Water Boss 255 User Manual

Series 255 Valve / 960 Control

Water Conditioning Control System

Dealer Installation, Operation and Maintenance Manual

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Location Selection

Water Line Connection

Drain Line Connection

Brine Line Connection

Brine Tank Overflow Connection

Placing Conditioner into Operation . . . . . . . . . 6

Initial Start-Up

Connecting the Control

Programming the Model 960 Control . . . . . . . 7

Level I Parameters

Level II Parameters

Special Notes for Level II Parameters

Refill Control Valve

Regeneration . . . . . . . . . . . . . . . . . . . . . . . . . 12

Manual Regeneration

Automatic Regeneration

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Removing the Control

Preventive Maintenance . . . . . . . . . . . . . . . . 15

Injector Screen and Injector

Water Meter

Disinfection of Water Conditioners . . . . . . . . 16

Sodium Hypochlorite 5.25%

Calcium Hypochlorite

Specifications. . . . . . . . . . . . . . . . . . . . . . . . .17

Pressure Graphs. . . . . . . . . . . . . . . . . . . . . . . 18

Control Valving Identification . . . . . . . . . . . . . 19

Valve Disc Operation . . . . . . . . . . . . . . . . . . . 19

Flow Diagrams . . . . . . . . . . . . . . . . . . . . . . . . 19

Replacement Parts. . . . . . . . . . . . . . . . . . . . .21

Splicing the Low Voltage Transformer Cord. .24

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 25

Alarms

Troubleshooting Procedures

IMPORTANT:

The plug-in transformer for t his equipment is rated for

indoor use only.

IMPORTANT:

Never attempt to work on this control while standing in

or near water without disc onnecting electrica l power to

the control.

2

Introduction

The Model 960 control provides sophisticated,

demand-based water conditioning by incorporating a

microprocessor and a water meter to electronically

monitor the amount of water used daily. This fully

programmable control allows you to fine tune the

conditioner’s operation to meet your customer’s

application. The Series 255 valve combines design

simplicity with reinforced Noryl* construction to provide

an uncommonly reliable appliance. The inherent

reliability of the system means a long life of efficient,

trouble-free water conditioning. If maintenance

becomes necessary, the Series 255/960 water

conditioning system offers a unique separation

capability illustrated in this manual.

*Noryl is a trademark of General Electric Company

Special Features

•

Memory Retention.

critical operating information in the control’s

memory is stored in a special electronic device.

This information includes the time of day, water

usage amounts, daily average water usage, all

programming data and the number of days since

the last regeneration. When power is restored, the

information is returned to the microprocessor and

operation res umes as if a n outag e never occurr ed.

The time of day will be late by the length of the

power outage. If an outage of one or more hours

occurs, the time of day sh ould be reset but no ot her

reprogramming is necessary. The optional

non-rechar geable b attery backup fea ture wi ll allow

the control to keep track of time and any water

usage for up to two days during a power outage.

•

Fully programmable regeneration cycle times.

The control is factory programmed with typical

regeneration cycle times for easy installation. The

control allo ws the Backwash, Rinse, and Purge

cycle times to be set by the installer to fine tune the

conditioner’s operation.

•

Automatic double regenerations for exhausted

resin beds.

the system capacity between regenerations, the

control will automatically call for a second

regeneration the next day even if no water is used.

This feature is included to make sure that an

exhausted resin bed is completely recharged.

•

Selectable reserve options.

programmed to operate with one of four different

reserve options (see Parameter P15, Table 3). The

options include starting a regeneration only at a

specific time of day or having an immediate

regeneration when the capacity is exhausted. The

control can also have a fixed reserve which is a

percentage of the total system capacity or a

If the water usage exceeds 150% of

During a power outage,

The control can be

variable reserve which adjusts the reserve

depending upon the water usage patterns of your

customer.

•

Separate Time of Day and Time of Regeneration

settings.

regeneration time for easy install a tion, but the

installer may set the regeneration to occur at any

time of the day.

•

WQA S-101 features.

programmed to freeze the values for Salt Amount

and Capacity so the cu stomer can’t alte r them after

installation (see Parameter P18, Table 3).

•

Selectable 12-or 24-hour clock.

P13, Table 3.)

•

Selectable U.S. or metric units of measur e.

grains per gallon of hardness, pounds of salt, and

kilograins of capacity for U.S. units. Use mill igrams

per liter of hardnes s, kilograms of salt and

kilograms of capacity for metric units (see

Parameter P12, Table 3).

•

Selectable calendar overri de.

available to automatically regenerate the

conditioner if the water usage hasn’t caused a

regeneration. The default value is zero which

disables this feature (see Paramete r P14, Table 3).

•

Design reliability.

many years of trou ble-free performance. The

metering system has only one moving part, t he

rotating turbine that measures water usage and

generates electrical pulses that are counted by the

microprocessor to determine the need to

regenerate.

•

Guest cycle.

achieved at any time by pressing the REGEN

button on the Model 960 front panel. It takes just a

few minutes for the regeneration to start. The

regeneration takes about two hours. This feature is

beneficial when the cust omer expects t o use mor e

than the normal amount of water; for example,

guest visits or an extra heavy laundry day.

