Warren Controls 1800 User Manual

INSTALLATION, OPERATION

& MAINTENANCE INSTRUCTIONS

Series 18OO

Heavy Globe control valves

TABLE OF CONTENTS

Overview ....................................... Cover

Valve Information ................................ 2

Information Present on Valve ..........3-4

Body vs. Application ........................... 5

Dimensions & Weights .....................6-7

Installation ........................................8-9

Maintenance ...................................... 10

Packing Adjustment .......................... 10

Parts/Overhaul .................................. 10

Parts Kits ......................................11-13

Drawings ......................................14 -21

PRODUCT OVERVIEW

This document covers the installation, operation and maintenance

of the Series 1800 Heavy Globe Control Valves presented in the

“Series 1800 Product Specication”, including the 1840 Two-Way

Single Seat Unbalanced Valve, the 1843 Two-Way Single Seat

Cylinder Balanced Valve, the 1850 Three-Way Mixing/ Diverting

Valve, and the 1852 Three-Way Diverting/ Mixing Valve. Warren

Controls Series 1800 Heavy Globe Control Valves feature rugged

high capacity bodies of iron, steel, or stainless steel with a variety

of trim materials and port sizes. The equal percentage and linear

plugs in the 2-way valves and linear plugs in the 3-way valves

provide excellent modulating control of a wide variety of uids.

The Series 1800 is ideally suited where value and long life are

important objectives for applications including but not limited to

the Chemical, District Energy, Food & Beverage, General Service,

Marine, Power, and Rening industries with temperatures from

-20 to 800ºF, severe service, high pressure drops, and corrosive

uids.

GENERAL INFORMATION

The instructions given herein cover generally the operation and

maintenance of subject equipment. Should any questions arise

which may not be answered specically by these instructions,

they should be referred to Warren Controls Inc. for further detailed

information and technical assistance. This manual cannot possibly

cover every situation connected with the operation, adjustment,

inspection, test, overhaul and maintenance of the equipment

furnished. Every eort is made to prepare the text of this manual

so that engineering and design data is transformed into the most

easily understood wording. Warren Controls Inc., in furnishing this

equipment and this manual, must presume that the operation and

maintenance personnel assigned thereto have sucient technical

knowledge and experience to apply sound safety and operational

practices which may not be covered herein. In applications where

Warren Controls Inc. furnished equipment is to be integrated

with a process or other machinery, these instructions should be

thoroughly reviewed to determine the proper integration of the

equipment into the overall plant operational procedures. Warren

Controls does not assume responsibility for the selection, use, or

maintenance of any product. Responsibility for proper selection,

use, and maintenance of any Warren Controls product remains

solely with the purchaser and end-user

ACTUATORS AND ACCESSORIES

Series 1800 Heavy Globe Control Valves are available with

a variety of actuators and accessories. These actuators and

accessories have separate instructions. For complete control

valve installation, operation, and maintenance instructions see

also the instructions for the actuator and accessories in use.

VALVE IDENTIFICATION

To use these instructions it is necessary to identify the conguration of the valve. Factory assembled control valves have a

nameplate mounted on the actuator. The valve’s part number (P/N) is present on the plate. The part number represents the

conguration of the control valve. To identify the valve’s type, size, actuator, accessories, and other characteristics decode the

part number using conguration table. If the information is incomplete, incorrect, or not present contact the factory with the

valve serial number listed on the plate. (See Information Present on Control Valves section for location of part number, serial

number, and other important information on valve.)

