Water Factory Systems SQC Pro User Manual

SQC Pro

Owner's Manual

This Manual is for the Installation, Operation,

and Maintenance of the

™

WATER FACTORY SYSTEMS

SQC Series

Reverse Osmosis (RO) Drinking Water Appliance

98-91220 1009

Installer: Leave with Homeowner.

INTRODUCTION

This manual explains the installation, operation and maintenance of the Water Factory Systems™SQC

Series Reverse Osmosis (RO) Drinking Water Appliances. Please read each section of this manual carefully. The specific model chosen should be appropriate for the local water conditions and the customer's

needs. Check the Performance Data Sheet for the performance characteristics and the conditions of use.

The Water Factory Systems undercounter RO drinking water appliances are designed to connect permanently to a home plumbing system. To ensure that the installation conforms to your state and local

plumbing codes, it is recommended that the installation be performed by a qualified installation specialist

for RO drinking water appliances or a licensed plumber. Failure to install the system as instructed will

VOID the warranty.

Caution: The RO membrane cartridge is shipped with a preservative solution inside.

Make sure to flush it thoroughly as directed before the first use.

TABLE OF CONTENTS

I. Installation Instructions

A. Determine the appliance location....................................................................................3

B. Prepare the area for installation ......................................................................................

C. Prepare the appliance for installation ..............................................................................4

D. Make the faucet mounting hole ......................................................................................4

E. Mount the faucet..............................................................................................................5

F. Install the feed water tapping valve and tubing ..............................................................6

G. Prefill and sanitize the storage tank................................................................................7

H. Install the drain connection ............................................................................................7

I. Install the purification assembly and storage tank ..........................................................8

J. Make the tubing connections ..........................................................................................8

K. Install the icemaker hookup (optional) ............................................................................8

L. Start up the appliance .................................................................................................... 9

M. Flush the appliance of the preservative and check the operation ..................................9

N. Cleanup and paperwork ..................................................................................................9

O. Appendix for basement installations ..............................................................................10

P. Installation troubleshooting..............................................................................................11

3

II. Operation & Maintenance Instructions

A. Important water quality assurance requirements ............................................................12

B. Replacing the filter cartridges..........................................................................................12

C. Replacing the RO membrane cartridge ..........................................................................13

D. Sanitizing the RO appliance............................................................................................13

E. Long term non-use ..........................................................................................................14

A. DETERMINE THE APPLIANCE LOCATION

neatly away from the working area. Arrange a light for the work

If a basement installation is called for, determine where the

Special mounting brackets and hardware may be necessary to

It is a good idea at this time to check the condition of the

I. Installation Instructions

The appliance can be located under a sink or in a basement

depending on space availability and the customer's preference. If

a basement installation is selected, additional tubing, hardware

and fittings may be needed and a hole will have to be made from

inside the cabinet, through the floor, to the basement. Never

install it in an area of the home where the temperature may drop

to freezing, because damage to the appliance may occur. It will

be important that appropriate, protected, electrical service be

available at the appliance location. If not already available, make

sure to contract the necessary work prior to appliance installation.