•

Manual double regeneration.

regenerations can be run by pressing the REGEN

push button after the first regeneration has been

running for at least one minute. This can be used to

recharge the resin bed that has operated without

salt for an extended period of time.

The control defaults to a 2:00 a.m.

The control can be

(See Parameter

Use

One to 30 days are

Solid-state electronics assure

An extra regeneration can be

Back-to-back

Superior Design

• Fewer parts than any control system of

comparable function and most controls of lesser

function.

• The valve may be indexed manually with or without

power to any one of its service or regeneration

positions. The Regeneration Cycle Indicator on the

3

control face plate indicates control valve po sition.

• No dynamic seals that could cause leakage

through wear or fatigu e.

• Control accepts Noryl brass manifold or modular

bypass valve without modification, offering

complete versati lity and easy plumbing for any

installation.

• Brining control valve built into system eliminates

need for an external brine valve.

• Drain flow control is built into the valve to control

backwash and fast rinse flow rates.

Superior Operation

• Direct acting system functions independently of

water pressure. No pistons or diaphragms that

require a minimum water pressure to operate.

• Five-cycle operation provides for downflow

conditioned water, upflow backwash, downflow

brining and slow rinse, downflow fast rinse, and

refill of the brine tank.

• Valve discs are held closed by water pressure and

are leak tight. Valve seats are in a vertical position,

which is the position least vulnerable to plugging.

• System operation cannot get out of phase or

sequence. The control always returns to a fixed

conditioned water position after regeneration.

• Bypass water is automatically available during

regeneration.

