Page 1

WPL606 Thermal Label Printer

User’s Guide

For Wasp Technologies

DT/TT Printer

Copyright Wasp Bar Code Technologies 2004.

All rights reserved.

No part of this publication may be reproduced or transmitted in any form or by any

means without the written permission of Wasp Bar Code Technologies. The

information contained in this document is subject to change without notice.

Wasp is a trademark of Wasp Bar Code Technologies. All other trademarks are the

property of their respective owners.

Document Revised August 13th, 2001

Page 2

CONTENTS

1. Product Introduction 1

1.1 Specification..............................................................................................................1

1.1.1 Printer.....................................................................................................................1

1.1.2 Environment..........................................................................................................1

1.1.3 Hardware...............................................................................................................1

1.1.4 Bar Code...............................................................................................................2

1.2 Optional Items...........................................................................................................2

1.3 Supplies.....................................................................................................................2

1.3.1 Label Specification..............................................................................................2

1.3.2 Ribbon Specification...........................................................................................2

2. Getting Started...............................................................................3

2.1 Unpacking and Inspection......................................................................................3

2.2 Equipment Checklist................................................................................................3

2.3 Printer Parts...............................................................................................................3

2.4 Buttons, Indicators and adjustment knobs..........................................................5

3. Set Up.............................................................................................7

3.1 Setting Up the Printer...............................................................................................7

3.2 Ribbon Installation...................................................................................................7

3.3 Label Roll Installation..............................................................................................9

3.4 Peel-off Sensor Installation (Sold Separately)..................................................10

3.5 Loading Label For Peel-off Mode........................................................................11

3.6 Self-test.....................................................................................................................12

3.7 Dump Mode.............................................................................................................12

4. Calibration....................................................................................14

4.1 Printer Initialization.................................................................................................14

4.2 Gap/Black Mark Sensor Calibration Utility.........................................................15

4.3 Troubleshooting Guide..........................................................................................16

5. Printer Maintenance....................................................................17

5.1 Print Head Cleaning...............................................................................................17

5.2 Printer Cover Cleaning..........................................................................................17

5.3 Internal Parts Cleaning..........................................................................................17

6. Support and Warranty.................................................................18

6.1 Product Support......................................................................................................18

6.2 Warranty Information..............................................................................................18

Appendix 1: LCD Control Panel Operation Map...........................19

Page 3

1. Product Introduction

Thank you for purchasing the W606 bar code printer. This guide will describe

all of the common operations needed to operate and maintain your W606.

1.1 Specification

1.1.1 Printer

Item Specification

Printing Mode Thermal transfer and direct thermal

Resolution

Max. Print Length 1000 mm ( 39.4” )

Max. Print Width 104 mm ( 4” )

Print Speed 3,4,5,6 ips

1.1.2 Environment

Temperature 5 - 40 OC ( 41OF - 104 OF )

Humidity 30 % - 85 %

Temperature -10 - 60 OC ( 14 OF - 140 OF )

Humidity 20 - 95 %

Ventilation Free air environment

203DPI

Operating Environment

Storage Environment

1.1.3 Hardware

Label gap sensor, Paper end sensor, Ribbon end

Sensors

Memory

Interface

Power 100 - 240 V universal switching power supply.

sensor, Ribbon near end sensor, Black mark

sensor, Head open sensor, Case open sensor,

Label taken sensor, Paper near end sensor.

Flash ROM (2MB), DRAM (2MB) and 8M optional

flash ROM (memory module)

RS-232C, Centronics (SPP), USBV1.1, Internal LAN

adapter (optional).

