Page 1

W aters 2790

Separations Modul e

Quick Start Guide

34 Maple Street

Milford, MA 01757

71500279003, Revision A

Page 2

NOTICE

The information in this document is subject to change without notice and should not be

construed as a commitment by Waters Corporation. Waters Corporation assumes no

responsibility for any errors that may appear in this document. This manual is believed to

be complete and accurate at the time of publication. In no event shall Waters Corporation

be liable for incidental or consequential damages in connection with, or arising from, the

use of this manual.

© 1999 WATERS CORPORATION. PRINTED IN THE UNITED STATES OF AMERICA.

ALL RIGHTS RESERVED. THIS BOOK OR PARTS THEREOF MAY NOT BE

REPRODUCED IN ANY FORM WITHOUT THE WRITTEN PERMISSION OF THE

PUBLISHER.

Alliance , M il len n iu m , P IC, S y m metry, and Waters a re r egist er ed tr ad emarks of Waters

Corpor ation.

LAC/E and SAT/IN are t rade mar k s o f Waters Corporat io n.

Eppendorf is a registered trademark of Brinkmann Instruments, Inc.

MassLynx, BioLynx, OpenLynx, and Micromass are trademarks of Micromass UK Limited.

All other trad em a rk s a re th e sole p r op er ty o f th eir res pe ctive own er s .

Page 3

Summary of This Guide

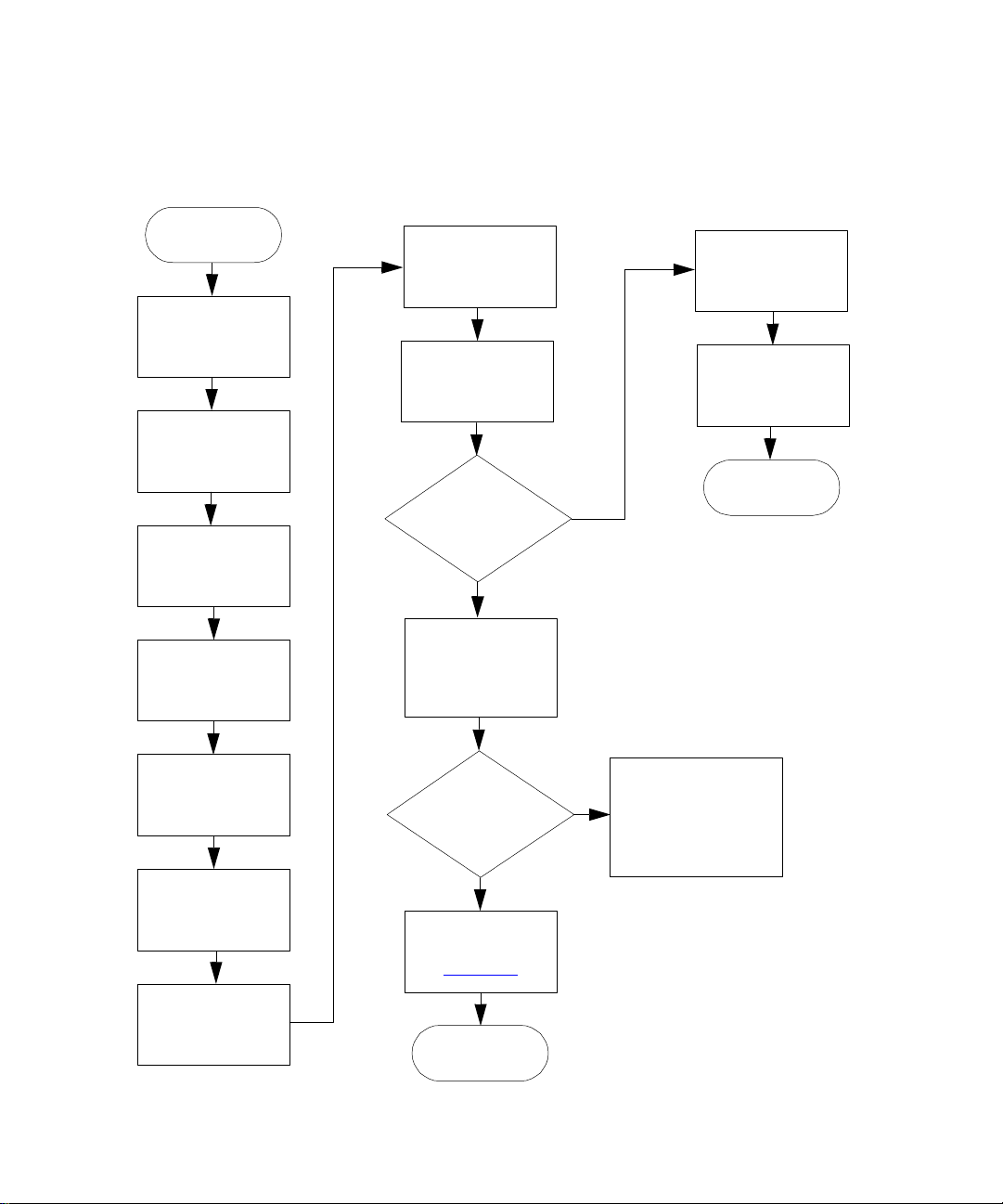

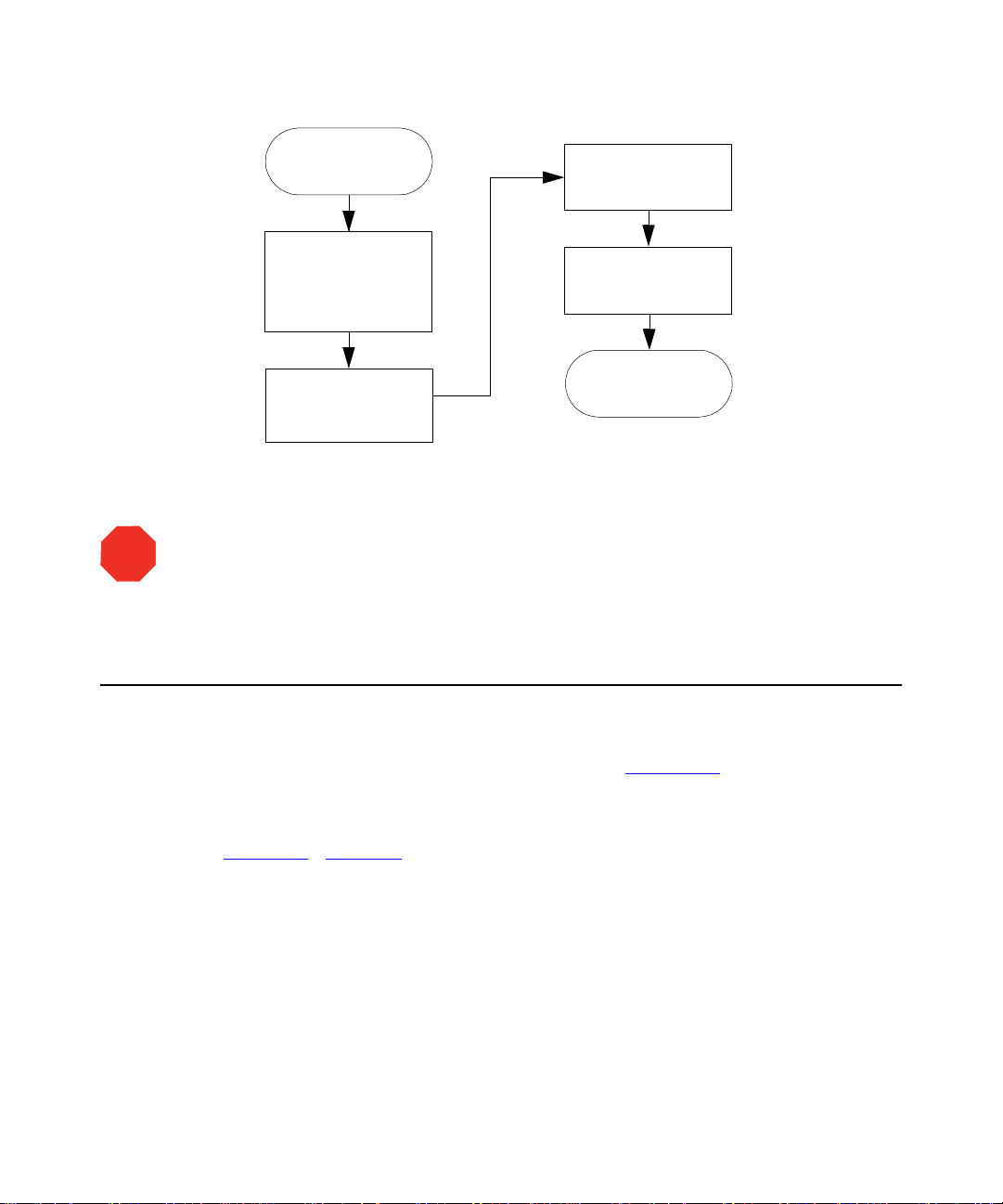

The following figure summarizes the information contained in this Quick Start Guide. Use it

as a reference after reading the entire document.

Start

Power on the

2790

Configure the

2790

Degas Solvents

Configure the Plate

Type(s)

Load the Sample

Plates

Perform an

Automatic Run?

Yes

No

Set Flow Rate and

Composition

Select Direct

Function

Function Begins

Prime the

Solvent

Management

System

Prime the

Plunger-Seal-Wash

Pump

Prime the

Needle-Wash Pump

Refresh the Syringe

Create/Edit

Separations

Methods/Sample

Sets

Using

High-Throughput

Options?

No

Follow the

Procedures in

Section 4.1

Run Ends as

Programmed

Yes

Refer to Section 6.2,

Waters 2790

Separations Module

Operator’s Guide

Page 4

Conventions Used in This Guide

The

Waters 2790 Separations Module Quick Start Guide

uses the following conventions:

• Bold text indicates user input or action. For example, press

• When you are instructed to “press the X key,” press the indicated keypad key.

• When you are instructed to “press the X screen key,” press the key directly below

the key name displayed on the screen.

Enter

Notes, Attentions, and Cautions

This guide uses the following conventions for Notes , Attentions, and Cautions:

• Notes call out information that is important to the operator. For example:

Record your results before you proceed to the next step.

Note:

• Attentions provide information about preventing possible damage to the system or

equipment. For example:

To avoid damaging the detector flow cell, do not touch the flow cell

To avoid chemical or electrical hazards, always observe safe laboratory

To avoid electrical shock and possible injury, remove the power cord from

STOP

Attention:

window.

• Cautions provide information essential to the safety of the operator. For example:

Caution:

practices when you operate the system.

Caution:

the rear panel of the instrument before you perform the procedures in this section.

.

Page 5

1

Introduction

The

Waters 2790 Separations Module Quick Start Guide

features of the Waters

2790 Separations Module and describes how to make a run.

Who Should Use This Guide?

This guide is intended for both novice and experienced chromatographers who need to

operate the 2790 Separations Module.

What Is in This Guide?

The

Waters 2790 Separations Module Quick Start Guide

information to help you set up the 2790 and make a run.

For additional information, or if you want to learn how to modify any procedures in this

guide, refer to the

If you are using the 2790 as part of an Alliance

MassLynx software), ensure you become familiar with the procedures in:

• Waters Allian ce LC/MS Sy ste m Qu ick Sta rt Guid e

Waters 2790 Separations Module Operator’s Guide

HT LC/MS system (controlled by the

introduces you to the basic

contains basic procedural

.

• MassLynx NT Guide to Data Acquisition

• MassLynx NT User’s Guide

•

MassLynx NT BioLynx Guide

•

MassLynx NT OpenLynx Guide

(optional)

(optional)

Before You Begin

Ensure you have performed the following before you use the 2790:

• Your system is properly installed. Refer to the

Operator’s Guide

• You r separation methods and sam ple sets are created and stored. Refer to the

Waters 2790 Separations Module Operator’s Guide

Separation Methods and Sample Sets.

• Become familiar with the front panel and keypad operating procedures described in

the

Waters 2790 Separations Module Operator’s Guide

Display and Keypad.

, Chapter 2, Installing the 2790 Separations Module.

Waters 2790 Separations Module

, Chapter 5, Creating and Editing

, Section 3.1, Using the 2790

5

Page 6

If you are using the 2790 for high-throughput applications, refer to the

Separations Module Operator’s Guide,

Chapter 6, Making Automatic Runs and Setting Up

Waters 2790

for High-Throughput Operation.

