continu

Gleichstrom

Corrente continua

Corriente continua

Alternating current

Courant alternatif

Wechselstrom

Corrente alternata

Corriente alterna

Protective conductor terminal

Borne du conducteur de protection

Schutzleiteranschluss

Terminale di conduttore con protezione

Borne del conductor de tierra

Frame or chassis term inal

Borne du cadre ou du châssis

Rahmen- oder Chassisanschluss

Terminale di struttura o telaio

Borne de la estructura o del chasis

Caution or refer to manual

Attention ou reportez-vous au guide

Vorsicht, oder lesen Sie das Handbuch

Prestare attenzione o fare riferimento alla guida

Actúe con precaución o consulte la guía

Caution, hot surface or high temperature

Attention, surface chaude ou température élevée

Vorsicht, heiße Oberfläche oder hohe Temperatur

Precauzione, superficie calda o elevata temperatura

Precaución, superficie caliente o temperatura elevada

Page 9

Commonly Used Symbols (Continued)

Caution, risk of electric shock (high voltage)

Attention, risque de commotion électrique (haute tension)

Vorsicht, Elektroschockgefahr (Hochspannung)

Precauzione, rischio di scossa elettrica (alta tensione)

Precaución, peligro de descarga eléctrica (alta tensión)

Caution, risk of needle-stick puncture

Attention, risques de perfor at io n de la tail le d’u n e aigu il le

Vorsicht, Gefahr einer Spritzenpunktierun g

Precauzione, rischio di puntura con ago

Precaución, riesgo de punción con aguja

Caution, ultraviolet light

UV

Attention, rayonnement ultrviolet

Vorsicht, Ultraviolettes Licht

Precauzione, luce ultravioletta

Precaución, emisiones de luz ultravioleta

Page 10

2996 PDA Detector Information

Intended Use

The Waters® 2996 PDA Detector can be used for in-vitro diagnostic testing to analyze

many compounds, including diagnostic indicators and therapeutically monitored

compounds. When you develop methods, follow the “Protocol for the Adoption of

Analytical Methods in the Clinical Chemistry Laboratory,” American Journal of

Medical Technology, 44, 1, pages 30–37 (1978). This prot ocol covers good operating

procedures and techniques necessary to validate system and method performance.

Biological Hazard

When you analyze physiological fluids, take all necessary precautions and treat all

specimens as potentially infectious. Precautions are outlined in “CDC Guidelines on

Specimen Handling,” CDC – NIH Manual, 1984.

Calibration

Follow acceptable methods of calibration with pure standards to calibrate methods. Use a

minimum of five standards to generate a standard curve. The concentration range should

cover the entire range of quality-control samples, typical specimens, and atypical

specimens.

Quality Control

Routinely run three quality-control samples. Quality-control samples should represent

subnormal, normal, and above-normal levels of a compound. Ensure that quality-control

sample results are with in an ac cept ab le range, and evaluate precision from day to day and

run to run. Data collected when qua lity- contr ol samp les are out of range may not be val id.

Do not report this data until you ensure that chromatographic system performance is

acceptable.

General Maintenance

To clean the outside of the Waters 2996 PDA Detector, use only a soft lint-free paper or

cloth dampened with mild soap and water.

Page 11

Table of Contents xi

Preface................................................................................................................ xix

Chapter 1

Installation

........................................................................................................... 1

1.1 Installation Site Requirements .......................................................................... 1

1.2 Power Connections............................................................................................ 2

1.3 Millennium32 Workstation Connections ........................................................... 3

1.3.1 Connecting the IEEE-488 Cable.......................................................... 4

1.3.2 Setting the IEEE-488 Address ............................................................ 5

1.4 Non-IEEE-488 Communication Connections................................................... 6

1.4.1 Connecting Analog Output Cables ...................................................... 6

1.4.2 Connecting Event Cables .................................................................... 7

1.5 Fluidic Connections........................................................................................... 9

1.6 Starting Up and Shutting Down the Detector.................................................. 11

Chapter 2

Diagnostics and Calibration

.......................................................................... 15

2.1 Diagnostics...................................................................................................... 15

2.2 User-Initiated Diagnostics............................................................................... 17

2.3 PDA Calibration.............................................................................................. 18

Chapter 3

Maintenance

...................................................................................................... 19

3.1 Flow Cell Maintenance ................................................................................... 19

3.1.1 Flushing the Flow Cell....................................................................... 20

3.1.2 Removing the Flow Cell ................................................................... 20

3.1.3 Disassembling and Cleaning the Flow Cell ...................................... 22

3.1.4 Installing the Flow Cell Assembly .................................................... 24

Table of Contents

Page 12

xii Table of Contents

3.2 Replacing the Lamp ........................................................................................ 25

3.3 Replacing the Fuses......................................................................................... 27

Chapter 4

Principles of the 2996 PDA Detector Optics

.............................................. 29

4.1 2996 Detector Optics....................................................................................... 29

4.2 Resolving Spectral Data.................................................................................. 31

4.3 Measuring Light at the Photodiode................................................................. 32

4.4 Computing Absorbance Data Points............................................................... 35

4.4.1 Calculating Absorbance..................................................................... 35

4.4.2 Resolution ......................................................................................... 38

4.4.3 Filtering Data .................................................................................... 38

Chapter 5

Spectral Contrast Theory

.............................................................................. 41

5.1 Comparing Absorbance Spectra...................................................................... 41

5.2 Representing Spectra as Vectors ..................................................................... 42

5.2.1 Vectors Derived from Two Wavelengths .......................................... 43

5.2.2 Vectors Derived from Multiple Wavelengths ................................... 43

5.3 Spectral Contrast Angles................................................................................. 44

5.4 Undesirable Effects ......................................................................................... 47

5.4.1 Detector Noise ................................................................................... 47

5.4.2 Photometric Error ............................................................................. 48

5.4.3 Solvent Changes ............................................................................... 48

5.4.4 Threshold Angle ............................................................................... 48

Page 13

Table of Contents xiii

Appendix A

Detector Specifications

................................................................................... 51

Appendix B

Spare Parts

........................................................................................................ 53

Appendix C

Mobile Phase Absorbance

.............................................................................. 55

Index ................................................................................................................... 59

Page 14

xiv Table of Contents

Page 15

List of Figures xv

1-1 Waters 2996 PDA Detector Dimensions.................................................... 2

1-2 Detector Rear Panel ................................................................................... 3

1-3 Example of IEEE-488 Cable Connections................................................. 4

1-4 Locating the IEEE-488 Switches............................................................... 5

1-5 Analog Out Terminal Strip......................................................................... 7

1-6 Event Input/Output Terminal Strip ............................................................ 8

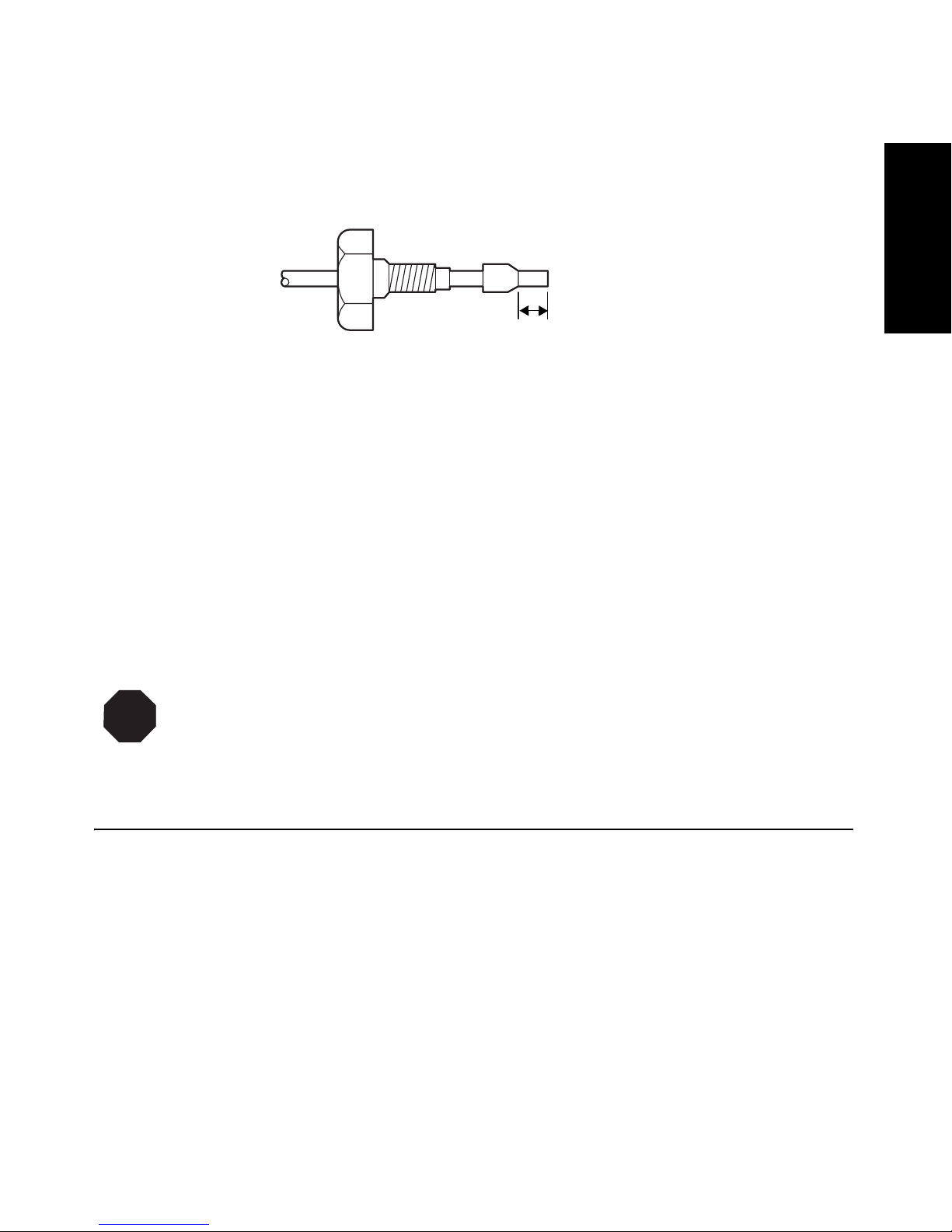

1-7 Compression Screw Assembly ................................................................ 11

1-8 2996 Detector Indicator Lights................................................................ 12

3-1 Removing the Flow Cell Assembly......................................................... 21

3-2 Flow Cell and Fluidic Connections Assemblies...................................... 22

3-3 Disassembling the Flow Cell................................................................... 23

3-4 Lamp Power Connector and Mounting Screws....................................... 26

3-5 Fuse Block ............................................................................................... 27

4-1 Optics Assembly Light Path.................................................................... 30