Page 4

1.1.4 Bar Code

Code 39, Code 93, Code128 subsets A B and C, Code 11, Codabar,

Interleaved 2 of 5, EAN-8, EAN-13, EAN-128, UPC-A, UPC-E, EAN, UPC, EAN

2 or 5 digit add-on, UPC 2 or 5 digit Add-on, CPOST, MSI Plessy, Postnet,

EAN-14, ITF-14, PDF-417, Maxicode, DataMatrix, QR Code

1.2 Optional Items

l Cutter module

l Peel off sensor

l Portable LCD keyboard

l Memory

l Internal or External Ethernet print server

1.3 Supplies

1.3.1 Label Specification

Item Specification

Type Roll and label, continuous, die-cut, fan-fold, ticket

Label Width 25.4 - 116 mm ( 1” - 4.4” )

Label Length 10 - 999 mm ( 0.4” - 39.33” )

Label Thickness 0.0 - 0.25 mm ( .003” - .001” )

Label Roll Diameter 203 mm Maximum ( 9.8” )

Roll Core Diameter 25 or 77 mm ( 1” or 3”)

Black Mark Width 3 mm Minimum ( .12” )

1.3.2 Ribbon Specification

Item Specification

Ribbon Width 25.4_114.3 mm ( 1” – 4.5” )

Ribbon Length 300 m Maximum ( 984’ )

Page 5

2. Getting Started

2.1 Unpacking and Inspection

After receiving the bar code printer, carefully inspect the device and its

packaging. The printer is specially packaged to withstand damage in shipping.

In case of evident damage, contact the carrier directly to specify the nature and

extent of damage. Please retain the packaging materials in case you need to

reship the printer.

2.2 Equipment Checklist

l W606 printer unit

l Quick installation guide

l Power cord

l Centronics interface cable

l 3” (76.2 mm ) paper core adapter

l Software CD disc

If any parts are missing, please contact Product Support. For contact

information see the Product Support section at the end of this document.

