Page 1

InventoryControl Printable Help

Page 2

Copyright © 2011

Wasp Barcode Technologies

th

1400 10

Plano, TX 75074

All Rights Reserved

St.

STATEMENTS IN THIS DOCUMENT REGARDING THIRD PARTY PRODUCTS OR SERVICES ARE BASED ON INFORMATION

MADE AVAILABLE BY THIRD PARTIES. WASP BARCODE TECHNOLOGIES AND ITS AFFILIATES ARE NOT THE SOURCE OF

SUCH INFORMATION. THE INFORMATION IN THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE.

Wasp Barcode Technologies, the Wasp logo, InventoryControl and Labeler are registered trademarks and/or trademarks of Wasp

Barcode Technologies in the United States and other countries. Other parties’ trademarks are the property of their respective

owners.

Software activation system licensed under Patent No. 5,490,216

Terms, conditions, features, hours and contact information in this document are subject to change without notice. Wasp is

committed to providing great products and exceptional customer service. Occasionally we may decide to update our selection and

change our service offerings so please check

InventoryControl Install Key ________________________

(Printed on shipped material)

InventoryControl Registration Key ________________________

(Obtained from www.waspbarcode.com\register

www.waspbarcode.com

)

for the latest information.

Page 3

Table of Contents

Chapter 1 - Getting Started...........................................................................................................................1

1.1 Introduction..........................................................................................................................................1

1.2 User Log On........................................................................................................................................1

1.3 Using the Sample Company................................................................................................................2

1.4 Set Up Cycle Overview........................................................................................................................3

1.5 Step One - Create Users.....................................................................................................................4

1.6 Step Two - Enter Company Information..............................................................................................4

1.7 Step Three - Define Sites and Locations.............................................................................................4

1.8 Step Four - Add Users.........................................................................................................................5

1.9 Step Five - Print Location Labels ........................................................................................................6

1.10 Step Six - Enter Suppliers.................................................................................................................6

1.11 Step Seven - Print the Supplier Report.............................................................................................6

1.12 Step Eight - Create Items..................................................................................................................6

1.13 Step Nine - Print Item Labels ............................................................................................................7

1.14 Step Ten - Add Inventory .................................................................................................................7

1.15 Step Eleven - Print the Inventory by Location Report.......................................................................8

Chapter 2 - Introductory Materials ................................................................................................................9

2.1 Barcode Best Practices.......................................................................................................................9

2.2 What is a Barcode?...........................................................................................................................10

2.3 Choosing a Label Printer...................................................................................................................11

2.4 Designing and Labeling Sites and Locations....................................................................................12

2.4.1 What is a Site?............................................................................................................................12

2.4.2 What is a Location? ....................................................................................................................12

2.4.3 Labeling Sites and Locations......................................................................................................12

i

Page 4

2.5 Identifying Tracki

2.6 Labeling Items...................................................................................................................................15

2.7 Using Cost Tracking and Average Costing FAQ...............................................................................16

2.8 Using Custom Fields .........................................................................................................................22

2.9 System Administrator Information.....................................................................................................24

Chapter 3 - Business Examples..................................................................................................................25

3.1 About Our Business Examples..........................................................................................................25

3.2 Business Example Overviews...........................................................................................................25

3.3 Setting Up Security Privileges Business Example............................................................................27

3.4 Setting Up Sites and Locations Business Examples.........................................................................30

3.5 Setting Up Suppliers Business Examples.........................................................................................32

3.6 Entering Items Business Examples...................................................................................................33

ng Needs................................................................................................................14

Chapter 4 - PC Operation Basics................................................................................................................34

4.1 User Log On......................................................................................................................................34

4.2 About the About Screen ....................................................................................................................36

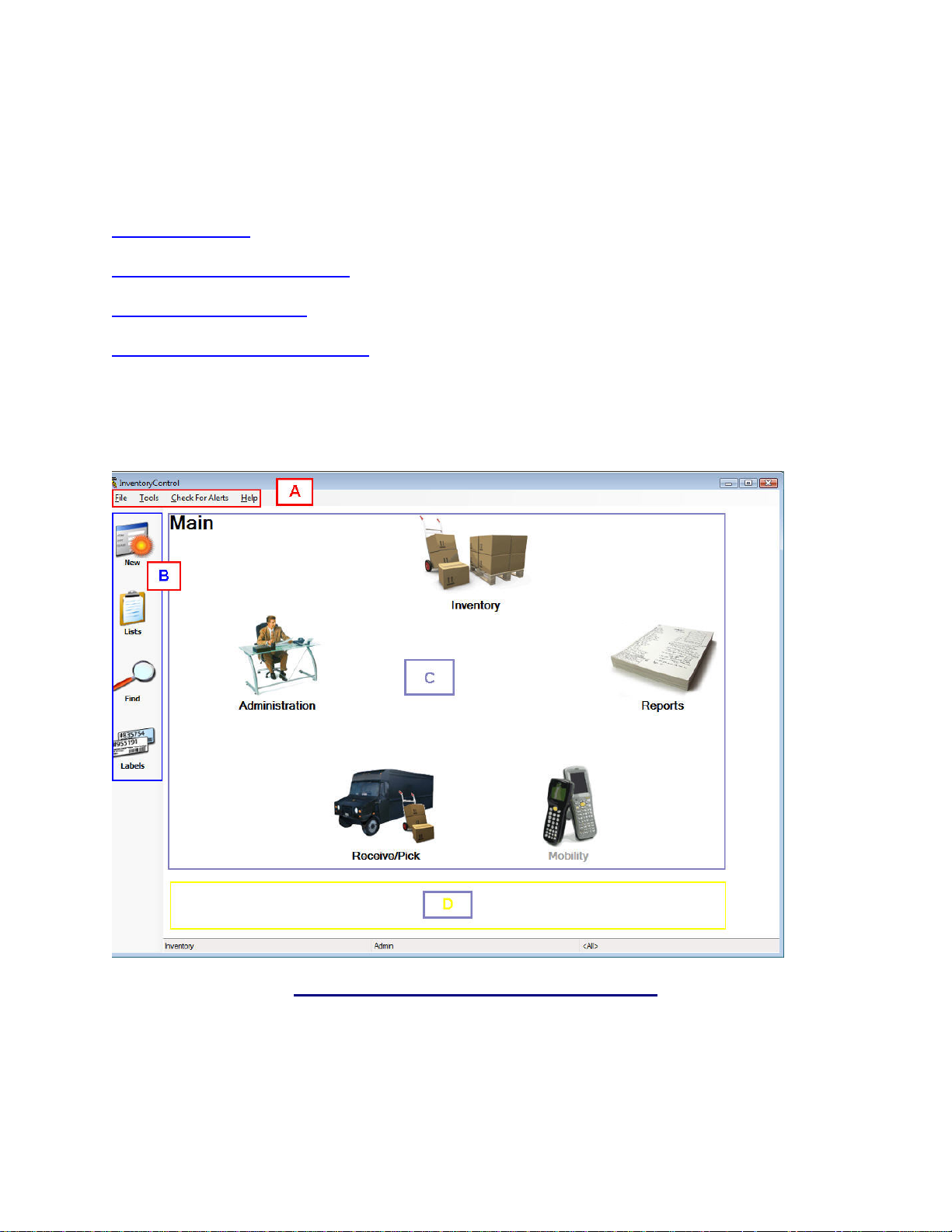

4.3 Main Screen ......................................................................................................................................38

4.3.1 Section A: Toolbar ......................................................................................................................39

4.3.2 Section B: Left-Hand Navigation.................................................................................................39

4.3.3 Section C: Main Functions..........................................................................................................40

4.3.4 Section D: Context-Sensitive Menus..........................................................................................40

4.5 Update License Screen.....................................................................................................................43

