Page 1

Waters 2410

Differential Refractometer

Operator’s Guide

34 Maple Street

Milford, MA 01757

71500241002, Revision 3

Page 2

NOTICE

The information in this document is subject to change without notice and should not be construed

as a commitment by Waters® Corporation. Waters Corporation assumes no responsibility for any

errors that may appear in this document. This guide is believed to be complete and accurate at the

time of publication. In no event shall Waters Corporation be liable for incidental or consequential

damages in connection with or arising from the use of this guide.

2001 WATERS CORPORATION. PRINTED IN THE UNITED STATES OF AMERICA.

ALL RIGHTS RESERVED. THIS DOCUMENT OR PARTS THEREOF MAY NOT BE

REPRODUCED IN ANY FORM WITHOUT THE WRITTEN PERMISSION OF THE

PUBLISHER.

Millennium® PIC and Waters are registered trademarks, and busLAC/E and PowerStation are trademarks of

Waters Corporation.

Micromass is a registered trademark and MassLynx is a trademark of Micromass Ltd.

All other trademarks or registered trademarks are the sole property of their respective owners.

Page 3

Note

: When you use the instrument, follow generally accepted procedures for quality

control and methods development.

If you observe a change in the retention of a particular compound, in the resolution

between two compounds, or in peak shape, immediately take steps to determine the

reason for the changes. Until you determine the cause of a change, do not rely upon the

results of the separations.

Note:

The installation category (Overvoltage Category) for this instrument is Level II. The

Level II category pertains to equipment that receives its electrical power from a local lev el,

such as an electrical wall outlet.

STOP

Attention:

responsible for compliance could void the user’s authority to operate the equipment.

Important:

par l’autorité résponsable de la conformité à la réglementation peut annuler de droit de

l’utilisateur à exploiter l’équipement.

Achtung

ausdrückliche Genehmigung der für die ordnungsgemäße Funktionstüchtigkeit

verantwortlichen Personen kann zum Entzug der Bedienungsbefugnis des Systems

führen.

Avvertenza:

espressamente approvate da un ente responsabile per la conformità annulleranno

l’autorità dell’utente ad operare l’apparecchiatura.

Atención

expresamente aprobado por la parte responsable del cumplimiento puede anular la

autorización de la que goza el usario para utizar el equipo.

Changes or modifications to this unit not expressly approved by the party

Toute modefication sur cette unité n’ayant pas été expressément approuvée

: Jedewede Änderungen oder Modifikationen an dem Gerät ohne die

eventuali modifiche o alterazioni apportate a questa unità e non

: cualquier cambio o modificación realizado a esta unidad que no haya sido

Page 4

Caution:

Use caution when working with any polymer tubing under pressure:

• Always wear eye protection when near pressurized polymer tubing.

• Extinguish all nearby flames.

• Do not use Tefzel tubing that has been severely stressed or kinked.

• Do not use Tefzel tubing with tetrahydrofuran (THF) or concentrated nitric or

sulfuric acids.

• Be aware that methylene chloride and dimethyl sulfoxide cause Tefzel tubing to

swell, which greatly reduces the rupture pressure of the tubing.

Attention

pression:

Vorsicht

angebracht:

: soyez très prudent en travaillant avec des tuyaux de polymères sous

• Portez toujours des lunettes de protection quand vous vous trouvez à proximité

de tuyaux de polymères.

• Eteignez toutes les flammes se trouvant à proximité.

• N'utilisez pas de tuyau de Tefzel fortement abîmé ou déformé.

• N'utilisez pas de tuyau de Tefzel avec de l'acide sulfurique ou nitrique, ou du

tétrahydrofurane (THT).

• Sachez que le chlorure de méthylène et le sulfoxyde de diméthyle peuvent

provoquer le gonflement des tuyaux de Tefzel, diminuant ainsi fortement leur

pression de rupture.

: Bei der Arbeit mit Polymerschläuchen unter Druck ist besondere Vorsicht

• In der Nähe von unter Druck stehenden Polymerschläuchen stets Schutzbrille

tragen.

• Alle offenen Flammen in der Nähe löschen.

• Keine Tefzel-Schläuche verwenden, die stark geknickt oder überbeansprucht

sind.

• Tefzel-Schläuche nicht für Tetrahydrofuran (THF) oder konzentrierte Salpeteroder Schwefelsäure verwenden.

• Durch Methylenchlorid und Dimethylsulfoxid können Tefzel-Schläuche quellen;

dadurch wird der Berstdruck des Schlauches erheblich reduziert.

Page 5

Precauzione

pressione:

• Indossare sempre occhiali da lavoro protettivi nei pressi di tubi di polimero

pressurizzati.

• Estinguere ogni fonte di ignizione circostante.

• Non utilizzare tubi Tefzel soggetti a sollecitazioni eccessive o incurvati.

• Non utilizzare tubi Tefzel contenenti tetraidrofurano (THF) o acido solforico o

nitrico concentrato.

• Tenere presente che il cloruro di metilene e il dimetilsolfossido provocano

rigonfiamento nei tubi Tefzel, che riducono notevolmente il limite di pressione di

rottura dei tubi stessi.

: prestare attenzione durante le operazioni con i tubi di polimero sotto

Advertencia:

• Protegerse siempre los ojos a proximidad de tubos de polimero bajo presión.

• Apagar todas las llamas que estén a proximidad.

• No utilizar tubos Tefzel que hayan sufrido tensiones extremas o hayan sido

• doblados.

• No utilizar tubos Tefzel con tetrahidrofurano o ácidos nítrico o sulfúrico

concentrados.

• No olvidar que el cloruro de metileno y el óxido de azufre dimetilo inflan los tubos

Tefzel lo que reduce en gran medida la presión de ruptura de los tubos.

manipular con precaución los tubos de polimero bajo presión:

Page 6

Caution:

specified by the manufacturer, the protection provided by the equipment may be

impaired.

The user shall be made aware that if the equipment is used in a manner not

Attention:

spécifiée par le fabricant, la protection assurée par le matériel risque d’être

défectueuses.

Vorsicht:

Verwenddung des Gerätes unter Umständen nicht ordnungsgemäß funktionieren.

Precauzione:

usta in un modo specificato dal produttore, la protezione fornita dall’apparecchiatura

potrà essere invalidata.

Advertencia:

especificada por el fabricante, las medidas de protección del equipo podrían ser

insuficientes.

Caution:

rating.

Attention:

puissance afin d’éviter tout risque d’incendie.

Vorsicht:

gleichen Typs und Nennwertes ersetzen.

Precauzione:

con altri dello stesso tipo e amperaggio.

L’utilisateur doit être informé que si le matériel est utilisé d’une façon non

Der Benutzer wird darauf aufmerksam gemacht, dass bei unsachgemäßer

l’utente deve essere al corrente del fatto che, se l’apparecchiatura viene

El usuario deberá saber que si el equipo se utiliza de forma distinta a la

To protect against fire hazard, replace fuses with those of the same type and

Remplacez toujours les fusibles par d’autres du même type et de la même

Zum Schutz gegen Feuergefahr die Sicherungen nur mit Sicherungen des

per una buona protezione contro i rischi di incendio, sostituire i fusibili

Precaución:

el riesgo de incendio.

sustituya los fusibles por otros del mismo tipo y características para evitar

Page 7

Caution:

power cord before servicing the instrument.

To avoid possible electrical shock, power off the instrument and disconnect the

Attention:

l’instrument et débranchez le cordon d’alimentation de la prise avant d’effectuer la

maintenance de l’instrument.

Vorsicht:

abgeschaltet und vom Netz getrennt werden.

Precauzione:

il cavo di alimentazione prima di svolgere la manutenzione dello strumento.

Precaución:

de alimentación antes de realizar cualquier reparación en el instrumento.

Afin d’éviter toute possibilité de commotion électrique, mettez hors tension

Zur Vermeidung von Stromschlägen sollte das Gerät vor der Wartung

per evitare il rischio di scossa elettrica, spegnere lo strumento e scollegare

para evitar choques eléctricos, apague el instrumento y desenchufe el cab le

Page 8

Commonly Used Symbols

Direct current

Courant continu

Gleichstrom

Corrente continua

Corriente continua

Alternating current

Courant alternatif

Wechs el s t r om

Corrente alternata

Corriente alterna

Protective conductor terminal

Borne du conducteur de protection

Schutzleiteranschluss

Terminale di conduttore con protezione

Borne del conductor de tierra

Frame or chassis terminal

Borne du cadre ou du châssis

Rahmen- oder Chassisanschluss

Terminale di struttura o telaio

Borne de la estructura o del chasis

Caution or refer to manual

Attention ou reportez-vous au guide

Vorsicht, oder lesen Sie das Handbuch

Prestare attenzione o fare riferimento alla guida

Actúe con precaución o consulte la guía

Page 9

Commonly Used Symbols

Caution, hot surface or high temperature

Attention, surface chaude ou température élevée

Vorsicht, heiße Oberfläche oder hohe Temperatur

Precauzione, superficie calda o elevata temperatura

Precaución, superficie caliente o temperatura elevada

Caution, risk of electric shock (high voltage)•Attention,

risque de commotion électrique (haute tension)

Vorsicht, Elektroschockgefahr (Hochspannung)

Precauzione, rischio di scossa elettrica (alta tensione)

Precaución, peligro de descarga eléctrica (alta tensión)

Caution, risk of needle-stick puncture

Attention, risques de perforation de la taille d’une aiguille

Vorsicht, Gefahr einer Spritzenpunktierung

Precauzione, rischio di puntura con ago

Precaución, riesgo de punción con aguja

(Continued)

Caution, ultraviolet light

Attention, rayonnement ultrviolet

Vorsicht, Ultraviolettes Licht

Precauzione, luce ultravioletta

Precaución, emisiones de luz ultravioleta

Page 10

Waters 2410 Differential Refractometer Information

Intended Use

The W aters® 2410 Differential Refractometer can be used for in-vitro diagnostic testing to analyze

many compounds, including diagnostic indicators and therapeutically monitoredcompounds. When

you develop methods, follow the “Protocol for the Adoption ofAnalytical Methods in the Clinical

Chemistry Laboratory,” American Journal ofMedical Technology, 44, 1, pages 30–37 (1978). This

protocol covers good operatingprocedures and techniques necessary to validate system and method

performance.

Biological Hazard

When you analyze physiological fluids, take all necessary precautions and treat all specimens as

potentially infectious. Precautions are outlined in “CDC Guidelines on Specimen Handling,” CDC

– NIH Manual, 1984.

Calibration

Follow acceptable methods of calibration with pure standards to calibrate methods. Use a minimum

of five standards to generate a standard curve. The concentration range should cover the entire

range of quality-control samples, typical specimens, and atypical specimens.

Quality Control

Routinely run three quality-control samples. Quality-control samples should represent subnormal,

normal, and above-normal levels of a compound. Ensure that quality-control sample results are

within an acceptable range, and evaluate precision from day to day and run to run. Data collected

when quality-control samples are out of range may not be valid. Do not report this data until you

ensure that chromatographic system performance is acceptable.

Page 11

Table of Contents

How to Use This Guide

Chapter 1

Waters 2410 Theory of Operation

1.1 Overview.........................................................................................................1-1

1.2 Theory of Operation........................................................................................ 1-2

1.2.1 Optical Refraction .............................................................................1-2

1.2.2 Differential Refractometry ................................................................1-7

1.2.3 Common RI Detection Problems ...................................................... 1-9

1.3 Principles of Operation.................................................................................. 1-10

1.3.1 Fluidics............................................................................................. 1-10

1.3.2 Optics .............................................................................................. 1-14

1.3.3 Electronics .......................................................................................1-15

Chapter 2

Installing the 2410 Refractometer

2.1 Introduction.....................................................................................................2-1

2.2 Site Selection and Power Requirements.......................................................... 2-2

2.3 Unpacking and Inspection............................................................................... 2-4

2.4 Making Electrical Power Connections............................................................ 2-5

2.5 Making Fluidic Connections...........................................................................2-5

2.5.1 Connecting a Column or Second Detector.........................................2-6

2.5.2 Connecting to Waste ......................................................................... 2-7

2.5.3 Connecting to a Drip Tray .................................................................2-8

Table of Contents xi

Page 12

Chapter 3

Making Signal Connections

3.1 Component Connection Overview.................................................................. 3-1

3.2 Making IEEE-488 Signal Connections ........................................................... 3-3

3.2.1 Connecting to a Waters Data System Using the IEEE-488 Bus ........3-3

3.2.2 Connecting to a Waters PowerLine System Controller ..................... 3-7

3.2.3 Connecting to a Manual Injector .......................................................3-7

3.3 Making Non-IEEE-488 Signal Connections................................................... 3-8

3.3.1 Connecting to a Stand-Alone 2690 Separations Module.................3-10

3.3.2 Connecting to the Waters 745/745B/746 Data Module .................. 3-13

3.3.3 Connecting to a Chart Recorder ...................................................... 3-15

3.3.4 Connecting to the Waters 845/860 ExpertEase System ..................3-16

3.3.5 Connecting Injection Trigger Signals .............................................3-16

3.3.6 Polarity Connections .......................................................................3-18

3.4 Connecting the External Column Heaters..................................................... 3-19

Chapter 4

Preparing Solvents

4.1 Common Solvent Problems............................................................................. 4-1

4.2 Selecting a Solvent.......................................................................................... 4-2

4.3 Solvent Degassing........................................................................................... 4-4

4.3.1 Gas Solubility.....................................................................................4-5

4.3.2 Solvent Degassing Methods .............................................................. 4-5

4.3.3 Solvent Degassing Considerations .................................................... 4-6

Chapter 5

Using the 2410 Refractometer

5.1 Using the Front Panel...................................................................................... 5-1

5.1.1 Keypad Functions .............................................................................. 5-4

5.2 Selecting Parameter Values .............................................................................5-9

xii Table of Contents

Page 13

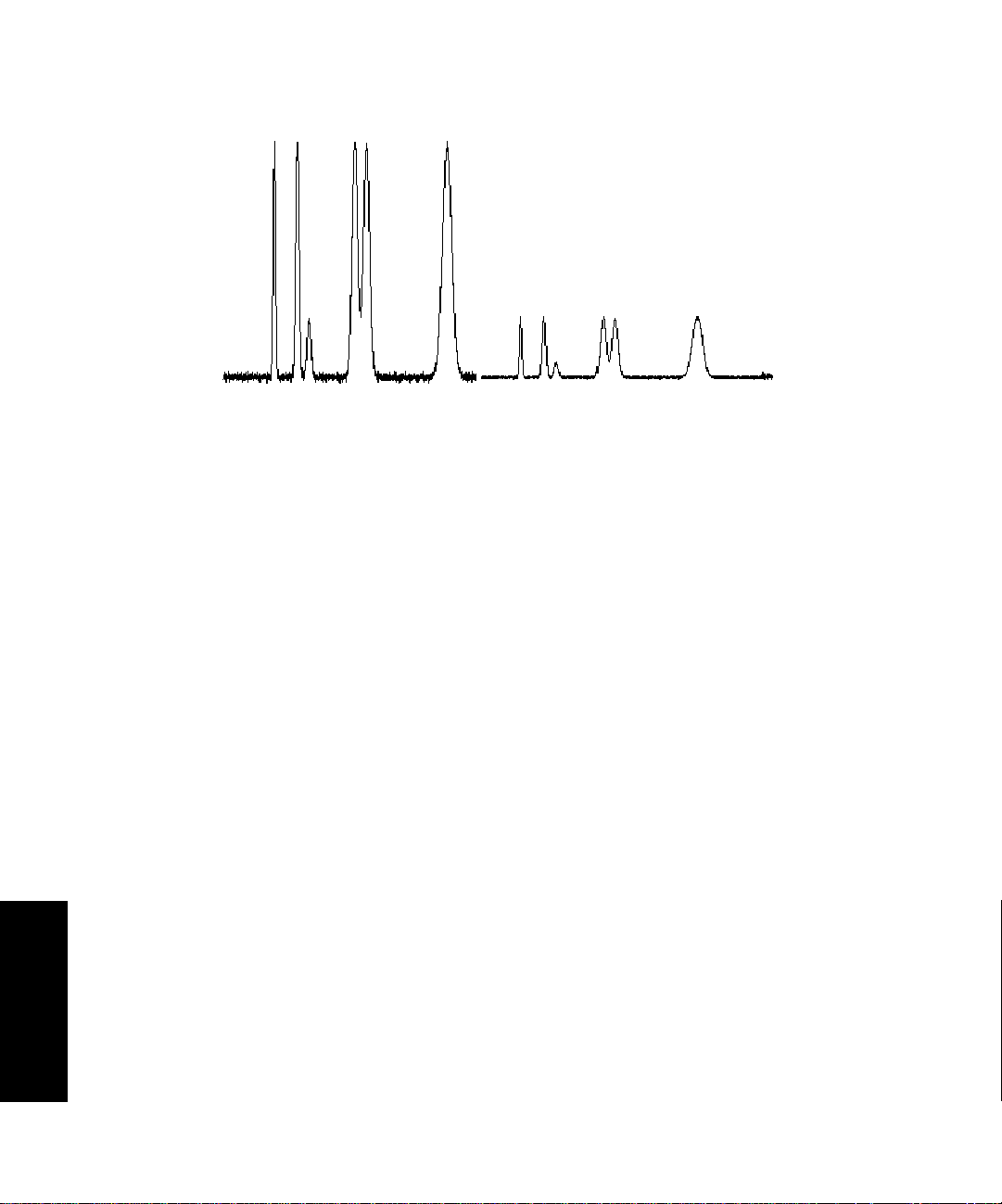

5.2.1 Sensitivity Guidelines ........................................................................5-9

5.2.2 Scale Factor Guidelines ...................................................................5-10

5.2.3 Time Constant Guidelines ...............................................................5-11

5.2.4 Temperature Guidelines (Ext1 °C, Ext2 °C, Int °C) .......................5-12

5.2.5 Polarity Guidelines ..........................................................................5-13

5.3 Starting Up the 2410 Refractometer..............................................................5-13

5.4 Shutting Down the 2410 Refractometer........................................................5-15

Chapter 6

Maintenance Procedures

6.1 Cleaning the Fluidic Path.................................................................................6-1

6.2 Replacing Fuses...............................................................................................6-3

Chapter 7

Troubleshooting

7.1 Troubleshooting Overvie w ..............................................................................7-1

7.2 Chromatography Troubleshooting...................................................................7-2

7.2.1 Abnormal Baseline.............................................................................7-3

7.2.2 Erratic or Incorrect Retention Times .................................................7-7

7.2.3 Poor Peak Resolution ........................................................................7-9

7.2.4 Incorrect Qualitative/Quantitative Results ......................................7-11

7.3 Diagnostics ....................................................................................................7-13

7.3.1 Operating the Startup Diagnostics....................................................7-13

7.3.2 Operating the User-Initiated Diagnostics ........................................7-13

7.4 Hardware Troubleshooting ............................................................................7-16

Chapter Appendix A

Specifications

Chapter Appendix B

Spare Parts/Accessories

Table of Contents xiii

Page 14

Appendix C

Warranty Information

C.1 Limited Express Warranty...............................................................................C-1