4-2 Benzene Spectrum at 1.2 nm Resolution................................................. 32

4-3 Photodiodes Discharged by Light............................................................ 33

4-4 Absorbance as a Function of Concentration............................................ 36

5-1 Comparing Spectra of Two Compounds.................................................. 42

5-2 Plotting Vectors for Two Spectra............................................................. 43

5-3 Spectra with a Large Spectral Contrast Angle......................................... 45

5-4 Spectra with a Small Spectral Contrast Angle......................................... 46

5-5 Absorbance Spectra of a Compound at Two Concentrations .................. 47

5-6 Effects of pH and Solvent Concentration on the Absorbance Spectrum of

p-Aminobenzoic Acid ............................................................................. 49

List of Figures

Page 16

xvi List of Figures

Page 17

List of Tables xvii

1-1 Site Requirements..................................................................................... 1

1-2 Event In Terminal Specifications on TTL or Switch Closure................... 9

1-3 Event Out Terminal Specifications on Contact Closure ........................... 9

1-4 LED Indicator Sequences During Startup............................................... 12

2-1 2996 Detector Troubleshooting .............................................................. 15

4-1 Optics Assembly Components................................................................ 30

A-1 2996 Detector Specifications.................................................................. 51

B-1 Spare Parts.............................................................................................. 53

C-1 Mobile Phase Absorbance Measured Against Air or Water................... 55

List of Tables

Page 18

xviii List of Tables

Page 19

xix

Preface

The Waters 2996 PDA Detector Operator’s Guide describes the p rocedures for installi ng,

maintaining, and troubleshooting the Waters

®

2996 PDA Detector. It also describes

detector optics and th e principle s of Spectral Contrast used in the Millenni um®

32

software

for analyzing the data from the PDA detector. Also included is information on vector

analysis, mobile phase absorbance, specifications.

This guide is intended for individuals who need to install, operate, maintain, and

troubleshoot the 2996 PDA Detector. It is also intended for users who need to understand

the Spectral Contrast principles underlying the processing of PDA Detector data by

Millennium

32

software.

Organization

This guide contains the following:

Chapter 1 describes how to install and set up the 2996 Detector.

Chapter 2 describes how to troubleshoot the 2996 Detect or.

Chapter 3 describes how to replace the flow cell, the lamp, and the fuse.

Chapter 4 explains the principles involved in resolving spectral data, measuring light

at the photodiode, verifying wavelengths, and computing absorbance data.

Chapter 5 describes the calculations used for Spectral Contrast.

Appendix A provides the specifications of the 2996 PDA Detector.

Appendix B lists recommended spare parts.

Appendix C provides a table of absorbances at several wavelengths for common

mobile phases.

Related Documentation

W at ers Li censes , Warranties, and Supp ort: Provi des software lic ense and warranty

information, describes training and extended support, and tells how Waters handles

shipments, damages, claims, and returns.

Millennium

32

Help: Describes al l Millennium32 windows, menus, menu selections,

and dialog boxes. Also includes reference information and procedures for performing

Page 20

all tasks required to use the Millennium32 software. Included as part of the

Millennium

Millennium

Millennium

32

software.

32

Software Ge tting Started Guide : Provides an introduction to the

32

System. Describes the basics of how to use Millennium32 software to

acquire data, develop a processing method, review results, and print a report. Also

covers basics for managing projects and configuring systems.

Millennium

to use Millennium

32

PDA Software Ge tting Started Guide : Describes the basics of how

32

PDA software to dev elop a PDA proces sing method an d to review

PDA results.

32

Millennium

Millennium

System Installation an d Configu ration Gui de: Describes

32

software installation, including the stand-alone workstation,

PowerStation™ system, and client/server system. Discusses how to configure the

computer and chromatographic instruments as part of the Millennium

covers the installation, config uration, a nd use of ac quisition s e rvers such as the

LAC/E

32

module, the busLAC/E card, and interface cards used to com municate with

serial instruments

Water s 29 96 PD A De tector Qual ificati on Workbook: Describes qualification

procedures for the 2996 PDA Detector.

Documentation Conventions

The following conventions may be used in this guide:

Convention Usage

32

system . Also

Bold Bold indicates user action such as keys to press, menu selections,

Italic Italic indicat es infor mation that you s upply such as varia bles. It also

Courier

Courier Bold

xx

and commands. For example, “Click Next to go to the next page.”

indicates emphasis and document titles. For example, “Replace

file_name with the actual name of your file.”

Courier indicates examples of source code and system output. For

example, “The

SVRMGR> prompt appears.”

Courier bold indicates characters that you type or keys you press in

examples of source code. For example, “At the

enter

set password oracle to access Oracle.”

LSNRCTL> prompt,

Page 21

Convention Usage

Keys The word key refers to a computer key on the keypad or keyboard.

Screen keys refer to the key s on the instrument located im mediately

below the screen. For example, “The A/B screen key on the 2414

Detector displays the selected channel.”

… Three periods indicate that more of the same type of item can

optionally follow. For example, “You can store filename1,

filename2, … in each folder.”

> A right arrow between menu options indicates you should choose

each option in sequence. For example, “Select File > Exit” me ans

you should selec t File from the menu bar, then select Exit from the

File menu.

Notes

Notes call out information that is helpful to the operator. For example:

Note: Record your result before you proceed to the next step.

Attentions

Attentions provide information about preventing possible damage to the system or

equipment. For example:

Attention: To avoid damaging the detector flow cell, do not touch the flow cell

STOP

Cautions

window.

Cautions provide information essential to the safety of the operator. For example:

Caution: To avoid possible burns, turn off the lamp at least 15 minutes before

removing it for replacement or adjustment.

Caution: To avoid possible electrical shock and injury, always turn off the detector

and unplug the power cord before performing maintenance procedures.

Caution: To avoid chemical or electrical hazards, always observe safe laboratory

practices when operating the system.

xxi

Page 22

xxii

Page 23

Installation Site Requirements 1

1

Chapter 1

Installation

The Waters® 2996 Photodiode Array (PDA) Detector operates in any standard laboratory

environment. The detector requires electrical power, sample and wast e fluidic lines, and

either the Millennium®

32

or MassLynx™ workstations. Optional connections on the

detector rear panel allow communication with chart recorders, data integrators, and other

instruments that are not compatible with Millennium

32

or MassLynx software control.

1.1 Installation Site Requirements

Install the 2996 PDA Detector at a site that meets the specifications in Table 1-1 and

Figure 1-1.

Table 1-1 Site Requirements

Factor Specification

Ambient temperature 4 to 40 °C (39 to 104 °F), not to vary more

than 1 °C per hour (to prevent drift)

Relative humidity 20 to 80%, noncondensing

Bench space Width: 11.5 in. (29 cm)

Depth: 24 in. (61 cm)

Height: 8.5 in. (22 cm)

Bench support Capable of supporting 31.5 pounds (14.3 kg)

Clearance At least 4 in. (10 cm) on the back side for

ventilation

Power Grounded ac, 100 to 240 Vac

Page 24

1

11.5 in. (29 cm)

WATERS 996

Photodiode Array

8.5 in.

(22 cm)

24 in.

(61 cm)

Sample Outlet

Figure 1-1 Waters 2996 PDA Detector Dimensions

1.2 Power Connections

Ensure that power connections for the 2996 PDA Detector are made according to the

procedures that follow.

Operating Voltage

The 2996 PDA Detector has a universal input power supply that requires no voltage

adjustmen t. The electrical power requiremen ts for the Waters 2996 PDA De tector are:

LAMP

Sample Inlet

Drain Line

• Voltage range: 100 to 240 Vac

• Total power: 100 VA

• Frequency range: 50 to 60 Hz

Fuses

The 2996 PDA Detector is shipped with fuses rated for North American operation. If you

operate the 2996 P DA Detect or in anot her loca tion, install t he IEC-rat ed fuses (supplie d in

2Installation

Page 25

Millennium32 Workstation Connections 3

1

the Waters 2996 Detector St ar tup Kit ) in the fu se h older in the rear of the de tecto r (re fer t o

Section 3.3, Replacing the Fuses).

Connecting the Power Cord

Connect one end of the 2996 Detector power cord to the rear panel power receptacle

(Figure 1-2) and the other end to a power outlet.

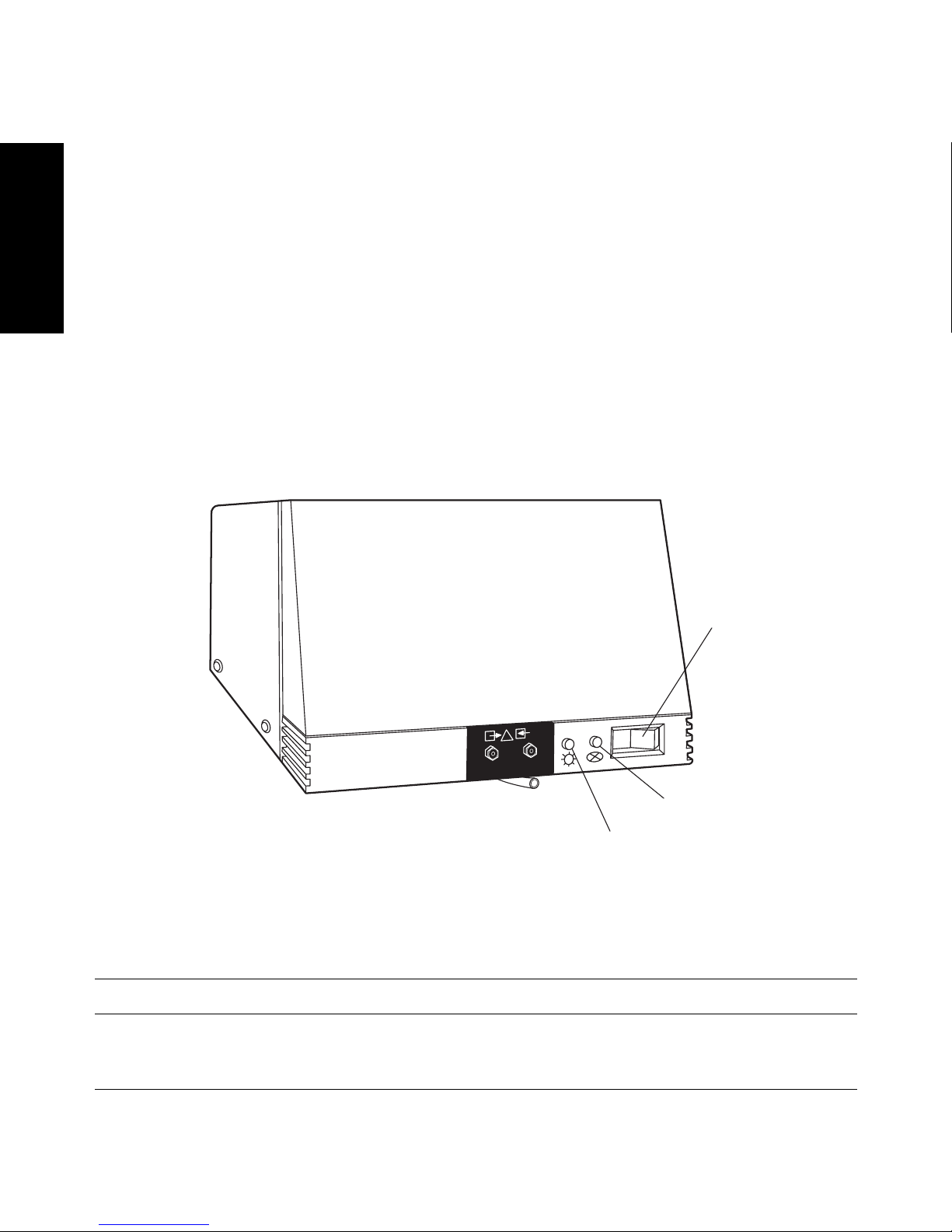

Figure 1-2 Detector Rear Panel

1.3 Millennium32 Workstation Connections

The 2996 Detector requires signal connections to the Millennium32 Work station over the

IEEE-488 bus. All detector control and data acquisition communications take place over

the IEEE-488 bus.

