Page 1

WPL305 Thermal Label Printer

User’s Guide

For Wasp Technologies

DT/TT Printer

Copyright Wasp Bar Code Technologies 2004.

All rights reserved.

No part of this publication may be reproduced or transmitted in any

form or by any means without the written permission of Wasp Bar

Code Technologies. The information contained in this document is

subject to change without notice.

Wasp is a trademark of Wasp Bar Code Technologies. All other trademarks are the property of their

respective owners.

Page 2

Contents

1. Introduction ............................................................................................1

2. Getting Started.......................................................................................1

2.1 Unpacking and Inspection .......................................... 1

2.2 Equipment Checklist ................................................... 1

2.3 Printer Parts................................................................. 2

3. Setup .......................................................................................................2

3.1 Setting Up the Printer.................................................. 2

3.2 Loading the Ribbon..................................................... 2

3.3 Loading Label Stock ................................................... 4

3.7 Top Cover Operation................................................... 5

4. Power on Utilities...................................................................................8

4.1 Initialization ................................................................. 8

4.2 Ribbon Sensor Calibration.......................................... 8

4.3 Gap/Black Mark Calibration ........................................ 9

5. Maintenance .........................................................................................11

5.1 Cleaning..................................................................... 11

6. Troubleshooting ..................................................................................11

6.1 LED Status ................................................................. 11

6.2 Print Quality............................................................... 12

7. Specifications.......................................................................................13

7.1 Printer Specifications................................................ 13

7.2 Label Stock Specifications ....................................... 13

7.3 Ribbon Specifications............................................... 14

7.4. LED and Button Operation....................................... 14

8. Product Support...................................................................................14

9. Warranty Information ..........................................................................14

Page 3

1. Introduction

Thank you for purchasing the W305 Thermal Transfer and Direct Thermal Bar

Code Printer. Although the printer takes only a small amount of space, it

delivers reliable, superior performance.

This printer provides both thermal transfer and direct thermal printing at user

selectable speed of: 2.0, 3.0, 4.0 or 5.0ips. It accepts roll feed, die-cut, and

fan-fold labels for both thermal transfer and direct thermal printing. All

common bar codes formats are available. Fonts and bar codes can be printed

in 4 directions, 8 different alphanumeric bitmap fonts and a build-in true type

font capability. You will enjoy high throughput for printing labels with this

printer.

2. Getting Started

2.1 Unpacking and Inspection

This printer has been specially packaged to withstand damage during

shipping. Please carefully inspect the packaging and printer upon receipt.

Please retain the packaging materials in case you need to reship the printer.

2.2 Equipment Checklist

n Printer

n Software CD disk

n Sample ribbon roll

n Sample label roll

n Label spindle (1 inch diameter core)

n 2 Label spindle fixed tabs with 1.5” core adapters

n Paper core

n 2 Ribbon supply/rewind spindles

n Parallel / Centronics cable

n Auto switching power supply

n Power cord

n Quick start guide

To unpack the unit, remove the packaging material and parts carefully from

the box. Remove and discard the tape holding the two halves of the printer

and the media door. Open the media door and remove the Styrofoam. Open

the printer and remove the two cushioning pads from the mouth of the printer.

Remove the protective covers over the media door and back viewing door.

Page 4

2.3 Printer Parts

turned off. In case the ribbon is installed but the printer does not detect the

Ribbon Access Window

LED Indicator

Feed Button

Printer Top Cover

Top Cover Open Lever

Figure 1: Top front view

3. Setup

3.1 Setting Up the Printer

1. Place the printer on a flat, secure surface.

2. Make sure the power switch is off.

3. Connect the printer to the computer with the Centronics or USB cable.

4. Plug the power cord into the power supply connector at the rear of the

printer, and then plug the power cord into a properly grounded

receptable.

