HIGH CAPACITY

PICV IOM

SERIES PICV

(Pressure Independent Control Valve)

TABLE OF CONTENTS

Overview / Operation .................... COVER

Configurations ...........................................2-3

Differential Pressure..............................4-8

Installation ...................................................8-9

Dimensions .......................................... 10-12

Weights .........................................................13

Maintenance ...............................................13

Water Quality ..................................... 13-14

VM5000E & VM1500E................ 15-22

TR5000X ............................................. 23-27

DPRV Actuator ..........................................28

Parts/Overhaul ................................. 32-37

Stem Adapter Setting Gages ..............38

OVERVIEW

This document covers the installation, operation and maintenance

of Series PICV (Pressure Independent Control Valves). The Series PICV

maximizes efficiency and energy savings by providing precise control

of maximum differential temperatures across a coil or heat exchanger

independent of variations in system pressure. The Series PICV

consists of two functional controlling segments. The first segment

is an electrically actuated control valve, capable of responding to

a control signal from a controller that is not part of the PICV. The

second segment is connected in series with the first, and serves to

sense and regulate a preset flowing differential pressure across the

control valve segment. Both segments include pressure balanced

control elements of industrial quality manufactured in accordance

with ISO 9001. The PICV has a rangeability of 50:1, meaning that

OPERATION

One of the primary factors that influence the flow of fluid through a

control valve is the amount of pressure, or differential pressure across

it. At any point in valve plug travel, flow through a valve will typically

increase if differential pressure is raised, and decrease if it is lowered.

A change in pumping pressure can therefore produce a change

in rate of flow that is not related to the system controller’s output

signal. With pressure independence, the amount of water flowing

through a valve and the controlled load (i.e. heat exchanger coil) is

more accurately controlled as a function of the control signal, and is

less dependent upon varying pump pressure. Stability in the control

system is enhanced when pressure independence is provided, and the

control valve’s installed flow characteristic more closely resembles its

inherent, or constant-pressure characteristic.

The Series PICV (Pressure Independent Control Valve) consists of

two functional controlling segments. The first segment is a pressurebalanced control valve, actuated by either a high-thrust electric motor

PICV_IOM_REVF_0114

good control performance can be achieved when the minimum flow

requirement is as low as 1/50 of the maximum flowing GPM (LPS). A

wide range of sizes, materials of construction, pressure ratings and

control characteristics provide flexible configuration to meet almost

any specification or system requirement. The Series PICV is factory

assembled, complete with sensing lines, check valve pressure taps,

and actuators, and is ready for field installation as a complete unit. The

Series PICV is pre-calibrated to a customer-specified set differential

pressure from 2-8 PSIG (0.14-0.55 BARG), and includes a means for

calibration adjustment. A separate, customer supplied, differential

pressure gauge may be installed between the check valve pressure

taps on the PICV to allow for monitoring of the set differential pressure.

actuator or pneumatic diaphragm actuator. The electric actuator

provides precise positioning of the valve closure mechanism, and

responds quickly and precisely to the electronic control signals

supplied to them. The second segment is a differential pressure control

valve that operates independently of the control valve segment.

This segment is self-powered (self-operating) and does not burden

or interact with the building automation control system. By quickly

raising or lowering its own resistance to flow, the differential pressure

control segment of the PICV regulates and stabilizes the pressure drop

across the control valve segment by absorbing unused head pressure.

This compensates for changes in pumping pressure resulting from

pump

switching or from varying flow demands in it’s own,

or parallel flow paths and results in pressure independent

operation.

NOTE: The maximum differential pressure across the entire PICV is

approximately 2 x (Set Differential Pressure) at max flow

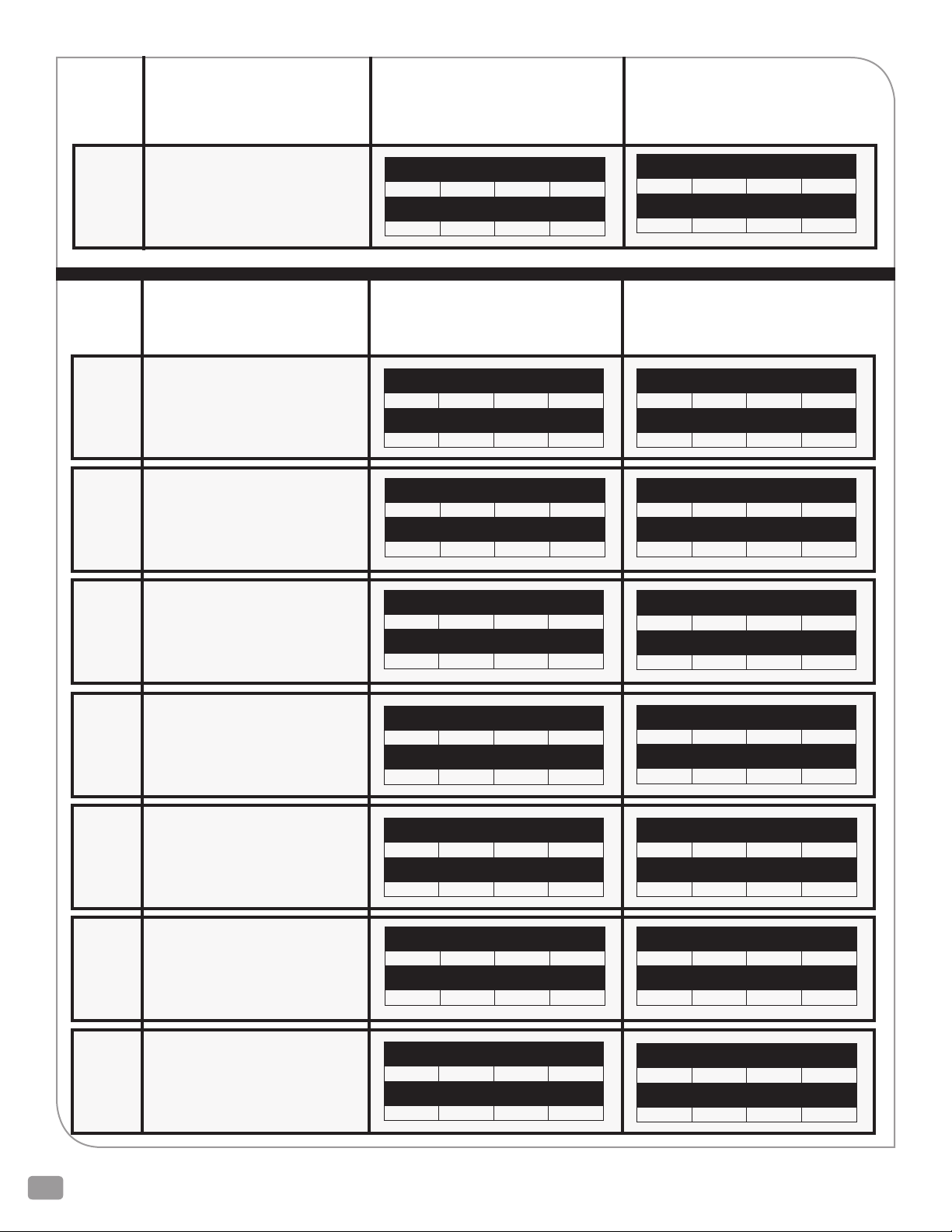

CONFIGURATIONS

Control

Valve

Size

P2

2.5” DN65

P3

3” DN80

P4

4” DN100

P5

5” DN125

P6

6” DN150

P8

8” DN200

P1

10” DN250

Control

Valve

Flange

0

ANSI 125

Flanges

2

PN16

Flanges

Control

Valve

Profile

22

Type of

Control

Valve

Body

(Sizes P8

& P1)

23

Type of

Control

Valve

Body

(Sizes

P2-P6)

Control

Valve Trim

Size

F

Control Valve

Trim Size Full

X

Control Valve

Trim Size

Extended

1

Control Valve

Trim Size 1SR

2

Control Valve

Trim Size 2SR

Control Valve

Trim Material

S

Stainless Steel

B

Bronze

Control Valve

Motor

E020

VM1500E Fail As Is

E021

VM1500E - w/

VMS-25

BCM

E022

VM5000E -

Fail As Is

E023

VM5000E - w/

VMS-25

BCM

TIG1

TR5000-X

-Fail As Is

for all exceot

P6_23XX

Extended Port

TIG2

TR5000-X

-Fail As Is

Extended Port

Only

DPRV

Size

P2

2.5” DN65

P3

3” DN80

P4

4” DN100

P5

P6

6” DN150

P8

8” DN200

P1

10” DN250

VALVE BODIES

Body Material: Cast Iron

End Connections: ANSI 125LB FF Flanges, PN16 FF Flanges

Trim Designs: Type 23 - Single Seat Cylinder Balanced, ANSI Class III Leakage

Type 22 and 72 - Double Seat Balanced, ANSI Class III Leakage

Trim Material: Bronze or 300 Series Stainless Steel

EPDM Seal (Type 23 w/Bronze Trim)

Fluoraz Seal (Type 23 w/Stainless Steel Trim)

Fluid: Chilled Water Typical, Water or Water/Glycol from 35 °F- 180°F (2°C - 82°C )

Trim Limits: Stainless Steel: MAX Flowing Differential Pressure, 150 PSIG (10.3 BARG)

Bronze: MAX Flowing Differential Pressure, 100 PSIG (6.9 BARG)

Packing: Long-Life Multi-Stack EPDM Lip Packing - Water / Water-Glycol Service

5” DN125

DPRV

Flange

DPRV

Trim

DPRV Actuator

Material

DS

DB

DPRV Type

72 Portion

w/ SS Trim

DPRV Type

72 Portion

w/ Brz

Trim

2L

DPRV Actuator Cast

Iron, w/ Low DP Spring

2M

DPRV Actuator Cast

Iron, w/ Medium DP

Spring

0

ANSI 125

Flanges

2

PN16 Flanges

Note: Must

match control

valve

Body Pressure Temperature Ratings

Iron Body

Temperature 125 FLG & PN16

O

F

35 to 180 1.7 to 82.2 150 10.20

O

C PSIG BARG

ELECTRIC ACTUATOR SPECIFICATIONS (VM-1500E AND VM-5000E)

Valve Usage: VM-1500E [Valve sizes 2 1/2, 3 & 4 Inch DN65, DN80 & DN100],

VM-5000E [Valve sizes 5, 6, 8 & 10 Inch DN125, DN150, DN200, DN250]

Control Signal: 4-20 mAdc (Factory Setting), 0-20 mAdc, 0-10 Vdc or 2-10 Vdc

and Floating, Self-Adjusting, Field Selectable (Dip Switch)

Power Consumption: VM-1500E 12VA, VM-5000E 25VA

Timing: VM-1500E [102 sec. / inch, 4.02 sec. / mm], VM-5000E [76 sec. / inch, 2.99 sec./mm]

Feedback Signal: 4-20 mAdc (Factory Setting), 0-10 Vdc or 2-10 Vdc

Failure Mode: Fail-As-Is [Without VMS-25 BCM (Back-up Control Module)]

Fail-Safe [With VMS-25 BCM (Back-up Control Module)]

Manual Override: Yes

Construction: Polycarbonate Motor Housing with Steel Linkage & Yoke.

Case has one 1/2 inch (1.27 cm) NPSM Conduit Adapter

Connections: Coded Screw Terminals

Locations: NEMA Type 3 / IP54

Temperature Limits: Ambient 32°F - 122°F ( 0°C - 50°C )