Note: If an inject start signal is not available over the IEEE-488 bus, you must provide a

signal at the Event In 1 terminals on the 2996 Detector rear panel (Section 1.4.2,

Connecting Event Cables).

TP01452

AC Input

Page 26

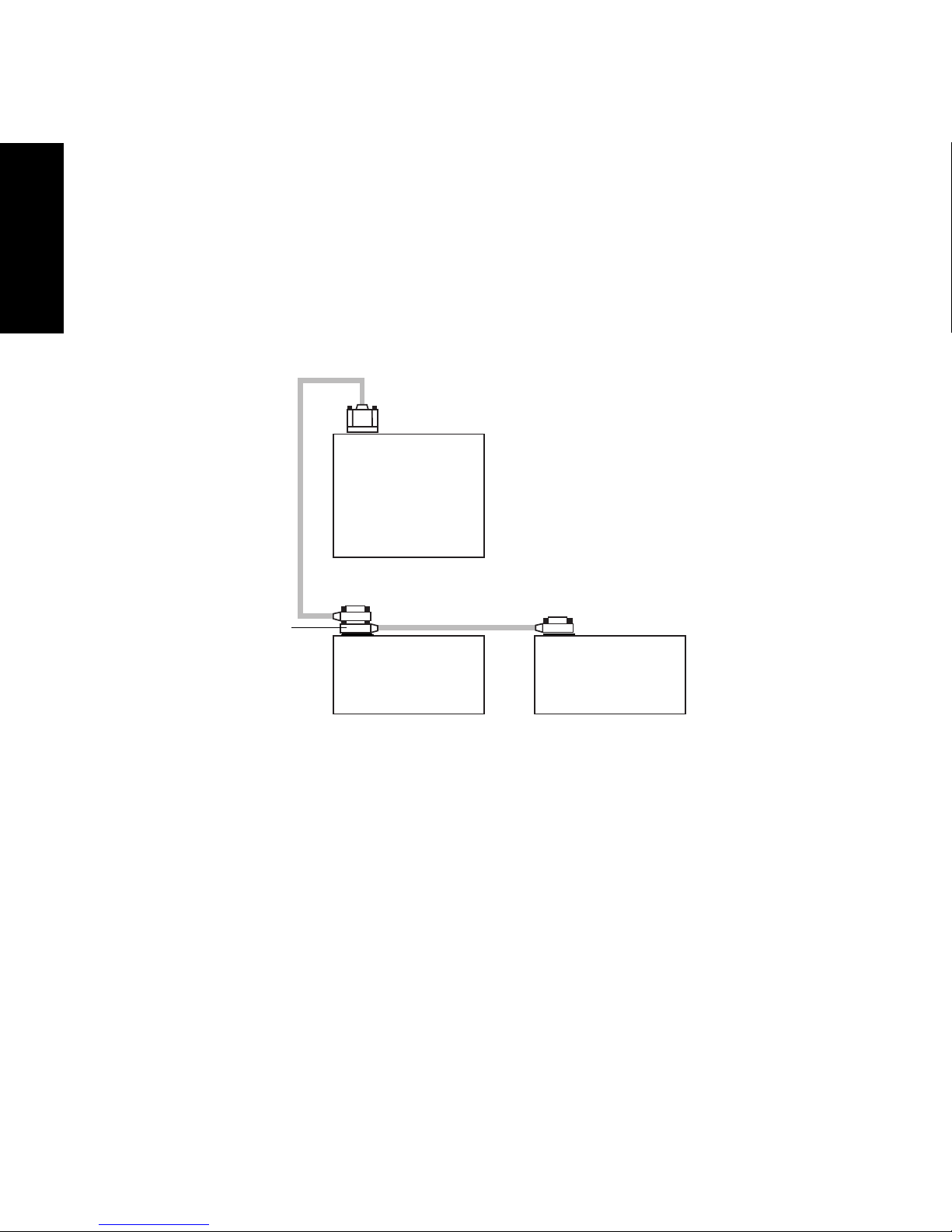

1.3.1 Connecting the IEEE-488 Cable

To connect the 2996 Detector to a Millennium32 Workstation:

1

1. Connect one end of the IEEE-488 ca ble to t he IEEE-488 recepta cle on t he rear panel

of the 2996 Detector. Connect the other end of the cable (stackable connector for

daisy-chaining additional instruments) to the IEEE-488 connector on any of the

other instruments in your chromatographic system (Figure 1-3).

Waters

IEEE-488

Cable

IEEE-488

Connector

Millennium

busLAC/E Card

(on Workstation)

Waters

Alliance

Separations Module

32

IEEE-488 Cable

Waters 2996

Detector

Note: The order in which you connect IEEE-488 devices to the busLAC/E card on

the workstation is not important. For example, you can connect the 2690

Separations Module before or after the 2996 Detector.

2. Use another IEEE-488 cable to connect to the stackable connector on the first

instrument and the IEEE-488 connector on another instrument.

3. Repeat step 2 for each IEEE-488 instrument in your chromatographic system, up to

a maximum of 14 IEEE-488 instruments.

Note: Keep in mind cable-length limitations when you set up your system. For a list

of IEEE-488 interface guidelines, refer to the Millennium

Configuration Guide.

4Installation

TP01544

Figure 1-3 Example of IEEE-488 Cable Connections

32

System Installation and

Page 27

Millennium32 Workstation Connections 5

1

4. Ensure that all IEEE-488 cable screws are fastened finger-tight.

Cable Lengths

The maximum length of all cables connecting instruments to one busLAC/E is 2 meters

multiplied by the numb er of devices (or 20 mete rs, whichever is smaller).

The maximum length of cable between devices is 4 meters.

Note: The maximum number of devices to be connected together is 14.

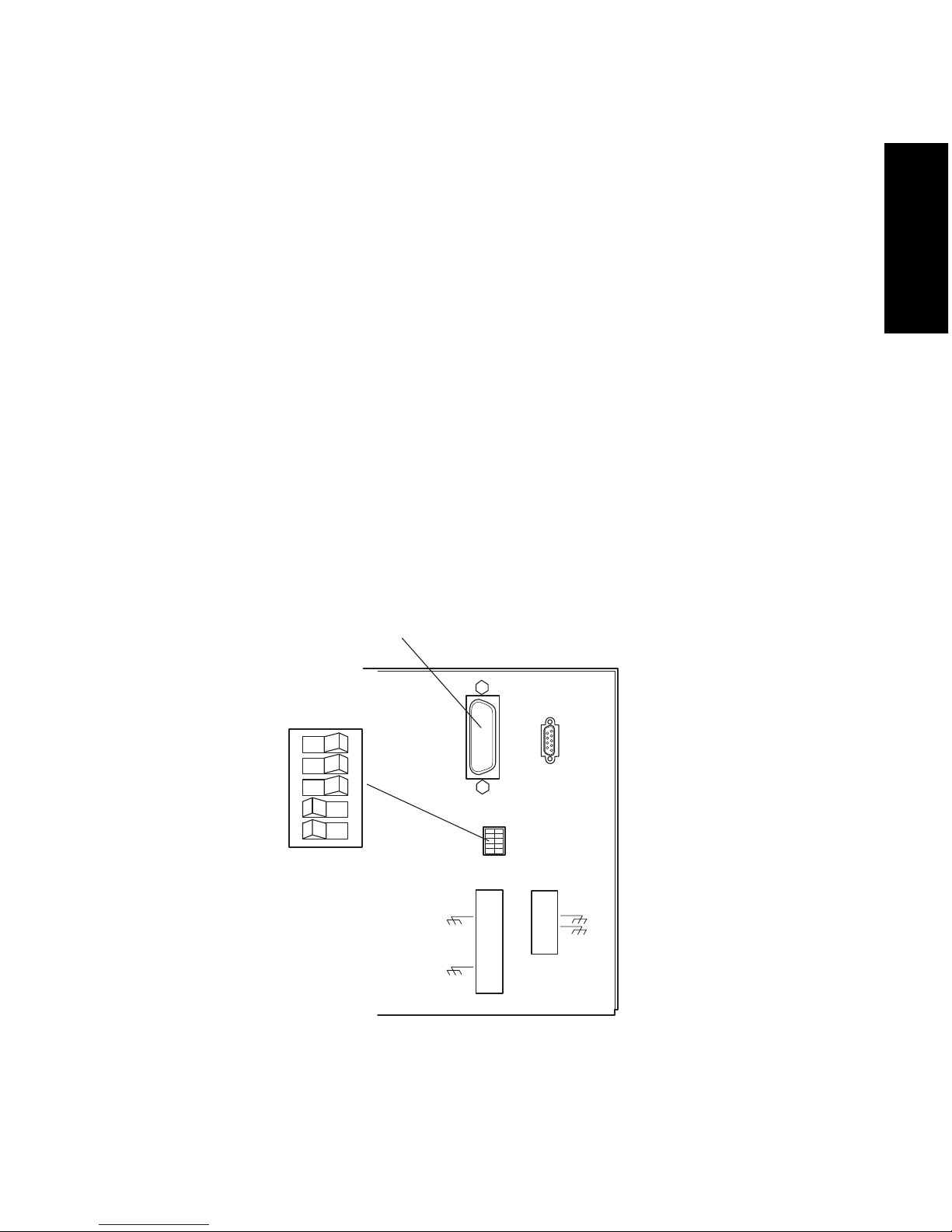

1.3.2 Setting the IEEE-488 Address

To set the IEEE-488 address for the 2996 Detector:

Use a small screwdriver (or similar device) to set the IEEE-488 switches on the detector

rear panel (Figure 1-4) to the IEEE-488 address of the 2996 Detec tor. The address must be

a number from 2 to 29 and must be different than that of any other component connected

to your acquisition server.