Rear Paper Guides

Wall

Plug

USB

Centronics

/ Parallel

RS-

Power

Power Switch

Figure 2: Back of Printer Parts

Power Supply

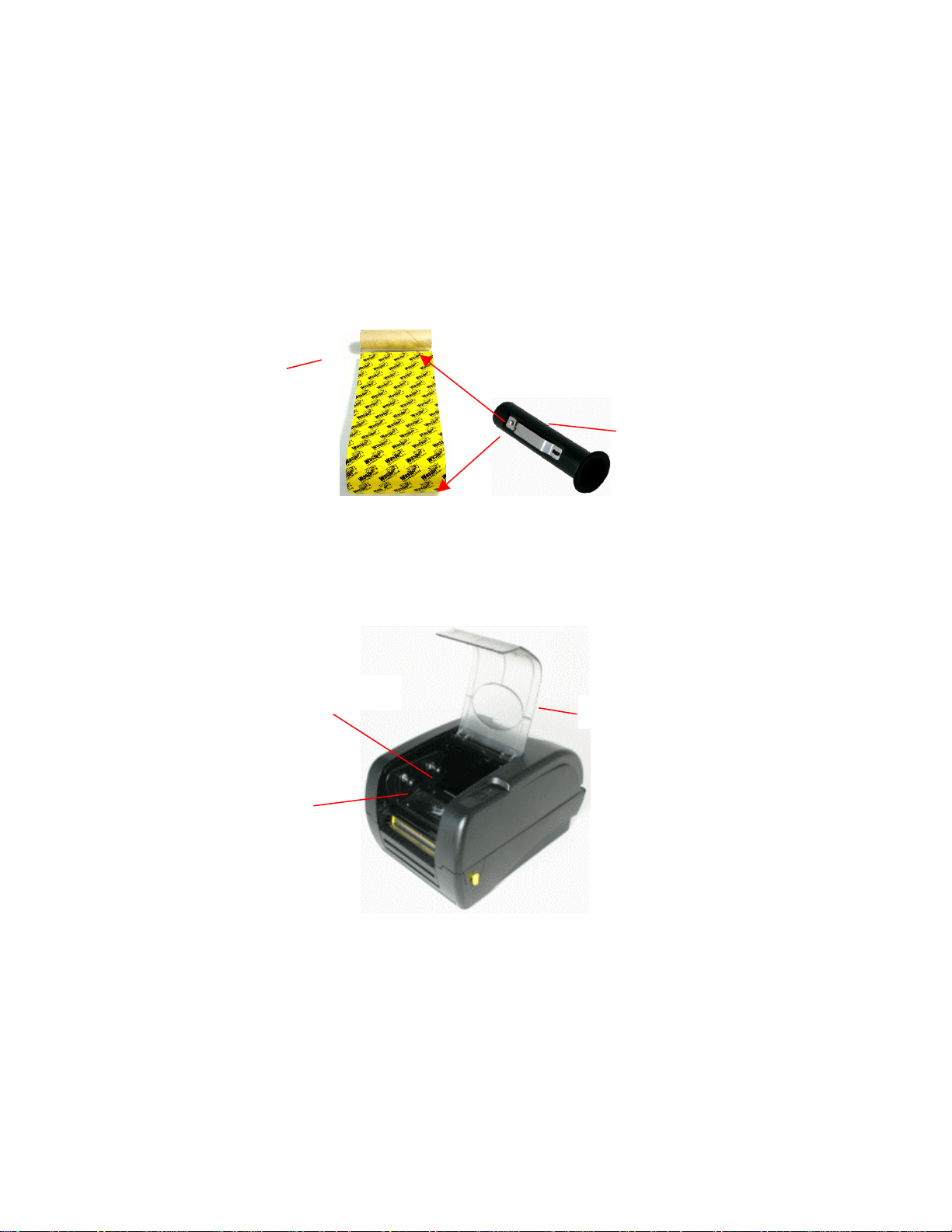

3.2 Loading the Ribbon

The printer automatically detects if a ribbon is installed after power on and will

switch to thermal transfer or direct thermal printing mode. If printer does not

detect the ribbon, the motor that drives the ribbon rewind spindle will be

Page 5

ribbon, please refer to the ribbon calibration procedure to calibrate the ribbon

Ribbon Core

Rewind Core

sensor.

NOTE: If you are using direct thermal labels you should not load a ribbon.

1. Push down on the ribbon access window to unlock and open the cover.

2. Wasp Ribbons come with the cardboard rewind core already attached to

the ribbon for ease of accurate installation. Arrange the ribbon and core as

seen in the picture below so that the core is rolled out about 4 inches and

the dull side of the printer ribbon is facing toward you. On Wasp Ribbons

the Wasp logo should face you.

Spindle

3. Put the two spindles into the two cores from the right. Make sure the right

side of the spindle is flush with the core after insertion.

