Page 1

Waters 2489

UV/Visible Detector

Operator’s Guide

71500142102 / Revision A

Copyright © Waters Corporation 2007.

All rights reserved.

Page 2

Copyright notice

© 2007 WATERS CORPORATION. PRINTED IN THE UNITED STATES OF

AMERICA AND IRELAND. ALL RIGHTS RESERVED. THIS DOCUMENT

OR PARTS THEREOF MAY NOT BE REPRODUCED IN ANY FORM

WITHOUT THE WRITTEN PERMISSION OF THE PUBLISHER.

The information in this document is subject to change without notice and

should not be construed as a commitment by Waters Corporation. Waters

Corporation assumes no responsibility for any errors that may appear in this

document. This document is believed to be complete and accurate at the time

of publication. In no event shall Waters Corporation be liable for incidental or

consequential damages in connection with, or arising from, its use.

Trademarks

Waters is a registered trademark of Waters Corporation. Empower, e-SAT/I N,

and MassLynx are trademarks of Waters Corporation.

Other trademarks or registered trademarks are the sole property of their

respective owners.

Customer comments

Waters’ Technical Communications departme nt invites you to tell us of any

errors you encounter in this document or to suggest ide as for otherwise

improving it. Please help us better understand what you expect from our

documentation so that we can continuously improve its accuracy and

usability.

We seriously consider every customer comment we receive. You can reach us

at tech_comm@waters.com.

ii

Page 3

Contacting Waters

Contact Waters® with enhancement requests or techn ical questions regard ing

the use, transportation, removal, or disposal of any Waters prod uct. You can

reach us via the Internet, telephone, or conventional mail.

Waters contact information

Contacting medium Information

Internet The Waters Web site includes phone numbers

for Waters locations worldwi de. Go to

www.waters.com, and click About Waters >

Worldwide Offices.

Telephone In the USA or Canada, phone 508 478-2000.

Conventional mail Waters Corporation

34 Maple Street

Milford, MA 01757

USA

iii

Page 4

Safety considerations

Some reagents and samples used with Waters® instruments ca n po se

chemical, biological, and radiological hazard s. Be sure you are aware of the

potentially hazardous effects of all substances you work with. Always observe

Good Laboratory Practice (GLP) guidelines, published by the U.S. Food and

Drug Administration, and consult your organization’s safety representative

for guidance.

When you develop methods, follow the “Pro tocol for the Ado ption of Analyt ical

Methods in the Clinical Chemistry Laboratory,” Ame rican Journal of Medical

Technology, 44, 1, pages 30–37 (1978). This protocol addresses good operating

procedures and the techniques necessary to validate system and method

performance.

Safety advisories

Consult Appendix A for a comprehensive list of warning and caution

advisories.

Operating this detector

When operating this detector, follow standard quality control procedures and

the guidelines presented in this section.

iv

Page 5

Symbols

P

Symbol Definition

Intended use

The Waters® 2489 UV/Visible detector can be used for in vitro diagnostic

testing to analyze many compounds, including diagnostic indicators and

therapeutically monitored compounds . However, only professionally trained

and qualified laboratory personnel should use the instrument for those

purposes.

E C RE

Authorized representativ e of the

European Community

Confirms that a manufactured

product complies with all applicable

European Community directives

For in vitro diagnostic use

IV D

The Waters 2489 UV/Visible Detector is CE-marked according to

the European Union In Vitro Diagnostic Device Directive

98/79/EC.

Calibrating the detector

To calibrate the detector, follow acceptable calibration methods using at least

five standards to generate a standard curve . The concentration range for

standards should cover the entire range of quali ty-control samples, typical

specimens, and atypical specimens.

v

Page 6

Quality control

Routinely run three quality-control samples that represent subnormal,

normal, and above-normal levels of a compound. Ensure that quality-control

sample results fall within an acceptable range, and evaluate precision from

day to day and run to run. Data col lected when qualit y control samples are ou t

of range might not be valid. Do not r eport the se dat a until you ar e cert ain that

the instrument performs satisfactorily.

When analyzing samples from a com plex matrix such as soil, tissue,

serum/plasma, whole blood, and so on, note that the matrix co mponents can

adversely affect results. To minimize these matrix effec ts, Waters

recommends you adopt the following measures:

• Prior to the instrumental analysis, use appropria te sample

pretreatment such as protein precipitation, liquid/liquid extraction

(LLE), or solid phase extraction (SPE) to remove matrix interferences.

• Whenever possible, verify method accuracy and precision using

matrix-matched calibrators and QC samples.

• Use one or more internal standard compounds, preferably isotopically

labeled analytes.

vi

Page 7

IVD authorized representative

Waters Corp o ra tion (Microm a ss UK Ltd.)

Floats Road

Wythenshawe

Manchester M23 9LZ

United Kingdom

Telephone: +44-161-946-2400

Fax: +44-161-946-2480

Contact: Quality manager

Waters Corporation (Micromass UK

Limited) is registered in the United

Kingdom with the Medicines and

Healthcare Products Regulatory Agency

(MHRA) at Market Towers, 1 Nine Elms

Lane, London, SW8 5NQ. The reference

number is IVD000167.

vii

Page 8

viii

Page 9

Table of Contents

1 Theory and Principles of Operation .................................................. 1-1

Detector description ........................................................................................ 1-2

Features . ................... .................... .................... .................. .................... ..... 1-2

Principles of operation .................................................................................... 1-4

Detector optics.................................................................................................. 1-4

Optics assemb l y light path ................................ ... ............. .. .. .............. .. ..... 1-5

Waters TaperSlit Flow Cell ........................................................................ 1-6

Filtering noise ............................................................................................. 1-7

Wavelength verification and test.................................................................... 1-9

Operational modes .......................................................................................... 1-11

Single wavelen g th mo de...... .. .. .............. .. .. ............. ... .......................... .. ... ..... 1-11

Primary para me t er s . ... ............. .. .. .............. .. .......................... .. .............. .. . 1-11

Secondary parameters .............................................................................. 1-12

Dual wavelength mode .................................................................................. 1-12

Chart Out selec t i on mo de s ............. ............. .. .......................... ... .. ............ 1-1 3

Spectrum scanning ...... ............................. ..................................................... 1-13

Cuvette operations......................................................................................... 1-14

RatioPlot......................................................................................................... 1-15

MaxPlot .......................................................................................................... 1-15

Thermal wander management....................................... .. .. ........................... 1-15

2 Installing the Detector .......................................................................... 2-1

Preparing for installation ............................................................................... 2-2

Site selection and power requirements ....................................................... 2-4

Site selection .................................................................................................... 2-4

Power requirements......................................................................................... 2-5

Unpacking and inspecting............................................................................... 2-5

Unpacking ................................................................................................... 2-6

Inspecting .................................................................................................... 2-6

Table of Contents ix

Page 10

Making fluid line connections ....................................................................... 2-6

Connecting columns .................................................................................... 2-7

Assembling the fittings ............................................................................... 2-8

Making connec ti o n s ............. ... .......................... .. ... ............. .. ....................... 2-9

Making electrical power connections .......................................................... 2-9

Detector rear panel ................................................................................... 2-10

Making signal connections ............................................................................ 2-11

Making I/O sign al co n n e ct i o n s ............................. .. .. ............. .. ................. 2-12

I/O signals .................................................................................................. 2-13

Making Ethernet connections ....................................................................... 2-14

Making Ethern et connectio n s w ith Wa ters data syste ms .............. ... .. ... 2-14

Starting a method ..................................................................................... 2-16

Turning the de t ec t or lamp on or off ............ .. .. ............. ... ............. .. .......... 2-16

Connecting the detector to a separations module ................................... 2-18

Generating Auto Zero ............................................................................... 2-18

Generating Chart Mark on Inject ............................................................ 2-19

Connecting to other devices ......................................................................... 2-20

Required mat eri a l s ....................... ... .......................... .. .. .............. .. ............ 2-21

Connecting the cables ............................................................................... 2-21