System Description

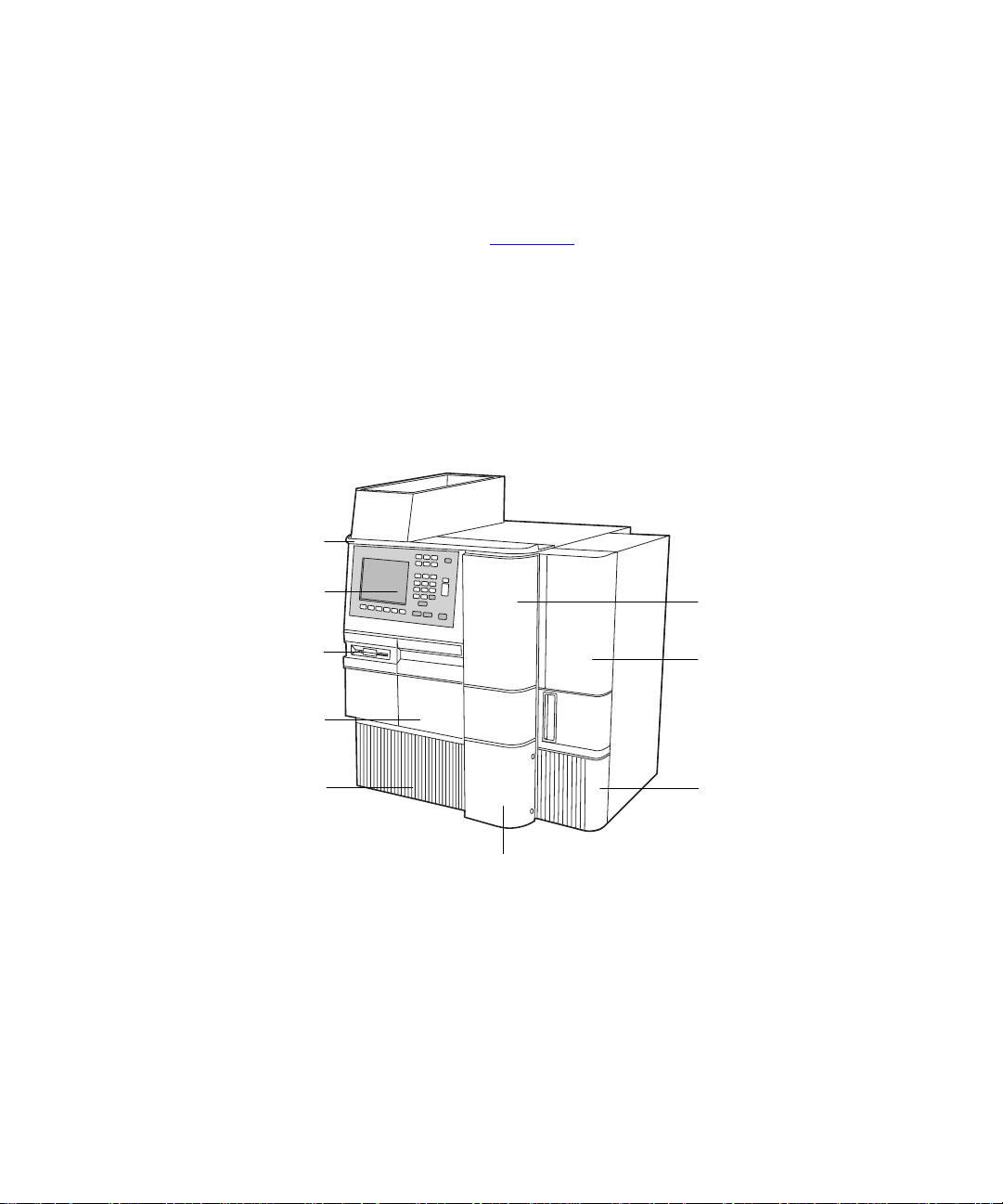

The Waters 2790 Separations Module (Figure 1-1) integrates a solvent management

system and a three-axis sample management system to provide high-throughput analysis

for HPLC, LC/MS, or flow injection-mass spectrometry applications.

When the 2790 is installed with a sample heater/cooler and a column heater, it is known

as the 2790XE. Refer to the

Waters 2790 Separations Module Operator’s Guide

Section B.3, 2790 Module Options, for information about the 2790 Separations Module

options.

Solvent Bottle Tray

Detector Drip Tray

,

Front Panel Display

and Key board

Floppy Disk

Drive

Sample Compartment

Access Door

Solvent Delivery Tra y

Access Door

Solvent Conditioning

Tray Access Door

Syringe Compartment

Door

Column Heater

Module

Column Selection Valve

(Optional) Door

TP01354

Figure 1-1 Waters 2790XE Separations Module (Front View)

The sample management system in the 2790 uses an XYZ needle assembly, up to four

sample plates of up to 384 wells each, for a total capacity of 1536 samples. The 2790 uses

a variety of plate types including several that are preconfigured (refer to the

Separations Module Operator’s Guide

, Table 3-6 and Table B-5).

Waters 2790

6 Introduction

Page 7

Operating Mode s

The 2790 Separations Module can operate in one of the following modes:

• Stand-alone HPLC system controller

• Component of an LC/MS system controlled b y MassLynx

As a stand-alone HPLC system controller, the 2790 manages both the solvent delivery

and sample management systems as well as controlling one or more detectors. The 2790

controls the sample plates using a rotating carrier. Optionally, the 2790 can also control a

three-column, six-column, or column regeneration selection valve.

An LC/MS system that includes the 2790 and the Waters ZMD mass spectrometer is

designated as a Waters Alliance HT LC/MS System. For further information on MassLynx

control of the 2790, refer to the

Waters Allianc e LC /MS System Quick St art Guid e

1.1 Powering On the 2790

To power on the 2790, move the power switch (located at the top of the left side panel) to

the I (ON) position. The startup diagnostics routine begins.

Startup Diagnostics

The startup diagnos tics routine performs tests on the:

™

software

.

• CPU board

• Memory (ROM and RAM)

• Keypad

•Display

• External communicat ion system

• Digital signal processor (DSP)

• Floppy disk drive

When initial startup diagnostics tests are complete, the front-panel screen displays the

tests results, as shown in Figure 1-2

Figure 1-2 Diagnostic Test Results Screen

.

Powering On the 2790 7

Page 8

The Main Screen

If the initial tests of the startup diagnostics routine are successful, the Main screen

(Figure 1-3

continues, the status of each of diagnostic test appears in the banner area of the Main

screen. If the startup diagnostics routine fails, refer to the

Module Operator’s Guide,

routine finishes, the 2790 enters the Idle mode.

) appears in the front panel display. As the star t up diagno stics routine

Waters 2790 Separations

Section 8.5, Troubleshooting. When the startup diagnostics

Bann er Area

Data Area

Screen K ey Area

Figure 1-3 Main Screen

Some 2790 screens have additional screen keys that are not visible when you

Note:

display the screen f or the first time. Press the

keys.

1.2 Configuring the 2790

Before you can operate the 2790, you need to configure the 2790 operating parameters.

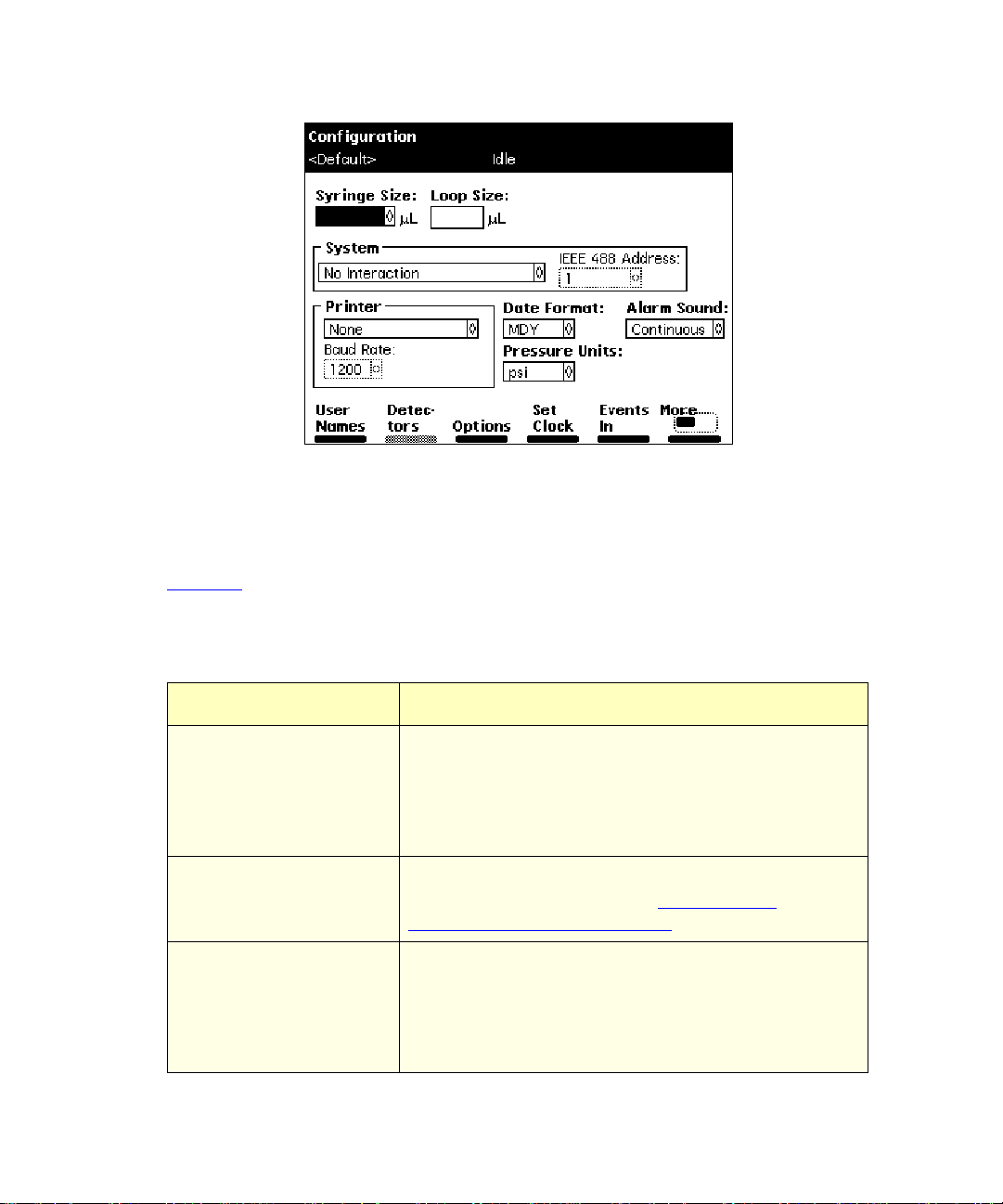

Press the

(Figure 1-4

8 Introduction

Config

screen key in the Main screen to display the Configuration screen

).

screen key to displa y additional screen

More

Page 9

500

Figure 1-4 Configuration Screen

50

1.2.1 Setting Configuration Parameters

Ta ble 1-1 describes the parameters you can set for your system configuration.

Ta ble 1-1 Configuration Parameters

Parameter Description

Syringe Size and Loop

Size

System Specifies the operating mode and the IEEE-488 bus

Printer Specifies the type of printer and baud (data transfer)

Specifies the sizes of the syringe and sample loop.

These values are preset at the factory. Change these

values when you install a different-sized syringe and/or

sample loop (see the

Operator’s Guide,

address (when required). See Se ction 1.2.2,

Configuring the Operating Mode.

rate and flow control.

The baud rate is automatically set to 1200 if you

Note:

Waters 2790 Separations Module

Table 7-5).

set the 746 Integrator as the printer type.

Configuring the 2790 9

Page 10

Ta ble 1-1 Configuration Parameters (Continued)

Parameter Description

Date Format Specifi es MM/D D/ YYYY (f o r e xample, 0 3/ 28/1999 for

March 28, 1999) or DD.MM.YYYY (28.03.1999 for 28

March 1999).

Alarm Sound Specifies the type of alarm (continuous or single beep).

Pressure Units Specifies psi (pounds per square inch), kPa (kPascal),

or bar.

1.2.2 Confi guring the Operating Mode

On the Configuration screen, you configure the operating mode as follows.

No Interaction Mode

In this stand-alone mode, the 2790 is not connected to the IEEE- 488 interface bus , b ut

can control non-IEEE-488 devices in the HPLC system using the I/O connections on the

rear panel. Refer to the

Making Analog Signal Connections, for the procedure to make I/O connections.

Waters 2790 Separations Module Operator’s Guide,

Section 2.5.2,

To set the 2790 to No Interaction mode:

1. Select

operating modes.

2. Select

3. Press

System

No Interaction

Exit

System Controller Mode

In this stand-alone mode, the 2790 can control up to th ree de tector ch annels on t he

IEEE-488 bus. The channels can include up to two UV detector channels (a Waters 2487

Dual λ Detector and/or a Waters 486 Tunable Absorbance Detector) and one RI detector

channel (Waters 2410 or 410 Differential Refractometer).

Refer to the

Digital Signal Connections, for inf ormation on making IEEE-488 connections. You can also

control other HPLC components using the I/O connections. Refer to the

Separations Module Operator’s Guide,

for the information on making I/O connections.

10 Introduction

Waters 2790 Separations Module Operator’s Guide,

in the Configuration screen, then press

, then press

.

Section 2.5.2, Making Analog Signal Connections,

Enter

.

to display the list of

Enter

Section 2.5.3, M a k i ng

Waters 2790

Page 11

To set the 2790 to Sys tem Controll er mode:

1. Select

operating modes.

2. Select

3. P ress the

interface bus addresses) appears.

4. Press

For information on setting detector parameters in a separation method, see the

System

System Controller

a. Press

absorbance channels and one RI detector) may appear in the list.

b. Press the OK screen key to return to the Configuration screen.

Exit

2790 Separations Module Operator’s Guide,

in the Configuration screen, then press

, then press

Detectors

Scan

.

screen key. A li st of active devices (with their IEEE-488

to update the list of devices. Up to th ree dete ctors ( t wo

Section 5.2.6, Setting Detector Parameters.

Enter

.

Enter

to display the list of

Waters

Controlled by MassLynx Mode

In this remote control mode, the Micromass MassLynx NT s oftware (Version 3.3 or higher)

uses the IEEE-488 interface to control the 2790, and up to two detectors, including the:

• Micromass mass spectrometry (MS) detec tor

• Waters 996 PDA Detector

• Other Waters detectors, such as the 2487 Dual λ Absorbance Detector

To set the 2790 to Controlled by MassLynx mode:

1. Select

operating modes.

2. Select

is highlighted.

3. Press

4. Select an address that is unused by other chromatographic components connected

to the Micromass computer, then press

5. Press

System

Controlled by MassLynx

Enter

Exit

in the Configuration screen, then press

, then press

to display a list of addresses.

.

Enter

. The 2790 is ready to be controlled from the MassLynx computer.

. The IEEE-488 Address field

Enter

to display the list of

Enter

Configuring the 2790 11

Page 12

Operate Gradient by Event In Mode

In this mode, an external autosampler (a Waters 2700 Sample Manager, for example)

initiates the start of the chromatographic run and performs the inject function (instead of

can

the 2790). In t his mo de, t he 2790 has n o cont rol of IEEE -488 devices, but

non-IEEE devices using the I/O connections on the rear panel. Refer to the

Separations Module Operator’s Guide,

for information on I/O connections.

To set the 2790 to Operate Gradient b y Event In mode:

Section 2.5.2, Making Analog Signal Connections,

control

Waters 2790

1. Select

operating modes.

2. Select

3. Press

Events In conditions, refer to the

Guide

Conditions for Events In” discussion.

4. S et the Stop Flow field to the appropriate condition (

Low

On Low

5. S et the Hold 1 f ield to the appropr iate condition (

press

System

Operate Gradient by Event In

Events In

, Section 3.2.1, Setting Configuration Parameters, the “Specifying Signal

), then press

• Select

• Select

Flow I/O terminals of the 2790 is a high (more positive) TTL-level.