4. Pull the cover access lever to open the printer

5. Hold the ribbon with the wide end of the spindle on the right and lower the

rewind core through the back of the ribbon compartment

Back Hub

Ribbon Access Window

Front Hub

Figure 3: Ribbon installation

6. Attach the ribbon spindle to the Back Hub by placing the left side of the

spindle against the knob with the spring on it and compressing with the

ribbon spindle. Slide the right side down over the other knob. The ribbon

spindle should not be able to be removed without re-compressing the

spring. You may have to turn the ribbon until the grooves on the spindle

align and it clicks into place.

7. Reach between the two halves of the printer and gently pull the rewind

spindle and core under and around the print head and mount it on the

Front Hub as above.

8. Rotate the ribbon rewind core away from you until the black ribbon is on

the rewind core.

Page 6

Make sure both the ribbon access window and the printer top cover are

1” Label Spindle

1.5” Core Adapter

closed when powering up the printer.

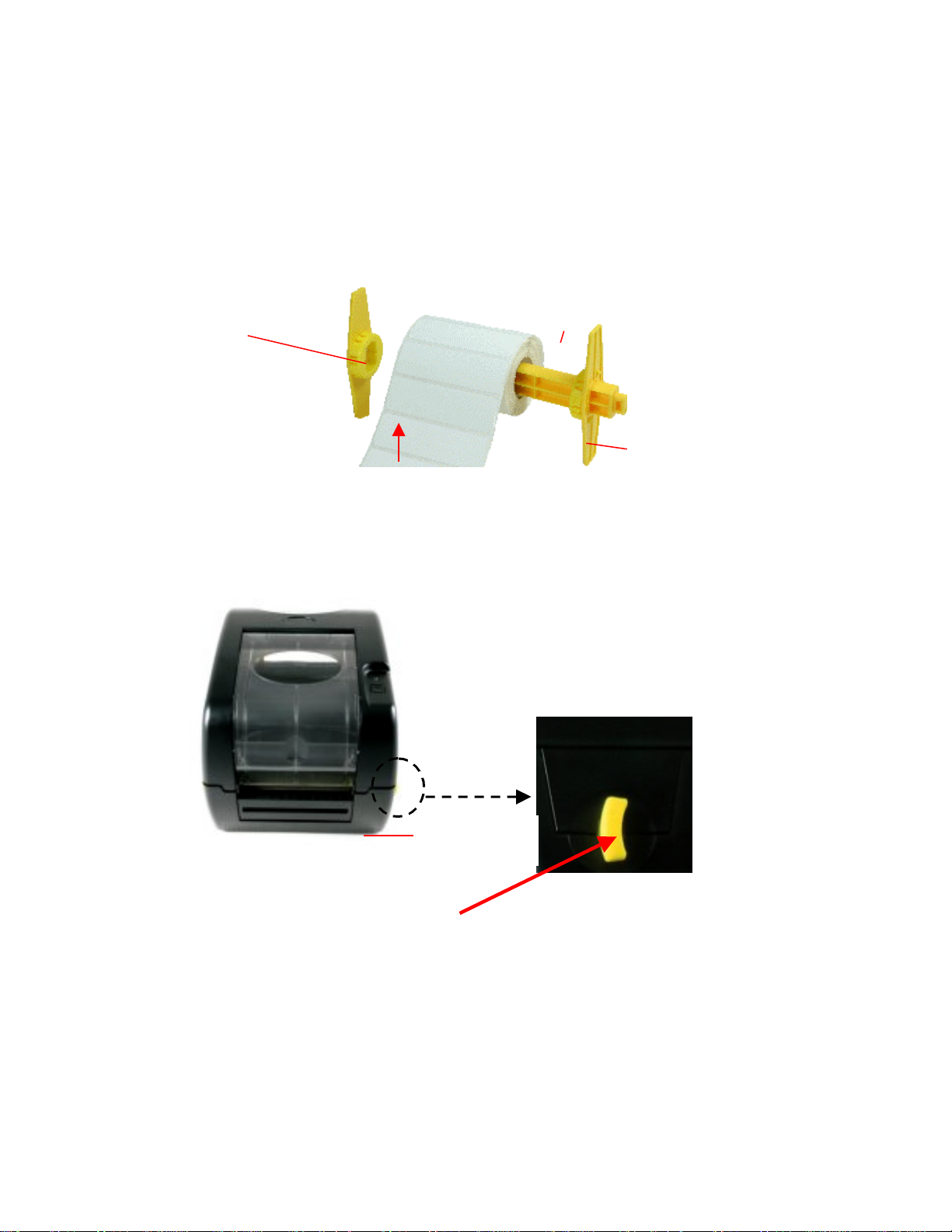

3.3 Loading Label Stock

1. Insert a 1” label spindle into the label roll. If your paper core is 1 inch, you

can remove the 1.5” core adapters from the centering tab. If the label width

is 4 inches wide, the two centering tabs are not required.

Printing Side

Face Up

Centering Tab

Figure 4: Label Roll Installation

2. Open the printer’s top cover by pulling the yellow top cover open levers

located on each side of the printer and lifting the top cover. A top cover

support at the rear of the printer will hold the printer top cover open.

Lower Cover

Figure 5: Pull the lever to open the cover

3. Place the roll of labels onto the center of the paper roll mount.

Page 7

Printer Top Cover

Paper Roll Mount

Support Bar

Paper Guide

Teflon Bar

Top Cover Open Lever

Figure 6: Label installation

4. Feed the paper, printing side face up, under the Teflon bar and the paper

guide and pass over the platen.

5. Adjust the yellow center-biased paper guides to slightly touch the edges of

the label backing.

6. To close the printer top cover, lift the cover to the ultimate open angle then

use both hands to close the cover gently. Close the printer top cover

slowly and make sure the cover locks latch securely.

Note:

1. Make sure hands are not placed in the printer when close the top

cover.

2. Do not allow the top cover to slam closed.

3. Failure to securely close and lock the cover will result in poor

print quality.

3.7 Top Cover Operation

To Open:

1. When facing the front of the printer pull the cover release levers on both

sides of the printer towards you.