Mounting: Factory Aligned, Vertical Above Centerline of Control Valve

Consult factory for preconfigured alternate orientations

VMS-25 BCM (BACK-UP CONTROL MODULE) SPECIFICATIONS

Actuator Usage: VM-1500E & VM-5000E

Required for Fail Safe Operation

Failure Direction: Field Selectable

Power Consumption: 24VAC, 40VA

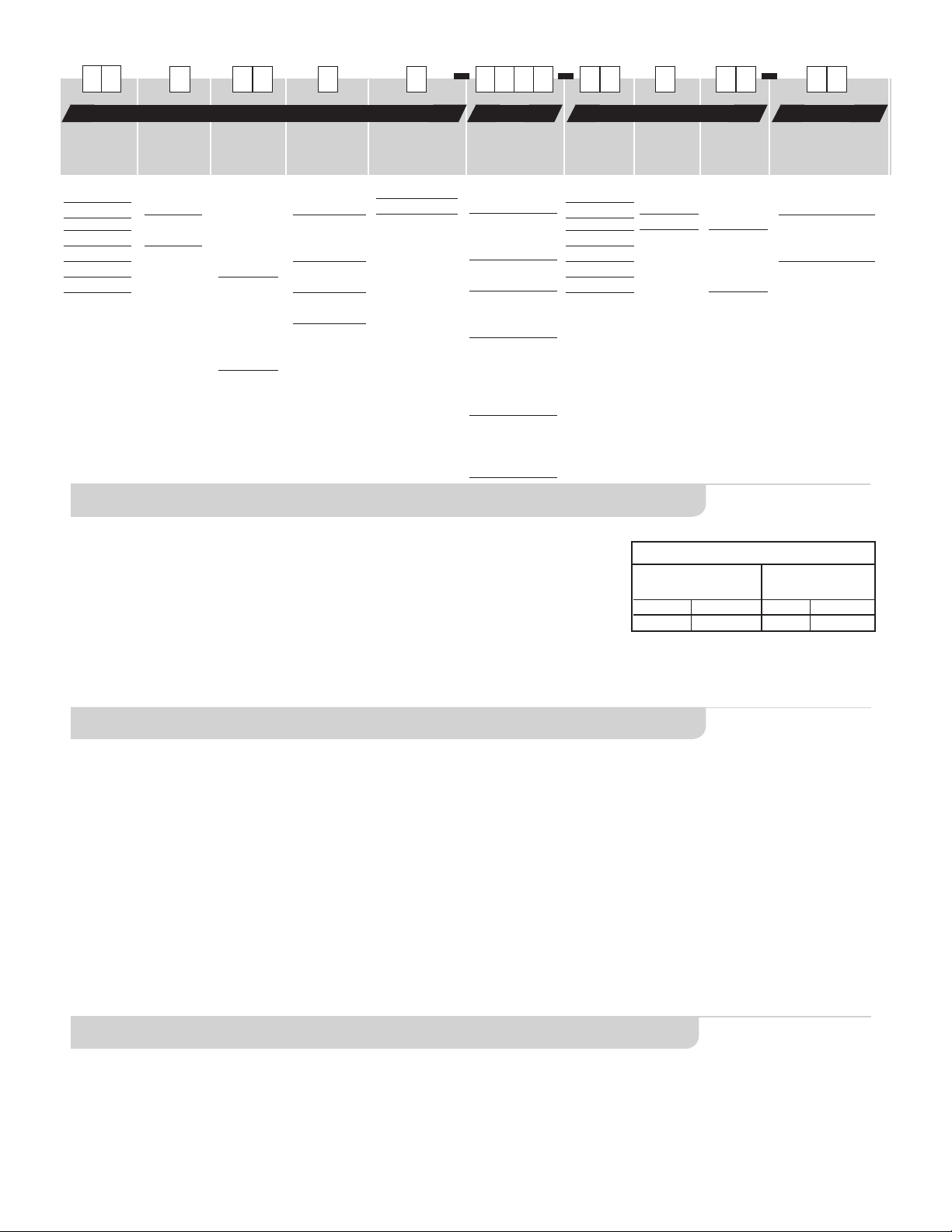

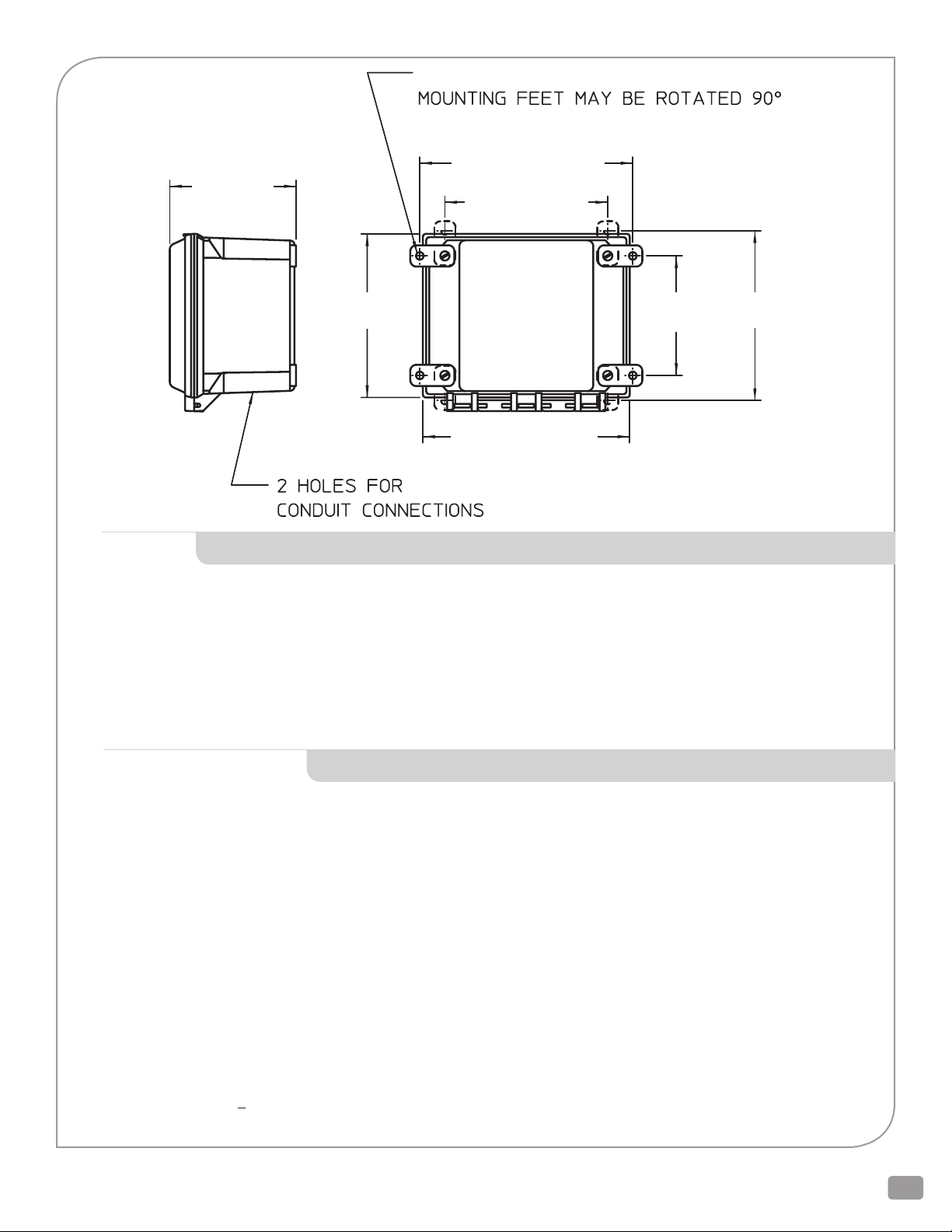

Construction: Battery w/Circuit Board & Transformer, in Nema 4 Enclosure

Mounting: Wall Mount

Weight: 4.25 lbs (2 kg)

VMS-25 BCM

5.19 in

(13.18 cm)

4X 0.31 in (0.79 cm)

8.75 in (22.23 cm)

6.69 in (16.99 cm)

THRU MOUNTING FOOT

6.72 in

(17.O7 cm)

8.5 in (21.59 cm)

1/2 in (1.27 cm)

4.91 in

(12.47 cm)

6.97 in

(17.7O cm)

DPRV DOUBLE ACTING DIAPHRAGM ACTUATOR WITH SPRING ASSIST

Control Signal: Differential Pressure from Control Valve,

2.0 to 8 PISG (0.14 to 0.55 BARD)

150 PSIG (10.3 BARD) Max Static

Fluid: Chilled Water Typical, Water or Water/Glycol from 35 °F- 180°F (2°C - 82°C )

Spring Pack: Low DP Spring: Adjustable 2 to 6 PSIG (0.14-0.41 BARD)

Medium DP Spring: Adjustable 5 to 8 PSIG (0.34-0.55 BARD)

Construction: Cast Gray Iron Class G3000, epoxy coated, epoxy coated spring, SS components, Woven Buna-N, nylon reinforced.

Temperature Limits: Ambient 32°F - 122°F ( 0°C - 50°C )

Mounting: Factory Aligned, Vertical Above Centerline of Control Valve

Consult factory for preconfigured alternate orientations

ELECTRIC ACTUATOR SPECIFICATIONS (TR5000-X)

Valve Usage: 5, 6, 8, & 10 inch, DN125, DN150, DN200, DN250

Control Signal: 4-20 mAdc (Factory Setting), 0-10 Vdc, 2-10 Vdc, or 0-20 mAdc; Field Selectable (Dip Switch)

Control Action: Direct Acting, Actuator Shaft Extends on Increasing Signal (Factory Setting) or

Reverse Acting, Actuator Shaft Retracts on Increasing Signal; Field Selectable (Dip Switch)

Power Supply: 220 VAC

Power Consumption: 12VA

Timing: 90.68 Seconds / Inch (3.57 s/mm)

Feedback Signal: 4-20 mAdc (Factory Setting), 0-10 Vdc, 2-10 Vdc, or 0-20 mAdc

Field Selectable (Dip Switch); Feedback Signal Increase as Actuator Shaft Extends (Factory Setting) or Feedback

Signal Increases as Actuator Shaft Retracts; Field Selectable (Dip Switch)

Failure Mode: Fail Actuator Shaft Retracted on Loss of Signal (Factory Setting) or Fail Actuator Shaft Extended on Loss of Signal

Field Selectable (Dip Switch); Actuator Shaft Fails In Last Position on Loss of Power

Manual Override: Yes

Construction: Die Cast Aluminum Motor Housing & Yoke. Painted.

Case Has Two PG11 Cable Glands Accepts 0.197 to 0.394 inch (5mm to 10mm) Diameter Cable

Connections: Coded Screw Terminals

Locations: NEMA Type 3 / IP54

Temperature Limits: Ambient 14˚F to 122˚F ( -10˚C to 50˚C )

Relative Humidity: < 95% RH (40ºC)

Mounting: Factory Aligned, Vertical Above Centerline of Control Valve; Consult factory for preconfigured alternate orientations

PRESSURE INDEPENDENT CONTROL VALVE PICV_IOM_REVF_0114

3

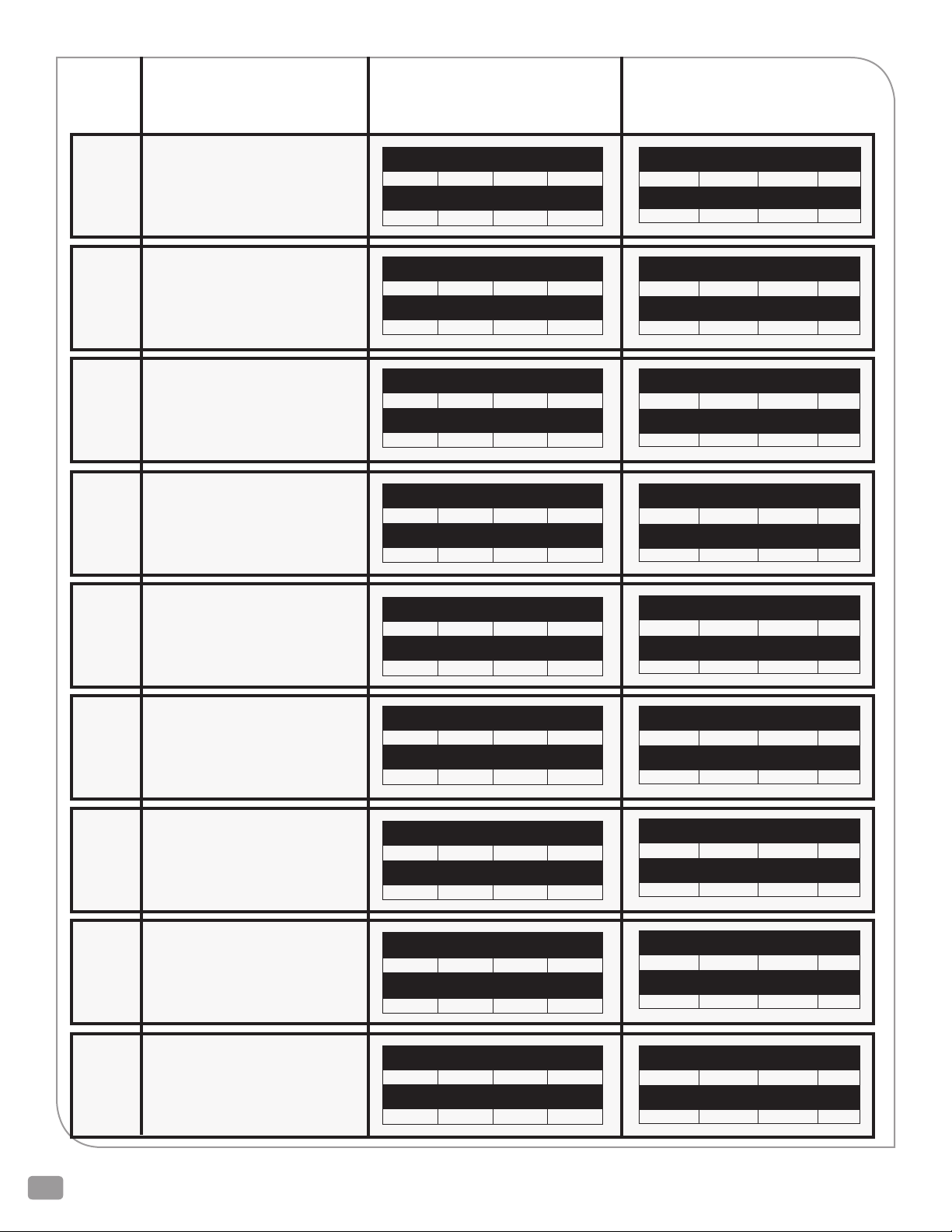

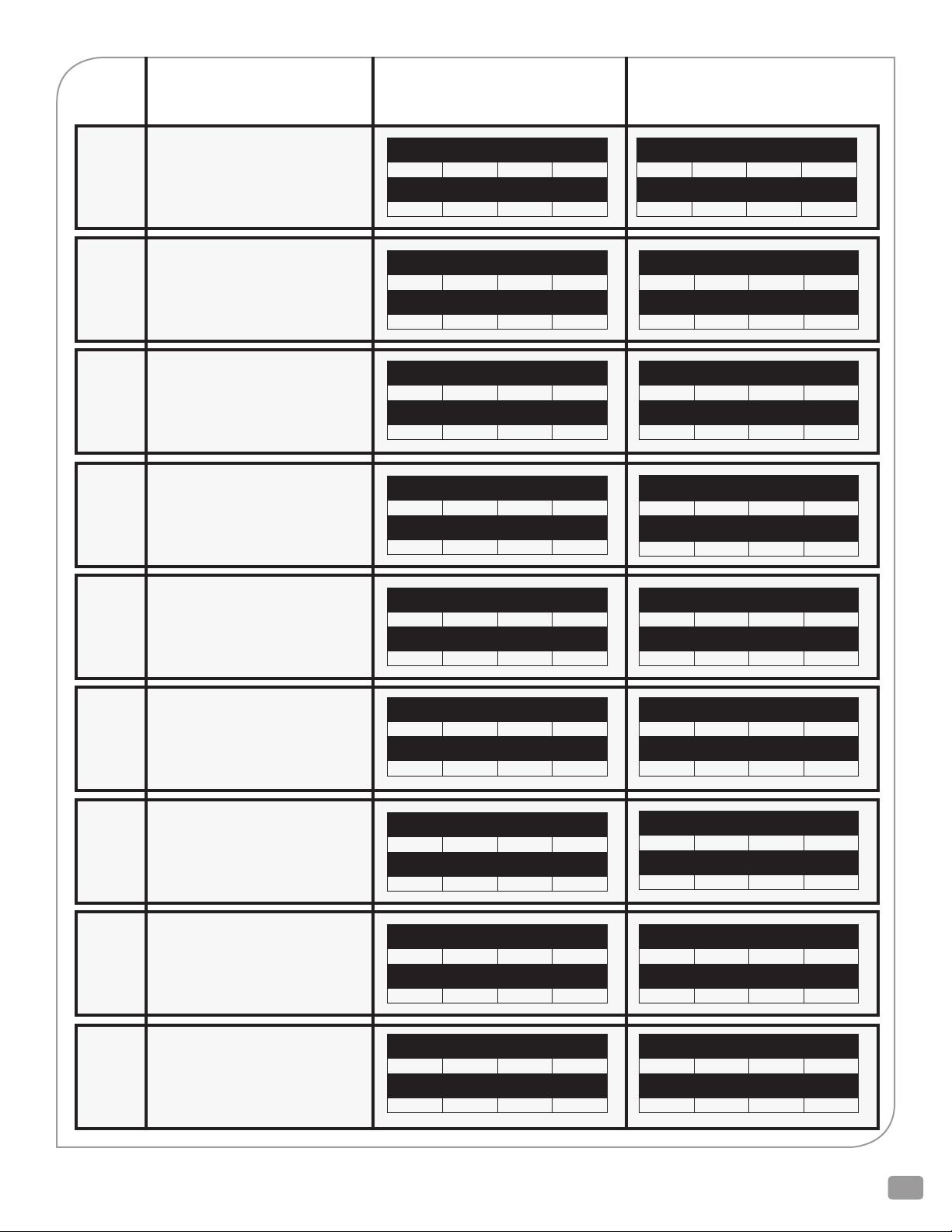

FLANGE

PRODUCT MODEL

(where ‘x’ is a configurable option)