2.3 Printer Parts

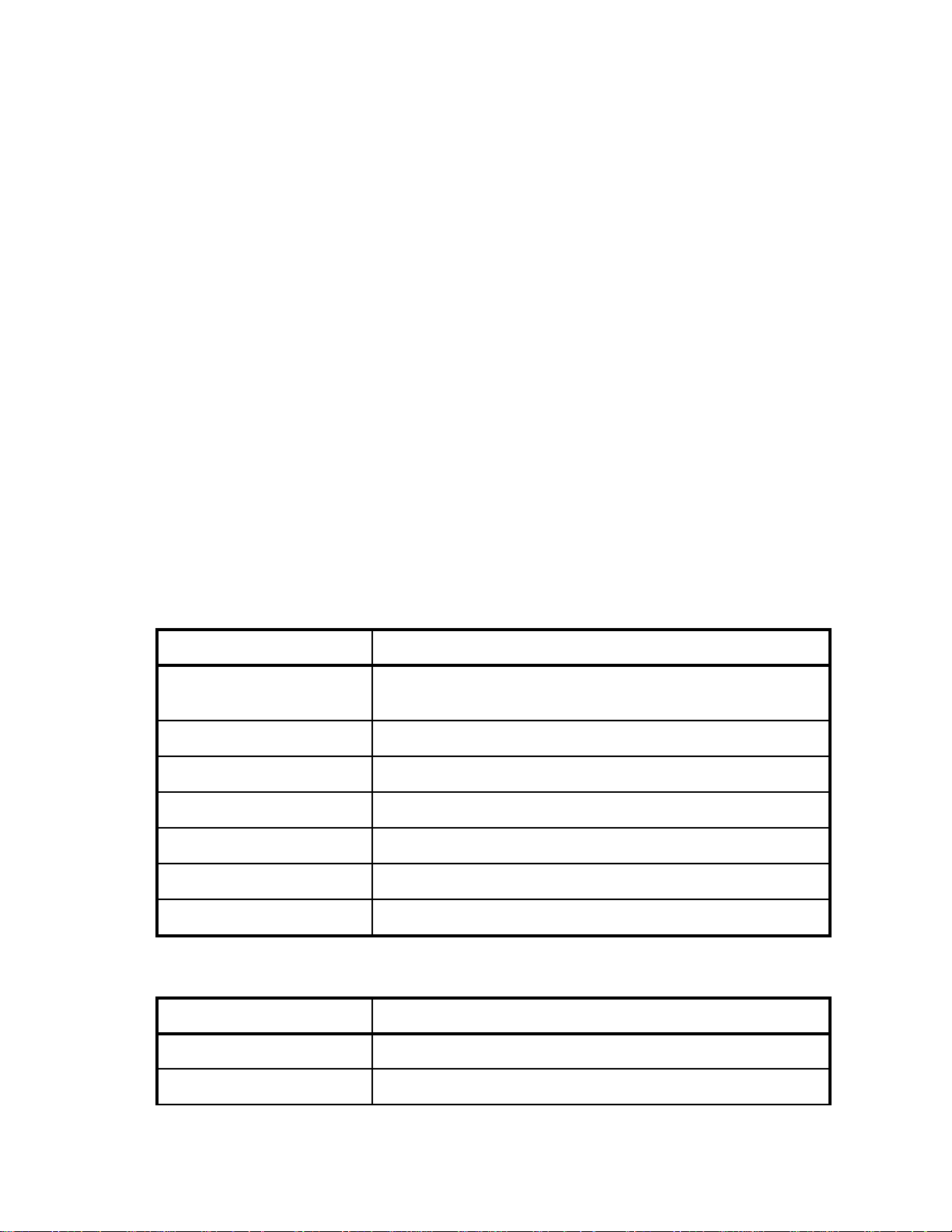

Page 6

External Label

Feed Opening

Centronics Port

USB port

RS-232C Port

Power Switch

Power Supply

Connector

Figure 2: Printer rear view

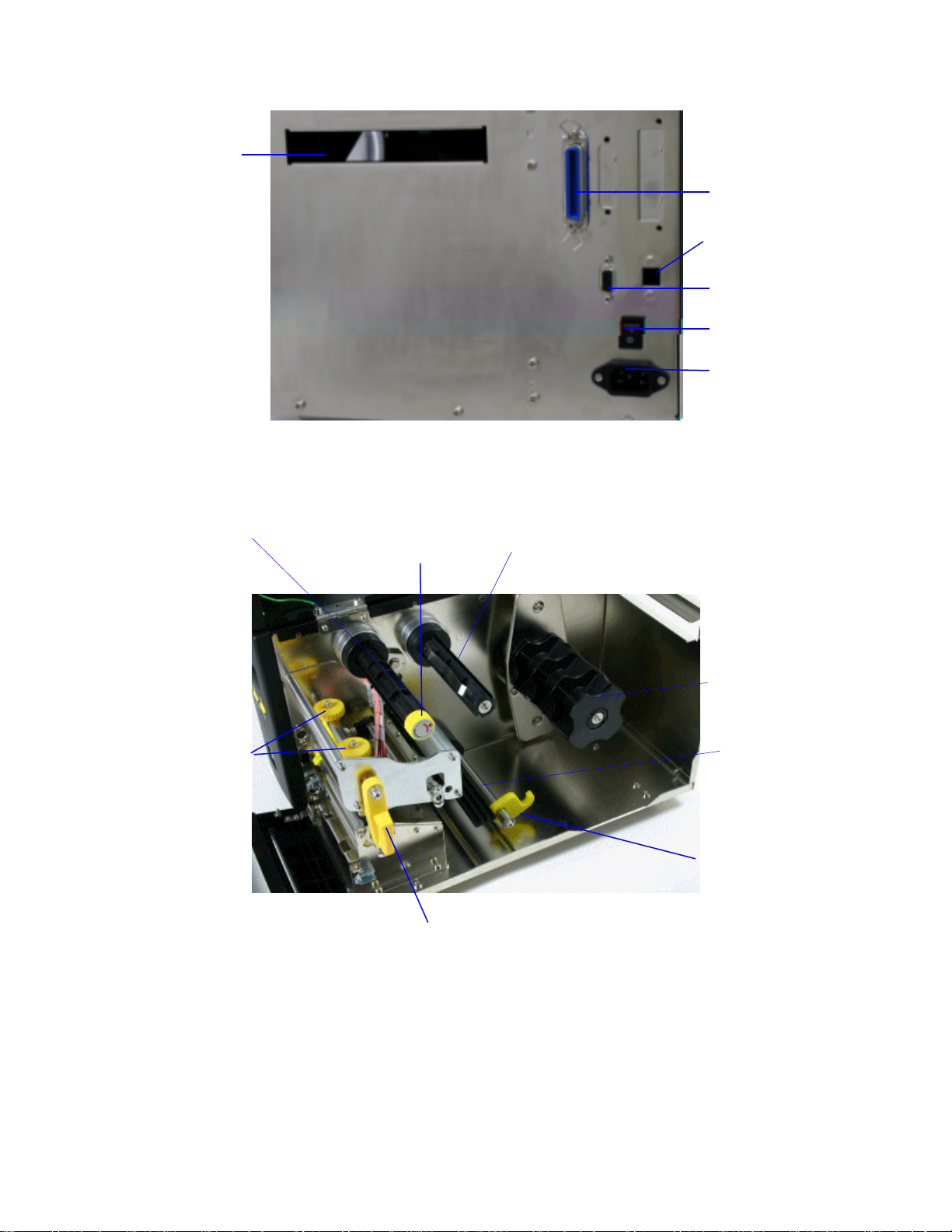

Ribbon Rewind Spindle

Print Head Pressure

Adjustment Knob

Ribbon Tension

Ribbon Supply Spindle

Adjustment Knob

Label Spindle

Media Guide Bar

Label Guide

Print Head Lift Lever

Figure 3: Printer interior view

Page 7

2.4 Buttons, Indicators and adjustment knobs

Power Indicator

When the printer is in the power-on state, the Power indicator is lit.

On-Line Indicator

This green On-Line indicator is lit when the printer is ready. The On-Line

indicator blinks when in PAUSE mode.

Error Indicator

The red Error indicator illuminates in the event of a printer error, such as

memory full, carriage open, cutter error and so forth.

MENU/SELECT Button

Press the MENU button to enter printer setup mode. Press the MENU button

again to advance the cursor to the next menu item. (Printer Setup, Sensor

Setup, System Setup, File Setup and Printer Test) For more information, please

refer to Appendix 1 for the structure and operation logic of the menu.

PAUSE/EXE/INC Button

This button combines three functions:

A. PAUSE: If the printer is in the Ready status, pressing the PAUSE:

(1) Stops at the completion of printing of the current label

(2) The On-Line LED flashes, and

(3) The printer holds all data in memory. This allows for trouble-free