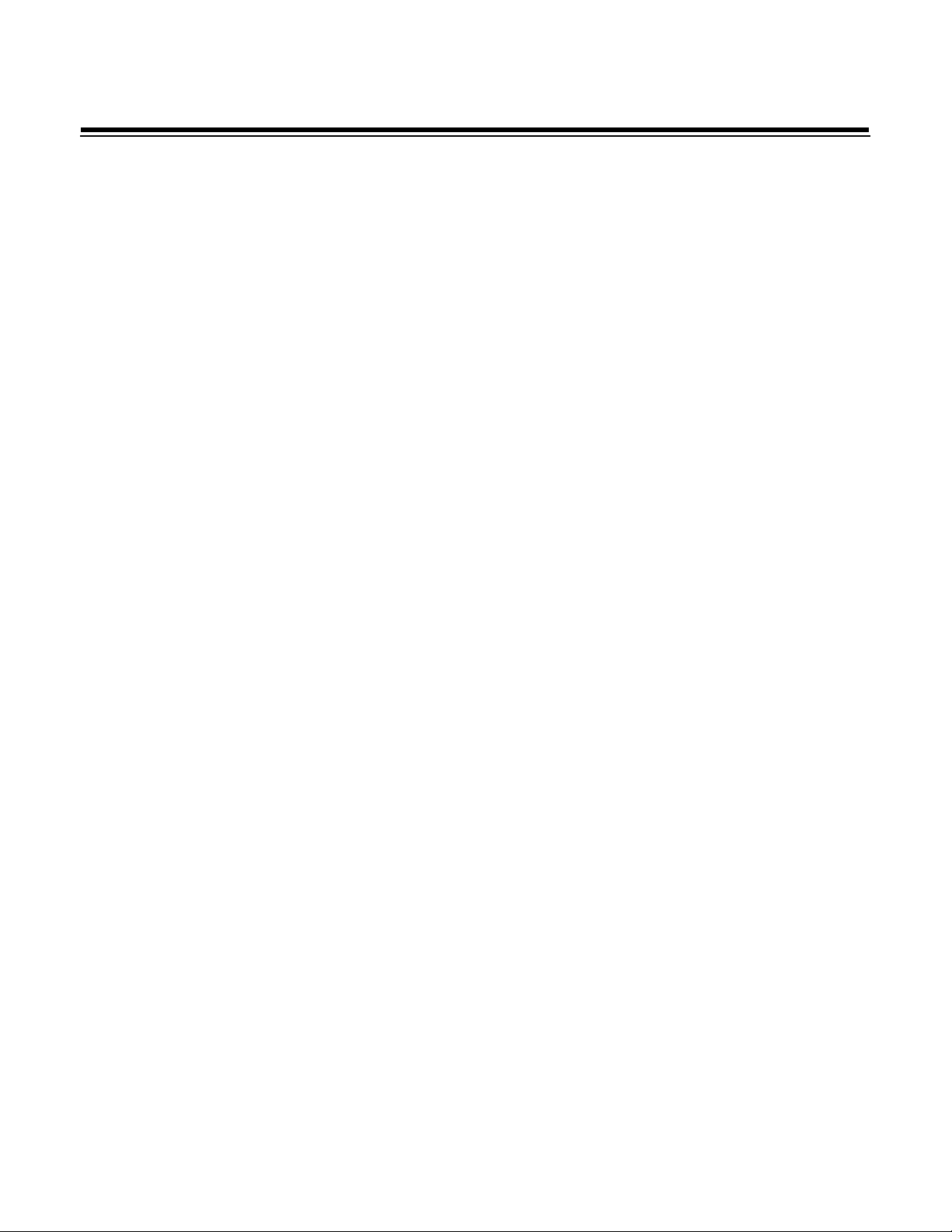

Air Check

Figure 1 - Control

Optional Bypass

Brine Line Fitting Connection 1/4-inch NPT

Inlet Connection 3/4-inch or 1-inch NPT or BSPT

Drain Connection 3/8-inch or 1/2-inch NPT or BSPT

Outlet Connection 3/4-inch or 1-inch NPT or BSPT

Tank Thread 2-1/2-inch - 8 Male NPSM

Figure 2 - Tank Adapter

4

Installation

All plumbing must co nf orm t o loc al co des . In sp ect th e

unit carefully for carrier shortage or shipping damage.

Location Selection

The following considerations must be taken into

account when selecting the location for the water

conditioning system.

• Locate the system as close to a drain as possible.

• If supplementary water treating equipment is

required, make sure that adequate additional

space is available. Locate the brine t a nk in an

accessible place so that salt can be easily added.

• Do not install any unit closer than 10 feet (3 m) of

piping between the outlet of the conditioner and

the inlet of a water heater. Water heaters can

transmit heat back down the cold water pipe into

the control valve. Hot water can severely damage

the conditioner.

A 10-foot (3-m) total pipe run (including bends, elbows,

etc.) is a reasonable distance to prevent hot water

damage. A positive way to prevent hot water from

flowing from a heat source to the conditioner is to

install a check valve in the soft water piping from the

conditioner. If a check valve is installed, make sure that

the water heating unit is equipped with a properly rated

temperature and pressure safety relief valve. Always

conform to local codes.

• Do not locate the unit in an area where the

temperature ever falls below 34

o

120

F (49oC).

o

F (1oC) or over

• Do not install the unit near acid or acid fumes.

• Do not expose the unit to petroleum products.

