Page 1

Page 2

Page 3

WLS 8400

Product Reference Guide

February 2005

Page 4

© 2005 by Wasp Technologies. All rights reserved.

No part of this publication may be reproduced or used in any form, or by any electrical or mechanical

means, without permission in writing from Wasp Technologies. This includes electronic or

mechanical means, such as photocopying, recording, or information storage and retrieval systems.

The material in this manual is subject to change without notice.

The software is provided strictly on an “as is” basis. All software, including firmware, furnished to

the user is on a licensed basis. Wasp Technologies grants to the user a non-transferable and nonexclusive license to use each software or firmware program delivered hereunder (licensed program).

Except as noted below, such license may not be assigned, sublicensed, or otherwise transferred by

the user without prior written consent of Wasp Technologies. No right to copy a licensed program

in whole or in part is granted, except as permitted under copyright law. The user shall not modify,

merge, or incorporate any form or portion of a licensed program with other program material, create

a derivative work from a licensed program, or use a licensed program in a network without written

permission from Wasp Technologies. The user agrees to maintain Wasp Technologies’s copyright

notice on the licensed programs delivered hereunder and to include the same on any authorized

copies it makes, in whole or in part. The user agrees not to decompile, disassemble, decode, or

reverse engineer any licensed program delivered to the user or any portion thereof.

Wasp Technologies reserves the right to make changes to any software or product to improve

reliability, function, or design.

Wasp Technologies does not assume any product liability arising out of, or in connection with, the

application or use of any product, circuit, or application described herein.

No license is granted, either expressly or by implication, estoppel, or otherwise under any Wasp

Technologies, intellectual property rights. An implied license only exists for equipment, circui ts,

and subsystems contained in Wasp Technologies products.

Wasp Technologies is a registered trademark of Wasp Technologies. Other product names

mentioned in this manual may be trademarks or registered trademarks of their respective companies

and are hereby acknowledged.

Wasp Technologies

1400 10th St.

Plano TX 75074

http://www.waspbarcode.com

2

Page 5

Contents

About This Guide

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Chapter Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Notational Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvi

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvi

Service Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvi

Wasp Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvii

Chapter 1.

Getting Started

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Unpacking the Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Setting Up the Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Installing the Interface Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Connecting Power (if required) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Removing the Interface Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Configuring the Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Page 6

iv

WLS 8400 Product Reference Guide

Chapter 2.

Scanning

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Beeper Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

LED Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Scanning in Hand-Held Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Aiming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Scanning in Hands-Free Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Decode Zone. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Chapter 3.

Maintenance and Technical Specifications

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Technical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Scanner Signal Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Chapter 4.

User Preferences

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Scanning Sequence Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Errors While Scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

User Preferences Default Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

User Preferences. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Set Default Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Beeper Tone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Beeper Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Power Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Laser On Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Beep After Good Decode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Trigger Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Aim Duration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Page 7

Contents

Chapter 5.

Keyboard Wedge Interface

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Connecting a Keyboard Wedge Interface . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Keyboard Wedge Default Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Keyboard Wedge Host Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Keyboard Wedge Host Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Keyboard Wedge Country Types (Country Codes) . . . . . . . . . . . . . . 5-8

Ignore Unknown Characters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Keystroke Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Intra-Keystroke Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Alternate Numeric Keypad Emulation . . . . . . . . . . . . . . . . . . . . . . . 5-12

Caps Lock On. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Caps Lock Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Convert Wedge Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Function Key Mapping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

FN1 Substitution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Send Make and Break. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Keyboard Maps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

ASCII Character Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

v

Chapter 6.

RS-232 Interface

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Connecting an RS-232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

RS-232 Default Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

RS-232 Host Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

RS-232 Host Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Parity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

Check Receive Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Stop Bit Select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Data Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

Hardware Handshaking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

Software Handshaking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-18

Host Serial Response Time-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Page 8

vi

WLS 8400 Product Reference Guide

RTS Line State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-21

Beep on <BEL>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

Intercharacter Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-23

Nixdorf Mode A/B and OPOS/JPOS Beep/LED Options . . . . . . . .6-24

Ignore Unknown Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-25

ASCII / Character Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-26

Chapter 7.

USB Interface

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Connecting a USB Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

USB Default Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

USB Host Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-7

USB Device Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-7

USB Country Keyboard Types (Country Codes) . . . . . . . . . . . . . . . .7-8

USB Keystroke Delay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-10

USB CAPS Lock Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-11

USB Ignore Unknown Characters. . . . . . . . . . . . . . . . . . . . . . . . . . .7-12

Emulate Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-13

USB Keyboard FN 1 Substitution . . . . . . . . . . . . . . . . . . . . . . . . . . .7-14

Function Key Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-14

Simulated Caps Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-15

Convert Case. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-15

ASCII Character Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-16

Chapter 8.

Symbologies

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Scanning Sequence Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-5

Errors While Scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-5

Symbology Default Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-6

UPC/EAN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-10

Enable/Disable UPC-A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-10

Enable/Disable UPC-E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-10

Enable/Disable UPC-E1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-11

Enable/Disable EAN-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-11

Page 9

Contents

Enable/Disable EAN-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Enable/Disable Bookland EAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-12

Decode UPC/EAN/JAN Supplementals. . . . . . . . . . . . . . . . . . . . . . 8-13

UPC/EAN/JAN Supplemental Redundancy. . . . . . . . . . . . . . . . . . . 8-15

Transmit UPC-A/UPC-E/UPC-E1 Check Digit. . . . . . . . . . . . . . . . 8-15

UPC-A Preamble . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

UPC-E Preamble. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

UPC-E1 Preamble. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19

Convert UPC-E to UPC-A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-20

Convert UPC-E1 to UPC-A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-21

EAN-8/JAN-8 Extend. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

Code 128 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

Enable/Disable Code 128 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

Enable/Disable UCC/EAN-128 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

Enable/Disable ISBT 128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-23

Code 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

Enable/Disable Code 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

Enable/Disable Trioptic Code 39 . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-24

Convert Code 39 to Code 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-25

Code 32 Prefix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-26

Set Lengths for Code 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-27

Code 39 Check Digit Verification . . . . . . . . . . . . . . . . . . . . . . . . . . 8-29

Transmit Code 39 Check Digit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-30

Code 39 Full ASCII Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-31

Code 93 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-32

Enable/Disable Code 93 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-32

Set Lengths for Code 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-32

Code 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-34

Code 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-34

Set Lengths for Code 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-34

Code 11 Check Digit Verification . . . . . . . . . . . . . . . . . . . . . . . . . . 8-36

Transmit Code 11 Check Digits . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-37

Interleaved 2 of 5 (I 2 of 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-38

Enable/Disable Interleaved 2 of 5. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-38

Set Lengths for Interleaved 2 of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . 8-38

I 2 of 5 Check Digit Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-41

vii

Page 10

viii

WLS 8400 Product Reference Guide

Transmit I 2 of 5 Check Digit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-42

Convert I 2 of 5 to EAN-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-42

Discrete 2 of 5 (D 2 of 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-44

Enable/Disable Discrete 2 of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-44

Set Lengths for Discrete 2 of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-44

Codabar (NW - 7). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-46

Enable/Disable Codabar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-46

Set Lengths for Codabar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-47

CLSI Editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-49

NOTIS Editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-49

MSI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-50

Enable/Disable MSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-50

Set Lengths for MSI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-50

MSI Check Digits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-52

Transmit MSI Check Digit(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-53

MSI Check Digit Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-53

RSS (Reduced Space Symbology) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-54

RSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-54

RSS Limited . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-54

Convert RSS to UPC/EAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-55

Redundancy Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-56

Redundancy Level 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-56

Redundancy Level 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-56

Redundancy Level 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-57

Redundancy Level 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-57

Security Level. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-58

Security Level 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-58

Security Level 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-58

Security Level 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-59

Security Level 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-59

Bi-Directional Redundancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-60

Chapter 9.