replacement of label stock and thermal transfer ribbon. A second

depression of the PAUSE button will restart the printer.

B. EXE/INC (Execute/Increment): If the printer is in the setup mode, Press INC

button to increase the value of parameters. Press EXE to execute the

selected item.

FEED/DEC Button

This button also has dual functions.

Press the FEED button and the printer will advance one label.

Press the DEC button to decrease the value of parameters.

Print Head Lift Lever

Page 8

the LCD display shows “Carriage Open” and the red Error light will come on.

After closing the print head lift lever, the On-Line light will blink. Press the FEED

button to re-register the label.

Ribbon Tension Adjustment Knob

The Ribbon Tension Adjustment Knob offers 6 levels of tension to adjust for

different widths of ribbon. Turn the ribbon tension knob clockwise and you will

hear a light click sound as the gear changes. The levels increase the tension

from 0 to the tightest at 5. You will hear a louder click when level 0 is selected

to indicate reset.

Note: Use the lowest setting possible for longer print head life.

Print Head Pressure Adjustment Knob

The Print Head Adjustment Knobs are used to fine tune print quality for different

thickness of media. Turning the knobs increases or decreases the pressure

on the media by the print head. The knobs should always be set to the same

level. If setting them to different levels fixes a printing problem you should clean

the print head and consider replacing it.