Water Line Connection

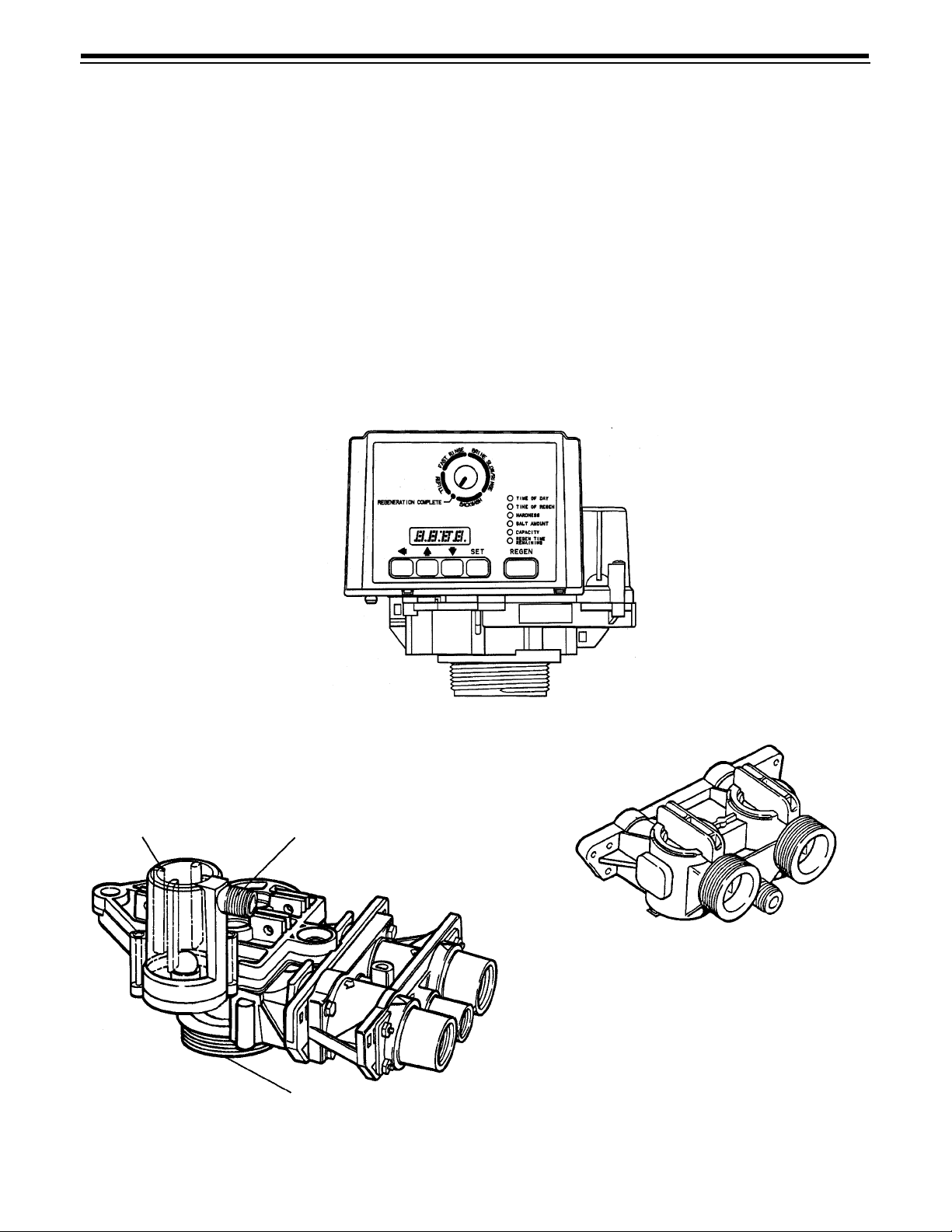

5

water pressure at the conditioner is not less than 40 psi

Brine Tank

Overflow Fitting

Installed

Connect 1/2-in. (13 cm)

I.D. Tubing or Hose and Run

to Drain

(2.8 bar). You may elevate an additional 2 feet (61 cm)

for each additional 10 psi (0 .7 bar).

Where drain line is elevated but empties into a drain

below the level of the control valve, form a 7-inch

(18-cm) loop at the far end of the line so that the bottom

of the loop is level with the drain line connection. This

will provide an adequate siphon trap (Figure 5).

Where a drain empties into an overhead sewer line, a

sink-type trap must be used.

IMPORTANT:

sewer line, or trap. Always allow an air gap between the

drain line and the wastewater to prevent the possibility

of sewage being back-siphoned into the conditioner.

Standard commercial practices have been

Note:

expressed here. Local codes may require changes to

these suggestions.

Never connect the drain line into a drain,

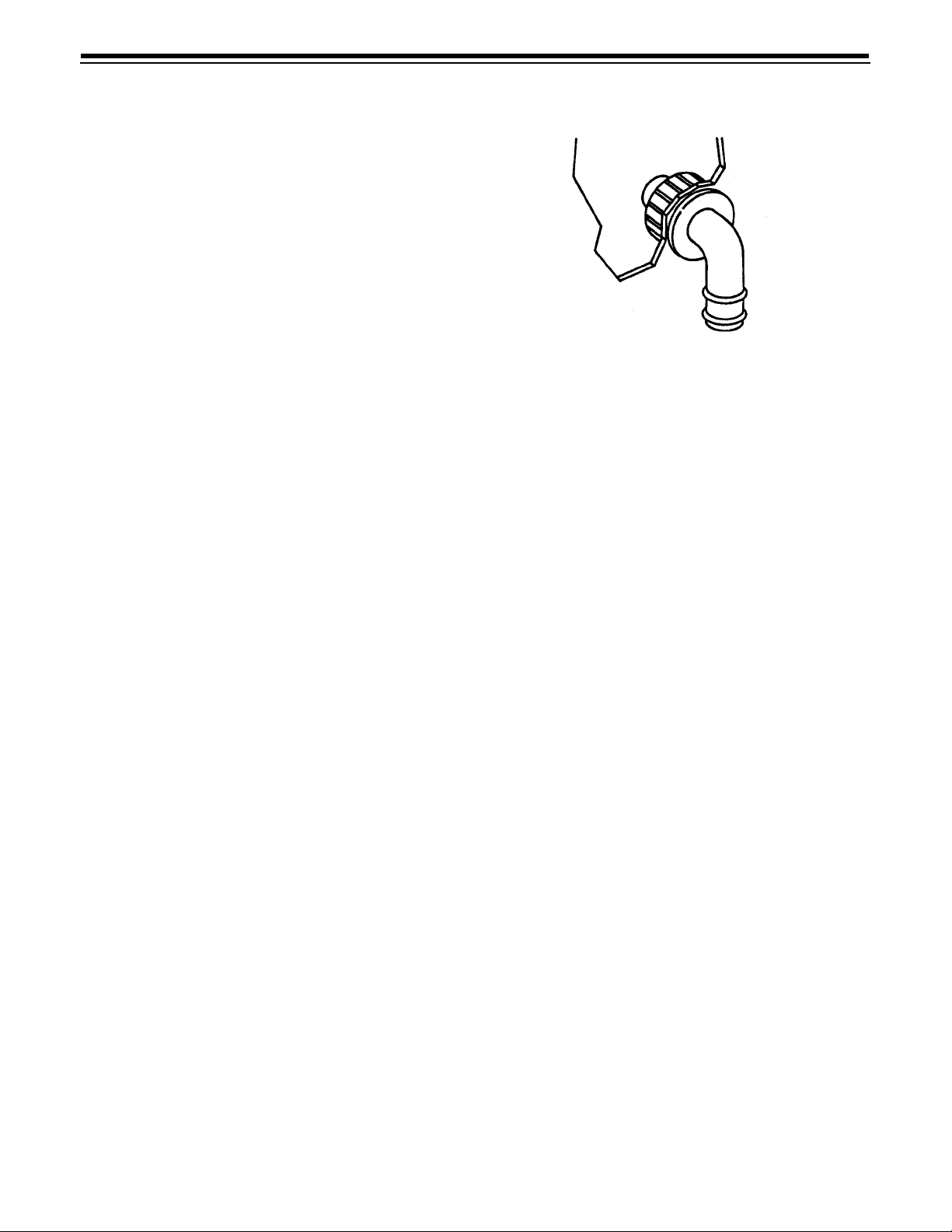

Brine Line Connection

Install an appropriate fitting onto the 1/4-inch male NPT

connection on the air check, Figure 7, and install a

length of flexible tubing between the air check fitting

and the brine pickup tube at the brine tank.

