Page 1

www.waspbarcode.com

Taking Stock of Your Inventory

Automated Technologies Boost

Productivity, Cut Expenses

Page 2

Taking Stock of Your Inventory

Introduction

Whether you're looking for a printer cartridge or medical vial stored in the supply closet; searching

for an installation part in a warehouse or seeking a box of the high-end sunglasses promoted in your

boutique's latest newspaper ad, inventory management is a critical component of any small or

midsize business. However, many business owners do not fully realize the costs associated with poor

inventory management, or the potential opportunity for improvement.

Inventory management, after all, requires a delicate balance. You must carry enough stock to satisfy

customer demands, yet overstocking can tie up valuable working capital, create inefficiencies and

lead to write-offs of yesterday’s fads. You don't want your maintenance staff sitting idly as they await

delivery of repair parts, nor do you want your warehouse to resemble General Motors. Today's

technology empowers you to focus on your business while simultaneously ensuring that you maintain

the right amount of inventory, office supplies and repair parts without over- or under-investing.

Taking Inventory

Inventory organization alone is critical. Add up the minutes, even hours, employees spend searching

for stock or supplies, and this effort becomes seriously expensive. If they cannot locate an item,

employees often will order replacement inventory, incurring rush-shipping charges, and the

additional expense of the redundant stock item. In the medical field alone, the average healthcare

organization wastes more than $1 million in supplies each year, noted Linda Leekley, RN, and

President of In the Know.

In the retail sector, inventory inaccuracies contributed

nearly 15% – or $5.59 billion – in losses.

- 2008 National Retail Security Survey Final Report

inventory inaccuracies due to administrative and paperwork errors contributed nearly 15% –

or $5.59 billion – in losses, according to the 2008 National Retail Security Survey Final Report.

As a rule of thumb, yearly inventory carrying cost is between 25% and 35% of the average value of

stocked inventory. Therefore, if your retail business stocks an average of $100,000 of inventory, your

annual carrying cost is $25,000 to $35,000. At a 15% loss rate, your organization has just incurred

an expense of $3,750 per year due to missing inventory.

Tabulate the tens of thousands of

dollars a business can all-too-easily tie

up in inventory, and it quickly becomes

apparent that inventory consumes

precious capital, becoming a huge

drain on cash flow. In the retail sector,

Unfortunately, the costs don't end there. If retailers and distributors don't pay careful attention to

their inventory, they also have to pay for storage for excess inventory, deal with obsolete inventory,

866.547.9277

1

Page 3

handle write-offs, cope with tax issues and depreciation, combat cash-flow and loan problems, and

face unnecessary expenses.

Consider, too, the negative impact on your customers as delays unfold. Unmet expectations may

damage your company’s reputation and, at worst, frustrated customers may turn to other suppliers

to satisfy their requests. When you also take into account the tasks that go unaccomplished as

employees scramble to find the toner, valves or sunglasses, it soon becomes clear why accurate

inventory-tracking is so critical to your business' success.

Fortunately, even small and midsize businesses can tap into today's technology to ensure they are

cost-effectively managing their stock of products for resale, internal use, repair and temporary usage.

The State of Inventory Management in Business

Progressive businesses have used inventory warehouse management systems (WMS) for years –

driving costs out of their supply chain, improving efficiency in their warehouses, and flowing

increased profit to their bottom line. A study by Aberdeen Research indicated companies with a fully

automated WMS system showed efficiency improvements well over 10%, with pick rates and

shipping accuracy rates of 99%. Further, when labor is factored in, these best-in-class companies

enjoyed reduced labor costs year-over-year compared to their peers, who incurred annual labor

increases in excess of 5% each year.