LOW DP SPRING

PERFORMANCE

MEDIUM DP SPRING

PERFORMANCE

ANSI125

ANSI125

ANSI125

ANSI125

ANSI125

P2023Fx-xxxx-P20Dx-2x

2 1/2” Standard Port

P30231x-xxxx-P30Dx-2x

3” 1 Size Reduced Port

P3023Fx-xxxx-P30Dx-2x

3” Standard Port

P40232x-xxxx-P40Dx-2x

4” 2 Sizes Reduced Port

P40231x-xxxx-P40Dx-2x

4” 1 Size Reduced Port

Set Differential Pressure (PSI)

2.0 3.1 4.2 5.3

Maximum flow (GPM)

92 114 133 150

Set Differential Pressure (PSI)

2.0 3.1 4.2 5.3

Maximum flow (GPM)

106 132 154 173

Set Differential Pressure (PSI)

2.0 3.1 4.2 5.3

Maximum flow (GPM)

127 158 184 207

Set Differential Pressure (PSI)

2.0 3.1 4.2 5.3

Maximum flow (GPM)

165 206 240 269

Set Differential Pressure (PSI)

2.0 3.1 4.2 5.3

Maximum flow (GPM)

204 254 295 332

Set Differential Pressure (PSI)

5.7 6.5 7.2 8.0

Maximum flow (GPM)

155 166 174 184

Set Differential Pressure (PSI)

5.7 6.5 7.2 8.0

Maximum flow (GPM)

179 191 201 212

Set Differential Pressure (PSI)

5.7 6.5 7.2 8.0

Maximum flow (GPM)

215 229 241 255

Set Differential Pressure (PSI)

5.7 6.5 7.2 8.0

Maximum flow (GPM)

279 298 314 331

Set Differential Pressure (PSI)

5.7 6.5 7.2 8.0

Maximum flow (GPM)

344 367 386 407

ANSI125

ANSI125

ANSI125

ANSI125

P4023Fx-xxxx-P40Dx-2x

4” Standard Port

P50232x-xxxx-P50Dx-2x

5” 2 Sizes Reduced Port

P50231x-xxxx-P50Dx-2x

5” 1 Size Reduced Port

P5023Fx-xxxx-P50Dx-2x

5” Standard Port

Set Differential Pressure (PSI)

2.0 3.1 4.2 5.3

Maximum flow (GPM)

240 299 348 391

Set Differential Pressure (PSI)

2.0 3.1 4.2 5.3

Maximum flow (GPM)

287 357 416 467

Set Differential Pressure (PSI)

2.0 3.1 4.2 5.3

Maximum flow (GPM)

335 417 486 546

Set Differential Pressure (PSI)

2.0 3.1 4.2 5.3

Maximum flow (GPM)

382 475 553 622

Set Differential Pressure (PSI)

5.7 6.5 7.2 8.0

Maximum flow (GPM)

406 433 456 481

Set Differential Pressure (PSI)

5.7 6.5 7.2 8.0

Maximum flow (GPM)

485 518 545 574

Set Differential Pressure (PSI)

5.7 6.5 7.2 8.0

Maximum flow (GPM)

566 604 636 670

Set Differential Pressure (PSI)

5.7 6.5 7.2 8.0

Maximum flow (GPM)

645 688 724 764

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

4

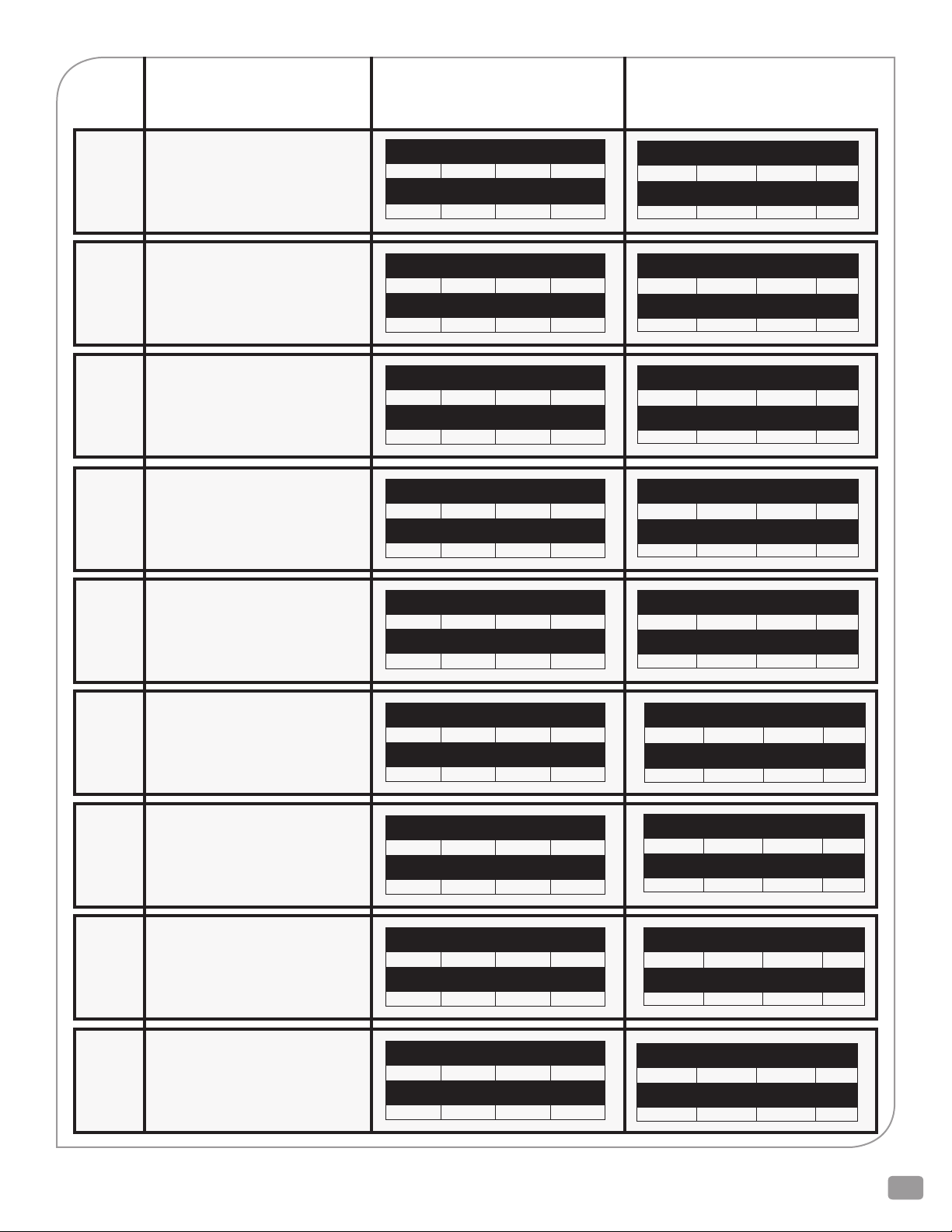

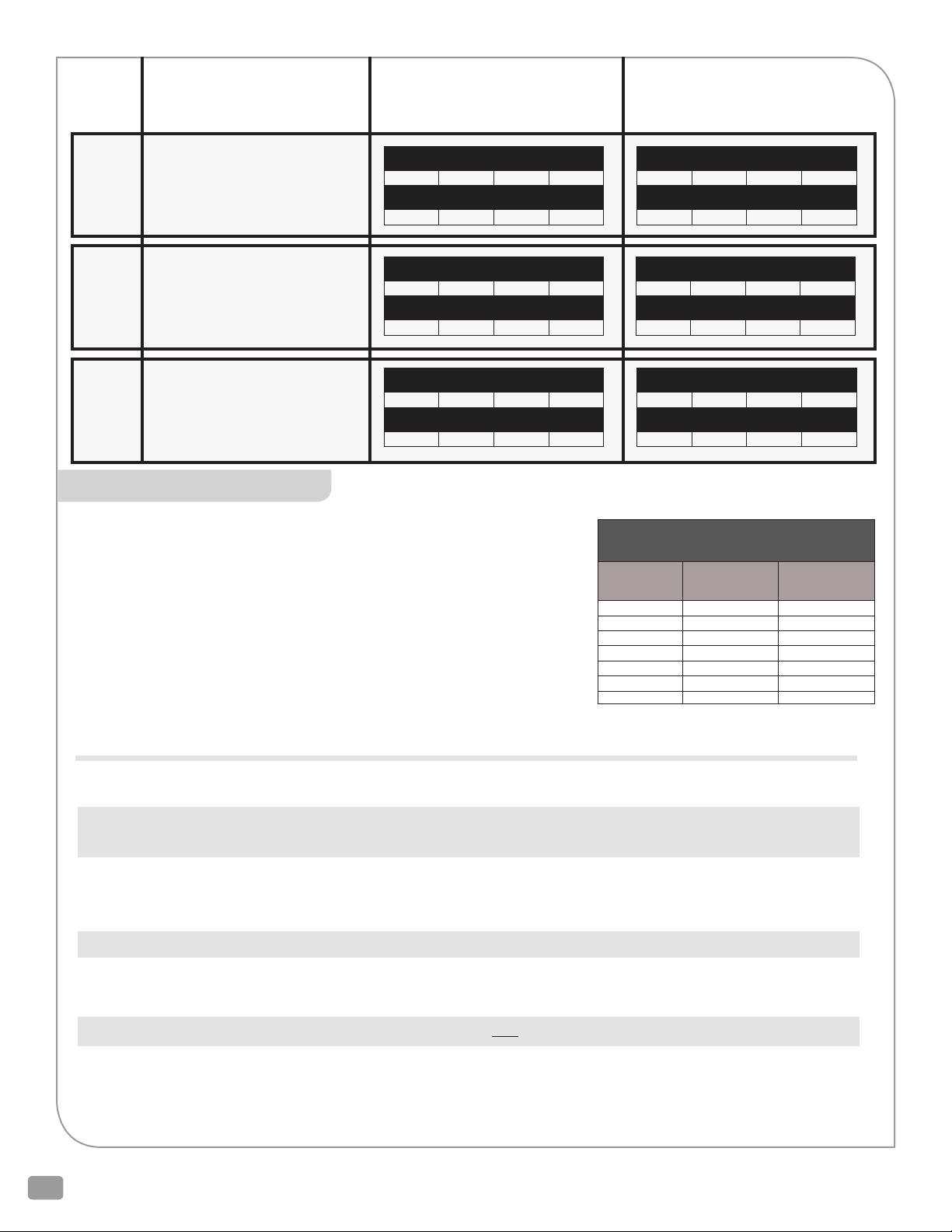

FLANGE

PRODUCT MODEL

(where ‘x’ is a configurable option)

LOW DP SPRING

PERFORMANCE

MEDIUM DP SPRING

PERFORMANCE

ANSI125

ANSI125

ANSI125

ANSI125

P60032x-xxxx-P60Dx-2x

6” 2 Sizes Reduced Port

P60231x-xxxx-P60Dx-2x

6” 1 Size Reduced Port

P6023Fx-xxxx-P60Dx-2x

6” Standard Port

P6023Xx-xxxx-P60Dx-2x

6” Extended Port

ANSI125

P80222S-xxxx-P80Dx-2x

8” 2 Sizes Reduced Port

SS Trim Only

Set Differential Pressure (PSI)

2.0 3.1 4.2 5.3

Maximum flow (GPM)

389 484 564 633

Set Differential Pressure (PSI)

2.0 3.1 4.2 5.3

Maximum flow (GPM)

445 555 646 725

Set Differential Pressure (PSI)

2.0 3.1 4.2 5.3

Maximum flow (GPM)

509 634 738 829

Set Differential Pressure (PSI)

2.0 3.1 4.2 5.3

Maximum flow (GPM)

594 739 861 967

Set Differential Pressure (PSI)

2.0 3.1 4.2 5.3

Maximum flow (GPM)

735 916 1066 1197

Set Differential Pressure (PSI)

5.7 6.5 7.2 8.0

Maximum flow (GPM)

657 701 738 778

Set Differential Pressure (PSI)

5.7 6.5 7.2 8.0

Maximum flow (GPM)

752 803 845 891

Set Differential Pressure (PSI)

5.7 6.5 7.2 8.0

Maximum flow (GPM)

859 918 966 1018

Set Differential Pressure (PSI)

5.7 6.5 7.2 8.0

Maximum flow (GPM)

1003 1071 1127 1188

Set Differential Pressure (PSI)

5.7 6.5 7.2 8.0

Maximum flow (GPM)

1241 1326 1395 1471

ANSI125

P80221S-xxxx-P80Dx-2x

8” 1 Size Reduced Port

SS Trim Only

ANSI125

ANSI125

P8023Fx-E02x-P80Dx-2x

8” Standard Port

P10222S-xxxx-P10Dx-2x

10” 2 Sizes Reduced Port

SS Trim Only

ANSI125

P10221S-xxxx-P10Dx-2x

10” 1 Size Reduced Port

SS Trim Only

Set Differential Pressure (PSI)

2.0 3.1 4.2 5.3

Maximum flow (GPM)

841 1048 1219 1370

Set Differential Pressure (PSI)

2.0 3.1 4.2 5.3

Maximum flow (GPM)

962 1197 1394 1565

Set Differential Pressure (PSI)

2.0 3.1 4.2 5.3

Maximum flow (GPM)

1039 1294 1506 1692

Set Differential Pressure (PSI)

2.0 3.1 4.2 5.3

Maximum flow (GPM)

1188 1479 1721 1934

Set Differential Pressure (PSI)

5.7 6.5 7.2 8.0

Maximum flow (GPM)

1421 1517 1597 1683

Set Differential Pressure (PSI)

5.7 6.5 7.2 8.0

Maximum flow (GPM)

1623 1734 1825 1923

Set Differential Pressure (PSI)

5.7 6.5 7.2 8.0

Maximum flow (GPM)

1755 1874 1972 2079

Set Differential Pressure (PSI)

5.7 6.5 7.2 8.0

Maximum flow (GPM)

2005 2142 2254 2376

PRESSURE INDEPENDENT CONTROL VALVE PICV_IOM_REVF_0114

5

FLANGE

PRODUCT MODEL

(where ‘x’ is a configurable option)

LOW DP SPRING

PERFORMANCE

MEDIUM DP SPRING

PERFORMANCE

ANSI125 P1022Fx-xxxx-P10Dx-2x

10” Standard Port

PRODUCT MODEL

FLANGE

PN16

PN16

PN16

(where ‘x’ is a configurable option)

P2223Fx-xxxx-P22Dx-2x

DN65 Standard Port

P32231x-xxxx-P32Dx-2x

DN80 1 Size Reduced Port

P3223Fx-xxxx-P32Dx-2x

DN80 Standard Port

Set Differential Pressure (PSI)

2.0 3.1 4.2 5.3

Maximum flow (GPM)

1358 1690 1967 2210

LOW DP SPRING

PERFORMANCE

Set Differential Pressure (BAR)

0.14 0.21 0.29 0.37

Maximum flow (LPS)

5.8 7.2 8.4 9.5

Set Differential Pressure (BAR)

0.14 0.21 0.29 0.37

Maximum flow (LPS)

6.7 8.3 9.7 11.0

Set Differential Pressure (BAR)