Make sure that all fittings and connections are

Note:

vacuum tight so that premature checking does not take

place. Pr emature checking occ urs wh en the ba ll i n th e

air check falls to the bottom before all brine is drawn

out of the brine tank. Refer to the

section in this manual for additional information.

Troubleshooting

Brine Tank Overflow Line Connection

In the event of a malfunction, the brine tank overflow

connection directs overflow to the drain instead of

spilling it on the floor where it could cause water

damage. Complete the foll owing step s to conn ect the

overflow fitting to the brine tank:

1. Locate the fitting hole on the side of the br ine tan k.

2. Insert the overflow fitting (not supplied) into the

tank and tighten with the plastic thumb nut and

gasket as illustrated in Figure 6.

3. Attach a length of 1/2-inch (1.3-cm) tubing (not

supplied) to the fitting and run to the drain.

Figure 6 - Overflow Line Connection

Do not elevate the overflow line higher than

Note:

3 inches (7.6 cm) below the bottom of the overflow

fitting. Do not tie into the drain line of the control unit.

The overflow line must be a direct, separate line from

the overflow fitting to the drain, sewer , or tub. Allow an

air gap as in the drain line connection, Figure 5.

Placing Conditioner into Operation

Initial Start-Up

After the water conditioning system is installed, the

conditioners should be disinfected before they are

used to treat potable water. Refer to the

Water Conditioners

the following step s to place the conditioner into

operation:

1. Remove the rear valve cover by pulling back on the

tab located on the lower rear edge of th e cover.

Next, lift the cover off the valv e, Figure 10.

2. Grasp the camshaft an d rotate it

COUNTERCLOCKWISE

of the control) until the indicator on the

regeneration cycle indicator points directly to the

word

BACKWASH

3. Fill the mineral tank with water. Turn the water

supply off and place the bypass valve(s) into the

“not in bypass” position. Open the water supply

valve

very slowly

position.

IMPORT ANT:

rapidly or too far , resin may be lost. In the

position, you should hear air escaping slowly from the

drain line.

If the water supply valve is opened too

section in this manual. Complete

(as viewed from the fr ont

.

to approximately the 1/4 open

Disinfection of

BACKWASH

4. When all of the air is purged from the tank (water

begins to flow stead ily fr om the dr ain), slowly op en

the main supply valve all the way. Allow the water

to run into the drain until clear. Turn off the water

supply and wait for about five minutes to allow all

trapped air to escape from the tank.

6

5. Add water to the brine tank (initial fill). With a

bucket or hose, add approximately 4 gallons

(15 liters) of water to the brine tank. If the tank has

a salt platform above the bottom of the tank, add

water until the l evel is approximat ely 1 inch (25 mm)

above the platform.

Figure 7 - Air Check

Open the water supply valve slowly to the fill open

position. Carefully rotate the camshaft

COUNTERCLOCKWISE

regeneration cycle indicator points directly to the

center of the

air check (Figu re 7) fills w ith wa te r an d wate r flo ws

through the brine line into the brine tank. Do not run for

more than two minutes. Rotate the camshaft

COUNTERCLOCKWISE

the center of the

Check that water is being drawn from the brine tank.

The water level in the brine tank will recede very slowly .

Observe the water level for at least three minutes. If the

water level does not recede, if it goes up, or if air enters

the transpar ent air check chamber and the ba ll falls and

seats, refer to the

manual.

REFILL

BRINE/SLOW RINSE

until the indicator on the

position and hold there until the

until the indicator points to

position.