Miscellaneous Scanner Options

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Scanning Sequence Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-4

Errors While Scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-4

Page 11

Contents

Miscellaneous Default Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Miscellaneous Scanner Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Transmit Code ID Character. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Scan Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Prefix/Suffix Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Scan Data Transmission Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

FN1 Substitution Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Transmit “No Read” Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Chapter 10.

Advanced Data Formatting

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Rules: Criteria Linked to Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Using ADF Bar Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

ADF Bar Code Menu Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Rule 1: The Code 128 Scanning Rule . . . . . . . . . . . . . . . . . . . . . . . 10-5

Rule 2: The UPC Scanning Rule . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

Alternate Rule Sets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

Rules Hierarchy (in Bar Codes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-7

Default Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-8

Special Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

Pause Duration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

Begin New Rule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

Save Rule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-9

Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

Quit Entering Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

Disable Rule Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

Code Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-12

Code Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-17

Message Containing A Specific Data String . . . . . . . . . . . . . . . . . 10-23

Actions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-28

Send Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-28

Setup Field(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-32

Modify Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-39

Pad Data with Spaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-41

ix

Page 12

x

WLS 8400 Product Reference Guide

Pad Data with Zeros . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-47

Beeps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-53

Send Keystroke (Control Characters and Keyboard Characters) . .10-54

Send Right Control Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-97

Send Graphic User Interface (GUI) Characters . . . . . . . . . . . . . . .10-97

Turn On/Off Rule Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-105

Alphanumeric Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-107

Appendix A.

Standard Default Parameters

Appendix B.

Programming Reference

Symbol Code Identifiers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

AIM Code Identifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Appendix C.

Sample Bar Codes

UPC-A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

UPC-E. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

UPC-E1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

EAN-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

EAN-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Code 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Trioptic Code 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Code 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Code 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Codabar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

MSI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Interleaved 2 of 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Page 13

Contents

Appendix D.

Numeric Bar Codes

0, 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

2, 3, 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-4

5, 6, 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-5

8, 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-6

Cancel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-7

Glossary

Index

xi

Page 14

xii

WLS 8400 Product Reference Guide

Page 15

About This Guide

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Chapter Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Notational Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvi

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Service Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

WASP Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Page 16

xiv

WLS 8400 Product Reference Guide

Page 17

Introduction

The WLS 8400 Product Reference Guide provides general instructions for setting up,

operating, maintaining, and troubleshooting the scanner. The WLS 8400 includes the

following variations of the scanner:

• WLS8400FZ: 1-D scanning

• WLS8400ER: extended range 1-D scanning.

Chapter Descriptions

• Chapter 1, Getting Started provides a product overview and unpacking

instructions.

• Chapter 2, Scanning describes parts of the scanner, beeper and LED definitions,

and how to use the scanner in hand-held and hands-free modes.

• Chapter 3, Maintenance and Technical Specifications provides information on

how to care for the scanner, troubleshooting, and technical specifications.

• Chapter 4, User Preferences provides the programming bar codes necessary for

selecting user preference features for the scanner.

• Chapter 5, Keyboard Wedge Interface provides information for setting up the

scanner for Keyboard Wedge operation.

• Chapter 6, RS-232 Interface provides information for setting up the scanner for

RS-232 operation.

• Chapter 7, USB Interface provides information for setting up the scanner for USB

operation.

• Chapter 8, Symbologies describes all symbology features and provides the

programming bar codes necessary for selecting these features for the scanner.

• Chapter 9, Miscellaneous Scanner Options includes commonly used bar codes to

customize how the data is transmitted to the host device.

• Chapter 10, Advanced Data Formatting (ADF) describes how to customize

scanned data before transmitting to the host.

• Appendix A, Standard Default Parameters provides a table of all host devices and

miscellaneous scanner defaults.

• Appendix B, Programming Reference provides a table of AIM code identifiers,

ASCII character conversions, and keyboard maps.

• Appendix C, Sample Bar Codes includes sample bar codes.

xv

Page 18

xvi

WLS 8400 Product Reference Guide

• Appendix D, Numeric Bar Codes includes the numeric bar codes to scan for

parameters requiring specific numeric values.

Notational Conventions

The following conventions are used in this document:

• Bullets (•) indicate:

• action items

• lists of alternatives

• lists of required steps that are not necessarily sequential.

• Sequential lists (e.g., those that describe step-by-step procedures) appear as

numbered lists.

• Throughout the programming bar code menus, asterisks (*) are used to denote

default parameter settings.

* Indicates Default

*Baud Rate 9600

Feature/Option

Related Publications

The WLS 8400 Quick S tart Guide provides general information to help the user get started

with the scanner. It includes basic set-up and operation instructions.

For the latest versions of the WLS 8400 Quick Sta r t Guide an d the WLS 8400 Product

Reference Guide go to: http://www.waspbarcode.com.

Service Information

If there is a problem with the equipment, contact the local Wasp Support. See page xvii for

contact information. Before calling, have the model number, serial numb er, and several of

the bar code symbols at hand.

Call Wasp Support from a phone near the scanning equipment so that the service person

can try to talk through the problem. If the equipment is found to be working properly and

the problem is symbol readability , Wasp Support will request samples of the bar codes for

analysis at our plant.

Page 19

If the problem cannot be solved over the phone, the equipment may need to be returned for

servicing. If that is necessary, specific directions will be given.

Wasp Technologies is not responsible for any damages

incurred during shipment if the approved shipping container is

not used. Shipping the units improperly can possibly void the

warranty. If the original shipping container was not kept,

contact Wasp Technologies to request another container.

Wasp Support

For service information, warranty information or technical assistance contact or call Wasp

Support at:

1400 10th Street

Plano, TX 75074

214-547-4100

xvii

Page 20

xviii

WLS 8400 Product Reference Guide

Page 21

1

Getting Started

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Unpacking the Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Setting Up the Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Installing the Interface Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Connecting Power (if required) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Removing the Interface Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Configuring the Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Page 22

1-2

WLS 8400 Product Reference Guide

Page 23

Getting Started

Introduction

The scanner combines excellent scanning performance and advanced ergonomics to

provide the best value in a lightweight laser scanner . Whether used as a hand-held scanner

or in hands-free mode in a stand, the scanner ensures comfort and ease of use for extended

periods of time.