0.14 0.21 0.29 0.37

Maximum flow (LPS)

8.1 9.9 11.6 13.2

Set Differential Pressure (PSI)

5.7 6.5 7.2 8.0

Maximum flow (GPM)

2292 2448 2576 2715

MEDIUM DP SPRING

PERFORMANCE

Set Differential Pressure (BAR)

0.39 0.45 0.5 0.55

Maximum flow (LPS)

9.8 10.5 11.0 11.6

Set Differential Pressure (BAR)

0.39 0.45 0.5 0.55

Maximum flow (LPS)

11.3 12.1 12.7 13.4

Set Differential Pressure (BAR)

0.39 0.45 0.5 0.55

Maximum flow (LPS)

13.5 14.5 15.3 16.0

PN16

PN16

PN16

PN16

P42232x-xxxx-P42Dx-2x

DN100 2 Sizes Reduced Port

P42231x-xxxx-P42Dx-2x

DN100 1 Size Reduced Port

P4223Fx-xxxx-P42Dx-2x

DN100 Standard Port

P52232x-xxxx-P52Dx-2x

DN125 2 Sizes Reduced Port

Set Differential Pressure (BAR)

0.14 0.21 0.29 0.37

Maximum flow (LPS)

10.5 12.9 15.1 17.1

Set Differential Pressure (BAR)

0.14 0.21 0.29 0.37

Maximum flow (LPS)

12.9 15.9 18.6 21.0

Set Differential Pressure (BAR)

0.14 0.21 0.29 0.37

Maximum flow (LPS)

15.3 18.7 22.0 24.8

Set Differential Pressure (BAR)

0.14 0.21 0.29 0.37

Maximum flow (LPS)

18.2 22.4 26.3 29.7

Set Differential Pressure (BAR)

0.39 0.45 0.5 0.55

Maximum flow (LPS)

17.6 18.9 19.9 20.8

Set Differential Pressure (BAR)

0.39 0.45 0.5 0.55

Maximum flow (LPS)

21.6 23.2 24.5 25.7

Set Differential Pressure (BAR)

0.39 0.45 0.5 0.55

Maximum flow (LPS)

25.5 27.4 28.9 30.3

Set Differential Pressure (BAR)

0.39 0.45 0.5 0.55

Maximum flow (LPS)

30.5 32.7 34.5 36.2

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

6

FLANGE

PRODUCT MODEL

(where ‘x’ is a configurable option)

LOW DP SPRING

PERFORMANCE

MEDIUM DP SPRING

PERFORMANCE

PN16

PN16

PN16

PN16

PN16

P52231x-xxxx-P52Dx-2x

DN125 1 Size Reduced Port

P5223Fx-xxxx-P52Dx-2x

DN125 Standard Port

P62232x-xxxx-P62Dx-2x

DN150 2 Sizes Reduced Port

P62231x-xxxx-P62Dx-2x

DN150 1 Size Reduced Port

P6223Fx-xxxx-P62Dx-2x

DN150 Standard Port

Set Differential Pressure (BAR)

0.14 0.21 0.29 0.37

Maximum flow (LPS)

21.3 26.1 30.7 34.6

Set Differential Pressure (BAR)

0.14 0.21 0.29 0.37

Maximum flow (LPS)

24.3 29.7 34.9 39.5

Set Differential Pressure (BAR)

0.14 0.21 0.29 0.37

Maximum flow (LPS)

24.7 30.3 35.6 40.2

Set Differential Pressure (BAR)

0.14 0.21 0.29 0.37

Maximum flow (LPS)

28.3 34.7 40.8 46.0

Set Differential Pressure (BAR)

0.14 0.21 0.29 0.37

Maximum flow (LPS)

32.4 39.6 46.6 53

Set Differential Pressure (BAR)

0.39 0.45 0.5 0.55

Maximum flow (LPS)

35.6 38.2 40.3 42.2

Set Differential Pressure (BAR)

0.39 0.45 0.5 0.55

Maximum flow (LPS)

40.5 43.5 45.9 48.1

Set Differential Pressure (BAR)

0.39 0.45 0.5 0.55

Maximum flow (LPS)

41.3 44.3 46.7 49.0

Set Differential Pressure (BAR)

0.39 0.45 0.5 0.55

Maximum flow (LPS)

47.3 51 54 56

Set Differential Pressure (BAR)

0.39 0.45 0.5 0.55

Maximum flow (LPS)

54 58 61 64

PN16

P6223Xx-xxxx-P62Dx-2x

PN16

DN150 Extended Port

P82222S-xxxx-P82Dx-2x

DN200 2 Sizes Reduced Port

SS Trim Only

PN16

P82221S-xxxx-P82Dx-2x

DN200 1 Size Reduced Port

SS Trim Only

PN16

P8223Fx-E02x-P82Dx-2x

DN200 Standard Port

Set Differential Pressure (BAR)

0.14 0.21 0.29 0.37

Maximum flow (LPS)

37.8 46.2 54 61

Set Differential Pressure (BAR)

0.14 0.21 0.29 0.37

Maximum flow (LPS)

46.7 57 67 76

Set Differential Pressure (BAR)

0.14 0.21 0.29 0.37

Maximum flow (LPS)

53 66 77 87

Set Differential Pressure (BAR)

0.14 0.21 0.29 0.37

Maximum flow (LPS)

61 75 88 99

Set Differential Pressure (BAR)

0.39 0.45 0.5 0.55

Maximum flow (LPS)

63 68 71 75

Set Differential Pressure (BAR)

0.39 0.45 0.5 0.55

Maximum flow (LPS)

78 84 88 93

Set Differential Pressure (BAR)

0.39 0.45 0.5 0.55

Maximum flow (LPS)

89 96 101 106

Set Differential Pressure (BAR)

0.39 0.45 0.5 0.55

Maximum flow (LPS)

102 110 116 121

PRESSURE INDEPENDENT CONTROL VALVE PICV_IOM_REVF_0114

7

FLANGE

PRODUCT MODEL

(where ‘x’ is a configurable option)

LOW DP SPRING

PERFORMANCE

MEDIUM DP SPRING

PERFORMANCE

PN16

P12222S-xxxx-P12Dx-2x

DN250 2 Sizes Reduced Port

SS Trim Only

PN16

P12221S-xxxx-P12Dx-2x

DN250 1 Size Reduced Port

SS Trim Only

PN16

P1222Fx-xxxx-P12Dx-2x

DN250 Standard Port

Set Differential Pressure (BAR)

0.14 0.21 0.29 0.37

Maximum flow (LPS)

66 81 95 107

Set Differential Pressure (BAR)

0.14 0.21 0.29 0.37

Maximum flow (LPS)

76 92 109 123

Set Differential Pressure (BAR)

0.14 0.21 0.29 0.37

Maximum flow (LPS)

86 106 124 140

INSTALLATION

Recommended Piping: ANSI 125 Flanges should mate with piping with 125 Lb or 150 Lb

Flat Faced Flanges.

Per ISA Recommended Piping Practices. Control valves perform best with a reasonable

amount of upstream and downstream straight pipe prior to elbows and strainers. The

general specification for this is 16 pipe diameters upstream of straight pipe and 5 pipe

diameters downstream of straight pipe as minimums. However, this is a broad specification

covering all pipe diameters and velocities. Many applications do not have this kind of

space. While more length of straight pipe is desirable, Warren Controls has produced a

table of minimum pipe diameters for use on our PICV. Failure to follow these guidelines

may lead to noticeable vibrations or noise for excessive turbulence in some applications

with significant head pressure. In the unlikely event of excessive noise or vibration, other

remedies like special low noise trim may be available but at the expense of the user or

installer when not following installation guidelines.

Set Differential Pressure (BAR)

0.39 0.45 0.5 0.55

Maximum flow (LPS)

110 118 125 131

Set Differential Pressure (BAR)

0.39 0.45 0.5 0.55

Maximum flow (LPS)

126 135 143 150

Set Differential Pressure (BAR)

0.39 0.45 0.5 0.55

Maximum flow (LPS)

144 155 163 171

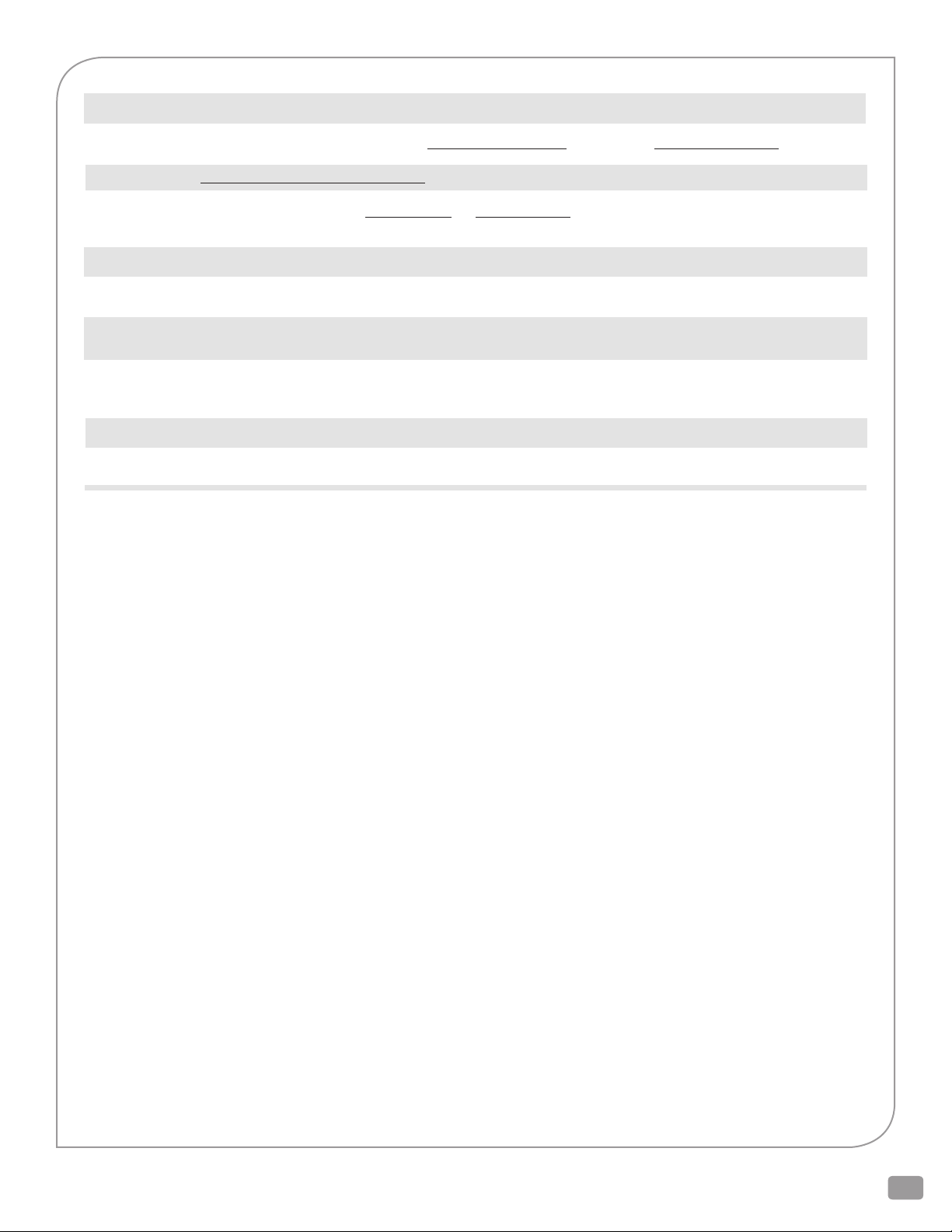

PICV Minimum Lengths of

Straight Pipe

PICV Size Upstream

Straight Pipe

2 ½” (DN65) 16” (40.64 cm) 12” (30.48 cm)

3” (DN80) 16” (40.64 cm) 12” (30.48 cm)

4” (DN100) 16” (40.64 cm) 12” (30.48 cm)

5” (DN125) 24” (60.96 cm) 12” (30.48 cm)

6” (DN150) 32” (81.28 cm) 12” (30.48 cm)

8” (DN200) 36” (91.44 cm) 14” (35.56 cm)

10” (DN250) 40” (101.6 cm) 16” (40.64 cm)

Downstream

Straight Pip

The above tables are recommended minimum lengths for good and stable performance. Wherever possible, longer runs of straight pipe

should be used for optimal performance and stability.

• Besurethattheflowmedium,ambienttemperatureandtheselectedlocationwillnotexceedthemaximumtemperatureofthePICV,

actuator, or accessories. Information can be found on the nameplate and product specifications regarding these limits.

• CheckPICVforanydamageduetoimproperstorageortransportation.Immediatelynotifyyoursalesorganizationofanydamaged

goods upon receipt. Do not attempt to move or disturb them further so photos may be taken. If the shipping container is noticeably

damaged, refuse receipt as the shipping company should be held liable, until a shipping representative is available to take photos.

• VerifythatthePICVisvisuallyingoodworkingorder–notbentorcracked.

• Followgoodpipingpractices.InstallabypassaroundthePICV.Installstopvalvesininletandoutletpipingtoprovidemeanstoisolate

PICV.

• THEPICVSHOULDBEINSTALLEDASAUNIT.THESEGMENTSSHOULDNOT BE SEPARATED FOR INSTALLATION.

• CarefullyremovethePICVfromshippingcratewithaportablehoistorcrane.ThePICVistooheavyforoneoreventwopeopletolift

and hand-install depending on size. The Crane or Hoist should use a strap or chain cradle around the central flanges of the two valve

assemblies to raise and maneuver the PICV into position at the pipe flanges. Efforts should be made to avoid damaging the sensing

lines and actuators during this installation procedure.

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

8

• ProtectPICVanddownstreamequipmentwithanupstreamself-cleaningstrainer.

• FormaximumefficiencyandminimumwearinstallPICVIN VERTICAL POSITION with the stems POINTING UPWARD.

• Besuretoleave 6 INCHES (15.24 CM) OF CLEARANCE above the actuators to allow for actuator removal.

• Beforeinstalling,besurePICVandpipingareCLEAN INSIDE and FREE OF SCALE, chips, welding spatter, and foreign material.

Thoroughly blow out or flush pipe lines.

• ThePICVmustbeinstalledwiththefluidflowinthedirectionofthearrowontheflowarrowplate.

• PipesmustbealignedsquarelywiththePICVateachconnection.

• Tightenflangeboltsevenlytopreventexcessivestressandthepossibilityofcracking.Ifmatingflangesareraisedfacedtheymustbe

machined flat.

• ThePICVandaccessories(ifsoequipped)areassembled,tested,andcalibratedatthefactoryasaunit.Thenameplatespecifiesset-up

parameters used.

• Supplyairorpower,instrumentsignal,andaccessoriesshouldbeconnectedtoportsorterminalsasindicatedonthePICV.

• Verificationandtuningofthesetdifferentialpressuremayberequiredunderactualoperatingconditions.