Connecting the de te ctor to Empower u si n g a n e-S A T /I N mo d ule ......... .. .. . 2-21

e-SAT/IN modu l e ............. .. ........................... .. .......................... ... ............. . 2-2 1

Connecting the detector to the e-SAT/IN module .................................... 2-23

Connecting the detector to a 745/745B/746 data module............................ 2-25

Connecting the detector to a chart recorder................................................. 2-27

Recorder signal .......................................................................................... 2-27

Chart marks .............................................................................................. 2-28

Connecting the detector to the Waters 600 Series Pump........................ .. .. 2-29

Fluid line connections ............................................................................... 2-29

Lamp on/off connections ........................................................................... 2-29

Auto Zero connections ............................................................................... 2-30

Chart Mark connections ........................................................................... 2-31

Inject Start con n e ctions ............... ... ............. .. .. ............. ... ......................... 2-3 2

Pump and detect o r In je ct Start conne ct i o n s ............ .. .. .............. .. .. .......... 2-33

Connecting the detector to the Waters 717plu s Autos ampler..... ................ 2-33

x Table of Contents

Page 11

Auto Zero connections ............................................................................... 2-34

Inject Start con n e ctions ............... ... ............. .. .. ............. ... ......................... 2-3 5

Connecting the detector to a fraction collector............................................. 2-36

3 Preparing the Detector ......................................................................... 3-1

Initializing the detector .................................................................................. 3-2

Diagnostic test failure ................................................................................. 3-3

Using the operator interface .......................................................................... 3-3

Using the display ............................................................................................. 3-3

Absorbance and message icons ................................................................... 3-4

Using the keypad ............................................................................................. 3-6

Navigating the u se r i n te rface ................... .. ... ............. .. .. ............. ... .............. 3-12

Navigating to and from the absorbance screen ................. .. .................... 3-12

Setting up a run ..................... .. .. ............. ... ............. .. .. ............. ... .............. 3-13

Primary and secondary functions ................................................................. 3-14

Operating the Trace and Scale functions ................................................. 3-20

Operating other detector functions............................................................... 3-22

Configuring the detector ........................................................................... 3-22

Configuri ng ev e n t i n pu t s (contact closu res) .............. .. .............. .. ............ 3-2 3

Setting pulse pe riods ............................. .. .............. .. .. ............. .. ... ............. . 3-24

Setting displa y co n t ra st .. ........................... .. .. ............. .. ........................... . 3-2 5

Displaying system info .............................................................................. 3-25

Using Help ................................................................................................. 3-26

Operating the detector................................................................................... 3-26

Overview of detector operation .. ............. ... .. ............. .. ............. ... .............. 3-26

Operating modes .............................................. .. ........................... .. .......... 3-26

Stand-alone operation ............ ............. .. ............. ... .. ............. .. .............. .. ... 3-27

Remote contro l .......... ... ............. .. .. .............. .. ............. .. ........................... .. . 3-27

Verifying the detector.................................................................................... 3-27

Before you begin ........................................................................................ 3-27

Recording samp l e an d r ef e re n c e b ea m energies .. .. .......................... ... .. ... 3-28

Verifying peak response ............................................................................ 3-29

Wavelength calibration ................................................................................. 3-30

Operating the detector in single wavelength mode ..................................... 3-31

Table of Contents xi

Page 12

Operating the detector in dual wavelength mode........................................ 3-32

Changing from single to dual wavelength mode ............................ .. ....... 3-33

Obtaining a RatioPlot ............................................................................... 3-34

Obtaining a MaxPlot ................................................................................. 3-35

Programming timed events, threshold events, and methods...................... 3-35

Timed events .......... .. ........................... .. ............. ... .. ............. .. ................... 3-36

Threshold events ....................................................................................... 3-39

Storing a method ....................................................................................... 3-40

Retrieving a method .................................................................................. 3-41

Viewing events within a method .............................................................. 3-42

Resetting a method ................................................................................... 3-42

Clearing events ......................................................................................... 3-43

Scanning spectra ............................................................................................. 3-44

Before you begin............................................................................................. 3-44

Scanning new spectra.................................................................................... 3-48

Zero scan .................................................................................................... 3-49

Running the sample scan ................... ....................................................... 3-52

Storing a spectrum......................................................................................... 3-56

Getting information about a stored spectrum.............................................. 3-56

Reviewing a stored spectrum ........................................................................ 3-57

Subtracting a spectrum................................................................................. 3-57

Replaying a spectrum.................................................................................... 3-58

Scanning using the cuvette ........................................................................... 3-59

Before you begin ........................................................................................ 3-60

Cuvette scanning procedure ........................................................ .. ........... 3-60

Scanning using a flow cell and a syringe...................................................... 3-62

Conserving lamp life...................................................................................... 3-62

Shutting down the detector........................................................................... 3-65

Removing buffered mobile phase ............................................................. 3-65

Shutting down the detector ............ .. ............. .. ............. ... .. ............. .. ........ 3-65

xii Table of Contents

Page 13

4 Maintaining the Detector ............................................. ........................ 4-1

Contacting Waters Technical Service .......................................................... 4-2

Maintenance considerations .......................................................................... 4-2

Safety precautions ........................................................................................... 4-2

Spare parts....................................................................................................... 4-2

Proper operating procedures ......................................................................... 4-3

Removing the fr o nt le f t pa n e l co ve r............... .. .. ............. .. ........................... .. . 4-3

Routine maintenance................................ ..................................... .................. 4-4

Maintaining the flow cell ................................................................................ 4-4

Flushing the flow cell....................................................................................... 4-5

Removing and cleaning the flow cell............................................................... 4-6

Disassemblin g a n d re a ssembling th e fl o w ce l l............. .. .. .............. .. .............. 4-6

Before you begin .......................................................................................... 4-6

Tools required .............................................................................................. 4-7

Removing the flow cell assembly ................................................................ 4-7

Disassembling the flow cell ...................................................................... 4-10

Inspecting, cleaning, and replacing damaged flow cell components ...... 4-13

Rebuilding th e fl o w ce l l . ............. .. .............. .. .. ............. .. .............. .. ............ 4-13

Replacing th e fl o w ce l l ............. .. ............. ... ............. .. ............. .. .............. .. . 4-15

Replacing the lamp ......................................................................................... 4-16

Lamp characteristics ................................................................................. 4-16

Lamp energy and performance ................................................................. 4-16

When to replace the lamp ......................................................................... 4-17

Removing the la mp.......... ............. .. ............. ... ............. .. .. ............. ... ............. . 4-18

Installing the new lamp................................................................................. 4-21

Recording the new lamp serial number........................................................ 4-23

Setting the lamp threshold............................................................................ 4-25

Replacing fuses ................................................................................................ 4-26

5 Error Messages, Diagnostic Tests, and Troubleshooting ............. 5-1

Error messages .................................................................................................. 5-2

Startup erro r me ssages ......... .............. .. ............. .. ............. ... ............. .. .. .......... 5-2

Table of Contents xiii

Page 14

Error messages preventing operation............................................................. 5-5

User-selected diagnostic tests ........................................................................ 5-8

Overview........................................................................................................... 5-8

Using the diagnostic tests ............................................................................. 5-11

Contacting Waters Technical Service ...................................................... 5-11

Using the sample and reference energy diagnostic tests ........................ 5-11

Using the Input & Output diagnostic tests ............................................. 5-12

Displaying Auto Zero offsets ..................................................................... 5-13

Setting fixed absorbance value ................................................................. 5-13

Setting fixed vol t age output ................... ... .. ............. .. ........................... .. . 5-14

Using the lamp, display, and keypad diagnostic tests ............................ 5-15

Using the Change Lamp diagnostic test .................................................. 5-15

Using the other detector diagnostic tests ................................................ 5-17

Service diagnostic tests ................................................................................. 5-19

Troubleshooting .............................................................................................. 5-19

When you contact Waters.............................................................................. 5-19

Diagnostic tests.............................................................................................. 5-20

Power surges.................................................................................................. 5-20

Hardware troubleshooting ............................................................................ 5-20