• Select

Flow I/O terminals of the 2790 is a low (more negative) TTL-lev el .

When you configure the 2790 with a Waters 2700 Sample Manager , select

Note:

.

Enter

• Select

Inject 1 terminals of the 2790 is a high (more positive) TTL-level to start a

chromatographic run and prevent an injection by the 2790.

in the Configuration screen, then press

, then press

to display the Events In dialog box. For information on defining

Enter

Waters 2790 Separations Module Operator’s

.

Enter

Ignore

On High

On Low

On High

if the Stop Flo w I/O t ermin als of t he 2790 are not used.

if the output signal from the external autosampler to the Stop

if the output signal from the external autosampler to the Stop

On High

.

if the output signal from the external autosampler to the Hold

to display the list of

Enter

.

Ignore, On High

or

On Low

, or

On

), then

• Select

Note:

On Low

6. S et the Logic field to Or, then press

12 Introduction

On Low

Inject 1 terminals of the 2790 is a low (more negative) TTL-level to start a

chromatographic run and prevent an injection by the 2790.

if the output signal from the external autosampler to the Hold

When configuring the 2790 with a Waters 2700 Sample Manager , select

.

.

Enter

Page 13

7. S et the Hold 2 field to

8. Press OK to save your selections and exit from the Events In dialog box.

Ignore

1.2.3 Specifying Report Options

, then press

Enter

.

The 2790 can generate a

operation, if a printer or integrator is connected.

Use Port A of the RS-232 connector to connect a cable from the 2790 to a serial

Note:

report

– a record of injections – during stand-alone or remote

printer or to a Waters 746 Data Module.

To define the information to be sent to a printer, integrator, and/or floppy disk:

1. In the Configuration screen, press the

Options dialog box (Figure 1-5

).

Reports

screen key to display the Report

Figure 1-5 Report Options Dialog Box

2. From the drop-down list, select the destination for the report.

3. S elect an option from the Separation Method list, then press any numeric key to

enable or disable the option. An “X” in the check box indicates the option is

enabled. The options are:

•

Gradient ta ble

•

I/O eve n t table

•

Detector table

– Generates the gradient table

– Generates the I/O table

– Generates the detector table

Configuring the 2790 13

Page 14

•

Event overview

– Generates an overview of all merged tables

•

Misc. parameters

•

System config

•

Per-inject data

values for temperature and pressure, the time and date of each injection, and

the bar code number

•

Alarms

injection

4. Press the OK screen key to exit from the Report Options dialog box ( or press the

Cancel

your changes).

– Generates a list of the error conditions that occur during each

screen key to exit from the Repor t Options dialog box without saving

– Generates a list of all parameters not included in tables

– Generates a list of the instrument configuration parameters

– Generates a list of the minimum, maximum, and average

1.2.4 Specifying an Auto Shutdown

The Auto Shutd own f eatu re allows y ou t o set up t he 2790 to sh ut down auto m atic all y after

a specified period of inactivity. Inactivity is defined as:

• No keyboard use

• No injections performed

• No changes sent to the 2790 from a remotely connected MassLynx computer

• An error condition that suspends the operation of the 2790

You can use Auto Shutdown to:

• Minimize solvent flow when a run ends unattended

• Disable the vacuum degasser

• Disable temperature controls

• Turn off detector lamps

To enable an Auto Shutdown:

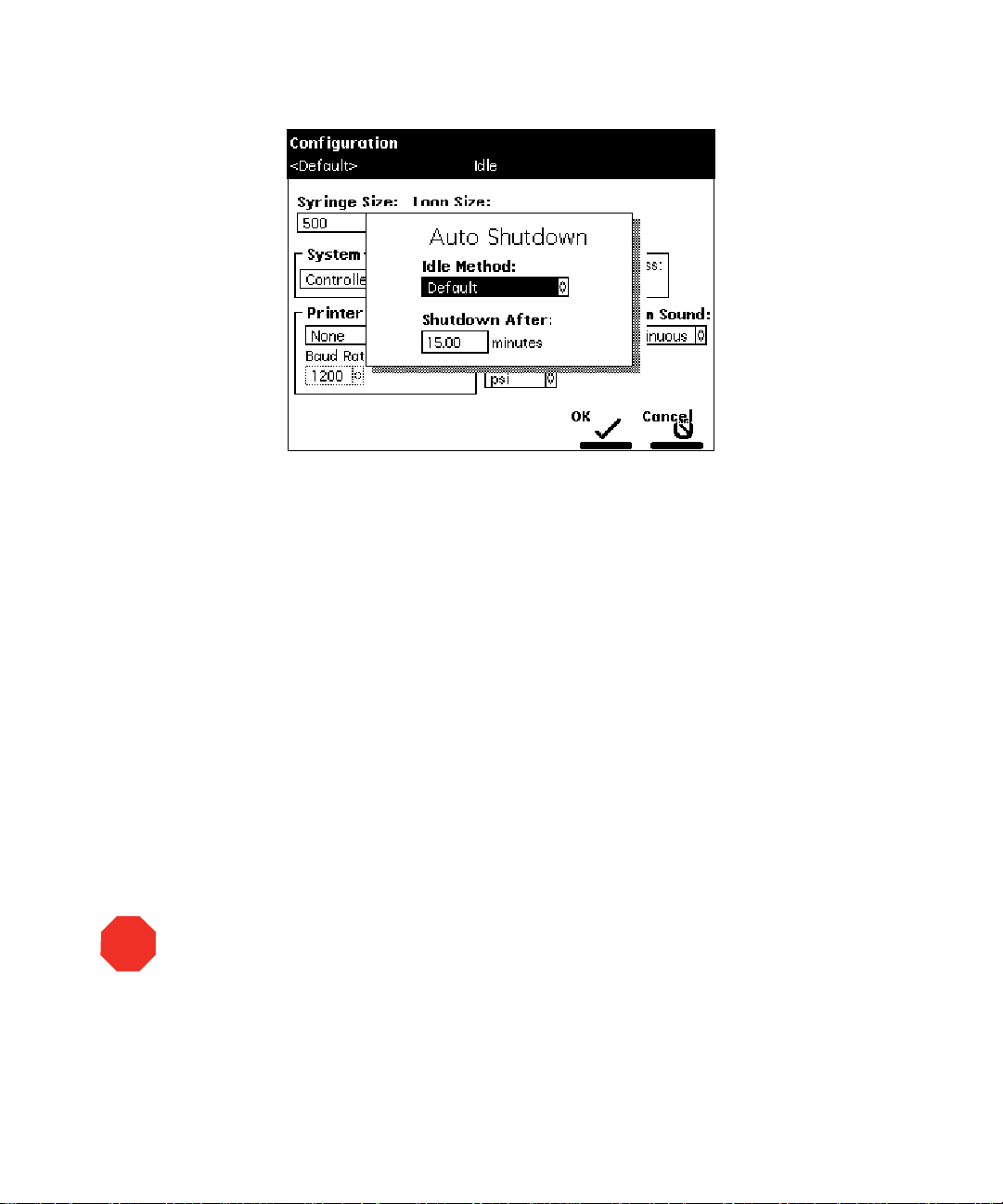

1. Press the

2. P ress the

(Figure 1-6

14 Introduction

Config

Auto Shutdown

screen key in the Main screen, then press the

).

screen key.

More

screen key. The Auto Shutdown dialog box appears

Page 15

Figure 1-6 Auto Shutdown Dialog Box

3. I n the Idle Method field, select the separation method to be applied when the

2790 is shut down. Only the

applied during the shutdown period.

4. I n the Shutdown After field, enter a time period of inactivity after which you want

the 2790 to shut down (or press

5. P ress the OK screen key. The 2790 shuts down when there has been no activity

for the specified period.

6. Press

If you want to use Auto Shutdown to power off a 2487 or 486 detector lamp, specify

Note:

a Lamp Off event and a time of INIT in the I/O Events Timed Table screen (see the Waters

2790 Separations Module Operator’s Guide, Section 5.2.5, Setting I/O Parameter Values).

to return to the previous screen.

Exit

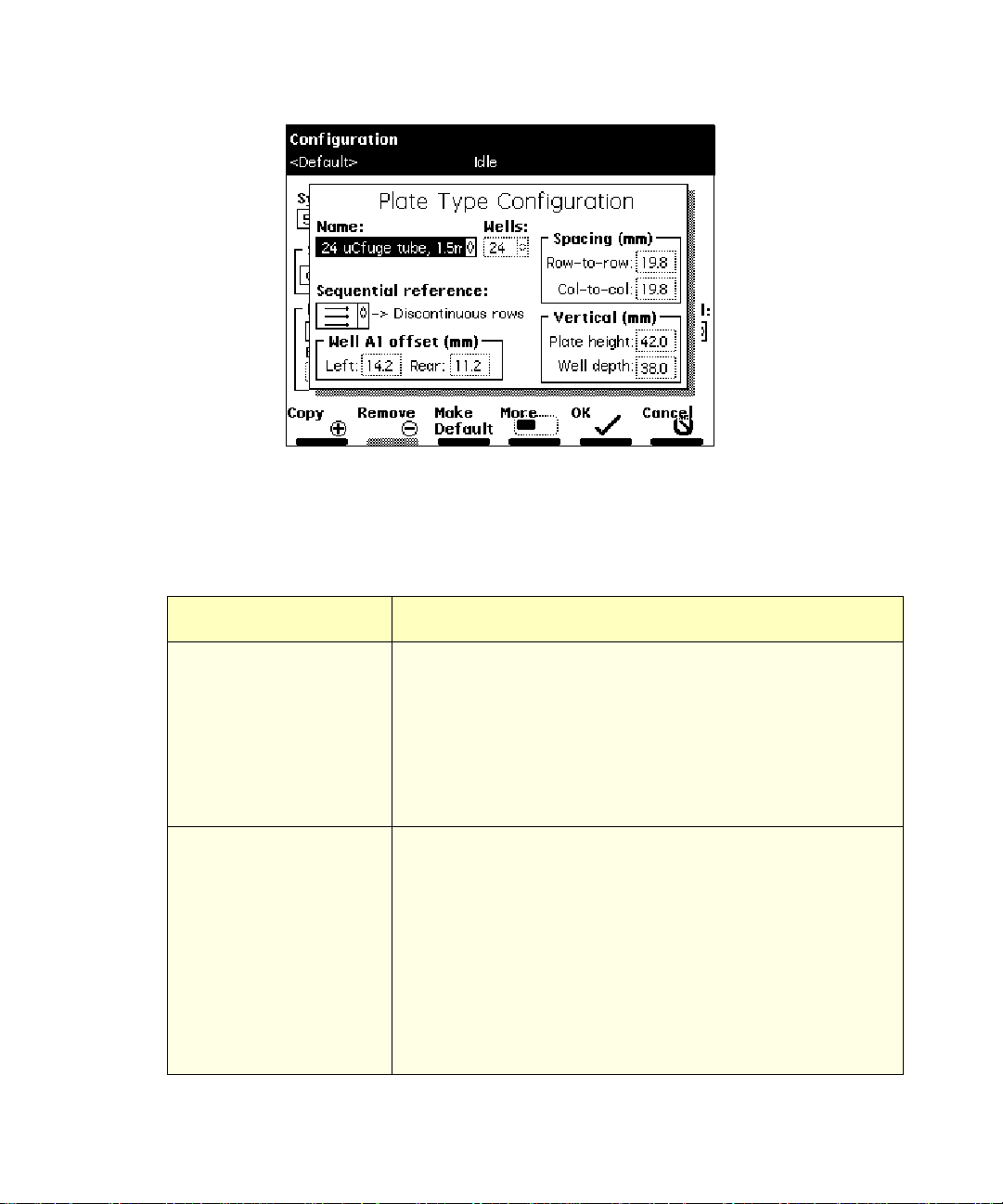

1.2.5 Configuring Plate Types

initial

conditions in the method you select are

to disable Auto Shutdown).

Clear

STOP

Attention:

Operator’ s Guide, Table B-5, before configuring plates for the 2790 Separations Module.

Read all the recommendations in the footnotes to Table B-5.

There are 15 possible plate types you can configure for use with the 2790, some of which

are preconfigured and not editable.

Waters recommends you consult the Waters 2790 Separations Module

Configuring the 2790 15

Page 16

When you select a preconfigured plate type, the parameter fields indicate the

Note:

measured dimensions for the specific plate, which are not editable (indicated by a dotted

line surrounding the field).

To customize a preconfigured plate type for the 2790:

STOP

1. In the Configuration screen, press the

Type Configuration dialog box (Figure 1-7

2. Select the plate type from t he Name dr op-down list. The remaining (noneditable)

fields fill with values corresponding to the selected plate type. To configure a

custom plate, see the “

3. I n the Sequential reference field, select the processing order (see Table 1-5

Ta ble 1-2

describes the fields in the Plate Type Configuration dialog box. See the

Configuring Custom Plates” discussion below.

2790 Separations Module Operator’s Guide

their dimensions) for use with the 2790.

Attention:

Using incorrect dimensions can cause needle damage.

Plate Types

).

, Tabl e B-5 for recommended plate types (and

screen key to display the Plate

Waters

).

16 Introduction

Page 17

Figure 1-7 Plate Type Configuration Dialog Box

Ta ble 1-2 Plate Type Configuration Parameters

Field Description

Name Name of the plate type. Use up to 30 characters to identify a

plate type. Some of the 15 plate types are preconfigured.

To mov e from one plate type to the adjacent plate type in the

drop-down list, press the

Previous

or

screen key. The

Next

default plate type appears with an asterisk in the Name field

and the words “Default Plate Type” are displayed below the

Name field.

Wells Number of wells on the plate selected in the Name field. The

parameters for each plate type are:

Number of Wells Number of Rows

24

48

48R

96

384

4

6

8

8

16

Number of Columns

6

8

6

12

24

Configuring the 2790 17

Page 18

Ta ble 1-2 Plate Type Configuration Parameters (Continued)

Field Description

Sequential reference Direction and sequence of well injections for the selected

plate. See Table 1-5.

Well A1 offset (mm)

Left

The distance from the center of the A:1 well to the left outer

edge of the plate

Rear

The distance from the center of the A:1 well to the rear outer

edge of the plate. See Figure 1-9.