2. Lift the top gradually.

There are two stop positions for the top cover. Position 1 and 2 are

indicated on the label below.

Note: To hold the cover open at position 1, you must lift the cover

higher than the stopping point at position 1 and gently lower the

cover to stopping point 1. Do not let the cover free fall!

3. Fully open the top cover and gently lower it to stop position 2.

Page 8

Figure 7: Top cover support is fixed at position 2

4. To close the cover, lift up the top cover to the ultimate angle then close the

top cover gently and it will be kept at a stop position between 1 and 2 for a

while. The cover will close automatically after several minutes. If you want

to speed the closing, use both hands to gently push down the top cover to

close it and make sure the cover is latched on both sides.

Note: Do not place your hands between top cover and lower cover

when closing the top cover!

Figure 8: Top cover is fully open and ready to close

Page 9

Figure 9: Use both hands to close the top cover

5. Do not force the cover! If you are not sure if top cover is locked at a stop

position, please do not push top cover to close it or the top cover will be

damaged. Instead, open the top cover as wide as it will go and close the

cover again. Use both hands to push top cover to close it.

Page 10

4. Power on Utilities

There are three power-on utilities to set up and test printer hardware.

1. Printer initialization

2. Ribbon sensor calibration

3. Gap or black mark sensor calibration

Note: You must run the #2 and #3 utilities after running the #1 to properly set

up the printer.

4.1 Initialization

Printer initialization is used to clear DRAM and restore printer settings to

factory defaults. The only one exception is ribbon sensitivity, which will not be

restored to default.

1. Turn the printer power off.

2. Press and hold the FEED button and then turn on the printer.

3. The LED will turn orange, blink red 5 times, blink orange 5 times and then

blink green 5 times. Release after the first green light blink.

4. Printer configuration will be restored to defaults as below after initialization.

WARNING: This will reset all saved settings in the printer.

Parameter Default setting

Speed W305, 127 mm/sec (5 ips)

Density 7

Label Width 4.25” (108.0 mm)

Label Height 2.5” (63.4 mm)

Sensor Type Gap sensor

Gap Setting 0.12” (3.0 mm)

Print Direction 0

Reference Point 0,0 (upper left corner)

Offset 0

Tear Mode On

Peel off Mode Off

Cutter Mode Off

Serial Port Settings

Code Page 850

Country Code 001

Clear Flash Memory No

4.2 Ribbon Sensor Calibration

Note: Please make sure the ribbon is properly installed before doing this

calibration.