A Safety Advisories ..................... ..... ........................................................ A-1

Warning symbols ............................................................................................... A-2

Task-specific hazard warnings........................................................................ A-2

Warnings that apply to particular instruments, instrument components, and

sample types A-3

Burst warning ............................................................................................. A-3

Mass spectrometer flammable solvents warning ...................................... A-3

Mass spectrometer shock hazard ............................................................... A-4

Biohazard warning ...................................................................................... A-4

Chemical hazard warning ........................................................................... A-5

xiv Table of Contents

Page 15

Caution symbol .................................................................................................. A-5

Warnings that apply to all Waters instruments ......................................... A-5

Electrical and handling symbo l s ............. .. ... .. .. .. .. .............. .. .. .. .. ... .. .. .......... A-13

Electrical symbols.......................................................................................... A-13

Handling symbols .......................................................................................... A-14

B Detector Specifications ....................................................................... B-1

Operational specifications ............................................................................. B-2

Optical specifications ..................................................................................... B-4

Optional Waters TaperSlit Flow Cell specifications ............................... B-5

C Spare Parts ............................................................................................ C-1

D Solvent Considerations ....................................................................... D-1

Introduction ...................................................................................................... D-2

Clean solvents.................................................................................................. D-2

Solvent quality................................................................................................. D-2

Preparation checklist....................................................................................... D-2

Water................................................................................................................ D-2

Using buffers...................... .. .. .............. .. .......................... .. ........................... .. . D-2

Tetrahydrofuran .............................................................................................. D-3

Solvent misc ib ility ....... .. ... .. ............. .. ... .. .. ............. .. ... .. .. .. ............. ... .. .. .. ......... D-3

How to use miscibility numbers...................................................................... D-5

Buffered solvents ............................................................................................. D-6

Head height ....................................................................................................... D-6

Solvent visc os i t y ............. ... .. .. .. .. .............. .. .. .. ... .. ............. .. .. ... .. .. ............. ... .. .. .. D-6

Mobile phase solvent degassing ................................................................... D-6

Gas solubility ........................ .. .. .......................................................... .. .. ......... D-7

Effects of intermolecul ar fo rces ....................... .. .............. .. ............. .. .......... D-7

Effects of temp e ra t u re .... .. .............. .. .. ............. .. ........................... .. ............ D-7

Effects of par tia l pre ssure ........ ............. .. ........................... .. ............. ... .. ..... D-7

Table of Contents xv

Page 16

Solvent degassing methods ............................................................................ D-8

Sparging ........................................................................................................... D-8

Vacuum degassi n g ..................................... .. ... ............. .. ........................... .. .. ... D-8

Solvent degassing considerations ................................................................... D-8

Sparging ... .. .... ..... .... .. ..... .... .. ..... .... ..... .. .... ..... .. .... ..... .... .. ..... .... .. ..... .... ..... .. ... D-8

Vacuum Degassing ...................................................................................... D-9

Wavelength selection ...................................................................................... D-9

UV cutoffs for common solvents...................................................................... D-9

Mixed mobile phases...................................................................................... D-10

Wavelength selection for chromophore detection......................................... D-11

xvi Table of Contents

Page 17

1 Theory and Principles of

Operation

This chapter summarizes the Waters® 2489 UV/Visible Detector features

and describes the theory and principles of operation.

Contents:

Topic Page

Detector description 1-2

Principles of operation 1-4

Operational modes 1-11

See also: Appendix B for system specifications and Appendix D for

information on high-performance liquid chromatograp hy (HPLC)

solvent considerations.

1-1

Page 18

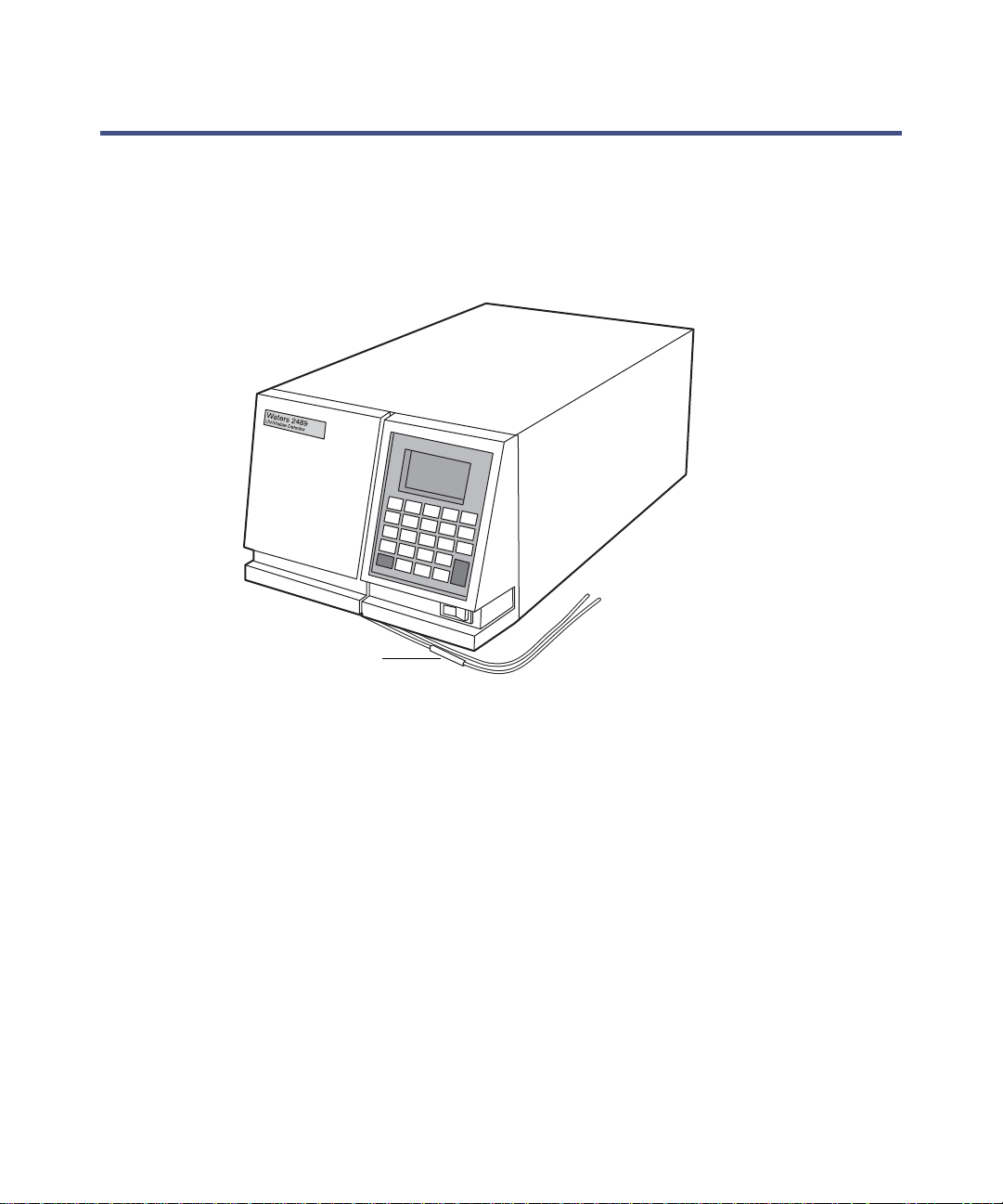

Detector description

The Waters 2489 UV/Visible Detector is a two-channel ultraviolet/visible

(UV/Vis) detector designed for high-performance liquid chromatography

(HPLC) applications.

Waters 2489 UV/Visible Detector

Inlet

The detector can oper ate ei ther as a s ta nd-alone unit (w ith a char t record er or

integrator) or as an integral part of a Waters chromatography system.

The detector can be configured with Empower™ or MassLynx™ software

systems.

Features

The detector operates from 190 to 700 nm. The detector uses optics with an

enhanced illumination system for improved performance. These design

features increase the optical throughput and sensitivity and reduce

bandwidth for an overall increase in signal-to-noise ratio and improved

linearity.