Spacing (mm)

Row-to-row

The distance from the centerline of the wells in one row to

the centerline of the wells in an adjacent row

Col-to-col

The distance from the centerline of the wells in one column

to the centerline of the wells in an adjacent column. See

Figure 1-9.

Vertical (mm)

Plate height

Well depth

1

Tot al plate height

The well depth (distance from the top of the plate to the

bottom of the well)

1

See the

plates recommended for use with the 2790.

Waters 2790 Separations Module Op erator’s Guide

, Table B-5, for dimensions of the

Configuring Custom Plates

You can use one of the preconfigured plate types to create a custom plate. Before

Note:

following the next procedure, select the preconfigured plate type that most resembles the

custom plate you want to create.

Required Materials

To make plate measurements, you need a ruler or straight-edge scaled in millimeters.

To configure a custom plate:

1. In the Plate T ype Configuration dialog box, press the

Custom Plate Name field (Figure 1-8

).

screen key to display the

Copy

18 Introduction

Page 19

Figure 1-8 Custom Plate Name Field

2. E nter a custom plate nam e (see the

Operator’s Guide

, Section 3.1.2, Using the Keypad, the “Entering an

Alphanumeric String” discussion), then press

Waters 2790 Sepa rations Mod ule

. The Plate Type

Enter

Configuration parameter fields become editable (surrounded by a solid line).

3. Using a ruler or straight-edge scaled in millimeter s, measure the dimensions for

the custom plate as shown in Figure 1-9

and Figure 1-10, then enter each

parameter in the appropriate field in the Plate Type Configuration dialog box.

4. P ress the OK screen key to store the custom plate (or press the

Cancel

screen

key to discard the changes).

To delete the selected custom plate type, press the

Remove

screen key. The

Remove screen key is active only when a custom plate name is displayed in the

Custom Plate Name field. You c annot remove a preconfigured plate type.

To make the displayed plate type the default plate type, press the

Make De fa u l t

screen key. The factory-default plate type is 96 well, 300 µL. The words “Default

Plate Ty pe” are displayed below the default plate name in the Plate Type

Configuration dialog box.

Press the

Press the

Previous

Print

or

screen key to move from one plate type to another.

Next

screen key to print a copy of the plate configuration list to a

floppy disk or printer (if a printer is connected to your 2790).

Configuring the 2790 19

Page 20

The Needle Depth Offset parameter (

Note:

Figure 1-10

) is used to specify an offset from

the well bottom to accommodate sample vials or sedimentation. Enter the Needle Depth

Offset in the Sample screen when you are creating or editing a separation method (see

the Waters 2790 Separations Module Operator’s Guide, Section 5.1, Creating and Editing

Separation Methods).

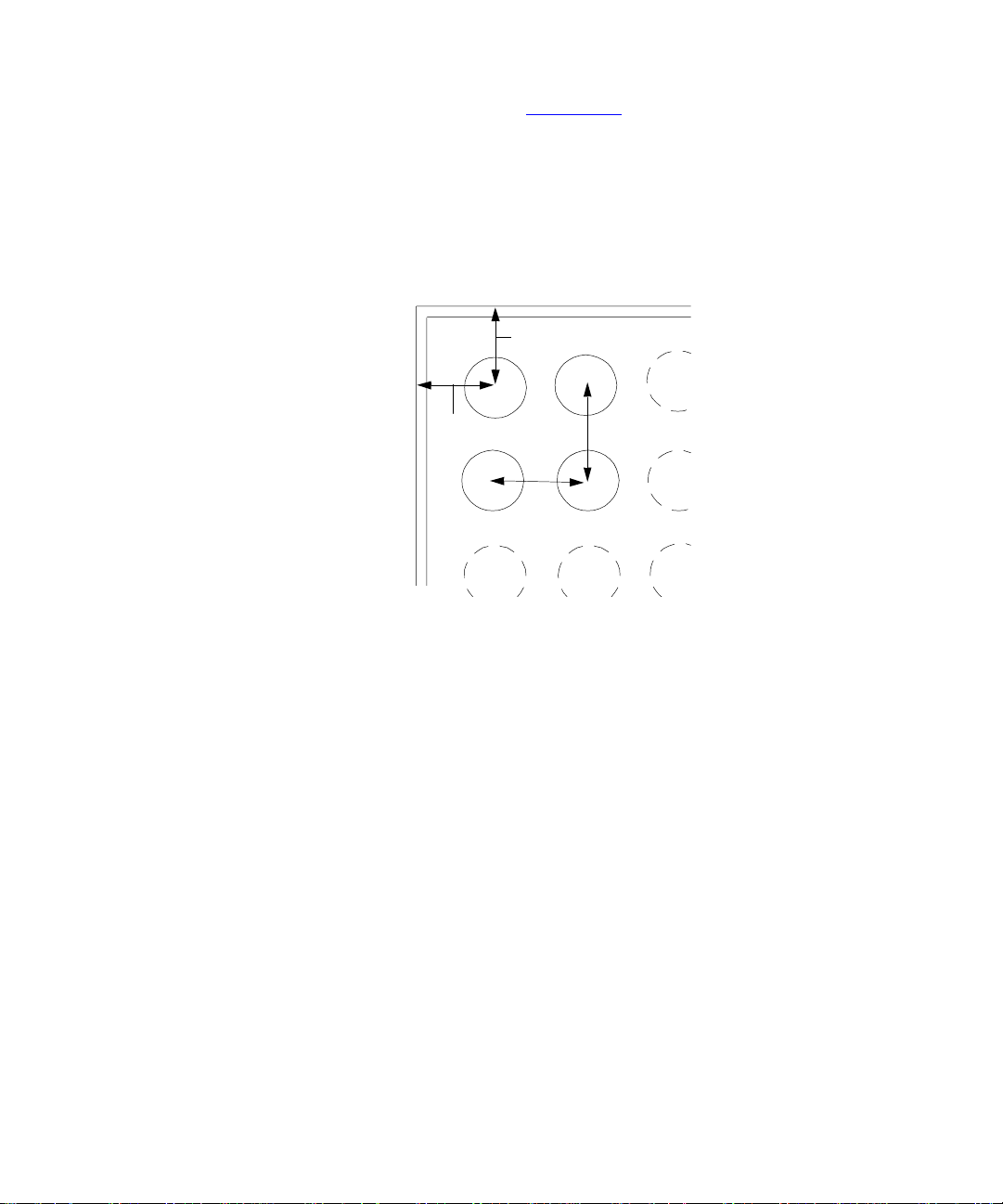

To p View Dimensions

Note:

Measure the A1 Left

and A1 Rear Ref erence points

(left and rear well of fsets) from

the outer edge of the plate.

1

A1 Rear

Reference

A

2

3

Outer Edge

of Plate

A1 Left

Reference

B

Column-to-Column

Spacing

Row-to-Row

Spacing

C

Figure 1-9 Plate Parameters (Top View)

20 Introduction

Page 21

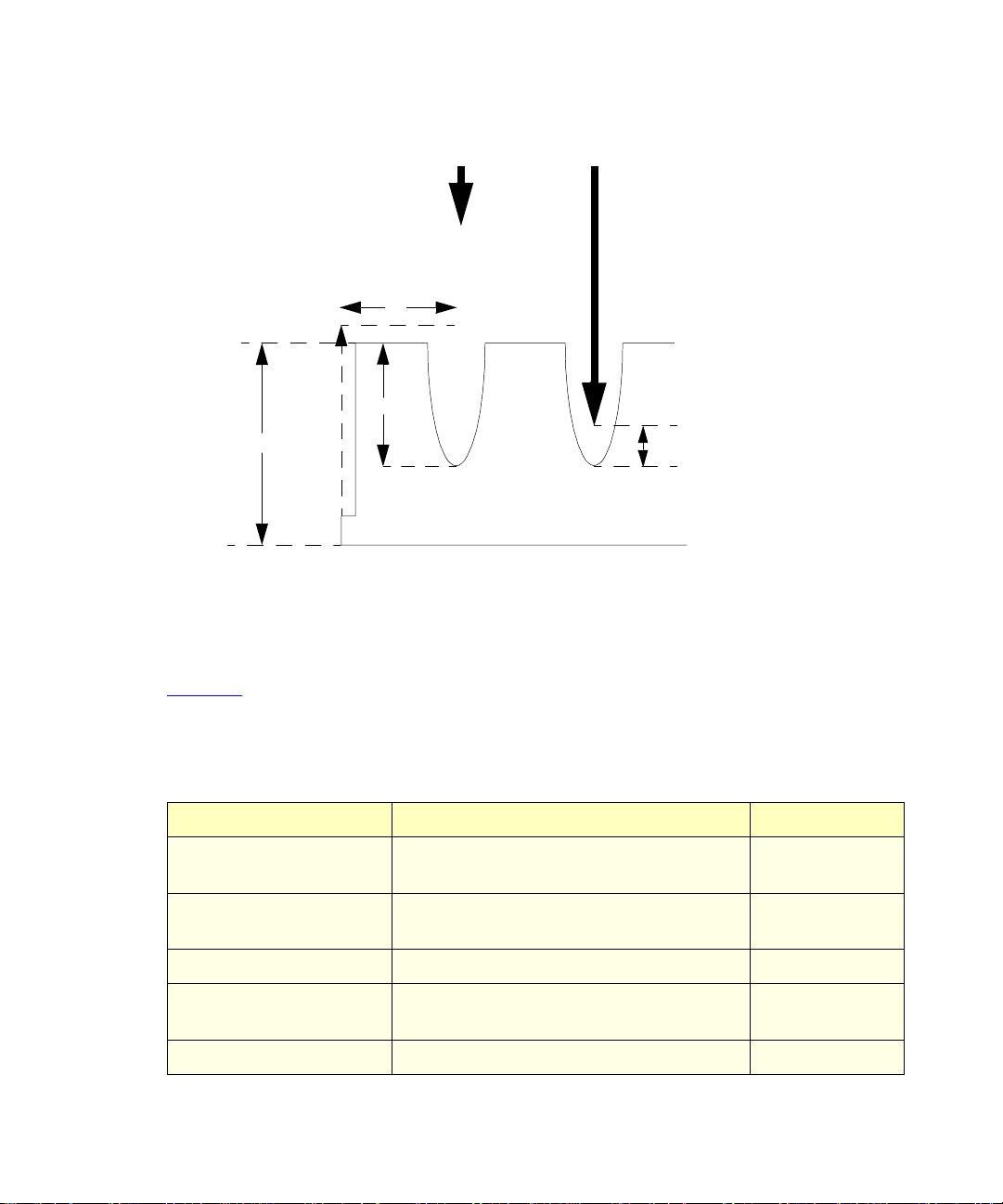

Side View Dimensions

Needle Up

A

Well Depth

Plate Height

*

The Needle Depth Offset parameter i s part of the separation method. See the

Module Operator’s Guide

, Section 5.1, Creating and Editing Separation Methods.

Needle Down

Needle Depth Offset

Waters 2790 Separations

Figure 1-10 Plate Parameters (Side View)