Troubleshooting

section in this

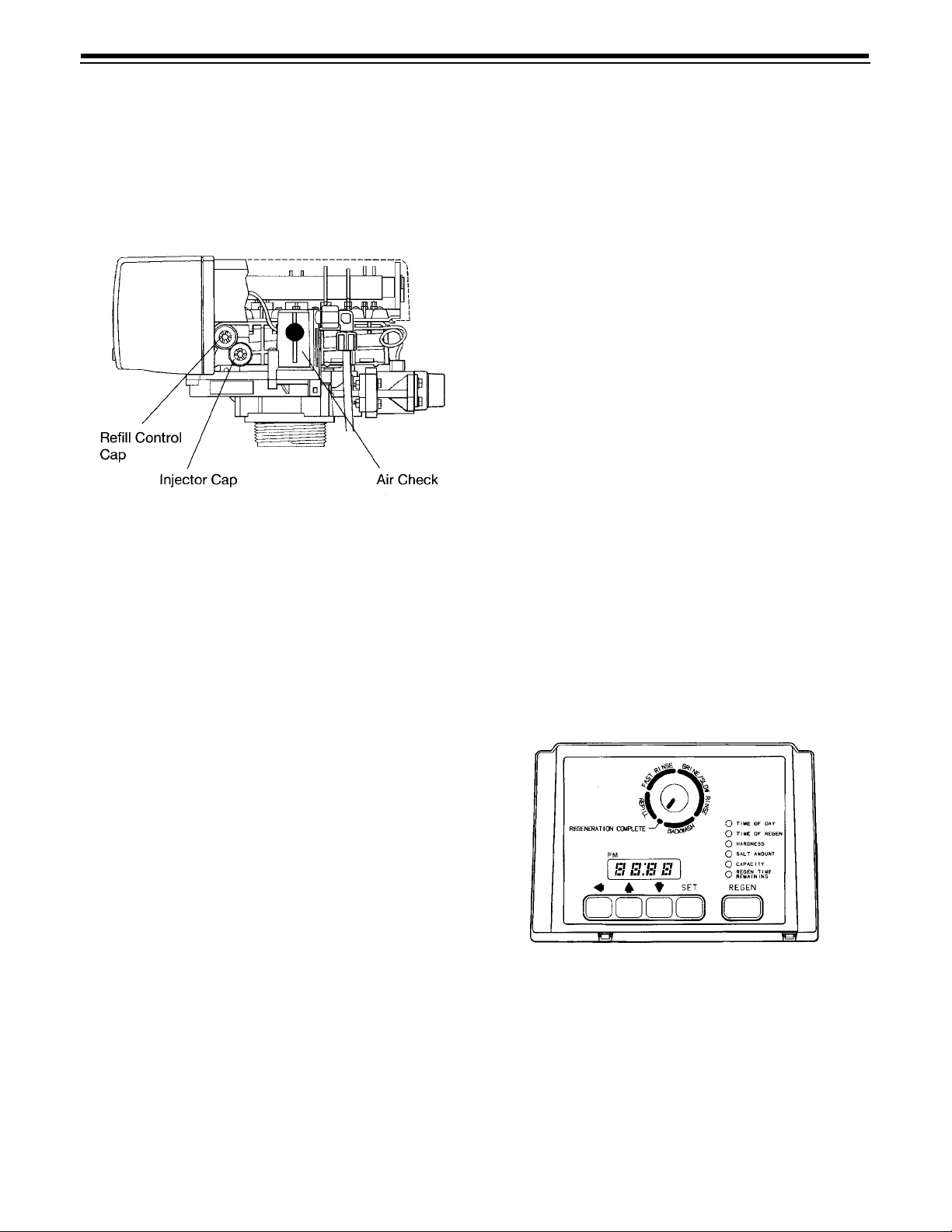

Connecting the Control

The control has default values for mos t parameters that

were set at the factory, but there are key items that

need to be entered at the time of installation:

• Time of Day

• Time of Regeneration

• Hardness

• Salt Amount

• Capacity of the Unit

• Refill Controller Value

• Brine Draw Rate

Determine from Tables 1 and 3 what these values

should be before applying power to the control. It is

also helpful to read the

Control

When the conditioner is operational, complete the

following steps to connect the Model 960 control:

section if you want to set other parameters.

• Connect the control to the wall transformer

cable. The power con nection is located on the

underside of the c ontrol on the left sid e (refer t o

Figure 1). Insert the barrel style connector into

the power plug.

• Plug the wall-mount transformer into an

electrical outlet that is not controlled by a wall

switch.

• If the cord length of the transformer is too short,

an optional 15-foot low voltage extension cord

may be purchased (contact your original

equipment dealer for details) o r the wire ma y be

spliced as shown in Figure 19 on page 24.

Programming the Model 960

When the water is being drawn from the brine tank,

rotate the camshaft

indicator points to

from a nearby faucet until the water is clear and soft.

COUNTERCLOCKWISE

REGEN COMPLETE

until the

. Run water

Figure 8 - Faceplate of 960 Control

Programming the Model 960 Control

This section covers all aspects of programming the

control. The control is shipped from the factory with

default values for Hardness and Capacity. These

default values will result in a system capacity of

100 gallons (1 cubic meter). While the control will

operate with these values, they should be changed to

meet the actual operating conditions.

7

Note that some parameters have a single unit of

measure option such as the Rinse Time which is only

entered in minutes. Other parameters have dual units

such as Salt Amount which can be entered in pounds

or kilograms. To select which units ar e active, look for a

comment in the NO TES column of Tables 1 and 3 . It will

reference another parameter that selects which units

are active. For exam ple, Parameter P12 (Table 3)

selects U.S. units if it is set to

to “1.