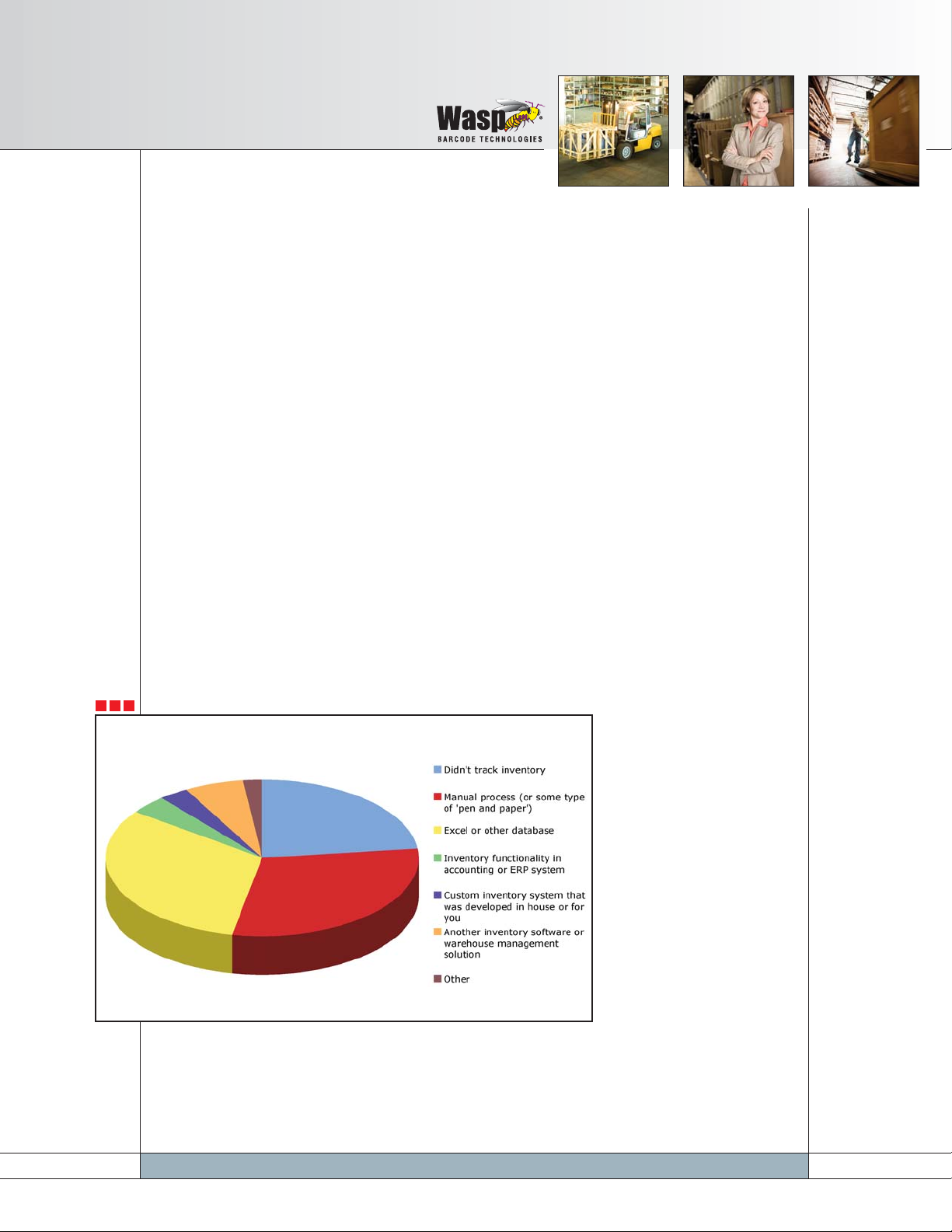

How Small Businesses Commonly Track Inventory

2%

3%

4%

32%

Source: Wasp customer survey June 2010

inventory tracking system. Interestingly, 23% didn’t track inventory at all. Some tried to use

inventory functionality in their accounting system. Thirty percent resorted to manual methods using

pen and paper, and 32% turned to spreadsheets or general purpose database software.

6%

23%

30%

www.waspbarcode.com

In spite of these benefits,

many small businesses don’t

track inventory using an

automated system, often

perceiving such systems as

unaffordable or unnecessarily

complicated for basic

inventory management. In a

recent survey of small

businesses by Wasp Barcode,

more than 80% of their

customers had not used any

type of automated system

prior to implementing an

2

Page 4

Taking Stock of Your Inventory

While applications like spreadsheets are well-designed for their specific purposes and provide some

initial visibility, they are inadequate to monitor the constant ebb and flow of office supplies, parts and

materials or other inventory items.

This was the case for Process Control Outlet, a small industrial

electronics reseller. Initially, the company used its accounting

application to try and track the hundreds of industrial electronics items

it sells. However, the software’s limited inventory-management

capabilities made it difficult for sales representatives to see what was

in stock, leading to delays in fulfilling customer orders. Sales agents

often resorted to manually verifying product availability in the warehouse, wasting valuable sales time

and frustrating customers who were waiting for an answer.

For its part, Amarillo National Bank, a regional bank in west Texas, used two complex Excel

spreadsheets to manage its inventory of pens, deposit slips, paper and other necessary items. One

spreadsheet had 60 tabs; the second had about 40 tabs. It regularly took at least a full day each

month to update the spreadsheet. Plus, errors were easily introduced, and took considerable time to

reconcile. In the end, the difficulty and inefficiency of monthly updates to the file, combined with

errors, resulted in tens of thousands of dollars in write offs each year.