C.2 Shipments, Damages, Claims, and Returns.....................................................C-4

Index

xiv Table of Contents

Page 15

Figures

1-1 Waters 2410 Differential Refractometer..................................................1-1

1-2 Effect of Density on RI............................................................................ 1-4

1-3 Refraction of Light................................................................................... 1-5

1-4 Presence of Sample Changes the Photodiode Signal...............................1-6

1-5 How Refraction Changes

1-6 Waters 2410 Refractometer Fluidics...................................................... 1-11

1-7 Waters 2410 Refractometer Fluidic Paths..............................................1-13

1-8 Waters 2410 Differential Refractometer Optics Bench

Assembly Light Path..............................................................................1-15

2-1 Major Steps in Installing the 2410 Differential Refractometer................2-1

2-2 Dimensions of the 2410 Refractometer ................................................... 2-2

2-3 Waters 2410 Refractometer Rear Panel ...................................................2-4

2-4 Fluidic Connections.................................................................................2-6

2-5 Ferrule and Compression Screw Assembly ............................................. 2-7

f

.......................................................................1-8

3-1 Waters 2410 Differential Refractometer Rear Panel................................ 3-2

3-2 Overview of Connecting Components to the

2410 Differential Refractometer.............................................................. 3-3

3-3 Waters Millennium System IEEE-488 Connections................................ 3-4

3-4 Waters 845/860 System IEEE-488 Connections......................................3-4

3-5 Waters Alliance System IEEE-488 Connections .....................................3-5

3-6 Waters PowerLine System Controller IEEE-488 Connections................ 3-7

3-7 Waters 2410 Rear Panel Analog-Out/Event-In Connectors.....................3-9

3-8 Auto Zero Connections Between the 2690 Separations Module

and the 2410 Refractometer................................................................... 3-11

3-9 Chart Mark Connections Between the 2690 Separations Module

and the 2410 Refractometer................................................................... 3-12

3-10 Chart Mark and Auto Zero Connections Between

the 2690 Separations Module and the 2410 Refractometer................... 3-13

Table of Contents xv

Page 16

3-11 Connections to a Waters 745/745B/746 Data Module........................... 3-14

3-12 Analog Output Connections to a Chart Recorder .................................. 3-15

3-13 Analog Output Connections to the Bus SAT/IN Module....................... 3-16

3-14 Auto Zero Connectionto a Manual Injector...........................................3-17

3-15 Chart Mark Connections to a Manual Injector ...................................... 3-18

3-16 2410 Refractometer External Column Heater Ports ..............................3-20

5-1 Display, LED Indicators, and Keypad......................................................5-2

5-2 Effects of Sensitivity Settings................................................................5-10

5-3 Effects of Filter Time Constant Settings................................................5-12

6-1 Removing and Replacing Fuses...............................................................6-4

xvi Table of Contents

Page 17

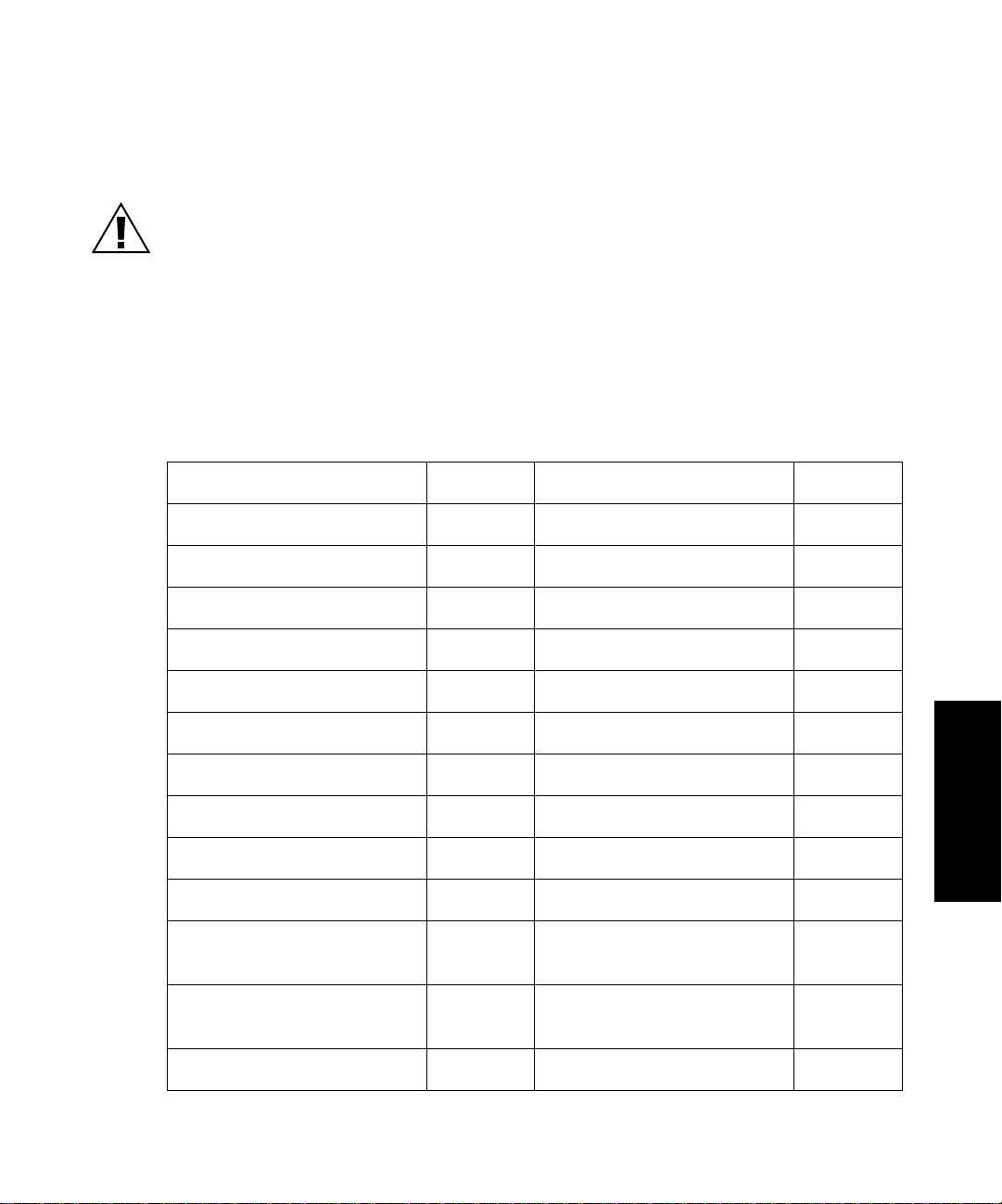

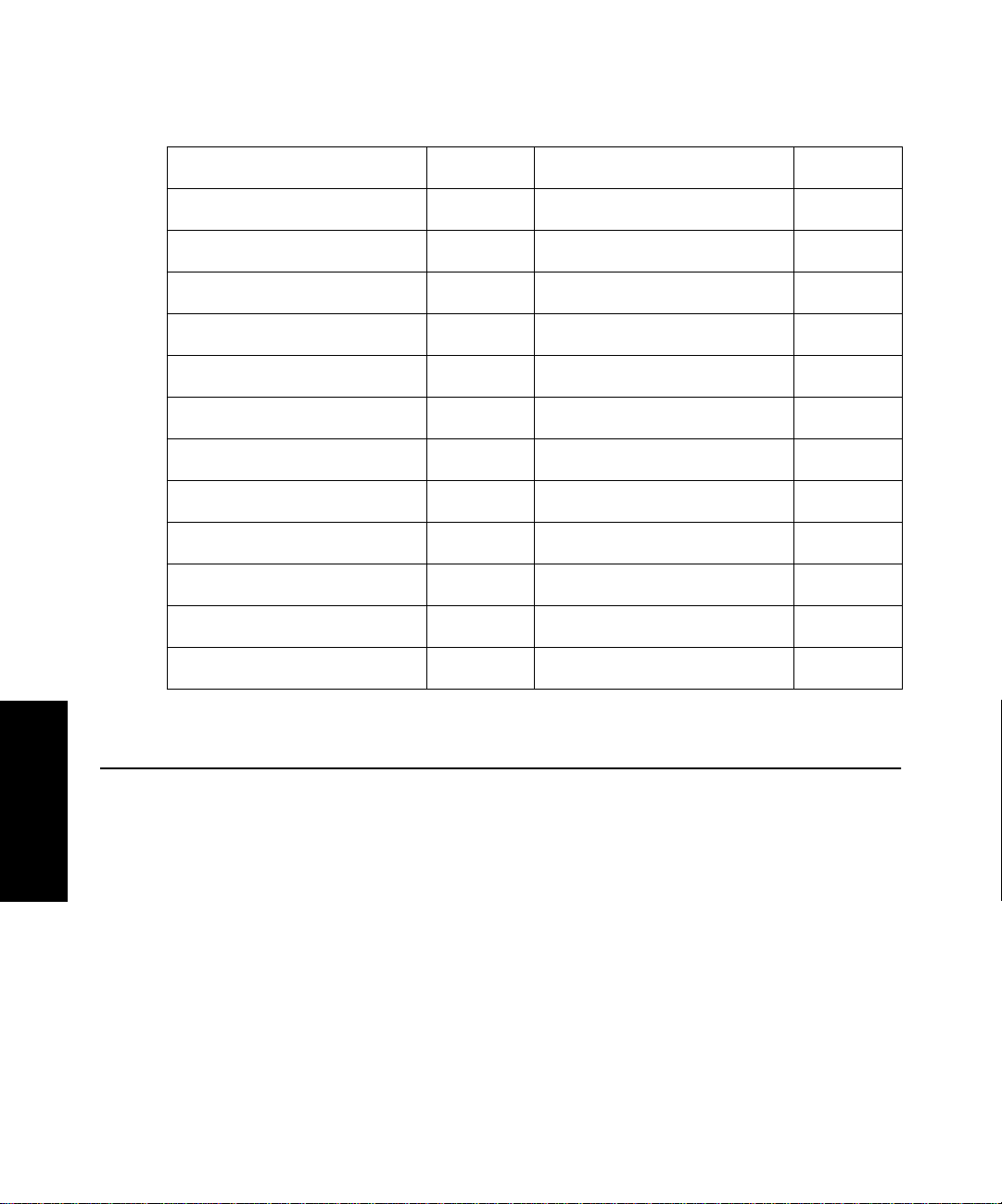

Tables

1-1 Fluidic Line Inner Diameters............................................................ 1-12

2-1 Installation Site Requirements.................................................................2-3

3-1 Component Connection Summary...........................................................3-1

3-2 Waters 2410 Refractometer Inject Start Connections........................ 3-6

3-3 Waters 2410 Connections to a Manual Injector ................................ 3-7

3-4 Waters 2410 Analog-Out/Event-In Connections............................... 3-9

3-5 Auto Zero Connections Between the 2690 Separations Module

3-6 Chart Mark Connections Between the 2690 Separations Module

3-7 Chart Mark and Auto Zero Connections Between the

3-8 Analog Output Connections to a 745/745B/746 Data Module ........ 3-13

3-9 Analog Output Connections to a Chart Recorder............................ 3-15

and the 2410 Refractometer ........................................................... 3-10

and the 2410 Refractometer ........................................................... 3-11

2690 Separations Module and the 2410 Refractometer................... 3-12

3-10 Analog Output Connections to the Bus SAT/IN Module................. 3-16

3-11 Auto Zero Connections to a Manual Injector.................................. 3-17

3-12 Chart Mark Connections to a Manual Injector ................................ 3-18

3-13 Polarity Options............................................................................. 3-19

4-1 Refractive Indices of Common Solvents..................................................4-3

5-1 Indicator LED Functions..........................................................................5-3

5-2 Keypad Functions............................................................................ 5-4

6-1 Voltage and Fuse Requirements...............................................................6-4

7-1 Abnormal Baseline Troubleshooting................................................ 7-4

7-2 Retention Time Troubleshooting...................................................... 7-7

Table of Contents xvii

Page 18

7-3 Resolution Troubleshooting ........................................................... 7-10

7-4 Incorrect Results Troubleshooting.................................................. 7-12

7-5 User Diagnostics............................................................................ 7-14

7-6 Waters 2410 Hardware Troubleshooting ......................................... 7-16

A-1 Operational Specifications...................................................................... A-1

A-2 Integrator Output..............................................................................A-2

A-3 Optical Component Specifications....................................................A-2

A-4 Environmental Specifications...........................................................A-2

A-5 Dimensions ......................................................................................A-3

A-6 Electrical Specifications...................................................................A-3

A-7 Power Source Specification..............................................................A-3

B-1 Recommended Spare Parts ...............................................................B-1

C-1 Waters 2410 Warranty Periods.................................................................C-4

xviii Table of Contents

Page 19

How to Use This Guide

Purpose of This Guide

The

Waters 2410 Differential Refractometer Operator’ s Guide

Waters® 2410 Differential Refractometer and provides installation and maintenance procedures.

Audience

This guide is intended for use by anyone interested in installing, using, maintaining, and

troubleshooting the 2410 differential refractometer.

Structure of This Guide

The

Waters 2410 Differential Refractometer Operator’s Guide

appendixes. Each page is marked with a tab and a footer to facilitate access to information within

the chapter or appendix.

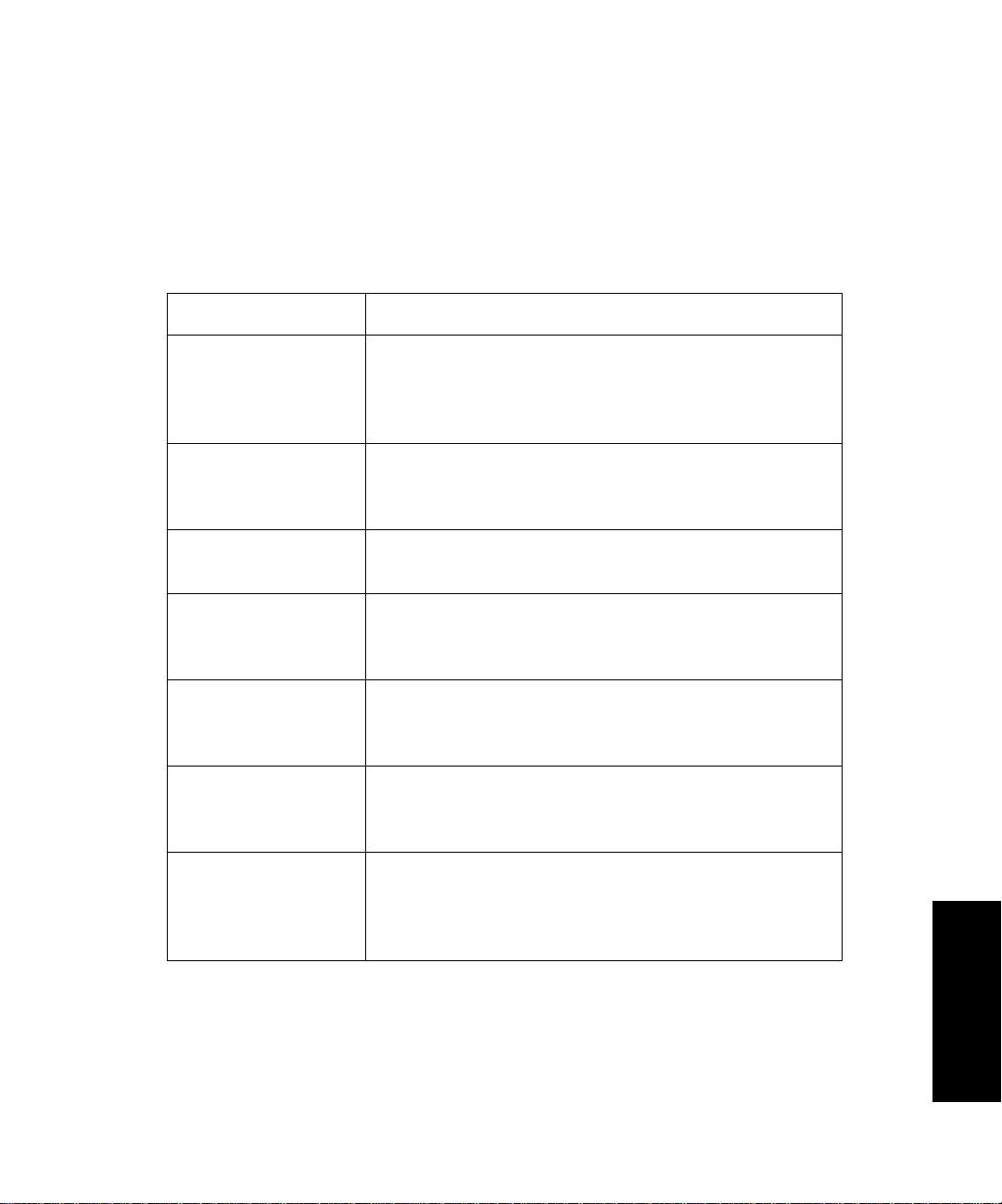

The table below describes the material covered in each chapter and appendix.

describes the features and use of the

is divided into chapters and

Chapter 1, Waters 2410

Theory of Operation

Chapter 2, Installing the

2410 Refractometer

Chapter 3, Making

Signal Connections

Chapter 4, Preparing

Solvents

Chapter 5, Using the

2410 Refractometer

Chapter 6, Maintenance

Procedures

Chapter 7,

Troubleshooting

Describes the product and the principles of differential

refractometry and 2410 differential refractometer operation.