9600 bps, none parity,

8 data bits, 1 stop bit

Please follow the steps below to calibrate the ribbon sensor.

1. Turn the printer power off.

2. Press and hold the FEED button then turn on the printer.

3. The LED will turn orange then blink red 5 times. Release after the first red

blink and before the 5rd.

4. If the ribbon is properly installed the light will turn green. If it is not it will

turn red and blink.

Page 11

4.3 Gap/Black Mark Calibration

Gap/black mark sensor sensitivity should be calibrated at the following

conditions:

1. A brand new printer

2. Change label stock

3. Printer initialization

Please follow the steps below to calibrate the sensor.

1. Turn the printer power off.

2. Press and hold the FEED button then turn on the printer.

3. The LED will turn orange, blink red 5 times and then blink orange 5 times.

Release after the first orange blink and before the 5th orange blink.

Calibrating the gap/black mark sensor will measure the label length, print the

internal configuration and then enter dump mode.

The self-test printout can be used to check for dot damage on the print head

and can be used to check printer configurations and available memory space.

Turn the printer off and back on to resume normal printing.

Figure 10: Self-test printout

Print head check pattern

Firmware version

Firmware checksum

Printed mileage (meter)

Serial port configuration

Country code

Print speed (inch/sec)

Print darkness

Label size (inch)

Gap distance (inch)

Gap/black mark sensor sensitivity

Numbers of download files

Total & available memory space

Page 12

The printer will enter dump mode after printing the printer configuration. In

dump mode, all characters will be printed in 2 columns as in the figure below.

ASCII Data

Hex decimal data

related to left

column of ASCII

data

Figure 11: Dump mode printout

The left side characters are received from your system and the right side data

are the corresponding hexadecimal values of the characters. Dump mode

allows users to verify and debug the program. Turn the printer off and back on

to resume normal printing.

Page 13

5. Maintenance

5.1 Cleaning

Use one or more of the following supplies that meets your needs:

n Cleaning pens

n Cleaning swabs

n Lint-free cloth

Printer Part Method

Printer Head n Let the print head to cool for one minute.

n Use a cleaning pen to swab the print elements.

Platen Roller n Rotate the platen roller and wipe it thoroughly

with 70% alcohol and a cleaning swab, or lintfree cloth.

Exterior n Wipe it with water-dampened cloth.

Interior n Brush or air blow.

6. Troubleshooting

This section lists common problems and some suggested solutions. Problems

are indicated by the LED light pattern.

6.1 LED Status

LED Status / Color Printer Status Solution Number

Off off 1

Solid Green on 2

Blinking Green Pause 3

Blinking Red Stopped 4

1. No power.

n Turn on the power switch.

n Check if the green LED is lit on the power supply. If it is not on, the

power supply may be broken.

n Check both power connection from the power cord to the power

supply and from the power supply to the printer power jack.

2. The printer is on and ready to use.

n No action necessary.

3. The printer is paused.

n Press the feed button to resume printing.

4. The printer is out of label or ribbon or the printer settings are not

correct

Out of label or ribbon

n Load a roll of labels and follow the instructions in Loading the

Labels, then press the feed button to resume printing.

n Load a ribbon and follow the instructions in Loading the Ribbon

then press the feed button to resume printing.

Printer setting is not correct

Page 14

Utilities.

6.2 Print Quality

Continuous feeding labels

n The printer settings may be wrong. Please do the Initialization and

Gap/Black Mark Calibration.

No print on the label

n Is the label or ribbon loaded correctly? Follow the instructions in

Loading the Labels or Loading the Ribbon.

n Has the ribbon run out? Follow the instructions in Loading the

Ribbon.

Poor print quality

n Top cover is not closed properly. Close the top cover completely and

make sure the right side and left side levers are latched to the top

cover properly.

n Clean the thermal print head.

n Adjust the print density setting.

n Ribbon and paper media are not compatible.

Page 15

7. Specifications

7.1 Printer Specifications

Item W305

Mechanism

Resolution 203 dpi.

Max. Print Width 108 mm.

Max. Print Length 1000 mm ( 39” ).

Ribbon Capacity 300 meter with 1” core. (Max. OD 67 mm)

Printing Speed 2, 3, 4 and 5 ips.