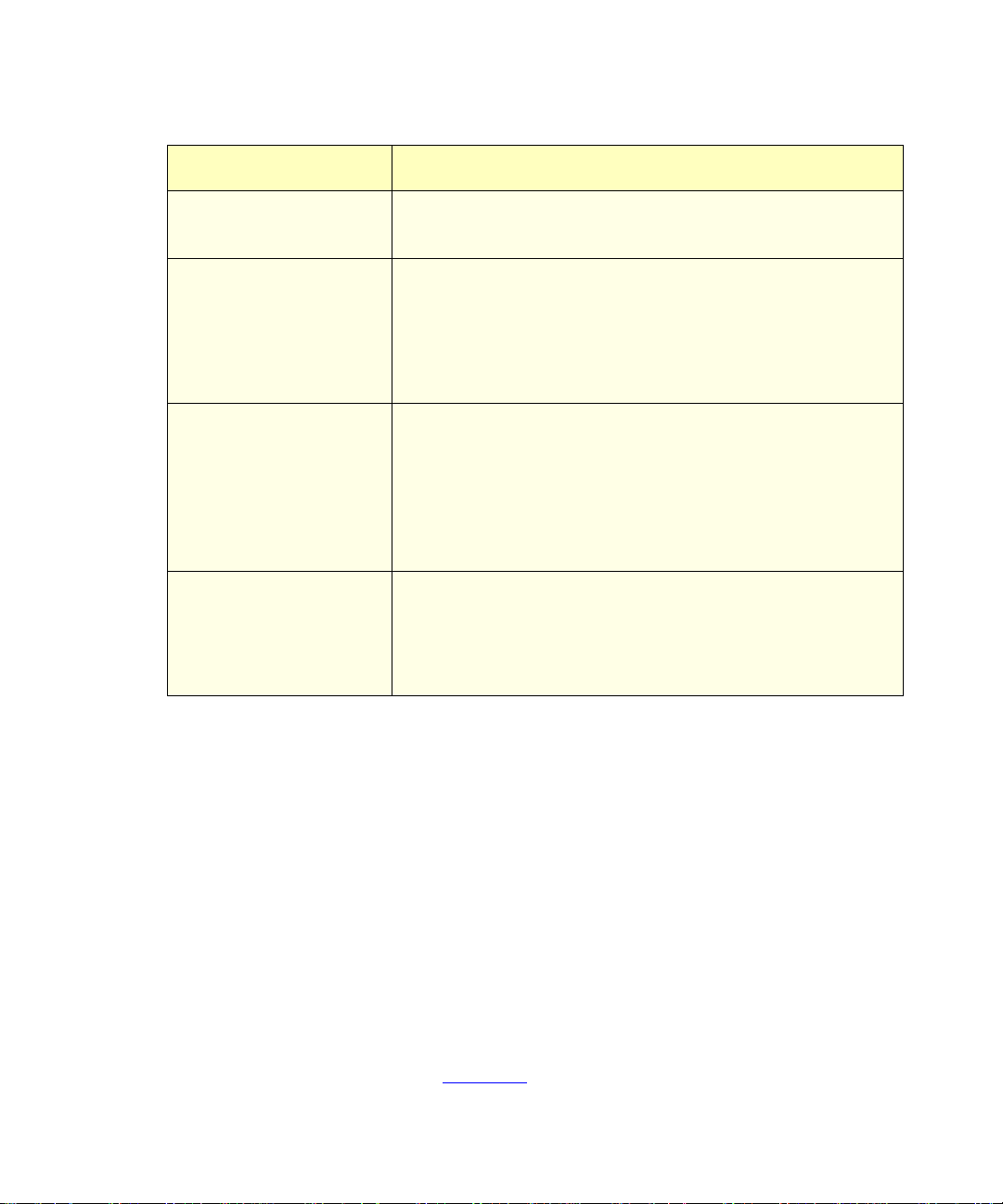

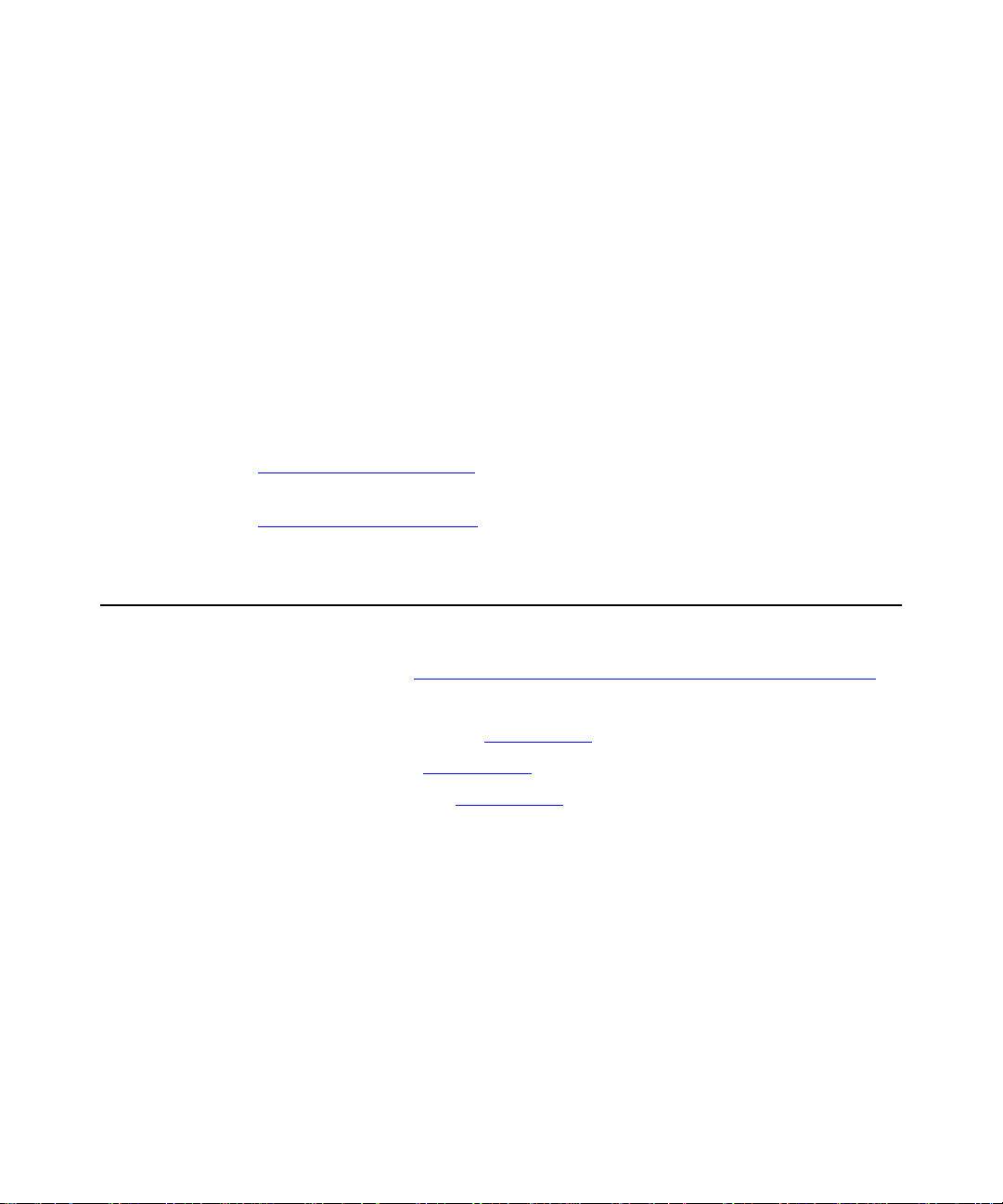

Ta ble 1-3

describes the preconfigured plate types for the 2790. The plate type names

appear as displayed in the Name field of the Plate Type Configuration dialog box.

*

Table 1-3 2790 Preconfigured Plate Types

Plate Type Name Description Part Number

24 uCfuge tube, 1.5 mL 24-well, 1.5 mL microcentrifuge tube

405000560

holder

24 vial (open access), 2 mL24-well, 2 mL vial, open access plate 200000114

48 vial holder, 2 mL 48-well, 2 mL vial holder 405000562

48 uCfuge tube, 0.5 mL 48-well, 0.5 mL microcentrifuge tube

405000561

holder

96 well w/700 uL insert 96-well with 700 µL glass insert plate 186000349

Configuring the 2790 21

Page 22

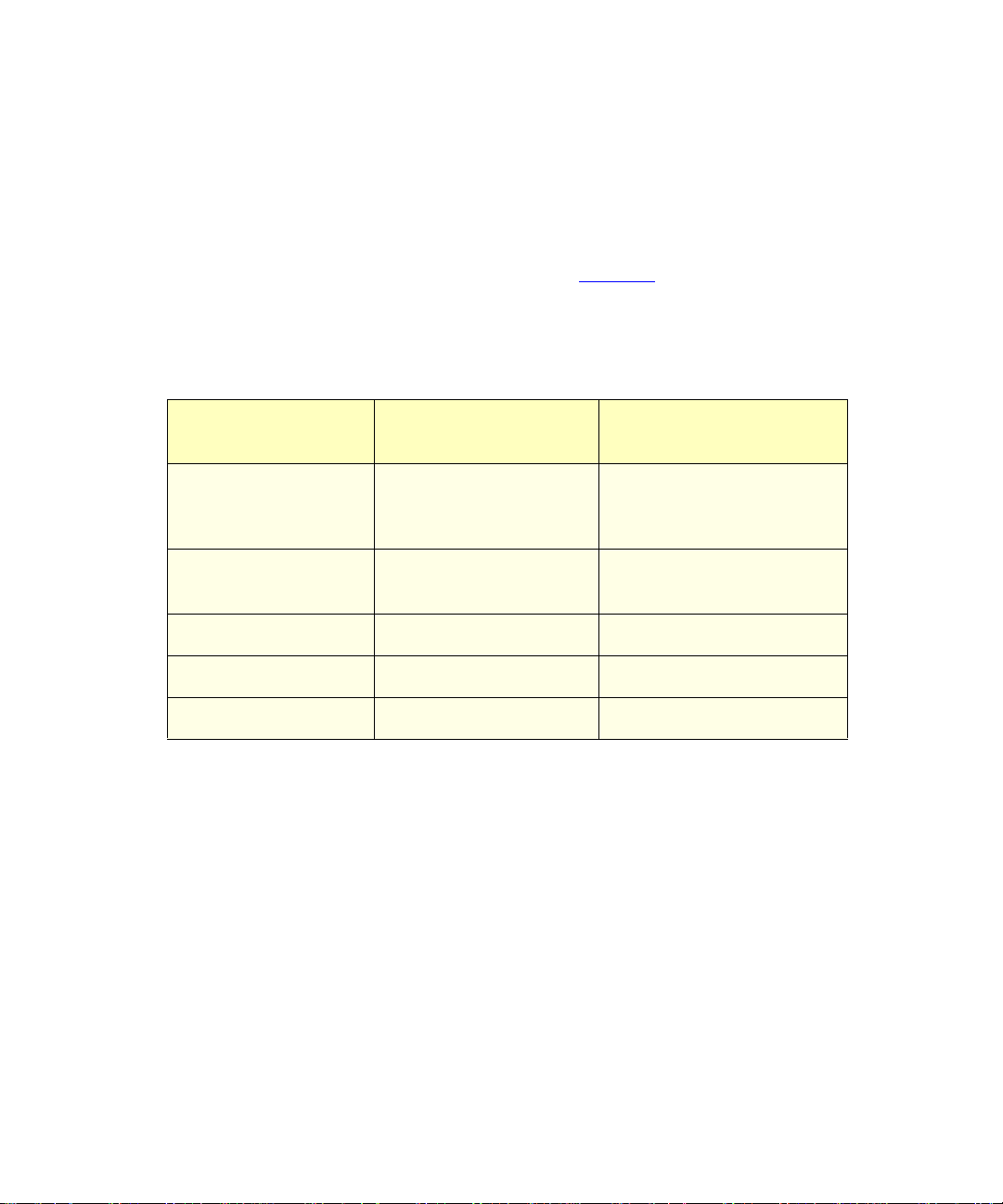

Table 1-3 2790 Preconfigured Plate Types (Continued)

Plate Type Name Description Part Nu mb er

96 well (tall), 350 uL 96-well tall, 350 µL polypropylene WAT058943

96 well (tall), 1 mL 96-well tall, 1 mL, polypropylene WAT058957

96 well (tall), 2 mL 96-well tall, 2 mL, polypropylene WAT058958

96 well, 300 uL

(Default)

96-well, 300 µL, polypropylene or

polystyrene

Non-Waters

384 well, 80 uL 384 well, 80 µL, polystyrene Non-Waters

1

Check the dimensions of all non-Waters plates . For more information on these and other

2790-compatible plates, see the

Waters 2790 Separation s Mo dule Operator’s Guide

1.3 Preparing the Solvent Management System

For optimal performance of t he 2790, y ou need to prepare the solvent and the sample

management systems for operation. Preparing the solvent management system inv olves:

1

*

, Table B-5.

1. Preparing solvent reservoirs (Section 1.3.1

2. Degas sing solvents (Section 1.3.2

)

3. P rim ing the plunger-seal-wash pump (Section 1.3.3

4. P rim ing the s olvent management system (Section 1.3.4

)

)

)

For information on preparing the sample management system, see Section 1.4,

the Sample Management System.

To maintain the efficiency of the solvent management system, and to obtain

Note:

accurate, reproducible chromatograms, use only HPLC-grade solvents.

Preparing

22 Introduction

Page 23

Caution:

Material Safety Data Sheets for the solvents you use.

Observe safe laboratory practices when you handle solvents. Refer to the

1.3.1 Preparing Solvent Reservoirs

Choose solvent reservoirs that provide a snug fit for the reservoir caps supplied in the

startup kit. Waters recommends 1-L reservoirs.

To maintain adequate s olvent head pressure and ensure proper solvent

To prevent solvent overflow, Waters recommends that pressurized solvent

Section 2.4, Making Fluidic Connections.

STOP

STOP

Attention:

delivery, position the solvent reservoirs above the level of the solvent management

system, at least 20 inches (50.8 cm) above the laboratory bench.

Attention:

reservoir bottles not be used. Pressures above 5 psi can cause solvent to be forced

through the internal components of the gradient proportioning valve (GPV), possibly

causing a spillover into the solvent waste reservoir or an ad verse m ix tur e w it h other

solvents in the GPV.

Install the solvent and vent lines as described in the

Operator’s Guide,

1.3.2 Degassing S olvents

Do not run the degasser in Continuous mode unless solvent is flowing through

For optimum efficiency when running the degasser in Normal mode, ensure that all

Only three analytical solvents are degassed using the 2790 in-line degasser. The

STOP

Attention:

the supply tubes. Without solvent flow, e xc ess solvent vapor may condense in the

degasser vacuum chamber walls, which could lead you to suspect a vacuum chamber

leak.

Note:

degasser solvent lines are filled with solvent.

Note:

sample management system uses the fourth (D) chamber of the in-line degasser to degas

the purge solvent. To degas a fourth analytical solvent, use an external solvent degasser,

such as the Waters Two-Channel In-line Vacuum Degas ser (P/N WAT079700) or the

Waters Four-Channel In-line Vacuum Degasser (P/N WAT079800).

Waters 2790 Separations Module

To control the in-line vacuum degasser :

1. Press

2. P ress the

Menu/Status

(Figure 1-11

Next Page

).

. The Status screen is displayed.

screen key (if necessary) to display the Degasser fields

Preparing the Solvent Management System 23

Page 24

3. S elect the

degasser modes:

Degasser

mode field, then press

to display the following list of

Enter

•

Normal

•

Continuous

•

Disable

Degasser Modes

4. S elect the desired operating mode, then press

The Vac pump field displays the current status of the degasser vacuum pump.

The Pressure field displays the current vacuum level in psi, bar, or kPa.

– The degasser cycles on and off on a pressure-regulated cycle.

– The degasser is always on.

– The degasser is always off.

psia

Figure 1-11 Degasser Modes on Status Screen

.

Enter

1.3.3 Priming the Plunger-Seal-Wash Pump

The plunger-seal-wash solvent lubricates the solvent management system plunger and

flushes away solvent or precipitated salts forced past the plunger seal from the

high-pressure side of the solvent piston chamber (see the

Module Operator’s Guide

Required Materials

You need the following materials:

• Tubing adapter (startup kit)

• 30-mL syringe (startup kit)

• Seal-wash solution

24 Introduction

, Figure 7-2).

Waters 2790 Separations

Page 25

Ensure the plunger-seal-wash supply line (labeled “Seal Wash In”) is in the

Note:

plunger-seal-wash solvent bottle and that the plunger-seal-wash waste line is in an

appropriate waste container.

To prime the plunger-seal-wash pump:

1. Disconnect the inlet filter from the plunger-seal-wash inlet tube.

2. Connec t the tubing adapter to the syringe.

3. Fill the syringe with plunger-seal-wash solution, then connect the syringe

assembly to the plunger-seal-wash inlet tube.

4. I n the Main screen, press the

screen key. The Prime Seal Wash dialog box appears (Figure 1-12

When the Prime Seal Wash procedure is not running, the dialog box reads

Note:

screen key, then press the

Diag

“Idle.”

Figure 1-12 Prime Seal Wash Dialog Box

Prime SealWsh

).

5. Press the

on the syringe plunger to push plunger-seal-wash solvent through the system.