Describes the 2410 differential refractometer installation

procedures.

Describes how to connect other components of your

chromatography system to the 2410 differential refractometer.

Discusses the importance of filtering and degassing solvents for

effective operation.

Describes how to power on and off and operate the 2410

differential refractometer.

Describes maintenance and parts replacement procedures for the

2410 differential refractometer.

Provides tables describing symptoms, possible causes, and

corrective actions for 2410 differential refractometer operational

problems.

xix

Page 20

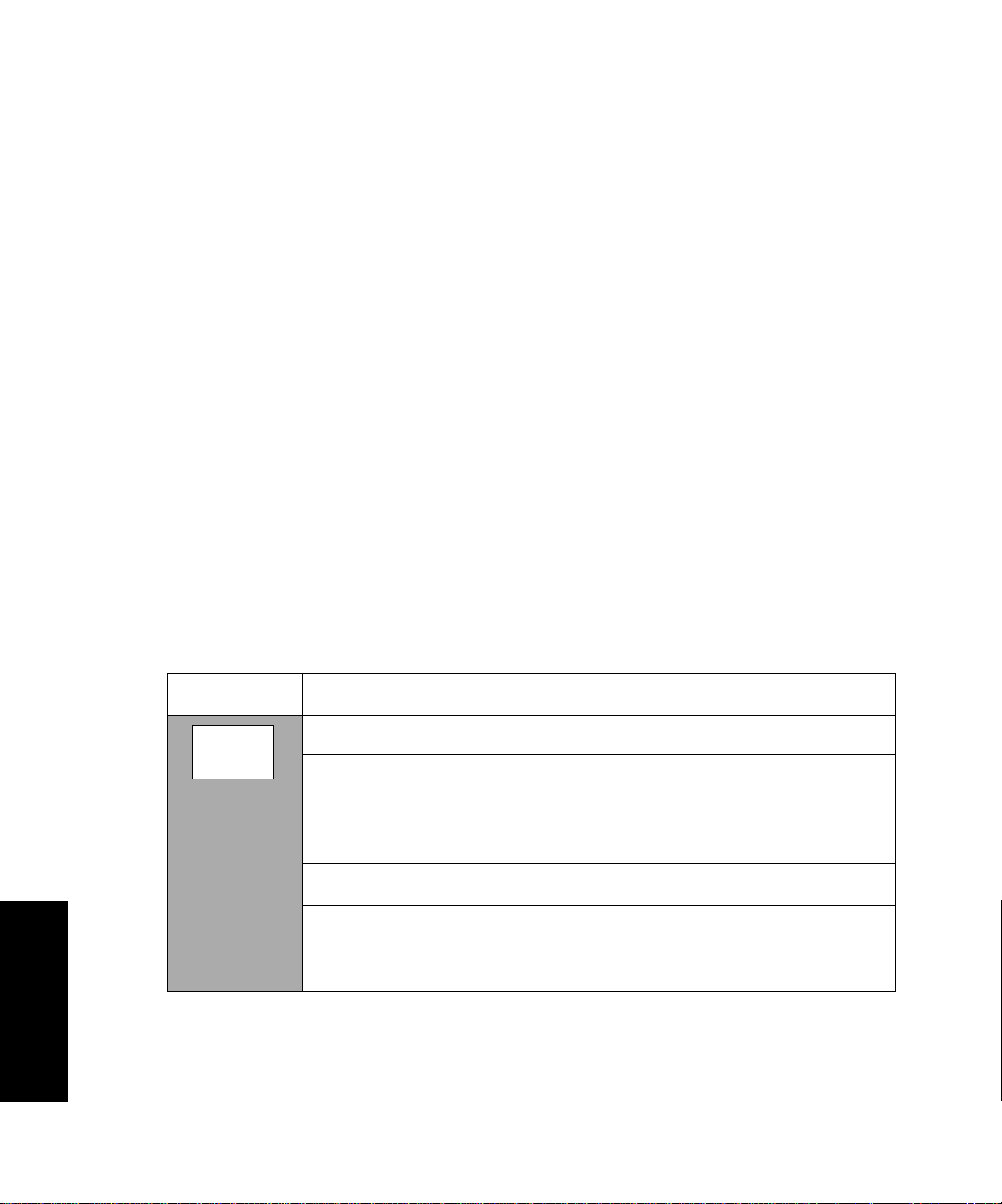

Appendix A,

Specifications

Provides specifications for the 2410 differential refractometer.

Appendix B, Spare

Parts/Accessories

Appendix C, Warranty

Information

Lists the recommended spare parts for the 2410 differential

refractometer.

Includes warranty and service information for the 2410 differential

refractometer.

Related Documents

The following table lists other documents related to the operation of the Waters 2410 Differential

Refractometer.

W aters 2690 Separ ations Module

Operator’s Guide

Waters 600E Multisolvent

Delivery System User’s Guide

Waters Bus SAT/IN Module

Installation Guide

Millennium Software User’s

Guide, Vol. I and Vol. II

Describes the procedures for unpacking, installing, using,

maintaining, and troubleshooting the Waters 2690

Separations Module.

Describes the procedures for installing, using, maintaining,

and troubleshooting the Waters 600E Multisolvent Delivery

System.

Provides the procedures for installing the Waters Bus

SAT/IN Module.

Describes the Millennium Chromatography Manager

software used in both the Millennium 2010 workstation and

the Millennium 2020 client/server system.

xx

Page 21

Conventions Used in This Guide

This guide uses the following conventions to make text easier to understand.

•

Bold

text indicates user action. For example:

Press 0, then press

•

Italic

text denotes new or important words, and is also used for emphasis. For example:

An

instrument method

• Instructions to click a specific icon include the icon in the left column of the page. For

example:

Click the Projects view icon. The Projects vie w appears with all e xisting project folders.

Notes, Attentions, and Cautions

• Notes call out information that is important to the operator. For example:

Note:

Record your results before you proceed to the next step.

• Attentions provide information about preventing possible damage to the system or

equipment. For example:

Enter

for the remaining fields.

tells the software how to acquire data.

STOP

Attention:

window.

• Cautions provide information essential to the safety of the operator. For example:

Caution:

practices when operating the system.

Caution:

and unplug the power cord before you perform maintenance procedures.

Caution:

before removing it for replacement or adjustment.

To avoid damaging the detector flow cell, do not touch the flow cell

To avoid chemical or electrical hazards, always observe safe laboratory

To avoid the possibility of electrical shock, always power off the detector

To avoid the possibility of burns, power off the lamp at least 30 minutes

xxi

Page 22

xxii

Page 23

Chapter 1

Waters 2410 Theory of Operation

1.1 Overview ........................................................... 1-1

1.2 Theory of Operation.......................................... 1-2

1.3 Principles of Operation.................................... 1-10

Page 24

Page 25

1

Waters 2410 Theory of

Operation

This chapter introduces you to the Waters® 2410 Differential Refractometer. It summarizes the

2410 differential refractometer features and the principles of differential refractometry, and

describes the theory and principles of operation.

Refer to Appendix A, Specifications, for system specifications, and to

Solvents

1.1 Overview

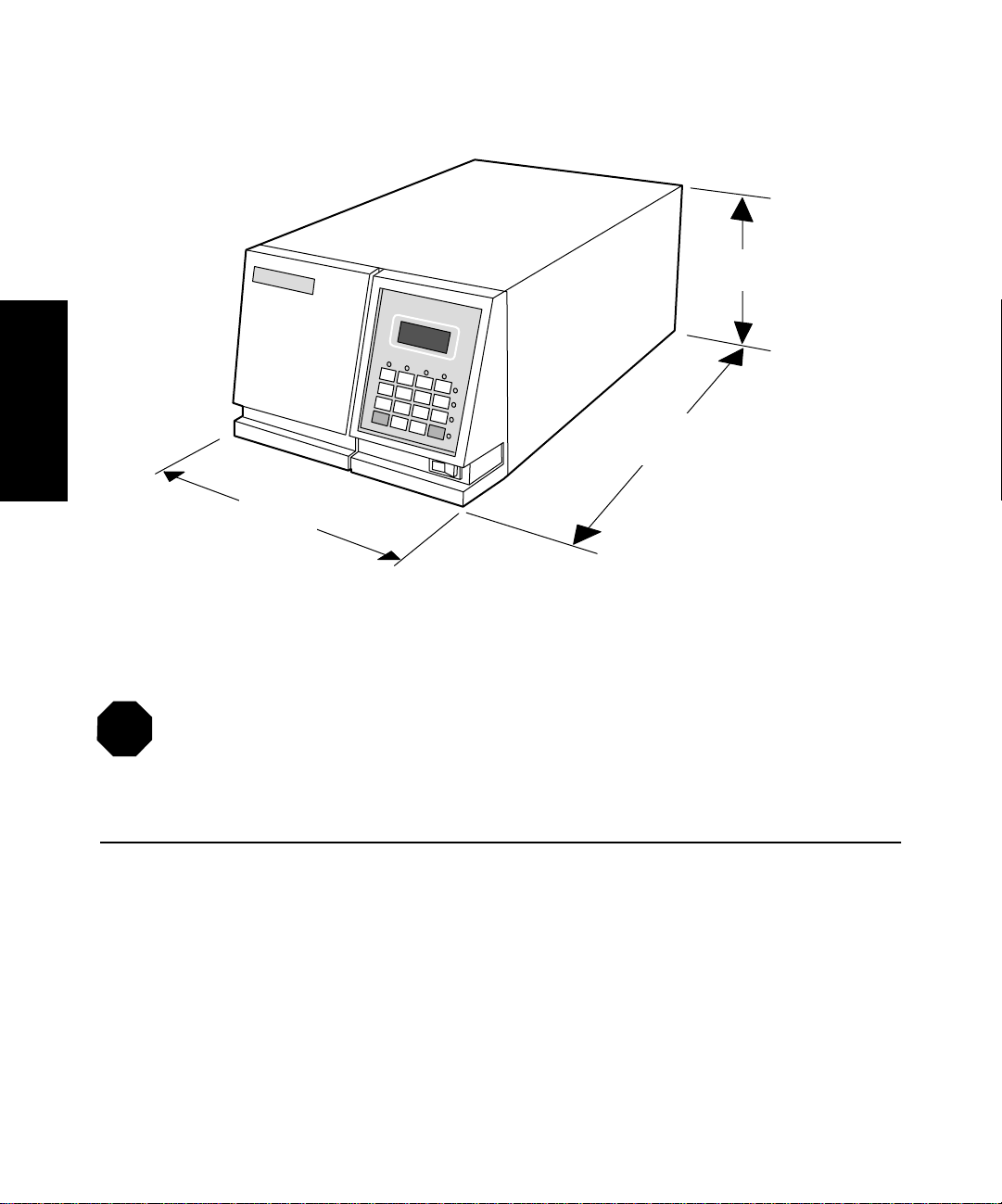

The Waters 2410 Differential Refractometer, shown in Figure 1-1, is a differential refractive index

detector designed for high performance liquid chromatography applications. It can operate as a

stand-alone unit with an integrator or chart recorder, or with a Waters system controller or Waters

data system.

, for solvent considerations.

1

Chapter 4, Preparing

Waters 2410

Differential Refractometer Detector

TP01531

Figure 1-1 Waters 2410 Differential Refractometer

Overview 1-1

Page 26

1

Range and Sensitivity

The 2410 detector functions with solvents with refractive indices between 1.00 and 1.75. The

measurement range of the instrument is 5 × 10–8 to 5 × 10–3 refractive index units full scale

(RIUFS).

Features

Features of the 2410 differential refractometer include:

• Patented countercurrent heat exchanger and temperature-controlled cell for stable operation

under varying conditions

• Auto zero and auto purge for automated operation

• Built-in pressure relief to protect flow cell

• Auto diagnostics

• Two external column heater controls

• Battery backup to retain parameter settings when the detector is powered off or during power

interruptions

• Long-life LED light source

1.2 Theory of Operation

The W aters 2410 Dif ferential Refractometer uses optical refraction to monitor the concentrations of

sample components in your eluent. This section describes:

• Optical refraction

• Differential refractometry

• Common problems in refractometry

1.2.1 Optical Refraction

When a beam of light passes from one medium into another, it changes its speed. If the light enters

the second medium at an angle that is not perpendicular to the medium’s surface, the light is bent

(refracted).

The extent to which a medium refracts light is its

velocity of light in a vacuum to the velocity of light in the medium. It is a physical property of the

medium, with a dimensionless integer value represented by the letter n.

This section discusses:

• Factors that affect RI

1-2 Waters 2410 Theory of Operation

refractive inde x

(RI), calculated as the ratio of the

Page 27

• Measuring refraction

• Using changes in RI for sample detection

Factors That Affect RI

The refractive index of a medium is solely dependent on the speed of light in the medium. The

speed of light in a medium is constant for a given wa velength of light at a specified temperature and

pressure.

Wavelength

The refractive index of a medium has a specific value that changes with the wavelength of the

incident light beam. Since the 2410 differential refractometer uses monochromatic light at a fixed

wavelength, the effect of different wavelengths of light on RI is not discussed in this guide.

Density

The density of the medium also affects its RI. At a fixed wavelength, the relationship between the

density of a medium and its RI is generally, but not necessarily, linear. The most important of the

factors that affect the density of a medium are:

• Composition

• Temperature

• Pressure

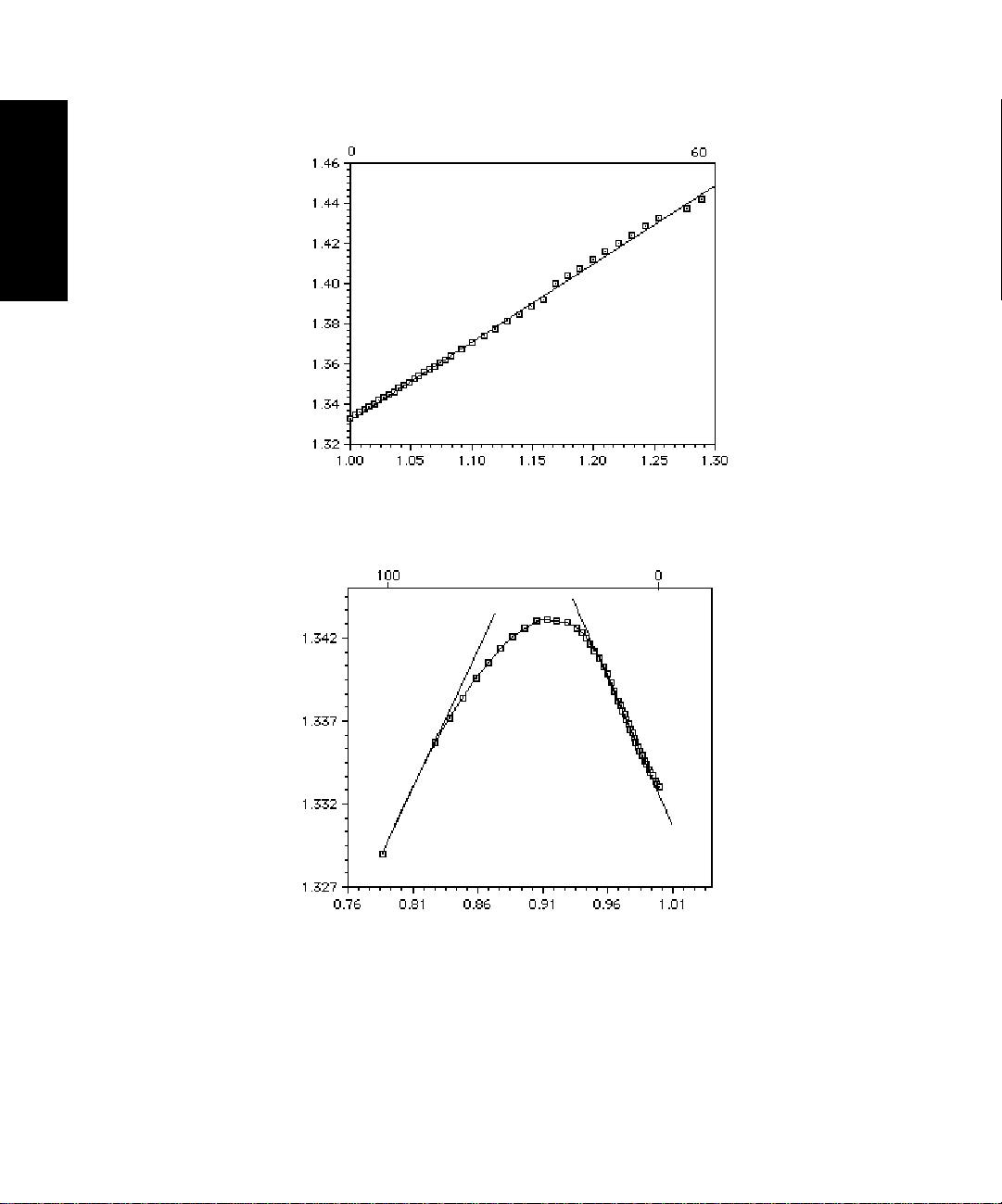

Figure 1-2 illustrates the effect of density on the RI of two solutions. The refractive index of a

sucrose solution changes linearly with concentration over this range of compositions, but a

methanol solution exhibits a nonlinear region between concentrations of 45 and 55 percent.