PRESSURE INDEPENDENT CONTROL VALVE PICV_IOM_REVF_0114

9

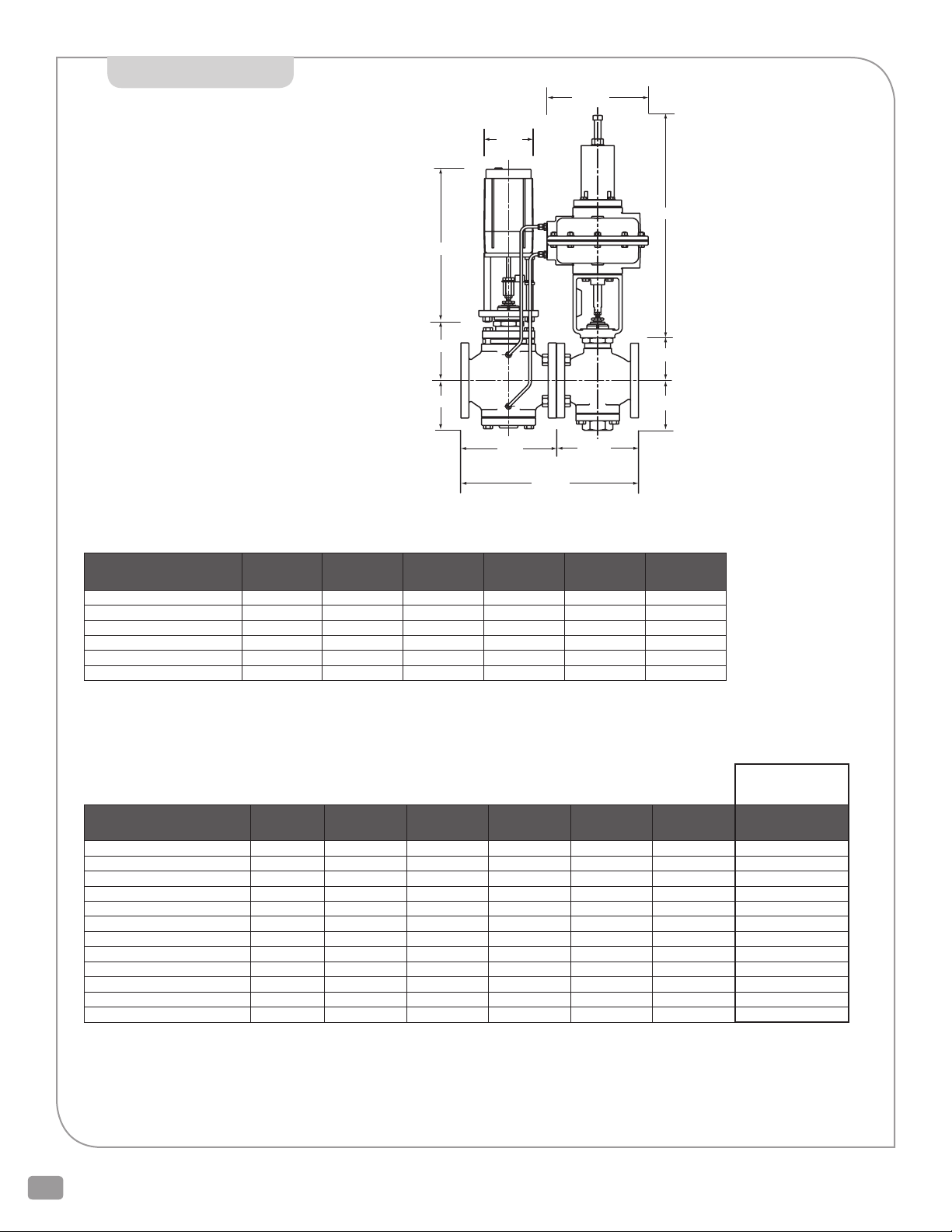

DIMENSIONS

ddpv

PICV SIZES:

2 1/2-4 IN (DN65-DN100)

Control Valve (Left)

Hcv

ccv

Bcv

dcv

WITH VM1500E ACTUATOR

Hdpv

cdpv

Bdpv

Acv Adpv

Xcdp

MODEL LISTING SIZE Acv Bcv Ccv Dcv Hcv

P2023xx-E02x-P20Dx-xx 2-1/2 9 in 4-3/4 in 5-3/4 in 4-7/8 in 14-3/4 in

P3023xx-E02x-P30Dx-xx 3 10 in 5-3/8 in 6-5/8 in 4-7/8 in 14-3/4 in

P4023xx-E02x-P40Dx-xx 4 13 in 6-3/8 in 7-3/4 in 4-7/8 in 14-3/4 in

P2223xx-E02x-P22Dx-xx DN65 22.86 cm 12.07 cm 14.61 cm 12.38 cm 37.47 cm

P3223xx-E02x-P32Dx-xx DN80 25.40 cm 13.65 cm 16.83 cm 12.38 cm 37.47 cm

P4223xx-E02x-P42Dx-xx DN100 33.02 cm 16.19 cm 19.69 cm 12.38 cm 37.47 cm

Acv +/- 1/16 in (0.16 cm) All other dimensions are maximum Allow 6 in (15.24 cm) above actuator for removal service

Total

Differential Pressure Valve (Right)

Model Listing SIZE Adpv Bdpv Cdpv Ddpv Hdpv Xcdp

P2023xx-E02x-P20Dx-2L 2-1/2 7-3/4 in 4-7/8 in 4-1/8 in 9-3/4 in 22-1/8 in 16-13/16 in

P2023xx-E02x-P20Dx-2M 2-1/2 7-3/4 in 4-7/8 in 4-1/8 in 9-3/4 in 26-3/4 in 16-13/16 in

P3023xx-E02x-P30Dx-2L 3 9 in 5-1/8 in 4-3/8 in 9-3/4 in 22-1/8 in 19-1/16 in

P3023xx-E02x-P30Dx-2M 3 9 in 5-1/8 in 4-3/8 in 9-3/4 in 26-3/4 in 19-1/16 in

P4023xx-E02x-P40Dx-2L 4 11-3/8 in 6-3/8 in 5-1/4 in 9-3/4 in 22-1/8 in 24-7/16 in

P4023xx-E02x-P40Dx-2M 4 11-3/8 in 6-3/8 in 5-1/4 in 9-3/4 in 26-3/4 in 24-7/16 in

P2223xx-E02x-P22Dx-2L DN65 19.69 cm 12.38 cm 10.48 cm 24.77 cm 56.20 cm 42.70 cm

P2223xx-E02x-P22Dx-2M DN65 19.69 cm 12.38 cm 10.48 cm 24.77 cm 67.95 cm 42.70 cm

P3223xx-E02x-P32Dx-2L DN80 22.86 cm 13.02 cm 11.11 cm 24.77 cm 56.20 cm 48.42 cm

P3223xx-E02x-P32Dx-2M DN80 22.86 cm 13.02 cm 11.11 cm 24.77 cm 67.95 cm 48.42 cm

P4223xx-E02x-P42Dx-2L DN100 28.89 cm 16.19 cm 13.34 cm 24.77 cm 56.20 cm 62.07 cm

P4223xx-E02x-P42Dx-2M DN100 28.89 cm 16.19 cm 13.34 cm 24.77 cm 67.95 cm 62.07 cm

combined*

* Includes gasket between Control Valve and Differential Pressure Valve

Adpv +/- 1/16 in (0.16 cm) Xcdp +/- 1/8 in (0.32 cm) All other dimensions are maximum

Allow 6 in (15.24 cm) above actuator for removal service

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

10

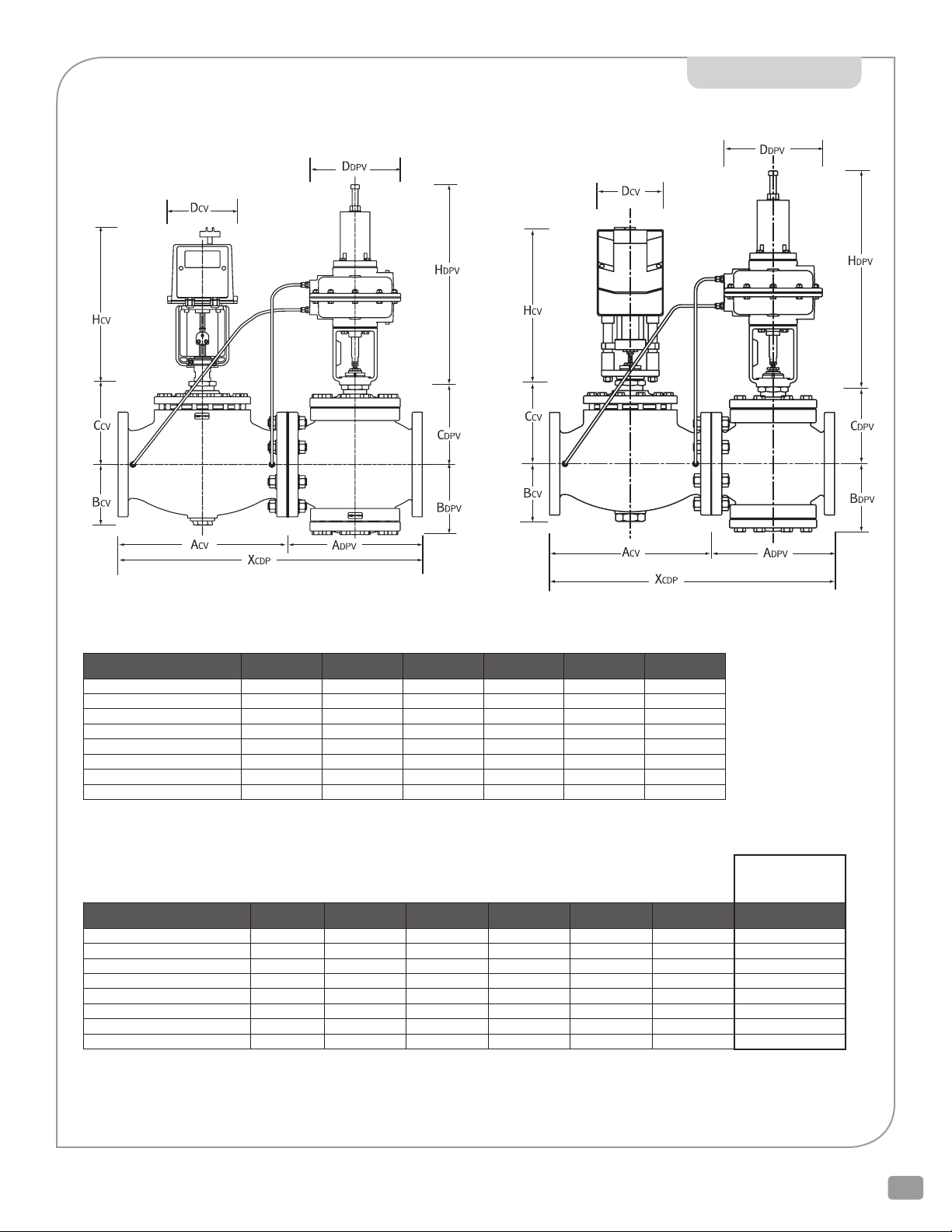

PICV SIZES: 5-6 IN (DN125-DN150)

WITH TR5000 ACTUATOR WITH VM5000E ACTUATOR

DIMENSIONS

Control Valve (Left)

MODEL LISTING SIZE Acv Bcv Ccv Dcv Hcv

P5023xx-E02x-P50Dx-xx 5 15-3/4 in 5-3/4 in 8-1/4 in 6-5/8 in 15-1/4 in

P5023xx-TIG1-P50Dx-xx 5 15-3/4 in 5-3/4 in 8-1/4 in 7-1/2 in 16-1/4 in

P6023xx-E02x-P60Dx-xx 6 17-3/4 in 6-1/2 in 8-7/8 in 6-5/8 in 15-1/4 in

P6023xx-TIGx-P60Dx-xx 6 17-3/4 in 6-1/2 in 8-7/8 in 7-1/2 in 16-1/4 in

P5223xx-E02x-P52Dx-xx DN125 40.01 cm 14.61 cm 20.96 cm 16.83 cm 38.74 cm

P5223xx-TIG1-P52Dx-xx DN125 40.01 cm 14.61 cm 20.96 cm 19.05 cm 41.28 cm

P6223xx-E02x-P62Dx-xx DN150 45.09 cm 16.51 cm 22.54 cm 16.83 cm 38.74 cm

P6223xx-TIGx-P62Dx-xx DN150 45.09 cm 16.51 cm 22.54 cm 19.05 cm 41.28 cm

Acv +/- 1/16 in (0.16 cm) All other dimensions are maximum Allow 6 in (15.24 cm) above actuator for removal service

Differential Pressure Valve (Right)

Model Listing SIZE Adpv Bdpv Cdpv Ddpv Hdpv Xcdp

P5023xx-xxxx-P50Dx-2L 5 12 in 6-7/8 in 7-5/8 in 9-3/4 in 22-1/8 in 27-13/16 in

P5023xx-xxxx-P50Dx-2M 5 12 in 6-7/8 in 7-5/8 in 9-3/4 in 26-3/4 in 27-13/16 in

P6023xx-xxxx-P60Dx-2L 6 14-1/8 in 7-5/8 in 8-1/2 in 9-3/4 in 22-1/8 in 31-15/16 in

P6023xx-xxxx-P60Dx-2M 6 14-1/8 in 7-5/8 in 8-1/2 in 9-3/4 in 26-3/4 in 31-15/16 in

P5223xx-xxxx-P52Dx-2L DN125 30.48 cm 17.46 cm 19.37 cm 24.77 cm 56.20 cm 70.64 cm

P5223xx-xxxx-P52Dx-2M DN125 30.48 cm 17.46 cm 19.37 cm 24.77 cm 67.95 cm 70.64 cm

P6223xx-xxxx-P62Dx-2L DN150 35.88 cm 19.37 cm 21.59 cm 24.77 cm 56.20 cm 81.12 cm

P6223xx-xxxx-P62Dx-2M DN150 35.88 cm 19.37 cm 21.59 cm 24.77 cm 67.95 cm 81.12 cm

* Includes gasket between Control Valve and Differential Pressure Valve

Adpv +/- 1/16 in (0.16 cm) Xcdp +/- 1/8 in (0.32 cm) All other dimensions are maximum