Print Head

Pressure

Knobs

Print Head

Burn Line

Knobs

Figure 4: Print head adjustment knobs

Print Head Burn Line Adjustment Knob

The Print Burn Line Adjustment Knobs are used to fine tune print quality for

different thickness of media. Turning the knobs adjusts the print head’s burn

line forward or backward as it relates to the platen roller.

Caution: incorrectly adjusting these knobs can lead to poor print quality and

may cause damage to the printer. Proceed with caution.

The print head burn line default is set for general purpose printing media (plain

paper and paper thickness less than 0.20mm). The print head moves 0.7mm

for each 360 degree turn. Poor print quality when using paper thicker than

0.20mm may be due to the print head burn line not being at the optimized

position. To correct this, increase the head pressure and adjust the knobs

counter-clockwise to move print head burn line forward then print again.

Continue to adjust and test print as necessary until the image is clear.

Page 9

3. Set Up

3.1 Setting Up the Printer

1. Place the printer on a flat, secure surface

2. Make sure the POWER switch is off

3. Connect the printer to the computer with the provided RS-232C,

Centronics/Parallel, or USB cable

4. Plug the power cord into the power supply connector at the rear of the

printer, and then plug the power cord into a properly grounded power outlet

3.2 Ribbon Installation

1. Turn the power to the printer off

2. Open the printer right side cover and front panel

3. Raise print head lift lever and remove the old ribbon by firmly grasping the

media and pulling it off of the spindle

4. Wasp ribbons are wound with the dull ink side out and come with the

rewind spindle connected to the ribbon. Slide the ribbon onto the ribbon

supply spindle so that when the rewind spindle is extended toward the

back of the printer the Wasp logo is facing up. Slide the ribbon about half

way onto the spindle

Ribbon

Supply

Spindle

Print Head

Lift Lever

Open

Figure 5: Ribbon placed onto Supply Spindle

5. Wrap the ribbon under the print head and out the front of the printer. The

Wasp logo will be facing down toward the platten roller. The Platen Roller

is the black rubber roller bar that advances the media

Rewind

Spindle

Print Head

Rewind

Core

Platen

Roller

Page 10

Figure 6: Ribbon under Pint Had

6. Pull the paper core up to the rewind spindle and slide it on. Slide both the

ribbon and rewind spindle all the way to be flush with the case side of the

spindle. The Wasp logo will face up again

Flush with

Case

Figure 7: Ribbon placed onto Rewind Spindle

7. Roll the rewind spindle by hand until some of the actual ribbon shows in

the front of the printer. The Wasp logo will roll over the top of the spindle.

Ribbon in

front

Figure 8: Ribbon wound into printing position

8. The ribbon must route above the black ribbon sensor.

Figure 9: Ribbon Sensor and Ribon placement

Ribbon

Ribbon

Sensor

Page 11

3.3 Label Roll Installation

1. Open the printer panels and the print head lift lever

2. Rotate the Label Guide clockwise away from the Media Guide Bar

3. Insert a new label roll into the label spindle

4. Pull labels leading edge forward under the black media guide bar,

through the gap/black mark sensor and place the label leading edge onto

the Platen Roller

Print Head

Lever

Platen

Roller

Figure 10: Insert a label roll into label spindle.