1

Theory of Operation 1-3

Page 28

1

Weight Percent Sucrose in Water

Refractive Index

Density (g/mL)

Weight Percent Methanol in Water

Refractive Index

Figure 1-2 Effect of Density on RI

1-4 Waters 2410 Theory of Operation

Density (g/mL)

Page 29

Measuring Refraction

The extent to which a beam of light is refracted when it enters a medium depends on two factors:

• The angle at which the light enters the new medium (the

• The refractive indices of the new media

angle of incidence

)

1

The angle of a refracted light beam through the new medium is its

angle of refraction

.

Figure 1-3 illustrates the relationship between angle of incidence, angle of refraction, and refractive

index.

Incoming Light Beam Perpendicular to Surface

Angle of Incidence

Medium 1, RI = n

Medium 2, RI = n

Refracted Light Beam

θ

2

1

2

Angle of Refraction

θ

1

Figure 1-3 Refraction of Light

The relationship between the refractive indices of the two media and the angles of incidence and

refraction is described by Snell’s Law:

n1(sin

θ

where:

θ

= Angle of incidence

1

θ

= Angle of refraction

2

n

= RI of medium 1

1

n

= RI of medium 2

2

) = n2(sin

1

θ

)

2

Theory of Operation 1-5

Page 30

You can use Snell’s Law to calculate the RI of a sample solution from the angle of incidence, the RI

of the solvent, and the angle of refraction.

1

Using Changes in RI for Sample Detection

As the separated components of a sample pass through the refractometer flow cell:

• The composition of the sample solution in the flow cell changes.

• The RI of the solution changes.

• The light beam passing through the solution is refracted.

The refractometer detects the position of the refracted light beam, creating a signal that differs from

the baseline signal.

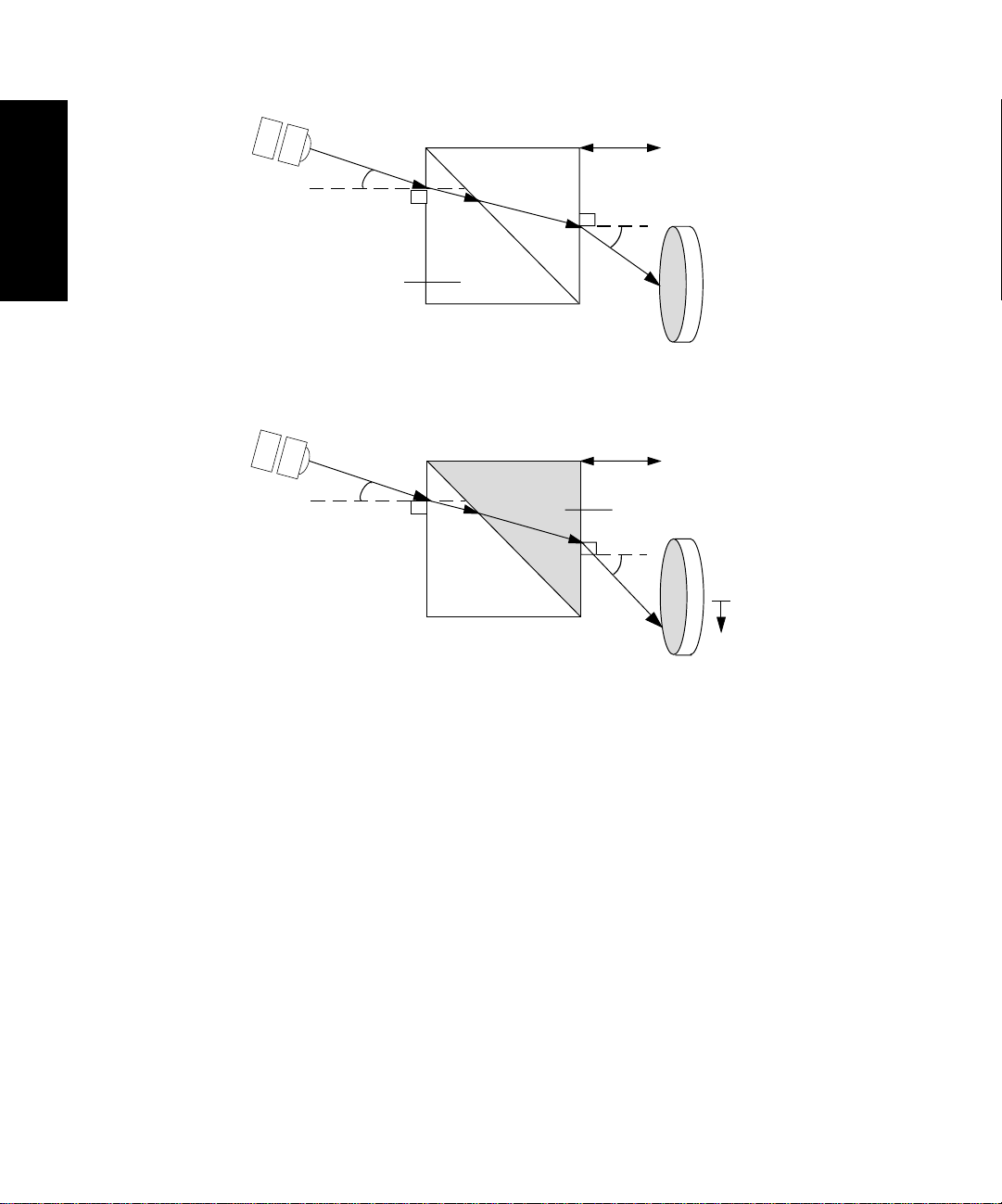

Figure 1-4 shows how refraction by the sample in the flow cell changes the proportion of light on

each element of the photodiode.

Dual Element

Dual-Element

Photodiode

Photodiode

Collimating

Collimating

Lens

Lens

Sample Side

Sample Side

of Flow Cell

of Flow Cell

Sample in

Sample in

Sample Side

Sample Side

of Flow Cell

of Flow Cell

Reference

Reference Side

of Flow Cell

Side of

Flow Cell

Figure 1-4 Presence of Sample Changes the Photodiode Signal

1-6 Waters 2410 Theory of Operation

Incident Light

Reference Side

of Flow Cell

Reference Side

of Flow Cell

Page 31

By keeping wavelength, temperature, and pressure constant, the changes in RI measured by the

refractometer are due only to changing sample concentration. A solution with a high concentration

of a solute refracts a beam of light more than a dilute solution. Therefore, high concentrations of

sample yield large peaks.

1.2.2 Differential Refractometry

The 2410 differential refractometer can measure extremely small changes in refractive index to

detect the presence of sample. The small difference in RI between a reference solution and a sample

solution is referred to as ∆n. ∆n is expressed in refractive index units (RIU).

The 2410 differential refractometer measures ∆n values as small as 5 × 10–8 RIU by detecting the

difference in the amount of light falling upon each of the elements of the dual-element photodiode

(see Figure 1-4).

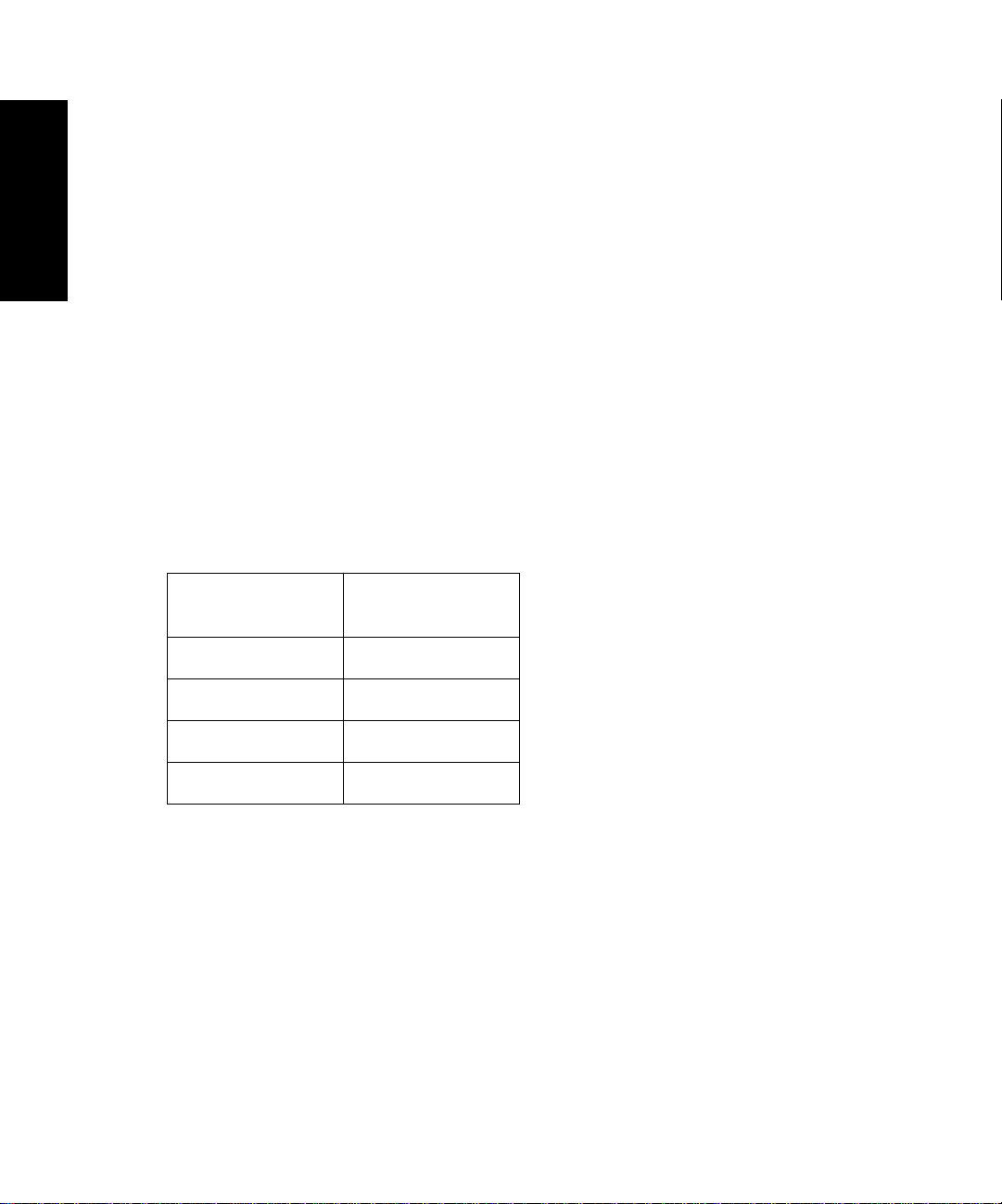

External Angle of Deflection

The amount of light falling upon the elements of the photodiode is determined by the external

angle of deflection (φ), as shown in Figure 1-5. The φ determines the magnitude of the shift (∆x) of

the image cast on the photodiode by the light beam.

Figure 1-5 illustrates the external angle of deflection (φ) and its dependence on the difference in RIs

between the reference and sample sides of the flow cell.

1

Theory of Operation 1-7

Page 32

1

θ

Reference Side

of Flow Cell

θ

n

n

n + ∆n

n

Y

φ

Y

Sample Side

of Flow Cell

φ

= ∆x

Figure 1-5 How Refraction Changes

Effect of Refraction on

As the beam of light moves along the light path to the photodiode, it encounters and is refracted by

the air in the optics bench assembly, the fused quartz walls of the flow cell, the solvent in the

reference side of the flow cell, and the solution in the sample side of the flow cell.

Of these refractors, only the solution in the sample side of the flow cell changes over the course of a

run. As a result, the reference external angle of deflection (φ) does not change until a change in the

RI of the sample causes the light beam to be refracted from its zero position.

1-8 Waters 2410 Theory of Operation

φ

φ

Page 33

The relationship between the external angle of deflection (φ) and the RI of the sample solution is

expressed as:

∆n ≅ φ/tan

where: ∆n =Difference in RI between the solvent and the solvent-sample solution

φ

=External angle of deflection (in radians)

θ

=Angle of incidence (in radians)

θ

Effect of Refraction on the Photodiode Signal

The change in φ determines the shift (∆x) of the light beam on the photodiode. Because the 2410

differential refractometer uses a dual-pass optics bench assembly , the light beam passes through the

flow cell twice before reaching the photodiode, doubling the image shift.

The relationship between the image shift (∆x) at the 2410 detector photodiode and the change in RI

of the solution is expressed as:

∆x = 2Y(tanθ) ∆n

where: ∆x = Distance of the image shift at the photodiode

Y = Distance from the flow cell to the photodiode

θ

=Angle of incidence

∆n =Difference in RI between solvent and sample solution

The angle of incidence (θ) and the distance to the photodiode (Y) are fixed in the refractometer, so

the equation becomes:

1

∆x = C ∆n

Where: C = A constant representing the fixed values

By detecting how far the image shifts (∆x), the refractometer measures the difference in RI (∆n)

between the solvent-sample solution and the solvent alone.

The shift in the amount of the light beam striking each element of the dual-element photodiode

results in a change in the output voltage from the 2410 detector. The integrator or chart recorder

registers the changes in output voltage as peaks in your chromatogram.

1.2.3 Common RI Detection Problems

Changes in solution density caused by factors other than sample concentration are the most

common source of problems in RI detection. Changes in solution density can be due to:

• Environmental factors such as changes in temperature or pressure

• Inhomogeneities in the solution

Theory of Operation 1-9

Page 34

1

Environmental Factors

Even small changes in ambient temperature can cause baseline drift. Backpressure pulses from a

dripping waste tube can cause short-term baseline cycling. Refer to Chapter 7, T roubleshooting, for

more information.

Inhomogeneities in Solution

The differential refractometer measures the difference in refraction between a pure reference

solvent and a homogeneous sample solution within a chromatographic band. If the sample solution

is not homogeneous, the light passing through the sample may be absorbed, scattered, or refracted

unpredictably. This can result in shifts in retention time and broad, tailing peaks. Most common

inhomogeneity problems are due to improper solvent preparation. See Chapter 4, Preparing

Solvents, for more information.