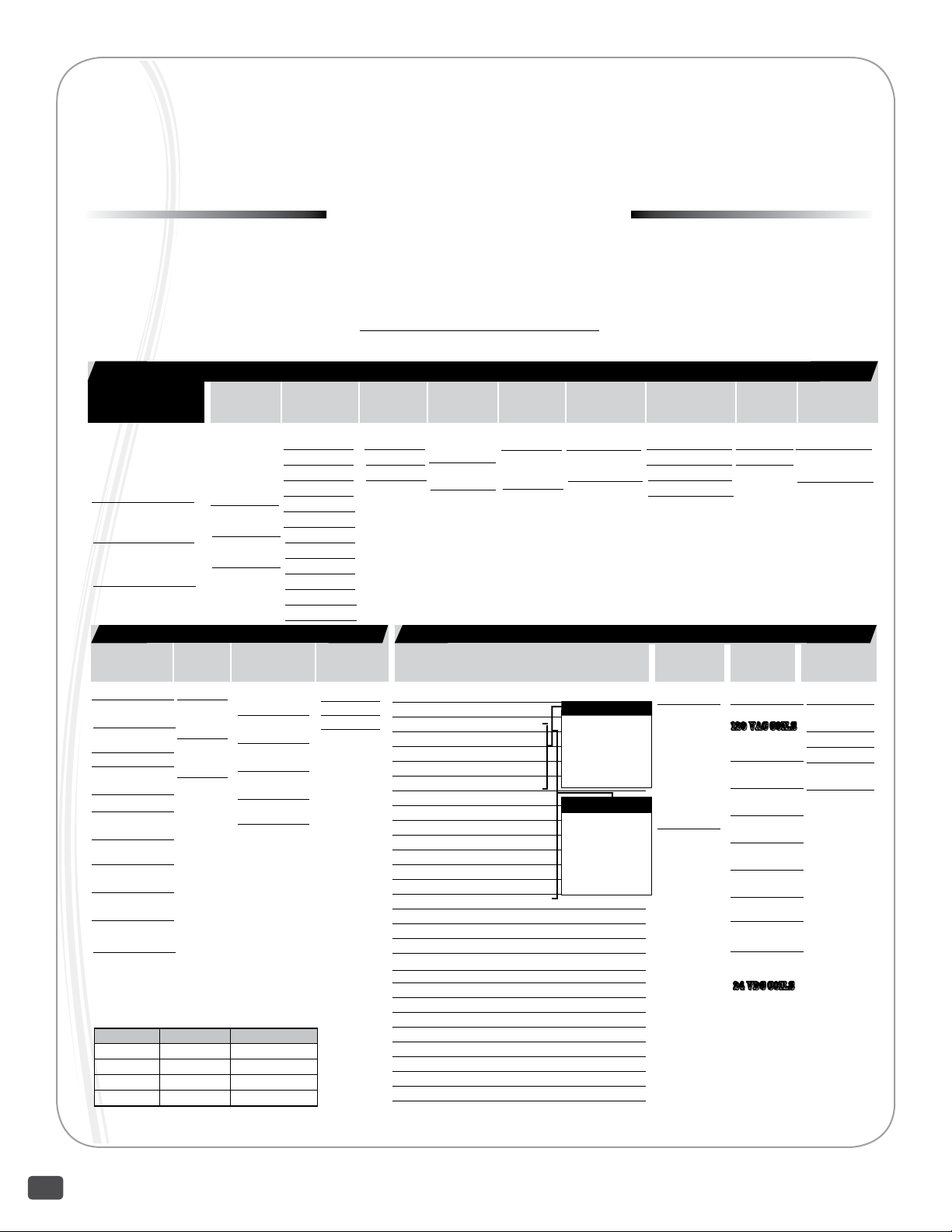

VALVE BODY

Model

Valve

Type

Size

Body

Material

End

Connection

Trim Style Trim Material Trim Cv

Packing

Type

Bonnet

Construction

18H 2” - 4” Bodies

Diaphragm:

84” or 115”

Cylinder: 6”

or 8”

18J 6” - 12” Bodies

Diaphragm: 115”

Cylinder: 8” or

18K

1/2” - 1 1/2”

Bodies

Diaphragm: 84”

12”

40 2-Way,

Single Seat

43 2-Way

CageBalanced

50 3-Way

Mixing

52 3-Way

Diverting

050 1/2 inch

075 3/4 inch

100 1 inch

150 1-1/2 inch

200 2 inch

250 2-1/2 inch

300 3 inch

400 4 inch

600 6 inch

800 8 inch

010 10 inch

012 12 inch

ACTUATOR

Actuator

Action

Spring Range

Series

00 None

DIAPHRAGMS:

84 DL84

(84 Sq.In.)

8X DL84XR

15 DL115

(115 Sq.In.)

5X DL115XR

CYLINDERS:

C2 6” Spring Fail

(for 18H)

C3 8” Spring Fail

(for 18H)

C4 8” Spring Fail

(for 18J)

C5

12” Spring

Fail

(for 18J)

FAILURE MODES:

MODE VALVE TYPE ACTUATOR ACTION

Closed 40/43 Reverse

Open 40/43 Direct

Upper Closed* 50/52 Direct

Upper Open 50/52 Reverse

*Standard

0 None

R Reverse

Stem

Fail Down

D Direct

Stem

Fail Up

0 None or

Cylinder

L Low

3-9psi R/D

F Full

3-15psi R/D

H High

9-15 psi R/D

X Xtra-High

DL115XR

W WCB

F CF8M

R Cast Iron

F 125/150 lb.

Flanged

G 250/300 lb.

Flanged

E Equal %

L Linear

Types

50/52

Linear only

ACCESSORIES

Handwheel Positioners, I/P’s & Limit Switches

0 None

R Reverse

D Direct

0000

None

POSITIONERS:

BxP_ BLX Pneumatic

BxE_ BLX ElectroPneumatic

BxI_ BLX ElectroPneu. Intrn. Safe

BxX_ BLX ElectroPneu. Exp. Proof

BxF_ BLX ElectroPneu. Fail Freeze

76P_ Moore760 Pneumatic

76E_ Moore760 Electro-Pneumatic

Siemens PS2 Electro-Pneumatic

P24_

P2H

Siemens

P2P_

P2F_

PX11 Mark 1 Series - 2 ea. SPDT

PX12 Mark 1 Series - 2 ea. SPDT w/2k Pot.

PX13 Mark 1 Series - 2 ea. SPDT w/4-20 Feedback

PX14 Mark 1 Series - 4 ea. SPDT

PX15 Mark 1 Series - 6 ea. SPDT

I/P’s Use with Diaphragm Only

MAP1 Type 500X I/P, 3-9 PSI

MAP2 Type 500X I/P, 9-15 PSI

MAP3 Type 500X I/P, 3-15 PSI

MAP4 Type 500X I/P, 1-17 PSI

MAP5 Type 500X I/P, 6-30 PSI

MAP6 Type 550X I/P, 0-30 PSI

MAP7 Type 550X I/P, 0-60 PSI - For 15 or 5X only

MAP9 Type 950X I/P, 3-15 EXP

PS2 2,3,4 Wire HART

Siemens PS2 PROFIBUS PA

Siemens

PS2 FOUND. FIELDBUS

PROXIMITY SWITCHES:

x digit spec.

F Full Range Signal,

3-15 PSI or 4-20mA

L Low of Split Range,

3-9 PSI or 4-12mA

H High of Split Range,

9-15 PSI or 12-20mA

0 No Additions

L w/Mech. Lmt Swtch’s

F w/4-20 Feedback

B w/Swtch’s &

Feedback

NOTE:

L,F,B not available

S 316 SS

6 Alloy 6

Wrapped

4th digit spec.