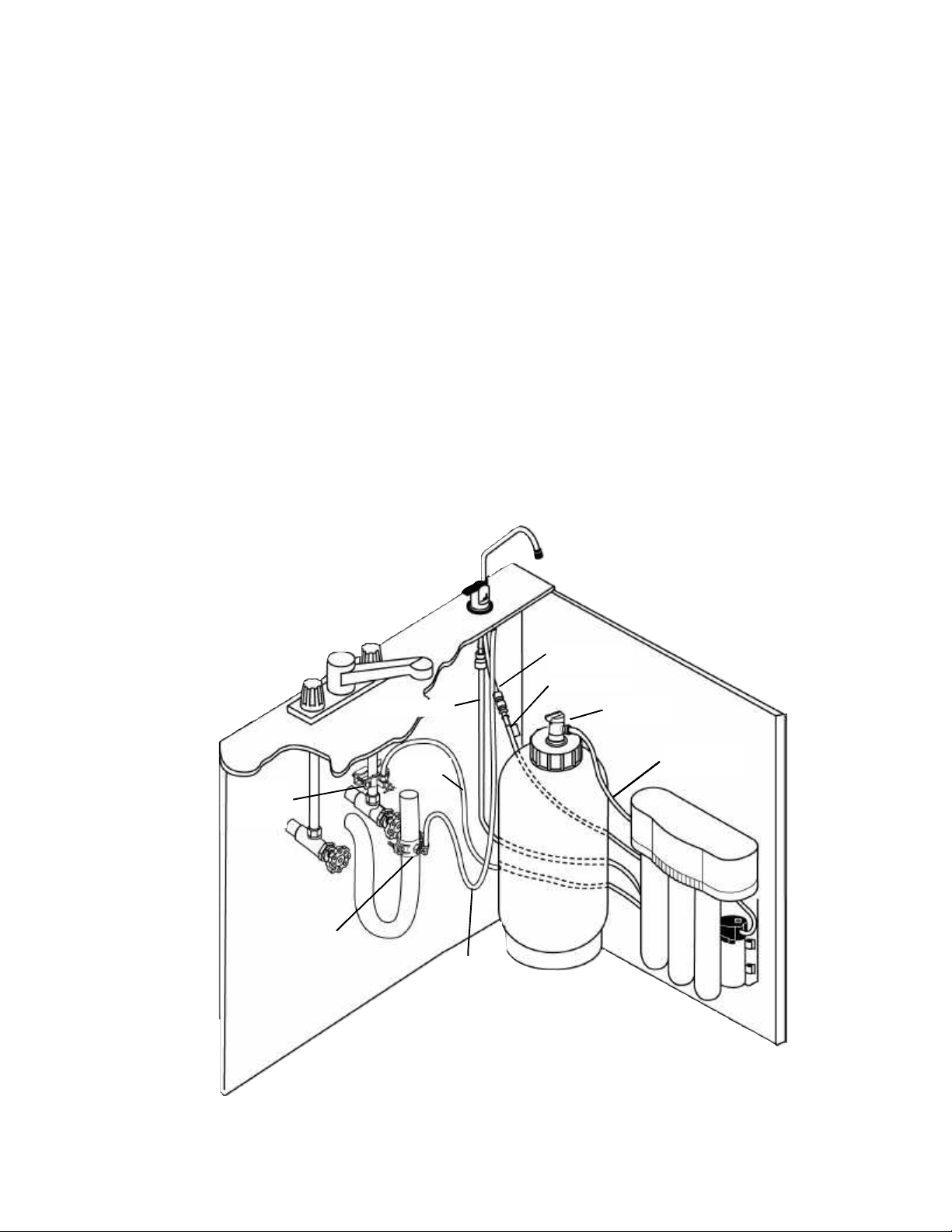

The exact placement of the various components of the

appliance will vary from installation to installation. The

installer, in conjunction with the customer, must decide on

where to place the faucet, tank and purification assembly by

balancing the homeowner's convenience with ease of installation and servicing. (See Fig. 1 & 7). A nearby electrical outlet

will also be required for proper installation of this device.

Considerations for an icemaker or other remote hookup

should be predetermined, including routing and any additional

tools, fittings, and tubing that may be required.

B. PREPARE THE AREA FOR INSTALLATION

Remove supplies from under the sink and stack them

area, if necessary.

components will be located and how they will be mounted.

secure the appliance to a wall or ceiling joists.

Inspect the cold water supply line and determine if any

special fittings, in addition to what is included in the kit, are

required.

NOTE:

undercounter plumbing for any existing or potential leaks. Any

items of concern should be repaired prior to installation of the

drinking water device.

Feedwater

Tapping

Valve

Drain Saddle

3/8” Blue Tubing

1/4” Orange

Sink Drain

Tubing

1/4” Green Tubing

Red SFC Tubing

Storage Tank

Valve

3/8” Yellow

Tubing

Storage Tank

3/8” Black

Tubing

Purification Assembly

* 110/60 (220/50) Electrical Connection

Necessary at This Location

Fig. 1

3

C.

PREPARE THE APPLIANCE FOR

INSTALLATION

Procedure:

Set up the chassis punch per the instructions and tighten the

-

Form a shallow putty dam around the hole area and fill it

Carefully drill a pilot hole through the porcelain/enamel and

Important:

Insert the pilot tip of the spring-loaded porcelain cutter into

porcelain cutter, making certain a complete ring has been

pressure, cut away the inner porcelain/enamel disc down

touch the outer rim of the cut porcelain/enamel. Continue

that it is always in a sharpened condition. Dull cutters are

Open the shipping carton and remove the components.

Check to see that all of the installation parts are present. They

should include the purification assembly, storage tank, faucet,

installation hardware, RO membrane cartridge and tubing.

Check to see that the air supply in the empty tank is approximately 7 psi (48 kPa). Adjust it if necessary. If an optional

percent rejection monitor is selected, the probes should be

installed at this time. Follow the instruction that came with the

monitor. To ensure you the highest level of purity, the RO

membrane cartridge has been shipped separately in a sealed

plastic bag. Follow the steps below to install the RO membrane cartridge.

STEP 1: Cut open the sealed plastic bag and remove the RO

membrane cartridge.