Label

Spindle

Label

Guide

Media Guide

Bar

Gap / Black

Mark

Detector

Gap

Detector

Handle

Label

Guide

Figure 11: Media guide bar the gap/black mark detector

5. Adjust the label guide by sliding it along its bar to meet the width of the

label. Then rotate the Label Guide counter-clockwise and secure it to the

Media Guide Bar

6. Adjust the Gap Detector to overlap at least one inch of the label by moving

the yellow Gap Detector Handle located under the media and just in front

of the media guide bar

7. Close the print head lift lever

8. Close the lower front panel and printer cover

9. Turn the power on

10. Go to section 4.2 Gap / Black Mark Detector Sensor Calibration and

calibrate the labels

Page 12

3.4 Peel-off Sensor Installation (Sold Separately)

1. Turn the printer off

2. Open the lower front panel

3. Snap the peel-off sensor onto the bar that is under the print head pressure

adjustment knobs horizontally

Bar

Peel-off sensor

Figure 12: Peel Sensor attached to bar

Socket for Peel-off

sensor

Figure 13: Peel Socket

4. Plug the Peel-off sensor into the socket by sliding it along the bar into the

socket

Figure 14: Peel Sensor into Socket

5. Close the panels and turn the printer back on

6. If you are printing from windows you must turn peel off mode on in the

Advanced Setup section of Printing Preferences for this printer

7. Go to section 4.2 Gap / Black Mark Detector Sensor Calibration and calibrate

the labels

Page 13

3.5 Loading Label For Peel-off Mode

1. Open the front and top printer doors

2. Open the print head left lever

3. Pull several inches of labels out through the front of the printer and remove

the label(s) from the backing

4. Feed the label backing between the platen roller and the silver peeler roller

then press the MENU button several times to advance the label backing

through the rollers.

5. Either advance the backing or roll back the labels to take the slack out of the

media.

Tear Bar

Label

Platten

Roller

Label

Backing

Peeler

Roller

Figure 15: Peeler installation

6. Close the print head lift lever.

7. Close the front panel and feed the excess backing through the bottom of the

front panel.

Label

Label

Backing

Figure 16: Front panel media location with Peeler

8. Press the FEED button several times to align the labels and recalibrate

Page 14

3.6 Self-test

To initiate the self-test mode, press the MENU button to advance the selection to

Printer Test. Press the EXE button to enter the submenu and press the MENU

button to advance the selection to Printer Config. Press EXE button to print the

printer’s internal settings. During self-test, a check pattern is used to check the

performance of the thermal print head. Following the check pattern, the printer

prints internal settings as listed below:

Print head check pattern

Firmware version

Firmware checksum

Printed mileage (meter)

Serial port configuration

Country code

Print speed (inch/sec)

Print darkness

Label size (inch)

Gap distance (inch)

Gap/black mark sensor sensitivity

Numbers of download files

Total & available memory space

Figure 17: Printout of self-test

3.7 Dump Mode

To enter dump mode, press the MENU button to select the Printer Test menu.

Press EXE then SELECT until Dump Mode Off is displayed. Press INC to

change the display to Dump Mode On. In this mode, any character sent from the

host computer will be printed in two columns as shown in Figure 18.

On the left side of the paper are the characters received, and on the right side

are the corresponding hexadecimal values. This is used for verification of

programming commands or debugging of printer programs. Reset the printer

by pressing the FEED button.

Page 15

ASCII Data

Hex decimal

data related to

left column of

ASCII data

Figure 18: Printout of dump mode

Page 16

4. Calibration

There are two power-on button combinations to initialize the printer settings

and to calibrate sensors on the W606.

4.1 Printer Initialization

Printer Initialization will restore printer settings to defaults. Do this if labels are

printing incorrectly and all other solutions have failed to solve the problem.

Default settings:

Item Default Value

Mileage N/A No Yes

Check Sum N/A No Yes

Serial Port 9600,n,8,1 Yes Yes

Code Page 850 Yes Yes

Country Code 001 Yes Yes

Tear Mode On Yes Yes

Peel Mode Off Yes Yes

Cutter Mode Off Yes Yes

Offset 0 Yes Yes

Reference Point 0,0 Yes Yes

Print Direction 0 Yes Yes

Speed 4 IPS Yes Yes

Cleared by

Initialization

Property Saved

when Turning off

Power

Density 08 Yes Yes

Label Size 3”x3” (77X77mm) Yes Yes

Gap/Bline Sensor Gap Sensor Yes Yes

Gap(Bline) 0.12” (3 mm) Yes Yes

Transparency 17 Yes Yes

Ribbon Sensor

Sensitivity

LCD Language English Yes Yes

Aux. LED Off Yes Yes

Aux. Buzzer Off Yes Yes

Download Files N/A No Yes

RTC N/A No No

1 Yes Yes

Page 17

To initialize the printer:

1. Turn off the printer power

2. Hold down the PAUSE and FEED buttons and turn on the printer power

3. Release the buttons once the Power, On-Line, and Error lights are lit

Note: The printing method, thermal transfer or direct thermal printing, will be

set automatically at the activation of printer power by checking for the

ribbon. If there is no ribbon the printer will go into direct thermal printing

mode.