1-2 Theory and Principles of Operation

Page 19

The detector has the following capabilities:

• Stand-alone programmability – Stores up to five user- def ined programs

(or methods) consisting of up to 50 programmable timed events and two

threshold events each.

• Single or dual wavelength – Monitors absorbance at one or two discrete

wavelengths.

• Wavelength verification reference filter – Ensures wavelength accuracy.

• Automatic second order filter – Automatically engaged for wavelengths

370 nm and greater and removed for wavelengths 369 nm or less.

• Spectrum scan and storage – Supports spectrum scan, display,

subtraction, storage, and playback, in addi tion to standard absorbance

and UV/Vis functionality.

• Cuvette qualification – Facilitates qualification of the detector by

insertion of a standard in a cuvette without breaking any fluid line

connections. Waters qualification kits are available in cuvette form to

support this feature. This feature als o allows you to use the detector as a

benchtop spectrophotometer.

• Cuvette sample analysis – Allows the spectrum of any sample placed in

the cuvette to be recorded.

• Method editing and storage – Supports basic me thod programming,

storage, and retrieval from the front panel.

• Full diagnostic capability – Supports buil t-in diagnostic t ools to optimize

functionality and performance.

• Two contact closure outputs – The detector has two configurable

switches, each of which can accommodate a maximum of +

30 Vdc, 1.2-A

current carry, and 0.5-A current switching. The switches (SW1 and

SW2) can trigger fraction collectors and other external devices, as well

as activate based on time, absorbance threshold, or ratio criteria.

• Improved thermal wander management– To mitigate thermal

instability caused by ambient temperature changes, the detector has

improved insulation (for better air flow acros s the optics bench) and a

variable speed fan that will run at higher or lower speeds as needed.

• Median Baseline Filter (MBF) - A variation of the data mode, t he MBF is

intended to decrease the effects of gradient separations on the

chromatographic baseline. The MBF enhances the UV detector's

baseline stability by decreasing its curvature, making the development

of integration methods easier.

Detector description 1-3

Page 20

Principles of operation

To use the detector effectively, you should be famili ar wit h i ts optical and

electronic design and the theory and principles of its operation.

This section describes the following parts and functions of the detector:

•Optics

• Wavelength verification and test

•Flow cell

• Electronics

Detector optics

The Waters 2489 UV/Visible Detector optics are based on a Fastie-Ebert

monochromator and include the following:

• High brightness deuterium (D

• Two mirrors: one off-axis ellipsoidal mirror and one spherical mirror

• Filter wheel

• Shutter, wavelength calibration filter , and second order filter

• Entrance slit

• Blazed, plane holographic diffraction grating

• Beamsplitter

• Sample and reference photodiodes

• Waters TaperSlit™ Flow Cell (its entrance is the exit slit of the

monochromator)

• Cuvette holder

) lamp

2

1-4 Theory and Principles of Operation

Page 21

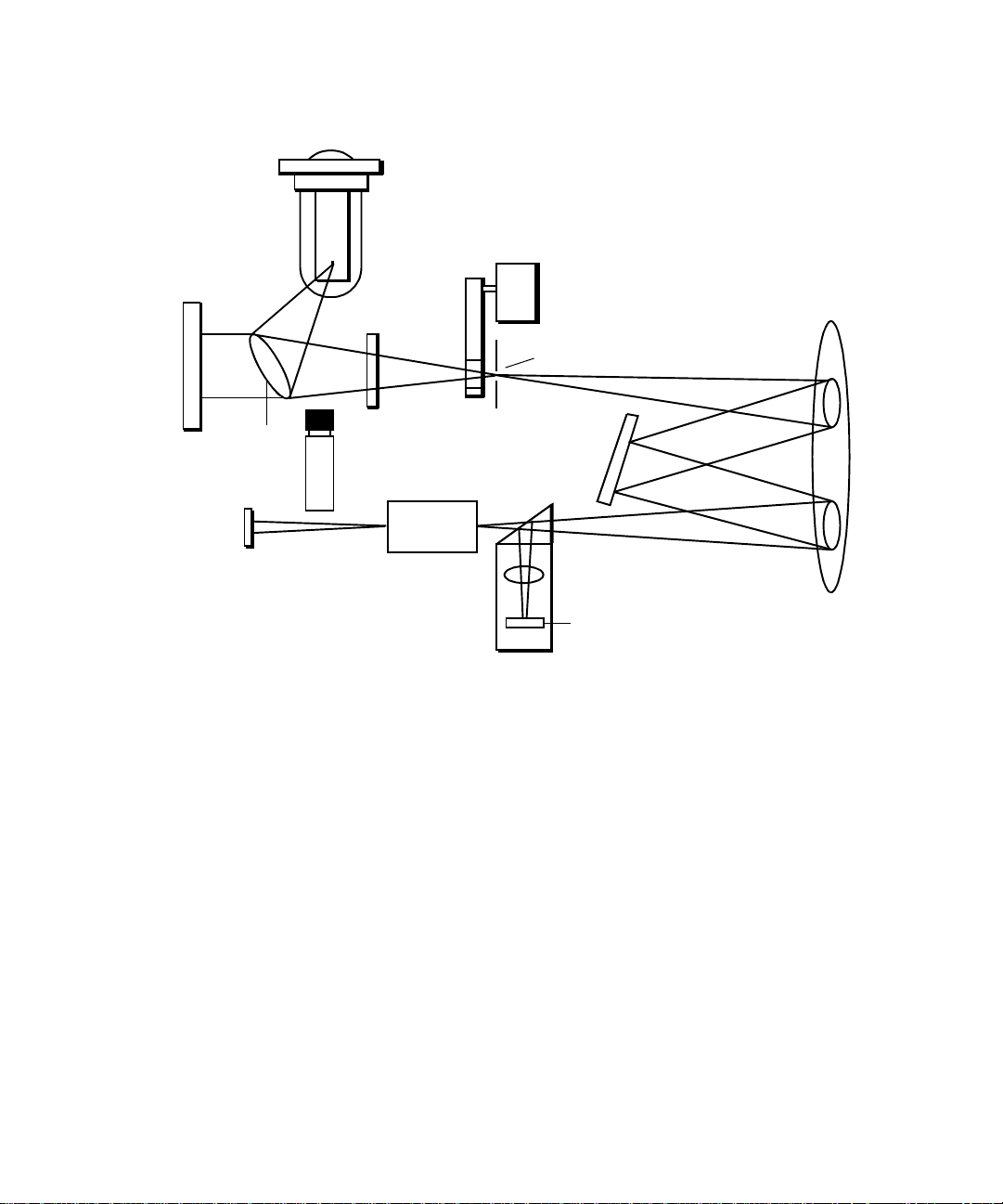

Waters 2489 UV/Visible Detector optics assembly

D2 lamp

Filter

wheel

Slit

Grating

TaperSlit

Flow Cell

Beamsplitter

Reference

photodiode

Ellipsoidal

mirror

Sample

photodiode

Window

Optional

cuvette

Spherical

mirror

Optics assembly light path

The detector provides an extremely effic ient design for exceptionally high

light throughput. It operates as follows:

1. The ellipsoidal mirror collects li ght from the lamp and focuses it through

the filter wheel onto the entrance slit. The spherical mirror directs light

toward the grating. A different portion of the spherical mirror focuses

dispersed light of a particular wavelength band, determined by the

grating angle, onto the entrance of the flow cell. Light exiting the flow

cell passes through the cuvette location to the sample photodiode.

2. The beamsplitter, located just ahead of the flow cell, diverts a portion of

the light to a reference photodiode.

3. When you enter a new wavelength through the det ecto r’s f ront pane l (o r

through Empower™ or MassLynx™ softwar e ), the detector rotates the

grating to the appropriate position.

Principles of operation 1-5

Page 22

4. The preamplifier board integrates and digi tizes the currents from the

photodiodes for processing by the signal processing electronics and

output to a computer, chart recorder, or integrator.