6. When the plunger-seal-wash solvent is flowing out of the plunger-seal-wash

waste tube, press the

If you do not press

minutes.

screen key to begin the seal-wash priming procedure, then push

Start

screen key.

Halt

, the seal-wash pump priming procedure stops after 15

Halt

Preparing the Solvent Management System 25

Page 26

7. Press the

to return to the Main screen.

Note:

wash solvent, depending on your application.

8. Rem ove the syringe and adapter, reconnect the filter, and place the

plunger-seal-wash inlet tube into the purge/plunger-seal-wash solvent reservoir.

Close

You can use the same solvent for both the purge solvent and the plunger seal

screen key to return to the Diagnostics screen, then press

Exit

For more information on performing diagnostics procedures, see the

Separations Module Operator’s Guide

, Chapter 8, Diagnostics and Troubleshooting.

Waters 2790

1.3.4 Priming the Solvent Management System

Prime the solvent management system using the:

• Dry prime direct function when the solvent lines are dry

(see Section 2.2.1,

• Wet prime direct function when you want to switch from one solvent to another

(see Section 2.2.2,

Dry P r im ing).

Wet Priming).

1.4 Preparing the Sample Management System

Prepare the sample management system for operation after you have prepared the

solvent management system (Section 1.3,

Preparing the sample management system involves:

1. Priming the needle-wash pump (Section 1.4.1

2. Ref reshing the syr inge (Section 1.4.2

3. Loading the sample plates (Section 1.4.3

Before using the sample management system for the first time, become familiar with the

procedures in the

Performing Direct Functions, and Section 4.3, Monitoring System Status.

Waters 2790 Separations Module Operator’s Guide,

Preparing the Solvent Management System).

)

)

)

Section 4.2,

1.4.1 Priming the Needle-Wash Pump

The needle-wash pump flushes the needle in the sample management system with wash

solvent, prev enting carryover of sample between injections. The needle wash also extends

the life of the inject port seat by removing buffered mobile phase and sample from the

needle.

26 Introduction

Page 27

Prime the needle-wash pump when one or both of the following occurs:

• There is a lack of flow in the needle-wash system.

• You are changing the wash solvent.

Selecting the Needle-Wash and Purge Solvents

Use a needle-wash solvent based on the sample and mobile phase chemistries, making

sure all solutions/buffers are miscible and soluble. Table 1-4

purge solvents recommended for use with certain mobile phase conditions. High sample

concentrations may require other needle wash solvents.

Ta ble 1-4 Suggested Needle-Wash and Purge Solvents

lists some needle-wash and

Chromatographic

Condition

Buffered aqueous,

reversed-phase

Wash Solvent Purge Solvent

50 to 100% MeOH or

ACN

90% H2O, 10% MeOH or

ACN to 50% H

MeOH or ACN

Nonaqueous,

100% MeOH Mobile phase

reversed-phase

Normal phase Mobile phase Mobile phase

GPC Mobile phase M obi le phase

Ion exchange 90% H2O, 10% MeOH H2O

Required Materials

You need the following materials:

• 30-mL syringe (startup kit)

• Tubing adapter (startup kit)

• Wash solvent

O, 50%

2

Be sure the needle-wash fluidic lines and reservoirs are installed properly (see the

Note:

Waters 2790 Separations Module Operator’s Guide, Section 2.4.5, Installing the Wash

Reservoirs).

Preparing the Sample Management System 27

Page 28

To prim e the needle-wash pump:

1. Remove the inlet filter from the needle-wash inlet tube.

2. Connec t the syringe adapter to the 30-mL syringe.

3. Fill the syringe with wash solvent and connect it to the wash-solvent inlet tube.

4. P ress the

5. P ress the

box appears (Figure 1-13

screen key in the Main screen. The Diagnostics screen appears.

Diag

Prime NdlWash

screen key. The Pr ime Needle Wash Solvent dialog

).

Figure 1-13 Prime Needle Wash Solvent Dialog Box

6. P ress the

screen key to begin the needle wash, then press lightly on the

Start

syringe plunger to push need le-wash solvent t hrough the needle-wash system. If

solvent does not flow out of the needle-wash-waste tubing within 30 seconds,

press

a second time.

Start

If solvent still does not flow out of the waste line, check for leaks in the tubing or

sample management compartment.

7. When needle-wash solvent flows out of the needle-wash waste tube, press the

Halt

If you do not press

seconds.

8. Press the

to return to the Main screen.

9. Rem ove the syringe and adapter, reconnect the filter, and place the solvent line

back in the needle-wash solvent reservoir.

28 Introduction

screen key.

Close

, the needle-wash prime procedure stops after 30

Halt

screen key to return to the Diagnostics screen, then press

Exit

Page 29

For more information on performing diagnostics procedures, see the

Separations Module Operator’s Guide

1.4.2 Refreshing the Syringe

Refresh the syringe whenever you do any of the following:

• Prime the solvent management system

• Change solvents

• See bubbles in the syringe

• Star t using the 2790 at the beginning of each day

Waters 2790

, Chapter 8, Diagnostics and Troubleshooting.

STOP

Attention:

To prevent degradation to the syringe and valves, avoid the use of salt buffers

in the purge solvent. Use a low concentration (0% to 50%) organic-aqueous solvent that is

similar to the mobile phase, initial gradient conditions, or sample diluent (see

When you purge the syringe for the first time or when you change the purge solvent,

Note:

set the number of syringe strokes to 80 and the replacement volume to

600

Table 1-4

µ

L. This

).

volume fills the entire degasser chamber and the associated inlet tubing (with the standard

500-µL syringe installed).

To refresh the syring e:

1. Press the

Menu/Status

key. The Status screen appea rs (Figure 1-14

).

psia

Figure 1-14 Status Screen

Preparing the Sample Management System 29

Page 30

2. Turn on the degasser by selecting either

Degasser drop-down list (see the

Guide

, Section 4.3, Monitoring System Status).

Waters 2790 Separations Module Operator’s

Normal

or

Continuous

mode in the

3. P ress the

(Table 2-1

4. S elect the

dialog box appears (Figure1-15

Direct Function

).

Refresh Syringe

Figure 1-15 Refresh Syringe Dialog Box

screen key. A list of direct functions appears

option, then press

).

. The Refresh Syringe

Enter

5. E nter the number of s yringe strokes and the replacement volume of degassed

solvent in the appropriate field. Start with

replacement volume. To pr ime a new or dry instrument, or when you change the

purge solvent, refer to the previous Note.

6. P ress the

screen key. The Refresh Syringe cycle begins.

OK

1.4.3 Loading the Sam ple Pla tes

Attention:

STOP

30 Introduction

the needle or XYZ mechanism.

The 2790 plate carrier holds up to four rectangular plates that you load through the front

panel compart men t door (F igure 1-16

located in the left rear corner and the front edge of the plate is behind the guide button on

the front edge of the carrier (Figure 1-16

Using vial caps smaller than 8.8 mm in diameter (outer diameter) can damage

syringe strokes and

12

). Load each plate so that position A:1 (or 1) is

).

600

µL

Page 31

The plate carrier guides hold each plate loosely in place until the plate is moved to the

Inject position. At that time, a plate positioning spring pushes the plate toward the A:1 (left

rear) corner and holds it in position.

STOP

To move the plate carrier from one position to the next, press the

Next

press the color-coded plate number screen key in the Door Is Open dialog box

(Figure 1-17

Attention:

).

The 2790 cannot draw or inject samples when the sample compartment door

is open.

Guide

Button

Plate Carrier

Compartment Door

screen key or the

Sample

(Open)

TP01631

TP01631

Figure 1-16 Positioning the Sample Plate

If you power on the 2790 with the sample compar tment door open, close the door,

Note:

then reopen it to replace a sample plate on the carrier.

To load the plates onto the plate carrier:

1. Open the 2790 sample compartment door. The Door Is Open dialog box appears

(Figure 1-17

).

Preparing the Sample Management System 31

Page 32

2. P ress the

screen key or select the desired plate number to position the

Next

plate carrier for loading the appropriate plate.

Carrier plate positions are numbered 1 through 4, with individual color

identification as follows:

Position 1 Blue

Position 2 Yellow

Position 3 Red

Position 4 Green

3. Load the plate into the sample compartment with well A:1 (or position 1) at the

left rear position as the plate is loaded into the carrier.

4. Repeat s teps 2 and 3 until all plates are loaded.

5. Close t he s ample compartment door. The Door Is Open dialog box closes and

you return to the previous screen.

The 2790 uses

to locate samples on the plates. For example, sample positions on a:

• 24-vial plate are designated A-D:1-6

• 48-well plate are designated A-F:1-8 or A-H:1-6

32 Introduction

Figure 1-17 Door Is Open Dialog Box

plate logic

(based on letter labels for rows and number labels f or columns)

Page 33

• 96-well plate are des igna ted A-H:1-12

• 384-well plate are designated A-P:1-24

The 2790 also uses a simple numerical well location scheme, where well number 1 is

located at Row 1, Column 1. You can customize the processing order (also known as the

sequential reference

Ta ble 1-5

.

) in the Plate Type Configuration dialog box. See Figure 1-7 and

Position A:1 (or 1) is always located at the left rear of a plate as it is loaded into the carrier.

(Figure 1-16

).

Ta ble 1-5 Sequential Well Location Schemes for Sample Processing Order

Processing Order Icon Function Example (48 Wells)

Left to right, top to

bottom

Increasing columns,

then increasing

rows. Also called

Discontinuous

(horizontal).

Top to bottom, left to

right

Increasing rows,

then increasing

columns. A lso called

Discontinuous

(vertical).

Horizontal

serpentine

Left to right until end

of row, then right to

left starting at next

row. Also called

Continuous

(horizontal).

Vertical ser pentine Top to bottom until

end of column, then

bottom to top

starting at the next

column. Also called

Continuous

(vertical).

12345678

12345678

A

9 10111213141516

B

17 18 19 20 21 22 23 24

C

25 26 27 28 29 30 31 32

D

33 34 35 36 37 38 39 40

E

41 42 43 44 45 46 47 48

F

12345678

1 7 13 19 25 31 37 43

A

2 8 14 20 26 32 38 44

B

3 9 15 21 27 33 39 45

C

4 10162228344046

D

5 11172329354147

E

6 12182430364248

F

12345678

A

12345678

B

16 15 14 13 12 11 10 9

C

17 18 19 20 21 22 23 24

D

32 31 30 29 28 27 26 25

E

33 34 35 36 37 38 39 40

48 47 46 45 44 43 42 41

F

12345678

1 12132425363748

A

2 11142326353847

B

3 10152227343946

C

4 9 16 21 28 33 40 45

D

5 8 17 20 29 32 41 44

E

6 7 18 19 30 31 42 43

F

Preparing the Sample Management System 33

Page 34

For more information on configur ing sam ple plates, see Section 1.2.5, Configuring Plate

Type s . For more information on selecting individual well locations or grouping wells, see

Section 2.2.8,

Selectin g Wells for Making Injectio ns .

1.5 Preparing the 2790 for Operation

This section outlines in flowchart form the steps to prepare the 2790 for oper ation starting

from three different conditions:

• New or dry

• Powered off or left idle with no solvent flow

• Changing solvents (for example, from a buffered to an organic solvent)

The priming, purging, equilibrating, and other procedures outlined here are described in

detail in Section 2.1,

Accessing Direct Functions.

Figure 1-18

outlines how to prepare a new or dry 2790 for operation.

34 Introduction

Page 35

Start

Fill the Solvent

Reservoirs with Fresh

Solv ent Filtered and

Degasse d b y Vacuu m

Filtration

(Section 1.3.2

a

)

Prime the

Plunger-Seal-Wash

Pump (Section 1.3.3

If Running a Gradient

(for Example, A:B), Set

the A an d B

Composition Fields in

the Status Screen to

50%

)

, Then Wet P rime

for 2 min. at

5.00

mL/min.

(Section 2.2.2

)

Set the Degasser to

Continuous (See

“

Equilibrating Solvents

in the Vacuum

Degasser” in

Section 2.2.2

)

Perform a Dry Prime to

Fill Each Solvent Line

and

Degasser Chamber

(Section 2.2.1

)

Equilibrate the Solvent

in the De gasser

Chamber for 5 min at

a Flow Rate of

mL/min

“

Equilibrating Solvents

a

(See

0.000

in the Vacuum

Degasser” in

Section 2.2.2

b

)

Perform a Wet Prime

(for One of the

5.00

10

mL/min

min at

)

Solvents) for

(Section 2.2.2

Prime the Needle -

Wash Pump

(Section 1.4.1

)

Repeat th e Wet Prim e

at the Same Rate and

Time for Each of the

Remaining Sol vents

Set the Degasser to

Normal

(See “

Equilibrating

Solvents in the

Vacuum Degasser” in

Section 2.2.2

)

Equilibrate for a

Minimum of 10 Col umn

Volumes

(Section 2.2.5

)

Refr esh the S yringe f or

a Minimu m of

80

Cycle s and a

Replacement Volume

600

of

(Section 1.4.2

µL

)

System Is Ready

a. To maximize degasser efficiency, Wate rs recommends tha t all four solvent reservoirs be filled (the

fou rth chamber i s used for degassing the purge solvent). If you choose wat er as an “unused”

solvent, change the water weekly to pre vent bacterial contamination.

b. Except for the bri ef period of time required to equilibrate solvents in the degasser, do no t run the

degasser without solvent flow. Refer to the

Waters 2790 Separ ations Module Operator’s Guide

,

Section 1.2.2, the “In-Line Vacuum Degasser” discussion.

Figure 1-18 Preparing a New or Dry 2790 for Operation

Preparing the 2790 for Operation 35

Page 36

Figure 1-19 outlines how t o prepare fo r operation a 2790 t hat is po wer ed off or i s idle with

no solvent flow.