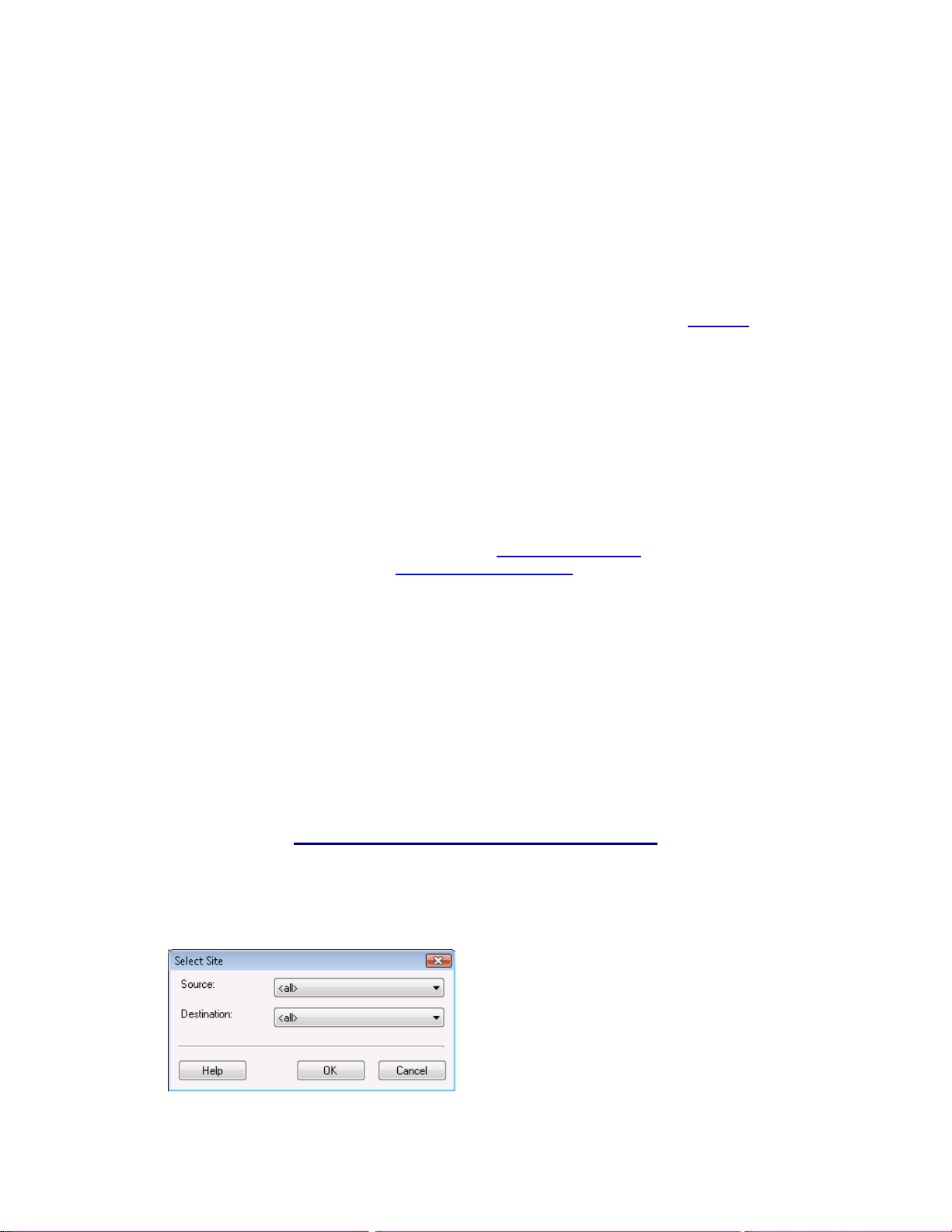

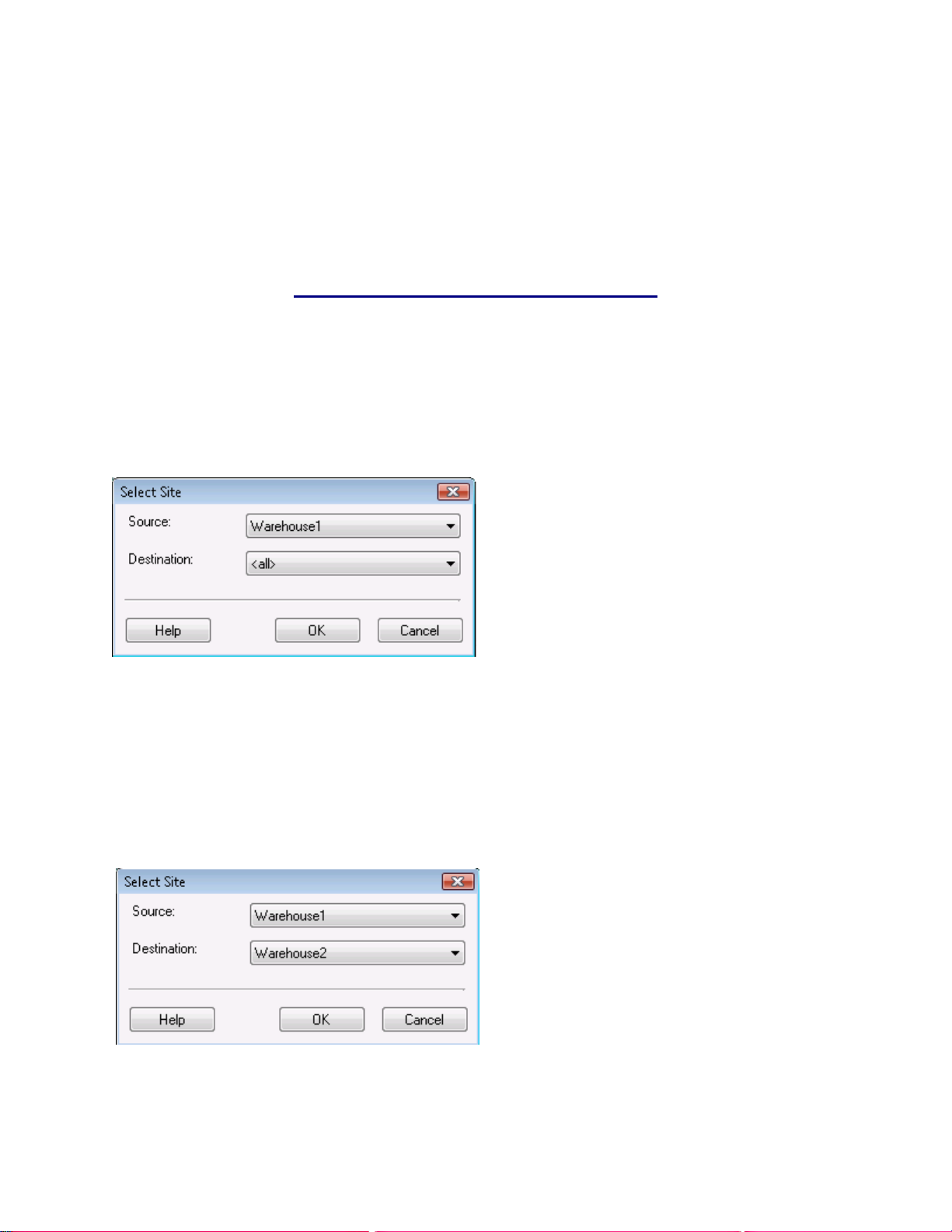

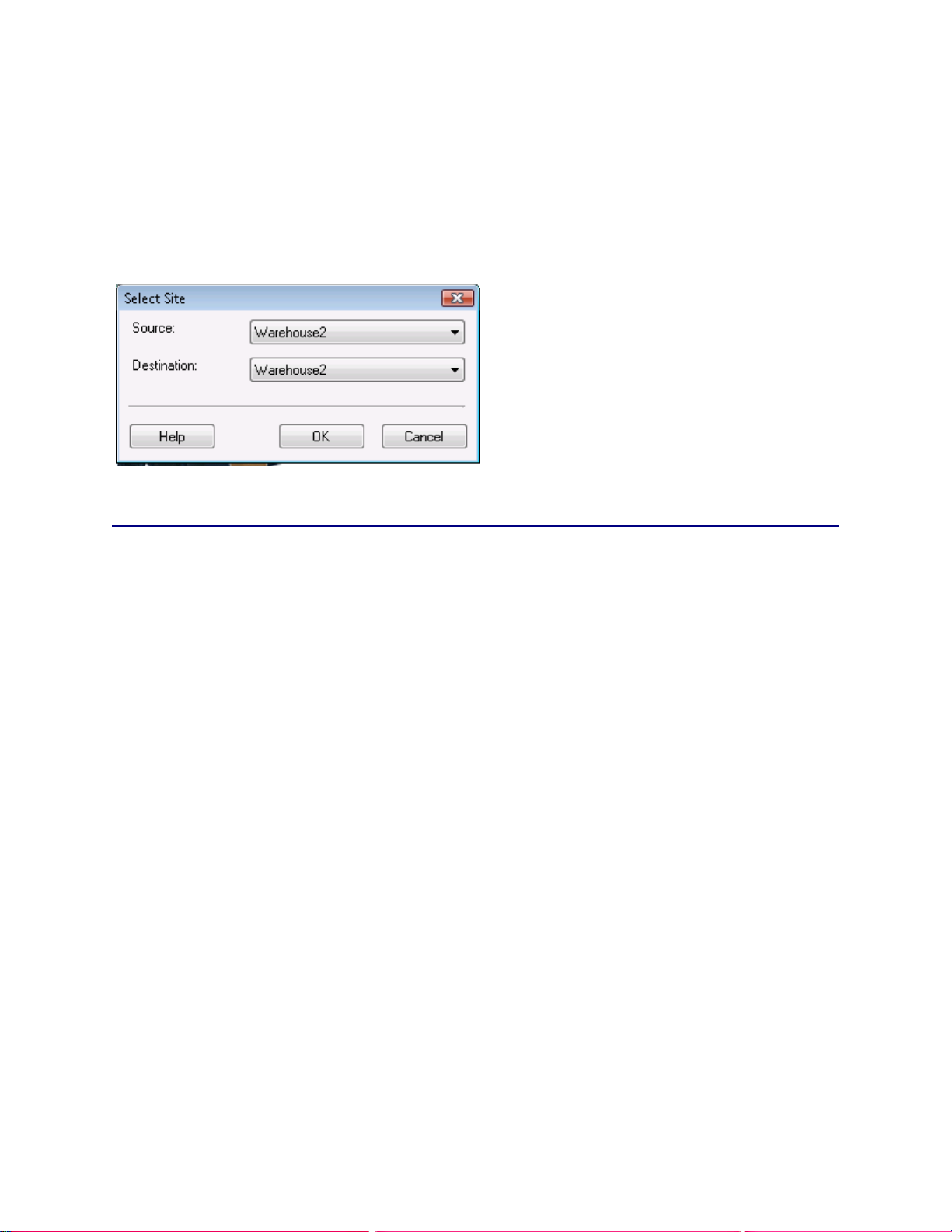

4.6 Selecting Sites...................................................................................................................................45

4.6.1 How to Select Sites:....................................................................................................................45

4.6.2 Source and Destination Examples:.............................................................................................46

4.7 Logging Out.......................................................................................................................................48

ii

Page 5

4.8 Check

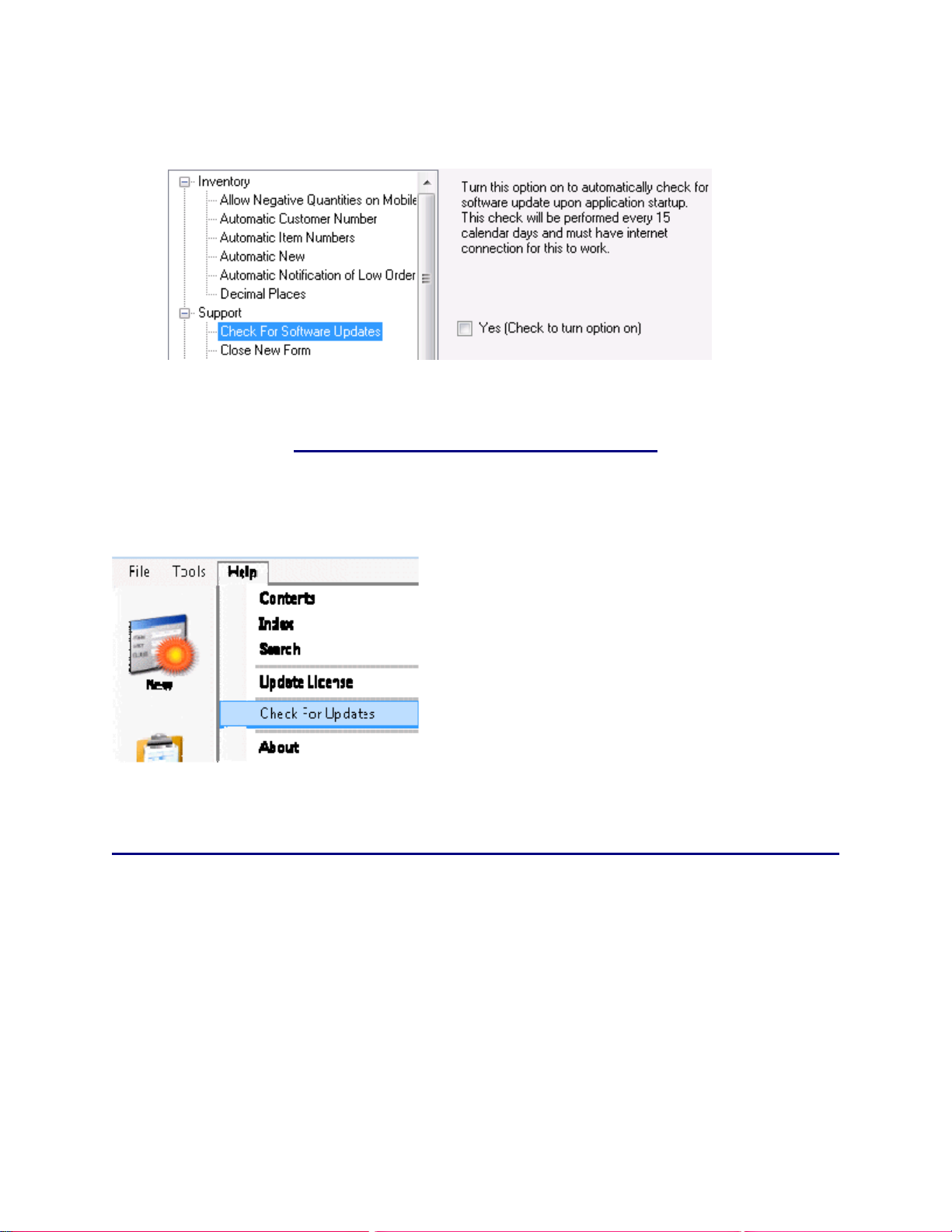

4.8.1 Disabling the Automatic Version Check Feature:.......................................................................49

