Electric Actuator Instructions

E024, E025, E026,

E029 & E030

BAC IOM

TABLE OF CONTENTS

Electric Actuator Specifications..............................2

Overview ........................................................................3

Actuator Wiring Diagrams ........................................4

VMS-35 Specifications and Wiring Diagram ......5

VMS -35 Installation and Testing ............................6

VMS -35 Battery Replacement ................................7

Removal of E024 & E025 ...........................................8

Installation of E024 &E025 .......................................8

Removal of E026, E029 & E030................................9

Installation of E026, E029 & E030 ...........................9

Set-up ........................................................................... 10

Control Action ........................................................... 11

Power Failure Direction E025 & E026 ................ 12

Indicator Lights ......................................................... 13

Installation Drawings ........................................14-15

BAC_IOM_RevA_0214

92500115 RevA

ELECTRIC ACTUATOR SPECIFICATIONS*

Valve Usage: E024, E025 [Valve sizes 1/2 to 4 Inch]

E026 [Valve sizes 1 to 6 Inch]

E029, E030 [Valve sizes 1-1/4 to 10 Inch]

______________________________________________________________________________________________

Power supply: 24 VAC ± 20% 50/60 Hz, 24 VDC ± 10%

______________________________________________________________________________________________

Power Consumption: E024 6 VA

E025, E026 21 VA

E029 10 VA

E030 50 VA (Actuator 10VA, VMS-35 40VA)

______________________________________________________________________________________________

Timing: 90 seconds full stroke max

______________________________________________________________________________________________

Control Signal: 2-10 Vdc (default), 4-20 mAdc [with KR500 (resistor kit)]

______________________________________________________________________________________________

Feedback Signal: 2-10 Vdc

______________________________________________________________________________________________

Signal Failure Direction: E024, E029 Fail Closed or Lower Port Closed (default), or

Fail Open or Upper Port Closed

E030 Fail-Safe (this choice dictates Power Failure Mode)

E025, E026 Fail Closed or Lower Port Closed (default), or

Fail Open or Upper Port Closed

______________________________________________________________________________________________

Power Failure Mode: E024, E029 Fail-In-Place

E030 Fail-Safe

E025, E026 Fail Closed or Lower Port Closed (default), or

Fail Open or Upper Port Closed

______________________________________________________________________________________________

Capacitor: E025, E026 Capacitor charge time 5 to 20 seconds

______________________________________________________________________________________________

Manual Override: Yes, with supplied Allen Key (4mm E024, E025 / 5mm, E026, E029, E030)

______________________________________________________________________________________________

Construction: Aluminum die cast Yoke, plastic Housing

______________________________________________________________________________________________

Connections: 3 foot long 4 Conductor 18 gauge wire, pigtail (may include fifth pink colored conduc-

______________________________________________________________________________________________

Enclosure Type: NEMA 2, IP54, UL 2

______________________________________________________________________________________________

Noise Level: E024, E025 45 dBA

E026 60 dBA

E029, E030 65 dBA

______________________________________________________________________________________________

Environmental: Operating: Ambient + 32°F to +122°F (0 to +50°C)

Humidity: 5 to 95% RH non-condensing

Storage: -40°F to +176°F [-40°C to +80°C]

______________________________________________________________________________________________

Orientation: Factory Aligned per drawings

tor only used for factory programming. Do Not Use or Connect)

* See page 5 for VMS-35 Specifications

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

2

ADAPTION POWER

(E024, E029, E030) (E025, E026)

OVERVIEW

The actuators feature a native

2-10 Vdc Control Signal.

Installation of the KR500

Resistor Kit converts the

Control Signal input to 4-20

mAdc. When using 4-20 mA

input, terminate the 500 ohm

resistor from the KR500 resistor

kit between the White and

Black actuator wires. When

using the VMS-35, this can be

easily done between the NO1

and LN terminals for Actuator

1 and between the NO2 and LN

terminals for Actuator 2.

A single wire brings a 2-10 Vdc

Feedback Signal. The Feedback

Signal is not available using

4-20 mAdc.