Meanwhile, the Health Sciences Learning Center, a department of Pensacola State College, stockpiled

supplies in closets scattered around the campus, resulting in a lot of expensive, unnecessary

duplication. A spreadsheet accounting for the inventory items initially helped generate an accurate

It regularly took at least a full day each

month for Amarillo National Bank to

updated their inventory spreadsheets.

Built to Order

So what should inventory software do?

A quality inventory management system enables you to know, track and locate every item that enters

your company's doors, whether you'll use it internally, lend it to a customer, use it to repair

equipment or sell it outright. With its location capabilities, an inventory management solution gives

detailed information on an item's locale. For example, a piece of inventory can be found in a site –

such as a warehouse or supply room – and at a specific location within that site, like aisle 3,

section A, shelf 1. Depending on your company's preference, the software can use additional means

including serial numbers, lot numbers, date codes or pallets – to further distinguish each item.

list of all the supplies stored throughout the campus, but

was too unwieldy and time-consuming for ongoing

transactions. Plus, they wanted to keep accurate cost of

the ever-changing inventory, and the spreadsheet was not

suited to this need.

–

3

866.547.9277

Page 5

Likewise, these solutions should track the quantity on-hand, sold and on-order. If you order in bulk,

the software should automatically break-down the order into smaller quantities or units of measure

(UOM).

An inventory management system should give you visibility into your inventory's location, what's

moving, and what's stagnant, allowing you to make informed decisions about purchasing, marketing,

and advertising. In turn, this helps make your business more profitable and allows you to better

serve your customers.

What Technology to Use

One of the best and most affordable ways to track inventory is using a barcode-based inventory

system. A barcode is simply a graphical representation of a number or text string. The white spaces

and black lines represent the underlying data. Using barcodes virtually

eliminates human data entry errors when adding, removing, and

counting inventory. Scanning an item and/or location with a barcode

scanner or mobile computer is fast, easy, and efficient, and ensures that

data is always accurate. Barcodes are an ideal way for small businesses

to improve inventory efficiency and migrate from manual or spreadsheet

approaches without incurring the expense or complexity of a Radio

Frequency Identification (RFID)-based system.

Using barcodes, inventory control software tracks by an item number. While this is generally a

number you create for an inventory item, it also can be the item’s existing product or UPC number.

The software also can track inventory items by serial number, lot number, date code, and pallet.

Items can be monitored on a PC or mobile device.

The software should generate customized purchase and pick orders, support multiple suppliers for

each item, and track non-inventory items like supplies. In addition, leading inventory software

providers let you assemble and disassemble components and raw materials to create finished goods

for inventory, and enable you to receive alerts for past-due checked-out items, low-inventory and

expiring items. Inventory solutions should empower your business to be proactive, current and

accurate.

Inventory systems may use wireless networks to provide real-time data on your organization’s

inventory. Often, the cost and complication of implementing wireless infrastructure is daunting to

some businesses. As an alternative, inventory systems that update data by physically connecting to

your PC eliminate this layer of cost and complexity, while still delivering accurate stock data. In some

cases, inventory software is sold as an all-in-one, integrated solution complete with mobile

www.waspbarcode.com

4

Page 6

Taking Stock of Your Inventory

computer, barcode printer and software. This eliminates the need for integrating and testing separate

vendors’ products, a sometimes time-consuming and confusing proposition. In the retail

environment, you may choose an inventory solution that incorporates point of sale (POS) functionality.

The Supply Chain

Because of its spreadsheet-based inventory system, Amarillo National Bank was forced to write off

tens of thousands of dollars each year, since it could not account for inventory supply items and bill

its internal departments in a timely and accurate fashion. Driven to reduce costs – and by the

demands of accounting and human resources – the financial institution researched its options

Amarillo National Bank saves 16 hours a

month – or $12,000 per year – using a

before selecting a barcode-based inventory software

solution.

barcode-based inventory software solution.

automatically trigger purchase orders. When the bank receives items into inventory, it scans them

using a barcode scanner and checks them against the original purchase order, virtually eliminating

input errors and ensuring accurate knowledge of the inventory on-hand.

The bank saves about 16 hours a month – or $12,000 per year – that can be devoted to higher-value

tasks, estimated Cody Cadenhead, assistant purchasing agent at Amarillo National Bank. And the

accounting personnel have saved dozens of hours billing the branch offices, he said.

"Write-offs have dropped from tens of thousands of dollars to just a few hundred dollars per year,"

Cadenhead added.

Within the medical field, the Health Sciences Learning Center at Pensacola State College opted for a

barcode-based software application that included a

mobile computer because of the solution's intuitiveness

and user-friendliness, said Christa Ruber, supervisor.

The integrated technology helped the department slash

inventory by 65%; it optimized its inventory levels,

stocking just 1,750 items in two centralized supply

rooms instead of 5,000-plus items in closets around the campus, said Ruber. The money saved by

reducing inventory was a welcome outcome given the shrinking budget the school faced, she noted.