1.3 Principles of Operation

This section describes the design of the 2410 refractometer and its principles of operation,

including:

• Fluidics

• Optics

• Electronics

1.3.1 Fluidics

The fluidic path of the 2410 refractometer includes the following components, some of which are

shown in Figure 1-6:

• Countercurrent heat exchanger

• Flow cell, with sample and reference sides

• Solenoid valve

• Pressure relief valve

• Inlet and outlet tubing

1-10 Waters 2410 Theory of Operation

Page 35

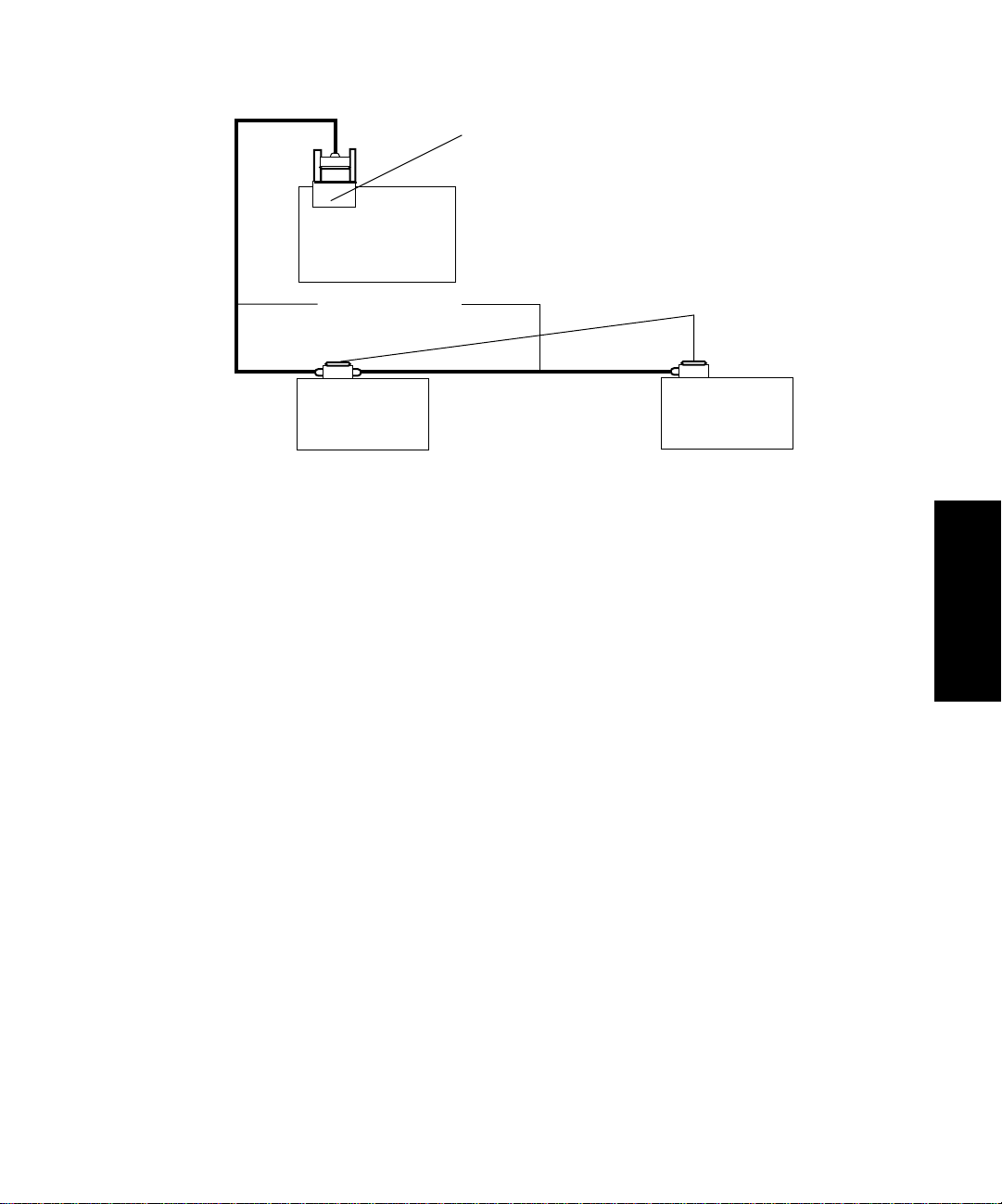

Pressure Relief

Valve

Solenoid

Valve

Outlet T ubing

(Blue)

Inlet Tubing (Red)

TP01532

Figure 1-6 Waters 2410 Refractometer Fluidics

Countercurrent Heat Exchanger

The 2410 refractometer uses a patented countercurrent heat exchanger to minimize temperature

fluctuations in the sample stream. In the countercurrent heat exchanger, the sample and reference

inlet and outlet lines run adjacent to each other. All four lines are copper-coated to facilitate heat

exchange.

1

Flow Cell

The flow cell consists of two fused quartz hollow prisms. Each has an inlet and outlet. One of the

prisms is the sample side of the flow cell through which a constant flow of eluent passes during

analysis.

The other prism is the reference side of the flow cell. It is filled with clean solvent when you purge

the 2410 refractometer during equilibration. When you switch from purge to normal operation, the

solenoid valve opens and the pressure relief valve shuts, stopping the flow of solvent through the

reference prism but leaving the cell filled with solvent.

Principles of Operation 1-11

Page 36

1

Solenoid V alve

During normal operation, the solenoid valve remains open. Fluid that passes through the sample

side of the flow cell flows through the solenoid v alv e and out through the outlet tubing (blue) to the

waste reservoir.

When you purge the 2410 refractometer, the solenoid valve closes, causing fluid passing through

the sample side of the flow cell to flow out through the reference side of the flow cell, through the

purge outlet tubing (blue).

Pressure Relief Valve

During normal operation, the pressure relief valve is closed, opening only if the pressure gets too

high. This protects the flow cell, which has a maximum pressure rating of 100 psi.

During purging, fluid moving through the sample and reference sides of the flow cell goes out

through the pressure relief valve to the waste reserv oir . Figure 1-7 indicates the paths of solvent and

sample in the 2410 refractometer during normal operation and during a purge. Table 1-1 provides

the inner diameters of the sample and reference fluidic lines.

Table 1-1 luidic Line Inner Diameters

Fluidic Line

Sample In 0.009

Sample Out 0.040

Reference In 0.020

Reference Out 0.040

Inner Diameter

(inches)

1-12 Waters 2410 Theory of Operation

Page 37

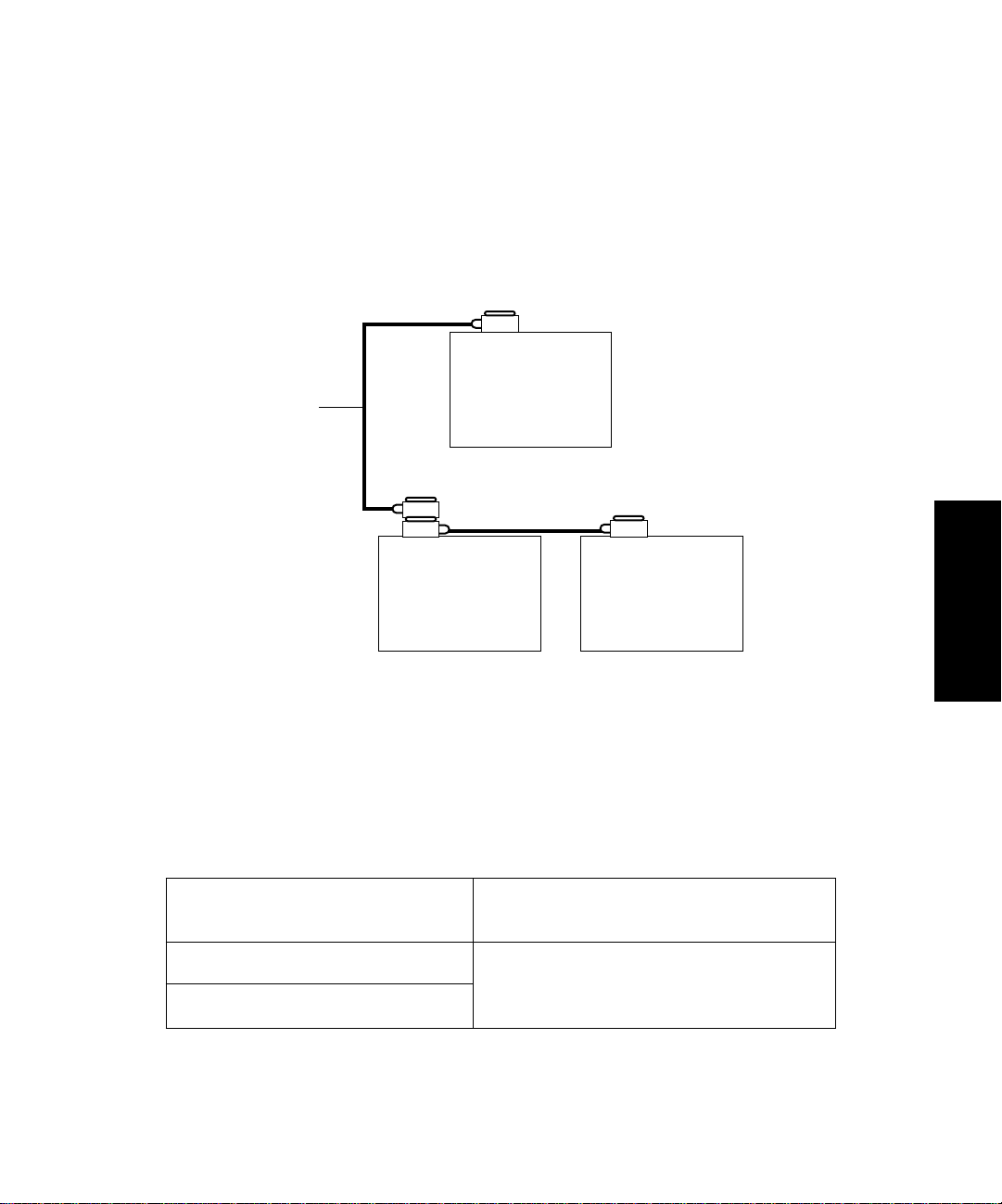

Pressure

Relief

Valve

Flow Cell

Reference

Side

T Block

Sample

Side

Solenoid

Heat ExchangerHeat Exchanger

1

Valve

= normal flow path

= purge flow path

Purge Out Out Port In Port

Figure 1-7 Waters 2410 Refractometer Fluidic Paths

from Columnto Waste to Waste

(red) (blue)(blue)

Fluidic Path During Analysis

During analysis, the solvent-sample:

1. Flows in through the inlet tubing port.

2. Passes through the Sample In tube of the countercurrent heat exchanger.

3. Flows through the sample side of the flow cell.

4. Flows out though the Sample Out tube of the countercurrent heat exchanger.

5. Passes through the solenoid valve to the outlet tubing port.

Fluidic Path During Purge

When you purge the 2410 refractometer fluidic path, solvent:

1. Flows in through inlet tubing port.

2. Passes through the Sample In tube of the countercurrent heat exchanger.

Principles of Operation 1-13

Page 38

1

3. Flows through the sample side of the flow cell.

4. Flows out through the Sample Out tube of the countercurrent heat exchanger to the

closed solenoid valve.

5. Passes through the Reference In tube of the countercurrent heat exchanger.

6. Flows through the reference side of the flow cell.

7. Flows out through the Reference Out tube of the countercurrent heat exchanger.

8. Flows out through the pressure relief valve to the purge outlet tubing port.

1.3.2 Optics

The 2410 refractometer optics bench assembly (Figure 1-8) consists of the following components:

• LED source lamp

• LED lens mask

• LED lens

• Flow cell, with sample and reference sides

• Mirror

• Collimating lens

• Dual-element photodiode

Figure 1-8 shows the path of the light beam as it passes through the components in the optics bench

assembly.

As shown in Figure 1-8:

1. Light from the LED is focused by the focusing lens through the aperture and collimating

lens to form a beam.

2. The light beam passes through the sample and reference sides of the flow cell to the

mirror.

3. The light beam is reflected back through both sides of the flow cell and the collimating

lens to the dual-element photodiode.

The difference in the amount of light striking the elements of the photodiode (because of sample

refraction) results in a deflection from the baseline on the chromatogram.

1-14 Waters 2410 Theory of Operation

Page 39

Collimating Lens

LED Lens

Figure 1-8 Waters 2410 Differential Refractometer Optics Bench Assembly Light Path

Dual-Element

Photodiode

LED

Lens

Mask

Flow Cell

MirrorHeat Exchanger CoilsLED

1.3.3 Electronics

1

TP01536

The 2410 refractometer has both analog and digital components, and includes hardware such as the

front panel keyboard and printed circuit (PC) boards and their interconnections. The following PC

boards are included in the 2410 refractometer electronics.

• CPU Board – Provides the interface between the analog input signals from the optics and

the microprocessor, for further signal conditioning. Generates analog output signals, drives

the LED, Auto Zero, and signal compensation electronics, and stores and executes input

from the front panel keypad and the rear panel contact closures. Provides communication

between the 2410 refractometer and external devices through the IEEE-488 interface and

terminal strip input/output connections.

• Front Panel Board – Controls the keypad, indicators, and display.

• Power Distribution Board – Distributes DC voltages to the CPU board, fan, and heaters.

Provides the electronic switching for control of the oven compartment.

Principles of Operation 1-15

Page 40

1

1-16 Waters 2410 Theory of Operation

Page 41

Chapter 2

Installing the 2410

Refractometer

2.1 Introduction....................................................... 2-1

2.2 Site Selection and Power Requirements............ 2-2

2.3 Unpacking and Inspection................................. 2-4

2.4 Making Electrical Power Connections .............. 2-5

2.5 Making Fluidic Connections............................. 2-5

Page 42

Page 43

2

Installing the 2410 Refractometer

This chapter describes the procedures for selecting the site for installing the Waters 2410

Differential Refractometer, unpacking and inspecting the instrument, installing fuses, and making

fluidic connections. For information on connecting the 2410 refractometer to other devices, see

Chapter 3.

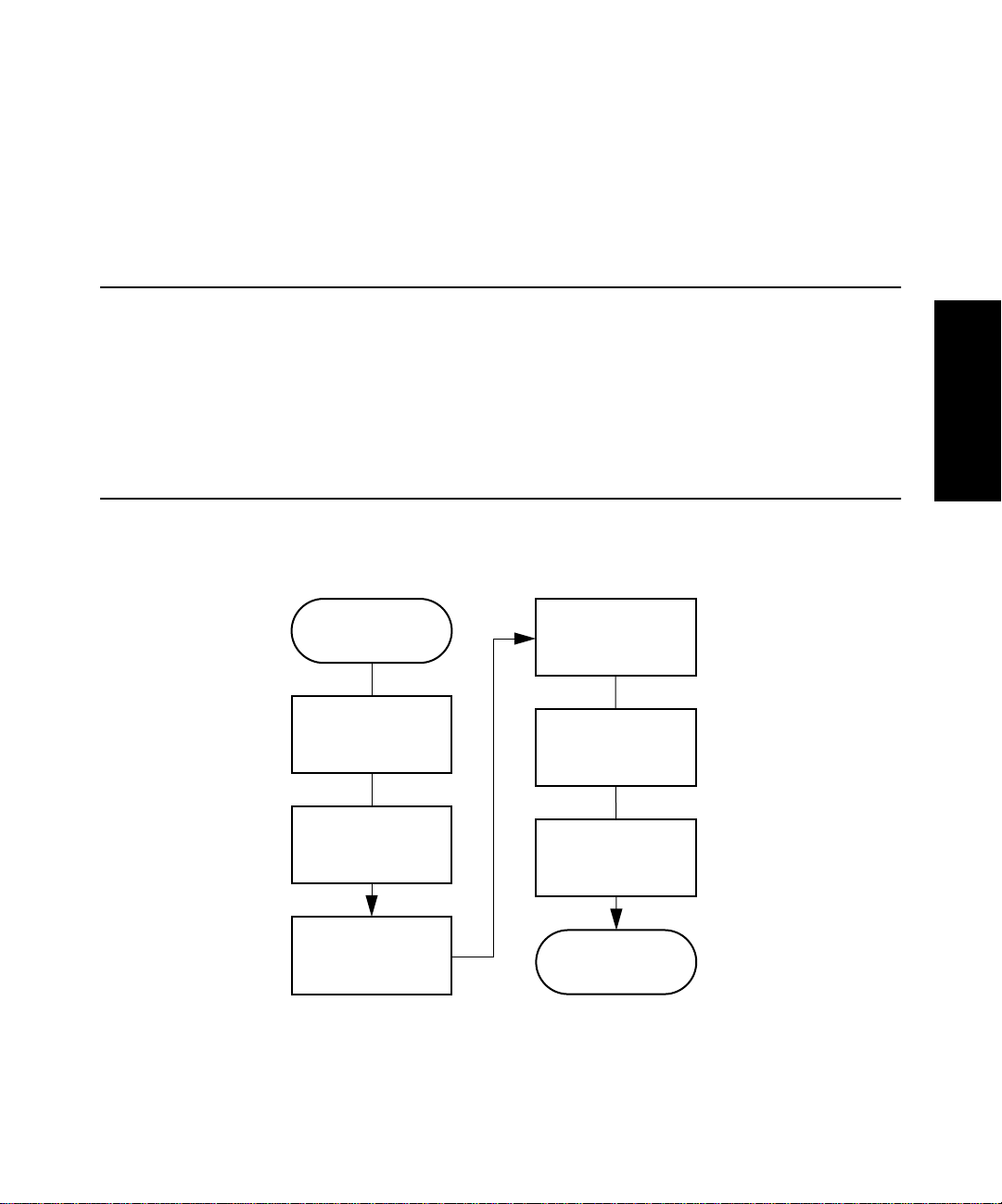

2.1 Introduction

Figure 2-1 shows the major steps in installing the Waters 2410 Differential Refractometer.

2

Start installation

procedure.

Select appropriate

site.

Unpack and

inspect.

Install 2410

refractometer.

Figure 2-1 Major Steps in Installing the 2410 Differential Refractometer

Make power

connections.

Make fluidic

connections.

Make signal

connections to

other devices.

Installation

complete.