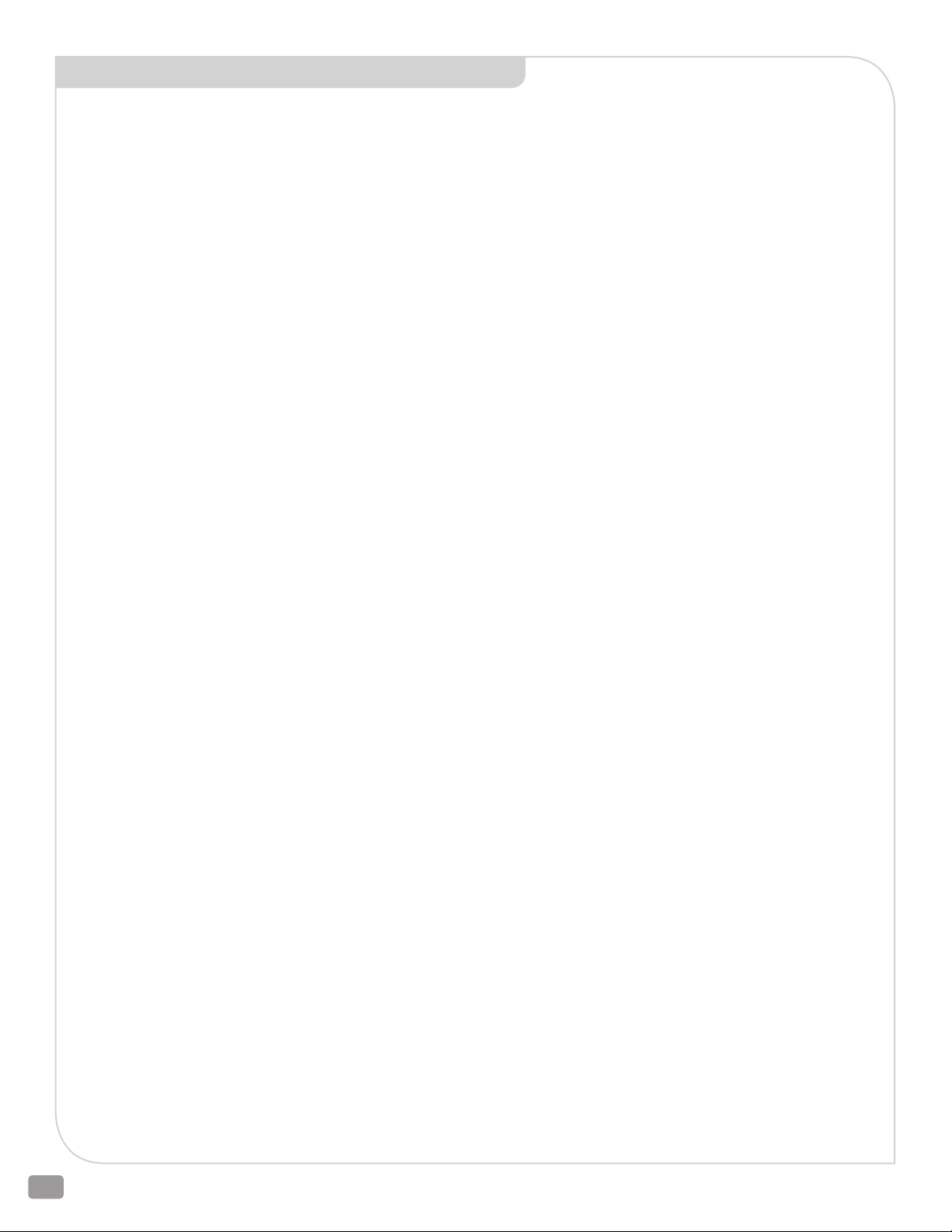

Manual Override is possible by turning off the power,

pressing the Manual Override button and rotating the

supplied Allen key in the Socket.

To raise the actuator stem turn the Allen key counterclockwise.

!

DANGER

PRESS THE MANUAL OVERRIDE BUTTON IN FIRMLY WHILE

OPERATING THE MANUAL OVERRIDE. FAILURE TO DO SO WHILE

THE ACTUATOR IS POWERED OR BEING DRIVEN TO THE POWER

FAILURE DIRECTION CAN CAUSE SERIOUS PERSONAL INJURY

AND DAMAGE THE ACTUATOR.

The Rotation Switch can be adjusted to set the direction the

Control Signal opens and closes the valve (and Loss of Signal

direction in some actuators) in the field without actuator

removal.

Adaption (Auto-Calibration - green LED), a combined

Adaption/ Power button to reset and relearn the valve

stroke as well as indicate the actuator is powered. When

the Button is pressed, the actuator will drive one full cycle

to its mechanical end stops OR the valves mechanical seats.