F Full Port

1 1st Port

2 2nd Port

3 3rd Port

Air Filter

Regulators

0 None

A

Type 300,

0-30 PSI,

B

Type 300,

0-60 PSI

C

Type 300,

0-120 PSI,

D

Type 350SS,

0-100 PSI

Reduction

Reduction

Reduction

T Teflon

G Graphite

ASCO

Solenoids

0 None

120 VAC COILS

A 8320G184

3-Way Brass

B 8320G202

3-Way SS

J 8342G1

4-Way Brass

K 8342G701

4-Way SS

L EF8320G184

3-Way EXP

M EF8320G202

3-Way EXP

V EF8342G1

4-Way

EXP

W

EF8342G701

4-Way EXP

24 Vdc COILS

Z 8320G184

3-Way Brass

S 450 Tmax

x 800F Tmax

w/Ext. Bonnet

Special

Options

0 None

S Special

or Set-up

T SS Tubing

G SS Tagging

B SS Tubing

and Tagging

Br.

SS

Br.

SS

Opts

2600 Emrick Blvd • Bethlehem, PA 18020 • USA •800-922-0085 • www.warrencontrols.com

2

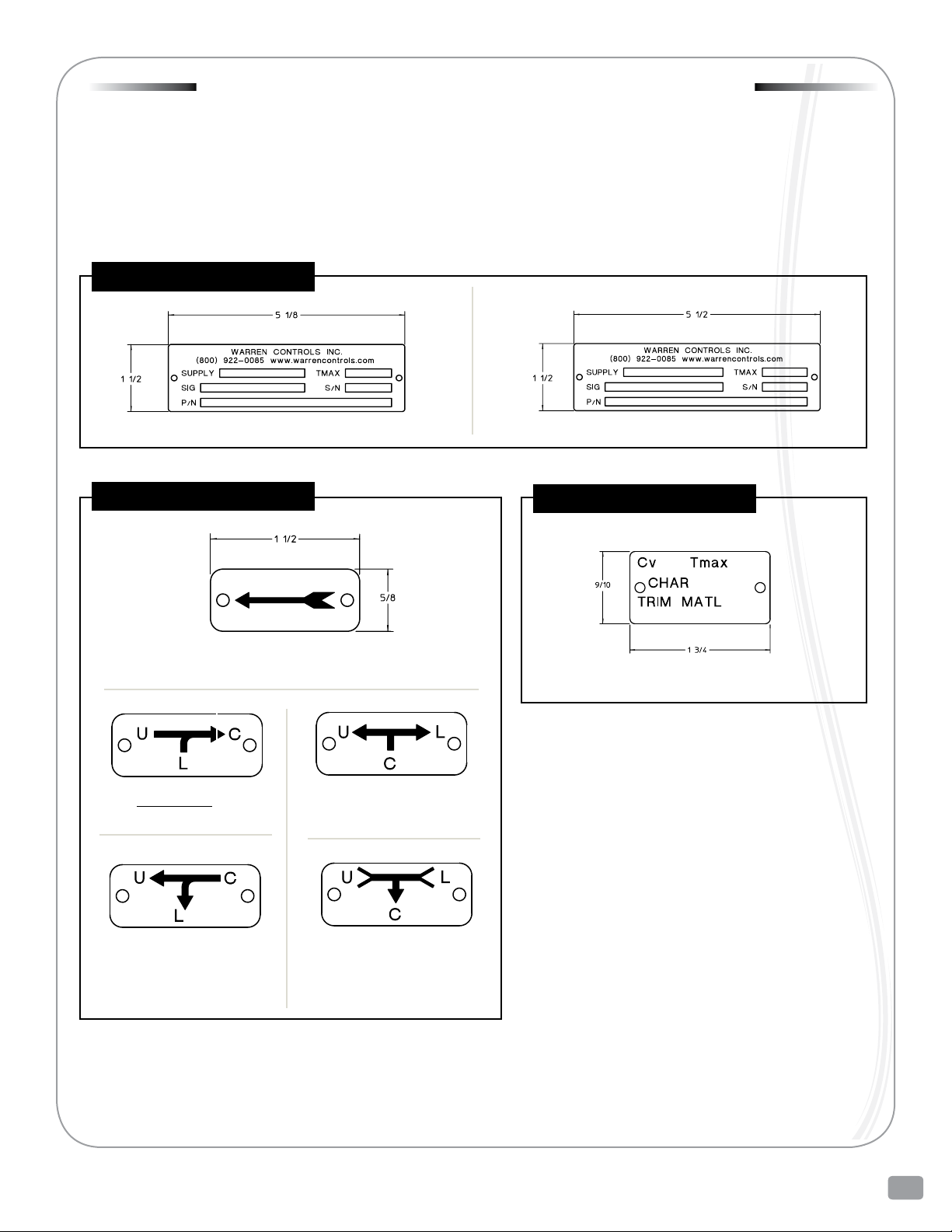

INFORMATION PRESENT ON CONTROL VALVES

There is a great deal of information present on each control valve ranging in importance from the part number and serial

number to the color of the paint and casting numbers. This information is important for identifying the valve, installing it

correctly, and obtaining parts. Examples of the current factory nameplates and flow arrow plates used on Series 1800

control valves are shown here. The accompanying table identifies the information present and where to find it on the

control valve. There may also be other casting numbers and foundry marks present that do not provide useful information.

Customer specific tagging may also present. The plates used, and information present, on Warren Controls other product

lines or older valves may be different, contact the factory for details.