Introduction 2-1

Page 44

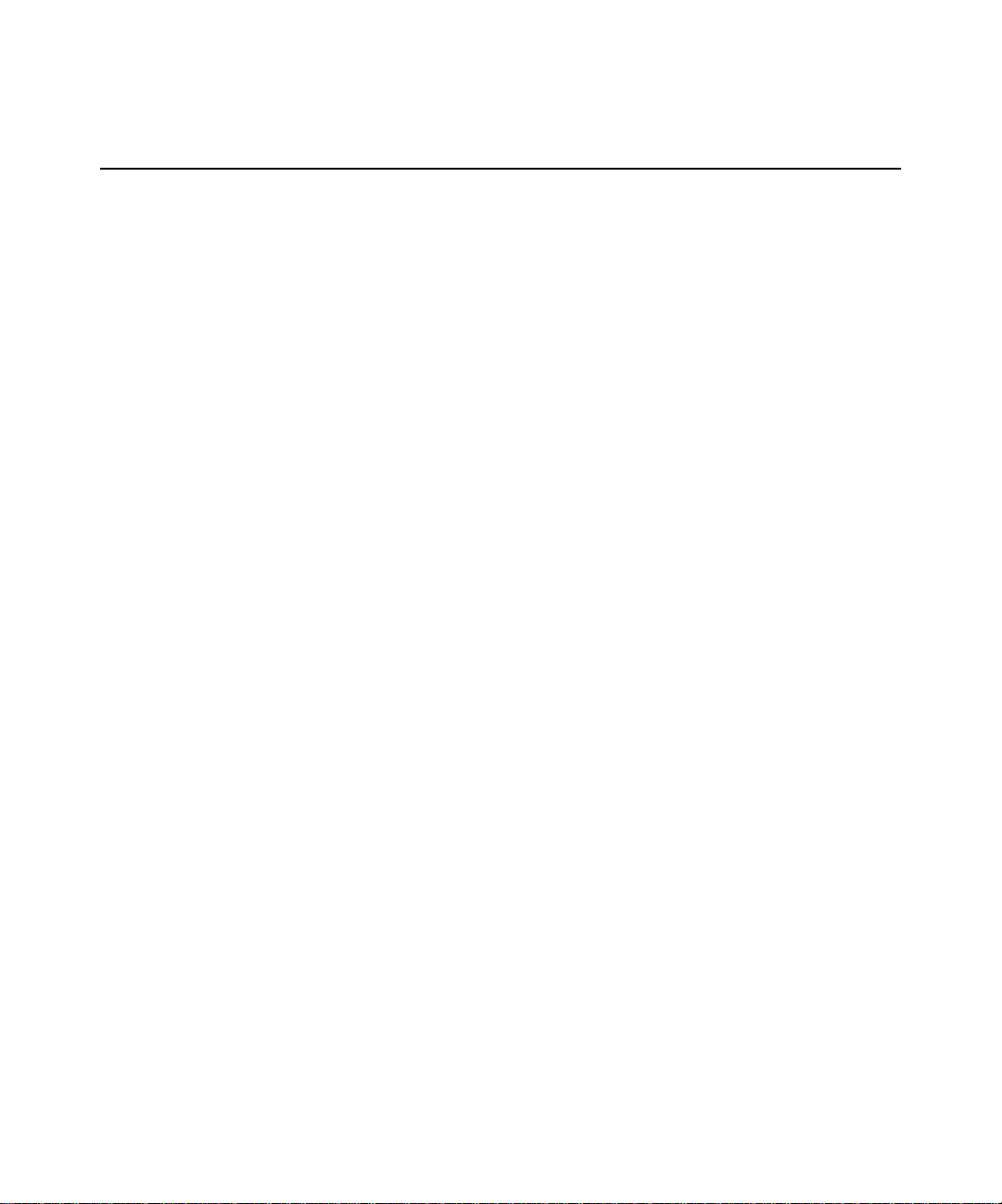

Figure 2-2 shows the dimensions of the 2410 refractometer.

2

STOP

Waters 2410

Differential Refractometer Detector

19.8 inches (50.3 cm)

11.2 inches (28.4 cm)

Figure 2-2 Dimensions of the 2410 Refractometer

Attention: Access to the instrument inside the top cover is not required. All required

access is through the left front panel where the fluidic connections are located (see

Section 2.5, Making Fluidic Connections).

8.2 inches (20.8 cm)

TP01530

2.2 Site Selection and Power Requirements

Reliable operation of your 2410 refractometer depends on a proper installation site and a suitable

power supply.

Site Selection Requirements

Install the Waters 2410 Differential Refractometer in an area that meets the requirements listed in

Table 2-1.

2-2 Installing the 2410 Refractometer

Page 45

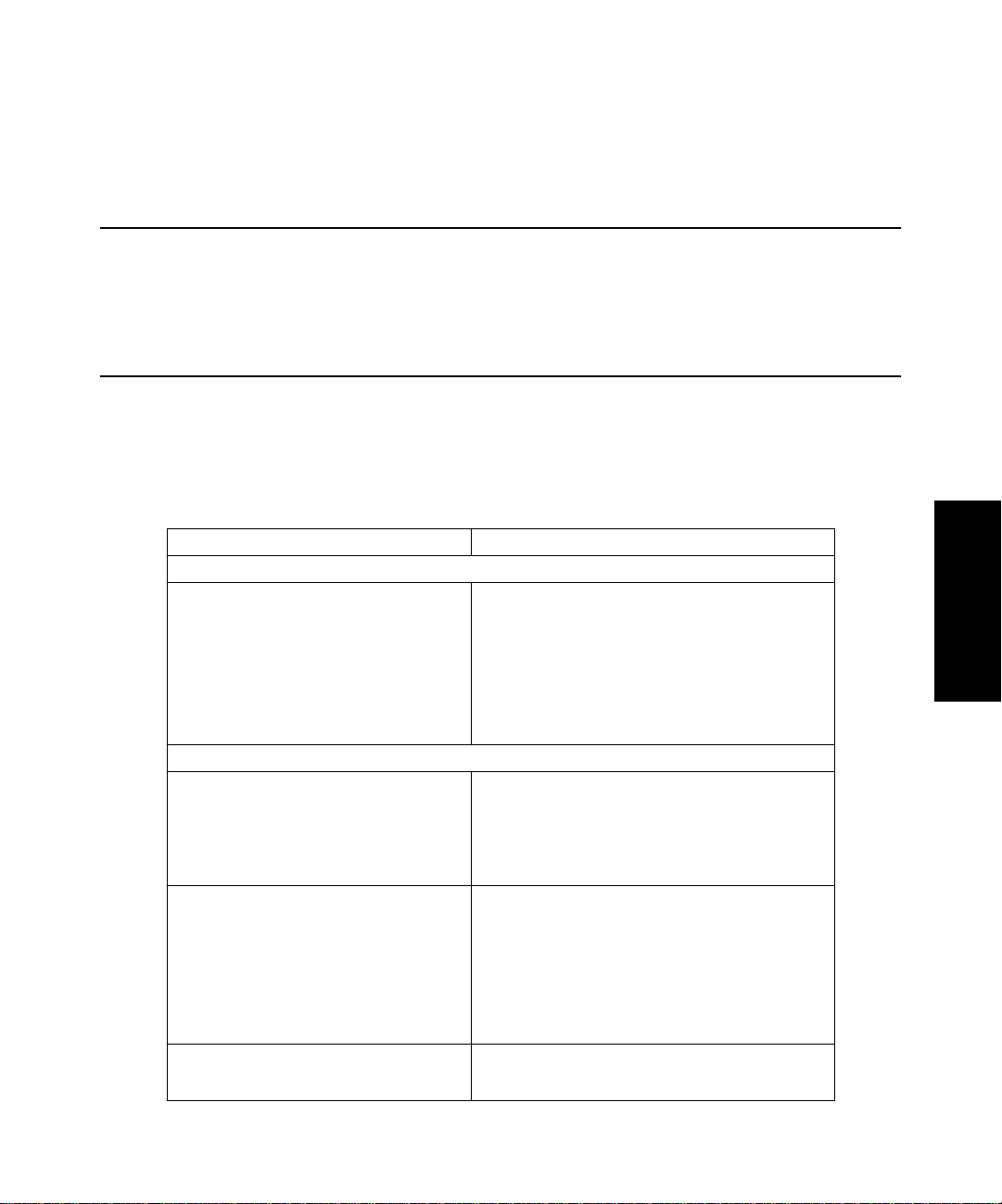

Table 2-1 Installation Site Requirements

Parameter Requirement

Operating temperature range +15 °C to +32.2 °C (59 °F to 90 °F); avoid direct

exposure to sunlight and heating/cooling vents.

Storage temperature range –40 °C to 70 °C (–104 °F to 158 °F)

Relative humidity 20% to 80%, noncondensing

Storage humidity range 0% to 90%, noncondensing

Bench space At least 11.2 in. (28.4 cm) wide × 24.8 in. (63 cm)

deep × 8.2 in. (20.8 cm) high (includes 5 in. [12.7

cm] clearance at rear)

Static electricity < 8 kV contact

Power Grounded ac, 100/240 Vac, 50/60 Hz

Surface orientation Level (ensures proper drip tray function)

Power Requirements

2

The 2410 refractometer, which operates over the range 100 Vac to 240 Vac, is shipped from the

factory with two 2.0 A fuses.

Caution: To avoid electrical shock, power off the 2410 refractometer and unplug the

power cord from the rear panel receptacle before you replace a fuse.

Caution: T o reduce the risk of fire hazard, alwa ys replace the fuse with the same type and

rating.

The two fuses are located above the power input receptacle within the power input module on the

rear panel (Figure 2-3).

Site Selection and Power Requirements 2-3

Page 46

Inputs

and Outputs

AB

2

Ext. 2

Ext. 1

Fuse Holder

Figure 2-3 Waters 2410 Refractometer Rear Panel

To replace a fuse in the 2410 refractometer, see Section 6.2, Replacing Fuses.

2.3 Unpacking and Inspection

The Waters 2410 refractometer shipping carton contains:

• Certificate of Structural Validation

• Waters 2410 Differential Refractometer

• Startup Kit

• Waters 2410 Differential Refractometer Operator’s Guide

• Release Notes

IEEE-488

Interface

Connection

Power Input

Receptacle

TP01531

To unpack the 2410 refractometer:

1. Check the contents of the shipping carton against the packing list to ensure you have

received all items.

2. Save the shipping carton for future transport or shipment.

2-4 Installing the 2410 Refractometer

Page 47

If you see any damage or discrepancy when you inspect the contents of the carton, immediately

contact the shipping agent. U.S. and Canadian customers only , also contact W aters T echnical Service

at (800) 252-4752. Other customers, call your local W aters subsidiary or your local W aters T echnical

Service Representative, or call Waters corporate headquarters for assistance at (508) 478-2000 (U.S.).

Note: Make sure the instrument serial number on the rear panel nameplate or inside the

left front panel corresponds to the number on the instrument validation certificate.

For more information about shipments, damages, and claims, see Appendix C, Warranty

Information.

2.4 Making Electrical Power Connections

To connect the 2410 refractometer to the ac power supply:

1. Plug the receptacle end of the power cord into the ac power input receptacle on the rear panel

of the detector (Figure 2-3).

2. Plug the other end of the power cord into a properly grounded ac power source.

For information about the remaining rear panel electrical connections, see Chapter 3, Making

Signal Connections.

2.5 Making Fluidic Connections

Caution: To avoid chemical hazards, always observe good laboratory practices when

handling solvents. Refer to the Material Safety Data Sheets for solvents in use.

This section describes the procedures for connecting the 2410 refractometer to:

• A column or another detector

• A waste container

• The drip tray

2

The fluidic connections for the 2410 refractometer are located to the left of the keypad on the front

panel (Figure 2-4).

Making Electrical Power Connections 2-5

Page 48

Pressure Relief

Valve

Solenoid Valv e

2

Outlet Tubing

(blue)

Drip Tray Fitting

(under oven)

Inlet Tubing (red)

Figure 2-4 Fluidic Connections

2.5.1 Connecting a Column or Second Detector

Note: If you are using more than one detector in your system, the W aters 2410 Diff erential

Refractometer must be connected as the last detector in line.

Required Materials

• 1/16-inch stainless steel tubing, 0.009-inch ID (from Startup kit)

• Waters 1/16-inch stainless steel tubing cutter or file

• Pliers, cloth-covered

• Two compression fittings and ferrules (from Startup kit)

• 5/16-inch open-end wrench

TP01532

To connect a column or other detector to the 2410 refractometer:

1. Measure the minimum length of tubing needed to connect the column or other detector

outlet to the inlet tubing port.

2-6 Installing the 2410 Refractometer

Page 49

2. Cut the tubing to the required length.

a. Use the stainless steel tubing cutter or a file with a cutting edge to scribe the

circumference of the tubing at the desired end point.

b. Grasp the tubing on both sides of the scribed mark with cloth-covered pliers (to prevent

marring the surface) and gently work the tubing back and forth until it separates.

c. File the ends smooth and straight for maximum column efficiency, and remove all

burrs.

3. Slide a compression screw and ferrule over one end of the tubing, as shown in

Figure 2-5.

Compression

Screw

Tube

Distance (determined by

TP01139

Figure 2-5 Ferrule and Compression Screw Assembly

4. Bottom the tubing in the inlet tubing port fitting of the refractometer, then seat the

ferrule by tightening the compression screw 3/4-turn past finger-tight with the 5/16-inch

open-end wrench.

5. Repeat steps 3 and 4 to connect the tubing to the outlet fitting of the column or another

detector.

each application, such as

union or column fitting)

2.5.2 Connecting to Waste

Because the 2410 refractometer flow cell is very sensitive to backpressure, be sure to use waste

tubing that is 0.040-inch ID and that is no more than 18 to 24 inches (45 to 60 cm) long.

Ferrule

2

Tubing End (straight and

smooth to achieve maximum

column efficiency)

Required Materials

• 1/16-inch stainless steel tubing, 0.040-inch ID (from Startup kit)

• Waters 1/16-inch stainless steel tubing cutter or file

• One compression fitting and ferrule (from Startup kit)

Making Fluidic Connections 2-7

Page 50

2

• 5/16-inch open-end wrench

• Waste container

To connect the 2410 refractometer to waste:

1. Cut the minimum length of tubing needed, as described in Section 2.5.1, Connecting a

Column or Second Detector.

2. Slide the compression fitting and ferrule over one end of the 0.040-inch tubing, as

shown in Figure 2-5.

3. Bottom the tubing in the outlet tubing port fitting of the refractometer, then seat the

ferrule by tightening the compression screw 3/4-turn past finger-tight with the 5/16-inch

open-end wrench.

4. Place the waste container lower than, or at the same level as, the 2410 refractometer.

5. Place the free end of the tubing in the waste container.

STOP

Attention: The maximum pressure for the 2410 refractometer flow cell is 100 psi. The

flow cell could be damaged if this pressure is exceeded.

2.5.3 Connecting to a Drip Tray

The 2410 refractometer contains a drip tray underneath the flow cell behind the front panel to direct

solvent leaks to the front of the unit.

Connecting the drip tray is usually unnecessary, but, if you connect it, be sure to position the waste

container below the drip tray outlet.

Required Materials

• PTFE tubing, 0.063-inch ID (from the Startup kit)

• Razor blade

To connect the drip tray:

1. Cut a length of PTFE tubing sufficient to reach between the drip tray and the waste

container.

2. Connect the tubing to the white plastic fitting located under the oven of the 2410

refractometer (see Figure 2-4).

3. Insert the other end of the tubing into the waste container.

2-8 Installing the 2410 Refractometer

Page 51

Chapter 3

Making Signal

Connections

3.1 Component Connection Overview .................... 3-1

3.2 Making IEEE-488 Signal Connections ............. 3-3

3.3 Making Non-IEEE-488 Signal Connections..... 3-8

3.4 Connecting the External Column Heaters....... 3-19

Page 52

Page 53

3

Making Signal Connections

This chapter describes procedures for making signal connections between the Waters 2410

Differential Refractometer and other HPLC system components.

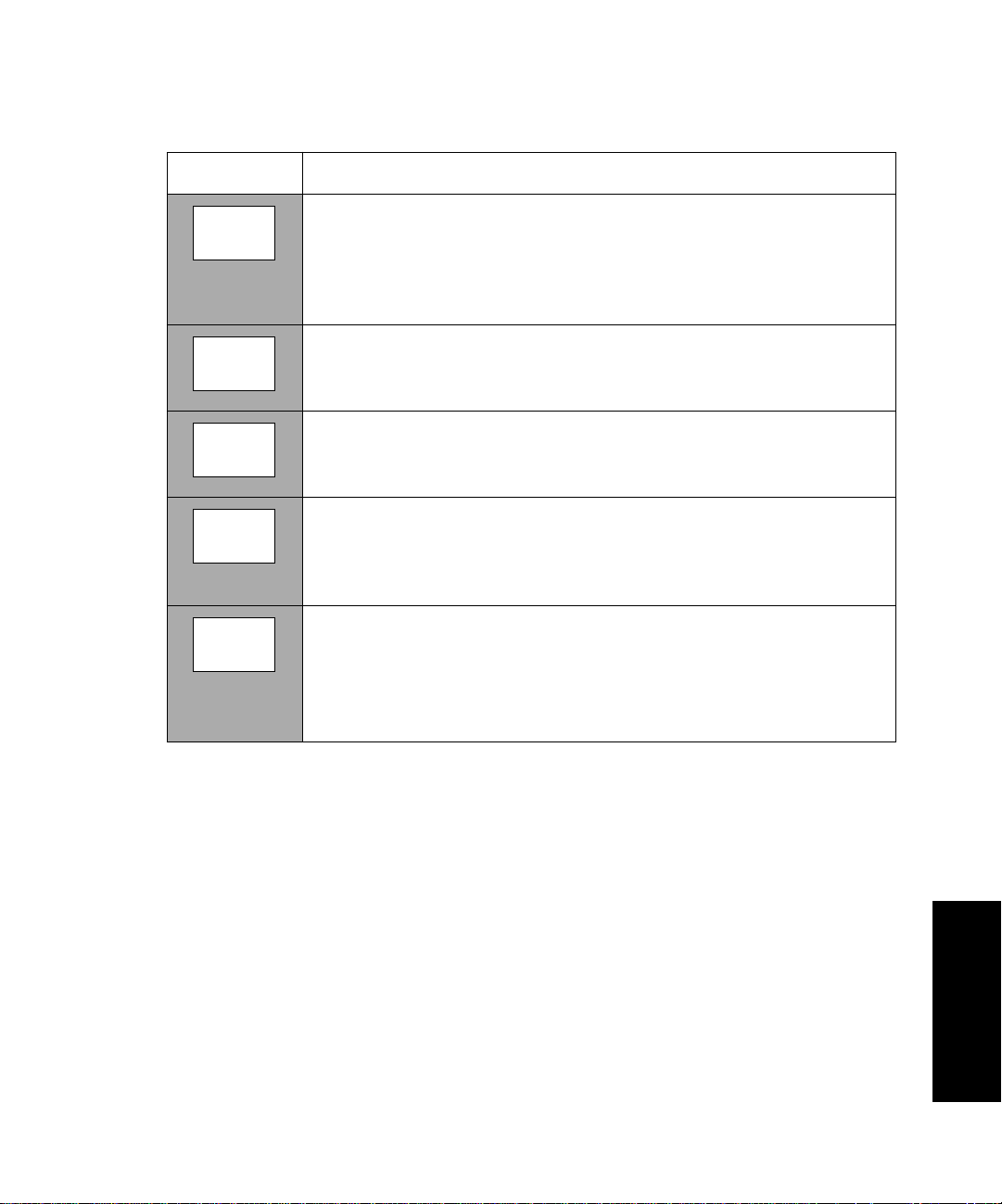

3.1 Component Connection Overview

Table 3-1 summarizes the signal connections needed to connect the 2410 refractometer to other

HPLC system components.