1-3

Figure 1-1. WLS 8400 Scanner

This scanner supports:

• Standard RS-232 connection to a host.

• Keyboard Wedge connection to a host, where scanned data is interpreted

keystrokes. The following international keyboards are supported (for Windows

environment): North America, German, French, French Canadian, Spanish, Italian,

Swedish, UK English, Japanese, and Brazilian-Portuguese.

TM

Page 24

1-4

WLS 8400 Product Reference Guide

• USB connection to a host. The scanner autodetects a USB host and defaults to the

HID keyboard interface type. Other USB interface types may be selected by

scanning programming bar codes. The following international keyboards are

supported (for Windows

Canadian, Spanish, Italian, Swedish, UK English, Japanese, and Brazilia nPortuguese.

™ environment): North America, German, French, French

Unpacking the Scanner

Remove the scanner from its packing and inspect it for damage. If the scanner was damaged

in transit, call Wasp Support at one of the telephone numbers listed on page xvii. KEEP

THE P ACKING . It is the approved shipping container and should be used if the equipment

ever needs to be returned for servicing.

Page 25

Getting Started

Setting Up the Scanner

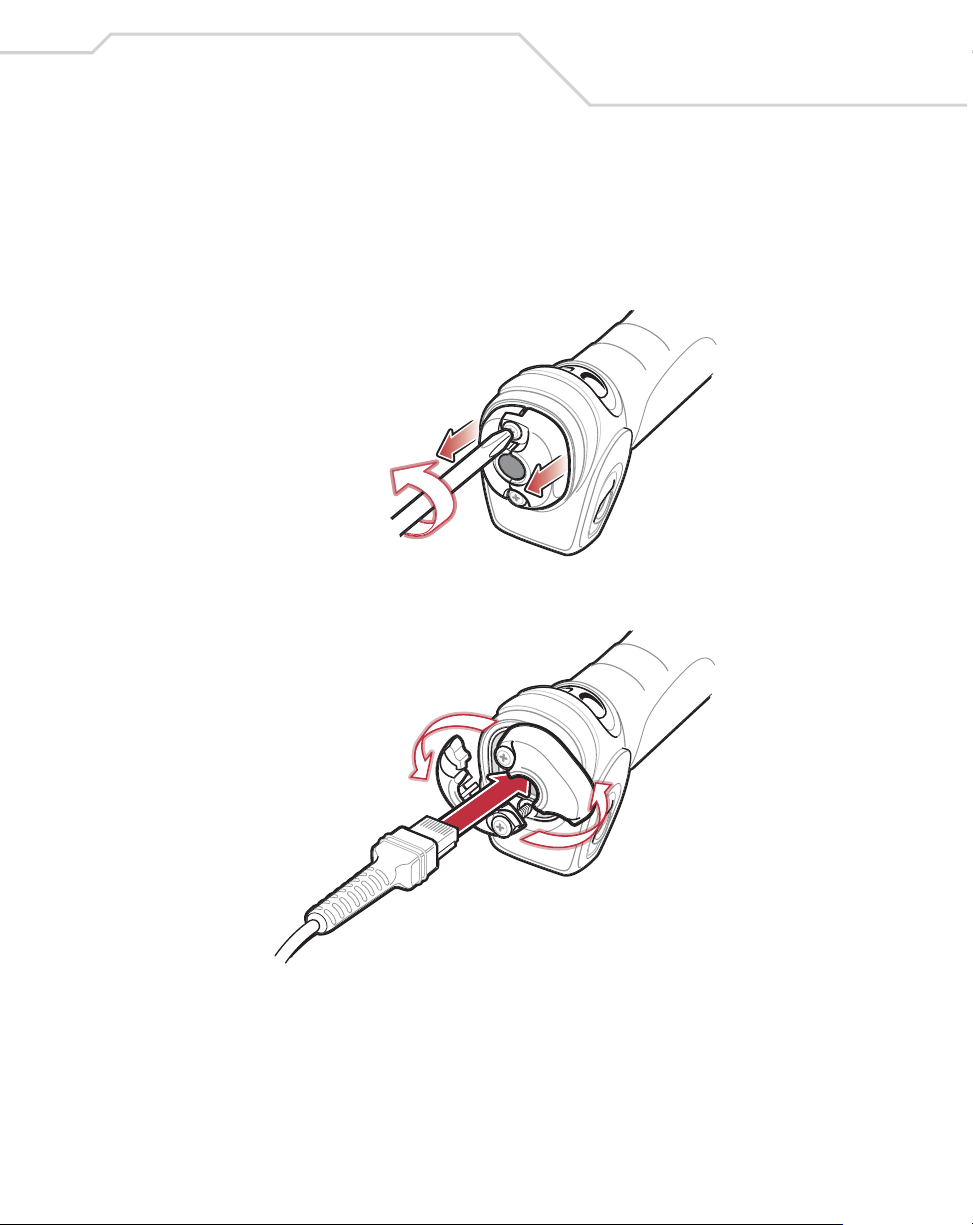

Installing the Interface Cable

1. Loosen the two screws on the cable clamp at the bottom of the scanner and gently

pull the clamp away from the bottom of the scanner.

2. Open the clamp and plug the interface cable modular connector into the cable

interface port on the bottom of the scanner handle.