Upon completion of this cycle the actuators working range

(Control Signal, Feedback Signal and running time) will be

adjusted to the actual stroke of the actuator.

Status (yellow LED) to confirm communication.

BAC_IOM_RevA_0214

3

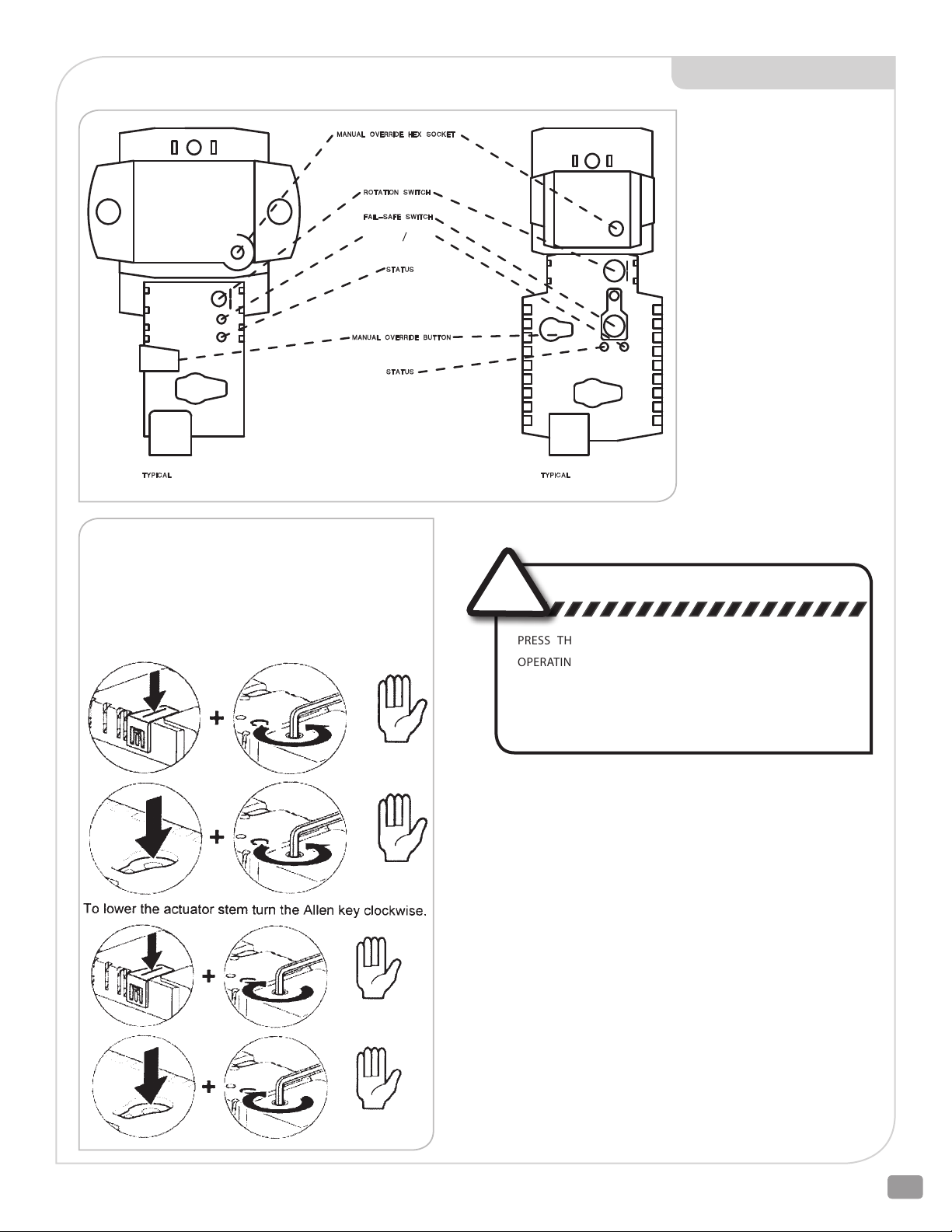

2-10 VDC

Line

Volts

24 VAC

CLASS 2

TRANSFORMER

2-10 VDC

CONTROL

SIGNAL

2-10 VDC

FEED-

BACK

ACTUATOR

BK #1 ( )

RD #2 ( )

WH #3 (Y)

OR #5 (U)