ACTUATOR NAMEPL ATES

DL84 DL115 & CL

FLOW ARROW PLATES

2-WAY FLOW

3-WAY MIXING 3-WAY DIVERTING

VBA NAME PL ATES

INDUSTRIAL VBA

3-WAY MIXING

AS DIVERTING

3-WAY DIVERTING

AS MIXING

Series 1800 IOM1800 A 1209

3

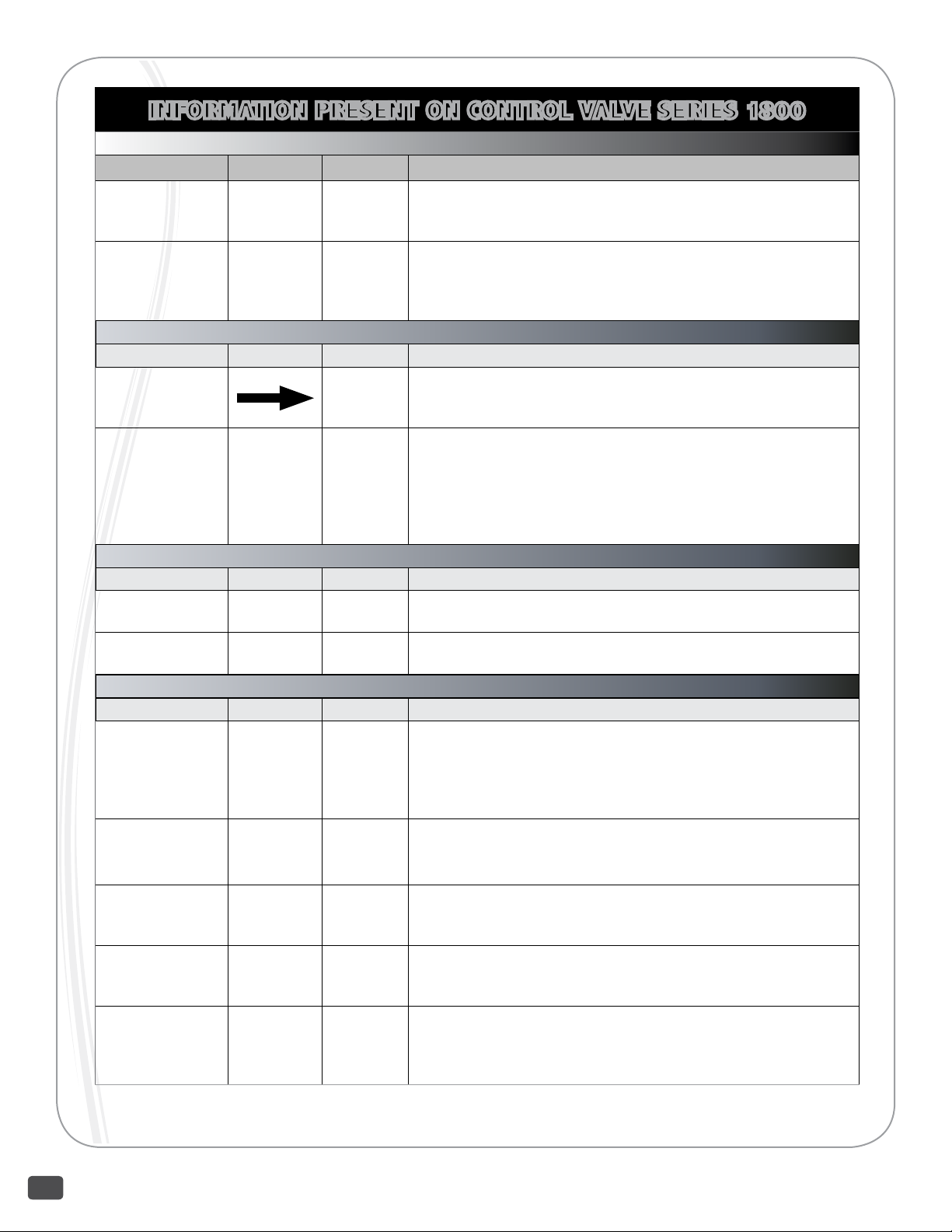

INFORMATION PRESENT ON CONTROL VALVE SERIES 1800

Part Number & Serial Number

Information Symbol(s) Location Notes

Part number

(Configuration)

P/N On

actuator

• On Actuator Nameplate attached to leg(s) of actuator.

Serial number S/N On

actuator

and

valve body

Flow Direction(s)

Information Symbol(s) Location Notes

Flow direction

through valve

Port locations

for 3-way valves

Input Signal & Supply

Information Symbol(s) Location Notes

Input signal SIG On

Supply pressure SUP or

Valve Attributes

Information Symbol(s) Location Notes

Maximum

temperature rating

of valve body

U upper

port,

L lower

port,

C common

port

SUPPLY

TMAX or

Tma x

On valve

body

On valve

body

actuator

On

actuator

On

actuator

and

valve body

• On Actuator Nameplate attached to leg(s) of actuator.

• Sales order number only stamped on top of valve body bonnet.*

* Number stamped using approximately 1/8 inch tall characters

• On Flow Arrow Plate attached to valve body bottom port

flange (1800 3-way) between the end connections.

•

Arrow cast on valve body between the end connections (1800 2-way).

• On Flow Arrow Plate attached to valve body bottom port

flange (1800 3-way) between the end connections.

• On Actuator Nameplate attached to leg(s) of actuator.

• On Actuator Nameplate attached to leg(s) of actuator.

• On Actuator Nameplate attached to leg(s) of actuator.

• On Industrial VBA Nameplate attached to valve body bonnet

flange between the end connections on side opposite flow arrow

plate.

Tri m Cv

(Flow coefficient)

Trim style

(Characteristic)

Trim material TRIM MATL On valve

Valve body

material

2600 Emrick Blvd • Bethlehem, PA 18020 • USA •800-922-0085 • www.warrencontrols.com

4

Cv On valve

body

CHAR On valve

body

body

On valve

body

• On Industrial VBA Nameplate attached to valve body bonnet

flange between the end connections on side opposite flow arrow

plate.

• On Industrial VBA Nameplate attached to valve body bonnet

flange between the end connections on side opposite flow arrow

plate.