Start

Set the Degasser to

Continuous

“

Equilibrating

(See

Solv ents in the

Va cu um De ga sse r”

Section 2.2.2

Perform a Wet Prime

(for One of the

Solvents) for

7.500

mL/min

(Section 2.2.2

Repeat the Wet Prime

at the Same R at e an d

Time f or Each Solv ent

2

in

)

min at

)

Equilibrate* the

Solvent in the

Degasser Chamber

for 5 min. at a Flow

0.000

Rate of

(See

Solvents in the

V acu um Dega ss er”

Section 2.2.2

If You Are Runn ing a

Gradient (for Example,

A:B), Set the A and B

Composition Fields in

the Status Screen to

50%

, Then Wet Prime

for 3 min at

mL/min (Section 2.2.2

mL/min

“

Equilibrating

5.00

in

)

Set the Degasser to

Normal

“

Equilibrating Solvents

in the Vacuum

Equilibrate for a

Minimum o f 10 Col umn

(Section 2.2.5

Refresh the Syringe for

a Minimu m of

)

Replac ement Volume

(Section 1.4.2

System Is Ready

(See

Degasser”

Section 2.2.2

Cycle s and a

of

volumes

600

µL

in

)

)

12

)

* Except for the brief period of time re quired to equilibrate solvents in the degasser, do not run the degasser

without solvent flow. Refer to the

“In-L ine Vacuum Degasser” discussion, and Section 1.3.2

Waters 2790 Separations Module Operator’s Guide

in this guide for more details.

, Section 1.2.2, the

Figure 1-19 Preparing an Idle or Powered-Off 2790 for Operation

36 Introduction

Page 37

Figure 1-20 outlines how to change from a buffered solvent to an organic solvent.

Start

Remove the S olvent

Line from the

Reservoir with the

Buffer ed Solve nt

Remove the Solvent

Line from the

HPLC-Grade Water

STOP

Using a Flow Rate of

2.000

mL/min, Perform

a Wet Prime Until Air

Begins to Enter the Line

Place the Previously

Removed Solvent Line

Prime for 10 min. at

Attention:

(Section 2.2.2

into Filter ed

HPLC-Grade Water

and Perform a Wet

mL/min.

(Section 2.2.2

To avoid precipitating salts in the 2790, use an intermediate solvent

)

5

)

such as water when you change from buffers to high-organic-content solvents.

Fill a Clean Solvent

Reservoir with the

Organi c Solvent and

Plac e th e S olv e nt L in e

in the Reservoir

Perform the Steps in

Figure 1-19

For more information, refer to the Waters 2790 Separations Module Operator’s

Guide, Section D.3, Solvent Miscibility.

* Except for the brief period of time required to equilibrate solvents in the degass er, do not run the degasser

in Continuous mode without solvent flow. Refer to the

Section 1.2.2, the “In-Line Vacuum Degasser ” discussion, an d Section 1.3.2

Wa ters 2790 Separ ations Module Operator’s Guide

in this guide for more details.

Figure 1-20 Changing from a Buffered Solvent to an Organic Solvent

,

Preparing the 2790 for Operation 37

Page 38

2

Performing Direct Functions

You can perform many functions through the front panel controls when the 2790 is in

System Controller mode or No Interaction mode (see the

Module Operator’s Guide,

Section 3.2.3, Configuring the Operating Mode).

Waters 2790 Separations

You perform

functions be performed automatically as par t of a separation method (see the

2790 Separations Module Operator’s Guide

Separation Methods).

Direct functions are:

• Dry pr iming (Section 2.2.1

• Wet priming (Section 2.2.2

• Refreshing the syringe (Section 1.4.2

• Purging the 410 or 2410 (if RI detector is installed) (Section 2 .2.3

• Washing the needle (Section 2.2.4

• Equilibrating the system (Section 2.2.5

• Conditioning the column (Section 2.2.6

• Injecting samples (Section 2.2.7

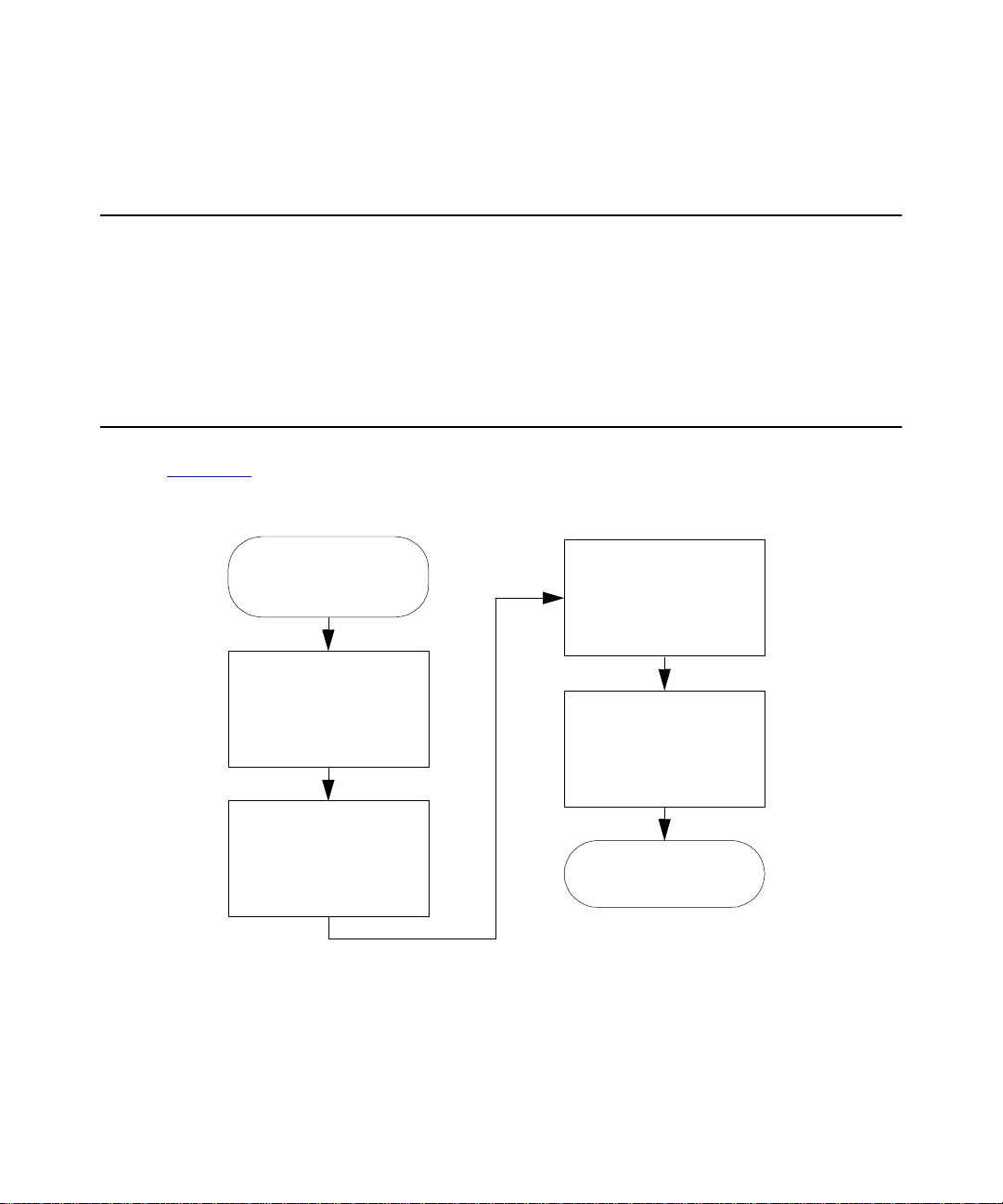

Figure 2-1

functions.

To perform direct functions when the 2790 is controlled by the MassLynx software,

Note:

you need to exit MassLynx control and configure the 2790 for No Interaction mode (see

the Waters 2790 Separations Module Operator’s Guide, Section3.2.3, Configuring the

Operating Mode).

dire ct fun c ti ons

outlines the procedure for using the 2790 front panel to perform direct

as needed during operation. You can also specify these

Waters

, Section 5.1, Creating and Editing

)

)

)

)

)

)

)

)

For information on configuri ng the MassLynx software, see the

Data Acquisition

38 Performing Direct Functions

or the

Waters Alliance LC/ M S S y ste m Qu ick St art Gu ide

MassLynx NT Guide to

.

Page 39

Menu/

Press

Status

Key

Select Separat ion

Method, or Enter

Parameter Values in

the Status Screen

Direct

Press

Function

Select the Direct

Function to Perform

Enter the Function

Parameters

The Function

Begins to Run

Figure 2-1 Steps to Setting Up a Direct Function Control Run

If you make any changes to an existing separation method in the Status

STOP

Attention:

screen, the Method field changes to <direct>, the separation method name in the banner

area is enclosed within brackets (< >), and the current isocratic conditions (with no timed

events) are applied.

2.1 Accessing Direct Functions

To access direct functions:

1. Press

Menu/Status

2. S elect an existing separation method or enter parameter values.

3. P ress the

(Figure 2-2

Direct Function

). Table 2-1 describes the direct functions.

to display the Status screen (Figure 1-14

screen key. A list of direct functions appears

).

Accessing Direct Functions 39

Page 40

Figure 2-2 Direct Functions List

4. S elect a function, then press

described in the following sections. See the

Operator’s Guide

, Section 3.1.2, Using the Keypad, the “Entering and Editing

. Follow the instructions for each function, as

Enter

Waters 2790 Separations Module

Values” discussion, if necessary.

Ta ble 2-1 Direct Functions

Direct Fu nct i on Description Reference

Dry Prime Opens the fluidic path (from the selected

solvent reservoir to the prime/vent valve)

Section 2.2.1, Dry

Priming

to replace air with solvent, t hen performs

a prime.

We t P rim e Replaces solvent in the fluidic path from

the reservoirs through the Prime port of

Section 2.2.2, Wet

Priming

the inject valve to waste. Use to change

the solvent(s) in the system.

Refresh Syringe Refills the syringe with fresh, degassed,

purge solvent.

Section 1.4.2,

Refreshing the

Syringe

40 Performing Direct Functions

Page 41

Table 2-1 Direct Functions (Continued)

Direct Fu nct i on Description Reference

Purge 410/2410

(if applicable)

Wash Needle Washes both the outside and inside of

Equilibrate Selects a column position (if applicable)

Condition Column Selects a column position (if applicable)

Inject Samples Injects a sample one or more times from

Purges the Waters 410 or 2410 RI

detector reference cell.

the needle using wash solvent.

and specifies the system equilibration

time.

and delivers mobile phase using the

gradient table specified in the current

separation method.

the specified well(s) using the selected

method.

2.2 Performing Direct Functions

Section 2.2.3, Purging

the 410 or 2410

Reference Cell

Section 2.2.4,

Washing the Needle

Section 2.2.5,

Equilibrat ing th e

System

Section 2.2.6,

Conditioning the

Column

Section 2.2.7,

Injecting Samples

2.2.1 Dry Priming

Use the dry prime option to prime the system when the fluidic path in the solvent

management system is filled with air.

Required Materials

You need a 30-mL syringe (startup kit).

To perform a dry pri me:

1. Set up the reservoirs as described in Section 1.3.1,

2. I nsert the solvent tubing into the appropriate reservoir(s). Be sure the detector

waste line and the sample loop waste line drain into an appropriate container.

3. Gently shake the filters in the reservoirs to remove any bubbles that may be

trapped.

Preparing Solvent Reservoirs.

Performing Direct Functions 41

Page 42

4. A ttach an empty syringe to the prime/vent valve, as shown in Figure 2-3, then

open the valve by turning it counterclockwise 1/2-turn.

5. Press

Menu/Status

The syringe does not lock onto the prime/vent valve; hold it in place while you

Note:

pull on the plunger.

to display the Status screen (Figure 1-14

TP1359A

TP01359A

Figure 2-3 Prime/Vent Valve with Syringe

).

6. P ress the

(Figure 2-2

7. Select

(Figure 2-4

42 Performing Direct Functions

Direct Function

).

Dry Prime

).

screen key. The Direct Functions list appears

, then press

. The Dry Prime dialog box appears

Enter

Page 43

Figure 2-4 Dry Prime Dialog Box

8. P ress the s creen key corresponding to the solvent line you want to prime.

9. Withdraw the syringe plunger to pull solvent through the t ubi ng. You may need t o

exert force to pull the air and solvent through the system. Continue until you pull

all the air through the solvent line into the syringe.

10. Repeat steps 7 to 9 for each solvent line you want to prime, then close the

prime/vent valve.

11. Press a screen key corresponding to the solvent line with which you want to

prime the system.

Waters recommends that you prime using the solvent with the lowest

Note:

viscosity to help purge air from the lines, especially if the in-line vacuum degasser is

installed.

12. Enter the length of time (in minutes) to prime the solvent management system in

the Enter a duration field. Start with a value of 5 minutes. Press the

screen key.

The solvent management system starts the prim ing function. At the end of the

priming period, the solvent management system turns off and the 2790 enters

the Idle mode.

13. Perform a wet prime, as described below.

Continue

Performing Direct Functions 43

Page 44

2.2.2 Wet Priming

STOP

STOP

Attention:

To avoid damaging the plunger seals, perform a wet prime only when there is

solvent in the solvent management system fluidic path.

Perform a wet prime:

• When you want to change reservoirs or solvents

• If the 2790 has been idle for some time

• If you have just completed a dry prim e

The wet prime replaces solvent in the path from the reservoirs through the Prime position

of the inject valve to waste. If the solvent lines are dry, perform the dry prime procedure

before continuing (see Section 2.2.1,

Attention:

To avoid having salts precipitate in the 2790, use an intermediate solvent such

Dry Priming).

as water when you change from buffers to high-organic-content solvents. Refer to the

Waters 2790 Separations Module Operator’s Guide, Section D.3, Solvent Miscibility, for

information on solvent miscibility.

To perform a wet prime:

1. Press

2. I n the Composition field, enter

Menu/Status

priming.

to display the Status screen (Figure 1-14).

% for the solvent you want to use for wet

100

Waters recommends that you star t the wet prime using the solvent with the

Note:

lowest viscosity to help purge air from the lines.