Common

Hot

Input, 2 to 10 VDC

Output, 2 to 10 VDC

4-20 MADC

Line

Volts

24 VAC

CLASS 2

TRANSFORMER

4-20 MADC

CONTROL

SIGNAL

2-10 VDC

FEED-

BACK

ACTUATOR

BK #1 ( )

RD #2 ( )

WH #3 (Y)

OR #5 (U)

Common

Hot

Input, 2 to 10 VDC

Output, 2 to 10 VDC

KR500

RESISTOR

ACTUATOR WIRING DIAGRAMS

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

4

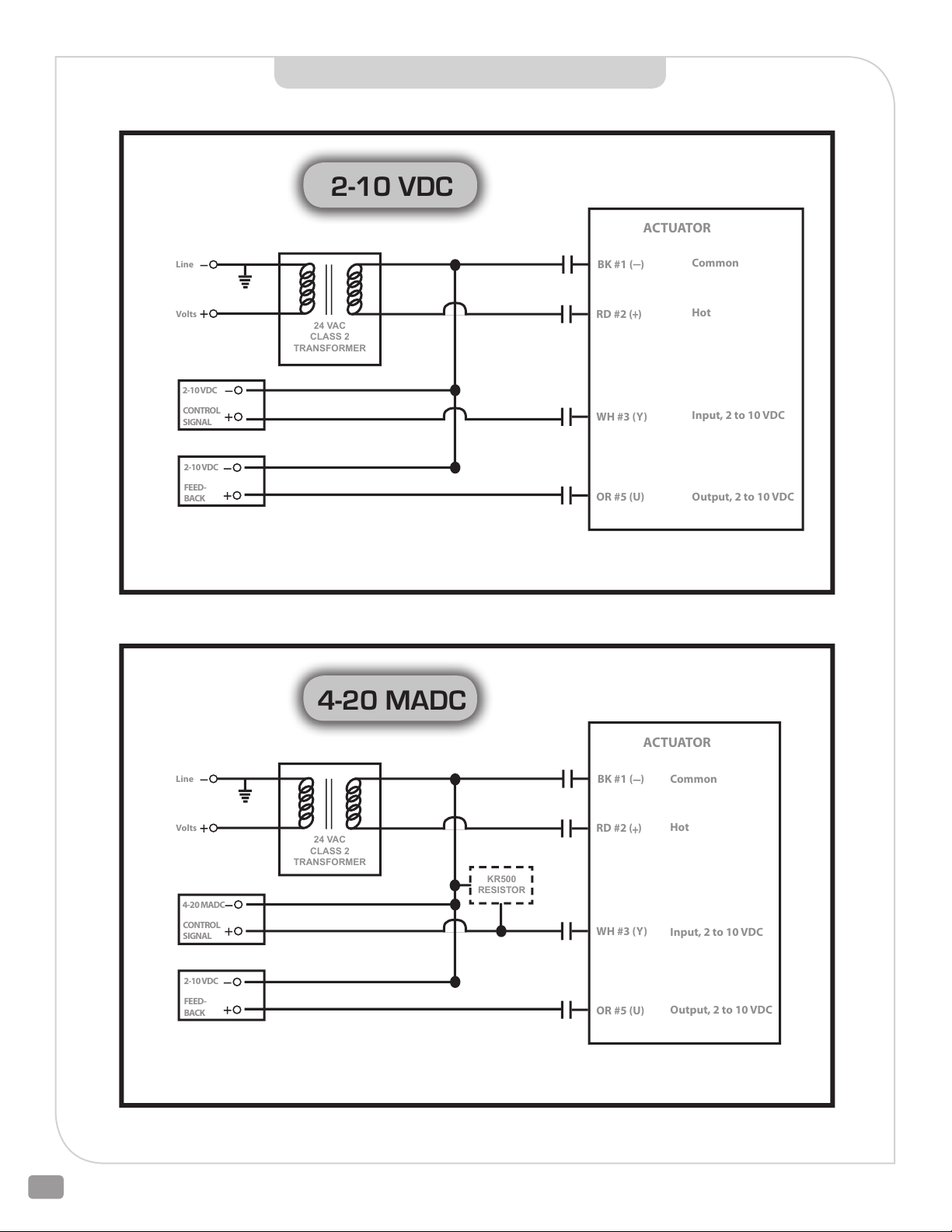

VMS-35 BCM

Power

24 VAC

HOT

Existing Jumper

L LN RC LN TG BT AC LNNC1 C1 NO1

NC2 C2

NO2

CONTROL SIGNAL (S)

(RECOMMENDED)

(RECOMMENDED)

OUTPUT TO

ACTUATOR A

OUTPUT TO

ACTUATOR B

(IF USED)

Actuator BActuator A

1. The VMS-35 can power one (1) or two (2) actuators.

2. Energize 24 VAC before connecting red lead to battery.

3. Also read actuator wiring and setup instructions.

4. To prevent signal interference proper signal wire cable

shielding is recommended.