• On Industrial VBA Nameplate attached to valve body bonnet

flange between the end connections on side opposite flow arrow

plate.

• If the factory applied paint is black the valve body material is

iron. If WCB is cast on the valve, and or the factory applied paint

is gray, the valve body material is steel. If CF8M is cast on the

valve the valve body material is 316 stainless steel.

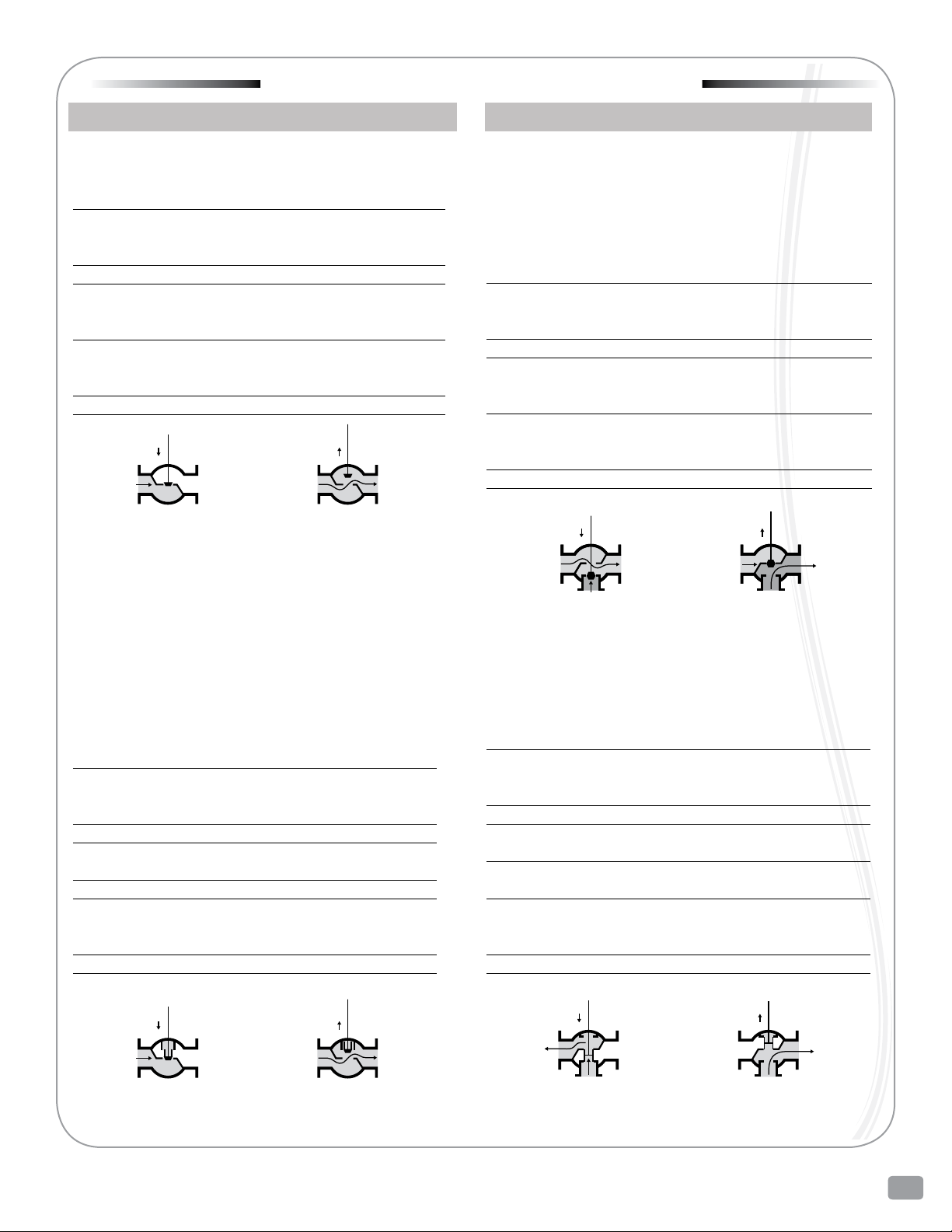

BODY STYLE VERSUS APPLICATION

Stem Down

The upper port opens

and the lower port closes

Upper PortLower Port

Common Port

Stem Up

The upper port closes

and the lower port opens

Upper Port Lower Port

Common Port

Flow

Stem Down

The upper port opens

and the lower port closes

Upper PortCommon Port

Lower Port

Flow

Flow

Flow

Stem Up

The upper port closes

and the lower port opens

Upper Port Common Port

Lower Port

Flow

Stem Down

The upper port opens

and the lower port closes

Upper PortCommon Port

Lower Port

Flow

Flow

Flow

Stem Up

The upper port closes

and the lower port opens

Upper Port Common Port

Lower Port

Flow

Stem Down

The upper port opens

and the lower port closes

Upper PortLower Port

Common Port

Flow

Flow

Stem Up

The upper port closes

and the lower port opens

Upper Port Lower Port

Common Port

Flow

Stem Down

The valve closes

Stem Up

The valve opens

Stem Down

The upper port opens

and the lower port closes

Upper PortCommon Port

Lower Port

Flow

Flow

Flow

Stem Up

The upper port closes

and the lower port opens

Upper Port Common Port

Lower Port

Flow

Flow

Flow

Stem Down

The valve closes

Stem Up

The valve opens

2-Way Valves (Control of Liquids, Gases, and Steam)

1840 Two-Way Single Seat Unbalanced Valve

The most commonly applied solution with ANSI Class IV shut-off.