Refer to the Millennium

32

System Installation and Configuration Guide for the correct

IEEE-488 GPIB switch settings.

Figure 1-4 Locating the IEEE-488 Switches

IEE 488 ADDRESS

12345

OPEN

TP01457

IEEE-488

Address

Switches

IEEE-488 Cable Connection

Page 28

1.4 Non-IEEE-488 Communication Connections

1

Non-IEEE-488 communication connections on the 2996 Detector include:

• Analog Outputs – The 2996 Detect or provides two, unattenuated, 1 volt-per

absorbance-unit analog output channels to integrators, chart recorders, or other

components.

• Event Inputs and Outputs – The 2996 Detector sends and receives contact closure

signals to and from other instruments.

You make all non-I EEE-488 c ommunicat ion ca ble c onne ction s to t he 299 6 Detec tor a t the

rear panel on the analog/event terminal (Figure 1-2).

Attention: To meet the regulatory requirements of immunity from external electrical

STOP

disturbances that may affect the performance of this instrument, do not use cables longer

than 9.8 feet (3 meters) when you make connections to the screw-type barrier terminal

strips. In addition, ensure that you always connect the shield of each cable to chassis

ground.

1.4.1 Connecting Analog Output Cables

The values of the analog output signals generated by the 2996 Detector are specified by

parameter values set from the Millennium

Millennium

32

Help.

32

Workstation. For details, refer to the

Required Materials

• One small, flat-blade screwdriver

• One electrical insulation stripping tool

• Analog signal cables (included with the Waters 2996 Detector Startup Kit)

Procedure

To connect the 2996 Detector to a device that receives analog output signals:

1. Pull off the ana log out te rminal strip from the 2996 Detec tor rear pa nel (Figure 1-5).

This step simplifies the following steps.

2. Insert the appropriate bare wires at one end of an analog signal cable into the

positive (+) and negative (–) terminals of Analog Out 1 (Figure 1-5). Tighten the

two screws to secure the + and – wires.

6Installation

Page 29

3. Connect the other end of the analog signal cable to the appropriate analog input

terminal on the external device, being sure to maintain negative-to-negative and

positive-to-positive continuity.

4. Reinstall the Ana log Output Terminal strip.

Removable Analog Output

Terminal Strip

+

Analog Out 1

-

123456

+

Analog Out 2

-

Figure 1-5 Analog Out Terminal Strip

1

IEE 488 ADDRESS

TP01456

1.4.2 Connecting Event Cables

The 2996 Detector has four terminal strip connections for contact closure signals:

• Two input signal terminals (generally used for inject start)

• Two output (programmable event table) signal terminals

If an inject start s ignal is not ava ilable over the IEEE-488 bus , you must provide a signal at

Event In 1 terminal on the 2996 Detector rear panel. Manual injectors such as the

Rheodyne 7725i provide a cable that connects the injector to an Event In terminal on the

2996 Detector rear panel.

The values of the event output signals generated by the 2996 Detector are specified by

parameter values set from the Millennium

Millennium

32

Help.

32

Workstation. For details, refer to the

Non-IEEE-488 Communication Connections 7

Page 30

Required Materials

• Small flat-blade screwdriver

1

• One electrical insulation stripping tool

• Event signal cables (included in the Waters 2996 Detector Startup Kit)

Procedure

To connect the 2996 Detector to an external event input or output device:

Pull off the event terminal strip from the rear panel (Figure 1-6). This simplifies the

following steps:

1. Insert the bare wires at one end of the event signal cable into the positive (+) and

negative (–) slots of the appropriate event input or output terminal (Figure 1-6).

Tighten the two screws to secure the + and – wires.

2. Connect the other end of the event signal cable to the appropriate event input or

event output terminal on the external device.

3. Reinstall the event terminal strip.

Removable Event

Input/Output

Terminal Strip

8Installation

Event

Out 2

Event

Out 1

Event

In 2

+

1234567890

+

Event

In 1

IEE 488 ADDRESS

Figure 1-6 Event Input/Output Terminal Strip

TP01455

Page 31

Fluidic Connections 9

1

Electrical Specifications

Before you connect an external device to an event input or output terminal, refer to the

electrical specifications in Table 1-2 and Table 1-3.

1.5 Fluidic Connections

Required Materials

• 5/16-inch open-end wrench

• 0.009-inch (0.23 m m) ID stainless steel tubing (included in the 2996 Detector

Startup Kit)

Table 1-2 Event In Terminal Specifications on TTL or Switch Closure

Parameter Specification

Low trigger <1.8 V

High trigger >3.0 V

Protected to ±30 V

Minimum pulse width 30 msec (this may lim it compatibility

with valves that require a quick pulse)

Maximum current 5 mA

Table 1-3 Event Out Terminal Specifications on Contact Closure

Parameter Specification

Maximum power 10 W

Maximum current 0.5 A at 20 V

Maximum voltage 24 V RMS

STOP

Attention: To avoid damage to the 2996 Detector electronics, be sure you make the

proper electrical connections as outlined in this section.

Caution: To avoid chemical hazards, always observe safe laboratory practices when

handling solvents. Refer to the Material Safety Data Sheets for the solvents in use.

Page 32

• Stainless st eel tubing cutter or scri bing file

• Pliers, plastic- covered, or with cloth

1

• Compression screw assemblies, three

Procedure

To make fluidic connections to the 2996 Detector:

1. Measure the lengths of tubing needed to connect:

• The column outlet to the 2996 Detector inlet

Note: Keep the length of this tubing as short as possible to prevent band

broadening.

• The 2996 Detector outlet to a waste collection bottle

Note: Ensure the length of this tubing is at least 1 to 2 feet (30 to 60 cm) to prevent

air bubbles from forming in the flow cell.

2. Cut the two lengths of tubing as follows:

a. Use a Waters 1/16-inch stain less stee l tubing cu tter o r a file with a cu tting edge to

scribe the circumference of the tubing at the desired break point.

b. Grasp the tubing on both sides of the sc ri bed mark with cl ot h- or pl ast ic-covered

pliers (to prevent marring the surface), then gently work the tubing back and

forth until it separates.

c. File the tubing ends smooth and straight to minimize dead volume and band

3. Assem ble a compre ssion fittin g (Figure 1-7 ) at both ends of the col umn outlet line

and at one end of the detector outlet line.

10 Installation

broadening.

Page 33

Compression

Screw

Ferrule

Tubing

Distance Determined by

the Union or Column Fitting

TP01139

Figure 1-7 Compression Screw Assembly

End Must be Straight

and Smooth to Prevent

Dead Volume

4. Seat one end of the column outlet tubing in the fitting of the column outlet, then

tighten the compression screw about 3/4-turn past finger-tight (using the 5/16-inch

open-end wrench).

5. Seat the other end of the tubi ng in the fitt ing of the detector inlet, then tighten the

compression screw as in step 4.

6. Seat the end of the detect or ou tl et tu bing wi th t he compress ion f itting in the detect or

outlet fitting, then tighten the compression screw about 3/4-turn past finger-tight.

Insert the other end of the tubing in the waste container.

1

STOP

Attention: To avoid damage to the flow cell, avoid pressures approaching its maximum

allowable pressure, 1000 psi (70 kg/cm

2

).

1.6 Starting Up and Shutting Down the Detector

The entire startup procedure takes less than 1 minute. Once completed, you should allow

the 2996 Detector to warm up for at least 1 hour before running an analysis. Follow the

procedures in this section to ensure reliable detector performance.

Starting Up the Detector

To start up the 2996 Detector:

1. In your instrument method, set the solvent delivery system or pump to deliver

1 mL/min of degassed mobile phase. For details, refer to the Millennium

Starting Up and Shutting Down the Detector 11

32

Help.

Page 34

12 Installation

1

Note: Use only thoroughly degassed HPLC-grade solvents. Gas in the mobile

phase may form bubbles in the flow cell and cause the detector to fail the Reference

Energy diagnostic.

2. Flush the detector for 10 minutes or until no bubbles appear in the outlet line.

3. Press the 0/1 (Off/On) switch on the front panel of the detector (Figure 1-8) to the

1 (On) position.

4. Observe the Lamp and Status indicator LEDs on the front panel of the detector

(Figure 1-8).

• If both lights remain illuminated, the detector passed the internal diagnostics.

• If either indicator light blinks or is off, refer to the troubleshooting tables in

Chapter 2, Diagnostics and Calibration.

5. Wait 1 hour for the 2996 Detector to stabilize before acquiring data.

Figure 1-8 2996 Detector Indicator Lights

Table 1-4 LED Indicator Sequences During Startup

Lamp LED Status LED Indicates Troubleshooting

OFF OFF No power or CPU

failure.

Check ac source and main

fuse. Contact Waters Technical Service.

TP01460

LAM

P

WATERS 2996

Photodiode Array

Detector

Lamp Indicator

Status Indicator

On/Off Switch

Page 35

Starting Up and Shutting Down the Detector 13

1

Shutting Down the Detector

To shut down the 2996 Detector:

1. If the mobile phase contains buffers, set the solvent delivery syst em or pump to

deliver 1 mL/min of HPLC-grade water for 10 minutes. Otherwise, set the solvent

delivery system or pump to deliver 1 mL/min of degassed methanol for 10 minutes.

2. Press the 0/1 (Off/On) switch on the front panel of the detector to the 0 (Off)

position.

OFF FLASHING The 2996 is running

power-on self-tests.

FLASHING FLASHING 2996 has failed one of

the self-tests.

Contact Waters Technical

Service.

OFF FLASHING The 2996 is running

Confidence tests.

ON FLASHING Lamp start was

successful. The 2996

is starting calibration.

ON FLASHING for more

than 30 seconds

The 2996 may not

have calibrated

correctly.

Could be air bubble in flow

cell (Table 2-1). Contact

Waters Technical Service.

ON ON Calibration was

successful.

Table 1-4 LED Indicator Sequences During Startup (Continued)

Lamp LED Status LED Indicates Troubleshooting

Page 36

1

14 Installation

Page 37

Diagnostics 15

2

Chapter 2

Diagnostics and Calibration

The Waters 2996 Photodiode Array Detector automatically runs a series of internal

diagnostics upon sta rt up. The indica tor LEDs on the front of the detec tor and message s at

the Millennium

32

Wor kstation show the results of the start up interna l diagnostics

(Figure 1-8).

If you need to determine the cause of a problem during operation of the detector, you can

run the same internal diagnostics from the Millennium

32

Workstation. Additional

information about the performance of the detector is also available through the PDA

Calibration window, accessed from Run Samples in the Millennium

32

software.

