Page 1

QUICK START GUIDE

Wasp DuraLine

Industrial Scanner

WASP WLS 8400 ER/FZ SERIES

Dura

www.waspbarcode.com

Page 2

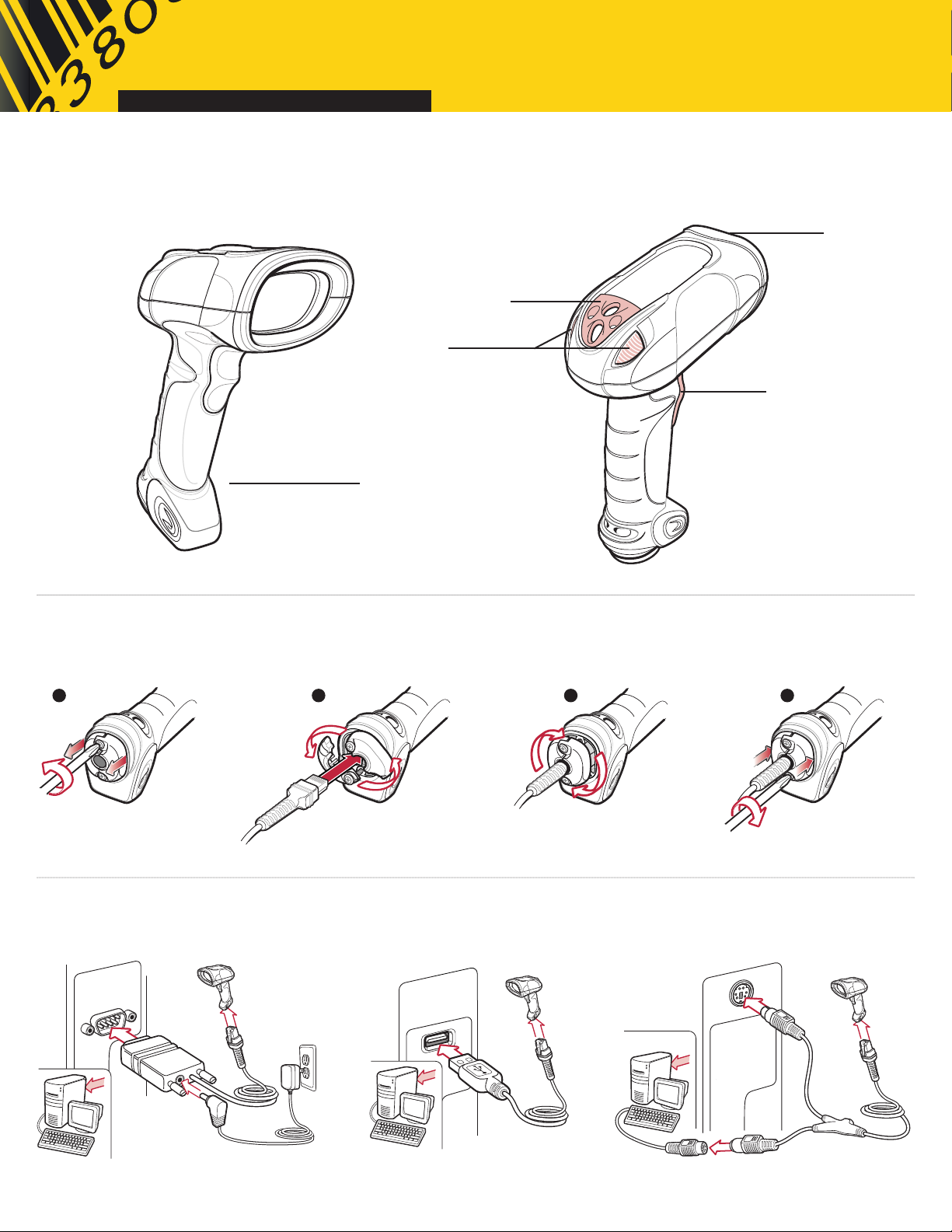

WASP DURALINE INDUSTRIAL SCANNER

Laser Scanner (ER, FZ)

Scan Window

Tether Plate

LED Indicators

Scan Trigger

CORD ATTACHMENT

1 2 3 4

HOST INTERFACES

Note: Cable may vary depending on configuration

RS-232 Keyboard WedgeUSB

Page 3

TROUBLESHOOTING

Scanner not working

No power to scanner

Check system power;