4.8.2 Performing a Manual Check:......................................................................................................50

4.9 Item Stock Level List Screen.............................................................................................................51

4.10 Alerts ...............................................................................................................................................52

4.11 Adding Notes...................................................................................................................................54

Chapter 5 - Creating New Data...................................................................................................................55

5.1 Creating a New Site...........................................................................................................................55

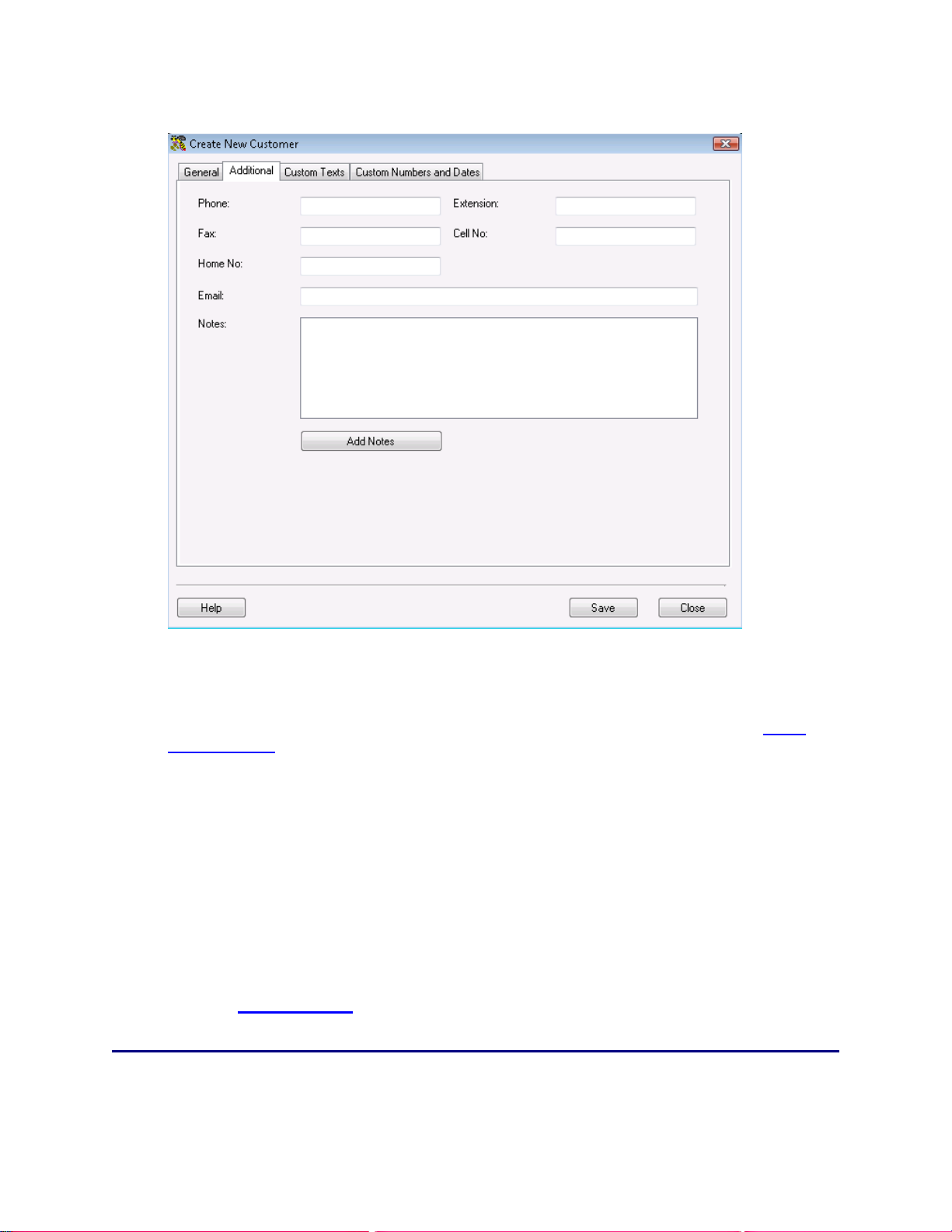

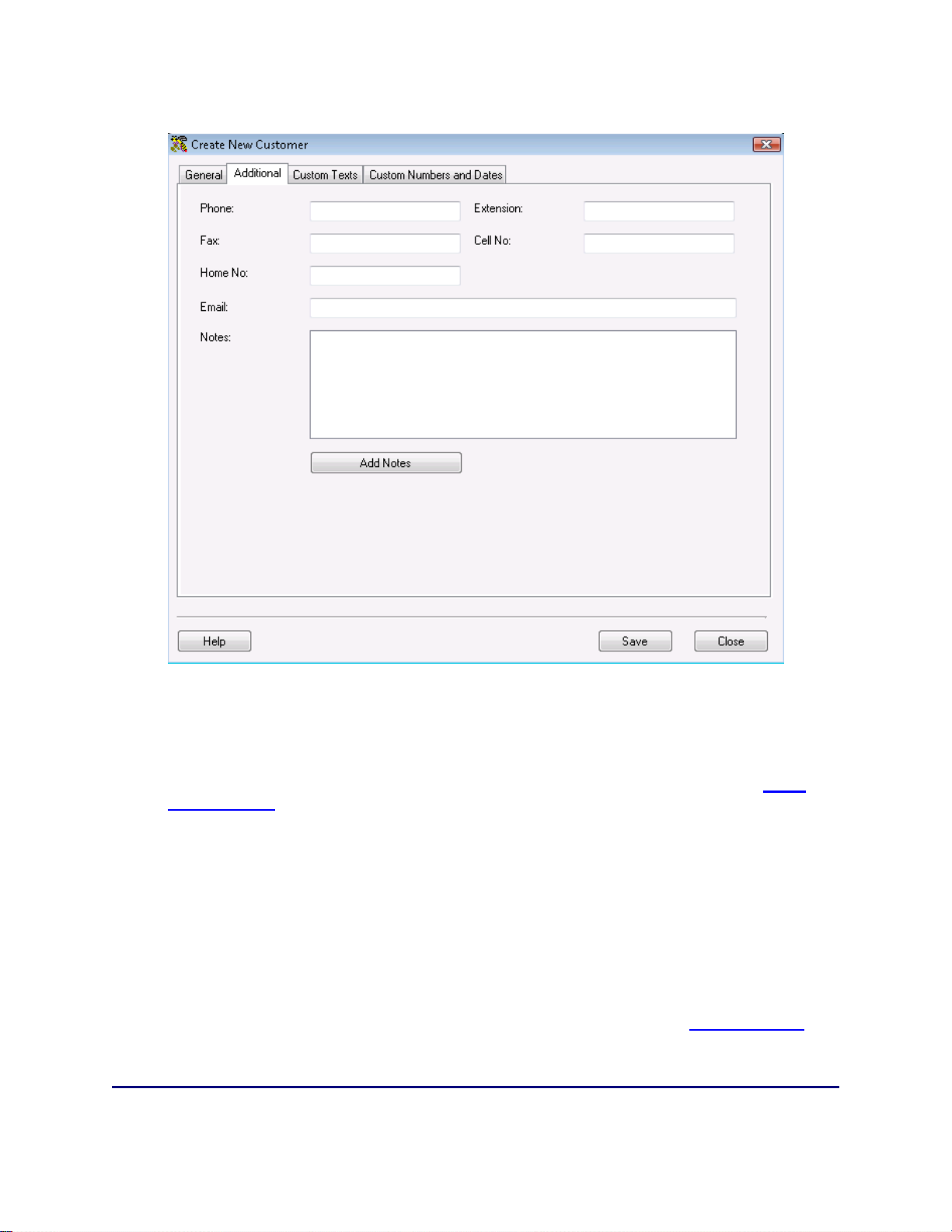

5.2 Creating New Customers..................................................................................................................57

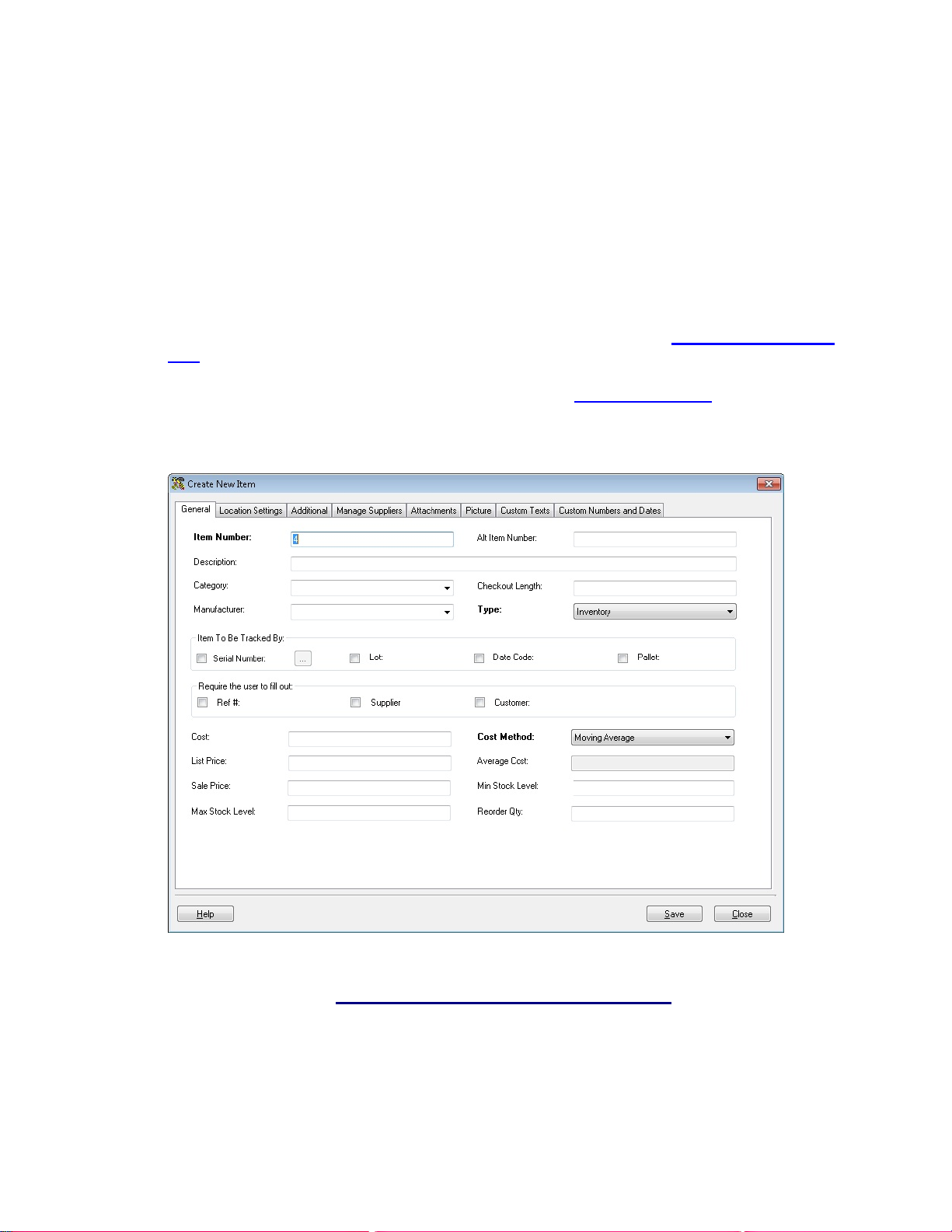

5.3 Creating New Inventory and Non-Inventory Items............................................................................60