If you encounter a problem that you cannot troubleshoot (Section 2.1, Diagnostics),

contact Waters T e chnical Servi ce at (800) 25 2-4752, U.S. and Canadian customers only.

Other customers, cal l you r l ocal Waters sub sidiary or your local Waters Technical Service

Representative in Milford, Massachusetts (U.S.A.) for assistance.

2.1 Diagnostics

Refer to Table 2-1 to troubleshoot problems encountered during startup diagnostics and

during detector operation.

Table 2-1 2996 Detector Troubleshooting

Symptom Possible Cause Corrective Action

Both LEDs off No power 1. Check line cord connections.

2. Check outlet for power.

Blown fuse Replace fuse (Section 3.3, Replacing

the Fuses).

Status light bl inks and

lamp light is off

The 2996 is running

Confidence tests.

Page 38

16 Diagnostics and Calibration

2

Status light bl inks and

lamp light on

Failed startup

diagnostics

Reseat and check alignment of flow

cell.

Flush the flow cell (Section 3.1.1,

Flushing the Flow Cell).

Insuffic ie nt energy

reaching photodiode

array because of air

bubble, or dirty flow

cell can cause shutter

diagnostic to fail

Flush the flow cell (Section 3.1.1,

Flushing the Flow Cell).

To prevent air bubbles from forming,

check that there is a 1- to 2-foot (30 - to

60-cm) length of 0.009-inch

(0.23-mm) ID tubing connected to the

detector waste outlet.

Weak lamp Replace lamp (Section 3.1.2,

Removing the Flow Cell).

Shutter failure

message

Shutter failed Run the Shutter diagnostic. For details,

see Millennium

32

Help.

Detector not

responding to

Millennium

32

Workstation

Detector not

connected to

busLAC/E or to

LAC/E

32

Acquisition

Server in t he

Millennium

32

Workstation

Check IEEE-488 cable connections,

tighten connectors.

Incorrect IEEE-488

address

1. Ensure that the 2996 Detector

IEEE-488 address is unique and

within the range 2 to 29 (see the

Millennium

32

System Instal lation

and Configuration Guide).

2. Rescan the IEEE-488 bus. For

details, see Millennium

32

Help.

Table 2-1 2996 Detector Troubleshooting (Continued)

Symptom Possible Cause Corrective Action

Page 39

User-Initiated Diagnostics 17

2

2.2 User-Initiated Diagnostics

Note: The system administrator can restrict access to the 2996 Detector diagnostics by

disabling user access to Run Samples. For details, refer to the Millennium

32

Help.

There are two types of user-initiated PDA diagnostic tests:

• Internal Tests – Tests run by the instrument firmware that help you determine the

source of a malfunction. These tests do not require connections to external devices.

• Interactive Tests – Tests that check analog output and event input/output signal

communications between the detector and connected external devices. These tests

require connections to pump flow and/or test equipment.

You can run all user -initia ted diagnos tics from Run Sampl es in the Mill ennium

32

software.

For more information on Run Samples and PDA diagnostics, refer to

the Millennium

32

Help.

Change in reference

spectrum

Mobile phase contain s

gas or is contaminated

Prepare fresh mobile phase and degas

thoroughly.

Air bubbles trapped in

flow cell

Reseat and check alignment of flow

cell.

Flush the flow cell, or apply slight

backpressure on the detector waste

outlet.

T o prevent ai r bubbles, check that there

is a 1- to 2-foot (30- to 60-cm) length

of 0.009-inch (0.23-mm) ID tubing

connected to the detector waste outlet.

Solvent in drain line Leak from flow cell

gasket

Rebuild flow cell with a new gasket

(Section 3.1.3, Disassembling and

Cleaning the Flow Cell).

Leak from flow cell

fittings

Check fittings for overtightening or

undertightening, and replace fittings if

necessary.

Table 2-1 2996 Detector Troubleshooting (Continued)

Symptom Possible Cause Corrective Action

Page 40

18 Diagnostics and Calibration

2

2.3 PDA Calibration

You can adjust, or calibrate, the 2996 Detector to ensure that wavelength readings are

accurate. Recalibrate the 2996 Detector only if the Wavelength Accuracy diagnostic (in

the Internal Diagnostics tests) fails. Calibration allows you to correct small errors in

wavelength which may be caused by aging optics or excessive vibration.

You calibrate the 2996 Detector using the PDA Calibration window, which you access

from Run Samples and which allows you to:

• View the effects of exposure time on photodiode saturation for a given wavelength

range.

• Verify the wavelength location of the deuterium spectrum Balmer lines (486.0 nm

and 656.1 nm).

• Recalibrate to set the 486-nm peak at the proper wavelength.

• Ensure precise data for library matching.

Note: The system administrator can restrict access to the PDA Calibration window by

disabling access to Run Samples.

Note: Ensure that the flow cell is clean before you check calibration (Section 3.1.1,

Flushing the Flow Cell).

To prepare for calibration:

1. Set the pump t o deli ver 1 mL/min of degassed methan ol fo r 10 minut es. If metha nol

is not miscible with the previous solvent, flush with a miscible sovent before

switching to methanol.

2. If you have been using buffers, flush with HPLC-quality water at 1 mL/min for

10 minutes, then switch to methanol for 10 minutes.

Note: Ensure that the solvent is miscible with the previous mobile phase.

For information on pe rforming calibration, refer to the M illen nium32 Help.

STOP

Attention: Recalibrating the wavelength requires that spectral libraries be reentered.

Page 41

Flow Cell Maintenance 19

3

Chapter 3

Maintenance

This chapter covers main tenanc e of the Waters 2996 Photo diode Ar ray De tect or flow cel l,

lamp, and fuse.

3.1 Flow Cell Maintenance

The flow ce ll requires m aintenance w hen:

• The reference spectrum changes.

• The cell fluid leaks out of the drain tube.

• The Lamp diagnostic (in the Millennium

32

PDA Diagnostics window) fails and the

lamp status light is on (Table 2-1).

• The 2996 Detector causes high backpressure.

Note: Conditions other than a dirty flow cell may cause decreased lamp intensity. For

more information, refer to Chapter 2, Diagnostics and Calibration.

Flow cell maintenance consists of:

• Flushing the flow cell

• Removing the flow cell

• Disassembling and cleaning the flow cell

• Installing the flow cel l assembly

Caution: To avoid possible electric shock, do not remove the 2996 Detector power

supply covers. The power supply does not contain user-serviceable components.

Page 42

20 Maintenance

3

3.1.1 Flushing the Flow Cell

Required Materials

• HPLC-grade water

• HPLC-grade methanol

If the flow cell requires cleaning, first try flushing it with solvent.

Procedure

To flush the flow cell:

1. Select a solvent compatible with the samples and mobile phases that you have been

using. If you have been using buffers, flush with HPLC-grade water for 10 minutes

at 1 mL/min, then switch to a low-su rface-tension solvent s uch as metha nol.

2. Set pump flow to 1 mL/min, then run the pump for 10 minutes.

3. Test the lamp energy by perf orming the Lamp diagnostic test. For details, refer to

the Millennium

32

Help.

If the lamp diagn ost ic fails and the lamp has not been used more than 2000 hours or

1 year (whichever comes first), disassemble the flow cell and clean the flow cell

components using the procedure described in Section 3.1.2, Removing the Flow

Cell.

3.1.2 Removing the Flow Cell

Note: You do not need to shut down the 2996 Detector to remove and replace the

flow cell.

Required Materials

• 5/16-inch open-end wrench

• Phillips screwdriver

• Powder-fr ee gloves

STOP

Attention: Ensure that the solvent is miscible with the previous mobile

phase.

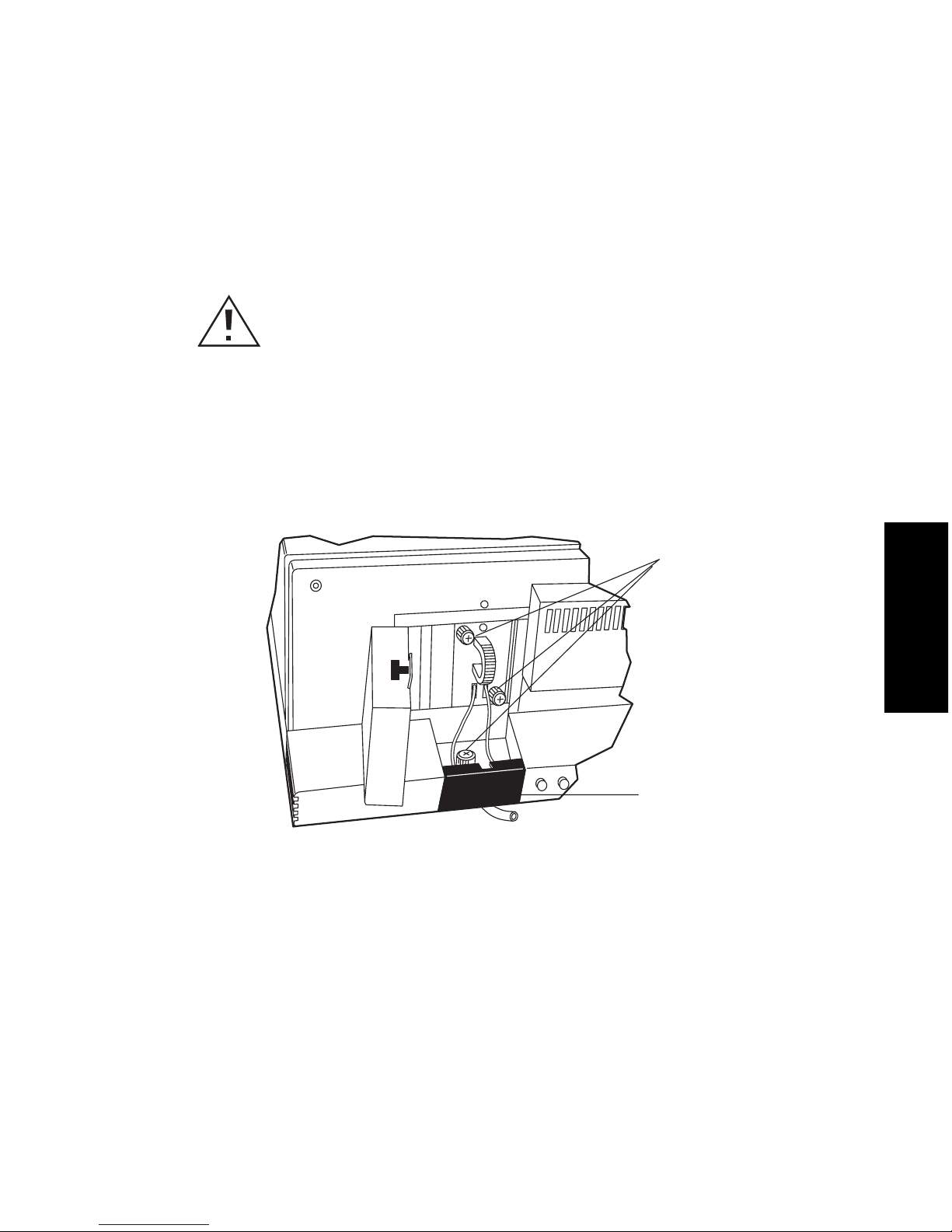

Page 43

Flow Cell Maintenance 21

3

Procedure

To remove the 2996 Detector flow cell:

1. Set the flow to 0.0 mL/min.

2. Power off the solvent delivery system or pump to avoid exposure to chemicals.

3. Use the 5/16-inch wrench to disconnect the fluidic lines at the front of the detector.

4. Lift up the 2996 detector front cover and pull the front cover from the detector

chassis.