5. When using long wire runs and a 2 – 10 Vdc signal,

signal and power cables should be run in separate

conduits to avoid interference.

NOTES

VMS-35

OR#5(U)

WH#3(Y) RD#2(+) BK#1(-)

OR#5(U)

WH#3(Y) RD#2(+) BK#1(-)

BACKUP CONTROL MODULE

SPECIFICATIONS

Actuator Usage: E030 (E030 includes a VMS-35 BCM), E029, E024

Power supply: 24 VAC ± 20% 50/60 Hz

Power Consumption: 40 VA (add VA rating for actuator used)

Number Actuators: One or Two

Construction: Battery w/Circuit Board, Charger and Transformer

Enclosure Type: NEMA 4X, IP66, UL 4X, CSA 4X

Flame Retardant: UL 50

Construction: UV Stabilized Fiberglass Reinforced Polyester,

Polycarbonate Hinge and Closed Cell Neoprene Gasket

Connections: Two 1/2 IN conduit with one plug

Number Batteries: One

Initial Charge: 2-4 hours

Battery Life: Up to 5 years … Replacement battery

model UB1213 / 12V, 1.3 Ah

Mounting: Feet for Wall Mount (4.91” x 8.75” centers)

Environmental: Operating/ Storage: Ambient +32°F to +104°F

(0 to +40°C) – due to battery

Weight: 4.25 lbs (2 kg)

VMS-35 WIRING DIAGRAM

TERMINALS

L System Power 24 VAC (+)

LN System Neutral (-)

RC Remote Control

BT Battery Test (+)

TG Test Ground (-)

C1 Control Signal 1st Actuator (+)

C2 Control Signal 2nd Actuator (+)

NC1 Not Used

NC2 Not Used

NO1 Relay Normally Open 1st Actuator

NO2 Relay Normally Open 2nd Actuator

AC 24 VAC Out (+)

Operation:

Proportional Normal: Terminal L is connected to 24 VAC building

power. Terminal LN completes the circuit to BK. Actuator responds to

modulating input signal.

Power Failure: Terminal AC changes to 24 V square wave from battery/

inverter. A relay breaks the connection between Terminals C1 and NO1

forcing the actuator to return to the rotation switch position (See page

11 for explanation of rotation switch position).

Loss of Signal: Terminal AC uses 24VAC building power. The control

signal is broken forcing the actuator to return to the rotation switch

position (See page 11 for explanation of rotation switch position).

BAC_IOM_RevA_0214

5

INSTALLATION

1. Disengage the 24 VAC building power circuit before wiring. Verify that the battery inside the VMS-35 has its wires disconnected and

leave them that way for now. Disconnect them if they are connected.

2. Connect the VMS-35 to the actuator(s) as shown on wiring diagram. The VMS-35 can power one or two actuators.

Actuator A: Connect terminal N01 to white wire from actuator to drive the valve stem to the rotation switch position. Connect terminal

AC to red wire from actuator to provide power. Connect grounded reference – negative/black wire from actuator to terminal LN. Also

connect the control signal (-) to the black wire from the actuator. Connect terminal C1 to the control signal positive (+). If the control

signal is 4-20mADC a KR500 500 ohm resistor is required. Terminate the resistor between terminals N01 an LN.

Actuator B: Connect terminal N02 to white wire from actuator to drive the valve stem to the rotation switch position. Connect terminal

AC to red wire from actuator to provide power. Connect grounded reference – negative/black wire from actuator to terminal LN. Also

connect the control signal (-) to the black wire from the actuator. Connect terminal C2 to the control signal positive (+). If the control

signal is 4-20mADC a KR500 500 ohm resistor is required. Terminate the resistor between terminals N02 an LN.

3. While still disconnected, wire the VMS-35 to 24 volts AC power. Connect the hot to terminal L then neutral to terminal LN.