5.3.1 Accessing the Create New Item Screen:....................................................................................61

5.3.2 General Information Tab:............................................................................................................62

ing for Software Updates.........................................................................................................49

5.3.3 Location Settings Tab:................................................................................................................66

5.3.4 Additional Information Tab:.........................................................................................................68

5.3.5 Manage Suppliers Tab:...............................................................................................................70

5.3.6 Custom Text and Custom Numbers and Dates Tab:..................................................................72

5.3.7 Saving the New Item:..................................................................................................................72

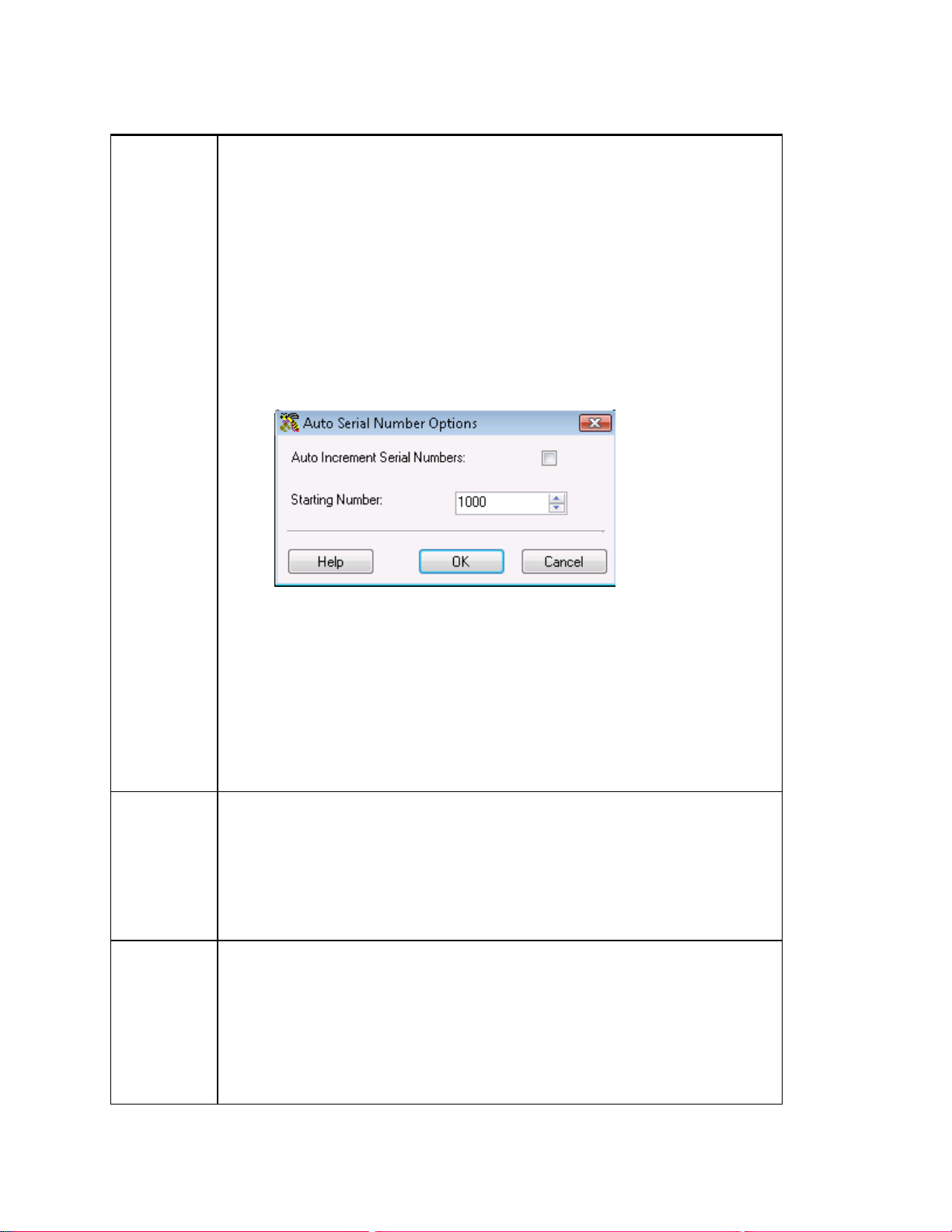

5.6 Automatic Serial Numbers.................................................................................................................73

5.7 Creating New Locations....................................................................................................................74

5.8 Creating New Manufacturers.............................................................................................................76

5.8 Creating New Suppliers.....................................................................................................................80

Chapter 6 - Editing Data..............................................................................................................................84

6.1 Editing Items......................................................................................................................................84

6.2. Editing Assembly Items....................................................................................................................84

6.3 Editing Kit Items.................................................................................................................................85

iii

Page 6

6.4 Editing Sites

6.5 Editing Locations (or a Site and Location).........................................................................................85

6.6 Edit Customer....................................................................................................................................86

6.7 Editing Suppliers................................................................................................................................86

6.8 Editing Manufacturers........................................................................................................................86

6.9 Editing Pick Orders............................................................................................................................86

6.10 Editing Purchase Orders.................................................................................................................87

Chapter 7 - Assembly Items........................................................................................................................88

7.1 Assembly Overview...........................................................................................................................88

7.2 Creating an Assembly Item...............................................................................................................89

7.2.1 Accessing the New Assembly Item Screen:...............................................................................90

7.2.2 General Information Tab:............................................................................................................91

.......................................................................................................................................85

7.2.3 Location Settings Tab:................................................................................................................95

7.2.4 Assembly Tab:............................................................................................................................97

7.2.5 Additional Information Tab:.........................................................................................................99

7.2.6 Manage Suppliers Tab:.............................................................................................................101

7.2.7 Custom Text and Custom Numbers and Dates Tab:................................................................102

7.2.8 Saving the New Item:................................................................................................................102

7.3 Building Assembly Items .................................................................................................................103

7.4 Disassembling Assembly Items.......................................................................................................107

Chapter 8 - Using the List Screens...........................................................................................................112

8.1 Working with Lists............................................................................................................................112

8.1.1 Section A: Toolbar ....................................................................................................................113

8.1.2 Section B: Contents List ...........................................................................................................119

8.1.3 Section C: Buttons:...................................................................................................................121

iv

Page 7

8.1.4 Context

8.2 Item List Example............................................................................................................................123

8.3 Inventory List Example....................................................................................................................124

8.4 Site List Example.............................................................................................................................125

8.5 Location List Example .....................................................................................................................126

8.6 Customer List Example ...................................................................................................................127

8.7 Manufacturer List.............................................................................................................................128

8.8 Supplier List.....................................................................................................................................129

8.9 Pick Order List Example..................................................................................................................130

8.10 Purchase Order List Example .......................................................................................................131

8.11 Transaction List Example..............................................................................................................132

Chapter 9 - Inventory ................................................................................................................................133

-Sensitive Menus:.........................................................................................................121

9.1 Inventory Menu................................................................................................................................133

9.2 Manually Adding Inventory..............................................................................................................135

9.3 Removing Inventory.........................................................................................................................140

9.4 Moving Inventory.............................................................................................................................144

9.5 Checking In Inventory......................................................................................................................148

9.6 Checking Out Inventory...................................................................................................................152

9.7 Adjusting Inventory Amounts...........................................................................................................156

9.7.1 Adjusting Inventory:..................................................................................................................156

9.7.2 Duplicate Serial Numbers Warning:..........................................................................................160

Chapter 10 - Kit Items...............................................................................................................................161

10.1 Kitting Overview.............................................................................................................................161

10.2 Creating a Kit Item.........................................................................................................................163

10.2.1 Accessing the Create New Items Screen:..............................................................................163

v

Page 8

10.2.2 Kit Inf

10.2.3 Additional Information Tab:.....................................................................................................168

10.2.4 Custom Text and Custom Numbers and Dates Tab:..............................................................169

10.2.5 Saving the New Item:..............................................................................................................169

10.3 Removing Kit Items .......................................................................................................................170

Chapter 11 - Pick Orders ..........................................................................................................................174

11.1 Pick Order Overview......................................................................................................................174

11.2 Creating a Pick Order....................................................................................................................175

11.3 Editing Pick Orders........................................................................................................................179

11.4 Pick Order List Example................................................................................................................180

11.5 Picking Orders...............................................................................................................................181

Chapter 12 - Purchase Orders/Receiving..............................................................................................185

ormation Tab: ................................................................................................................166

12.1 Purchase Orders/Receiving Overview ..........................................................................................185

12.2 Creating a New Purchase Order...................................................................................................188

12.3 Editing Purchase Orders...............................................................................................................192

12.4 Purchase Order List Example .......................................................................................................193

12.5 Receiving Inventory from Purchase Orders ..................................................................................194

12.6 Purchase Order FAQ.....................................................................................................................198

12.7 Deleting Purchase Orders/Pick Orders.........................................................................................199

12.8 Receive/Pick Menu........................................................................................................................200

12.9 Managing Payment Methods.........................................................................................................202

12.9 Managing Payment Methods.........................................................................................................202

12.9.1 Adding Payment Methods:......................................................................................................202

12.9.2 Deleting/Printing/Exporting Payment Methods:......................................................................203

12.10 Managing Shipping Methods.......................................................................................................206

vi

Page 9

12.10.1 Adding Shipping Methods

12.10.2 Deleting/Printing/Exporting Ship Methods:...........................................................................207

12.11 Formatting PO and Pick Order Numbers....................................................................................210

12.12 Email Distribution List..................................................................................................................213

Chapter 13 - Creating/Editing/Printing Labels...........................................................................................214

13.1 Selecting a Label Printer...............................................................................................................214

13.2 Using the Labels Menu..................................................................................................................215

13.2.1 Editing Labels: ........................................................................................................................215

13.2.2 Creating Custom Labels:........................................................................................................216

13.2.3 Browsing to an Existing Label:................................................................................................217