5. Open the flow cell access door by pulling the black thumbtab, then pull the door

gently toward you (Figure 3-1).

Figure 3-1 Removing the Flow Cell Assembly

6. Use the Phillips screwdr iver to loosen the thr ee thumbs crew s that hold the flo w

cell assembly to the optics bench and the thumbscrew that secures the bracket

holding the flui dic co nne ction s, then detach th e bra cket .

7. Pull the flow cell assembly gently toward you to remove it from the detector

(Figure 3-2).

Caution: To avoid the possibility of leaking mobile phase, do not disconnect

the inlet or outlet fluidic lines while there is pressure in the chromatographic

system. Always vent your system before disconnecting fluidic lines.

TP01462

Thumbscrews

Holding Flow

Cell Assembly

and Bracket

Fluidic Connections

(Inside Bracket)

Thumbscrews

Holding Flow

Cell Assembly

and Bracket

Page 44

Flow Cell Body

Lens Holder

Assembly

3

Fluidic

Connections

Figure 3-2 Flow Cell and Fluidic Connections Assemblies

Bracket

TP01463

3.1.3 Disassembling and Cleaning the Flow Cell

Attention: The lens surface finish and the alignment of the lenses are critical to the

STOP

STOP

performance of the 2996 Detector. Be careful not to touch or damage the lenses and the

lens holders.

Attention: To prevent lens contamination, use powder-free gloves when disassembling,

inspecting, cleaning, or replacing parts within the flow cell or when removing or replacing

the flow cell within its assembly.

Required Materials

• TORX™ T10 screwdriver

• Small, flat-blade screwdriver

• Lens tissue or nonparticulating swab

22 Maintenance

Page 45

Flow Cell Maintenance 23

3

• HPLC-grade methanol

• Belleville spring washer

• Flow cell gasket

• Powder-fr ee gloves

Procedure

To disassemble and clean the flow cell (and lenses):

1. Use the TORX T10 screwdriver to remove the three screws that secure one of the

lens holder assemblies (Figure 3-3).

Figure 3-3 Disassembling the Flow Cell

2. Use the small, flat-blade screwdriver to gently pry the lens assembly from the flow

cell body at the slots.

3. Use a lens tissue or a nonparticulating swab to wipe the lens with methanol.

STOP

Attention: Solvents other than methanol may damage a disassembled flow

cell. In normal use, the gasket protects the lens holder from solvents.

TP01464

Gasket

Flow Cell Disk

Lens Assembly

Flow Cell Disk

Belleville

Spring

Washer

Lens Assembly

Flow Cell

Body

Spring

Washer

Slot for

Removing

Lens

Assembly

Screws

Page 46

24 Maintenance

3

4. Remove and discard the gasket.

5. Repeat steps 1 through 4 to remove, disassemble, and clean the other lens holder

assembly.

6. Use methanol and a nonparticulating swab to clean the flow cell body.

Reassembling the Flow Cell

To reassemble the flow cell (Figure 3-3):

1. Insert a replacement gasket into one side of the flow cell body.

2. Align the screw holes of the lens assembly with the holes in the flow cell body.

3. Place the new Belleville spring washers (with the concave side facing out) onto the

lens assembly.

4. Place the flow cell disk over the lens assembly.

5. Insert the three screws using the TORX T10 driver to gradually tighten each screw,

alternating between the screws in a clockwise pattern. Tighten until the screws meet

the flow cell disk, the n tighten each screw 1/4-turn. If a torque screwdriver is

available, tighten the screws to 16 in-oz (0.113 N-m).

6. Check for leaks. If you find any leaks, repeat step 5.

7. Repeat steps 1 through 5 to reassemble the other side of the flow cell.

3.1.4 Installing the Flow Cell Assembly

To in stall the flow cell assembly:

1. While you hold the flow cell assembly in a vertical orientation (Figure 3-2), insert

the assembly into the optics bench. Note that the flow cell is self-aligning and uses

the guide pins on the optics bench.

2. Gently push the front of the assembly until it seats on the front alignment pins.

3. Hand-tighten the thumbscrews.

4. Reconnect the fluidic lines.

STOP

Attention: Be careful not to overtighten the screws.

STOP

Attention: The alignment of the flow cell in the optics bench is critical to detector

operation. Be careful not to damage the flow cell body.

Page 47

Replacing the Lamp 25

3

5. Replace the front cover.

6. Flush the flow cell (Section 3.1.1, Flushing the Flow Cell).

3.2 Replacing the Lamp

Replace the lamp in the 2996 Detector when either of the following conditions exists:

• The sampling rate requires an excessively long exposure time (more than

100 milliseconds).

• Intensity is low enough that sensitivity is not sufficient for your method.

Note: An improperly inserted flow cell could appear to be a problem with the lamp.

Note: If lamp intensity is low, but the lamp has not been used for 2000 hours, you may be

able to increase lamp intensity by cleaning the flow cell (Section 3.1, Flow Cell

Maintenance).

Absorbance by the mo bile phase also affects the apparent lamp intensity. For example,

acetonitrile is more transparent than methanol at wavelengths less than 220 nm.

Caution: To avoid electrical hazards and exposure to UV light, turn off the power and

disconnect the power cord before you begin this procedure.

Caution: The lamp and housing are extremely hot. To avoid the possibility of contacting

hot surfaces, allow the lamp to cool for 15 minutes before you handle the lamp assembly

or surfaces close to the lamp.

STOP

Attention: Do not touch the lamp glass while unpacking or inserting the lamp. Touching

lamp glass damages the lamp and reduces life expectancy.

STOP

Attention: To prevent lamp glass contamination, use powder-free gloves when

removing or replacing the lamp.

Caution: The lamp may be very hot! Please allow it to cool for at least 15 minutes before

you attempt to remove it.

Page 48

3

Required Materials

• Slotted head screwdriver

• Powder-fr ee gloves

Caution: To avoid electrical hazards when you perform the following procedure, power

off the 2996 Detector and disconnect the power cord.

Procedure

To replace the la mp:

1. Power off the 2996 Detector, disconnec t t he power cord, and allow the lamp to cool

for at least 15 minutes.

Caution: To avoid the possibility of contacting hot surfaces, wait at least

15 minutes after powering off the detector before you handle the lamp.

2. Lift up the front panel cover and pull it away from the chassis.

3. Open lamp secure panel.

Alignment

Notch

Mounting

Screws

Figure 3-4 Lamp Power Connector and Mounting Screws

26 Maintenance

Lamp

Lamp Power

Connector

Lamp Usage

Indicator

TP01466

Page 49

Replacing the Fuses 27

3

4. Use a slotted head screwdriver to unscrew the two mounting screws.

5. Grip the metal base of the lamp, pull the lamp out, and set it aside. Do not pull the

wires to remove the lamp.

6. Carefully unpack the replacement lamp.

7. While wearing powder-free gloves and holding the lamp by its base, position the

lamp so that the not ch in the base aligns with the pos it ioning pin in the optics bench.

8. Insert the lamp and secure it with the two screws. Make sure that the lamp base is

flush against the lamp housing.

9. Reconnect the lamp power connector (Figure 3-4).

10. Secure the lamp access panel.

11. Install the front panel cover.

12. Reconnect the power cord and power on the 2996 Detector.

3.3 Replacing the Fuses

Replace the fuses unde r the conditions indicated in the troub les hooting table (Section 2.1,

Diagnostics). The 2996 Detector requires two 2 A, 250 V fuses (5 mm × 20 mm).

To replace the two fuses in the 2996 Detector:

1. Power off the 2996 Detector and remove the power cord.

2. Locate the fuse block below the power cord plug (Figure 3-5) on the rear panel.

Figure 3-5 Fuse Block

Caution: To avoid electrical hazards, power off the 2996 Detector and disconnect the

power cord before you perform the following procedure.

Squeeze Side Clips to

Access Fuses

Page 50

3. Squeeze the two side clips on the fuse block while you pull out the block.

4. Remo ve the fuses from the block, then ins tall the new fuses.

5. Position the fuse block with the small tab pointing down, then push in the block

until the side clips engage.

6. Connect the power cord, then power on the 2996 Detector.

3

28 Maintenance

Page 51

2996 Detector Optics 29

4

Chapter 4

Principles of the 2996 PDA

Detector Optics

To use the Millennium32 PDA software effectively, you must be familiar with the

principles of operation of the optics and electronics of the Waters 2996 PDA Detector.