Waters TaperSlit Flow Cell

The Waters TaperSlit Flow Cell used in this detector renders the detector

baseline less sensitive to changes in mobile phase refractive index (RI). RI

changes occur during gradient separations or res ult from temperature or

pump-induced pressure fluctuations.

To achieve RI immunity, a combination of a spherical mirror, a lens at the

entrance of the flow cell, and a taper to the internal bore of the flow cell

prevents light rays from striking the internal walls of the flow cell. An

additional feature of the TaperSlit flow cell and the reason for its name is the

shape of the flow cell entrance, which matches the shape of the entrance slit.

The detector achieves higher light throughput for a given spec tral resolution

via the TaperSlit cell design, compared to a conventional flow cell with a

circular entrance.

As shown in the figure below, in a conventional cell, light bends and hits the

wall of the flow cell. Four beams go in, but only two come out. In the Waters

TaperSlit Analytical Cell, the combination of the lens and Taper Slit bore

geometry prevents light from hitting the cell walls. Four beams go in, and four

beams come out.

1-6 Theory and Principles of Operation

Page 23

Comparison of flow cell characteristics

0

Conventional Cell

UV

Light

Window

Waters TaperSlit™

Analytical Cell

UV

Light

Lens

Window

Window

TP0153

The standard analytical, inert, and LC/ MS cells have a path length of 10 mm.

The semi-prep and microbore cell path length is 3 mm. The autopurification

cell path length is 1.0 mm. A variabl e path length flow c ell (path length 0. 15 to

3 mm) is also available.

Filtering noise

The detector provides a Hamming filter to minimize noise. The Hamming

filter is a digital finite impulse response filter, which creates peak height

degradation and enhances the filtering of high frequency noise.

The behavior of the filter depends on the filter time constant you select. You

can program a filter time to be Fast, Slow, Normal, or Other. If you select

Fast, Slow, or Normal, you do not need to enter a value. The filter constant is

determined by the data rate. If you select Other, you can enter a value.

However, the value you enter will be rounded up or down to a value based on

the data rate.

Principles of operation 1-7

Page 24

The filter time constant adjusts the f ilter response time to achieve an optimal

signal-to-noise ratio. Select ing Other and entering a value of 0.0 disables all

filtering.

Lower time constant settings produce these effects:

• Narrow peaks with minimal peak distortion a nd time delay

• Very small peaks become harder to discriminate from baseline noise

• Less baseline noise is removed

Higher time constant settings produce these effects:

• Greatly decrease baseline noise

• Shorten and broaden peaks

The software includes fast or normal filtering cons tants at each data rate that

are appropriate for high speed or high sensitivity applications respectively.

The following figure shows the relationship between increased filter time

constant and absorbance.

1-8 Theory and Principles of Operation

Page 25

Filter Time Constant comparison

Tip: Although the peak shape shows some distortion and the signal output is

delayed with different time constants, the peak area remains the same.

Wavelength verification and test

The detector deuterium arc lamp and the integral erbium filter exhibit peaks

in the transmission spectrum at known wavelengths.

Upon startup, the detector verifies calibration by comparing the locations of

these peaks with expected wavelengt hs based on cali bration data stored in the

detector’s m e m o r y . If th e results of thi s v e ri fication dif fer from the stor ed

calibration by more than 1.0 nm, the detector displays a Wavelength

Verification Failure message. The detector verif ies rather than r ecalibrates on

startup to avoid errors that may occur because of residual material s left i n the

flow cell and /o r the cuvette.

TP02833

Principles of operation 1-9

Page 26

Requirement: Always ensure that the cuvette is removed and the cuvette

holder and front left panel door are secured during startup verification.

You can initiate a manual wavelength calibration at any time. A manual

calibration replaces the previous calibration data with new data. See

“Wavelength calibration” on pag e 3-30 for the manual wavelength calibration

procedure.

The verification and calibration algorithms are virtually iden tical. However,

the verification algorithm may issue an error message indicatin g that actual

data does not match stored data , wher e the calib ration algor ithm rep lace s the

stored data with the new data.

The detector wavelength verification procedures establish an approximate

Home position using a grating homing sensor. Once Home is established, the

detector locates and references the 656. 1-nm peak in the deuterium lamp

emission spectrum.

The integral erbium filter moves into the common light path ahead of the fl ow

cell entrance slit, enabling the detector to locate three additional spectral

features at these wavelengths:

• 256.7 nm (UV)

• 379.0 nm

• 521.5 nm

The verification tests for the det ect or require 5 minutes of lamp warmup time

so the lamp can stabilize.

If you run the detector continuously, Waters recommend s that you perform

wavelength verification weekly by turning off the detect or, then turning it on

again.

See also: “Wavelength calibration” on page 3-30.

1-10 Theory and Principles of Operation

Page 27

Operational modes

The detector operates in single or dual wavelength mode, allows spectrum

scanning using a flow cell or a cuvett e, and provide s RatioPlot , differe nce plot,

and MaxPlot functions.

Single wavelength mode

Single wavelength is the default mode of operation for the detector. The

detector supports monitoring of a single wavelength from 190 nm to 700 nm,

settable in 1-nm increments on channel A. You can configure the analog

outputs for channel B while the detector is operating in single wavelength

mode, so you can use channel B to obtain additional information about the

wavelength selected on channel A.

In single wavelength mode, the detector automatically engages the second

order filter for wavelengths 370 nm and above and removes it for wavelengths

under 370 nm. The second or der filte r is an op tical filt er that bloc ks unwanted

ultraviolet (UV) light from striking the diff raction grating and interfering

with absorbance detection above 370 nm.

You can configure several additional parameters when using the det ector in

single wavelength mode.

Primary parameters

The following are the major parameters you can use in single wavelength

mode:

• Wavelength in nm – Specifies a wavelength for channel A from 190 to

700 nm settable in 1-nm increments.

• Sensitivity in AUFS – Specifies the scaling factor for the analog output

channels and corresponds to the absorbance unit (AU) value where the

analog outputs saturate at full-scale values. Absorbance units full-scale

(AUFS) vary from 0.0001 to 4.000 AU.

Note: Changing the sensitivity (AUFS) setting affects the 2-V output.

• Chart polarity (+ or –) – Reverses the polarity of the charted

chromatogram. Select + for a normal chromatogram, or – for an inverted

chromatogram. This function changes t he direction o f the plot on the 2 -V

output, similar to reversing the leads to an external chart recorder.

Operational modes 1-11

Page 28

• Filter time constant – Programs a filter time in seconds. Options are

Fast, Slow, Normal, or Other. If yo u sele ct Fast, S low, or Nor mal, you d o

not need to enter a value. The filter constant is determined by the data

rate. If you select Other, you can enter a value, but the value you enter

will be rounded up or down to a value based on the data rate. Selecting

Other and entering a value of 0.0 disables all filtering.

• Analog rate – Specifies a value up to 80 Hz.

Secondary parameters

When on the absorbance (or HOME) screen in single wavelength mode,

pressing Next brings you to several pages of these secondary, or less

frequently specified, parameters:

• Absorbance offset (in mV)

• Auto zero on inject

• Auto zero on λ changes

“Primary and secondary functions” on page 3-14 and the Table titled

“Absorbance and message screen icons” on page 3-4 explain the functions,

ranges, and defaults of these parameter s.

Dual wavelength mode

In dual wavelength mode, the detector can monitor two wavelengths, one on

channel A and one on channel B. The sampling frequency is reduced to 1 or

2 Hz, limiting use of this mode to more standard chromatography where peaks

span at least 20 seconds to enable full characterization of a peak. You can use

dual wavelength mode to obtain additional information about an analyte by

running a RatioPlot or a MaxPlot.

The detector allows you to select any two wavelengths from 190 to 700 nm.

In dual wavelength mode, the following conditions apply:

• If both selected wavelengths are greater than 370 nm, the detector

applies the second order filter to block unwanted UV light.

• If both selected wavelengths are less than or equal to 370 nm, the

detector removes the second order filter.