13.3 Printing Labels from the List Screens............................................................................................218

Chapter 14 - Reports.................................................................................................................................220

:....................................................................................................206

14.1 Report Selection............................................................................................................................220

14.2 Report Viewer................................................................................................................................221

Chapter 15 - Administration ......................................................................................................................225

15.1 Administration Menu......................................................................................................................225

15.2 Company Information Screen........................................................................................................227

15.2.1 Entering Company Information:..............................................................................................227

15.2.2 Entering Multiple Address Types:...........................................................................................228

15.2.3 Deleting an Address Type: .....................................................................................................229

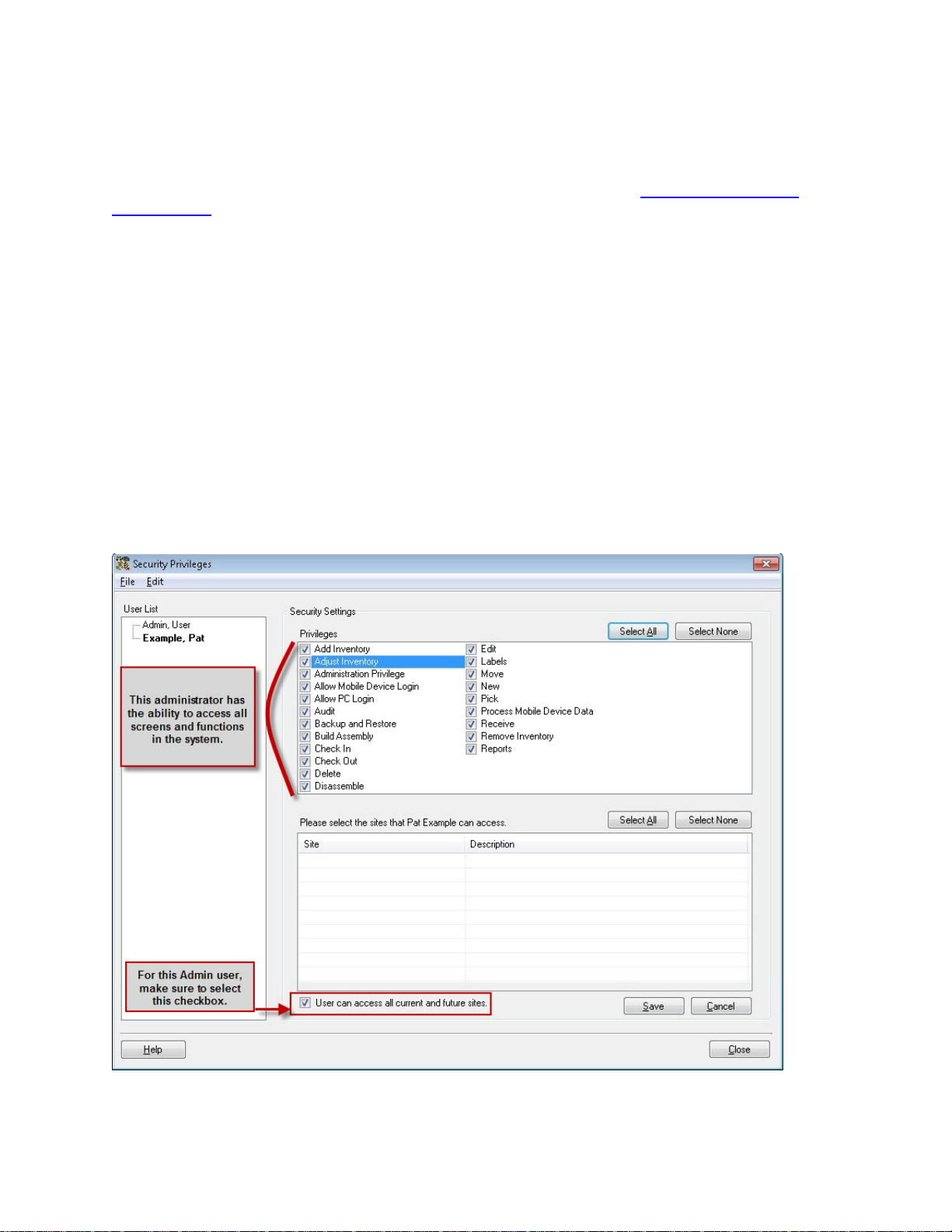

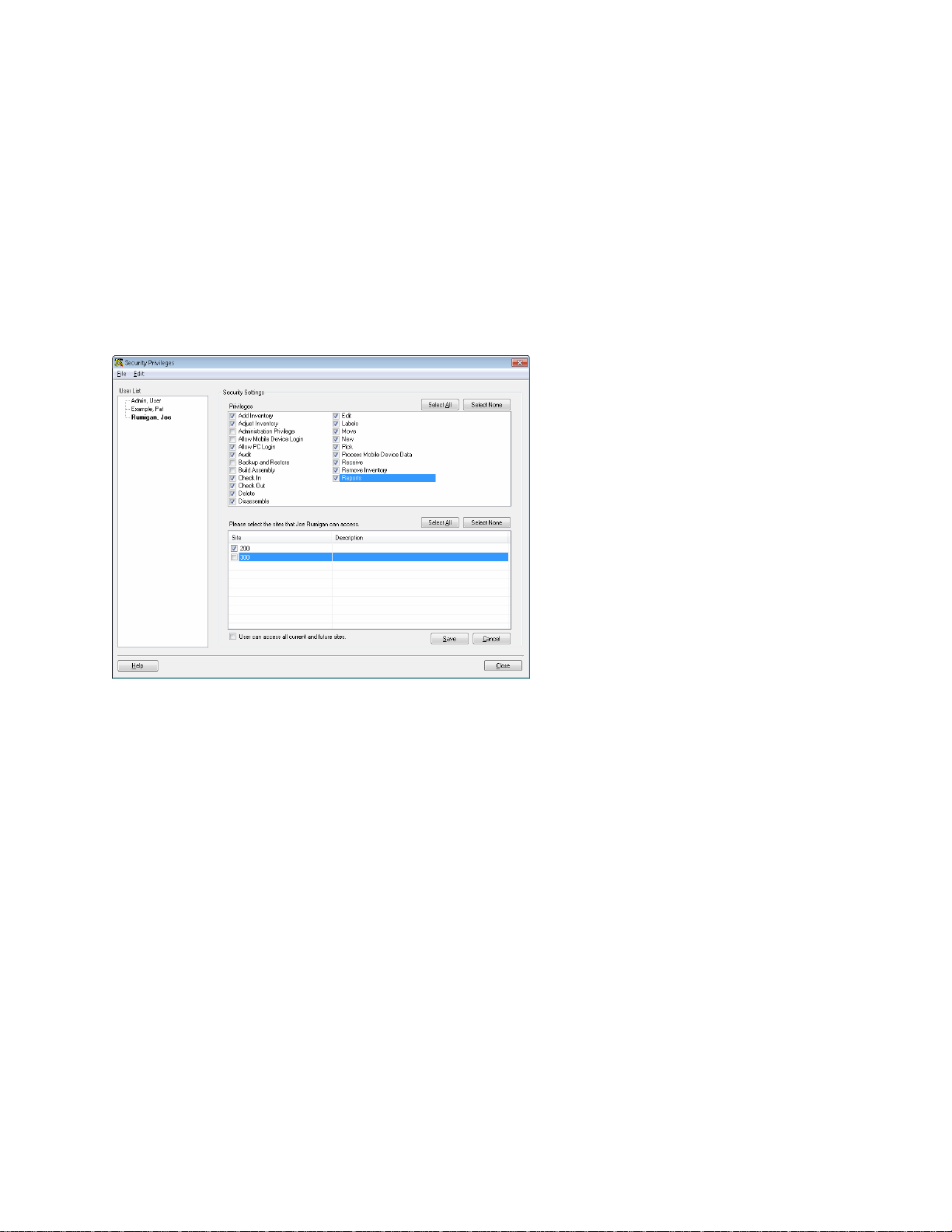

15.3 Adding Users/Editing Security Privileges......................................................................................230

15.3.1 Accessing the Security Privileges Screen:.............................................................................230

15.3.2 Adding Users to the Security Privileges Screen:....................................................................231

16.3.3 Editing User Profiles on the Security Privileges Screen:........................................................233

15.3.4 Making Users Inactive: ...........................................................................................................234

vii

Page 10

15.3.5 Copying Us

15.3.6 Security Privileges Definitions: ...............................................................................................235

15.4 Backing up the Database..............................................................................................................236

15.5 Restore the Database ...................................................................................................................237

15.6 Options Screen..............................................................................................................................238

15.6.1 Accessing the Options Screen:...............................................................................................240

15.6.2 Allow Negative Quantities on Mobile Devices........................................................................241

15.6.3 Allow Over Pick.......................................................................................................................242

15.6.4 Allow Over Receive ................................................................................................................242

15.6.5 Automatic Customer Number .................................................................................................242

15.6.6 Automatic Item Numbers:.......................................................................................................242

15.6.7 Automatic New........................................................................................................................242

er Security Profiles:..............................................................................................234

15.6.8 Automatic Notification of Low Order Items .............................................................................243

15.6.9 Decimal Places.......................................................................................................................243

15.6.10 Enforce Date Code as a True Date ......................................................................................243

15.6.11 Item Cost When Add Inventory from Mobile Device:............................................................243

15.6.12 Packing Slip for Session:......................................................................................................244

15.6.13 Transaction Code List:..........................................................................................................244

15.6.14 Check for Software Updates:................................................................................................244

15.6.15 Close New Form:..................................................................................................................244

15.6.16 Edit Field Names: .................................................................................................................245

15.6.17 Max Row Count:...................................................................................................................245

15.6.18 Previously Processed Mobile Data:......................................................................................245

15.6.19 Show Cost Information During Receiving:............................................................................246

15.6.20 Show Warning Messages:....................................................................................................246

viii

Page 11

15.6.21 SQL

15.6.23 Packing Slip CC Emails:.......................................................................................................247

15.6.24 Pick Order CC Emails:..........................................................................................................247

15.6.25 Purchase Order CC Emails: .................................................................................................247

15.6.26 SMTP Password:..................................................................................................................247

15.6.27 SMTP Port: ...........................................................................................................................247

15.6.28 SMTP Server: .......................................................................................................................247

15.6.29 SMTP SSL/TSL:....................................................................................................................247

15.6.30 SMTP User: ..........................................................................................................................248

15.7 Archiving Transactions..................................................................................................................249

15.8 Editing Field Names ......................................................................................................................250

15.8.1 Editing Field Names:...............................................................................................................250

Server Backup Location: ..............................................................................................246

15.8.2 Resetting Field Names to their Default Values:......................................................................252

15.9 Using Custom Fields .....................................................................................................................253

Chapter 16 - Importing/Exporting..............................................................................................................256

16.1 Importing Into the Database..........................................................................................................256

16.1.1 Tips for Importing Data:..........................................................................................................256

16.1.2 How to Import Data:................................................................................................................257

16.1.3 Required Import Fields: ..........................................................................................................261