ensure power supply,

if required, is connected

Incorrect interface

cable used

Ensure that correct

interface cable is used

Interface/power

cables are loose

Check for loose

cableconnections

Scanner decoding bar code, but data not transmitting to host

Scanner not programmed for

correct host interface

Check scanner host parameters

or edit options

Interface cable is loose

Check for loose cable connections

SCANNER PROGRAMMING BAR CODES

Start Here if you have a USB scanner

QUICK START GUIDE

Scanner not decoding bar code

Scanner not programmed

for bar code type

Ensure scanner is

programmed to read type

of bar code beingscanned

Scanned data incorrectly displayed on host

Scanner not programmed for correct host interface

Check scanner host parameters or edit options

Start Here if you have a keyboard wedge scanner

Bar code unreadable

Ensure bar code is not

defaced; try scanning

test bar code of same

bar code type

Distance between

scanner and bar

code incorrect

Move scanner

closer to or further

from bar code

Reset Defaults

Set Postamble

Erase All Rules

1

2

Begin New Rules

Send All Data

3

BEEPER INDICATIONS

Standard Use

Low/medium/high beep

Power up

USB Host Types Keyboard Wedge Host Types

Choose a Postamble

4

NOTE

Short high beep

Bar code decoded [if

decode beeper enabled]

<Enter>

Enter

<Tab>

Tab

If you do not need a Postamble scan Erase All Rules only.

1

4 long low beeps

Transmission error

detected; data is ignored

5

Save All Rules

LED INDICATIONS

Off

Scanner is on and

ready to scan, or no

power to scanner

Parameter Menu Scanning

High/low/high/low beep

Successful parameter

setting

www.waspbarcode.com

Green

Bar code is

High/low beep

Correct programming

sequence performed

©2005 Wasp Technologies. All rights reserved.

Wasp reserves the right to make changes to any product to improve reliability, function, or design. Wasp does not assume any product liability arising out of, or in connection with, the

application or use of any product, circuit, or application described herein. No license is granted, either expressly or by implication, estoppel, or otherwise under any patent right or patent,

covering or relating to any combination, system, apparatus, machine, material, method, or process in which Wasp products might be used. An implied license exists only for equipment,

circuits, and subsystems contained in Wasp products. Wasp and the Wasp logo are registered trademarks of Wasp Technologies. Other product names mentioned in this manual may be

trademarks or registered trademarks of their respective companies and are hereby acknowledged.

Wasp Technologies, 1400 10th Street, Plano, TX 75074, www.waspbarcode.com

Low/high beep

Incorrect programming

sequence or Cancel bar

code scanned

successfully decoded

Red

Transmission error

Page 4

WASP DURALINE INDUSTRIAL SCANNER

PATENTS

This product is covered by one or more of the following U.S. and foreign Patents:

U.S. Patent No. 4,593,186; 4,603,262; 4,607,156; 4,652,750; 4,673,805;

4,736,095;4,758,717; 4,760,248; 4,806,742; 4,816,660; 4,845,350; 4,896,026;

4,897,532; 4,923,281; 4,933,538; 4,992,717; 5,015,833; 5,017,765; 5,021,641;

5,029,183; 5,047,617; 5,103,461; 5,113,445; 5,130,520; 5,140,144; 5,142,550;

5,149,950; 5,157,687; 5,168,148; 5,168,149; 5,180,904; 5,216,232; 5,229,591;

5,230,088; 5,235,167; 5,243,655; 5,247,162; 5,250,791; 5,250,792; 5,260,553;

5,262,627; 5,262,628; 5,266,787; 5,278,398; 5,280,162; 5,280,163; 5,280,164;

5,280,498; 5,304,786; 5,304,788; 5,306,900; 5,324,924; 5,337,361; 5,367,151;

5,373,148; 5,378,882; 5,396,053; 5,396,055; 5,399,846; 5,408,081; 5,410,139;

5,410,140; 5,412,198; 5,418,812; 5,420,411; 5,436,440; 5,444,231; 5,449,891;

5,449,893; 5,468,949; 5,471,042; 5,478,998; 5,479,000; 5,479,002; 5,479,441;

5,504,322; 5,519,577; 5,528,621; 5,532,469; 5,543,610; 5,545,889; 5,552,592;

5,557,093; 5,578,810; 5,581,070; 5,589,679; 5,589,680; 5,608,202; 5,612,531;

5,619,028; 5,627,359; 5,637,852; 5,664,229; 5,668,803; 5,675,139; 5,693,929;

5,698,835; 5,705,800; 5,714,746; 5,723,851; 5,734,152; 5,734,153; 5,742,043;

5,745,794; 5,754,587; 5,762,516; 5,763,863; 5,767,500; 5,789,728; 5,789,731;

5,808,287; 5,811,785; 5,811,787; 5,815,811; 5,821,519; 5,821,520; 5,823,812;

5,828,050; 5,848,064; 5,850,078; 5,861,615; 5,874,720; 5,875,415; 5,900,617;

5,902,989; 5,907,146; 5,912,450; 5,914,478; 5,917,173; 5,920,059; 5,923,025;

5,929,420; 5,945,658; 5,945,659; 5,946,194; 5,959,285; 6,002,918; 6,021,947;