• If the selected wavelengths bracket the 370 nm threshold, the detector

does not apply the second order filter and issues a warning message that

any data collected for the wavelength above 370 nm may contain

1-12 Theory and Principles of Operation

Page 29

inaccuracies because of possible UV light interference (second order

effects).

Chart Out selection modes

When operating in dual wavelength mode, the d etector off ers these c hoices f or

analog output in addition to the selections off ered in single wavelength mode

and explained in “Single wavelength mode” on page 1-11. The default

selection for dual wavelength mode is Absorbance.

• Absorbance (A and B) – This is the standard LC mode where the curr ent

absorption is scaled and sent directly out the analog output. The scaling

depends on the AUFS setting and the absor bance offset. The abs orbance

value is scaled for the 2-V analog output. If a setting of 1 AU/V is

desired, you can set an AUFS of 2.0000 for either the A or B output

channels that can be controlled independently, even in single

wavelength mode.

• MaxPlot – This mode results in the output of the larger of the two

absorbance values, scaled to the selected AUFS sett ing. This mode is

useful when looking at multiple compounds with absorbancies at two

separate wavelengths with one data channel.

• RatioPlot (A/B) – This mode produces the ratio of absorbance from two

wavelengths. Theoretically, the ratio is constant for a pure

chromatographic peak and variable f or an impure peak. This re sults in a

nonsquared response. Instead of a programmable AUFS, the detector

provides minimum and maximum ratio values that scale the ratio plot

proportionally. In addition, a configurable minimum absorbance

threshold activates ratio output scaling only when it reaches the

absorbance at both wavelengths.

• Difference Plot (A-B) – This mode plots the arithmetic difference in

absorbance for the two monitored wavelengths.

Spectrum scanning

Note: When the detector is operating under the control of the Empower

software, the scanning function is disabled.

You can use the detector as a spectrophot ometer to acquire spectr a from either

the flow cell or the cuvette. You can scan and store up to three sp ectra (three

reference or zero scans, or three sample scans) in memory f or playback or to

compare with other spectra.

Operational modes 1-13

Page 30

The major difference between the detector and a double-beam

spectrophotometer is that the detector employs only one flow cell or cuvette,

rather than a simultaneous sample and a reference pair.

Recommendation: Use a matched pair of cuvettes for the zero and sample

scans.

The detector obtains an absorbance spectrum by perfor ming two types of scan

on the flow cell or using the cuvette:

• Zero scan – Characterizes the baseline abs orbance spe ctrum of a solvent.

• Sample scan – Subtracts the zero scan, so the results displayed or

charted are of the sample only.

To obtain a spectrum of a sample with the detector, you need to run a zero

scan first, followed by a sample scan. Typ icall y, the zero scan i s run wi th pure

solvent and the sample scan is of the analyte dissolved in that solvent.

Spectra can be simultaneously charted on the channel A output, or acquired

and stored in memory for later playback.

See also: “Scanning using the cuvette” on page 3-59 and “Scanning using a

flow cell and a syringe” on page 3-62.

Cuvette operations

The detector cuvette option is used to measure the absorbance spectrum of a

sample in a cuvette.

To generate and store a spectrum:

1. Acquire a zero scan, which measures the absorbance of the contents of

the cuvette and flow cell over the desired wavelength range.

2. Acquire a sample (absorbance) scan, which measures the absorbance of

the analyte dissolved in mobile phase.

The detector subtracts the zero scan from the sample scan to create a sample

spectrum.

Since the cuvette scan is acquired by measuring the absorbance from a light

path that includes both the flow cell and the cuvet te, the so lvent co ndit ions in

the flow cell should be identical for both scans. For a detailed explanation of

cuvette scanning, see “Scanning using the cuvette” on page 3-59.

1-14 Theory and Principles of Operation

Page 31

RatioPlot

The detector allows ratio plotting: comparing the absorbances of a compound

or analyte at two different wavelengths. The RatioPlot divides absorbanc es at

two selected wa v e l en gths and plots th e resulting rati o on a ch a r t re c order or

data system over one output channel (channel A). The RatioPlot is useful in

detecting hidden components present within individual peaks.

The RatioPlot of a spectrally homogeneous peak appears as a rectangular

wave. The RatioPlot of an impure peak appears as a distorted wave. When

obtaining a RatioPlot, you m ust be operating the detector in dual wavelength

mode; the RatioPlot is output on the selected channel.

For an explanation of the RatioPlot procedur e, see the discussio n “Obtaining a

RatioPlot” on page 3-34.

MaxPlot

The MaxPlot function monitors absorbance at two selected wavelengths and

plots the maximum absorbance value for each sample component. To obtain a

MaxPlot, you must operate the detector in dual wavelength mode. The

MaxPlot outputs the greater of the two absorbance values on the selected

channel.

For an explanation of the MaxPlot procedure, see the discussion “Obtaining a

MaxPlot” on page 3-35.

Thermal wander management

To mitigate thermal instability caus ed by ambient temperature changes, the

detector has improved insulation (for better air flow across the optics bench)

and a variable speed fan that will run at higher or lower speeds as needed.

You will hear the fan change speeds in response to the thermal changes. This

is normal operating behavior.

Operational modes 1-15

Page 32

1-16 Theory and Principles of Operation

Page 33

2 Installing the Detector

The Waters® 2489 UV/Visible Detector require s connec tio ns to e lectric al

power and to sample and waste lines to operate in any standard

laboratory environment. This chapter describes how to install the

detector and connect it to the electrical supplies and to other equipment

in an HPLC system.

Contents:

Topic Page

Preparing for installation 2-2

Site selection and power requirements 2-4

Making fluid line connections 2-6

Making electrical power connections 2-9

Connecting to other devices 2-20

2-1

Page 34

Preparing for installation

Major steps in installing the detector

Start installation

procedure

Select appropriate

site

Unpack and

inspect

Install detector

Make fluid line

connections

Make power

connections

Make signal

connections

Make connections

to other devices

Installation

complete

After installing the detector, you should verify its functions and keep the

verified chart output (if applicable) on file. Verification ensures proper

operation of the detector optics and electronics. For proper verification

procedures, see “Verifying the detector” on page 3-27.

2-2 Installing the Detector

Page 35

Detector dimensions

28.4 cm (11.2 inches)

20.8 cm (8.2 inches)

50.3 cm (19.8 inches)

TP02804

Caution: Do not access the instrument through the top cover. Access

the instrument through the front left p anel where the la mp housi ng,

flow cell assembly, and cuv ette holder are located.

Preparing for installati on 2-3

Page 36

Site selection and power requirements

Site selection

Install the detector in an area that meets the requirements listed in the table

below.

Installation site requirements

Parameter Requirement

Operating temperature

range

Storage temperature

range

Relative humidity 20% to <95%, noncondensing

Storage humidity range 0 to <95%, noncondensing

Bench space 12.7 cm (5 inches) clearance at rear

Vibration Negligible

Static electricity Negligible

Power Grounded ac, 100/240 Vac, 50/60 Hz

Requirement: You must mount the detector on a level surface to allow proper

function of the drip management system (drain tube), which you can connect

to a waste reservoir to divert solvent leaks from the flow cell.

4 to 40 °C (39 to 104 °F)

–30 to 60 °C

Power cord type required:

• SVT in the United States

• HAR type (or better) in Europe

For information regarding the type of

cord to use in other countries, contact

your local Waters distributor.

2-4 Installing the Detector

Page 37

Power requirements

Warning: To avoid electric shock,

• use the SVT- ty pe power cord i n th e Un i ted States an d H AR -type

(or better) co r d i n E u r ope.

• power-off and unplug the detector before performing any

maintenance procedures on the instrument.

• connect all HPLC system components to a common ground.

The detector requires

• grounded alternating current (ac) power source.

• minimal power transients and fluctuations.

• a line voltage of 100 to 240 Vac. (Power consumption is 185 volt amps.)

• operation in nominal voltage range of 100 to 240 Vac.

• a 3.15-A 250-V fast-blo fuse

Warning: To avoid electric shock, power-off the detector and unplug

the power cord before you replace the fuse.