”

and metric if it is set

“0”

Level I Parameters (Table 1)

Level I Parameters are identified as t hose t hat h ave an

LED indicator on the front panel. The green indicator

illuminates next to the name of the active control

setting. The end user has access to all of these

parameters which are explained in the Series 960

Operation and Maintenance Manual, R-360 (P/N

1017934). In general, pressing the down arrow (↓)

button displays the Level I Parame ters in t he foll owi ng

order:

• Time of Day

• Time of Regeneration

• Hardness

• Salt Amount

• Capacity

If you continue to press the down arrow (↓) button, the

parameters start over with Time of Day. Pressing the up

arrow (↑) button displays the parameters in reverse

order. Refer to Table 1 for a description of these

parameters and the available ranges for each

parameter.

Press the

display starts flashing. If you want to change this

number, press the up arrow (↑) button to increase the

number or the down arrow (↓) button to decrease the

number. To skip the number without changing, press

the left arrow (←) button. When you reach the far left

digit, pressing the left arrow (←) button will return you

to the far right digit.

If you press and hold either the up arrow (↑)

Note:

button or the down arrow (↓) button for more than

one second, the flashing number will increment or

decrement at the rate of 10 counts per second.

When the number is correct, press the left arrow (←)

button. The first number stops flashing and the next

number starts flashing. You can only change the

flashing number. Continue changing numbers until you

reach the desired setting. Press the

numbers stop flas hing and the con trol acce pts the new

setting. After approximately 30 seconds, the control

starts alternating the displ ay between Time of Day and

Capacity .

button and the far right number on the

SET

button. The

SET

If a beep sounds , the new setting is not accepted

Note:

because it was outside the allowable range. The old

value will be displayed.

Time of Day

Press the

of Day with the minutes digit blinking. If you want to

change this number, press the up arrow (↑) button to

increase the n umber or the down arrow (↓) button to

decrease the number. To skip the number without

changing, press the left arrow (←) button. The first

number stops flashing and the next number starts

flashing. You can only change the flashing number.

When you have reached the far left digit, pressing the

left arrow (←) button returns you to the far right digit.

Continue changing numbers until you reach the desired

setting. Press the

button. The display will show the Time

SET

button to enter the value.

SET

Time of Regeneration

The next value displayed is the Time of Regeneration.

It has a default value of 2:00 a.m. If this is not

acceptable, press the

number. Press the

2:00 a.m. is acceptable, press the down arrow (↓)

button.

SET

button and change the

SET

button to enter the value. If

Hardness

Hardness is the next value displayed. This value is the

water hardness expressed in grains per gallon

(milligrams per liter). The default value is 10 grains/

gallon (100 mg/L). If this is not acceptable, press the

button and ente r a ne w value . Any va lue b et ween

SET

3 and 250 grains per gallon (30 and 2500 milligrams per

liter) is allowed. Press the

value.

button to enter the new

SET

Salt Amount

Salt Amount is the next value displayed. The default

value for Salt Amount is 6 pounds (2.5 kilograms) of

salt; refe r to Table 2.

This is the total amount of salt for a regeneration,

Note:

not pounds per cubic foot. If 6 pounds is not

acceptable, press the

numbers. If 6 pounds is acceptable, press the down

arrow (↓) button.

button and change the

SET

Capacity

Capacity is the next value displayed and is expressed

in kilograins (kilograms). Refer to Table 2 for the

capacity setting that corresponds to the resin bed

volume and salt amount. The default value is

1.0 kilograin (0.1 kilogram). If this is not acceptable,

press the

between 0.1 and 140 kilograins (.01 and

14.00 kilograms) is allowed.

button and enter a new value. An y value

SET

8

If the calculation for the system capacity

Note:

exceeds 9999 gallons (99.99 cubic meters) (P5,

Capacity, divided by P3, Hardness,) the control will

display 9999 (99.99) for capacity until the water usage

has dropped the remaining capacity below that

number . When water is flowing through the system, the

colon in the Time of Day display will blink.