Note: When printer initialization is done, please calibrate the gap sensor

again.

4.2 Gap/Black Mark Sensor Calibration Utility

The gap/black mark sensor must be calibrated whenever the label media

changes or after printer initialization.

To calibrate the Gap/Black Mark Sensor:

1. Install the ribbon and label roll as the above-mentioned procedures, and

engage the print head lift lever.

2. Turn off printer power.

3. Hold down the PAUSE key and then turn on printer power. Release the

PAUSE key when “GAP/BLINE sensor calibrating….” message is shown

on the LCD display. The printer will calibrate the gap/black mark sensor

automatically.

Page 18

4.3 Troubleshooting Guide

The following guide lists the most common problems that may be encountered

when operating this bar code printer. If the printer still does not function after all

suggested solutions have been invoked, please contact the Customer Service.

Condition Reasons Solutions

No ribbon

No paper

Poor printing

quality

Power indicator

does not

illuminate

1. Out of ribbon

2. The ribbon is installed

incorrectly.

3. The ribbon sensor is not

been calibrated.

1. Out of labels

2. The label is installed

incorrectly.

3. The moveable gap/black

mark sensor is not placed

in the proper location.

1. Dirt is accumulated on the

print head.

2. The density setting is not

set properly

3. Ribbon and media are

incompatible.

4. The pressure of print head

is not set properly

1. The power cord is not

properly connected

1. Supply a new ribbon roll

2. Reinstall the ribbon using the

steps in section 3.2 Ribbon

Installation

3. Calibrate the ribbon sensor

1. Supply a new label roll

2. Reinstall the labels using the

steps in section 3.3 Label Roll

Installation

3. Please move the sensor to

the proper location

1. Clean the print head using the

steps in the section 5.1 Print

Head Cleaning

2. Adjust the print density in the

driver

3. Use the proper ribbon or

proper label roll.

4. Adjust the print head pressure

adjustment knob.

1. Please check the power cord

between printer and outlet.

1. The label size is not set

Paper jam

Carriage open The printer carriage is open. Please close the print carriage.

Memory full

(FLASH / DRAM)

No printout

printing through

serial port

properly.

2. Labels may be stuck in

side print mechanism.

The space of FLASH/DRAM is

full.

1. The serial port setting is not

consistent between host

and printer.

2. The serial port cable pin

configuration is not pin to

pin assignment.

1. a. Reset the label size.

b. Re-calibrate the

gap/black mark sensor.

2. Remove the stuck label.

Delete unused files in the

FLASH/DRAM. Maximum 50 files

saved in DRAM. Maximum 100

files saved in Flash Files.

1. Please reset the serial port

setting.

2. Please replace the cable with

pin to pin assignment.

Page 19

5. Printer Maintenance

The printer should be cleaned regularly to maintain high quality printing.

5.1 Cleaning the Print Head

1. Switch off and unplug the printer

2. Open the printer cover

3. Open the print head lift lever

4. Remove the ribbon. (If loaded)

5. Rub the Wasp Thermal Printer Cleaning Pen Part# 633808441012 tip

across the print head several times

6. Do not close the print head until the alcohol evaporates

7. Reload the ribbon, close the print head lift lever and close the printer cover

5.2 Cleaning the Outside of the Printer

1. Switch off and unplug the printer

2. Wipe the printer lightly using a lint-free cloth soaked in water or mild

detergent.

NOTE: Do not use harsh or abrasive cloth and solvent.