Warning: To reduce the risk of fire hazard, always replace the fuse

with the same type and rating.

Unpacking and inspecting

The detector is packed and shipped in one carton that contains the following

items:

• Waters 2489 UV/Visible Detector Startup Kit, which includes this guide

• Power cord

•Release notes

Site selection and power requirements 2-5

Page 38

Unpacking

To unpack the detector

1. Unpack the contents of the shipping carton. As you unpack the carton,

check the contents to make sure you have received all items.

2. Check the contents of the startup kit.

3. Save the shipping carton for future transpo rt or shipment.

Inspecting

If you see any damage or discrepancy when you inspect the contents of the

carton, immediately contact the shipping agent and Waters Technical Service

at 1-800-252-4752, U.S. and Canadian customers only. Other customers, call

your local Waters subsidiary or your local Waters Technical Service

Representative, or call Waters corporat e headquarters for assistance at

1-508-478-2000 (U.S.).

Tip: Make sure the instrument serial number, found on the nameplate on the

rear panel or inside the front left pane l of the detector, corresponds to the

number on the instrument integrity certificate.

For more information about the instrument warranty, see Waters Licenses,

Warranties, and Support Services.

Making fluid line connections

Before initial startup of the detector

1. Complete the fluid line connections described in this section.

2. Complete the electrical connections described in “Making electrical

power connections” on page 2-9.

Caution: Observe Good Laboratory Practices when handli ng

solvents. Refer to the Materi al Safety Data Sheets for the

solvents in use.

2-6 Installing the Detector

Page 39

Requirement: You must make the following fluid line connections on your

detector unit:

• Column connections

• Drip management system connections

Recommendations:

• Before completing the column con n e ctions, perform the veri fi c a ti on

procedures described i n “Verifying the detector” on page 3-27.

• Install a waste reservoir connected to the drain tube, located next to the

rubber foot on the front lower-left section of the detector.

©

• Use Tygon

tubing to connect the drain tube to the waste reservoir.

Caution: The detector, as shipped, ha s a standard analytical fl ow cell

pressure-rated at 1000 psi. To prevent damage, do not connect any

tubing or device that might cause backpressure to excee d the

pressure rating of the tubing or flow cell.

Connecting columns

The fluid line connections to the detector are located in the front right-hand

side of the flow cell assembly (see the figure below).

To make the inlet and outlet tubing connections

1. Attach the stainless s teel compression fitting and ferrule (supplied in

the startup kit).

2. Connect the inlet tubing to the column outlet. Ensure the tubing is

seated firmly, then tighten the compression screw.

3. Connect the Tygon

tubing to the flow cell outlet tubing and route to a

waste container.

Making fluid line connections 2-7

Page 40

Detector fluid line connections

Inlet

(labeled)

Outlet

Assembling the fittings

To assemble each fitting

1. Slide the compression screw over the tubing end, followed by the ferrule.

2. Mount the ferrule with its taper end facing the end of the tubing.

2-8 Installing the Detector

TP02810

Page 41

Ferrule and compression screw assembly

m

Compression screw

Ferrule

Tubing end (straight and

Tube

TP01139

Distance (determined by each

application, such as uni on or col umn fittin g)

smooth to achieve maximu

column efficiency)

Making connections

To make connections at the column outlet and detector inlet, and at the

detector outlet

1. Seat each tubing end in the appropriate fitting.

2. Seat each ferrule by tightening the compression screw 1/2-t urn past

finger-tight.

Requirement: To ensure accu ra t e verificati o n , p o w e r-on the dete ct or before

pumping any mobile phase or solvent through the flow cell.

Recommendation: To prevent reabsor ption of dissolved oxygen (for systems

using vacuum degassers), Waters recommends that you run the solve nt

degasser continuously when operating the detector at wavelengths less than

230 nm.

Making electrical power connections

To connect the detector to the ac power supply:

1. Plug the receptacle end of the power cord into the ac input connector on

the rear panel of the detector (see the figure below).

2. Plug the other end of the power cord into a properly grounded ac power

source.

Making electrical power connections 2-9

Page 42

Detector rear panel

The detector connects to other Waters components through rear panel

electrical connections.

Detector rear panel electrical connections

Inputs and

Outputs

Fan Vent

Power input

Fuse holder

TP02807

Rear panel connections enable the following signals:

• Analog outputs – There are two pairs of attenuated analog channel

outputs with each pair supporting 2-V output to external devices or data

systems. They are labeled I and II. For input/output voltage current

specifications, see the Table titl ed “Operational specifications” on

page B-2.

– The 2-V output for I and II is scaled based on the AUFS (absorbance

units full scale) setting for each channel. The detector does not

provide a traditional “unattenuated” dedicated 1-V/AU output

because of its enhanced working range above 2 AU.

– The detector analog output range specifications are – 0.1 V to 2.1 V.

– You can set the AUFS value individually for the output on each

channel. Volts per AU are calculated as follows:

Volts out = Absorbance × 2V/AUFS

2-10 Installing the Detector

Page 43

Example: An AUFS setting of 2.0000 provides a traditional 1-V/AU

output. An AUFS setting of 4.0000 provides a 0.5-V/AU output,

which supports chromatography above 2 AU.

• Switched outputs – There are two switch contact closures you can

program to turn on, off, toggle, pulse once for a defined duration, or

pulse repetitively for a specified period of time.

• Event inputs – There are four general-purpose TTL contact closures on

the detector A (inputs) terminal that support the following functions:

– Remote or inject start

–Lamp on/off

– Chart mark input

–Auto zero

• Ethernet interface – The Ethernet connection on the rear panel of the

detector allows remote control and direct data acquisition from Waters

Empower and MassLynx workstations.

Making signal connections

The rear panel of the detector (see the fi gure on page 2-10) pro vides two

analog connectors and an Ethernet communications port for operating the

detector with e x te r n a l de vi ces.

Make the signal connections to your detector, considering the following

conditions:

• Operating mode you select for the detector (stand-alone or remote

control)

• Types of instruments that make up your HPLC system

This section describes the input/output (I/O) and digita l signal connections

that you can make from the two rear panel connectors and the Ethernet

connector.

The figure below shows an overview of the steps involved in making signal

connections to the detector.

Making electrical power connections 2-11

Page 44

Overview of making signal connections

Start signal

connection procedure

Connect to Ethernet bus?

No

Connect to other devices?

No

Signal connections

complete

Yes

Yes

Install Ethernet

and inject start cables

Install event and I/O

cable(s)

Making I/O signal connections

The rear panel includes two removable connectors that hold the pins for the

I/O signals, as shown in the figure below. These connectors are keyed so that

you can insert them one way only.

2-12 Installing the Detector

Page 45

I/O signal inputs and outputs

I

II

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

TP01494

I/O signals

The table below describes each of the signals available on the I/O connectors.

Refer to Appendix B for details on the electrical specifications for the signals.

I/O signals for the detector

Signal Description

Inject Start

Lamp On/Off

Chart Mark

Auto Zero

Analog 1

a

a

a

a

b

TTL contact closure. Configurable input to initiate

sequencing of time-program med events. Defines the

start of a run (typically an injection) and resets and

starts the run-time clock to 0.00 minutes. Initial

conditions apply immediately.

Configurable input to allow an external device to turn

the deuterium lamp off and on.

Configurable input to add a chart mark (at 10% of full

scale) to either or both analog output channels.

Configurable input to auto zero either or both

channels.

2-V full-scale analog output signal of cha nnel A (sca led

to the current AUFS setting).

Making electrical power connections 2-13

Page 46

I/O signals for the detector

Signal Description

Analog 2

b

2-V full-scale analog output signal of cha nnel B (sca led

to the current AUFS setting).

Switch 1 (2) Used to connect to a fraction collector. Can be

Switch 2 (2)

a. Inject Start, Chart Mark, Auto Zero, and Lamp inputs are configurable from the detector first

Configuration screen by setting the appropriate parameter to High. See “Configuring event

inputs (contact closures)” on page 3-23 for more detail.

b. See the discussion of attenuation in the detector analog outputs in “Making electrical powe r

connections” on page 2-9.

controlled by threshold and timed events.