3. Press the

(Figure 2-2

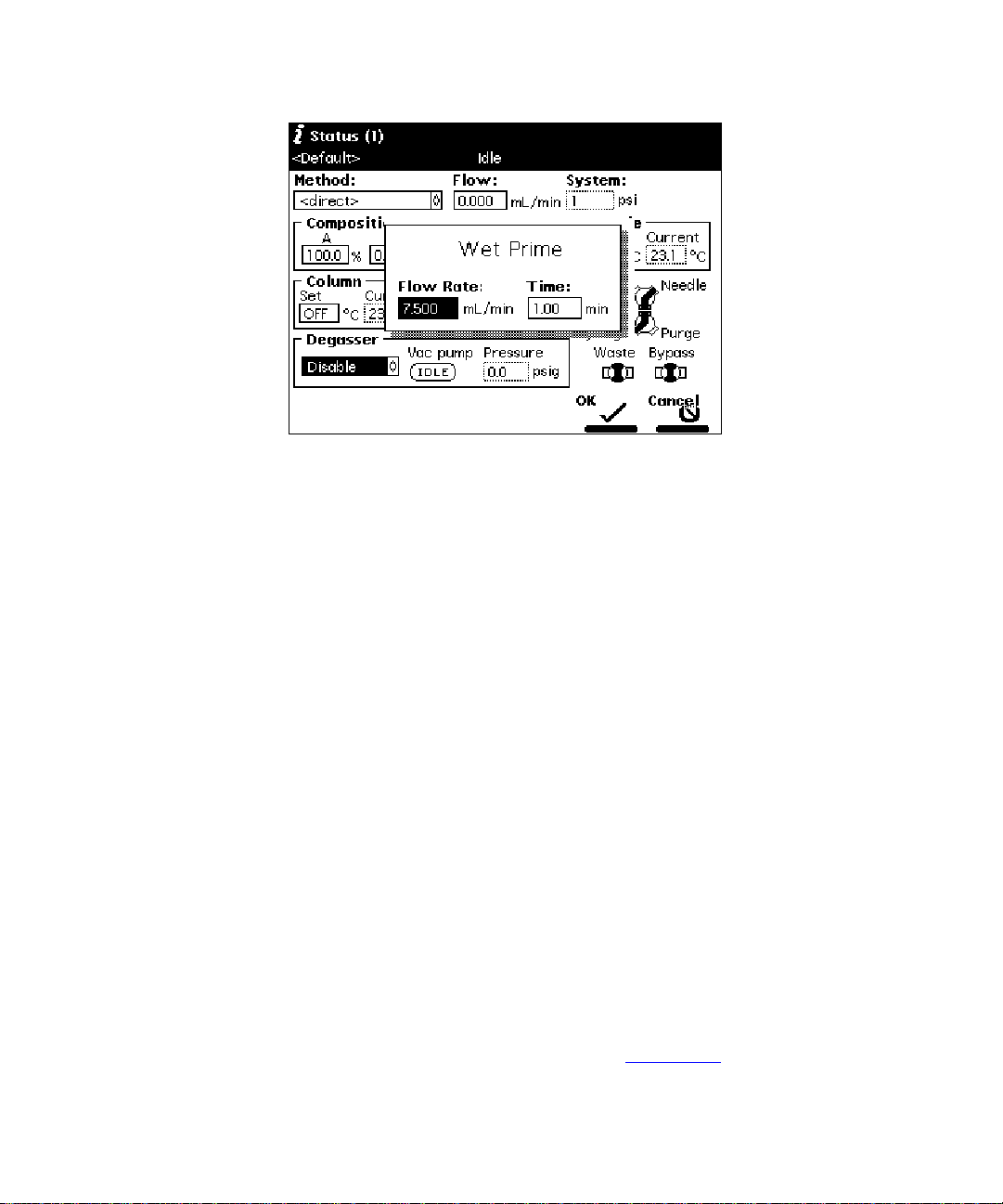

4. Select

(Figure 2-5

44 Performing Direct Functions

Direct Function

).

Wet Prime

).

screen key. The Direct Functions list appears

, then press

. The Wet Prime dialog box appears

Enter

Page 45

Figure 2-5 Wet Prime Dialog Box

5. Gently shake the filters in the reservoirs to remove any bubbles that may have

formed.

6. Enter the flow rate and time (duration) to prime (using the composition entered in

the Status screen), then press the

system begins the priming function.

At the end of the time period you specify, the solvent management system

returns to the previous conditions, and the 2790 enters the Idle mode.

7. Repeat steps 1 to 5 for each solvent, as appropriate.

screen key. The solvent management

OK

Equilibrating Solvents in the Vacuum Degasser

Wet priming occurs at flow rates that do not allow for thorough solvent degassing.

Therefore, after you perform a wet prime, the solvent remaining in the degasser chamber

lines needs to be degassed before solvent flow resumes. This is accomplished by setting a

zero flow rate for a short time period.

For more information on vacuum degassing, refer to the

Operator’s Guide

Vacuum Degasser” discussion.

To equilibrate solvents in the in-line vacuum degasser after you have wet primed the

system:

1. Press

2. E nter the initial solvent composition for the run.

, Section 1.2.2, Solvent Management System Features, the “In-Line

Menu/Status

to display the Status screen (Figure 1-14

Waters 2790 Separations Module

).

Performing Direct Functions 45

Page 46

3. S et the Degasser Mode parameter to

Normal

or

Continuous

.

4. P ress the

(Figure 2-2

5. Select

(Figure 2-5

6. Enter a flow rate of

key. At the end of the time per iod, the solvents are degassed and the 2790

enters the Idle mode.

The solvents in the in-line vacuum degasser are now equilibrated and the 2790 is

prepared to run.

Direct Function

).

Wet Prime

).

, then press

0.000

screen key. The Direct Functions list appears

. The Wet Prime dialog box appears

Enter

mL/min. and time of 5 min, then press the

2.2.3 Purging the 410 or 2410 Reference Cell

Purge the 410 or 2410 RI detector reference cell (and fluidic path) when you change

solvents or experience an unexpected loss in sensitivity due to excess noise or drift.

To purge the 410 or 2410 reference cell:

1. Press

2. E nter the flow rate and composition with which to purge the 410 or 2410

3. P ress the

Menu/Status

reference cell.

Direct Function

(Figure 2-2

).

to display the Status screen (Figure 1-14

screen key. The Direct Functions list appears

screen

OK

).

4. Select

appears (Figure 2-6

5. E nter the am ount of time (in minutes) to pump fresh solvent through the

reference cell, then press the OK screen key. The timer counts down as the

solvent is pumped through the detector reference cell.

46 Performing Direct Functions

Purge 410/2410

, then press

).

. The Purge 410/2410 dialog box

Enter

Page 47

Figure 2-6 Purge 410/2410 Dialog Box

2.2.4 Washing the Needle

The Wash Needle f unct ion:

• Washes the inject port and the interior and exterior of the needle

• Flushes the wash solvent out of the needle and inject port and replaces it with

degassed purge solvent

Use the Wash Needle function to:

• Ensure that the needle and inject por t are clean before the start of a new method

• V erify that the needle-wash system is primed and operating properly by checking for

flow through the waste tube

If the 2790 does not detect that a needle wash was performed since the last time

Note:

the 2790 was powered on, it performs an automatic needle wash before beginning any

injections, either those specified in a sample set or by using the Inject Samples direct

function.

Waters recommends using a high percentage organic wash solvent that is

Note:

compatible with your mobile phase and sample diluent, such as methanol or acetonitrile.

See Tab le 1-4.

STOP

Attention:

wash (see Section 1.4.1,

Make sure the needle-wash solvent line is primed before you perform a needle

Priming the Needle-Wash Pump).

Performing Direct Functions 47

Page 48

To wash the needle:

1. Press

Menu/Status

2. Press the

(Figure 2-2

3. Select

Wash Needle

(Figure 2-7

to display the Status screen (Figure 1-14

Direct Function

screen key. The Direct Functions list appears

).

, then press

Enter

).

Figure 2-7 Wash Needle Dialog Box

).

. The Wash Needle dialog box appears

4. E nter the number of wash cycles in the Wash cycles field (the default is 1).

5. E nter the am ount of time (in seconds) to wash the inject port and the needle

exterior in the appropriate fields.

6. Enter the replacement volume of degassed solvent in the appropriate field. Start

with

7. P ress the

µ

L replacement volume.

600

screen key. The Wash Needle cycle begins.

OK

If necessary, press the

suspend the wash cycle. When solvent flow stops, press the

screen key to end the Wash Needle cycle.

At the end of the final wash cycle, the Wash Needle function automatically flushes out the

needle-wash solvent and replaces it with degassed purge solvent.

48 Performing Direct Functions

Stop WashNdl

screen key or the

Stop Flow

key to

Abort WashNdl

Page 49

2.2.5 Equilibrating the System

During equilibration of the HPLC or LC/MS system, the 2790 delivers solvents and

maintains separation parameters (such as sample and column temperature, degasser

operation, and so on) at the conditions shown in the Status screen. The time needed to

equilibrate the system depends on environmental and application-specific factors.

To equilibrate the system:

1. Press

2. E nter the desired initial conditions. Alternatively, in the Method field, select the

3. P ress the

4. Select

Menu/Status

separation method that contains the initial conditions for equilibration.

Direct Function

(Figure 2-2

(Figure 2-8

).

Equilibrate

).

to display the Status screen (Figure 1-14

screen key. The Direct Functions list appears

, then press

. The Equilibrate dialog box appears

Enter

).

Figure 2-8 Equilibrate Dialog Box

5. E nter the am ount of time to equilibrate the system and the column position to

equilibrate (if applicable).

6. P ress the OK screen key. When the equilibration period ends, the 2790 enters

the Idle state. The flow rate remains at the value in the Flow field in the Status

screen.

Performing Direct Functions 49

Page 50

2.2.6 Conditioning the Column

Conditioning the column involves running a solvent gradient through the column without

injecting samples or running the Events table. You select a separation method (see the

Waters 2790 Separations Module Operator’s Guide

Separation Methods and Sample Sets) that contains the gradient parameters you want to

use, then the 2790 runs the gradient.

, Chapter 5, Creating and Editing

To run timed events without injecting a sample, select the

Note:

Inject Samples

option

from the Direct Functions list and enter an injection volume of 0 (see Section 2.2.7,

Injec ting Samples).

To condition the column:

1. Press

2. I n the Method drop-down list, select the separation method with the gradient

3. P ress the

4. Select

Menu/Status

parameters you want to use to condition the column, then press

Direct Function

(Figure 2-2

appears (Figure 2-9

).

Condition Column

to display the Status screen.

screen key. The Direct Functions list appears

, then press

).

. The Condition Column dialog box

Enter

Enter

.

Figure 2-9 Condition Column Dialog Box

5. I n the Column field, enter the column position to condition (if applicable).

50 Performing Direct Functions

Page 51

6. I n the Time f ield, enter the amount of time to c ondition the column. Ensure that

the time is equal to or greater than the time for the gradient defined in the

selected separation method plus any reequilibration time.

7. P ress the OK screen key. The solvent management system r uns the column

conditioning procedure for the specified time.

2.2.7 Injecting Samples

Using the front panel, you can inject one or more samples from one or more wells in a

sample plate. If no separation method is selected, the 2790 uses the instrument conditions

displayed in the Status screen. You c an use gradients and timed events by selecting a

separation method in the Method field. The current separation method is displayed in the

banner area.

STOP

Attention:

If you make any changes to an existing method in the Status screen, the

Method field changes to <direct>, the separation method name in the banner area is

enclosed within angle brackets (< >), and the current isocratic conditions (with no timed

events) are applied.

To inject a sa mp l e :

1. Place the prepared sample(s) or vial(s) into a plate, then insert the plate in the

sample compartment (see the

Section 3.4.3, Loading the Sample Plates).

2. Close t he sample compar t ment door.

3. Press

4. E nter the initial conditions. Alternatively, you can select

5. P ress the

6. Select

Menu/Status

separation method that contains the conditions to perform the injection.

Direct Function

(Figure 2-2

(Figure 2-10

in the Inject Samples dialog box.

).

Inject Samples

), displaying six parameter fields. Table 2-2 descri bes the parameters

to display the Status screen (Figure 1-14

, then press

Waters 2790 Separations Module Operator’s Guide

).

Method

screen key. The Direct Functions list appears

. The Inject Samples dialog box appears

Enter

, then select the

,

Performing Direct Functions 51

Page 52

Figure 2-10 Inject Samples Dialog Box

7. E nter a value in each field, then press

Enter

.

8. P ress the OK screen key to begin the injection(s), or press

the previous screen without injecting any samples.

Cancel

to re tu rn to

52 Performing Direct Functions

Page 53

Table 2-2 Inject Samples Dialog Box Parameters

Parameter Description Value Range

Location Specifies the plate carrier location. 1 to 4

Type Specifies the plate type. One of up to 15 (see

Section 1.2.5, Configuring Plate

Types)

Well(s) Specifies the well number or range

from which you want to make

injections.

Alternatively, you can press the

screen key to select one or more

wells using the Well Selector (see

Section 2.2.8,

Making Injections).

When entering a well range, use the •

key to separate entries. For example,

to inject samples from wells 1 through

20, enter

Inject(s) Specifies the number of injections per

well.

Volume Specifies the volume for each

injection. See the

Selecting Wells for

.

1.20

Waters 2790

Plate

Separations Module Operator’s

Guide

, Section 5.3.7, Setting Sample

Set Parameter Values, the “Injection

Volume” discussion.

Depending on plate type,

1 to 24, 48, 96, or 384

1 to 99

Maximum injection volum e

depends on the size of the

sample loop or 60% of syringe

volume, whichever is smaller.

If the most recently

Note:

applied separation method

specifies a Full Loop, then the

Volume field is not editable. See

the Waters 2790 Separations

Module Operator’s Guide,

Section 5.1, Creating and

Editing Separation Methods.

Run time Specifies the run time for each

injection

0 to 999.99 in minutes

Performing Direct Functions 53

Page 54

2.2.8 Selecting Wells for Making Injections

You can specify the well(s) from which to make injections by using the Well Selector

function. This function is available from any screen that displays the Plate screen key

(Configuration, Sample Set, and Run Samples screens).

To access the Well Selector when you are performing an Inject Samples direct function

(Figure 2-10

), press the

screen key. The Well Selector is displayed (Figure 2-11).

Plate

Well Location

(Plate Logic)

Well Locati on

(Numeric Identifier)

Number of W ells

Selected

Range of

Selected Wells

Sequential

Reference

To select the plate type:

1. Press the

screen key, then select from the drop-down list of available plate

Type

types.

2. Press

to accept the selected plate, or press the

Enter

return to the Well Selector without making a selection.

To select a single well:

1. Press the

Set by Number

can use the arrow keys to move to the specific well you want to specify.

2. Press • to set the selected well, or press