1-5

3. Gently tug the cable to ensure the connector is properly secured.

Page 26

1-6

WLS 8400 Product Reference Guide

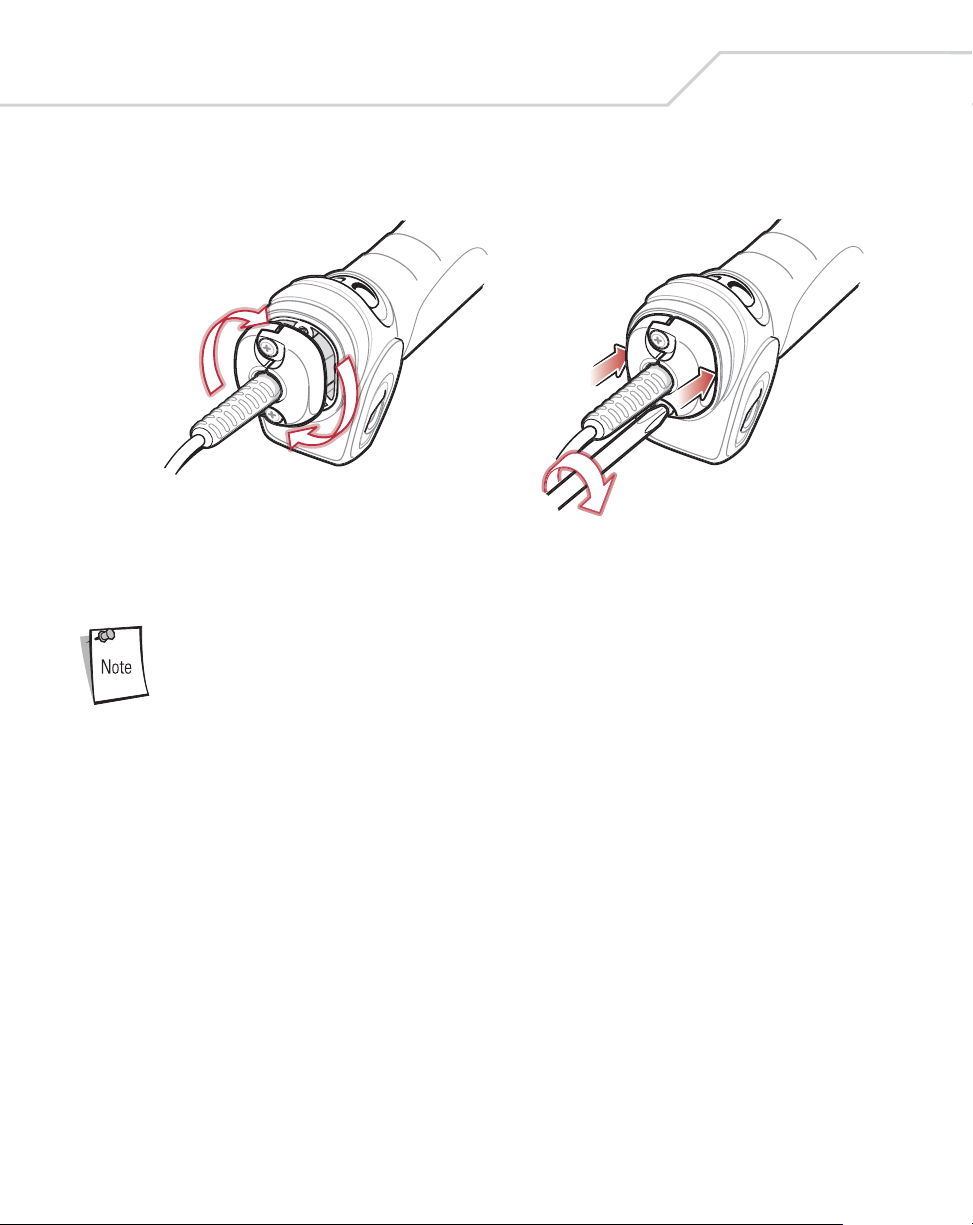

4. Close the clamp, push it back into place and tighten the screws on the clamp to

secure the cable into the bottom of the scanner.

5. Connect the other end of the interface cable to the host (see the specific host chapter

for information on host connections).

Different cables are required for different hosts. The connectors

illustrated in each host chapter are examples only. The connectors

may be different than those illustrated, but the steps to connect the

scanner remain the same.

Connecting Power (if required)

If the host does not provide power to the scanner, an external power connection is required

to power the scanner. To connect power:

1. Connect the interface cable to the bottom of the scanner, as described in Installing

the Interface Cable on page 1-5.

2. Connect the other end of the interface cable to the host (refer to the host manual to

locate the correct port).

3. Plug the power supply into the power jack on the interface cable. Plug the other end

of the power supply into an AC outlet.

Page 27

Getting Started

Removing the Interface Cable

1. Loosen the two screws on the cable clamp at the bottom of the scanner and gently

pull the clamp away from the bottom of the scanner.

2. Open the clamp and unplug the interface cable modular connector from the cable

interface port on the bottom of the scanner handle. Carefully slide out the cable.

3. Follow the steps for Installing the Interface Cable on page 1-5 to connect a new

cable.

Configuring the Scanner

Use the bar codes included in this manual to configure the scanner. See Chapter 4, User

Preferences and each host chapter for information about programming the scanner using

bar code menus.

1-7

Page 28

1-8

WLS 8400 Product Reference Guide

Page 29

2

Scanning

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Beeper Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

LED Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Scanning in Hand-Held Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Aiming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Scanning in Hands-Free Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

Decode Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

Page 30

2-2

WLS 8400 Product Reference Guide

Page 31

Scanning

Introduction

This chapter provides beeper and LED definitions, techniques involved in scanning bar

codes, general instructions and tips about scanning, and decode zone diagrams.

Scan

Tether Plate

LED

Indicators

Scan Trigger

2-3

Figure 2-1. Parts

Page 32

2-4

WLS 8400 Product Reference Guide

Beeper Definitions

The scanner emits different beeper sequences and patterns to indicate its status. Table 2-1

defines beep sequences that occur during both normal scanning and while programming the

scanner.

Table 2-1. Standard Beeper Definitions

Beeper Sequence Indication

Standard Use

Short low/short medium/short high

beep sequence

1 short high beep A bar code symbol was decoded (if decode beeper is enabled).

4 long low beeps A transmission error was detected in a scanned symbol. The data is

5 long low beeps Conversion or format error.

Short high/short high/short high/long

low beep sequence

Parameter Menu Scanning

Long low/long high beep sequence Incorrect programming sequence or ‘Cancel’ bar code scanned.

Short high/short low beep sequence Keyboard parameter selected. Enter value using bar code keypad.

Short high/short low/short high/short

low beep sequence

Short low/short high/short low/short

high beep sequence

USB only

4 short high beeps Scanner has not completed initialization. Wait several seconds and

Short low/short medium/short high

beep sequence after scanning a USB

Device Type.

Short low/short medium/short high

beep sequence occurs more than once.

Power up.

ignored.

RS-232 receive error.

Scanner remains in program mode.

Successful program exit with change in the parameter setting.

Out of host parameter storage space. Scan Set Default Parameter on

page 4-5.

scan again.

Communication with the bus must be established before the scanner

can operate at the highest power level.

The USB bus may put the scanner in a state where power to the

scanner is cycled on and off more than once. This is normal and

usually happens when the PC cold boots.

Page 33

Scanning

Table 2-1. Standard Beeper Definitions (Continued)

Beeper Sequence Indication

RS-232 only

1 short high beep A <BEL> character is received and Beep on <BEL> is enabled.

LED Definitions

In addition to beeper sequences, the scanner uses the two-color LED to indicate its status.

Table 2-2 defines LED colors that display during scanning.

Table 2-2. Standard LED Definitions

LED Indication

Off The scanner is on and ready to scan, or no power is applied to the

scanner.

Green A bar code was successfully decoded.

Red A data transmission error occurred.

2-5

Page 34

2-6

WLS 8400 Product Reference Guide

Scanning in Hand-Held Mode

Install and program the scanner (see Setting Up the Scanner on page 1-5). For assistance,

contact the local supplier or Wasp Support.

1. Ensure the scanner is properly connected to the host (see the appropriate host

chapter).

2. Aim the scanner at the bar code.

3. Press the scan trigger.

Figure 2-2. Scanning in Hand-Held Mode

4. Ensure the scan line crosses every bar and space of the symbol.

RIGHT

012345

5. Upon successful decode, the scanner beeps, and the LED turns green. For more

information on beeper and LED definitions, see Table 2-1 and Table 2-2.