6,029,894; 6,031,830; 6,036,098; 6,047,892; 6,050,491; 6,053,413; 6,056,200;

6,065,678; 6,067,297; 6,082,621; 6,084,528; 6,088,482; 6,092,725; 6,101,483;

6,102,293; 6,104,620; 6,114,712; 6,115,678; 6,119,944; 6,123,265; 6,131,814;

6,138,180; 6,142,379; 6,172,478; 6,176,428; 6,178,426; 6,186,400; 6,188,681;

6,209,788; 6,209,789; 6,216,951; 6,220,514; 6,243,447; 6,244,513; 6,247,647;

6,308,061; 6,250,551; 6,295,031; 6,308,061; 6,308,892; 6,321,990; 6,328,213;

6,330,244; 6,336,587; 6,340,114; 6,340,115; 6,340,119; 6,348,773; 6,380,949;

6,394,355; D305,885; D341,584; D344,501; D359,483; D362,453; D363,700;

D363,918; D370,478; D383,124;

D391,250; D405,077; D406,581; D414,171; D414,172; D418,500; D419,548;

D423,468; D424,035;

D430,158; D430,159; D431,562; D436,104.

Invention No. 55,358; 62,539; 69,060; 69,187, NI-068564 (Taiwan); No.

1,601,796; 1,907,875; 1,955,269 (Japan); European Patent 367,299; 414,281;

367,300; 367,298; UK 2,072,832; France 81/03938; Italy 1,138,713

ERGONOMIC RECOMMENDATIONS

Caution: In order to avoid or minimize the potential risk of ergonomic injury

follow the recommendations below. Consult with your local Health & Safety

Manager to ensure that you are adhering to your company's safety programs to

prevent employee injury.

• Reduce or eliminate repetitive motion

• Maintain a natural position

• Reduce or eliminate excessive force

• Keep objects that are used frequently within easy reach

• Perform tasks at correct heights

• Reduce or eliminate vibration

• Reduce or eliminate direct pressure

• Provide adjustable workstations

• Provide adequate clearance

• Provide a suitable working environment

• Improve work procedures.

REGULATORY INFORMATION

All Wasp devices are designed to be compliant with rules and regulations in

locations they are sold and will be labeled as required.

Any changes or modifications to Wasp Technologies equipment, not expressly approved

by Wasp Technologies, could void the user's authority to operate the equipment.

LASER LABELS

In accordance with Clause 5, IEC 825 and EN60825, the following

information is provided to the user:

ENGLISH

CLASS 1 CLASS 1 LASER PRODUCT

CLASS 2 LASER LIGHT

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

DUTCH / NEDERLANDS

KLASSE 1 KLASSE-1 LASERPRODUKT

KLASSE 2 LASERLICHT

NIET IN STRAAL STAREN

KLASSE-2 LASERPRODUKT

FRENCH / FRANÇAIS

CLASSE 1 PRODUIT LASER DE CLASSE 1

CLASSE 2 LUMIERE LASER

NE PAS REGARDER LE

RAYON FIXEMENT

PRODUIT LASER DE CLASSE 2

SPANISH / ESPAÑOL

CLASE 1 PRODUCTO LASER DE LA

CLASE 1

CLASE 2 LUZ LASER

NO MIRE FIJAMENTE EL HAZ

PRODUCTO LASER DE LA

CLASE 2

GERMAN / DEUTCH

KLASSE 1 LASERPRODUKT DER

KLASSE 1

KLASSE 2 LASERSTRAHLEN

NICHT DIREKT IN DEN

LASERSTRAHL SCHAUEN

LASERPRODUKT DER

KLASSE 2

RADIO FREQUENCY INTERFERENCE REQUIREMENTS

Tested to comply

with FCC Standards

FOR HOME OR OFFICE USE

ference in a residential installation. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications.

However there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected

• Consult the dealer or an experienced radio/TV technician for help.

Radio Frequency Interference Requirements – Canada

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Marking and European Economic Area (EEA)

Note: This equipment has been tested and

found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC

rules. These limits are designed to provide

reasonable protection against harmful inter-

LASER DEVICES

Wasp products using lasers comply with US 21CFR1040.10, and

IEC825-1:1993, EN60825-1:1994+A11:1996. The laser classification

is marked on one of the labels on the product.

Class 1 Laser devices are not considered to be hazardous when used for their

intended purpose. The following statement is required to comply with US and

international regulations:

Caution: Use of controls, adjustments or performance of procedures other

than those specified herein may result in hazardous laser light exposure.

Antenna’s, use only the supplied or an approved replacement antenna.

Unauthorized antennas, modifications, or attachments could cause damage and

may violate regulations.

Class 2 laser scanners use a low power, visible light diode. As with any very bright

light source, such as the sun, the user should avoid staring directly into the light

beam. Momentary exposure to a Class 2 laser is not known to be harmful.

Loading...

Loading...