STEP 2: Remove the white plug from the fitting at the bottom

of the cartridge by pushing in the small gray collet and pulling

out the plug simultaneously. (See figure 6.)

STEP 3: Remove the red plastic cap from the top of the cartridge.

STEP 4: Connect the red SFC reject tubing by inserting the

open end into the fitting at the bottom of the RO membrane

cartridge as far as it will go. Take note of the tag attached to

the SFC tube which indicates the outlet end.

STEP 5: Line up the cartridge ears (Fig. 9), insert the cartridge

and push it into the head until it is fully seated. Twist the cartridge 1/4 turn counterclockwise to lock it into place. The final

orientation should be such that the cartridge label faces

towards the front and the fitting is located towards the rear.

D. MAKE THE FAUCET MOUNTING HOLE

A wide variety of RO faucet mounting situations may be

encountered. The most common are stainless steel or ceramic

on metal sinks. Consult your dealer for any other materials

which may be encountered.

The faucet should be positioned so that it empties into the

sink and the spout swivels freely for convenience.

If the sink already has a hole provided that can accommodate the RO faucet, then no drilling is required.

1) Center punch a small indent at the center of the desired

faucet location.

2) Slowly drill the required pilot hole for the chassis punch.

3)

nut to cut the desired hole size.

4) Clean up all sharp edges with a file if necessary.

Porcelain/Enamel/Ceramic sink on sheet metal or cast iron

base; air gap or non air gap faucet.

Recommended tools:

• Variable speed drill

• Relton 7/8" porcelain cutter tool set (alternate 9/16"

porcelain bit may be used for a non-air gap faucet)

• Plumber's putty

It is important to understand what is involved in this proce

dure. First, the glassy layer of porcelain must be penetrated

through to the base metal. Second, a center disc of porcelain

must be removed while protecting the surrounding porcelain

against chipping or fracturing. Third, the base metal must be

drilled through to complete the hole.

Procedure:

1) Mark the center for the 7/8" hole.

2)

with enough water to lubricate the carbide drill bit.

3)

the base metal using a carbide type pilot drill.

Always operate the drill with light pressure at a slow

speed (300-400 rpm).

4)

the pilot hole.

5) Drill the porcelain/enamel using the spring-loaded

cut through the porcelain/enamel to the metal base.

6) Change to the metal cutter. With a slow speed and light

to the base metal. Make certain that the cutter does not

NOTE: Sprayers can be disconnected to provide a suitable

mounting hole for the RO faucet. A pipe cap or plug will be

required to seal the sprayer connection.

IMPORTANT: It is mandatory that safety glasses by worn during the sink hole drilling operations in order to prevent eye injury.

Before drilling the hole, always check underneath the sink to

ensure that nothing will interfere with mounting the faucet such

as reinforcing ribs, support brackets or the cabinet construction.

Stainless steel sink, air gap or non-air gap faucet.

Recommended tools:

• Center punch

• Variable speed drill and high speed drill bits

• Greenlee 7/8" chassis punch (alternate 9/16" may be used

for a non-air gap faucet)

• Protective gloves

with this bit to cut completely through the metal.

IMPORTANT: When using a porcelain cutter it is critical

known to chip sinks.

4

E.

MOUNT THE FAUCET

Undercounter installations generally require that the

3)

Connect the 1/4" green tubing supplied in the installation

Connect the 3/8" black tubing to the larger barb on the air

and the threaded nipple through the faucet mounting hole

washer (open side toward the air gap tubes) between the

After rechecking the faucet orientation, tighten the hex nut

From above the sink, make any minor orientation corrections

faucet's built-in air gap be used. In basement installations, the

built-in air gap does not have to be used if one is provided

elsewhere on the drain line.

For Basement Installations Without An Air Gap Module

See Installation Instructions O.

IMPORTANT: The Uniform Plumbing Code dictates that there

must be an air gap between the RO reject line and the waste

drain. An optional non-air gap faucet, which requires a smaller

9/16" mounting hole, is available to make basement installations easier.