4. Engage the 24 VAC building power.

5. Verify that building power is live then connect the loose red wire inside the VMS-35 enclosure to the positive (+) battery terminal and

the black wire to the negative (-) battery terminal.

NOTE: Engage the 24 VAC power to the VMS-35 before connecting the battery. Connecting the battery first causes the VMS-35 to go

into the power failure mode. If there are conditions other than power failure during which the actuator should be driven to the rotation

switch position (See page 11 for explanation of rotation switch position), replace the jumper between RC & LN with a contact that opens

on demand.

TESTING

Disconnecting the jumper between RC & LN, with building power on, will drive the actuator to the rotation switch position (See page 11

for explanation of rotation switch position).

Testing the VMS-35 and the charging system and battery is recommended yearly. To test charging measure the voltage between terminals

TG & BT. TG is negative. When the power supply is charging correctly the voltage will be 13 - 14 volts DC. To test the battery disconnect

LN or L, wait for the actuator to return to the rotation switch position (See page 11 for explanation of rotation switch position) and then

measure the voltage between TG & BT. A good and adequately charged battery will be between 10 - 12 volts DC.

The VMS-35 is a standby power supply.

It is intended to drive an actuator to either open or close a valve during a power failure. The VMS-35 can power one or two actuators.

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

6

VMS-35 (UB1213) BATTERY REPLACEMENT

NOTE Normal valve operation under 24 VAC power need not be interrupted

during battery replacement; however, the fail-safe function will not be avail-

able until the new battery is in place, connected and sufficiently charged (typi-

cally 2-4 hours).

1. Refer to the picture (left) to locate and disconnect the Red and

Black wires from the battery.

2. Remove the two battery mounting bracket screws and remove

the battery and bracket.

3. Place the bracket over the new battery and install the

assembly as shown, using the two screws removed in step 2

(above).

4. Connect the Black wire to the black (unmarked) terminal.

5. With 24 VAC power present, connect the Red wire to the

red terminal. VMS-35 circuitry will automatically charge the

battery. (If 24 VAC is not present, the valve may move to its

fail-safe position, depending upon residual charge in the new

battery.)

PROCEDURE:

6. Recycle or dispose of the old battery properly. Do not

incinerate!

BAC_IOM_RevA_0214

7

READ ALL INSTRUCTIONS CAREFULLY BEFORE BEGINNING.

REMOVAL OF E024 & E025

ACTUATORS FROM VALVE

SEE DRAWING D3400024 on page 14

1) Remove line pressure and isolate valve in piping.

2) Operate actuator so plug is off seat(s).

3)

Remove power and signal from actuator. For E025, after power is

removed, cycle Fail-Safe Switch from Up Arrow to Down Arrow

until actuator stem no longer moves. Adaption/Power (green

LED) changes from blinking to off. Return Fail-Safe Switch to

original position. If necessary use the manual override to operate actuator so plug is off seat(s) or travel stop in valve.

4) Unlock stem connector clamp, use fingers on the front and

back sides of black lock assembly to evenly raise the lock assembly.

5) Use actuator manual override to raise the stem connector until the stem adapter is disengaged. Warning: Do not loosen

the factory set adjustable height screws on the sides of

the actuator yoke linkage.

6) Loosen yoke locknut (item 3) until it is free of bonnet.

7) Remove spacer ring (item 2).

INSTALLATION OF E024 & E025

ACTUATORS ON THE VALVE

SEE DRAWING D3400024 on page 14

THE SILVER SPACER RING THAT COMES WITH THE ACTUATOR MUST BE ASSEMBLED ON TOP SIDE OF YOKE WITH TURNED DOWN (MACHINED) SIDE

FACING DOWN AS SHOWN ON DRAWING.

1) Push valve stem down until plug is seated. Note stem location.

2) Install hex jam nut (Item 4) on valve stem. Thread jam nut so

that one inch of threads are exposed between jam nut and

top of stem.

3) Hold jam nut on valve stem and turn the stem adapter (item

5) until it bottoms out on the valve stem. Tighten jam nut to

the bottom of the stem adapter to secure valve stem to stem

adapter. Warning: The valve stem should never be turned

while the plug is in contact with the seat otherwise the

seating surfaces will be damaged voiding the warranty.

4) Place actuator, spacer ring and yoke locknut over valve

stem and onto bonnet. Watch orientation of yoke locknut.