The bank immediately discarded its manual

spreadsheets and set minimum ordering levels to

Barcode-based software helped Pensacola

State College optimize its inventory levels,

slashing inventory by 65%

Just Fix It

Companies in the repair business also must keep careful track of the various pieces and components

flowing in and out of their doors.

866.547.9277

5

Page 7

When Ace A/C & Heating realized its spreadsheet-based inventory management simply wasn’t up to

the job, it bought a barcode-based mobile solution. The midsize business uses the technology to

manage its parts inventory, create reorder reports, review inventory reports to track item sales

history, and keep an accurate count of items in stock. In the past, Ace technicians – who earn about

$40 per hour – wasted around 20 hours each week obtaining parts that were not in the warehouse.

With the barcode-based system, Ace saves about $800 per week, or more than $40,000 per year. In

addition, Ace now can schedule service calls – and earn money – during the 20 hours technicians

used to travel to and from the supply depot. The return on investment arrived in less than a month.

“The product paid for itself in three weeks,” said Gary

Kincheloe, owner of Ace.

Ace A/C & Heating saves

Precision Drilling, which maintains and services 226 drilling

rigs, 229 service rigs and 28 snubbing units at its Technical

Support Center, had considered using the inventory module

for SAP's R/3 enterprise resource planning software, but it was overly complex. Yet the department

needed a tool to track the often-expensive components used to repair the rigs. When it selected a

barcode-based inventory solution, it eliminated unnecessary replacement of parts that can cost up to

$6,000 each; slashed reliance on overnight and second-day shipping for replacement parts, and is

able to track failure rates, maintenance schedules and save time previously spent locating parts, said

Lee Letawsky, parts technician and purchaser.

If a manufacturer recalls a part or there is a problem with a replacement-component, companies that

track replacement parts by serial number can easily locate these questionable parts. Companies can

rapidly search each piece's transaction history to determine when it was installed, who installed it,

and which supplier provided the part. This protects the business and its clients, further improving

customer service and cementing the client-seller relationship.

On the Market

Mention inventory, and most people immediately think of retail. And inventory is one of retailers'

biggest assets – and expenses. Advanced inventory management or inventory optimization is second

only to product quality in importance to retailers, researcher IDC found.

more than $40,000 per year

with the barcode-based system

So it's not surprising that retailers and distributors need quality solutions to track their inventory.

Mistakes cost money and time: $60 billion worldwide may be lost due to stock-outs driven by issues

rooted in retail floor inventory management, VDC Research Group found.

www.waspbarcode.com

6

Page 8

Taking Stock of Your Inventory

Rod Works needed a POS and inventory-control system for its four retail stores, two clearance

outlets, warehouse, and headquarters. It opted for an integrated solution that delivered automated

inventory tracking, e-mail invoices, and report generation, and worked with vendor-generated

barcodes. By leveraging integration between the POS system and warehouse database, Rod Works

automatically knew which items needed restocking in its stores so popular goods didn't remain on

warehouse shelves instead of shop shelves. This allowed the retailer to quickly restock hot-selling

items or free-up valuable shelf-space for faster moving products.

"As a result, we have realized a 65% reduction in the man-hours used for picking items for stores,"

said Aaron Brackett, retail director for Rod Works.

Likewise, the Sunglasses Shop got a return on its POS and inventory solution faster than expected,

said Daniel Puddick, director of the high-end retailer. Regular audits helped to eliminate stock errors

and the improved records and enhanced reporting have allowed the store to boost sales 200%.

“I was hoping the system would pay for itself in a year, but realistically, it had more than paid for

itself in just two months," he said.

Conclusion

You've invested in the products and equipment stored throughout your company and its warehouses,

and it also makes sense to invest in the resources to accurately and efficiently monitor, analyze and

swiftly locate these items. Today's inventory technologies allow you to track stock in your

company – while also improving cash flow, enhancing customer satisfaction, boosting productivity

and saving a lot of money.

Contacting Wasp Barcode Technologies

Wasp Barcode Technologies

1400 10th St.

Plano, TX 75074

© 2010 Wasp Barcode Technologies. All rights reserved. Wasp and the Wasp logo are registered trademarks of Wasp Barcode

Technologies. Windows is a registered trademark of Microsoft Corporation. Other brands and products are trademarks of their

respective holders. Product specifications and features are subject to change without notice. No part of this publication may be

copied, or used in any form or by any means, without the express written permission of Wasp Barcode Technologies.

Phone:

Fax: 214.547.4101

Web: www.waspbarcode.com

866.547.9277

7

866.547.9277

Loading...

Loading...