Allow 6 in (15.24 cm) above actuator for removal service

combined*

Total

PRESSURE INDEPENDENT CONTROL VALVE PICV_IOM_REVF_0114

11

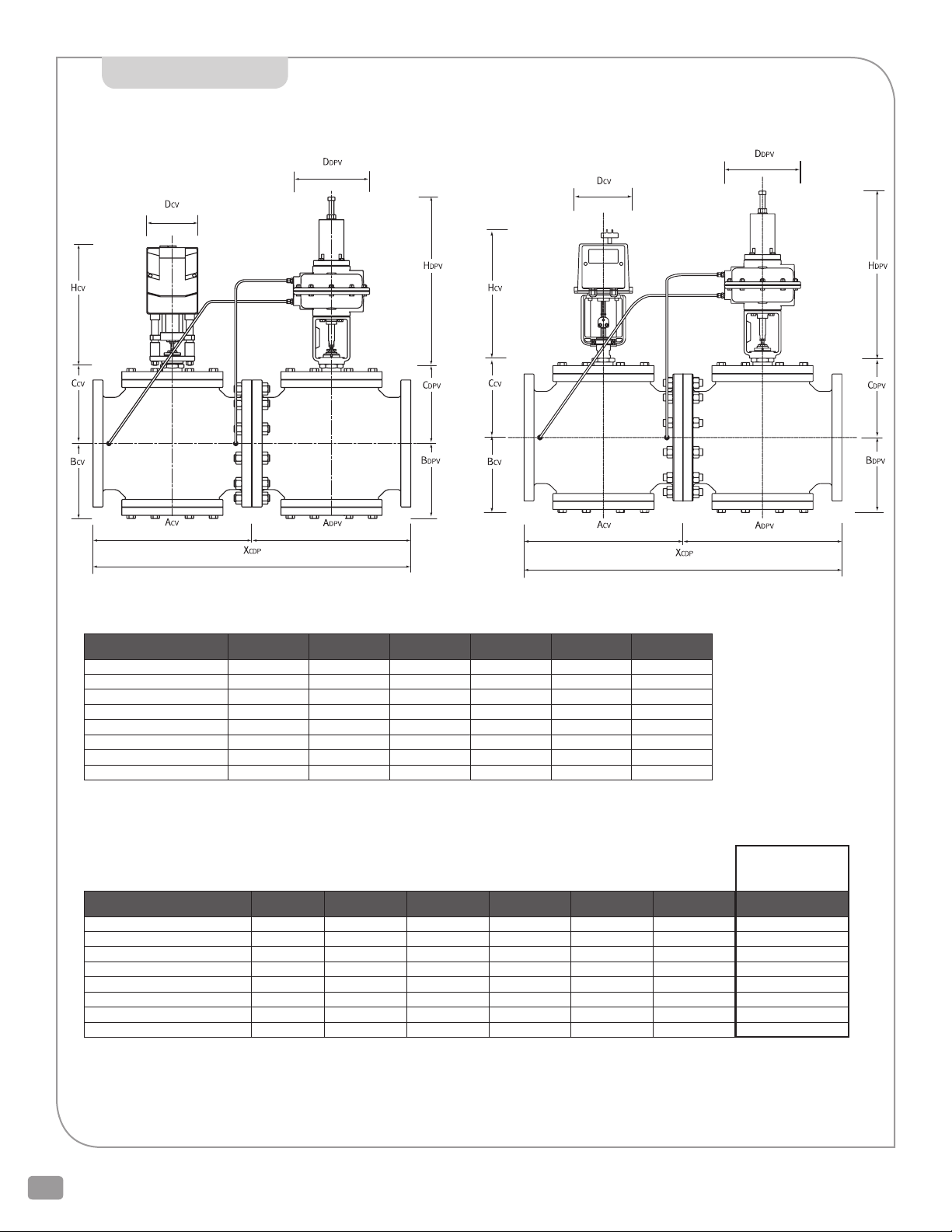

DIMENSIONS

PICV SIZES: 8-10 IN DN200-DN250

WITH TR5000 ACTUATORWITH VM5000E ACTUATOR

Control Valve (Left)

MODEL LISTING SIZE Acv Bcv Ccv Dcv Hcv

P8022xx-E02x-P80Dx-xx 8 16-1/4 in 8-7/8 in 9-5/8 in 6-5/8 in 15 in

P8022xx-TIG1-P80Dx-xx 8 16-1/4 in 8-7/8 in 9-5/8 in 7-3/8 in 16-1/4 in

P1022xx-E02x-P10Dx-xx 10 20 in 9-5/8 in 10-1/8 in 6-5/8 in 15 in

P1022xx-TIG1-P10Dx-xx 10 20 in 9-5/8 in 10-1/8 in 7-3/8 in 16-1/4 in

P8222xx-E02x-P82Dx-xx DN200 41.28 cm 22.54 cm 24.45 cm 16.83 cm 38.10 cm

P8222xx-TIG1-P82Dx-xx DN200 41.28 cm 22.54 cm 24.45 cm 18.73 cm 41.28 cm

P1222xx-E02x-P12Dx-xx DN250 50.80 cm 24.45 cm 25.72 cm 16.83 cm 38.10 cm

P1222xx-TIG1-P12Dx-xx DN250 50.80 cm 24.45 cm 25.72 cm 18.73 cm 41.28 cm

Acv +/- 1/16 in (0.16 cm) All other dimensions are maximum Allow 6 in (15.24 cm) above actuator for removal service

Dierential Pressure Valve (Right)

Model Listing SIZE Adpv Bdpv Cdpv Ddpv Hdpv Xcdp

P8022xx-xxxx-P80Dx-2L 8 16-1/4 in 8-7/8 in 9-5/8 in 9-3/4 in 22-1/8 in 32-9/16 in

P8022xx-xxxx-P80Dx-2M 8 16-1/4 in 8-7/8 in 9-5/8 in 9-3/4 in 26-3/4 in 32-9/16 in

P1022xx-xxxx-P10Dx-2L 10 20 in 9-5/8 in 10-1/8 in 9-3/4 in 22-1/8 in 40-1/16 in

P1022xx-xxxx-P10Dx-2M 10 20 in 9-5/8 in 10-1/8 in 9-3/4 in 26-3/4 in 40-1/16 in

P8222xx-xxxx-P82Dx-2L DN200 41.28 cm 22.54 cm 24.45 cm 24.77 cm 56.20 cm 82.71 cm

P8222xx-xxxx-P82Dx-2M DN200 41.28 cm 22.54 cm 24.45 cm 24.77 cm 67.95 cm 82.71 cm

P1222xx-xxxx-P12Dx-2L DN250 50.80 cm 24.45 cm 25.72 cm 24.77 cm 56.20 cm 101.76 cm

P1222xx-xxxx-P12Dx-2M DN250 50.80 cm 24.45 cm 25.72 cm 24.77 cm 67.95 cm 101.76 cm

* Includes gasket between Control Valve and Differential Pressure Valve

Adpv +/- 1/16 in (0.16 cm) Xcdp +/- 1/8 in (0.32 cm) All other dimensions are maximum

Allow 6 in (15.24 cm) above actuator for removal service

combined*

Total

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

12

PICV WEIGHTS

CONTROL VALVE

MODEL PICV SIZE

P2x23xx-E02x-P2xDx-2L 2-1/2 in, DN65 VM-1500E 2L 144.00 65.32

P2x23xx-E02x-P2xDx-2M 2-1/2 in, DN65 VM-1500E 2M 147.25 66.79

P3x23xx-E02x-P3xDx-2L 3 in, DN80 VM-1500E 2L 172.00 78.02

P3x23xx-E02x-P3xDx-2M 3 in, DN80 VM-1500E 2M 175.25 79.49

P4x23xx-E02x-P4xDx-2L 4 in, DN100 VM-1500E 2L 262.00 118.84

P4x23xx-E02x-P4xDx-2M 4 in, DN100 VM-1500E 2M 265.25 120.32

P5x23xx-E02x-P5xDx-2L 5 in, DN125 VM-5000E 2L 345.00 156.49

P5x23xx-E02x-P5xDx-2M 5 in, DN125 VM-5000E 2M 348.25 157.97

P5x23xx-TIG1-P5xDx-2L 5 in, DN125 TR5000-X 2L 335.40 152.14

P5x23xx-TIG1-P5xDx-2M 5 in, DN125 TR-5000-X 2M 338.65 153.61

P6x23xx-E02x-P6xDx-2L 6 in, DN150 VM-5000E 2L 438.00 198.68

P6x23xx-E02x-P6xDx-2M 6 in, DN150 VM-5000E 2M 441.25 200.15

P6x23xx-TIGx-P6xDx-2L 6 in, DN150 TR5000-X 2L 428.40 194.32

P6x23xx-TIGx-P6xDx-2M 6 in, DN150 TR-5000-X 2M 431.65 195.80

P8x22xx-E02x-P8xDx-2L 8 in, DN200 VM-5000E 2L 652.00 295.75

P8x22xx-E02x-P8xDx-2M 8 in, DN200 VM-5000E 2M 655.25 297.22

P8x22xx-TIG1-P8xDx-2L 8 in, DN200 TR5000-X 2L 642.40 291.39

P8x22xx-TIG1-P8xDx-2M 8 in, DN200 TR-5000-X 2M 645.65 292.86

P1x22xx-E02x-P1xDx-2L 10 in, DN250 VM-5000E 2L 945.00 428.65

P1x22xx-E02x-P1xDx-2M 10 in, DN250 VM-5000E 2M 948.25 430.12

P1x22xx-TIG1-P1xDx-2L 10 in, DN250 TR5000-X 2L 935.40 424.29

P1x22xx-TIG1-P1xDx-2M 10 in, DN250 TR-5000-X 2M 938.65 425.77

ACTUATOR

DPRV

ACTUATOR TOTAL WT (LBS) TOTAL WT (KG)

Weights for models with VM actuators do not include a VMS-25 BCM. Add 4.25 lbs (2kg) Actual shipping weights may vary.

MAINTENANCE

!

DANGER

Personal injury may result from uncontrolled

release of spring force. There is signicant

preload on the spring in the actuator on the

dierential pressure control segment (DPRV)

of the PICV. Disassembling the actuator will

release the spring force (preload) and may

cause serious personal injury.

maintenance free when properly selected and installed. Rebuilding of these valves

should not be necessary under normal operating conditions. For best operation

temperature, and flow within the limits of the valve (See Specification Section and

PICV Product Specification for details). In installations where high vibration exists,

Water should be in specification of the Warren Controls water quality guidelines.

Series PICV (Pressure Independent Control Valves) are for the most part

follow installation guidelines (See Installation); maintain the fluid pressures,

electrical and sensing connections should periodically be checked for integrity.

PACKING ADJUSTMENT

Series PICV packing is self-adjusting and requires no external adjustment.

UNDER NORMAL OPERATING CONDITIONS AND GOOD WATER QUALITY MANY YEARS OF MAINTENANCE FREE SERVICE CAN BE EXPECTED!

Control Valves in HVAC Water Systems

Fluid Quality and Service Life Guide Lines

The purpose of these guidelines is to avoid valve and water systems problems caused by poor water quality in HVAC systems. While all

cooling and heating systems are susceptible to problems, closed chilled water systems, including those containing brine or glycol, are

especially prone to system and valve problems. To achieve the satisfactory operation and maximum life of your Warren Controls valve, it is

important that the following recommendations are adhered to and that a water treatment, filtration and control specialists be consulted

before the system start-up.

PRESSURE INDEPENDENT CONTROL VALVE PICV_IOM_REVF_0114

13

VALVE PACKING LEAKS

The service life of valve stems and packing is dependent on

maintaining non-damaging fluid conditions. Inadequate treatment

or filtration, not in accordance with the recommendations of this

guide, or a qualified treatment specialist, can result in corrosion,

scaling, or abrasive particle formation. Scale and particles migrating

from pipe walls to control valves, will result in scratching the valve

stem, which will prevent the packing from sealing. This problem can

be avoided by the use of proper cleaning, treatment chemicals, and

storage procedures. Water must be treated and soft. Trace leaks of

hard water result in hard calcium carbonate particles on the outside

of the valve, which will scratch the sealing members creating a

packing leak. To avoid a damaging condition, the system should be

cleaned prior to start-up. Filtration equipment and strainers should

be employed as required and a regularly scheduled program of

water condition monitoring and treatment should be followed. Side

stream water filtration may be needed in closed systems, if there is

no regular blow down of the system.

STORAGE

Systems that are stored wet should be completely filled with

properly treated water and isolated to avoid slow leaks, which can

cause serious corrosion problems.

Control valve ‘hunting’ will cause excessive stroking of the valve

stem and result in premature failure of the valve packing seal. The

system must be stabilized to ensure reasonable packing life and

optimal control performance.

Over sizing of a control valve will result in an un-stable condition,

can result in, noise, vibration, premature trim and packing seal

failure. The use of the Warren Controls ValveWorks sizing program

Will facilitate the selection of the optimum valve.

COMMISSIONING

Thorough flushing of the system is necessary before start-up as new

systems, or old systems that have been shut down for an extended

period of time, will usually contain dirt, Weld slag, solder flux, and

pipe scale.

Drained system should be air dried, sealed, and treated with a

desiccant to prevent “atmospheric corrosion” of pipes, which is a

major source of pipe scale.

WATER QUALITY RECOMMENDED PARAMETERS

Chilled Water, Closed Loops, and Hot Water Systems up to 212°F (100° C).

8.0 < pH < 10.3

Conductivity < 3000 MMHS

!

C

CAUTION

The use of hydrazine can

result in the formation of

ammonia and must be controlled to prevent stress corrosion and embrittlement,

which can lead to fracture

of some brass alloys.

Water hardness should be less than 100 ppm of hard water ions (Ca++, Mg++), where 17.1 ppm = 1 Grain Hardness. Additionally, levels of

chloride and sulfate should remain less than 25 ppm. When water hardness is at unacceptable levels, a water softener expert should be

consulted.

hilled Systems

Hot Systems

Iron < 0.5 ppm

Copper < 0.5 ppm

100 ppm < Molybdenum < 150 ppm

(Mild Steel Corrosion Inhibitor)

200 ppm < Molybdenum < 250 ppm

(Mild Steel Corrosion Inhibitor)

400 ppm < Nitrite < 1000 ppm

(Mild Steel Corrosion Inhibitor)

Azole > 5 ppm free and available

(Yellow Metal Inhibitor)

Bacteria < 1000 cells/ml

(when system is cool)

ANTIFREEZE SOLUTIONS-GLYCOLS

The commonly used heat transfer glycol fluids are, either ethylene glycol or propylene glycol. Glycol concentrations of <25% often do not

provide sufficient corrosion inhibiting properties and at levels <20% can actually provide a food source for bacteria. As bacteria consume

the food and die off, a highly acidic condition can result. The recommended concentration for popular glycol based solutions is 25% to 60%.

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

14

VM5000E &

VM1500E

ACTUATOR

INSTRUCTIONS

Page

Actuator Set-up & Wiring .....................16-18

VMS-25 Installation & Wiring ....................18

VM1500E 4-20mA Feedback Kit .................19

VM5000E 4-20mA Feedback Kit ................20

VM1500E Removal & Installation .............. 21

VM5000E Removal & Installation ..............21

PRESSURE INDEPENDENT CONTROL VALVE PICV_IOM_REVF_0114

15

SET-UP

SP ........................ 24 volts AC power in

SN ....................... Common (Ground) and control signal negative

(See wiring diagrams)

Y .......................... Control signal in (Positive)

X .......................... Feedback signal out (Positive)

1 .......................... Override

3 .......................... Override

SWITCH FUNCTIONS

Switch OFF ON

1 Voltage Control Signal Milliamp Control Signal

2 2 - 10 Volts or 4 - 20 ma 0 - 10 volts or 0 - 20 ma

3 Direct Acting Reverse Acting

(Extend on increasing signal) (Retract on increasing signal)

4 Full Range Split Range

5 Low Range Signal High Range Signal

6 Proportional 3 Point Floating

7 Equal Percentage Valve (Default) Linear Valve

8 (Default) DO NOT USE

9 Reset Reset

Feedback Positive

0 - 10 or 2 - 10 Vdc

Control signal

Positive

24 volts ac

Common and control signal negative

If system is grounded, then ground SN

24 volts ac

Terminal 1 St em down

Terminal 3 St em up

Override

Common and

control signal negative

24 volts ac

In the over ride pos ition the Ac tuator i s driven

to the end p osition . Connect ing to term inal

1 drives t he stem dow n. Connec ting to

termin al 3 drives t he stem up.