Table 3-1 Component Connection Summary

Connector Type Component

IEEE-488 Connections

IEEE-488 Connector • Millennium Chromatography Manager

through the busLAC/E card

• Waters 845/860 Data System through

the LAC/E or busSAT/IN Module

• Waters PowerLine™ System Controller

• Waters 2690 Separations Module

Non-IEEE-488 Connections

Analog outputs • 745/745B/746 Data Module (integrator

or data system using the A/D interface)

• Chart recorder

• Compressed data output

Event inputs • System controller (used with the Waters

2690 Separations Module and the 600

Series solvent delivery system)

• Waters 700 series or a non-Waters

autosampler

• Waters or non-Waters manual injector

9-Pin DIN • Waters or non-Waters manual injector

• Two optional external column heaters

3

Component Connection Overview 3-1

Page 54

Figure 3-1 shows the rear panel locations of the connectors used to operate the 2410 refractometer

with external devices.

AB

Analog-Out

and Event-In

Connectors

3

9-Pin DIN

Connectors (for

External Column

Heaters)

Fuse Holder

IEEE-488 Interface

Power Input

Figure 3-1 Waters 2410 Differential Refractometer Rear Panel

The signal connections you need to make to your 2410 refractometer depend on the signal

connections available on the other instruments in your HPLC system.

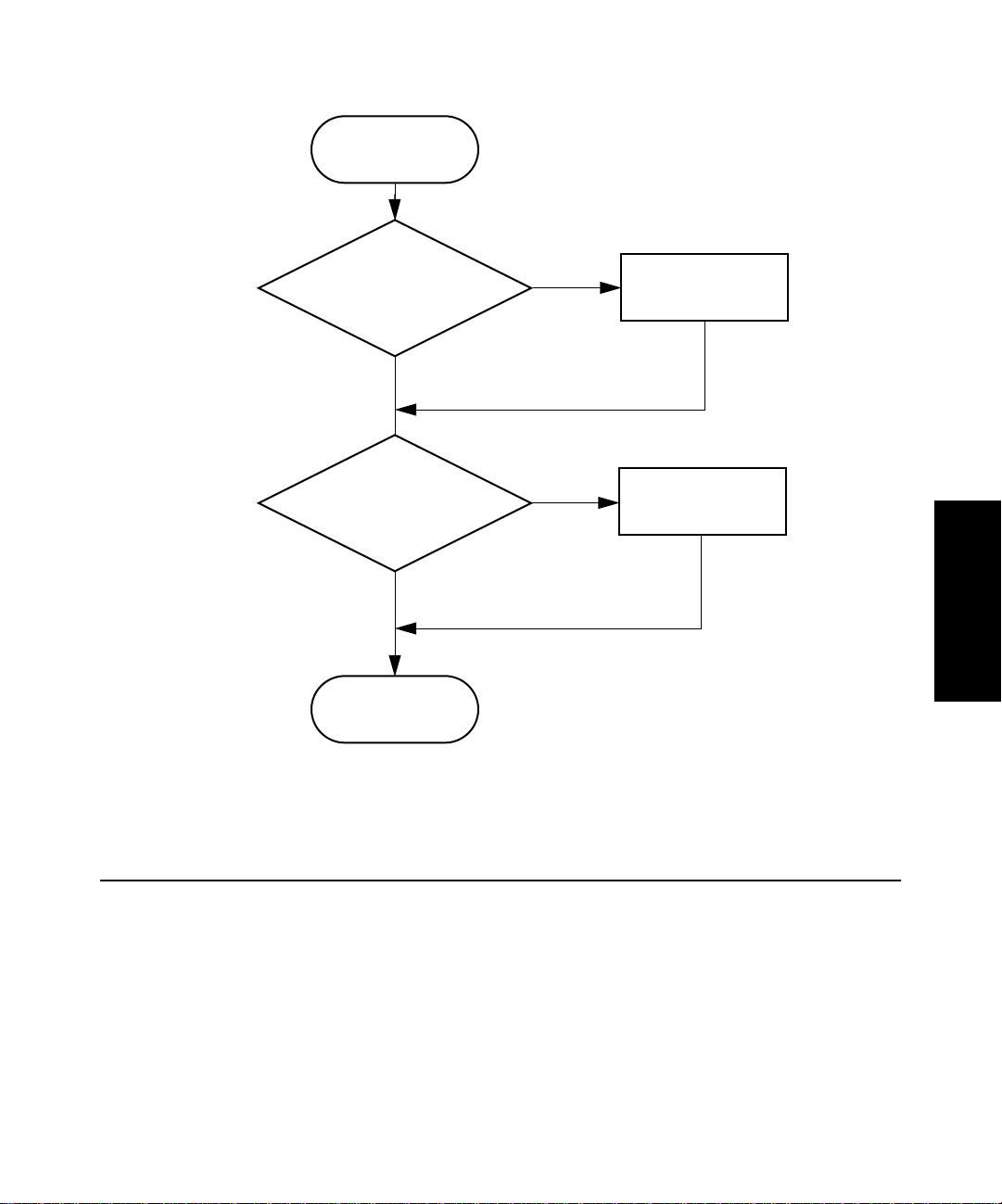

Figure 3-2 provides an overview of the steps to follow to connect the 2410 refractometer to other

instruments in your HPLC system.

TP01531

3-2 Making Signal Connections

Page 55

Start Signal

Connection Procedure

Connect to

IEEE-488

Bus?

No

No

Connect

to Non-IEEE

Instrument, Such as Integrator,

Chart Recorder,

bus SAT/IN,

etc.

No

Signal Connections

Complete

Yes

Yes

Install IEEE-488

Cable

Install Event and I/O

Cable(s)

Figure 3-2 Overview of Connecting Components to the 2410 Differential Refractometer

3

3.2 Making IEEE-488 Signal Connections

You can use the IEEE-488 bus to connect the 2410 refractometer to Waters or third-party data

systems.

3.2.1 Connecting to a Waters Data System Using the IEEE-488 Bus

You can use the IEEE-488 bus to connect the 2410 refractometer to a W aters data system in an y one

of the following configurations (see Figure 3-3, Figure 3-4, and Figure 3-5):

• Millennium Chromatography Manager through the busLAC/E™ card installed on the

computer (Figure 3-3)

Making IEEE-488 Signal Connections 3-3

Page 56

3

• Waters 845 or 860 system through a LAC/E module (Figure 3-4)

• Waters 2690 Separations Module as part of an Alliance system (Figure 3-5).

Bus LAC/E or Network LAC/E Card

Millennium

Chromatography

Manager

IEEE-488 Cables

IEEE-488

Connector

600 Series

Pump

717plus

Autosampler

2410

Refractometer

Figure 3-3 Waters Millennium System IEEE-488 Connections

IEEE-488 Connector

IEEE-488

Cable

IEEE-802.3

Ethernet Connector

Thin Wire

Ethernet Cable

600 Series

Pump

IEEE-488

Cables

717plus

Autosampler

Figure 3-4 Waters 845/860 System IEEE-488 Connections

3-4 Making Signal Connections

LAC/E Module

ExpertEase 845/860

Workstation

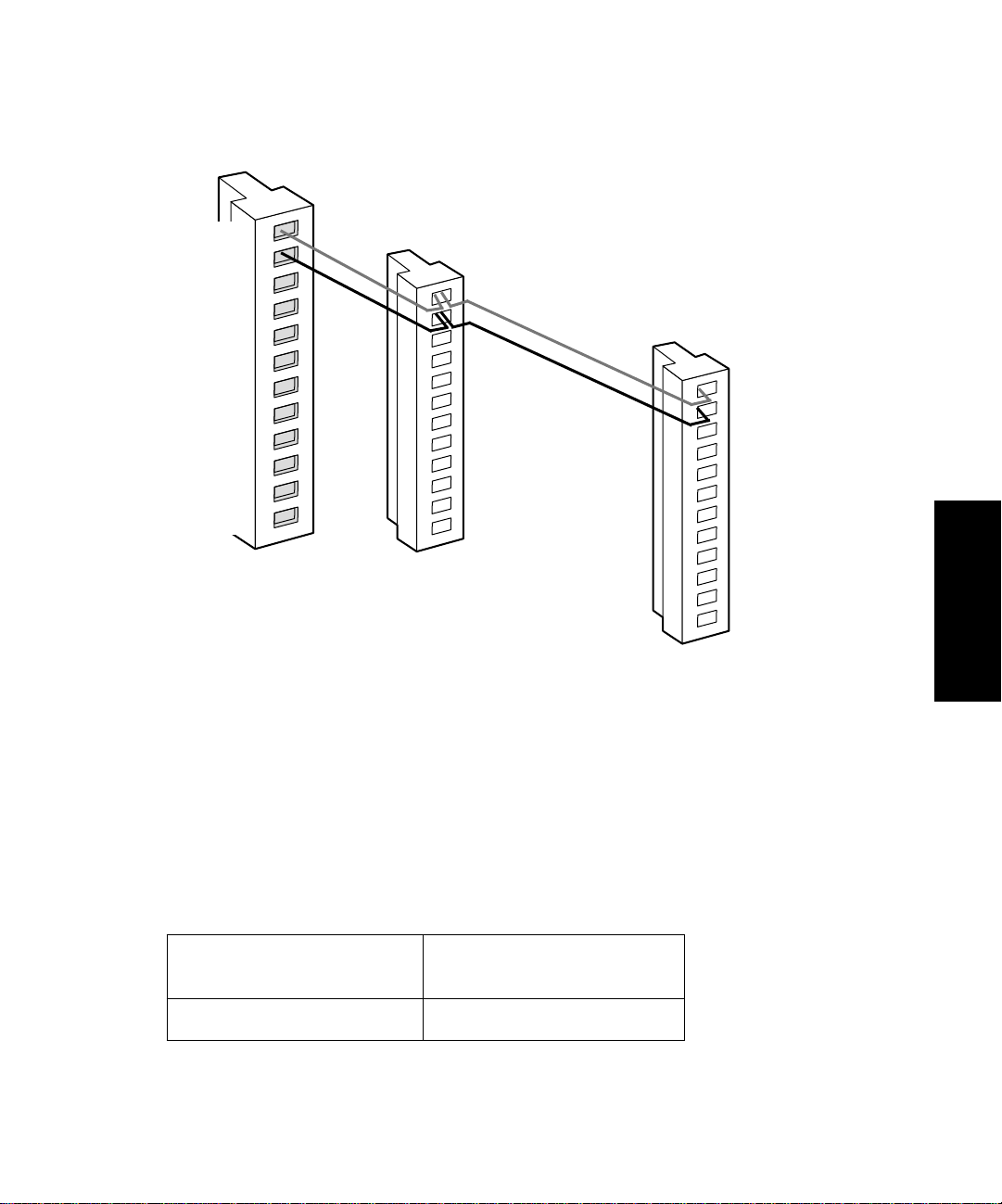

2410

Refractometer

Page 57

Millennium

Chromatography

Manager

Bus LAC/E or Network LAC/E Card

IEEE-488 Cables

2690

Separations

Module

Figure 3-5 Waters Alliance System IEEE-488 Connections

IEEE-488 Connectors

2410

Refractometer

Setting the IEEE-488 Address

Like all other IEEE-488 devices, the 2410 refractometer requires a unique IEEE-488 address to be

recognized by an IEEE-488 controller, such as a Millennium Chromatography Manager , b usLA C/E

module, or an Alliance™ or PowerLine™ System Controller.

The factory-set default IEEE-488 address for the 2410 differential refractometer is 10. To change

the IEEE-488 address:

1. Press 2nd Func, Clear, Clear, then press Enter. The value diag is displayed.

2. Press 2nd Func, 6, Enter.

3. Enter the number corresponding to the desired IEEE-488 address, then press Enter.

Note: IEEE-488 addresses must be unique for each instrument in an HPLC system and

must be between 2 and 29. Your HPLC system may require that the IEEE-488 address for

the 2410 refractometer be greater than that for other devices in the system. Consult your

data system or controller operator's manual for more information on IEEE-488

communications.

3

4. To exit the diagnostic functions, press 2nd Func, Clear, then press Enter.

Making Inject Start Signal Connections

When you are using an IEEE-488 data system with the 2410 differential refractometer, the data

system or controller must receive an inject start signal from the autosampler or manual injector to

initiate the data collection and time-based programs.

Making IEEE-488 Signal Connections 3-5

Page 58

Note: Depending on your system configuration, the inject start signal can be transmitted

through the IEEE-488 interface or the analog-out/event-in connectors on the 2410

refractometer rear panel. For information on non-IEEE-488 connections, see Section 3.3,

Making Non-IEEE-488 Signal Connections.

Table 3-2 summarizes the inject start connections for different system configurations.

Note: If multiple devices in your system require an inject start signal, connect trigger wires

from the same (inject out) terminal on the injector to each device.

Table 3-2 Waters 2410 Refractometer Inject Start Connections

3

Inject Start Output Source

Waters 715, 717, and 717plus,

and 2690 Separations Module, on

the IEEE-488 bus

W aters 715, 717, and 717plus not

on the IEEE-488 bus

W aters 2690 Separations Module

not on the IEEE-488 bus

Waters 712 Autosampler Chart Mark and Ground

Waters manual injector, or

third-party manual injector or

autosampler

IEEE-488 interface (see Section 3.2.1, Connecting to a

Waters Data System Using the IEEE-488 Bus)

Note: If you are using the Waters 845 or 860 Data

System, you must program the multi-method to Start

By LAC/E (refer to the ExpertEase Reference Guide

for details).

Chart Mark and Ground

Chart Mark and Ground or Auto Zero and Ground

Chart Mark and Ground

Inject Start Input Connection

(on the 2410 Refractometer)

3-6 Making Signal Connections

Page 59

3.2.2 Connecting to a Waters PowerLine System Controller

To connect the 2410 refractometer to a Waters PowerLine system controller, use the IEEE-488

interface cables as shown in Figure 3-6.

Each fluid-handling unit is configured with either of the following:

• Integrated manual injector (built in as part of the drawer or shelf unit)

• Externally connected manual injector or autosampler

PowerLine

Controller

(600 Series Solvent

IEEE-488

Cable

Delivery System or

2690 Separations

Module)

717plus

Autosampler

Figure 3-6 Waters PowerLine System Controller IEEE-488 Connections

3.2.3 Connecting to a Manual Injector

If you are using a manual injector with your IEEE-488 system, connect the signal cables from the

rear panel connector on the 2410 refractometer to the injector as indicated in Table 3-3.

Table 3-3 Waters 2410 Connections to a Manual Injector

2410 Refractometer

(Connector B)

Chart Mark + (red) One set of spade lug Chart Mark terminals

(the Waters injector includes two pairs of

Chart Mark – (black)

For information on injection trigger signals from a manual injector, see Section 3.3.5, Connecting

Injection Trigger Signals.

cables that are functionally identical)

2410

Refractometer

Manual Injector

3

Making IEEE-488 Signal Connections 3-7

Page 60

3

3.3 Making Non-IEEE-488 Signal Connections

To connect the 2410 refractometer to instruments that lack an IEEE-488 bus, you use the

analog-out/event-in (I/O) connectors on the rear panel (Figure 3-7). Figure 3-7 shows the two I/O

connectors (and their corresponding pin-outs) on the 2410 refractometer rear panel. Table 3-4

describes the functions of each connector.

This section describes signal connections between the 2410 refractometer rear panel

analog-out/event-in connectors and the following:

• Waters 2690 Separations Module (used independently of the IEEE-488 interface)

• Waters 745/745B/746 Integrator

• Chart recorder

• Waters SAT/IN module

• Waters or other manual injector

• Other manufacturer’s integrator or A/D interface device

Caution: To avoid electrical shock, power off the 2410 refractometer before making any

electrical connections.