Sizes: 6, 8, 10, 12 inch (See 5840 for smaller sizes)

Body:

WCB Steel or CF8M Stainless Steel 150LB Flange or

300LB Flange (6 thru 12)

Trim: EQ% or Linear, 316 Stainless Steel or Alloy 6

Packing: TFE V-Ring, Spring Loaded (+32 to 450°F)

Adjustable Graphite (+32 to 500°F)

Adjustable Graphite w/Extension Bonnet (+32to 800°F)

Temperature: +32 to 350°F (125 FLG)

Rangeability: 50:1

Stem Down

Flow direction is reversed when used with Cylinder Actuator Fail Closed.

ANSI B16.1 Iron 125LB Flange or 250LB Flange (6 thru 10)

+32 to 400°F (250 FLG)

+32 to 800°F (150 or 300 FLG)

Stem Up

Flow

The valve opens

Flow

The valve closes

3-Way Valves (Control of Liquids)

1850 Three-Way Mixing Valve

This valve has two inlets and one outlet, and is the simplest solution

for

mixing

applications the inlet pressures are near equal and control is possible from

5% to 95% of travel with inlet pressures up to 300 PSI. In the 1/2 through 2

inch sizes, the flow can be reversed for diverting if this port configuration is

desirable.

Sizes: 1/2, 3/4, 1, 1-1/2, 2, 2-1/2, 3, 4, 6, 8, 10, 12 inch

Body:

WCB Steel or CF8M Stainless Steel 150LB Flange or

300LB Flange (1/2 thru 12)

Trim: Linear, 316 Stainless Steel

Packing: TFE V-Ring, Spring Loaded ( +32 to 450°F)

Adjustable Graphite (+32 to 500°F)

Temperature: +32 to 350°F (125 FLG)

+32 to 400°F (250 FLG)

+32 to 800°F (150 or 300 FLG)

Rangeability: 30:1 (sizes 1/2 thru 2)

50:1 (sizes 2-1/2 thru 12)

or bypass applications with ANSI Class IVshut-off. In normal

ANSI B16.1 Iron 125LB Flange or 250LB Flange (8 thru 12)

Adjustable Graphite w/Extension Bonnet (+32 to

Stem Down

Upper PortCommon Port

Flow

Stem Up

Upper Port Common Port

Flow

800°F)

1843

Valve

A balanced valve that is an effective solution for higher pressures.

It requires less force to operate than unbalanced valves so smaller

Two-Way Single Seat Cylinder Balanced

actuators can be used. Its single seat o-ring seal design facilitates

ANSI Class IV shut-off. It is limited to cleaner fluids.

Sizes: 6, 8, 10, 12 inch (See 5843 for smaller sizes)

Body: ANSI B16.1 Iron 125LB Flange or 250LB Flange

WCB Steel or CF8M Stainless Steel 150LB Flange or

300LB Flange

Trim: EQ% or Linear, 316 Stainless Steel or Alloy 6

Packing: TFE V-Ring, Spring Loaded ( +32 to 450°F)

Adjustable Graphite ( +32 to 500°F)

O-Ring: Fluoraz 797

Temperature: +32 to 350°F (125 FLG)

+32 to 400°F (250 FLG)

+32 to 500°F (150 or 300 FLG)

Rangeability: 50:1

Stem Down

FlowFlow

The valve closes

Flow direction is reversed when used with Cylinder Actuator Fail Closed.

Stem Up

The valve opens

Flow

Lower Port

The upper port opens

and the lower port closes

Flow

Lower Port

The upper port closes

and the lower port opens

1852 Three-Way Diverting/Mixing Valve

Designed as a diverting valve with one inlet and two outlets with ANSI

Class II shut-off. However, flow can be reversed for mixing if this port

configuration is desirable. The difference between the upper port and lower

port pressure must not exceed 50PSID.

Sizes: 2-1/2, 3, 4, 6, 8, 10, 12 inch

Body:

WCB Steel or CF8M Stainless Steel 150LB Flange or

300LB Flange (2-1/2 thru 12)

Trim: Linear, 316 Stainless Steel or Alloy 6

Packing: TFE V-Ring, Spring Loaded (+32 to 450°F)

Adjustable Graphite (+32 to 500°F)

O-Ring: Fluoraz 797 (2-1/2 thru 4)

EPR (6 thru 12)

Temperature: +32 to 150°F (125 or 250 FLG, 8 thru 12)

+32 to 500°F (150 or 300 FLG, 2-1/2 thru 4)

+32 to 150°F (150 or 300 FLG, 6 thru 12)

Rangeability: 50:1

Upper PortLower Port

ANSI B16.1 Iron 125LB Flange or 250LB Flange (8 thru 12)

Stem Down

Common Port

The upper port opens

and the lower port closes

Stem Up

Upper Port Lower Port

Flow

Common Port

The upper port closes

and the lower port opens

Series 1800 IOM1800 A 1209

5

Body Pressure-Temperature Ratings:

Temperature

(F)