When the actuator settings are known, it is easier to make them

before the valve and actuator are installed in the system. When

power is first applied to the actuator, check to see that it moves

through its full range. If it does not, reset it by moving switch #9.

MANUAL OPERATION AND OVERRIDE

The actuator can be manually operated with a metric hex wrench. The

VM1500E uses a 4mm hex wrench. The VM5000E uses an 8mm hex

wrench. The socket is on top of the actuator. VM5000E actuators have

a clutch button that must be depressed while manually operating the

actuator. De-Energize the actuator before manual operation.

OVERRIDE

:

Connecting the neutral (terminal SN) to terminal 1 lowers the stem

and to terminal 3 raises the stem. This can be done by an external

switch or controller.

AUTOMATIC STROKE ADJUSTMENT

The stroke adjusts itself automatically. This happens the first time

power is applied or whenever the position of switch #9 is changed.

Adjustment takes several minutes during which the actuator will

move through its full stroke 2 or 3 times. The actuator remembers the

settings so a power failure does not cause the actuator to reset itself.

The automatic stroke adjustment does not work if the valve stroke

is greater than the limits of the actuator. The maximum strokes are:

VM1500E 1 1/2” 40 MM

VM5000E 2 1/8” 55 MM

Automatic stroke adjustment ensures that the signal range covers

the actual stroke of the valve.

RESET

Changing the position of switch #9 makes the actuator recalculate

the stroke. Do this if the actuator has been used on another valve,

tested without being on the valve, has been incorrectly mounted on

the valve, or has been taken off of the valve and reinstalled.

CONTROL SIGNALS

The actuator must be set for the control signal being used and

whether the signal is direct acting or reverse acting.

The acceptable signals are:

FLOATING

or any of the following proportional signals.

24 VOLTS AC 3 POINT

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

16

Full Range Split Range

Actuator

Stroke

Stroke

Flow

Valve

Flow

Signal

Actuator

Signal

Stroke

Stroke

Flow

Valve

Flow

Valve + Actuator

Signal

Flow

Valve

Stroke

Flow

Valve + Actuator

Signal

Stroke

Flow

Valve

Flow

Valve + Actuator

Signal

Stroke

Flow

Valve

Flow

Valve + Actuator

Signal

Flow

Valve

Flow

Valve + Actuator

Signal

Flow

Valve + Actuator

Signal

Flow

0 - 10 vdc 0 - 5 vdc 5 - 10 vdc

2 - 10 vdc 2 - 6 vdc 6 - 10 vdc

0 - 20 ma 0 - 10 ma 10 - 20 ma

4 - 20 ma 4 - 12 ma 12 - 20 ma

Split ranges allow two actuators to be operated in sequence from

one full range signal. Proportional signals are programmed with

switches 1 - 5. The actuators are set for floating control by turning

on switch #6. Turning switch #6 on deactivates switches 1 - 5.

Please note the wiring for floating control differs from the wiring for

proportional control.

SELECTING THE SIGNAL

Floating Switch #6 ON

Proportional Switch #6 OFF

SIGNAL SWITCH NUMBER

VOLTS 1 2 4 5

2 - 10 OFF OFF OFF OFF

0 - 10 OFF ON OFF OFF

2 - 6 OFF OFF ON OFF

6 - 10 OFF OFF ON ON

0 - 5 OFF ON ON OFF

5 - 10 OFF ON ON ON

When switch #6 is on

switches 1-5 are inactive.

DIRECT OR REVERSE ACTING

An increasing signal can either drive the valve stem down

(direct acting) or up (reverse acting).

Reverse Acting Switch #3 ON

Properly selected and sized control valves utilize the default

(OFF) positions for switches #7 & #8.

Contact Warren Controls (Ph: 800-922-0085) before repositioning

either switch.

FLOW CHARACTERISTIC:

Change Flow Characteristic Switch #7

IN THE OFF POSITION STEM TRAVEL IS PROPORTIONAL TO CONTROL SIGNAL AND DOES NOT ALTER THE FLOW CHARACTERISTIC OF

VALVE. THIS IS THE POSITION SWITCH #7 SHOULD BE IN NORMALLY.

When the stem travel of an actuator is proportional to the control

signal, the shape (flow characteristic) of the valve’s plug determines

the flow. PICV valves have an equal percentage flow characteristic.

An equal percentage valve opens slowly at the start so that 25%

stem travel results in less than 25% flow. When Switch #7 is in the

ON position the stroke is electronically adjusted so that an equal

percentage valve performs as if it had a linear flow characteristic. A

linear valve opens so that 25% stem travel results in 25% flow.

MILLIAMPS 1 2 4 5

4 - 20 ON OFF OFF OFF

0 - 20 ON ON OFF OFF

4 - 12 ON OFF ON OFF

12 - 20 ON OFF ON ON

0 - 10 ON ON ON OFF

10 - 20 ON ON ON ON

EQUAL PERCENTAGE VALVE & SWITCH #7 OFF

SWITCH 8: FACTORY DEFAULT OFF

The correct position for Switch #8 is OFF.

Do not use the Switch #8 ON. If Switch #8 is ON the valve will not function properly as a PICV.

NOTE: Previous models were equipped with three movable jumpers in place of the 9-switch block for actuator setup. For information about them contact

Warren Controls (Ph: 800-922-0085).

SIGNAL SWITCH NUMBER

Signal

Stroke

Flow

Signal

Valve + Actuator

EQUAL PERCENTAGE VALVE & SWITCH #7 ON

Signal

Actuator

Stroke

Signal

Valve + Actuator

PRESSURE INDEPENDENT CONTROL VALVE PICV_IOM_REVF_0114

17

PRODUCT: SERIES VM LINEAR ELECTRIC ACTUATORS

NATURE OF FAULT: Actuator motor does not de-energize at one end of travel. Actuator does not

respond to Input signal changes.

PROBABLE CAUSE: Over-travel device cannot reach limit switch activation point.

CORRECTIVE ACTION(S):

1. De-energize the actuator, both power and signal.

2. Remove the actuator cover and locate the two switches soldered onto the circuit board. Note

the small lever protruding through the board, between the switches.

3. Using a hex wrench, declutching if necessary, manually drive the actuator away from its’ end of

travel. Note that the lever moves to a “rest” position.

4. Loosen the circuit board mounting screws sufficiently to allow the board to be moved in its’

slotted mounting holes.

5. Position the board so the lever is centered between the switches and re-tighten the mounting

screws. Check position again, after tightening.

6. Re-energize the actuator, and perform “Auto-Stroke”. Observe that the actuator travels fully in

both directions, and comes to rest at the point dictated by the applied input signal.

For oating control, connect controller with dry contacts and

TERMINALS

L System Power 24VAC

LN System Neutral

BT Battery Test

RC Remote Control

TG Te st G rou nd

C1 Relay Common 1st Motor

C2 Relay Common 2nd Motor

NC1 Relay Normally Closed 1st Motor

NC2 Relay Normally Closed 2nd Motor

NO1 Relay Normally Open 1st Motor

NO2 Relay Normally Open 2nd Motor

AC 24 Volt Out

oating mid position between terminal NO1 and 1 and 3 for

Actuator A, and between terminal NO2 and 1 and 3 for Actuator B.

LEVER, CORRECTLY

POSITIONED

BETWEEN

SWITCHES

VMS-25

Operation:

Proportional Normal: Terminal AC is connected to 24

VAC building power. Terminal LN supplies power to

SN. Actuator responds to modulating input signal.

Power Failure: Terminal AC changes to 24V square

wave from inverter. Terminal C2 connects to Terminal

NC2. Terminal NC2 supplies power to Termial 1 or 3 to

drive actuator to fail safe position.

INSTALLATION

1. Connect the VMS-25 to the actuators as shown. Connect NC1 or

NC2 to terminal 1 on an actuator to drive the valve stem down during

power failure or to terminal 3 to drive the valve stem up during a

power failure.

2. Connect VMS-25 to 24 volts AC power.

3. Connect the red wire to the battery positive (+) and the black wire

to the battery negative (-).

Note: Connect the 24 volt power to the VMS-25 before connecting

the battery. Connecting the battery first causes the VMS-25 to

go into the power failure mode. If there are conditions other than

power failure during which the actuator should be driven to the end

position, replace the jumper between LN & RC with a contact that

opens on demand.

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

18

TESTING

Disconnecting the jumper between LN & RC, with building

power on, will drive the actuator to the power failure position.

Testing the VMS-25 and the battery. Measure the voltage

between TG & BT. TG is negative. When the power supply is charging

correctly the voltage will be 13 - 14 volts DC. Disconnect LN or L and

then measure the voltage between TG & BT. If the battery is good

and adequately charged the voltage will be Between 10 - 12 volts

DC. VMS-25 is a standby power supply for VM1500E and VM5000E

actuators. It is intended to drive these actuators to either open or

close a valve during a power failure. The VMS-25 can power one

VM5000E or two VM1500E actuators.

VM1500E MOTOR ACTUATOR

Installation of modication circuit board • PUR 1137

IN KIT NUMBER KVM1500EFB4TO20MA00

to convert native 2-10 vdc feedback output to optional 4-20 mAdc.

OVERVIEW:

VM motor actuators feature a native DC voltage position feedback output available

at motor terminals X (+) and SN (-). Addition of the optional circuit board shown

above converts the feedback output to 4-20 mAdc, available at terminals 4-20mA

(+) and N (-), capable of working into load resistances as high as 550 ohms. The

circuit operates on 24 vac fed from terminal SP (hot) to terminal SP on the mod.

board, and terminal SN (common) to terminal SN on the mod. board. A single wire

brings feedback from motor terminal X to mod. board terminal 2-10V. An adjustment potentiometer on the mod. board can calibrate the 4-20 mAdc feedback output at any critical point in the actuator’s travel. Nominal adjustment span, when

voltage feedback is 2 vdc, is from 3.5 to 4.5 mAdc output.

MATERIALS & TOOLS:

Wires and mounting screws are provided in the kit. The illustration that follows

shows RED wire insulation for power (hot), BLACK for power (neutral) and GREEN

for feedback. Stranded wire is used to avoid difficulty in connecting two wires to a

single terminal on the motor board. A small straight-bladed screwdriver is needed

for the wiring terminals, and a #2 Phillips screwdriver for the mounting screws

PUR 1137

4-20 mAdc Mod. Board

VM1500E KVM1500EFB4TO20MA00

A. Using two mounting screws, fasten the mod. board to the two existing bosses on the motor housing. Note the rectangular wire-

clearance cutout at the upper left.

B. Install the RED wire from motor board terminal SP to mod. board terminal SP.

C. Install the BLACK wire from motor board terminal SN to mod. board terminal SN.

D. Install the GREEN wire from motor board terminal X to mod. board terminal 2-10V.

E. Installation is complete. Connect the motor actuator in accordance with the Installation, Operating & Maintenance manual, except that

feedback output is now located at mod. board terminals 4-20mA (+) and N (-).

PRESSURE INDEPENDENT CONTROL VALVE PICV_IOM_REVF_0114

19

VM5000E MOTOR ACTUATOR

Installation of modication circuit board • PUR 1137

IN KIT NUMBER KVM5000EFB4TO20MA00

to convert native 2-10 vdc feedback output to optional 4-20 mAdc.

OVERVIEW:

VM motor actuators feature a native DC voltage position feedback output

available at motor terminals X (+) and SN (-). Addition of the optional circuit

board shown above converts the feedback output to 4-20 mAdc, available at

terminals 4-20mA (+) and N (-), capable of working into load resistances as

high as 550 ohms. The circuit operates on 24 vac fed from terminal SP (hot)

to terminal SP on the mod. board, and terminal SN (common) to terminal

SN on the mod. board. A single wire brings feedback from motor terminal

X to mod. board terminal 2-10V. An adjustment potentiometer on the mod.

board can calibrate the 4-20 mAdc feedback output at any critical point in

the actuator’s travel. Nominal adjustment span, when voltage feedback is 2

vdc, is from 3.5 to 4.5 mAdc output.

MATERIALS & TOOLS:

Wires and mounting screws are provided in the kit. The illustrations that follow show RED wire insulation for power (hot), BLACK for power (neutral) and

GREEN for feedback. Stranded wire is used to avoid difficulty in connecting

two wires to a single terminal on the motor board. A small straight-bladed

screwdriver is needed for the wiring terminals, and a #2 Phillips screwdriver

for the mounting screws

PUR 1137

4-20 mAdc Mod. Board

VM5000E KVM5000EFB4TO20MA00

A. Using four mounting screws, fasten the mod. board to the existing bosses on top of the motor housing. Note the semicircular

clutch clearance cutout on the right side.

B. Install the RED wire from motor board terminal SP to mod. board terminal SP.

C. Install the BLACK wire from motor board terminal SN to mod. board terminal SN.

D. Install the GREEN wire from motor board terminal X to mod. board terminal 2-10V.

E. Installation is complete. Connect the motor actuator in accordance with the Installation, Operating & Maintenance manual,

except that feedback output is now located at mod. board terminals 4-20mA (+) and N (-).

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

20

Read all instructions carefully before beginning.

TURNING THE ACTUATOR LEGS CAUSES DAMAGE TO THE ACTUATOR AND VOIDS THE WARRANTY.

REMOVAL OF VM1500E ACTUATOR FROM VALVE

1) Remove line pressure and isolate valve in piping.

2) Operate actuator so plug is o seat(s) and tabs of anti-rotation device

(Item 2) can be unbent in Step 5.

3) Loosen jamnut (Item 3) and thread to bottom of threads on valve

stem.

4) Loosen yoke locknut until it is free of bonnet.

5) Unbend tabs of anti-rotation device.

6) Remove anti-rotation device from stem connector so stem connector

may be turned.

7) Hold jamnut on valve stem and tur n the stem connector to disengage

from valve stem. The valve stem should never be turned while the

plug is in contact with the seat otherwise the seating surfaces

will be damaged.

8) Remove actuator from valve.

_______________________________________________

INSTALLATION OF VM1500E ACTUATOR ON VALVE.

THE BRASS SPACER THAT COMES WITH THE ACTUATOR MUST BE ASSEMBLED

ON BOTTOM SIDE OF YOKE AS SHOWN ON DRAWING C3400002.

1) Push valve stem down until plug is seated. Note stem location.