4.1 2996 Detector Optics

The 2996 Detector is an ultraviolet/visible light (UV/Vis) spectrophotometer with:

• 512 photodiodes

• Optical resolution of 1.2 nm per diode

• Operating wavelength range from 190 to 800 nm

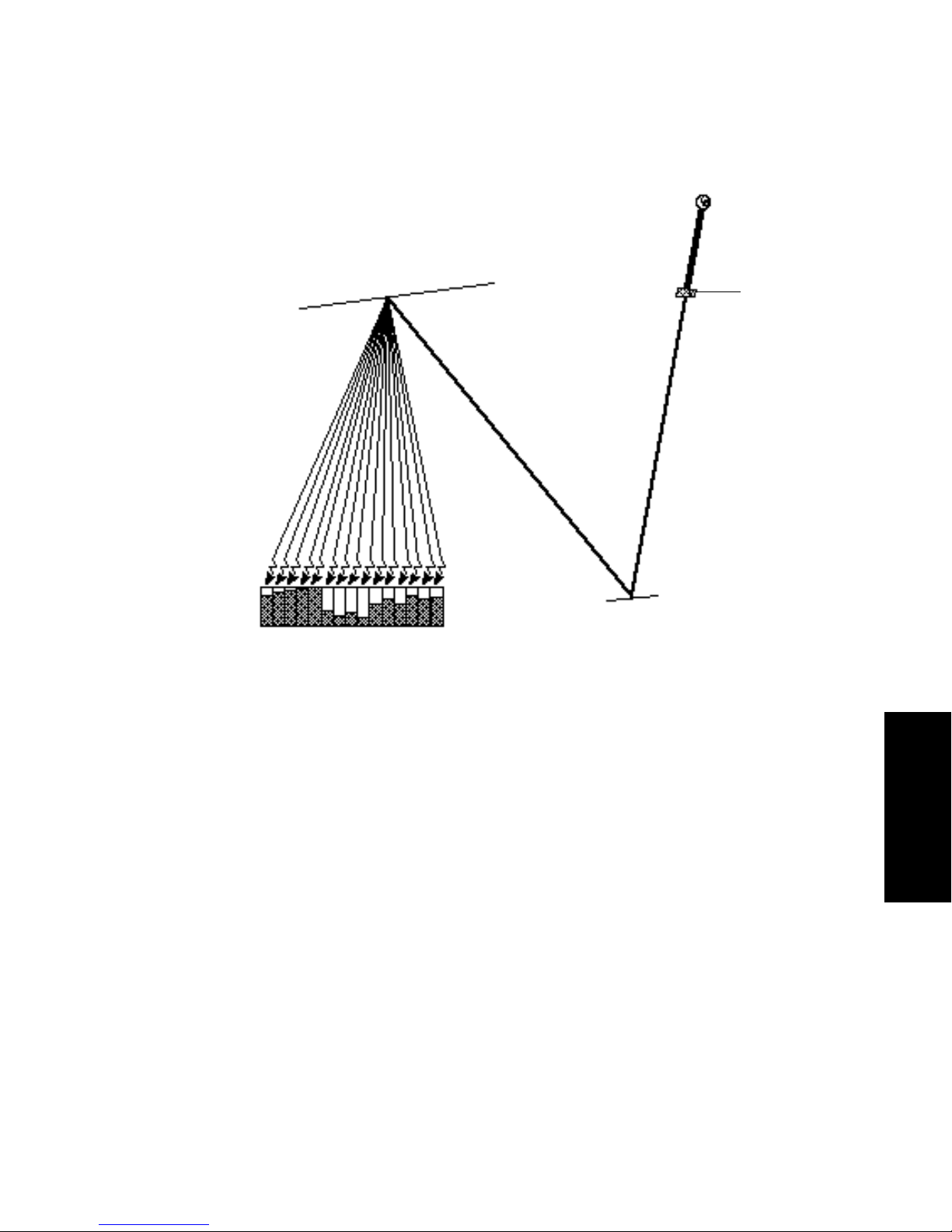

The light path through the optics assembly of the 2996 Detector is shown in Figure 4-1.

Page 52

30 Principles of the 2996 PDA Detector Optics

4

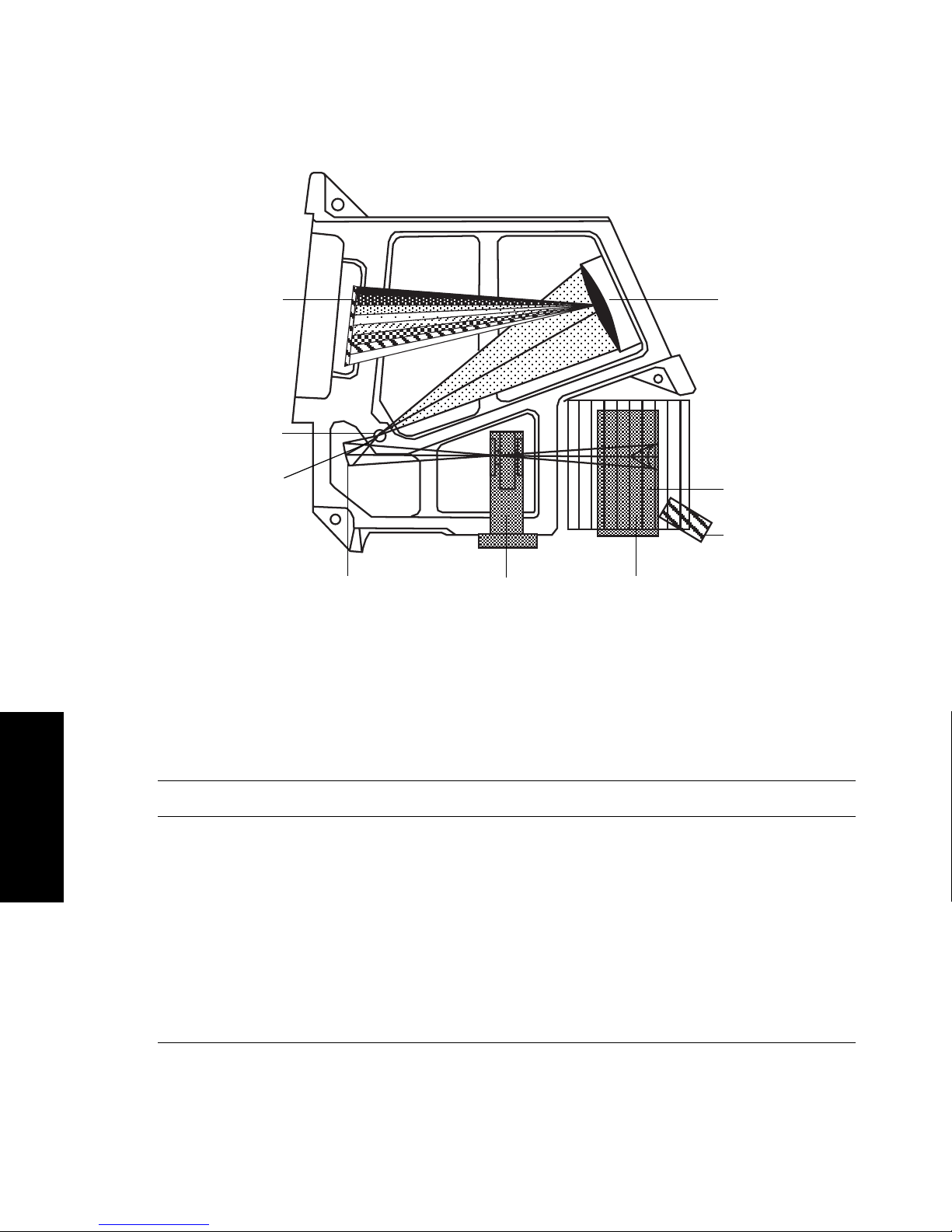

Figure 4-1 Optics Assembly Light Path

Table 4-1 describes the optics assembly components in the 2996 Detector.

Table 4-1 Optics Assembly Components

Component Function

Lamp and lamp

optics

Focuses light from the deuterium so urce lamp via a mirror through a

beamsplitter to the flow cell.

Beamspl itter and

reference diode

Reflects part of the light back to a reference diode, which measures

the intensity of the li ght emitted by the lamp. The detector uses this

measurement to keep the lamp output constant.

Flow cell

assembly

Houses the segment of the flow path (conta ining eluent and sa mple)

through which the polychromatic light beam passes. This arrangement of optical components, with the flow cell positioned between

the lamp and the grating, is commonly called reversed optics.

Reference

Diode

Beamsplitter

Assembly

50-µm Aperture

Lamp and

Lamp Optics

Spectrographic

Mirror and Mask

Shutter

Assembly

Flow Cell

Assembly

Grating

Photodiode

Array

Page 53

Resolving Spectral Data 31

4

4.2 Resolving Spectral Data

The ability to distinguish similar spectra depends on photodiode spacing and the

bandwidth of the light striking the photodiode. The bandwidth of the light striking the

photodiodes depends on the aperture width.

The apertu re width determines:

• Attainable wavelength bandwidth at the photodiode array

• Intensity of the light reaching the photodiode array (optical throughput)

The aperture creates a narrow beam that reflects from the grating to the photodiode array.

The wavelength that strikes a particular diode depends on the angle of reflection from the

grating.

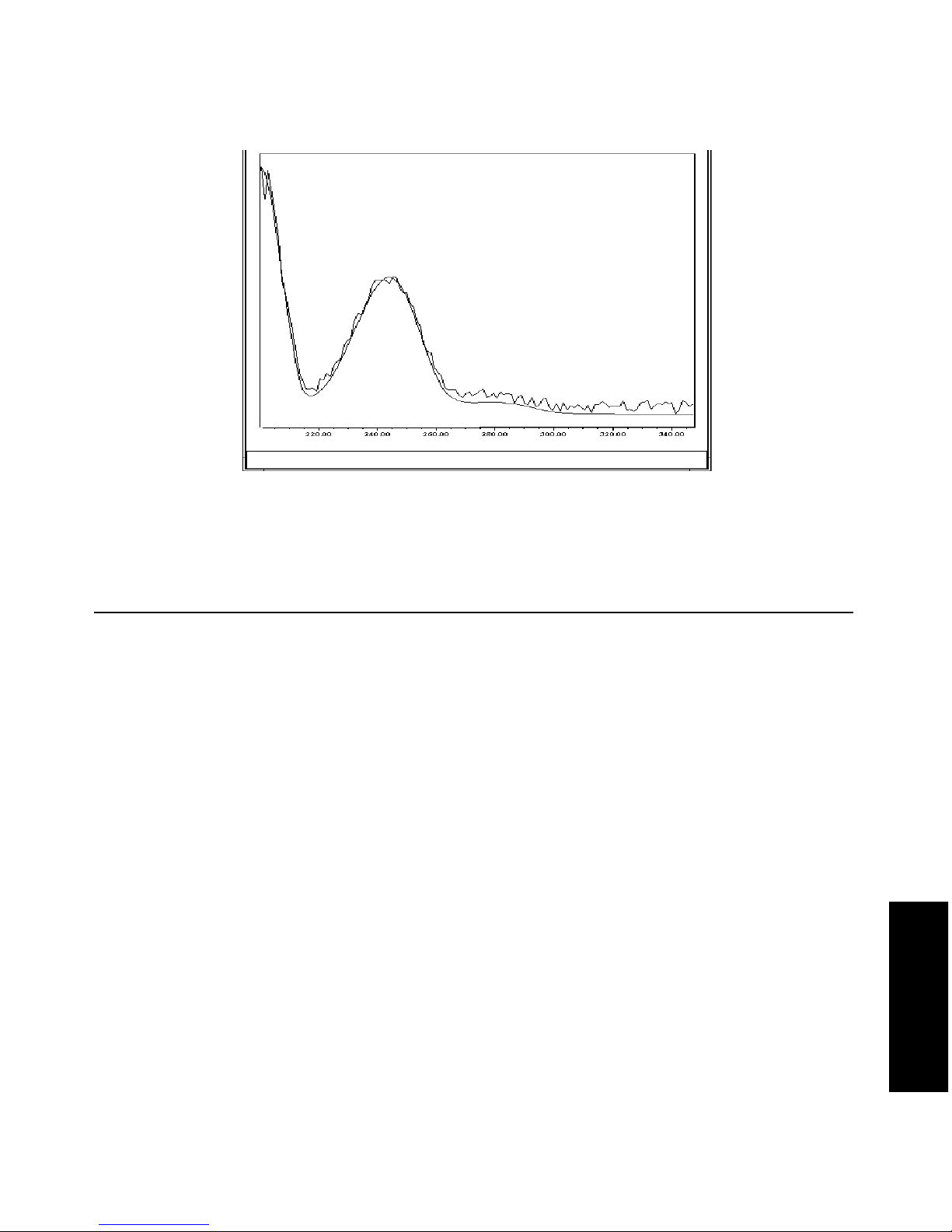

Figure 4-2 shows an absorbance spectrum of benzene obtained from the 2996 Detector

using the 50-µm aperture. In this spectrum, the wavelength resolution is sufficient to

resolve five principal benzene absorption peaks.