WRONG

012345

Page 35

Scanning

Aiming

Do not hold the scanner directly over the bar code. Laser light reflecting directly back into

the scanner from the bar code is known as specular reflection. This specular reflection can

make decoding difficult.

The scanner can be tilted up to 65° forward or back and achieve a successful decode (Figure

2-3). Simple practice quickly shows what tolerances to work within.

65°

2-7

65°

Figure 2-3. Optimum Scan Angles

Page 36

2-8

WLS 8400 Product Reference Guide

Scanning in Hands-Free Mode

The optional IntelliStand adds greater flexibility to the scanning operation. When the

scanner is seated in the stand’s “cup,” the scanner’s built-in sensor places the scanner in

hands-free mode. When the scanner is removed from the stand it operates in its normal

hand-held mode.

Adjust angle of

scanner “cup”

Scanner “Cup”

Adjust height

of IntelliStand

Figure 2-4. Inserting the Scanner in the IntelliStand

To operate the scanner in the IntelliStand:

1. Ensure the scanner is properly connected to the host (see the appropriate host

chapter for information on host connections).

2. Insert the scanner into the IntelliStand by placing the front of the scanner into the

stand’s “cup” (see Figure 2-4).

3. T o scan a bar code, present the bar code and ensure the scan line crosses every bar

and space of the symbol.

4. Upon successful decode, the scanner beeps and the LED turns green. For more

information on beeper and LED definitions, see Table 2-1 and Table 2-2.

Page 37

Decode Zone

W

i

d

t

h

o

f

F

i

e

l

d

Note: Typical performance at 68˚F (20˚C)

on high quality Code 39 and UPC symbols.

Scanning

in. cm

30

76.2

20

50.8

10

25.4

2-9

LS 3408

FZ

5 mil

7.25"

2.5"

7.5 mil

2.0" 15.75"

13 mil

1.0" 24"

100% UPC

20 mil (80%MRD)

0"*

20 mil (31%MRD)

40 mil

2.0"*

55 mil

4.0"*

in.

0 1020304050607080

0 25.4 50.8 76.2 101.6 127.0 152.4 177.8 203.2

cm

*Minimum distance determined by symbol length and scan angle

26.5"

39.5"

67.0"

Depth of Field

Figure 2-5. WLS 8400FZ Decode Zone

84.0"

90

228.6

00

10

25.4

20

50.8

30

76.2

Page 38

2-10

W

i

d

t

h

o

f

F

i

e

l

d

W

i

d

t

h

o

f

F

i

e

l

d

WLS 8400 Product Reference Guide

Note: Typical performance at 73.4˚F (23˚C)

on high quality Code 39 symbols.

LS 3408

ER

0.25" 20"

in.

cm

Note: Typical performance at 73.4˚F (23˚C)

on high quality Code 39 symbols.

LS 3408

ER

*

7.5 mil

10 mil

2" 32"

15 mil

3" 69"

20 mil

3" 94"

0 102030405060708090 100

0 25.4 50.8 76.2 101.6 127.0 152.4 177.8 203.2 228.6 254.0

15" 180"

55 mil

70 mil reflective

100 mil reflective

Depth of Field

365"

540"

in. cm

12

8

4

0

4

8

12

in. cm

72

48

24

0

24

48

72

30.5

20.3

10.2

0

10.2

20.3

30.5

182.9

121.9

61.0

0

61.0

121.9

182.9

in.

0 60 120 180 240 300 360 420 480 540 600

cm

0 152.4 304.8 457.2 609.6 762.0 914.4 1066.8 1219.2 1371.6 1524.0

Depth of Field

*Near range determined by degree of reflectivity and width of bar code.

Figure 2-6. WLS 8400ER Decode Zone

Page 39

3

Maintenance and Technical

Specifications

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

Scanner Signal Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Page 40

3-2

WLS 8400 Product Reference Guide

Page 41

Maintenance and Technical Specifications

Introduction

This chapter provides suggested scanner maintenance, troubleshooting, technical

specifications, and signal descriptions (pinouts).

Maintenance

Cleaning the scan window is the only maintenance required. A dirty window may affect

scanning accuracy.

• Do not allow any abrasive material to touch the window.

• Remove any dirt particles with a damp cloth.

• Wipe the window using a tissue moistened with ammonia/water.

• Do not spray water or other cleaning liquids directly onto the window.

3-3

Page 42

3-4

WLS 8400 Product Reference Guide

Troubleshooting

Problem Possible Causes Possible Solutions

Scanner emits short low/short

medium/short high beep sequence.

Table 3-1. Troubleshooting

Scanner is powering up. Normal when scanner is plugged

in.

Nothing happens when scan trigger

is pressed.

Scanner emits short low/short

medium/short high beep sequence

more than once.

Laser comes on, but scanner does

not decode the bar code.

No power to the scanner. Check the system power. Ensure

the power supply is connected if

the configuration requires a power

supply.

Power supply is not plugged in.

Incorrect host interface cable is

used.

Interface/power cables are loose. Ensure all cable connections are

Scanner is disabled. For Simple Serial Interface (SSI),

If using RS-232 Nixdorf B mode,

CTS is not asserted.

The USB bus may put the scanner

in a state where power to the

scanner is cycled on and off more

than once.

Scanner is not programmed for the

correct bar code type.

Bar code symbol is unreadable. Check the symbol to ensure it is not

Bar code is out of range from the

scanner.

Ensure that correct host interface

cable is used.

secure.

enable the scanner via the host

interface. Otherwise, see the

technical person in charge of

scanning.

Assert CTS line.

Normal during host reset.

Ensure the scanner is programmed

to read the type of bar code being

scanned.

defaced. Try scanning test bar

codes of the same bar code type.

See Appendix C, Sample Bar Codes

for test bar codes.

Move scanner closer to or further

from bar code.

Page 43

Table 3-1. Troubleshooting (Continued)

Problem Possible Causes Possible Solutions

Scanner emits 4 short high beeps

while attempting to scan.

Bar code is decoded, but data is not

transmitted to the host.

Scanned data is incorrectly

displayed on the host.

Maintenance and Technical Specifications

Scanner has not completed USB

initialization.

Scanner is not programmed for the

correct host type.

Interface cable is loose. Ensure all cable connections are

If 4 long low beeps are heard, a

transmission error was detected.

If 5 long low beeps are heard, a

conversion or format error was

detected.

Scanner is not programmed to

work with the host.

Wait several seconds and scan

again.

Scan the appropriate host

parameter bar codes.

secure.

Ensure the scanner's

communication parameters match

the host's setting.

Ensure the scanner's conversion

parameters are properly

configured.

Ensure proper host is selected.

For RS-232, ensure the scanner's

communication parameters match

the host's settings.

3-5

Scanner emits short high/short

high/short high/long low beep

sequence when it is not in use.

Scanner emits long low/long high

beep sequence while it is being

programming.

Scanner emits short low/short high/

short low/short high beep sequence

while it is being programming.

For a Keyboard Wedge

configuration, ensure the system is

programmed for the correct

keyboard type, and the CAPS

LOCK key is off.