2) Install hex jamnut (Item 3) on valve stem. Thread jamnut to bottom of

threads on stem.

3) Place actuator, yoke locknut, and anti-rotation device (Item 2) over

valve stem and onto bonnet. Watch orientation of yoke locknut and

anti-rotation device. Anti-rotation device must be oriented so tabs

can be bent around cross bar in Step 6. Actuator must rest on bonnet.

If necessary use actuator manual override to reposition the stem

connector. The manual override is at the top of the actuator. Turn

override using a 4mm hex wrench. Do not tighten yoke locknut at

this time.

4) Rotate actuator to desired orientation. For the factory default

actuator position face the actuator circuit board and install the

actuator on the valve with the valve upright and its inlet to the left.

Thread yoke locknut onto bonnet and tighten securely. Use a blunt

chisel and hammer for nal tightening.

5) Lift valve stem. Hold jamnut on valve stem and turn the stem

connector to engage valve stem. If necessary use actuator manual

override to reposition the stem connector. The valve stem should

never be turned while the plug is in contact with the seat

otherwise the seating surfaces will be damaged. The minimum

required stem engagement is 3/8 inch (9.53 mm). After required stem

engagement is reached thread jamnut up valve stem to contact stem

connector. Tighten jamnut to secure valve stem to stem connector.

6) Install anti-rotation device on cross bar and bend tabs over so stem

connector will not turn.

7) Push red travel indicators on leg of actuator into contact with cross

bar. Connect power to actuator. On circuit board turn dipswitch 9

ON then OFF. Actuator will perform automatic stroke adjustment. In

the stem down direction the plug must reach the seat in the valve

before the brass bar on the shaft inside the motor housing contacts

the bottom of the motor housing. The lever extending through the

hole in the circuit board deects to depress the upper microswitch on

the circuit board to stop the motor at that end of travel. In the stem up

direction the plug must reach the upper seat or travel stop inside the

valve before the stem connector contacts the bottom of the motor

housing. The lever extending through the hole in the circuit board

deects to depress the lower microswitch to stop the motor at that

end of travel. If necessary turn o power, loosen jamnut, remove antirotation device from stem connector, and repeat Steps 5 thru 7.

8) Turn o power. Make necessary dipswitch settings and additional

wiring connections. See Set-Up and Wiring sections of these

instructions.

9) Return power to actuator.

10) Return line pressure to valve.

11) Stroke valve several times to check operation.

Read all instructions carefully before beginning.

TURNING THE ACTUATOR LEGS CAUSES DAMAGE TO THE

ACTUATOR AND VOIDS THE WARRANTY.

REMOVAL OF VM5000E ACTUATOR FROM VALVE

1) Remove line pressure and isolate valve in piping.

2) Operate actuator so plug is o seat(s) and anti-rotation device (Item 2)

can be removed in Step 4.

3)

Loosen jamnut (Item 3) and thread to bottom of threads on valve stem.

4) Remove anti-rotation device from stem connector so stem connector

may be turned.

5) Loosen yoke locknut until it is free of bonnet.

6) Hold jamnut on valve stem and tur n the stem connector to disengage

from valve stem. The valve stem should never be turned while the

plug is in contact with the seat otherwise the seating surfaces

will be damaged.

7) Remove actuator from valve.

_______________________________________________

INSTALLATION OF VM5000E ACTUATOR ON VALVE.

THE BRASS SPACER THAT COMES WITH THE ACTUATOR MUST BE ASSEMBLED

ON BOTTOM SIDE OF YOKE AS SHOWN ON DRAWING C3400001.

1) Push valve stem down until plug is seated. Note stem location.

2) Install hex jamnut (Item 3) on valve stem. Thread jamnut to bottom of

threads on stem.

3)

Place actuator, yoke locknut, and anti-rotation device (Item 2) over

valve stem and onto bonnet. Watch orientation of yoke locknut and

anti-rotation device. Actuator must rest on bonnet. If necessary use

actuator manual override to reposition the stem connector. The

manual override is at the top of the actuator. There are t wo rubber caps

on the actuator cover. One cap covers the override; the second cap

covers the clutch. Remove both caps. Depress clutch and turn override

using an 8mm hex wrench. Replace caps when nished to protect

motor and circuit board. Do not tighten yoke locknut at this time.

4) Rotate actuator to desired orientation. For the factory default

actuator position face the actuator circuit board and install the

actuator on the valve with the valve upright and its inlet to the left.

Thread yoke locknut onto bonnet and tighten securely. Use a blunt

chisel and hammer for nal tightening.

5) Lift valve stem. Hold jamnut on valve stem and turn the stem

connector to engage valve stem. If necessary use actuator manual

override to reposition the stem connector. The valve stem should

never be turned while the plug is in contact with the seat

otherwise the seating surfaces will be damaged. The minimum

required stem engagement is 9/16 inch (14.29 mm). After required

stem engagement is reached thread jamnut up valve stem to contact

stem connector. Tighten jamnut to secure valve stem to stem

connector.

6) I

nstall anti-rotation device on cross bar so stem connec tor will not turn.

7) Push red travel indicators on legs of actuator into contact with cross

bar. Connect power to actuator. On circuit board turn dipswitch 9 ON

then OFF. Actuator will perform automatic stroke adjustment. In the

stem down direction the plug must reach the seat in the valve before

the cross bar on the actuator legs pushes the red travel indicators

on legs of actuator against the actuator base. The lever extending

through the hole in the circuit board deects to depress the upper

microswitch on the circuit board to stop the motor at that end of

travel. In the stem up direction the plug must reach the upper seat

or travel stop inside the valve before the cross bar pushes the red

travel indicators against the bottom of the motor housing. The valve

stem must not contact the bottom of the motor housing. The lever

extending through the hole in the circuit board deects to depress

the lower microswitch to stop the motor at that end of travel. If

necessary turn o power, loosen jamnut, remove anti-rotation device

from stem connector, and repeat Steps 5 thru 7.

8) Turn o power. Make necessary dipswitch settings and additional

wiring connections. See Set-Up and Wiring sections of these

instructions.

9) Return power to actuator.

10) Return line pressure to valve.

11) Stroke valve several times to check operation.

PRESSURE INDEPENDENT CONTROL VALVE PICV_IOM_REVF_0114

21

C3400001

C3400002

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

22

TR5000-X

ACTUATOR

INSTRUCTIONS

Page

Set-up & Wiring .................. 24-25

Removal & Installation ....... 26 -27

PRESSURE INDEPENDENT CONTROL VALVE PICV_IOM_REVF_0114

23

2

Made the actuator’s stem is concentric with the valve's stem

and made these two connecting faces keep coinciding.

Then lock the two screws on the clip.

The status after assembled, face and back.

Manual device operation

B

o

o

EY

B

o

o

EY

Take down the front cover, screw off the water

joint, for preparing wiring.

Make the wire through the water joint,

connect the wire to the terminal as required.

Fit on the water joint after wiring.

Install the front cover, screw the screw.

Front cover

through this hole

1

2

3

4

ERR

RUN

UL DL AL MAX MIN

ERR

RUN

UL DL AL MAX MIN

Connecting Sheet

TS-R5000220X12-E01-00

Mounting Orientation

180°

360°

Power

switch

Knob

Crank

Shut off and prepare for manual operation

Pull out the crank and go round 180 degree

Press down the knob to limit position, keep press

and start to turn the crank.

After finished the manual operation, release the knob,

and pull up the knob to the up limit position.

( Any release of press

is not allowed when

the crank running.)

1

2

3

4

S2 Switch setting

S2

Switch

Function Description

1 Flow character

ON LOG: equal-percentage

OFF LIN: equal-linear

2

Starting of input/

output signal

ON 20%:the starting input / output signal is 20% (namely 4~20mA or 2~10V)

OFF 0:the starting input / output signal is 0 (namely 0~20mA or 0~10V)

3 Type of input signal

ON II: input current signal

OFF UI: input voltage signal

with manual device

TR5000-X220-S.12

Chilled/hot water application

Not suitable downwards

Steam application

All above suitable

TR5000-X220S.12 / TR5000-X220-S.12-51

Rating force 5000N Input signal 0(2)~10VDC, 0(4)~20MA

Actual force 4500~5500N Output signal 0(2)~10VDC, 0(4)~20MA

Type of control proportional Voltage input impedance >100K

Power consumption 12VA Current input impedance <0.167K

Motor Synchronous motor with

permanent magnetic

Nominal stroke 42mm, 51mm Current output load <0.5K

Running speed 3.57s/ mm (50Hz) Up and down dead band ≤2.5%

Environmental temperature -10~50ºC (Operation condition) Sensititivity low ≤2% high ≤1.5%

Environmental humidity ≤95% RH(40ºC)

(Operation condition)

IP Degree IP54 Material of cover Aluminum die casting

RUNNING MODE Up/down straight travel Net weight of product 5.2 Kg

Voltage output load >1K

Material of bracket Aluminum die casting

(surface anti-rust process)

(surface anti-rust process)

WIRING

With switch S3-7 OFF (Factory Default), the self-stroking button must be

pressed for self-stroking to start. With switch S3-7 ON, self-stroking starts

each time the actuator is powered up. If switch S3-7 is ON, self-stroking

may also be started by pressing the self-stroking button for greater than

3 seconds. It is recommended that switch S3-7 be OFF.

The self-stroking function must be completed in order to calibrate the

TR5000 actuator to the travel of a valve.

Position the actuator ON-OFF switch in the OFF position. Position switch

S3-7 in the OFF position. Warning: If switch S3-7 is ON, the actuator

will start self-stroking as soon as power is applied. The sudden

movement and application of force may result in damage to the

valve and personal injury. After assembling the TR5000 actuator to the

Notes:

1. See separate instruction for installation of TR5000 actuator on PICV valves.

2. When self-stroking, the actuator cannot be controlled by the input signal.

3. The self-stroking function must be repeated each time the type of input signal or output (feedback) signal is changed.

The PCB has an aperture potentiometer. DO NOT adjust the aperture potentiometer. The aperture potentiometer is factory set to 100. If the aperture

potentiometer is adjusted to less than 100, the valve will not function properly as a PICV

PCB

CPU

aperture

potentiometer

self-stroking button

60

50

40

30

maximum

opening

auxiliary terminal

function digit

error light

70

1

2

UL

S2

S1

80

ERR

90

RUN

100

running light

3

6

5

4

AL

DL

DEBUGGING/SELF-STROKING

valve, connect the 220VAC power supply. Position the actuator ON-OFF

switch in the ON position. Then press the self-stroking button on the

PCB and hold (greater than 3 seconds) until the running light flashes

red (1Hz).

–Self-strokingstarts

–The actuator stem extends to the lower travel limit; the

running light flashes red (1Hz).

–The actuator stem retracts to the upper travel limit; the

running light flashes red (1Hz).

–The travel limitsare recorded inthe CPU; self-stroking is

finished (total process takes approx.150 seconds). The

actuator and running light return to normal operation.

ON-OFF SWITCH

5

1

3 4

2

II

UI

20%

0

UI

II

ON

S2

1

2

3 4

OFF

number digit

L

N

connecting terminal

7 8

6

S3

DW

DF

HS

DA

IO

UO

O

LS

RA

UP

RF

S3

1

2

3 4

220VAC

Y

E

The TR5000 actuator has an

ON-OFF switch.

The switc h must be in

the ON position for the

actuator to operate.

ON

OFF

S2 SWITCH SETTING

FACTORY DEFAULT

S2 Dip

Switch

Function

Start point of

S2-1

input/output

signal

Type of input

S2-2

signal

S2-3

Type of output

S2-4

(feedback)

signal

Operating

S3-5

mode

Loss of input

S3-6

signal mode

Self-stroking

S3-7

mode

S3-8 Sensitivity

Posi-

Description

tion

ON 20%: The start point of the input / output signal is 20% (The full input / output

signal is 4~20mA or 2~10V) (Factory Default)

OFF 0: The start point of the input / output signal is 0% (The full input / output signal is

0~20mA or 0~10V)

ON II: Input signal is current (mAdc) (Factory Default)

OFF UI: Input signal is voltage (Vdc)

ON When S2-2 is OFF, S2-3 MUST be ON

OFF When S2-2 is ON, S2-3 MUST be OFF (Factory Default)

ON IO: Output signal is current (mAdc) (Factory Default)

OFF UO: Output signal is voltage (Vdc)

ON DA: DA mode (When input signal is increasing, the actuator stem extends ) (Factory

Default)

OFF RA: RA mode (When input signal is increasing, the actuator stem retracts)

ON DW: On loss of input signal, the actuator fails to the minimum input signal position.

(Factory Default)

OFF UP: On loss of input signal, the actuator fails to the maximum input signal position.

ON DF: Self-stroking starts each time the actuator is powered up.

OFF RF: Self-stroking starts ONLY when the self-stroking button is pressed for >3 sec-

onds. (Factory Default)

ON HS: High sensitivity of input signal </=1.5%

OFF LS: Low sensitivity of input signal </=2% (Factory Default)

E g .1

ON

S2

OFF

1 2 3 4

S3

5 6 7 8

Input signal: 4-20mA

Output signal: 4-20mA

Operating Mode: DA

Loss of input signal mode: DW

Sensitivity of input signal 2%

Eg.2

ON

S2

OFF

1 2 3 4

Input signal: 0-10VDC

Output signal: 0-10VDC

Operating Mode: DA

Loss of input signal mode: DW

Sensitivity of input signal 2%

S3

5 6 7 8

_

<

_

<

LIGHTS AND DISPLAY

-- Running light (RUN): When the actuator stem retracts, the running light shows red; when the actuator stem extends, the running light shows green;

When the actuator is self-stroking, the running light flashes red (1Hz). The display does not show a value when the actuator is self-stroking.

-- Warning light (ERR): When the actuator has an error, the warning light will be lit. Errors include: The actuator cannot complete the self-stoking function.

The actuator cannot move the stem to the correct position for the input signal.

-- Display: The display has two parts. The first part, the single character on the left, is the function display; the second part, the three characters on the

right, is the numerical display.

DESCRIPTION OF DISPLAY:

Function

display

shows

A Numerical display shows aperture

C Numerical display shows input

F Numerical display shows output

When the actuator is running correctly, “C” and “F” alternate in the function display. When “C” is visible, the input signal percentage is shown in the

numerical display. When “F” is visible, the output signal percentage is shown in the numerical display.

Additional function terminal

1) Terminal 1,2 (UL): Non-functional, No terminal block present

2) Terminal 3,4 (DL): Non-functional, No terminal block present

3) Terminal 5,6 (AL): Fault SPDT input terminal (NO) When a fault occurs, this terminal will close. Faults include: The actuator cannot complete the self-

stoking function. The actuator cannot move the stem to the correct position for the input signal.

Notes: 1. Contact Capacity of SPDT:1A (125VAC/30VDC)

2. Contact Capacity external connection SPDT: more than 50mA /30VDC

Meaning Numerical

display

shows

Number

setting in percent

signal in percent

signal in percent

from

30~100

Number

from

0~100

Number

from

0~100

Meaning

Function display shows A and numerical display shows value from 30 to 100 as