+32° To 100° 175 400 285 740 275 720

150° 175 400 272 710 255 670

175° 170 385 266 695 245 645

200° 165 370 260 680 235 620

225° 155 355 252 673 230 605

250° 150 340 245 667 225 590

275° 145 325 237 661 220 575

300° 140 310 230 655 215 560

325° 130 295 222 650 210 548

350° 125 280 215 645 205 537

375° - 265 207 640 200 526

400° - 250 200 635 195 515

450° - - 185 620 182 497

500° - - 170 605 170 480

550° - - 155 587 155 465

600° - - 140 570 140 450

650° - - 125 550 125 440

700° - - 110 530 110 435

750° - - 95 505 95 425

800° - - 80 410 80 420

Pressure ratings are PSIG

For applications below 32º consult factory

125 FLG

Iron

250 FLG

Iron

150 FLG

Steel

300 FLG

Steel

150 FLG

St Steel

300 FLG

St Steel

Trim Materials

316 Stainless Steel 100 PSID

Alloy 6 300 PSID

Flowing

Differential

Pressure Limit

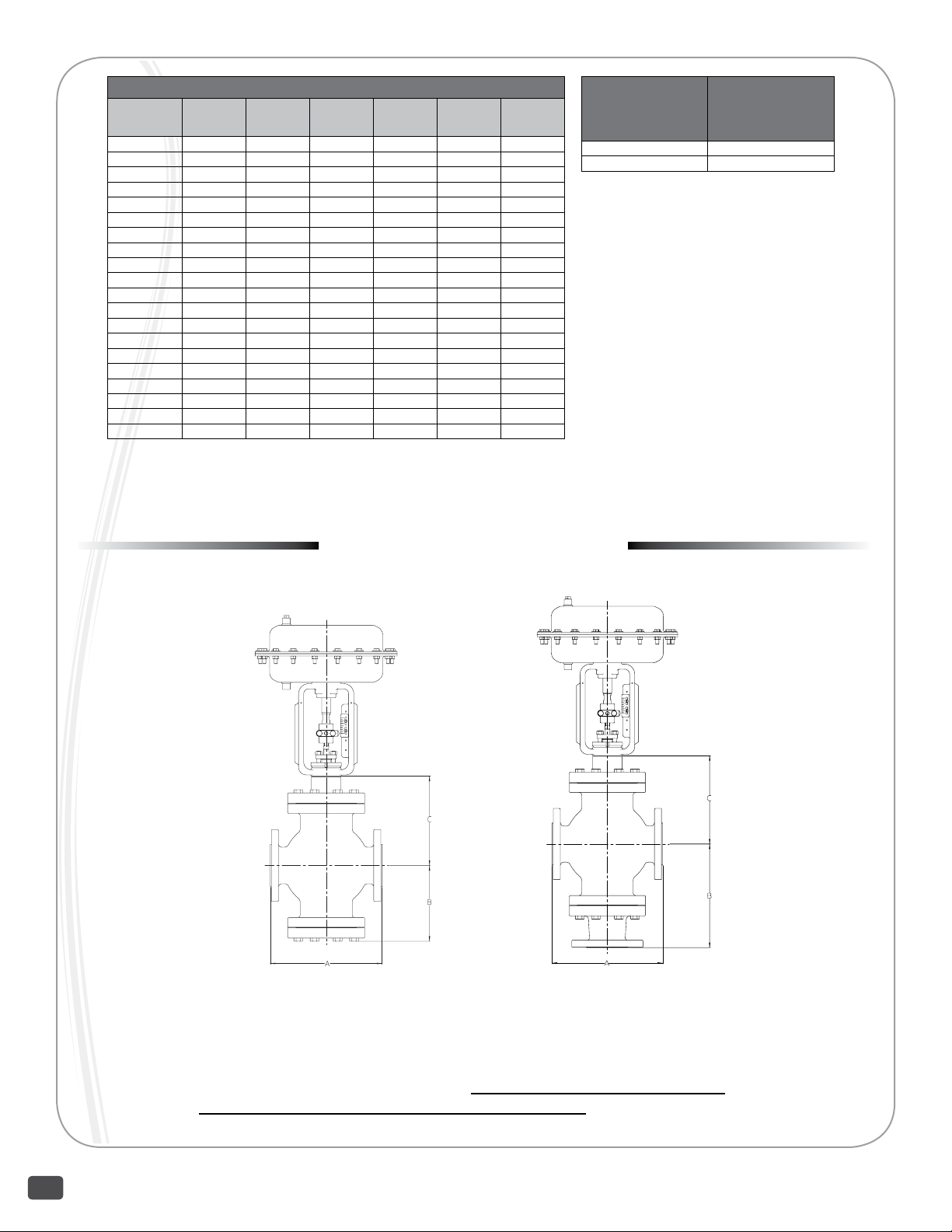

DIMENSIONS & WEIGHTS

2-WAY

3-WAY

Valves shown with DL84 Actuator as typical.

For additional actuator information see Series 1800 Product Specification and the

Installation Operation and Maintenance Instructions for the actuator in use.