Ensure editing options (e.g., UPCE to UPC-A conversion) are

properly programmed.

RS-232 receive error. Normal during host reset.

Otherwise, ensure the scanner's

RS-232 parity setting matches the

host setting.

Input error or ’Cancel’ bar code is

scanned.

Out of ADF parameter storage

space.

Ensure the correct numeric bar

codes, that are within range for the

parameter that is being

programmed, are being scanned.

Erase all rules and re-program with

shorter rules.

Page 44

3-6

WLS 8400 Product Reference Guide

Problem Possible Causes Possible Solutions

Scanner emits a short low/short

medium/short high beep sequence

after changing USB host type.

Scanner emits 1 short high beep

when it is not in use.

If after performing these checks the symbol still does not decode,

contact the distributor or call Wasp Support. See page xvii for the

telephone number.

Table 3-1. Troubleshooting (Continued)

The USB bus re-establishes power

to the scanner.

In RS-232 mode, a <BEL>

character is received and Beep on

<BEL> option is enabled.

Normal when the USB host type is

changed.

Normal when Beep on <BEL> is

enabled and the scanner is in RS232 mode.

Page 45

Maintenance and Technical Specifications

Technical Specifications

Table 3-2. Technical Specifications

Description

Item

Power Requirements 4.5 - 14VDC

Stand-By Current 50mA (max)

Power Source Depending on host:

Decode Capability UPC/EAN, Bookland EAN, UPC/EAN with supplementals, Code 128, UCC/

EAN 128, ISBT 128, Code 39, Trioptic Code 39, Code 93, Code 11, Interleaved

2 of 5, Discrete 2 of 5, Codabar (NW-7), MSI, RSS.

Beeper Operation User-selectable: Enable, Disable

Beeper Volume User-selectable: Three levels

Beeper T one User-selectable: Three tones

WLS 8400FZ WLS 8400ER

• host powered

• external power supply

3-7

Scan Repetition Rate 36 scans/second

Yaw Tolerance ± 50° from nominal ± 60° from nominal

Pitch Tolerance ± 65° from nominal ± 65° from nominal

Roll Tolerance ± 20° from nominal ± 10° from nominal

Print Contrast Minimum 25% minimum reflectance differential, measured at 650 nm.

Ambient Light Immunity

Indoor:

Outdoor:

Durability 6.5 ft (2.0 m) drops to concrete

Operating Temperature -22° to 122° F (-30° to 50° C)

Storage Temperature -40° to 158° F (-40° to 70° C)

Humidity 5% to 95% (non-condensing)

Weight (without cable) 12.35 oz. (350 g) 12.56 oz. (356 g)

450 Ft Candles (4,842 Lux)

8,000 Ft Candles (86,080 Lux)

450 Ft Candles (4,842 Lux)

4,000 Ft Candles (43,040 Lux)

Page 46

3-8

WLS 8400 Product Reference Guide

Table 3-2. Technical Specifications (Continued)

Description

Item

Dimensions:

Height

Width

Depth

Laser 650nm laser diode

Laser Classifications IEC 825-1 Class 2

ESD 20 kV area discharge

Minimum Element Width 5 mil (0.127 mm) 7.5 mil (0.191 mm)

Interfaces Supported Keyboard Wedge, RS-232, USB

Electrical Safety Certified Pending to UL1950, CSA C22.2 No.950. EN60950/IC950

Input Transient

Protection

7.34 in. (18.65 cm)

4.82 in. (12.25 cm)

2.93 in. (7.43 cm)

8 kV contact discharge

IEC 1000-4-(2,3,4,5,6,11)

WLS 8400FZ WLS 8400ER

EMI FCC Part 15 Class B, ICES-003 Class B European Union EMC Directive,

Australian SMA, Taiwan EMC, Japan VCCI/MITI/Dentori

Page 47

Scanner Signal Descriptions

Bottom of

Maintenance and Technical Specifications

Cable interface port

PIN 1PIN 10

3-9

Interface cable

modular

Figure 3-1. Scanner Cable Pinouts

Page 48

3-10

WLS 8400 Product Reference Guide

The signal descriptions in Table 3-3 apply to the connector on the scanner and are for

reference only.

Table 3-3. Scanner Signal Pin-outs

Keyboard

Pin RS-232

1 Reserved Reserved Jump to Pin 6

2 Power Power Power

3 Ground Ground Ground

4 TxD KeyClock Reserved

5 RxD TermData D +

6 RTS KeyData Jump to Pin 1

7 CTS TermClock D -

8 Reserved Reserved Reserved

9 Reserved Reserved Reserved

10 Reserved Reserved Reserved

Wedge USB

Page 49

4

User Preferences

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Scanning Sequence Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Errors While Scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

User Preferences Default Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

User Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Set Default Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Beeper Tone. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Beeper Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Power Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Laser On Time- . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Beep After Good Decode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Trigger Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Aim Duration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Page 50

4-2

WLS 8400 Product Reference Guide

Page 51

User Preferences

Introduction

The scanner can be programed to perform various functions, or activate different features.

This chapter describes each user preference feature and provides the programming bar

codes necessary for selecting these features for the scanner.

The scanner ships with the settings shown in the User Preferences Default Table on page

4-4 (also see Chapter A, Standar d Default Parameters for all host device and miscellaneous

scanner defaults). If the default values suit the requirements, programming may not be

necessary.

Feature values are set by scanning single bar codes or short bar code sequences. The

settings are stored in non-volatile memory and are preserved even when the scanner is

powered down.

If the USB cable is not being used, select a host type (see each host chapter for specific host

information). After hearing the power-up beeps, select a host type. This only needs to be

done once, upon the first power-up when connected to a new host.

To return all features to their default values, scan the Set All Defaults bar code on page 4-

5. Throughout the programming bar code menus, default values are indicated with asterisks

(

*).

4-3

* Indicates Default

*High Frequency

Feature/Option

Scanning Sequence Examples

In most cases, only one bar code needs to be scanned to set a specific parameter value. For

example, to set the beeper tone to high, simply scan the High Frequency (beeper tone) bar

code listed under Beeper Tone on page 4-5. The scanner issues a fast warble beep and the

LED turns green, signifying a successful parameter entry.

Other parameters, such as specifying Laser On Time or setting Data Transmission

Formats, require that several bar codes be scanned. See Laser On Time on page 4-7 and

Scan Data Transmission Format on page 9-7 for descriptions of this procedure.

Errors While Scanning

Unless otherwise specified, if an error is made during a scanning sequence, just re-scan the

correct parameter.

Page 52

4-4

WLS 8400 Product Reference Guide

User Preferences Default Parameters

T able 4-1 lists the defaults for user preferences parameters. T o ch ange any option, scan the

appropriate bar code(s) provided in the User Preferences section beginning on page 4-5.

See Chapter A, S tandar d Default Parameters for all user preferences,

hosts, symbologies, and miscellaneous default parameters.