Actuator base must rest on bonnet. If necessary, use the

manual override to raise the stem connector. Warning: Do

not loosen the factory set adjustable height adjustment

screws on the sides of the actuator yoke linkage.

5) Rotate actuator to desired orientation. For the factory

default actuator position the motor electrical wire end of the

actuator faces the outlet side of a 2-way valve, common port

on a 3-way mixing valve, and lower port on a 3-way diverting

valve. Thread yoke locknut onto bonnet and tighten securely.

Use blunt chisel and hammer for tightening.

6) Use actuator manual override to lower the stem connector

over the stem adapter. Lock stem connector clamp, use

fingers on the front and back sides of black lock assembly to

evenly lower the lock assembly.

8) Remove actuator from valve. Warning: Do not loosen the

factory set adjustable height screws on the sides of the

actuator yoke.

9) Hold jam nut (item 4) on valve stem and turn the stem adapt-

er (item 5) to disengage from valve stem. Warning: The valve

stem should never be turned while the plug is in contact

with the seat otherwise the seating surfaces will be damaged voiding the warranty.

10) Remove stem adapter from valve stem.

11) Remove jam nut from valve stem.

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

8

7 ) Push orange travel indicators together against both sides of

stem connector travel indicator.

8) Connect power and signal to actuator.

9 Press the Adaption (Auto-Calibration) button on the actuator

and wait until the cycle is complete.

10) Stroke valve several times to check operation.

11) Return line pressure to valve.

READ ALL INSTRUCTIONS CAREFULLY BEFORE BEGINNING.

REMOVAL OF E026 & E029/E030

ACTUATORS FROM VALVE

SEE DRAWING D3400025 on page 15

1) Remove line pressure and isolate valve in piping.

2) Operate actuator so plug is off seat(s).

3) Remove power and signal from actuator. For E026, after

power is removed, cycle Fail-Safe Switch from Up Arrow

to Down Arrow until actuator stem no longer moves.

Adaption/Power (green LED) changes from blinking to off.

Return Fail-Safe Switch to original position. If necessary

use the manual override to operate actuator so plug is off

seat(s) or travel stop in valve.

4) Remove stem connector hex nuts, remove stem connector

U-bolt.

5) While carefully manually holding stem connector clamp

open on the lower portion, use actuator manual override

to raise the stem connector until the stem adapter (item 2)

is disengaged.

INSTALLATION OF E026 & E029/E030

ACTUATORS ON THE VALVE

SEE DRAWING D3400025 on page 15

THE SILVER SPACER RING THAT COMES WITH THE ACTUATOR MUST BE

ASSEMBLED ON TOP SIDE OF YOKE AS SHOWN ON DRAWING.

1) Push valve stem down until plug is seated. Note stem location.

2) Install hex jam nut (Item 5) on valve stem. Thread jam nut so

that one inch of threads are exposed between jam nut and top

of stem.

3) Hold jam nut on valve stem and turn the stem adapter (item

2) until it bottoms out on the valve stem. Tighten jam nut to

the bottom of the stem adapter to secure valve stem to stem

adapter. Warning: The valve stem should never be turned

while the plug is in contact with the seat otherwise the

seating surfaces will be damaged voiding the warranty.

4) Place actuator, spacer ring and yoke locknut over valve stem

and onto bonnet. Watch orientation of yoke locknut. Actuator

base must rest on bonnet. If necessary, use the manual override to raise the stem connector.

5) Loosen yoke locknut (item 4) until it is free of bonnet.

6) Remove space ring (item 3).

7) Remove actuator from valve.

8) Hold jam nut (item 5) on valve stem and turn the stem

adapter to disengage from valve stem. Warning: The

valve stem should never be turned while the plug is in

contact with the seat otherwise the seating surfaces

will be damaged voiding the warranty.

10) Remove stem adapter from valve stem.

11) Remove jam nut from valve stem.

5) Rotate actuator to desired orientation. For the factory default

actuator position the motor electrical wire end of the actuator

faces the outlet side of a 2-way valve, common port on a 3-way

mixing valve, and lower port on a 3-way diverting valve. Thread

yoke locknut onto bonnet and tighted securely. Use blunt

chisel and hammer for tightening.

6) While holding the bottom of the stem connector open use the

actuator manual override to lower the stem connector over

the stem adapter. Install stem connector U-bolt through the

back half of the stem connector and tighten hex nuts. Evenly

torque the hex nuts per note 9 on drawing D3400025. Warn-

ing: The valve stem should never be turned while the plug

is in contact with the seat otherwise the seating surfaces

will be damaged.