16.1.4 Handling Import Errors:...........................................................................................................261

16.1.5 Notes on Importing Inventory:.................................................................................................262

16.2 Exporting to a Text File .................................................................................................................263

16.3 Related Data Fields.......................................................................................................................267

16.4 Import Specifics.............................................................................................................................269

16.4.1 Customer Import Format:........................................................................................................269

ix

Page 12

16.4.2 Inventory Import Format:

16.4.3 Item Import Format: ................................................................................................................271

16.4.4 Location Table Properties:......................................................................................................272

16.4.5 Manufacturer Table Properties:..............................................................................................273

16.4.6 Supplier Table Properties:......................................................................................................274

16.4.7 Data Type Definitions: ............................................................................................................275

Chapter 17 - Performing an Audit......................................................................................................278

17.1 Auditing Your Inventory.................................................................................................................278

17.2 Audit Flow Overview.....................................................................................................................279

17.3 Beginning the Audit .......................................................................................................................279

17.4 Using the Audit Screen..................................................................................................................280

17.5 Reviewing the Not Counted Items Report.....................................................................................283

........................................................................................................270

17.6 Reconciling the Counts .................................................................................................................283

17.7 Reviewing the Remainder of the Audit Reports............................................................................285

17.8 Ending the Audit............................................................................................................................285

Chapter 18 - Search Function...................................................................................................................286

18.1 Searching for Information..............................................................................................................286

18.2 Advanced Find...............................................................................................................................288

Chapter 19 – WDT2200............................................................................................................................291

19.1 WDT2200 - Setup the Device........................................................................................................291

19.2 WDT2200 - Creating the PDT Database.......................................................................................294

19.3 WDT2200 - Sending Data to PDT.................................................................................................299

19.4 WDT2200 - Receiving Data from PDT..........................................................................................304

19.5 WDT2200 - Data Cycle .................................................................................................................307

19.6 WDT2200 - Logging On ................................................................................................................307

x

Page 13

19.7 WDT2200 - Res

19.8 WDT2200 - Setting the Date and Time.........................................................................................310

19.9 WDT2200 - Main Menu.................................................................................................................313

19.10 WDT2200 - Interface...................................................................................................................314

19.11 WDT2200 - About Screen...........................................................................................................315

19.12 WDT2200 - Site Configuration ....................................................................................................315

19.13 WDT2200 - Adding Inventory......................................................................................................317

19.14 WDT2200 - Details Screen..........................................................................................................325

19.14.1 Viewing Details for Items with Tracked By options disabled: ...............................................325

19.14.2 Viewing Details for Items with One or More Tracked By Options Enabled: .........................327

19.15 WDT2200 - Adjusting Inventory ..................................................................................................329

19.16 WDT2200 - Auditing Inventory....................................................................................................336

etting the Device..................................................................................................308

19.17 WDT2200 - Moving Inventory......................................................................................................343

19.18 WDT2200 - Removing Inventory.................................................................................................351

19.19 WDT2200 - Removing Kit Items..................................................................................................359

19.20 WDT2200 - Picking Inventory for Orders ....................................................................................367

19.21 WDT2200 - Picking Kit Items ......................................................................................................373

19.22 WDT2200 - Receiving Inventory .................................................................................................380

Chapter 20 - Windows Mobile Device......................................................................................................386

20.1 Windows Mobile Device Data Cycle - Batch Device (No Wireless Connection)...........................386

20.2 Windows Mobile Device Data Cycle - Wireless Connection........................................................386

20.3 Windows Mobile Device - Interface...............................................................................................387

20.4 Windows Mobile Device - Default Settings ...................................................................................389

20.5 Windows Mobile Device - Rebooting.............................................................................................389

20.6 Windows Mobile Device - Enabling the Scanner ..........................................................................389

xi

Page 14

20.7 Windows Mobile

20.8 Setup and Synchronization Information ........................................................................................393

20.8.1 Batch Windows Mobile Device Synchronization.....................................................................393

20.8.2 Batch Windows Mobile Device - Setup the Mobile Device.....................................................394

20.8.3 Batch Windows Mobile Device - Sending the Database from the PC....................................403

20.8.4 Batch Windows Mobile Device - Retrieving Data from the Device.........................................409

20.8.5 Batch Pending Uploads Screen..............................................................................................411

20.8.6 Batch Mobile Devices Pending Uploads - Edit Transactions .................................................415

20.9 Wireless Devices...........................................................................................................................418

20.9.1 Windows Mobile Device Wireless Setup ................................................................................418

20.9.2 Enabling InventoryControl RF to Communicate with your Network Printer............................421

20.10 Tips for Setting Up and Using Windows Mobile Devices............................................................426

Device - Entering Alphanumeric Data................................................................392

20.10.1 WDT3200, 3200II, 3250 and 3250II Tips..............................................................................426

20.10.2 WPA1000 and WPA1000II Tips............................................................................................429

20.10.3 WDT1200, 1250, 1200II and 1250II......................................................................................435

20.11 Using InventoryControl and InventoryControl RF .......................................................................436

20.11.1 Windows Mobile Device - About Screen ..............................................................................436

20.11.2 Windows Mobile Device - Site Configuration........................................................................437

20.11.3 Windows Mobile Device - Pinning Fields..............................................................................438

20.11.4 Windows Mobile Device - Adding New Customers ..............................................................439

20.11.5 Windows Mobile Device - Adding a New Location...............................................................440

20.11.6 Windows Mobile Device - Adding New Suppliers.................................................................442

20.11.7 Windows Mobile Device - Adding Inventory.........................................................................443

20.11.8 Windows Mobile Device - Details Screen.............................................................................446

20.11.9 Windows Mobile Device - Checking Out Inventory...............................................................448

xii

Page 15

20.11.10 Windows Mobile Device - Checking In Inventory ...............................................................449

20.11.11 Windows Mobile Device - Moving Inventory......................................................................450

20.11.12 Windows Mobile Device - Removing Inventory..................................................................453

20.11.13 Windows Mobile Device - Removing a Kit Item..................................................................458

20.11.14 Windows Mobile Device - Receiving Inventory...................................................................461

20.11.15 Windows Mobile Device - Picking Items for Orders............................................................465

20.11.16 Windows Mobile Device - Picking Kit Items........................................................................468

20.11.17 Windows Mobile Device - Adjusting Inventory Quantities..................................................473

20.11.18 Windows Mobile Device - Auditing Inventory .....................................................................477

20.11.19 Windows Mobile Device - Searching for Information..........................................................482

20.12 Windows Mobile Device Troubleshooting...................................................................................485

Chapter 21 - Glossary...............................................................................................................................492

Index..........................................................................................................................................................495

xiii

Page 16

InventoryControl Printable Help

Chapter 1 - Getting Started

1.1 Introduction

We recommend that you read the information found in the Introductory Materials section of this Help file

and view the Getting Started prior to beginning setup of your system. The Introductory Materials and

video tutorials define key terms and explain concepts used throughout InventoryControl. These mate rials

provide valuable information to make the setup process smooth and simple.

In addition to explaining key terms and concepts, the Introductory Materials provide tips for creating your

inventory tracking system and provides real-world business examples detailing how you can customize

InventoryControl to work best for your needs. You will also find information on recommended guidelines

for creating barcodes in the Barcode Best Practices

your software you will find links to Business Examples. These examples detail how different business

types, using different versions of InventoryControl, setup their sites, locations, items, et c.

After you have reviewed these materials, click the Begin InventoryControl Set Up link below. A series of

steps will appear guiding you through the set up process. Each step provides a brief overview of the

process along with a link or links to the help topics containing detailed how to and explanatory

information.

section. As you work through the steps to set up

1.2 User Log On

The Log On screen appears when InventoryControl is first started and when you select File > Log Out.

Complete both fields, then click OK to logon to the system.

1

Page 17

InventoryControl Printable Help

The User Name field is not case sensitive.

The Password field is case sensitive. Asterisks will be displayed as you type the Password.

The first time you open InventoryControl you can enter the following information:

User Name: Admin

Password: (blank)

After log on, the password can be changed via File > Change Password.

The Admin account, or any other account with Administration Privilege, can use the Security Privileges

screen to add Users, set their privileges and reset their passwords. For more information on adding

users, please refer to the Adding Users/Editing Security Privileges

topic.

1.3 Using the Sample Company

The Sample Company contains a set of data you can use to learn about InventoryControl. You can

practice working with the features and functions contained in the software using this data.

You can enter information into the Sample Company; however, when upgrading to a new version, this

data will be lost. It is very important that you do not enter any information into the Sample Company that

you do not want to lose. The Sample Company is meant for training purposes only and should not be

used as your working database.

Accessing and Using the Sample Company

On the Log In screen, login as usual, making sure you select the Use Sample Database checkbox.

InventoryControl opens with InventoryControl - Wasp Inventory Sample Inc. displayed in the title bar.

2

Page 18

InventoryControl Printable Help

You can u

check inventory in and out, create purchase orders and pick orders, etc. On reports, the company name

and each address line will be followed by "trial". Mobile devices are not supported by the sample

database.

se the software as normal once logged in. You can create additional items and add inventory,

1.4 Set Up Cycle Overview

After you finish installing your software (using the InventoryControl Quick Start Guide as a reference) you

will need to set up your system by entering information into the software. This is referred to as a "cycle"

because in multi-warehouse installations you will need to repeat steps 3-7 for each site. The set up

process may take hours or even days depending on the size of your organization. While this m ay seem

overwhelming, keep in mind that the return on this time investment will pay off quickly. These steps will

result in a complete and accurate count of inventory that will allow you to start using InventoryControl to

manage your day-to-day business.

Keep in mind that you can continue to use your previous inventory tracking software while you are setting

up InventoryControl. The transition to InventoryControl should take place when you are ready to count

your inventory and enter the counts into the software.

Before starting this process, set aside a day or two when you can stop using the old system and transition

over to InventoryControl. The audit, or inventory counting, step must be done when you are not receiving

or shipping goods. Plan to perform the audit on a weekend or after hours, for example.

Set Up Cycle:

1. Design your barcode labeling system and designate barcode label ranges.

2. Import or input sites, locations, suppliers, manufacturers and customers into

InventoryControl.

3. Print barcodes and label sites and locations.

4. Import or input items, making sure to designate additional tracking needs like serial number

or lot.

5. Use your handheld or a report to do a complete inventory audit.

6. Using the audit results, print barcode labels for items and label every item.

7. Determine the best method of handheld use for your company and implement it.

If the initial setup process seems daunting, there are organizations that specialize in evaluating your

needs and setting up your warehouse for you using InventoryControl. If you need to find an organization

in your area to help with this process, please call Wasp Support and we will help you find an integrator.

3

Page 19

InventoryControl Printable Help

1.5 Step One - Create Users

Add Admin User - When you first log on to InventoryControl, you will use Admin as the user name and

leave the password blank. This default user profile gives you access to everything in the system. The

first step you should take upon logging in is to create at least one additional admin user (Administration

> Security). The new admin user should have rights to all areas of the system. You should also change

the password for the default admin profile. Since the default admin's password is initially blank, it is

important to change the password to prevent other users from logging in under this profile.