Table 4-1. User Preferences Default Table

Parameter Default Page Number

User Preferences

Set Default Parameter All Defaults 4-5

Beeper Tone High 4-5

Beeper Volume High 4-6

Power Mode Continuous On 4-7

Laser On Time 3.0 sec 4-7

Beep After Good Decode Enable 4-8

Trigger Mode Level 4-8

Aim Duration 0.0 sec 4-10

Page 53

User Preferences

User Preferences

Set Default Parameter

Scanning this bar code returns all parameters to the default values listed in Table A-1 on

page A-3.

Set All Defaults

Beeper Tone

T o select a decode beep frequency (tone), scan the Low Frequency, Medium Frequency,

or High Frequency bar code.

4-5

Low Frequency

Medium Frequency

*High Frequency

Page 54

4-6

WLS 8400 Product Reference Guide

Beeper Volume

T o select a beeper volume, scan the Low Volume, Medium Volume, or High Volume bar

code.

Low Volume

Medium Volume

*High V olume

Page 55

User Preferences

Power Mode

This parameter determines whether or not the scanner enters reduced power mode after a

decode attempt. When in reduced power mode, the scanner draws less current from its

power source.

*Continuous On

Reduced Power Mode

4-7

Laser On Time

This parameter sets the maximum time that decode processing continues during a scan

attempt. It is programmable in 0.1 second increments from 0.5 to 9.9 seconds. The default

Laser On Time is 3.0 seconds.

To set a Laser On Time, scan the bar code below. Next, scan two numeric bar codes

beginning on page D-1 in Chapter D, Numeric Bar Codes that correspond to the desired on

time. Single digit numbers must have a leading zero. For example, to set a Laser On Time

of 0.5 seconds, scan the bar code below, then scan the “0” and “5” bar codes. In case of an

error, or to change the selection, scan Cancel on page D-7.

Laser On Time

Page 56

4-8

WLS 8400 Product Reference Guide

Beep After Good Decode

Scan a bar code below to select whether or not the scanner beeps after a good decode. If Do

Not Beep After Good Decode is selected, the beeper still operates during parameter menu

scanning and indicates error conditions.

*Beep After Good Decode

(Enable)

Do Not Beep After Good Decode

(Disable)

Trigger Mode

The scanner has three trigger modes that can be used to scan bar codes. The desired trigger

mode can be set by using the bar codes below.

Level Trigger

When the trigger is pulled, an aiming dot appears for a programmable duration of time.

After this time, the aiming dot automatically turns into a standard laser scanning beam for

a full decode session. The laser scanning beam stays on until the laser-on timeout occurs, a

decode occurs, or the trigger is released. If the trigger is released before the aiming duration

expires, the laser shuts off and no decode occurs.

*Level

Page 57

User Preferences

Trigger Mode (continued)

Two Stage - Option 1

When the trigger is pulled, an aiming dot appears. This aiming dot remains while the trigger

is pulled. When the trigger is released, the aiming dot automatically turns into a standard

laser scanning beam for a full decode session. The laser scanning beam stays on until the

laser-on timeout occurs or a decode occurs. If the trigger is pulled again while in a decode

session, the scanner beam returns to an aiming dot.

Tw o Stage - Option 1

Two Stage - Option 2

When the trigger is pulled, an aiming dot appears. When the trigger is released, the aiming

dot turns off. Pulling the trigger twice in rapid succession turns on the standard laser

scanning beam for a full decode session. The laser scanning beam, stays on until the laseron timeout occurs, a decode occurs, or the trigger is released.

4-9

Tw o Stage - Option 2

Page 58

4-10

WLS 8400 Product Reference Guide

Aim Duration

When the scanner is in Level trigger mode (default mode), Aim Duration sets the amount

of time the aiming dot is seen before turning into a scanning beam. This parameter has no

affect when the scanner is in either of the Two Stage trigger modes. See Trigger Mode on

page 4-8 for a description of each of the trigger modes.

The aim duration is programmable in 0.1 second increments, from 0.0 to 9.9 seconds. The

default Aim Duration is 0.0 seconds. When set to 0.0 seconds, no aiming pattern appears

before a decode session.

To set an aim duration, scan the bar code below. Then scan two numeric bar codes,

available in Appendix D, Numeric Bar Codes, that correspond to the desired aim duration.

Durations less than 1.0 seconds must have a leading zero. For example, to set an aim

duration of 0.5 seconds, scan the bar code below, followed by the ‘0’ and the ‘5’ bar codes.

In case of an error, or to change the selection, scan the ‘Cancel’ bar code on page D-7.

Aim Duration

Page 59

5

Keyboard Wedge Interface

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Connecting a Keyboard Wedge Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Keyboard Wedge Default Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

Keyboard Wedge Host Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Keyboard Wedge Host Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Keyboard Wedge Country Types (Country Codes). . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Ignore Unknown Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Keystroke Delay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Intra-Keystroke Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Alternate Numeric Keypad Emulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

Caps Lock On. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

Caps Lock Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-12

Convert Wedge Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

Function Key Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

FN1 Substitution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

Send Make and Break . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

Page 60

5-2

WLS 8400 Product Reference Guide

Keyboard Maps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

ASCII Character Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Page 61

Keyboard Wedge Interface

Introduction

This chapter provides Keyboard Wedge interface information for setting up the scanner.

This interface type is used to attach the scanner between the keyboard and host computer.

The scanner translates the bar code data into keystrokes. The host computer accepts the

keystrokes as if they originate from the keyboard.

This mode of operation allows adding bar code reading functionality to a system design ed

for manual keyboard input. In this mode, the keyboard keystrokes are simply passed

through.

Throughout the programming bar code menus, default values are indicated with asterisks

(

*).

5-3

* Indicates Default

*North American

Feature/Option

Page 62

5-4

WLS 8400 Product Reference Guide

Connecting a Keyboard Wedge Interface

Female DIN Keyboard Keyboard

Figure 5-1. Keyboard Wedge Interface Connection with Y-cable

Male DIN Host

Y-cable

To connect the keyboard wedge interface Y-cable:

Interface cables vary depending on configuration. The connectors

illustrated in Figure 5-1 are examples only. The connectors may be

different than those illustrated, but the steps to connect the scanner

remain the same.

1. Turn off the host and unplug the keyboard connector.

2. Attach the modular connector of the Y-cable to the cable interface port on the

scanner. (See Installing the Interface Cable on page 1-5.)

3. Connect the round male DIN host connector of the Y-cable to the keyboard port on

the host.

4. Connect the round female DIN keyboard connector of the Y-cable to the keyboard

connector.

5. If required, attach the optional power supply to the connector in the middle of the

Y-cable.

6. Ensure that all connections are secure.

Page 63

Keyboard Wedge Interface

7. Turn on the host system.

8. Select the Keyboard Wedge host type by scanning the appropriate bar code from

the Keyboard Wedge Host Types section on page 5-7.

9. To modify any other parameter options, scan the appropriate bar codes in this

chapter.

Keyboard Wedge Default Parameters

Table 5-1 lists the defaults for Keyboard Wedge host parameters. To change any option,

scan the appropriate bar code(s) provided in the Keyboard W edge Host Parameters section

beginning on page 5-7.