Peeler function 2, 3 ips

Printing Method Direct thermal and thermal transfer printing.

Enclosure

Structure

Dimension

Operation Panel

Hardware

Sensor Transmissive sensor (offset 6 mm from liner

Memory 1M byte Flash memory

Interface RS-232C (max baud rate, 19,200 bps).

Power AC input: 100-240V universal auto switching power

Firmware

Font Type 8 alpha-numeric bitmap fonts, and 1 true type font.

Rotation 0, 90,180 and 270 degrees.

Symbology Formats 1D: Code 39, Code 93, Code 128UCC, Code128

Command Set WPL

Environment

Operation Temperature: 5_ ~ 40_.

Storage Temperature: -40_ ~ 60_.

Double-walled plastic.

Standard Model: 314mm(L) x 213mm(W) x 188mm(H)

One push switch, and one indicator LED (Green,

Orange, Red).

edge).

Reflective sensor (position adjustable).

Head open micro switch.

Ribbon end sensor

2M bytes DRAM

USB: V1.1.

Centronics.

supply.

DC output: 24V 3.75A.

subsets A.B.C, Codabar, Interleave 2 of 5, EAN-8,

EAN-13, EAN-128, UPC-A, UPC-E, EAN and

UPC2(5) digits add-on, MSI, PLESSEY, POSTNET,

CPOST

2D: PDF-417, Maxicode, and DataMatrix.

Relative Humidity: 25% ~ 85% (Non Condensing).

Relative Humidity: 10% ~ 90% (Non Condensing).

7.2 Label Stock Specifications

Item Specification

Type Label (Continuous , Die-cut , Fan-fold).

Page 16

Wound Type Outside wound.

Width 20mm ~ 112mm (0.78” ~ 4.4”).

Length 10mm ~ 1000mm (0.4” ~ 39”).

25.4mm ~ 1000mm (1” ~ 39”).(for peeler and cutter)

Thickness 0.06mm ~ 0.19mm. (2.3~7.4 mil), max. 150g/m

Roll Diameter 5”.

Roll Core Diameter 25.4mm ~ 76.2mm (1” ~ 3”).

Gap Height 2mm min.

Black Mark Height 2mm min.

Black Mark Width 8mm min.

7.3 Ribbon Specifications

Item Specification

Type Wax, Wax / Resin, Resin.

Core Diameter 1".

Width Max 110mm.

Capacity 300m with 1" core.

Wound Type Outside wound.

Ribbon End Clear or silver end tape.

7.4. LED and Button Operation

LEDColor Description

Green

Orange

Red

The power is on and the device is ready to use.

The system is detecting the paper and ribbon status.

Printing error, such as paper empty, ribbon empty,

cover opened, etc.

2

8. Product Support

If you experience any problems with your Wasp printer that you are unable to resolve,

use our online support site to register then call for technical assistance at (214) 5474100, Monday through Friday, 8:00 AM – 5:00 PM Central Standard Time. You must

register to be eligible for technical support. Our web site is

www.waspbarcode.com

You may also contact us in writing at:

Wasp Technologies

1400 10

th

Street

Plano, TX 75074

(214) 547-4100

(214) 547-4101 Fax

9. Warranty Information

Wasp printers are warranted against defects in workmanship and materials for a

period of one year from the date of shipment, provided that the product remains

unmodified and is operated under normal and proper conditions.

Note: Print heads are warranted for 90 days against defect in workmanship. Print

heads will be replaced during the 90 day period once it is determined that the

Page 17

This warranty is limited to repair or replacement at Wasp Technologies’ option, with

reasonable promptness after being notified. These provisions do not prolong the

original warranty term for any product which has been repaired or replaced by Wasp

Technologies.

This warranty applies to the original owner and does not extend to any product which

has been subject to misuse, neglect, accidental damage, unauthorized repair, or

tampering.

No other express warranty is given. The replacement or repair of a product is your

exclusive remedy. Any other implied warranty of merchantability or fitness is limited

to the duration of this written warranty. Some states, provinces and countries do not

allow how long an implied warranty lasts, so the above limitation may not apply to

you.

In no event shall Wasp Technologies be liable for consequential damages. Some

states, provinces, and countries do not allow the exclusion or limitation of incidental

or consequential damages, so the above may not apply to you.

Loading...

Loading...