1.6 Step Two - Enter Company Information

Enter Company Information - Next you should enter your company's information (Administration >

Company Info). On the Company Information screen you will enter your company's name and any

addresses needed for receiving, shipping, corporate correspondence, etc. The company name you enter

on this screen will appear on all reports and in the title bar of InventoryControl. In addition, if you have

the Pro or Enterprise version of InventoryControl, the company name and addresses you enter will

appear on Pick Orders and Purchase Orders created in the system.

When you set up your company information, you should enter all addresses to which you might receive

inventory, ship inventory, store inventory as well as your corporate address and other business

addresses. Having these addresses entered will save you and your employees a lot of time when

creating purchase orders and pick orders and when moving, picking, receiving, adding and removing

inventory.

1.7 Step Three - Define Sites and Locations

Define Sites and Define Locations - Now you are ready to begin entering sites and locations into the

database. Locations are the areas into which you will assign inventory, while sites contain the various

locations. Usually a site is a warehouse or other building, but it can be an office, a truck, a field, etc.

We suggest creating one site for each building or structure that contains inventory. InventoryControl

requires that you define at least one site containing at least one location. You can also have multiple

sites that contain multiple locations. There is no limit to the number of locations you can assign to a site.

View Business Examples

Note: WaspNest Inventory only supports one Site.

A location is typically shorthand for a physical place such as a shelf in your warehouse. Commonly used

conventions include Location codes like this:

01 02 05 (for Row #, Shelf #, Bin #)

For the purposes of keeping track of your inventory items, your locations should represent the placement

within the site. If your site is a warehouse, the locations are shelves or racks. If your site is a building,

the locations may be offices. If you have a fleet of trucks, the locations may be containers in the truck.

When deciding how to label each location, choose a numbering scheme that can be interpreted when

reading just the label. For example, if you have 7 rows of 5 shelves each and each shelf has four levels,

your barcode label scheme should look like A010200 or row A, shelf 01, level 02, bin 00. If you have

inventory on trucks in containers, the truck can be a site and each bin in the truck is a location. Put a

barcode label on the inside of the truck door so the person moving inventory into or out of the truck can

just scan and move. The barcode label should have the barcode and the human readable text

4

Page 20

InventoryControl Printable Help

ption of the location as well.

descri

A distribution business, for example, typically places inventory at a specific location in one or more

warehouses. InventoryControl requires that you define at least one Site containing at least one Location.

If you have multiple warehouses, you can set each one up as a Site, then create multiple locations within

each site to represent the specific areas where you will be storing inventory. For instance, you might

setup a Site as Warehouse 1 containing Locations Shelf 1, Shelf 2 and Shelf 3.

A fleet business might define each vehicle as a Site with multiple Locations (bins, for example) within

each vehicle. In this case you could setup a Site as Vehicle 1 with Locations of Bin1, Bin2 and Bin3. Or

each vehicle could be a single Location operating out of one or more Sites. For example, the Site might

be Docking 1 with locations of Vehicle 1, Vehicle 2, etc.

A retail business might have multiple Locations at one Site or multiple Locations within each of several

Sites. InventoryControl has the flexibility to be configured however it best suits your business needs.

Remember that though you must have at least one site containing one location, you could have multiple

sites that contain multiple locations. There is no limit to the number of locations you can assign to a site.

It is important to note that you can have the same Location code defined at more than one Site - for

instance, Warehouse 1 and Warehouse 2 may each have Location codes of Shelf 1 - so always pay

attention to which Site you are working with when performing Inventory transactions.

Setting up your locations now will allow you to just pick a location from a list when you begin adding

inventory later. It is possible, however, to define locations as you add inventory. If you would prefer to do

this, skip to Step 6 - Enter Suppliers

If you already have location information contained in another database, you may want to use

InventoryControl's Import function rather than manually entering in this information.

For additional information on formatting your Location numbers and descriptions, please refer to the topic

Barcode Best Practices

.

.

1.8 Step Four - Add Users

Add Users - You should enter all users who will be using the system and you can assign spe c ific rights

to each user that limit their activities to certain functions. It is a good idea to give each user his or her own

user name and password rather than sharing a single user profile, as this allows you to keep track of who

performs specific functions in the system. InventoryControl keeps a detailed transaction history of every

action performed in the software. Each time an item is added, removed, moved, etc., the transaction is

logged by InventoryControl and is listed with the user name of the person who performed the transaction,

the date/time of the transaction and the type of transaction on the Transaction List (Main Screen >

Lists > Transaction List).

View Business Examples

5

Page 21

InventoryControl Printable Help

1.9 Step Five - Print Location Labels

Print Location Labels - If you have set up more than one location and you will be using a mobile device

with an integrated barcode scanner, it is a good idea to create Location labels for each location you have

entered into the system. This allows you to quickly scan a barcode label when auditing or adjusting

inventory at that location or when adding, removing, picking or receiving inventory to or from that location.

For ideas and examples of how to configure your labels, click here.

You can print labels automatically after creating your locations or you can print from the Location List

After printing your labels, attach them to each location. For example, if your locations are shelves, attach

a label to each shelf to identify it.

.

1.10 Step Six - Enter Suppliers

Enter Suppliers - Suppliers are those businesses or individuals from which you will be obtaining your

inventory. Your business might require that each Item in your inventory have an associated supplier. You

can have one supplier or many providing you with inventory.

If you already have supplier information contained in another database, you may want to use

InventoryControl's Import function rather than manually entering in this information.

View Business Examples

1.11 Step Seven - Print the Supplier Report

Print the Supplier Report - If you have chosen to import your suppliers or manually enter all suppliers

prior to adding items, you should print and review the Supplier Report to make sure all the information

was entered correctly. To run the Supplier Report, from the Main screen, select the Reports icon. On

the Select Report

screen, double click Supplier Report.

1.12 Step Eight - Create Items

Create Items - Items represent the actual material or good that you will have in your inventory. The item

is a classification that contains information such as manufacturer, suppliers, a description of the item and

unit of measure information. The item is not part of your inventory until you add quantity to it and specify

a location for it. For example, you might create an Item entry for Mouse - Wireless. Then you can add

inventory, or quantity, to that item at a specific location.

On the Create New Item screen, you can assign the item to multiple locations and even designate one

location as the primary location for this item. The primary location will then pre-populate the screen when

removing, adding, receiving (Pro and Enterprise Version Only) and picking (Pro and Enterprise Version

Only) this item.

If you are using the Enterprise or Professional version of InventoryControl, you can also create items that

are non-inventory. This is useful if you need to create an item for marketing pamphlets, counter displays

or anything you need to have on-hand but don't necessarily want to include in your inventory amounts. In

addition, you can create Kit or Assembly Items. Please refer to the topics Assembly Overview

Kitting Overview

for more information.

and

6

Page 22

InventoryControl Printable Help

If you already have item informatio

InventoryControl's Import function rather than manually entering in this information. For more information

on importing locations, please refer to the topic Importing Into the Database

View Business Examples

n contained in another database, you may want to use

.

1.13 Step Nine - Print Item Labels

Print Item Labels - Labels can be printed directly from InventoryControl via the Item List screen, at the

time a new Item is created or you can access Wasp Labeler to edit or create new labels.

1.14 Step Ten - Add Inventory

Add Inventory - Now that your items have been created, you are ready to add inventory, or quantity to

those items at specific locations. Adding inventory is often referred to as receiving inventory. You can

think of this step as stocking the InventoryControl program with the inventory that is in your warehouse.

Remember that inventory is not the same thing as items, even though inventory is made of items.

Adding inventory to an item means you are adding quantity to that item.

When you are adding inventory, you will enter information specific to your inventory such as Location,

Quantity, and Cost as well as specific tracked by information such as serial number, date codes and

pallet codes. Each time you add inventory for an Item, the transaction is stored separately in

InventoryControl allowing for multiple Locations and cost averaging.

If you already have inventory information contained in another database, you may want to use

InventoryControl's Import function rather than manually entering in this information.

A Note on Importing Inventory

If you choose to import your inventory you

MUST run a backup of your system BEFORE

you import the inventory data. Name the

backup file something that indicates it was run

immediately prior to importing inventory so you

can easily identify it if needed later. If you find

errors on your import file after you import

inventory, you will need to restore this backup to

return the system to the pre-import state (your

other information will be there). After restoring,

you can fix the import file as needed and reimport. ****DO NOT re-import after you have

already imported inventory without first

restoring the backup.**** Re-importing over

existing inventory data will add more inventory

to your items rather than fixing problem data.

Congratulations! You are now on your way to populating your inventory database. To add more

Items to your database, just return to Step 4 to setup your new Item, then Add your inventory for that

Item.

7

Page 23

InventoryControl Printable Help

1.15 Step Eleven - Print the Inventory by Location Report

Print the Inventory by Location Report - Printing the Inventory Location Report will allow you to check

that your inventory has been entered correctly.

After you have added your inventory you are ready to begin using InventoryControl. Now you can setup

your mobile devices, if needed, and begin keeping track of your inventory.

8

Page 24

InventoryControl Printable Help

Chapter 2 - Introductory Materials

2.1 Barcode Best Practices

In InventoryControl, when you are asked for a number to identify sites, customers, items, locations etc.,

you should always use a short sequential set of numbers or numbers and characters. Enter the full text

description of the site or location in the description field, not the number field. These numbers can then

be printed as a barcode and used to scan locations into mobile devices. You should estimate the largest

number of sites or locations you will have and pick a range of numbers that are reserved for each. For

instance, if you have up to 60 sites, you should reserve 100 to 199 for your sites. Each new site you

enter will get a number from this range. If you want to more closely tie the number to the site, add a one

or two letter designation to the end of the site number.

For example, use 100US to designate the main US warehouse and 101UK for the warehouse in the

United Kingdom. If you expect to have a few hundred suppliers, reserve 1000 to 2000 for suppliers.

Manufacturers can have 500 to 599. Items should start at 20000. This range reservation serves two

purposes. First, it allows those who know the ranges to easily distinguish a designation for the

warehouse from the designation for an item if all they see is a barcode on a paper or a box. Second,

reserving a range of numbers makes the process of deciding wh at number to use for new designations

much easier. If you add a manufacturer and you already used 512, the next is 513. For example, if a

stray box is presented to the warehouse manager and she sees barcodes with 100US C050100, she

knows this box was stocked in the US warehouse on row C shelf 05 bin 01.00. The box may also have a

barcode with 20104 which she knows is the item number and can b e used to put the item back into

inventory. Without these barcodes, the box might have to be opened to identify the item and then

someone would have to track where it came from and where to put it away.

Another thing to consider when creating your numeric representation for locations and items is that some

devices only support a reduced set of characters. Some mobile devices, such as the WDT2200, do not

have a keyboard that can support lower case letters or the entire range of special characters. With these

devices, if your item number is 10000(1) you will not be able to type the item number or scan in the

number from a barcode because the parentheses character is not suppo rted. All o

Our internal barcode labels use Code 128 which supports both lower and uppe r case characters, all

numbers and many special characters.