Spectrograph

mirror and mask

The mirror focuses light transmitted through the flow cell onto the

aperture at the entrance to the spectrographic portion of the optic s.

The mirror mask defines the beam of light focused on the spectrograph mirror.

Aperture Controls wavelength resolution and intensity of light striking the

photodiodes. The width of the aperture is 50 µm.

Shutter assembly Prevents light from reaching the photodiode array except during

sampling and calibration. For details on the dark current, see

Section 4.4.1, Calculating Absorbance.

Grating Disperses the light into bands of wavelengths and focuses those

wavelength bands onto the plane of the photodiode array.

Second-order

filter

Reduces the contribution of second-order reflection of UV light

(less than 370 nm) to the light intensity observed at visible wavelengths (greater than 370 nm).

Photodiode array An array of 512 photodiodes arranged li nearl y. The diode width and

spacing provide a single wavelength resolution of 1.2 nm.

Table 4-1 Optics Assembly Components (Continued)

Component Function

Page 54

32 Principles of the 2996 PDA Detector Optics

4

Figure 4-2 Benzene Spectrum at 1.2 nm Resolution

4.3 Measuring Light at the Photodiode

The 2996 Photodiode Array Det ector mea sures the amount of light s triking the photodi ode

array to determine the absorbance of the sample in the flow c ell.

The array consists of 512 photodiodes arranged in a row. Each photodiode acts as a

capacitor by holding a fixed amount of charge.

Light striking a photodiode discharges the diode (Figure 4-3). The magnitude of the

discharge depends on the amount of light striking the photodiode.

nm

Absorbance

Page 55

Sample in flow cell

absorbs at specific

wavelengths.

Deuterium

Lamp

Grating

Light from grating

dispersed into 1.2-nm

wavelength beams

continuously

discharges diodes.

Mirror

Figure 4-3 Photodiodes Discharged by Light

Flow

Cell

The 2996 Detector measures the amount of current required to recharge each photodiode.

The current is proportional to the amount of light transmitted through the flow cell over

the interval specified by the diode exposure time.

Exposure Time

The 2996 Detector recharges each diode and reads the recharging current one diode at a

time. The interval between two readings of an individual diode is the exposure time. The

2996 Detector requires less than 10 msec to sequentially read all of t h e d iod es in the array

and process the data. The minimum exposure time is 10 msec. You can set exposure time

from 10 to 500 msec.

For example, if an exposure time is set to 50 milliseconds, the 2996 Detector:

1. Recharges diode 1 and reads the current required to recharge diode 1

2. Recharges diode 2 and reads the current required to recharge diode 2

4

Measuring Light at the Photodiode 33

Page 56

3. Sequentially recharges and reads the current required to recharge all the remaining

510 photodiodes

4. Waits approximately 45 msec before beginning the recharge-and-reading sequence

with diode 1 after all diodes have been recharged and read.

You set the exposure time parameter in the General tab of the 2996 PDA Instrument

Method Editor. You can specify either Auto Expo sure or Expo sur e T i me. For det ails, refe r

to the Millennium

32

Help.

4

Note: For best signal-to-noise performance, adjust the wavelength range optimize

autoexposure computations. For details, refer to the Millennium

32

Help.

Using the Auto Exposure Parameter

The Auto Exposure time parameter allows the 2996 Detector optics to calculate the

optimum exposure time needed to recharge the diodes based on lamp energy, lamp

spectrum, mobile phase absorbance, and the chosen wavelength range using a single

Deuterium light source from 190 to 800 nm. To minimize detector noise, Auto Exposure

adjusts the exposure time from 50 to 90% of full scale.

The Auto Exposure time setting ensures that the photodiodes are:

• Not saturating due to overexposure

• Operating above the range of normal, dark current discharge

With auto exposure enabled, the 2996 Detector:

• Calculates exposure time at the start of a run based on maximum light intensity

within the selected wavelength range

• Limits the exposure so that no diode within the given wavelength range discharges

more than 90%

• Provides proper settings for signal-to-noise and dynamic range for each run

The Auto Exposure time setting may not support certain combinations of sampling rates,

wavelength ranges, or filter time-constant settings required for your analysis. If this is the

case, you can set the exposure time manuall y to adjus t the exposure time from expe riment

to experim ent.

Using the Exposure Time Parameter

The Exposure Time parameter enables you to manually set the length of tim e the

photodiodes are exposed to light before they are read. The supported range is 10 to

500 msec.

34 Principles of the 2996 PDA Detector Optics

Page 57

Computing Absorbance Data Points 35

4

Note: Changing exposure times within a set of samples can cause changes in baseline

noise.

Be aware that increasing the Exposure Time parameter has the potential to saturate the

photodiodes. A longer exposure time may cause the 2996 Detector to lose the signal at

certain wavelengths because of diode saturation. When specifying the Exposure Time,

select a value that provides settings for an optimum signal-to-noise ratio over the

wavelength range of your analysis (see the next topic “Optimizing the Signal-to-Noise

Ratio”).

Optimizing the Signal-to-Noise Ratio

To optimize signal-to-noise ratios, choose an acquisition wavelength range that includes

only the wavelengths of interest and over which the mobile phase absorbs minimally

(Appendix C, Mobile Phase Absorbance). Setting the bandwidth to higher values can

improve signal-to-noise ratios.

4.4 Computing Absorbance Data Points

The 2996 Detector calculates absorbance values before transmitting the data to the

Millennium

32

database. To calculate absorbance, the 2996 Detector:

• Computes the absorb ance at each diode using the dark current and reference

spectrum (Section 4.4.1, Calculating Absorbance)

• Averages the absorbances at a particular wavelength as specified in the spectra per

second sample rate and reports the average as a single data point (Section 4.4.2,

Resolution)

• Can apply a filter (Section 4.4.3, Filtering Data)

4.4.1 Calculating Absorbance

The detector computes absorbance by subtracting the dark current and referenc e s pec tr um

from the acquired spectrum. Absorbance is based on the principles of Beer’s Law.

Page 58

36 Principles of the 2996 PDA Detector Optics

4

Beer’s Law

The relationship between the quantity of light of a particular wavelength arriving at the

photodiode and the concentration of the sample passing through the flow cell is described

by the Beer-Lambert Law (commonly called Beer’s Law). Beer’s Law is expressed as:

A = εlc

where:

A = absorbance

ε = molar absorptivi ty

l = path length (1.0 cm in the 2996 Detector normal flow cell)

c = molar concentration

Beer’s Law applies only to well-equilibrated dilute solutions. It assumes that the refractive

index of the sample remains constant, that the light is monochromatic, and that no stray

light reaches the detector element. As concentration increases, the chemical and

instrumental requirements of Beer’s law may be violated, resulting in a deviation from

(absorbance versus concentration) linearity (Figure 4-4). The absorbance of mobile phase

can reduce the linear range by the amounts shown in Appendix C, Mobile Phase

Absorbance.

Figure 4-4 Absorbance as a Function of Concentration

Ideal

Actual

Absorbance

Working Range

Background Absorbance

Concentration

Page 59

Dark Current

Photodiodes los e char ge over t ime even when t hey are not exposed t o light. Th e amount of

charge lost is called dark c urrent.

At the start of a chromatographic run, the 2996 Detector closes the shutter to take a dark

current reading for each d iode. Th e shutt er cl os es after th e exposu re ti me is c alcul ated an d

stays closed for the same interval as the exposure time.

The detector subtracts the dark current values from the current values recorded during

absorbance measurements for both the sample and the reference spectra.

Reference Spectrum

Immediately after the dark current measurement and before any components are eluted,

the 2996 Detector records a reference spectrum. The reference spectrum is a measure of

lamp intensity and mobile phase absorbance over the interval specified in the exposure

time taken with the shutter open.

Note: For best results, the reference spectrum should be representative of the initial

mobile phase.

Note: For extremely long exposure times, the dark current and reference spectrum

readings may take several seconds to finish.

Absorbance

The 2996 Detector calculates the absorbance for each diode at the end of each exposure

time using the following equation:

Sn Dn–()

Absorbance

n

where:

S = obtained during sample analysis

D = obtained during the dark current test

R = obtained from the reference spectrum

n = diode number

-------------------------

log=

Rn Dn–()

4

Computing Absorbance Data Points 37

Page 60

4.4.2 Resolution

The data reported by t he 2996 Detec tor to the Mill ennium32 database can be th e average of

a number of data points. After calculating absorbance, the detector averages absorbance

values based on:

• Spectral resolution

• Sample rate

Averaging Spectral Data Based on Resolution

Spectral resolution (or bandwidth) is the wavelength interval (in nanometers) between

data points in an acquired spectrum. The minimal resolution of the 2996 Detector is

1.2 nm. For example, in 3D mode, the 2996 Detector averages three adjacent diodes for

each reported wavelength when the spectral resolution is set in the Millennium

to 3.6 nm. In 2D mode, absorbance values are computed based on the bandwidth setting.

2D mode is supported in Millennium

Averaging Chromatographic Data Based On Sample Rate

Sample rate i s the nu mber of da ta point s per se cond r eported to the Mil lennium32 database.

The number of ti mes the p hotodio des are read d uring the sample r ate i nterv al is de pendent

on the exposure tim e. For example, if exposure time is 25 msec, and sample rate is 1 sec,

then readings per data point are:

32

software versions 4.0 or higher.

1000 msec

------------------------25 msec

40=

32

software

4

The readings are averaged and reported as a single data point.

Combining Spectral Resolution and Sample Rate

Spectral resolution and sample rate have opposite effects on noise and spectral detail.

Increasing the value of the spectral resolution parameter and decreasing the number of

spectra per second decrease the size of the data file.

Note: The data storage rate is based on wavelength range, spectral resolution, and

sample rate, which are set in the General tab of the 2996 PDA Instrument Method Editor.

For details, refer to the Millennium

32

Help.

4.4.3 Filtering Data