At this time, all of the mandatory parameters are filled

and the control is ready for operation. The display will

alternate between the Time of Day and Capacity if no

keys are pr essed for 30 second s. The Capacity valu e is

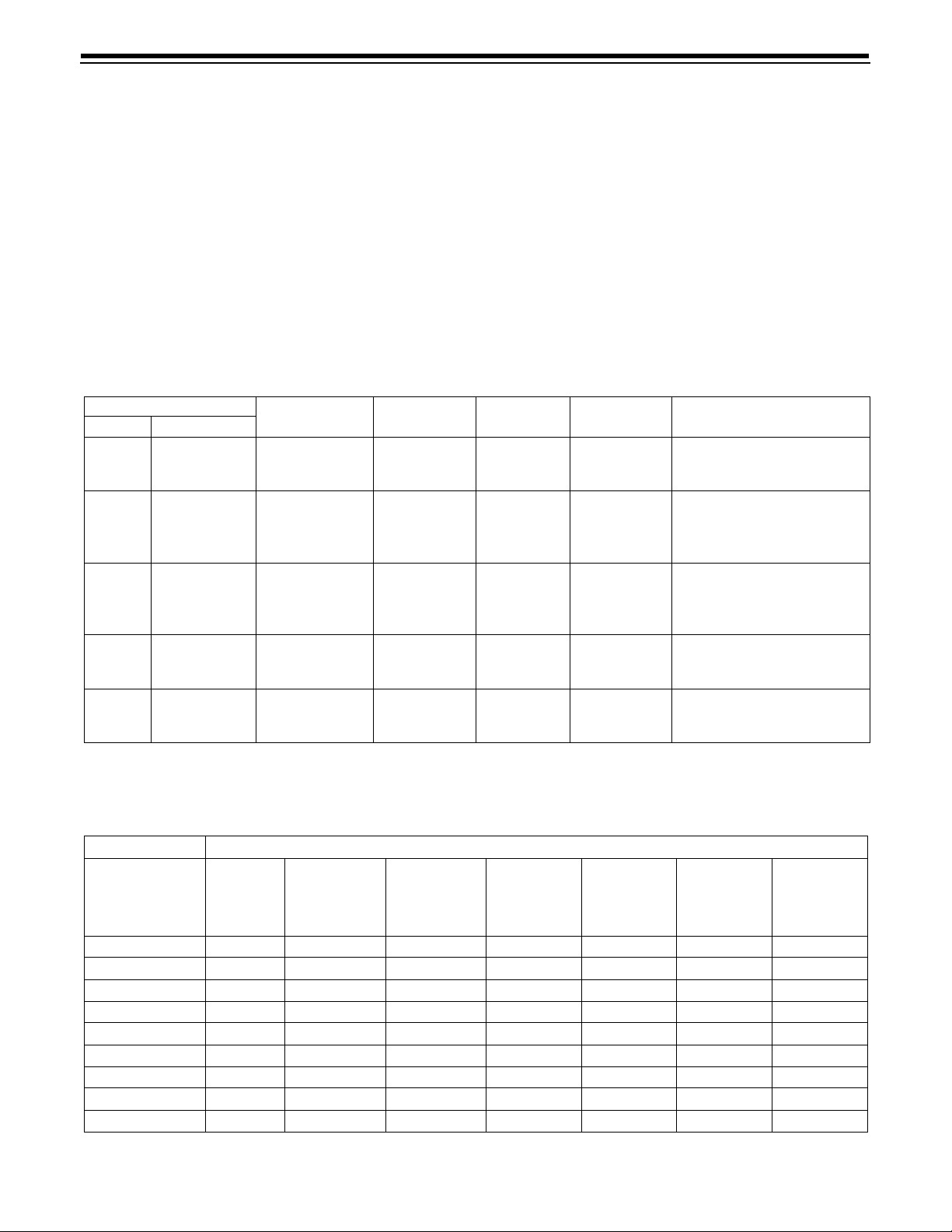

Table 1 - Programming Parameters

the volume remaining in gallons (cubic meters for

metric) before a regeneration is needed.

Verify proper power outage operation by briefly

removing power to the control. The unit will beep and

show the time of day when power is turned on.

If you wish to fine-tune the operation of this control,

refer to Table 3 for details concerning allowable val ues,

defaults, and parameter descriptions. The

programming procedure is the same for all of these

parameters.

Parameter

Name Description

P1

P2

P3

P4 Salt amount

P5

Time of day

AM or PM

Time of day

of

regeneration

Hardness of

water

Capacity of

unit

Range of

Values

1:00 to 12:59

00:00 to 23:59

1:00 to 12:59

AM or PM

00:00 to 23:59

3 to 250

30 to 2500

0.5 to 99.5

0.1 to 25.5

0.1 to 140.0

0.01 to 14.00

Minimum

Increments

1 None Hour:minute

1 2:00 AM Hour:minute

1

10

0.5

0.1

0.1

0.01

Default

10

100

6

2.5

1.0

0.1

Grains/gallon

Units of

Measure

mg/L

Pounds

Kilograms

Kilograins

Kilograms

Notes

Range depends on value

selected for P13. Enter th e

current time.

Range depends on value

selected for P13. Skip this

parameter to accept the

default or enter a new time.

Unit of measure depends on

value selected for P12. Test

water hardness and enter

that value.

Unit of measure and defau lt

depends on value selected

for P12. Refer to Table 2.

Unit of measure depends on

value selecte d for P12. Enter

the unit capacity.

Table 2 - Suggested Salt Settings

(

Pounds of Salt for Various Size Conditioners)

Resin Bed Volume

Kilograins of

Hardness

Capacity

0.5 ft

3

0.75 ft

3

1.0 ft

3

1.25 ft

3

1.5 ft

3

1.75 ft

3

2.0 ft

Setting

124.5- -----

169.05.0----20-8.56.0---24 - 14.0 8.5 7.0 - - 30 - - 15.0 11.0 9.0 - 32 - - 18.5 12.5 10.0 9.0 35 - - - 16.0 12.0 10.0 9.0

40 - - - 23.0 17.0 14.0 12.0

48 - - - - 28.0 21.0 17.0

3

9

Loading...

Loading...