InventoryControl uses the symbology called Code 128 for all the pre-built labels. All the scanners and

mobile devices Wasp supplies can read Code 128. Best practices suggest you use Cod e 128 because it

supports all numbers, upper and lower case characters and most special characters. It also reduces the

size of most common barcodes.

9

Page 25

InventoryControl Printable Help

2.2 What is a Barcode?

A barcode is a graphical representation of a set of numeric or alphanumeric characters that can be read

by a barcode scanner.

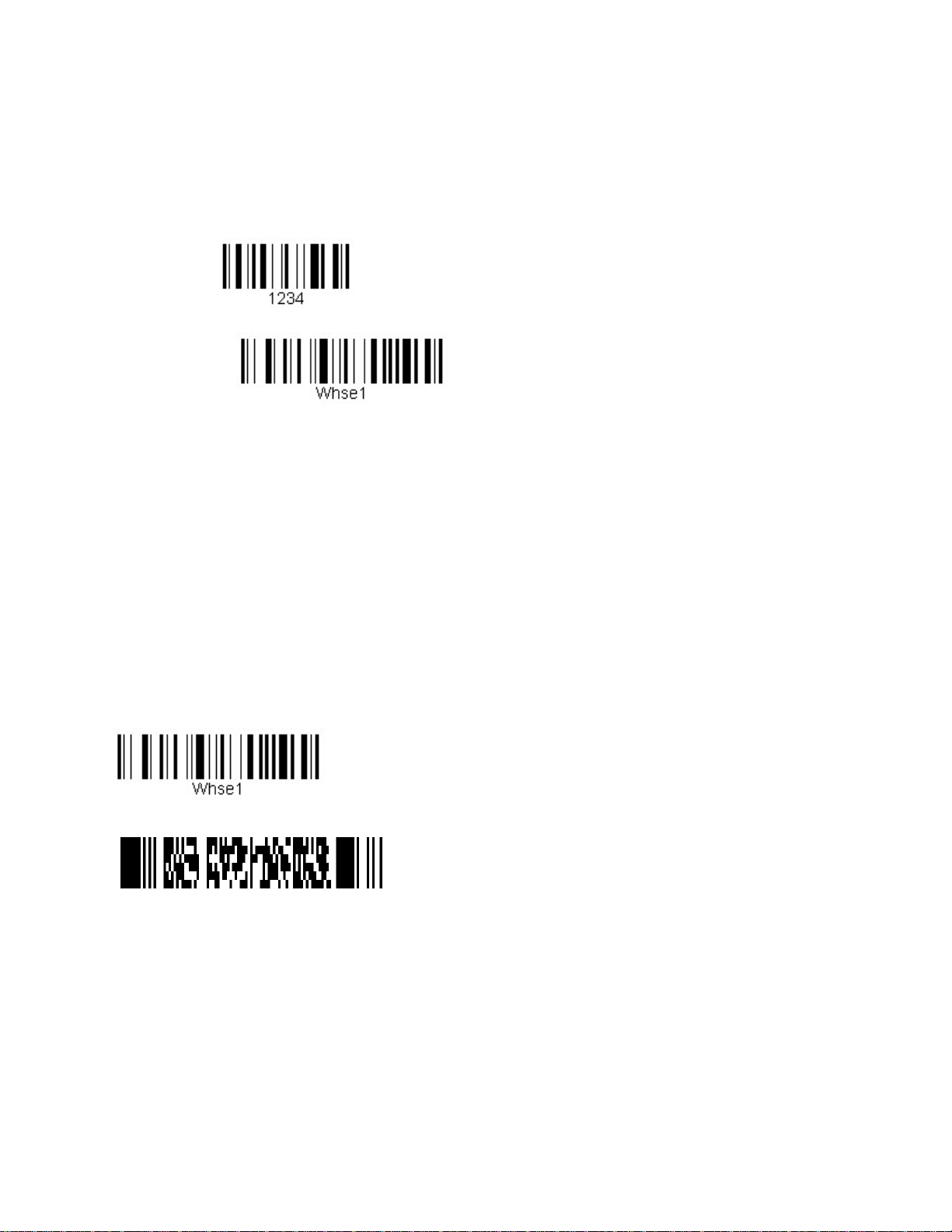

123 becomes:

Whse1 becomes:

Assigning a permanent barcode to each site, location, item, supplier and customer creates an

environment where a mobile device can be used to easily keep track of inventory movements and

alleviates the problem of data-entry errors.

Barcodes get wider with the amount of numbers and characters you want represented by them. A

barcode's width is determined by the amount of numbers or characters represented by the barcode.

Some barcode scanners have a limited width that they can read. If you have very long item numbers or

location numbers you may need to reconsider the numbering scheme or the scanner you a re using. Also

be aware that many of the less expensive barcode readers do not read barcodes that are bent, at an

angle, too small or damaged. Consider the possible disposition of your barcodes before choosing a

scanner.

There are many different barcode formats or symbologies. The different symbologies can be though of

as different fonts. The same characters are represented by different symbologies in different ways. For

example, the two symbologies below represent the same information (Whse1).

.

.

These different formats exist to provide ways to compress more data into smaller space, to represent a

different set of characters or to enable scanning at different angles or distances. InventoryControl uses

the symbology called Code 128 for all the pre-built labels. All the scanners and mobile devices Wasp

supplies can read Code 128. Best practices suggest you use Code 128 because it supports all numbers,

upper and lower case characters and most special characters. It also reduces the size of most common

barcodes.

Barcodes should be printed using a barcode printer or, if you are using Wasp Labeler, using a high quality

laser or ink jet printer. You want the barcode label to be high quality because low quality barcodes are

10

Page 26

InventoryControl Printable Help

harder to scan and usually do not last long. InventoryControl is bundled with Wasp Labeler, which can

print to a regular printer or a barcode printer. Remember to keep plenty of extra label stock and printer

ribbons to make sure you never run out. To determine how to best provide good quality labels for daily

use, consider the kind of printer you are using.

2.3 Choosing a Label Printer

Organizations that have several hundred new inventory items a week will need to have a dedicated

barcode label printer at each site. They should use a good quality label media and use the feature built

into InventoryControl that automatically prints inventory tags as soon as the item is received on the PC.

The printer needs to be rates for several hundred labels a day and needs to print fast enough to avoid

costly slowdowns that can be caused when waiting to put away items after they are received because the

labels are not printed. Look for models that can print 4-6 inches per second and can handle media up to

4" wide. Wasp's WPL606 line of printers work well in warehouse conditions.

Many organizations will not need a high-end printer but will still save money and will get better quality

long-lasting labels if they use a desktop barcode label printer. These printers allow you to print one or a

hundred labels without waste and they are quicker and cheaper than using a standard printer. Wasp's

WPL305 line of printers work great for smaller volumes of printing.

A laser printer using standard sheets of labels may work great where product turnover is slow, conditions

are well-controlled or new items are not added often. In this case, use the included Labeler software to

indicate what label stock is being used. Labeler ships with many standard label templates pre-configured.

Pre-print a few pages more than what you have in stock to prepare for new items.

11

Page 27

InventoryControl Printable Help

2.4 Designing and Labeling Sites and Locations

2.4.1 What is a Site?

The term Site is used to describe any grouping of locations where you plan to store and track inventory.

Usually a site is a warehouse building but it can be an office, a truck or a field, etc.

Site design may be simple if your entire inventory is stored your two warehouses. If this is the case you

can just use the name of the warehouse as the site description. Use a simple site number like W100 in

case you ever need to type the site number into a handheld device. For the site number you can use any

easily identifiable information about the site like its address or its designation like 140010th or W1400.

Since this product only has two levels of location tracking, you need to design your sites to describe all

the levels above the actual physical location of the inventory.

If you have trucks that are tied to a warehouse you can make their site description a composite of the

warehouse and truck number, W1400T12. If you have a different buildings containing various rooms in

which items will be stored, make a composite name of the building and room number, B201R10. You

should always make the site number something that can be barcoded so that it can be printed and

scanned. See Barcode Best Practices

.

2.4.2 What is a Location?

For the purpose of keeping track of your inventory items, your locations should represent the placement

within the site. If your site is a warehouse, the locations are shelves or racks. If your site is a building,

the locations may be offices. If you have a fleet of trucks, the locations may be containers in the truck.

When deciding how to label each location, choose a numbering scheme that can be interpreted when

reading just the label. For example, if you have 7 rows of 5 shelves each and each shelf has 4 levels,

your barcode label scheme should look like A010200 or Row A, Shelf 01, Level 02, Bin 00. If you have

inventory on trucks in containers, the truck can be a site and each bin in the truck is a location. Each bin

should get a numeric location designation like 100, 200 or 200. If you do not have locations within the

truck, each truck can be a location: T1, T2, T3. Put a label on the inside of the truck door so the person

moving inventory into the truck can just scan and move. The label barcode should have the barcode and

the human readable text description of the location as well.

2.4.3 Labeling Sites and Locations

Every location where inventory can be stored in your warehouse should have a printed barcode securely

attached near the location. This is important because adding, removing or moving inventory using the

InventoryControl software requires a location. All processes that require a location are both sped up and

made more accurate if you use a barcode to identify each location. Also using a consistent numbering

scheme makes finding items in the warehouse much easier. These labels can be stuck to the frame of

the shelves, attached to the bin, put on a card and hung from the racks or even stuck to the floor as in the

example below:

The first step for designing your labels is to decide on what type of label to print the barcode. A variety of

barcode label stock exists that can withstand any environment. There are two kinds of barcode label

12

Page 28

InventoryControl Printable Help

printers. Thermal transfer printers that work like an ink jet or laser printers that print by transferring ink

from a ribbon to the label paper (stock). Direct Thermal printers do not have a ribbon but use heat to print

onto a special label stock. The thermal transfer printers are more expensive to operate but can print on a

wider array of label stock and the labels last longer in various kinds of environments. Direct thermal

labels are cheaper but may fade if exposed to friction, heat or direct sunlight. Most barcode printers will

print both thermal transfer and direct thermal. You want a printer that will do both because what you are

using the label for will determine if you should use thermal transfer or the direct thermal. You may need

both kinds of labels available for printing.

For all kinds of organizations, you may want to consider using the cheaper direct thermal labels for

identifying individual items because you will put them on the packaging of items that will be discarded by

the consumer or on item tags used to identify the item at removal time. Use the cheaper label stock when

it will be used and discarded. It is often cheaper to reprint a few labels on the cheaper stock if one label

is damaged than to use the more expensive stock. You should label your warehouse locations with

labels that will last and can take some abuse because you don't want to have to continually reprint and

replace these labels.

If your labels contain information you want to be permanent, such as serial numbers, you should use

thermal transfer labels on a high quality label stock or, perhaps, polypropoline and a resin ribbon. The

importance of the label will determine what stock it is printed on. A serial number that you use for returns

or contract maintenance needs to be readable for a long time.

If your labels will be exposed to heat because of the device they are attached to or through exposure to

the sun you should use thermal transfer labels. For most locations ina fleet vehicle you should use

thermal transfer.