5.3 Cleaning the Internal Parts of the Printer

1. Switch off and unplug the printer

2. Open the printer right side cover

3. Remove the media and ribbon (If loaded)

4. Open the printer print head lift lever

5. Using a soft dry cloth, wipe the internal parts. Compressed air can also be

used to remove dust

6. The rubber roller can be cleaned with a damp cloth. Dry the roller after

cleaning

7. Install the ribbon and label, close the print head lift lever

8. Close the printer right side cover

Page 20

6. Support and Warranty

6.1 Product Support

If you experience any problems with your Wasp printer that you are unable to

resolve, use our online support site to register and report the problem then call for

technical assistance at (214) 547-4100, Monday through Friday, 8:00 AM – 5:00 PM

Central Standard Time. You must register to be eligible for technical support. Our

web site is

www.waspbarcode.com/support

You may also contact us in writing at:

Wasp Technologies

1400 10

Plano, TX 75074

(214) 547-4100

(214) 547-4101 Fax

th

Street

6.2 Warranty Information

Wasp printers are warranted against defects in workmanship and materials for a

period of one year from the date of shipment, provided that the product remains

unmodified and is operated under normal and proper conditions.

Note: Print heads are warranted for 90 days against defect in workmanship.

Print heads will be replaced during the 90 day period once it is determined that

the print head is defective.

This warranty is limited to repair or replacement at Wasp Technologies’ option, with

reasonable promptness after being notified. These provisions do not prolong the

original warranty term for any product which has been repaired or replaced by

Wasp Technologies.

This warranty applies to the original owner and does not extend to any product

which has been subject to misuse, neglect, accidental damage, unauthorized

repair, or tampering.

No other express warranty is given. The replacement or repair of a product is your

exclusive remedy. Any other implied warranty of merchantability or fitness is limited

to the duration of this written warranty. Some states, provinces and countries do not

allow how long an implied warranty lasts, so the above limitation may not apply to

you.

In no event shall Wasp Technologies be liable for consequential damages. Some

states, provinces, and countries do not allow the exclusion or limitation of incidental

or consequential damages, so the above may not apply to you.

Page 21

Appendix 1: LCD Control Panel Operation Map

1. Print Setup

2. Sensor Calib.

Speed

Density

Direction

* Tear Mode

Offset

Reference X

Reference Y

Exit

Auto. Gap

Manual Gap

Auto Bline

Manual Bline

Auto. Ribbon

Manual Ribbon

Exit

2 "/sec

0 to 15 (*8)

*0

Peel On

0~999 (*0)

0~999 (*0)

0~999 (*0)

*3"/sec

6"/sec

1

Cutter On

4"/sec

5"/sec

Cutter Batch

3. System Setup

Note:

1. Defaults are marked with an asterisk (*)

2. The parameters of shaded area can be accessed

by pressing the INC. or DEC. key to set the value.

Lang.

Code Page

* English

USA

SWE

SWI

865

Polski

BRI

SPA

437

865

Simplified Chinese

GER

ITA

* 850

863

Traditional Chinese

Japanese

FRE

DAN

852

860

Page 22

* 001

002

003

031

032

3. System Setup

4. File Mngment

Country

RS232 Setup

Restore Defaults

Exit

File List

Avail. Memory

039

041

061

351

Parity

Data Bit

Stop Bit(s)

Baud

57600

Exit

DRAM:

512KB free

FLASH:

1000KB free

038

042

055

358

* None

7

* 1

2400

56000

036

044

049

Even

* 8

2

4800

38400

034

045

048

033

046

047

Odd

*9600

19200

5. Printer Test

Delete File(s)

Exit

Print Config

* Dump Mode Off

Rotate Cutter

Mileage Info.

Exit

PAUSE: Del. All

FEED: Exit

Dump Mode On

MENU: Fwd.

PAUSE: Rev.

Mileage:(m)

000000000

Lables:(pcs)

000000000

Loading...

Loading...