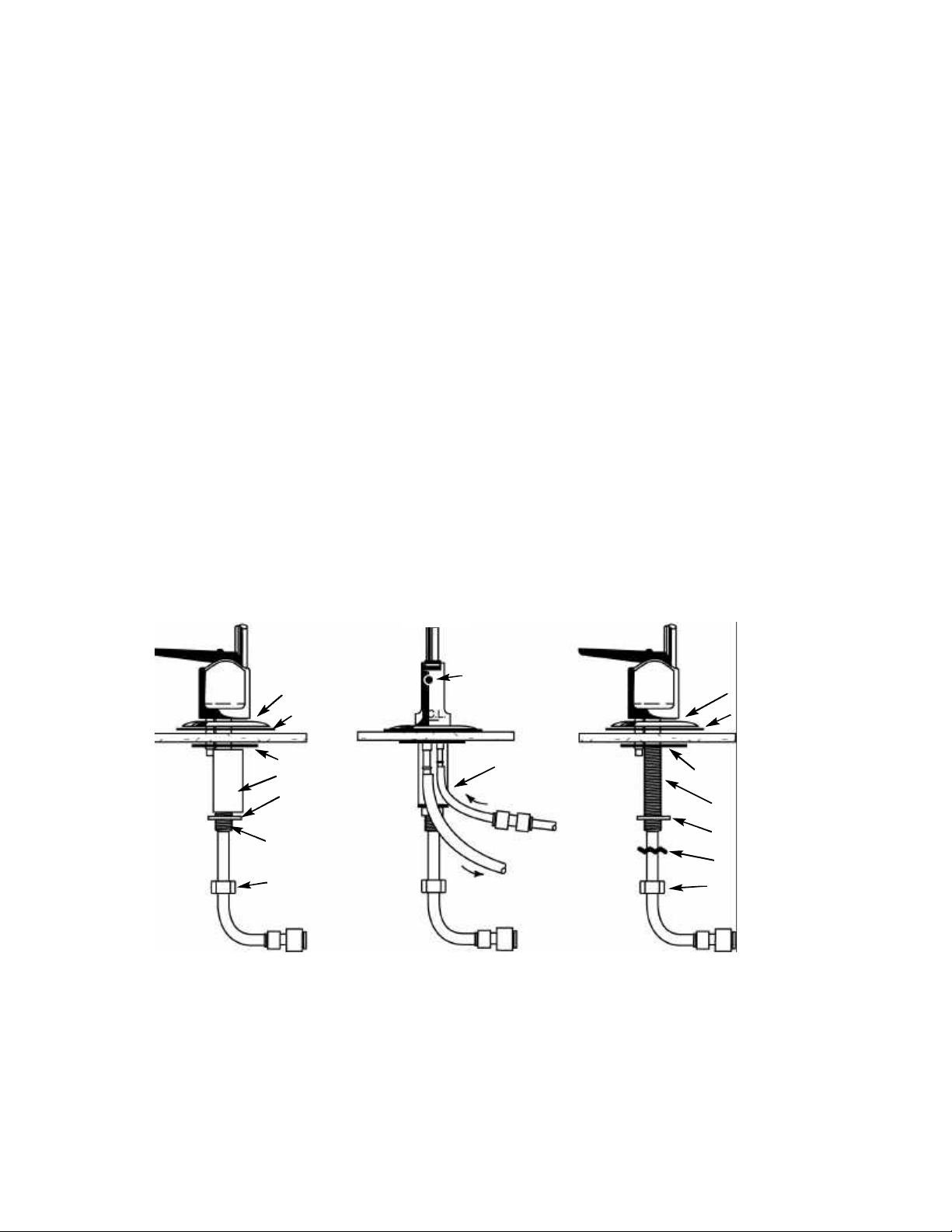

Undercounter Installation With An Air Gap Faucet:

1) Familiarize yourself with all of the components shown in

the air gap faucet diagram. (See Fig. 2)

2) Remove the hardware from the threaded nipple of the

faucet, except for the chrome base plate and the rubber

washer. The rubber washer may be replaced with a bead of

plumber's putty for a neater appearance.

kit to the smaller barb on the air gap faucet. Push it on

firmly until it seats.

4)

gap faucet. Push it on firmly until it seats.

5) From above the sink counter-top, feed the air gap tubing

and position the faucet spout over the sink.

6) From below the sink/countertop, install the white spacer

(open side toward the air gap tubing), flat washer and hex

nut onto the threaded nipple and tighten it by hand.

7) Back off on the hex nut just enough to slide the slotted

white spacer and the underside of the sink/countertop.

8)

with a 9/16" wrench until the faucet feels secure.

9)

by turning the faucet on its flats with a padded adjustable

wrench. Use care so as not to mar the chrome finish.

Faucet with Air Gap

Side View

Chrome base plate

Slotted washer

Spacer

Flat washer

Threaded nipple

Hex nut

Rubber washer

Blue 3/8” Product

water tubing

Back View

Air Gap hole

1/4” Standard

green tubing

Faucet without Air Gap

Side View

Special red “SFC”

tube from RO

Black 3/8” Reject

tubing to drain

Blue 3/8” Product

water tubing

Chrome base plate

Rubber washer

Plastic bottom washer

Threaded nipple

Flat washer

Star washer

Hex nut

Blue 3/8” Product

water tubing

Fig. 2

5

Loading...

Loading...