See Chapt er A, Standar d Default Parameters for all user preferences,

hosts, symbologies, and miscellaneous default parameters.

Table 5-1. Keyboard Wedge Host Default Table

Parameter Default Page Number

5-5

Keyboard Wedge Host Parameters

Keyboard Wedge Host Type IBM PC/AT& IBM PC Compatibles 5-7

Keyboard Wedge Country Types (Country

Codes)

Ignore Unknown Characters Enable 5-10

Keystroke Delay 0 msec (No Delay) 5-10

Intra-Keystroke Delay Disable 5-11

Alternate Numeric Keypad Emulation Disable 5-12

Caps Lock On Disable 5-12

Caps Lock Override Disable 5-13

Convert Wedge Data Do Not Convert Wedge Data 5-14

Function Key Mapping Disable 5-15

North American 5-8

Page 64

5-6

WLS 8400 Product Reference Guide

Table 5-1. Keyboard Wedge Host Default Table (Continued)

Parameter Default Page Number

FN1 Substitution Disable 5-15

Send Make and Break Send Make and Break Scan Codes 5-15

Page 65

Keyboard Wedge Interface

Keyboard Wedge Host Types

Keyboard Wedge Host Types

Select the keyboard wedge host by scanning one of the bar codes below.

*IBM PC/A T & IBM PC Compatibles

IBM PS/2 (Model 30)

5-7

IBM A T NOTEBOOK

IBM XT

NCR 7052

Page 66

5-8

WLS 8400 Product Reference Guide

Keyboard Wedge Country Types (Country Codes)

Scan the bar code corresponding to the keyboard type. If the particular keyboard type is not

listed, see Alternate Numeric Keypad Emulation on page 5-12.

*North American

German Windows

French Windows

French Canadian Windows 95/98

French Canadian Windows XP/2000

Page 67

Keyboard Wedge Interface

Keyboard Wedge Country Types (Country Codes) (continued)

Spanish Windows

Italian Windows

Swedish Windows

5-9

UK English Windows

Japanese Windows

Brazilian-Portuguese Windows

Page 68

5-10

WLS 8400 Product Reference Guide

Ignore Unknown Characters

Unknown characters are characters the host does not recognize. When Send Bar Codes

With Unknown Characters is selected, all bar code data is sent except for unknown

characters, and no error beeps sound on the scanner. When Do Not Send Bar Codes W ith

Unknown Characters is selected, bar code data is sent up to the first unknown character

and then an error beep sounds on the scanner.

*Send Bar Codes with Unknown Characters

(Enable)

Do Not Send Bar Codes with Unknown Characters

(Disable)

Keystroke Delay

This is the delay in milliseconds between emulated keystrokes. Scan a bar code below to

increase the delay when hosts require a slower transmission of data.

*0 msec (No Delay)

20 msec (Medium Delay)

Page 69

Keyboard Wedge Interface

Keystroke Delay (continued)

40 msec (Long Delay)

Intra-Keystroke Delay

When enabled, an additional delay is inserted between each emulated key depression and

release. This sets the Keystroke Delay parameter to a minimum of 5 msec, as well.

Enable Intra-Keystroke Delay

5-11

*Disable Intra-Keystroke Delay

Page 70

5-12

WLS 8400 Product Reference Guide

Alternate Numeric Keypad Emulation

This allows emulation of most other country keyboard types not listed in Keyboar d Wedge

Country Types (Country Codes) on page 5-8 in a Microsoft

environment.

Enable Alternate Numeric Keypad

*Disable Alternate Numeric Keypad

®

operating system

Caps Lock On

When enabled, the scanner emulates keystrokes as if the Caps Lock key is always pressed.

Enable Caps Lock On

*Disable Caps Lock On

Page 71

Keyboard Wedge Interface

Caps Lock Override

When enabled, on AT or AT Notebook hosts, the keyboard ignores the state of the Caps

Lock key . Therefore, an ‘A’ in the bar code is sent as an ‘A ’ no matter what the state of the

keyboard’s Caps Lock key.

Enable Caps Lock Override

*Disable Caps Lock Override

If both Caps Lock On and Caps Lock Override are enabled, Caps

Lock Override takes precedence.

5-13

Page 72

5-14

WLS 8400 Product Reference Guide

Convert Wedge Data

When enabled, the scanner converts all bar code data to the selected case.

Convert Wedge Data to Upper Case

Convert Wedge Da ta to Lower Case

*Do Not Convert Wedge Data

Function Key Mapping

ASCII values under 32 are normally sent as control key sequences (see Table 5-2 on page

5-19). When this parameter is enabled, the keys in bold are sent in place of the standard key

mapping. Table entries that do not have a bold entry remain the same whether or not this

parameter is enabled.

Enable Function Key Mapping

*Disable Function Key Mapping

Page 73

Keyboard Wedge Interface

FN1 Substitution

When enabled, this parameter allows replacement of any FN1 characters in an EAN128 bar

code with a keystroke chosen by the user. (see FN1 Substitution Values on page 9-9).

Enable FN1 Substitution

*Disable FN1 Substitution

Send Make and Break

When enabled, the scan codes for releasing a key are not sent.

5-15

*Send Make and Break Scan Codes

Send Make Scan Code Only

Page 74

5-16

WLS 8400 Product Reference Guide

Keyboard Maps

The following keyboard maps are provided for prefix/suffix keystroke parameters. To

program the prefix/suffix values, see the bar codes on page 9-6.

7014 5001 5002 5003 5004 5005 5006 5007 5008 5009 5010

7009

Figure 5-2. IBM PS2 Type Keyboard

5001

5003

5005

5007

5009

5002

5004

5006

5008

5010

7014

7009

5011

7008

7013

7013

5012

7010 7007

7012

7011

7002 7004 7005

7015

7017 7016

7006

7001

7008

7003

7018

7013

7012

7004

7011 7002

7003

7006

Figure 5-3. IBM PC/XT

Page 75

Keyboard Wedge Interface

5-17

5001

5003

5005

5007

5009

5002

5004

5006

5008

5010

7009

5002

5001

5003

5004

5005 5006

5007

5008

5009

5010

Figure 5-4. IBM PC/AT

5011

1048

5012

(1048 if double key)

1046

7008

7013

1045

5013

5014

5015

1043

5016

5018

5017

7013

5019

(7013 if double key)

7014

7012

7004

7011

7003

7002

Figure 5-5. NCR 7052 32-KEY

Page 76

5-18

WLS 8400 Product Reference Guide

5012

1068

1075

1082

1046

1066

1065

1072

1073

1079 1080

5002

5001

5003

5004

5005 5006

5007

5008

5009

5010

1067

1074

1081

5011

1048

(1048 if double key)

Figure 5-6. NCR 7052 58-KEY

1070

1069

1076

1077

1083 1084

1045

5013

5014

5015

1043

5016

5018

5017

7013

5019

(1043 if double key)

1071

1078

1085

1086

1087

1088

1089

1090