Making Ethernet connections

The detector rear panel also includes one Ethernet interface connector for

digital signal communications. Use this connector for devices such a s thes e:

• Network ad a pter card in the E m power work st a ti o n

• Solvent manager

• MassLynx version 4.1 or higher

The Ethernet connector m ates with standard Ethernet cable.

Caution: To avoid possible damage to components, power-off all

instruments on the Ethernet connector before you connect an

Ethernet cable to an instrument.

Making Ethernet connections with Waters data systems

When controlling the detector from a Waters data system or controller

(Empower or MassLynx workstation), you can use the Ethernet interface to

send and receive information from the data system.

When connecting via the Ethernet to these Waters data systems , you should

be aware of the following:

• When in dual wavelength mode, you m ust select a data rate of 1 point

per second in the data system method editor. In Empower software, the

data rate para me te rs defaults to 1 point per secon d.

2-14 Installing the Detector

Page 47

• The maximum range of the detector time constant setting depends on

the wavelength mode and data rate selected. See the Table titled

“Primary and secondary function (method) parameters” on page 3-19.

• Empower allows the detector to operate in both single and dual

wavelength modes with a wavelength range of 190 to 700 nm, and up to

4.0 AUFS.

To connect Ethernet cables from the detector to a Waters data system:

1. Connect the single receptacle end of the Ethernet cable to your data

system by attaching the cable to the network adapter (laboratory

acquisition and control environment, or LAC/E).

Note: The Ethernet cable is supplied with the Waters data system.

2. Connect the other end of the cable to the Ethernet connector on the

detector rear panel.

Caution: The maximum total cable length between Ethernet devices

in a system is 20 meters (65 feet). The maximum recommended cable

length between two Ethernet devices is 4 meters (13 feet). Longer

total cable lengths can cause intermittent Ethernet co mmunication

failures.

Ethernet connections to the detector in a Waters Empower System

busLAC/E or LAC/E32 card

Empower

workstation

Ethernet ca ble

Ethernet

connector

2489

Detector

Tip: When connecting the detector to a data system, all detec tor parameters

not configurable by the data system in use defer to local control.

Making electrical power connections 2-15

Page 48

Starting a met hod

To start a method on the detector at the start of an injection from the

separations module, make the c onnections summarized in the t able below and

illustrated in the figure below.

2695 Separations Module

(B Inputs and Outputs)

2489 Detector (II)

Pin 1 Inject Start Pin 1 Inject Start +

Pin 2 Inject Start Pin 2 Inject Start –

2695 separations module connections to the detector for starting a method

Waters 2695

B

Waters 2489

II

Turning the detector lamp on or off

Before you ca n tu rn the detector la mp on or off from th e s ep a rations modu l e ,

you need to configure the lamp on/off signal at the front panel. You must

change the default lamp configuration p arameter f rom Ignore to High or Low.

See the discussion “Configuring event inputs (cont a ct closures)” on page 3-23

for more information.

2-16 Installing the Detector

TP01525

Page 49

After configuring the detector lamp on/off signal, you can turn the lamp on or

off from the separations module by making t he connecti ons shown in the t able

and figure below.

Detector connections to separation module (lamp on or off)

2695 Separations Module

(A Outputs)

2489 Detector (II)

Pin 1 Switch 1 Pin 4 Lamp On/Off +

Pin 2 Switch 1 Pin 5 Lamp On/Off –

Separations module connections to the detector for turning the lamp on or

off

Waters 2695

A

Waters 2489

II

TP01524

Making electrical power connections 2-17

Page 50

Connecting the detector to a separations module

You can connect the detector to the separations module, when it is not under

the control of the Empower software, to perform the following functions:

• Auto Zero

• Chart Mark on Inject

Generating Auto Zero

To generate the Auto Zero function on the detect or at t he start of an injectio n,

make the connections summarized in the table and illustrated in the figure

below.

Detector connections to a separ ation module to generate Auto Zero

2695 Separations Module

(B Inputs and Outputs)

Pin 1 Inject Start Pin 9 Auto Zero +

Pin 2 Inject Start Pin 10 Auto Zero –

Before you can generate an auto zero from the separations module, you need

to configure the auto zero signal at the detector front panel. The de fault auto

zero signal is Low. See the discussion “Configuring event inputs (cont act

closures)” on page 3-23 for more information.

2489 Detector (II)

2-18 Installing the Detector

Page 51

Separations module connections to the det ector for Auto Zero on Inject

Waters 2695

B

Waters 2489

II

TP01527

Generating Chart Mark on Inject

To generate the Chart Mark function on the detector at the start of an

injection, make the connections summari zed in the table and illustrated in the

figure below.

2695 Separations Module

(B Inputs and Outputs)

2489 Detector (II)

Pin 1 Inject Start Pin 6 Chart Mark +

Pin 2 Inject Start Pin 7 Chart Mark –

Before you can generate a chart mark from the separations module, you need

to configure the chart mark signal at the detector front panel. The default

chart mark signal is Low. See the discussion “Configuring event inputs

(contact closures)” on page 3-23 for more information.

Making electrical power connections 2-19

Page 52

Separations module connections to the detector for Chart Mark on Inject

Waters 2695 Separations Module

B

Connecting to other devices

Waters 2489

II

TP01526

You can connect the detector to a wide range of HPLC system devices. This

section describes how to connect the det ector to the following devices:

• e-SAT/IN™ module (instead of Ethernet)

• Waters 745/745B/746 Data Module

• Chart recorder

• Waters 600 Series Pump

• Waters 717plus Autosampler

• Waters fraction collector

For details on connecting to other dat a modules , see the operator’s guide for

the module you are using.

2-20 Installing the Detector

Page 53

Required materials

When connecting cables to the terminals on the rear panel of the detector, you

need the following tools:

• Small flat-b l a de sc re w d r iver

• Electrical insulation stripping tool

Connecting the cables

To connect cables from other HPLC system devices to the I and II terminals

on the rear panel of the detector :

1. Remove terminal I or II (see Figure “I/O signal inputs and outputs” on

page 2-13).

2. Unscrew the connecting pin terminal.

3. Using the stripping tool, strip the wire down about 3 mm (1/ 8 inch ) from

the end.

4. Insert the st ri pped wire into th e ap propriate con n e ct or.

5. Tighten the screw until the wire is held securely in place.

6. Reinsert the terminal.

7. Press firmly to ensure that it is inserted fully.

Connecting the detector to Empower using an e-SAT/IN module

Acquiring da ta and contro l l ing the detect o r wi th Empower so ftware, by usi n g

the e-SAT/IN module instead of the Ethernet bus, requires connections

between the following hardware:

• Laboratory acquisition and control environment (LAC/E) module

(LAC/E

• Ethernet satellite interface (e-SAT/IN) module

e-SAT/IN module

The Waters e-SAT/IN module shown in the figure below translates analog

signals from devices such as the detector into digital form. It then transmits

these digital signals to the busLAC/E or LAC/E

Empower workstation.

32

Acquisition Server or busLAC/E card)

32

Connecting to other devices 2-21

card installed in the

Page 54

e-SAT/IN module (front panel)

Power

switch

LEDs

I/O connector

Analog inputs

To connect the detector to the Empower workstation:

1. Connect the detector to the e-SAT/IN module. (See “Connecting the

detector to th e e- SA T / IN module” on pag e 2-23.)

Caution:

• The e-SAT/IN module does not have a power switch. To prevent

damage to the module, always disconnect the power cord at either

the wall outlet or the power supply before attaching or removing

the power connection to the e-SAT/IN module.

• To ensure proper startup of the e-SA T/IN module, do not turn on

power to the module until you perform all procedures described in

the Waters e-SAT/IN Module Installa ti on Guide. Improper

startup can damage the unit and void the warranty.

TP02834

2-22 Installing the Detector

Page 55

Connecting the detector to the e-SAT/IN module

The e-SAT/ IN module conn e ct s to the detecto r th rough the B (i np u ts and