Attention: To meet the regulatory requirements of immunity from external electrical

STOP

disturbances that may affect the performance of this instrument, do not use cables longer

than 9.8 feet (3 meters) when you make connections to the analog-out/event-in

connectors. In addition, ensure you always connect the shield of the cable to ground at

one instrument only.

3-8 Making Signal Connections

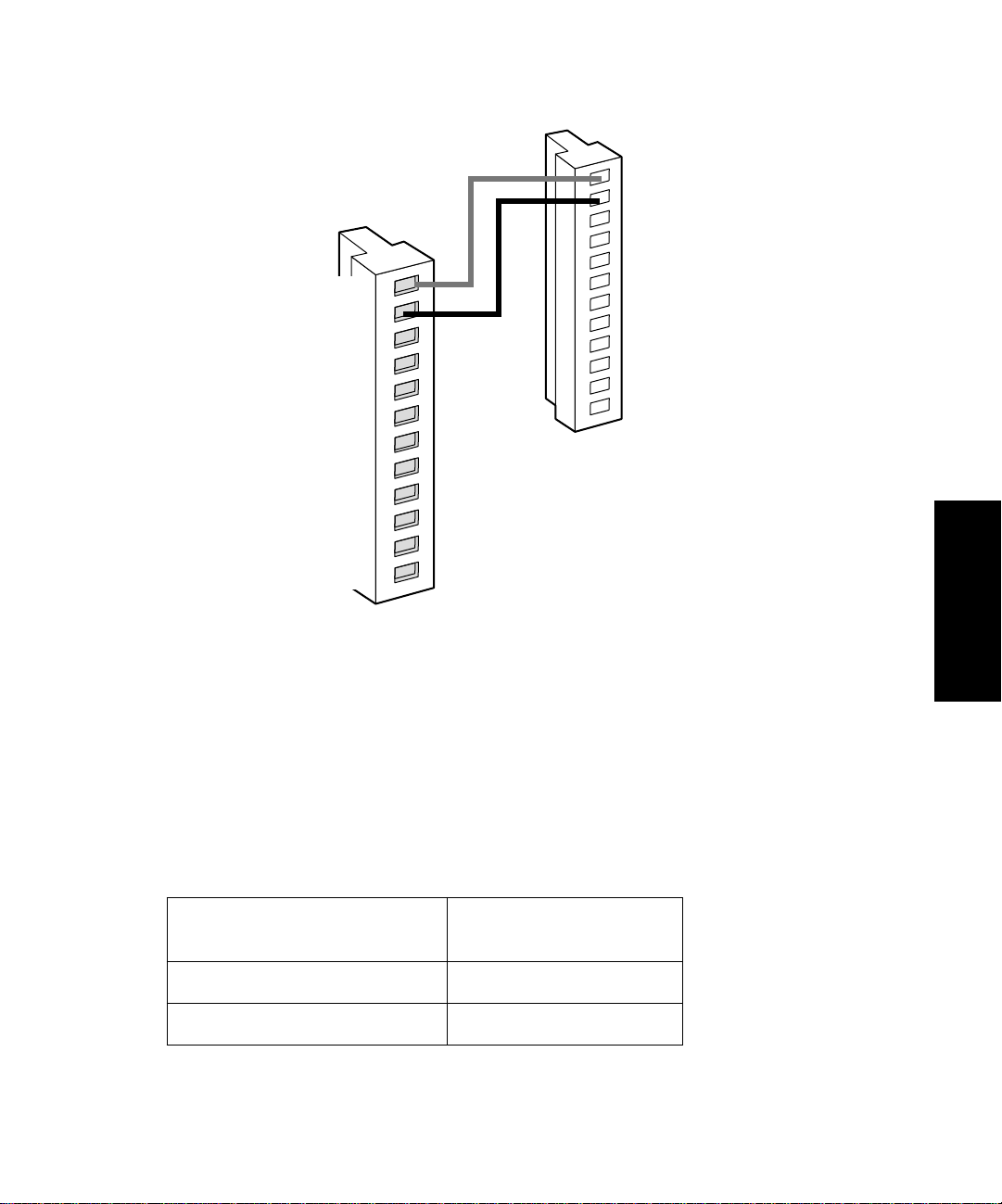

Page 61

A (Inputs and Outputs)

B (Inputs and Outputs)

1 Auto Zero +

2 Auto Zero –

3 Chassis Ground

4 Purge In +

5 Purge In –

6 Chassis Ground

7 Recorder Out +

8 Recorder Out –

9 Chassis Ground

10 Compressed Out +

11 Compressed Out –

12 Chassis Ground

1 Chart Mark +

2 Chart Mark –

3 Chassis Ground

4 Polarity 1 +

5 Polarity 1 –

6 Chassis Ground

7 Polarity 2 +

8 Polarity 2 –

9 Chassis Ground

10 Integrator Out +

11 Integrator Out –

12 Chassis Ground

Figure 3-7 Waters 2410 Rear Panel Analog-Out/Event-In Connectors

Table 3-4 describes the functions of the 2410 refractometer analog-out/event-in connectors.

Table 3-4 Waters 2410 Analog-Out/Event-In Connections

3

Signal Connections Description

Chart Mark

Polarity 1 and 2

Accept TTL-level (0 to +5 V) or contact closure

signals from an external instrument

Auto Zero

Purge

Recorder Out Sends a ±2 V (full scale) signal to a chart recorder

Integrator Out Sends a ±2 V (full scale) signal to an integrator or

computer

Compressed Out Sends a compressed (logarithmic) 0 to +10 mV

maximum output signal to a chart recorder or

integrator

Making Non-IEEE-488 Signal Connections 3-9

Page 62

3

3.3.1 Connecting to a Stand-Alone 2690 Separations Module

Note: When you use the 2690 Separations Module as the system controller on the

IEEE-488 bus, follow the instructions for connecting to a Waters PowerLine system

(see Section 3.2.2, Connecting to a Waters PowerLine System Controller).

When you use the 2690 Separations Module as a stand-alone controller (not on the IEEE-488 bus

or under Millennium software control), you can make the following signal connections using the

2410 refractometer analog-out/event-in connectors:

• Auto zero on inject

• Chart mark on inject

• Both chart mark and auto zero on inject

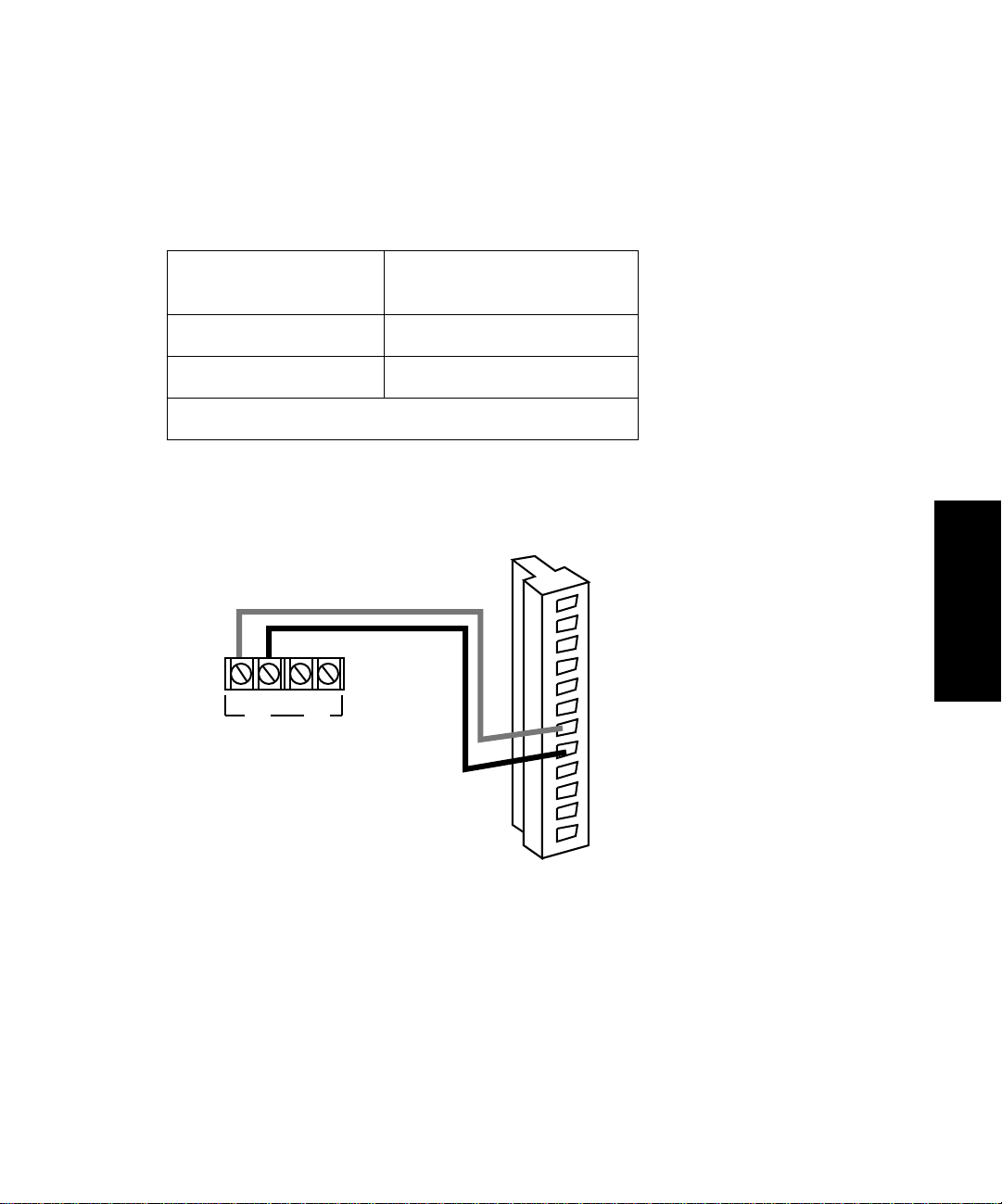

Generating Auto Zero on Inject

To generate the auto zero function on the 2410 refractometer at the start of an injection from the

2690 Separations Module, make the connections shown in Table 3-5 and Figure 3-8.

Table 3-5 Auto Zero Connections Between the 2690 Separations Module

and the 2410 Refractometer

2690 Separations Module

(Connector B)

Pin 1 Inject Start Pin 1 Auto Zero +

Pin 2 Inject Start Pin 2 Auto Zero –

3-10 Making Signal Connections

2410 Refractometer

(Connector A)

Page 63

Waters 2410 Refractometer

Connector A

Waters 2690

Connector B

Inject Start

Inject Start

Ground

Stop Flow+

Stop Flow–

Hold Inject 1+

Hold Inject 1–

Hold Inject 2+

Hold Inject 2–

Ground

Chart Out+

Chart Out–

Red

Black

1

2

3

4

5

6

7

8

9

10

11

12

1 Auto Zero+

2 Auto Zero–

3 Chassis Ground

4 Purge In+

5 Purge In–

6 Chassis Ground

7 Recorder Out+

8 Recorder Out–

9 Chassis Ground

10 Compressed Out+

11 Compressed Out–

12 Chassis Ground

TP01527

Figure 3-8 Auto Zero Connections Between the 2690 Separations Module

and the 2410 Refractometer

3

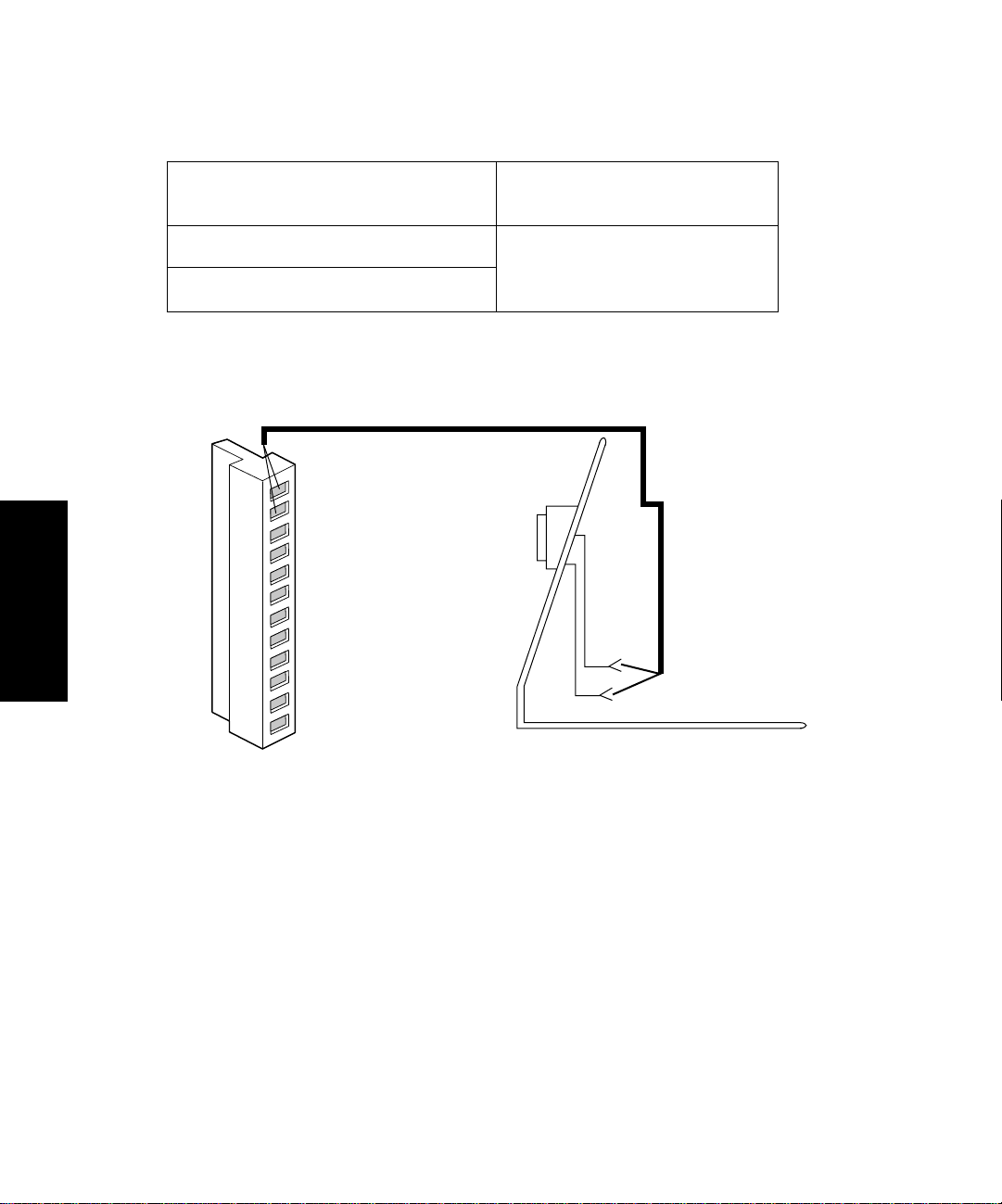

Generating Chart Mark on Inject

To generate the chart mark function on the 2410 refractometer at the start of an injection from the

2690 Separations Module, make the connections shown in Table 3-6 and Figure 3-9.

Table 3-6 Chart Mark Connections Between the 2690 Separations Module and the

2410 Refractometer

2690 Separations Module

(Connector B)

Pin 1 Inject Start Pin 1 Chart Mark +

Pin 2 Inject Start Pin 2 Chart Mark –

2410 Refractometer

(Connector B)

Making Non-IEEE-488 Signal Connections 3-11

Page 64

Waters 2410 Refractometer

Connector B

3

Waters 2690

Connector B

Inject Start

Inject Start

Ground

Stop Flow+

Stop Flow–

Hold Inject 1+

Hold Inject 1–

Hold Inject 2+

Hold Inject 2–

Ground

Chart Out+

Chart Out–

10

11

12

Red

1

2

3

4

5

6

7

8

9

Black

1 Chart Mark+

2 Chart Mark–

3 Chassis Ground

4 Polarity 1+

5 Polarity 1–

6 Chassis Ground

7 Polarity 2+

8 Polarity 2–

9 Chassis Ground

10 Integrator Out+

11 Integrator Out–

12 Chassis Ground

TP01527

Figure 3-9 Chart Mark Connections Between the 2690 Separations Module

and the 2410 Refractometer

Generating Chart Mark and Auto Zero

To generate both a chart mark and an auto zero signal from the 2690 Separations Module to the

2410 refractometer, make the connections shown in Table 3-7 and Figure 3-10.

Table 3-7 Chart Mark and Auto Zero Connections Between the 2690 Separations Module

and the 2410 Refractometer

2690 Separations

Module

(Connector B)

Pin 1 Inject Start Pin 1 Auto Zero + Pin 1 Chart Mark +

Pin 2 Inject Start Pin 2 Auto Zero – Pin 2 Chart Mark –

3-12 Making Signal Connections

2410 Refractometer

(Connector A)

2410 Refractometer

(Connector B)

Page 65

Waters 2690

Connector B

Inject Start

Inject Start

Ground

Stop Flow+

Stop Flow–

Hold Inject 1+

Hold Inject 1–

Hold Inject 2+

Hold Inject 2–

Ground

Chart Out+

Chart Out–

10

11

12

Waters 2410 Refractometer

1

2

3

4

5

6

7

8

9

Red

Black

Connector A

1 Auto Zero+

2 Auto Zero–