7) Connect power and signal to actuator.

8) Press the Adaption (Auto-Calibration) button on the actuator

and wait until the cycle is complete.

9) Stroke valve several times to check operation.

10) Return line pressure to valve.

BAC_IOM_RevA_0214

9

SET-UP

Prior to enabling the power perform the following check:

1. Verify the Control Signal. The default Control Signal is 2-10 Vdc (see the wiring diagram for 4-20 mAdc).

2. Review the Control Action by inspecting the Rotation Switch position.

3. Confirm the Power Failure mode by inspecting the Fail-Safe switch.

4. Verify that the actuator is correctly installed on the valve body

5. Enable the Power Source.

6. Perform manual Adaption (Auto-Calibration).

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

10

CONTROL ACTION

E024, E025, E026, E029 & E030 Actuators - Rotation Switch position. How the valve and actuator react to the Control Signal.

The Fail-Safe position during Loss of Power and Loss of Signal are identical for an E024 and E029/E030 with VMS-35.

FACING

Up Arrow

(E024 and E029/E030)

Down Arrow

(E024 and E029/E030)

Up Arrow

(E024 and E029/E030 w/VMS-35)

Down Arrow

(E024 and E029/E030 with VMS-35)

Up Arrow

(E025 & E026)

Down Arrow

(E025 & E026)

DESCRIPTION

Increasing Control Signal Closes, 2-way valves and Lower port for 3-way valve. Signal Failure Direction is Fail

Open (FO) 2-way valves and Fail Upper Port Closed for 3-way vales.

Decreasing Control Signal Closes, 2-way valves and Lower Port for 3-way valves. Signal Failure Direction is

Failed Closed (FC) for 2-way valves and Fail Lower Port Closed for 3-way valves.

Increasing Control Signal Closes, 2-way valves and Lower port for 3-way valve. Signal and Power Failure Direction is Fail Open (FO) 2-way valves and Fail Upper Port Closed for 3-way vales.

Decreasing Control Signal Closes, 2-way valves and Lower Port for 3-way valves. Signal and Power Failure

Direction is Fail Closed (FC) for 2-way valves and Fail Lower Port Closed for 3-way valves.

Increasing Control Signal Closes 2-way valves and Lower Port for 3-way valves. Signal Failure Direction is Fail

Open (FO) 2-way valves and Fail Upper Port Closed for 3-way valves.

Decreasing Control Signal Closes 2-way valves and Lower Port for 3-way valves. Signal Failure Direction is Fail

Closed (FC) for 2-way valves and Fail Lower Port Closed for 3-way valves.

(E024 and E029, E030)

BAC_IOM_RevA_0214

11

POWER FAILURE

E025 & E026 Actuators - Fail-Safe Switch position: Valve and actuator Power Failure Direction.

FACING

Up Arrow

(E025 & E026)

Down Arrow

(E025 & E026)

Switch must be fully in position shown or actuator will go to intermediate position on loss of power.

DESCRIPTION

Power Failure Direction is Fail Open (FO) 2-way valves and Upper Port

Closed for 3-way valves.

Power Failure Direction is Fail Closed (FC) for 2-way valves and Lower

Port Closed for 3-way valves.

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

12

INDICATOR LIGHTS

STATUS

(yellow LED)

OFF ILLUMINATED Normal (no faults)

OFF BLINKING Power Failure is active ( E025 & E026 only)

ILLUMINATED OFF Fault is detected

OFF OFF No Power or Capacitors charging

ILLUMINATED ILLUMINATED Auto-Calibration is running

ADAPTION/ POWER

(green LED)

DESCRIPTION

1

NOTE:

1) Verify Control and Feedback Wiring

and Signals if a Fault is detected.

BAC_IOM_RevA_0214

13

D3400024

2600 Emrick Blvd • Bethlehem, PA 18020 • USA • 800-922-0085 • www.warrencontrols.com

14

D3400025

BAC_IOM_RevA_0214

15

2600 EMRICK BLVD • BETHLEHEM, PA 18020 • USA •800-922-0085 • WWW.WARRENCONTROLS.COM

DEPENDABLE, RUGGED, PRECISION CONTROL VALVES AND ACCESSORIES

Loading...

Loading...