2600 Emrick Blvd • Bethlehem, PA 18020 • USA •800-922-0085 • www.warrencontrols.com

6

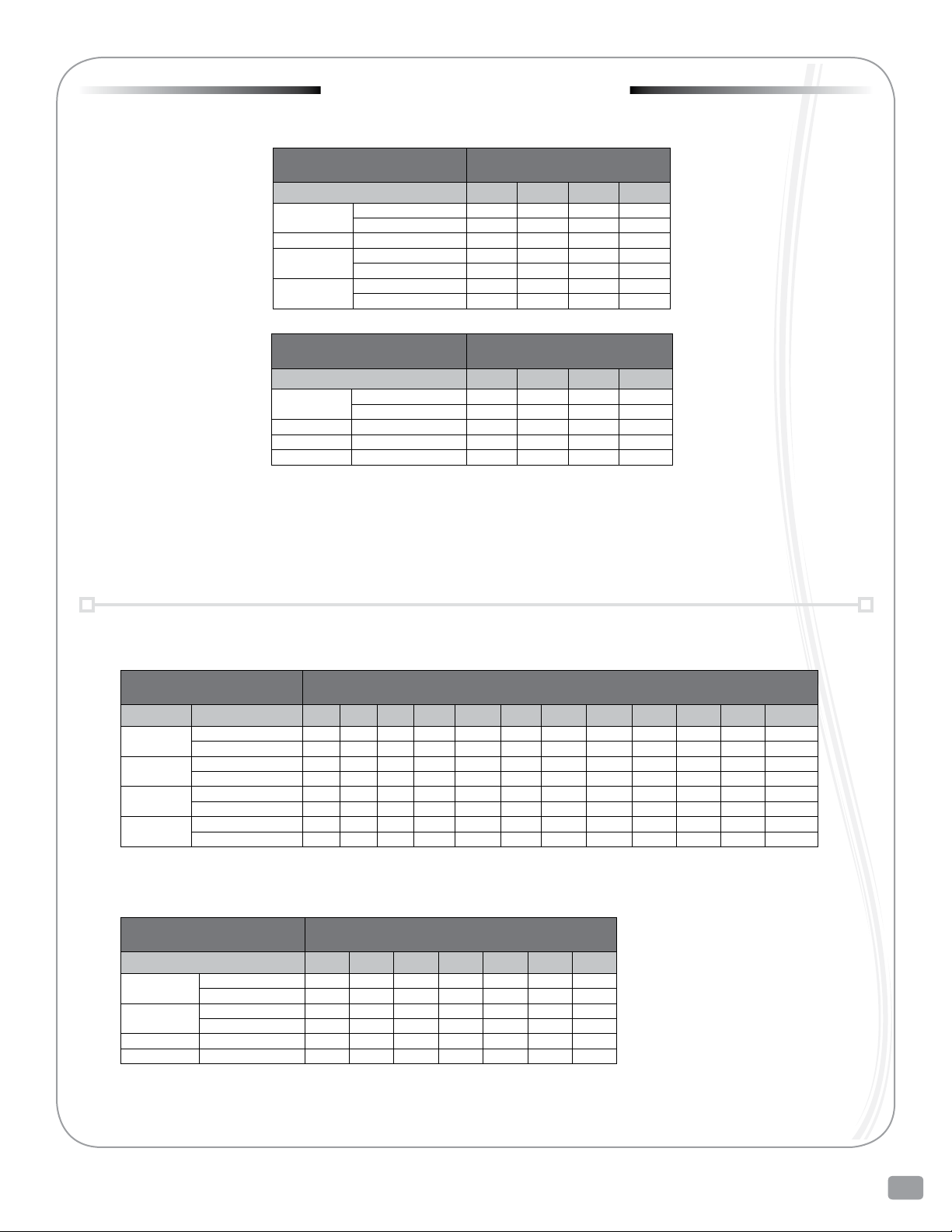

DIMENSIONS & WEIGHTS

2-WAY

Dimension (IN) 1840 Valve Size (IN)

6 8 10 12

A

B 11-7/8 13-3/4 15-1/4 15-1/4

C

Weight (LB)

125 or 150FLG 17-3/4 21-3/8 26-1/2 29

250 or 300FLG 18-5/8 22-3/8 27-7/8 30-1/2

Standard 13-7/8 15-1/4 16-1/8 17

Extension Bonnet 17-5/8 CF CF CF

Standard 390 650 1160 CF

Extension Bonnet 400 CF CF CF

Dimension (IN) 1843 Valve Size (IN)

6 8 10 12

A

B 11-7/8 13-3/4 15-1/4 15-1/4

C 14-1/2 15-7/8 16-3/4 17-3/4

Weight (LB) 455 760 1360 CF

Face to face dimensions conform to ANSI/ISA S75.03

CF = Consult factory

Actual Shipping Weights May Vary

125 or 150FLG 17-3/4 21-3/8 26-1/2 29

250 or 300FLG 18-5/8 22-3/8 27-7/8 30-1/2

3-WAY

Dimension (IN) 1850 Valve Size (IN)

1/2 3/4 1 1-1/2 2 2-1/2 3 4 6 8 10 12

A

B

C

Weight (LB)

Dimension (IN) 1852 Valve Size (IN)

A

B

C 9-1/2 10-1/4 11 14-1/2 15-7/8 16-3/4 17-3/4

Weight (LB) 140 210 390 545 900 1600 CF

125 or 150FLG 7-1/4 7-1/4 7-1/4 8-3/4 10 10-7/8 11-3/4 13-7/8 17-3/4 21-3/8 26-1/2 29

250 or 300FLG 7-1/2 7-5/8 7-3/4 9-1/4 10-1/2 11-1/2 12-1/2 14-1/2 18-5/8 22-3/8 27-7/8 30-1/2

125 or 150FLG 6-1/2 6-1/2 6-1/2 6-1/4 10 10-1/4 11-1/4 13-7/8 15-7/8 17-3/4 21-1/8 20-3/8

250 or 300FLG 6-5/8 6-3/4 6-3/4 6-1/2 10-1/4 10-5/8 11-5/8 14-1/8 16-1/4 18-1/4 21-3/4 21-1/8

Standard 5-1/2 5-1/2 5-1/2 6-1/8 8-1/8 8-7/8 9-5/8 10-3/8 13-7/8 15-1/4 16-1/8 17

Extension Bonnet CF CF CF CF CF CF 14-5/8 CF 17-5/8 CF CF CF

Standard CF CF CF CF CF 140 210 390 545 900 1600 CF

Extension Bonnet CF CF CF CF CF CF 215 CF 555 CF CF CF

2-1/2 3 4 6 8 10 12

125 or 150FLG 10-7/8 11-3/4 13-7/8 17-3/4 21-3/8 26-1/2 29

250 or 300FLG 11-1/2 12-1/2 14-1/2 18-5/8 22-3/8 27-7/8 30-1/2

125 or 150FLG 10-1/4 11-1/4 13-7/8 15-7/8 17-3/4 21-1/8 20-3/8

250 or 300FLG 10-5/8 11-5/8 14-1/8 16-1/4 18-1/4 21-3/4 21-1/8

Face to face dimensions conform to ANSI/ISA S75.03

CF = Consult factory

Actual Shipping Weights May Vary

Series 1800 IOM1800 A 1209

7

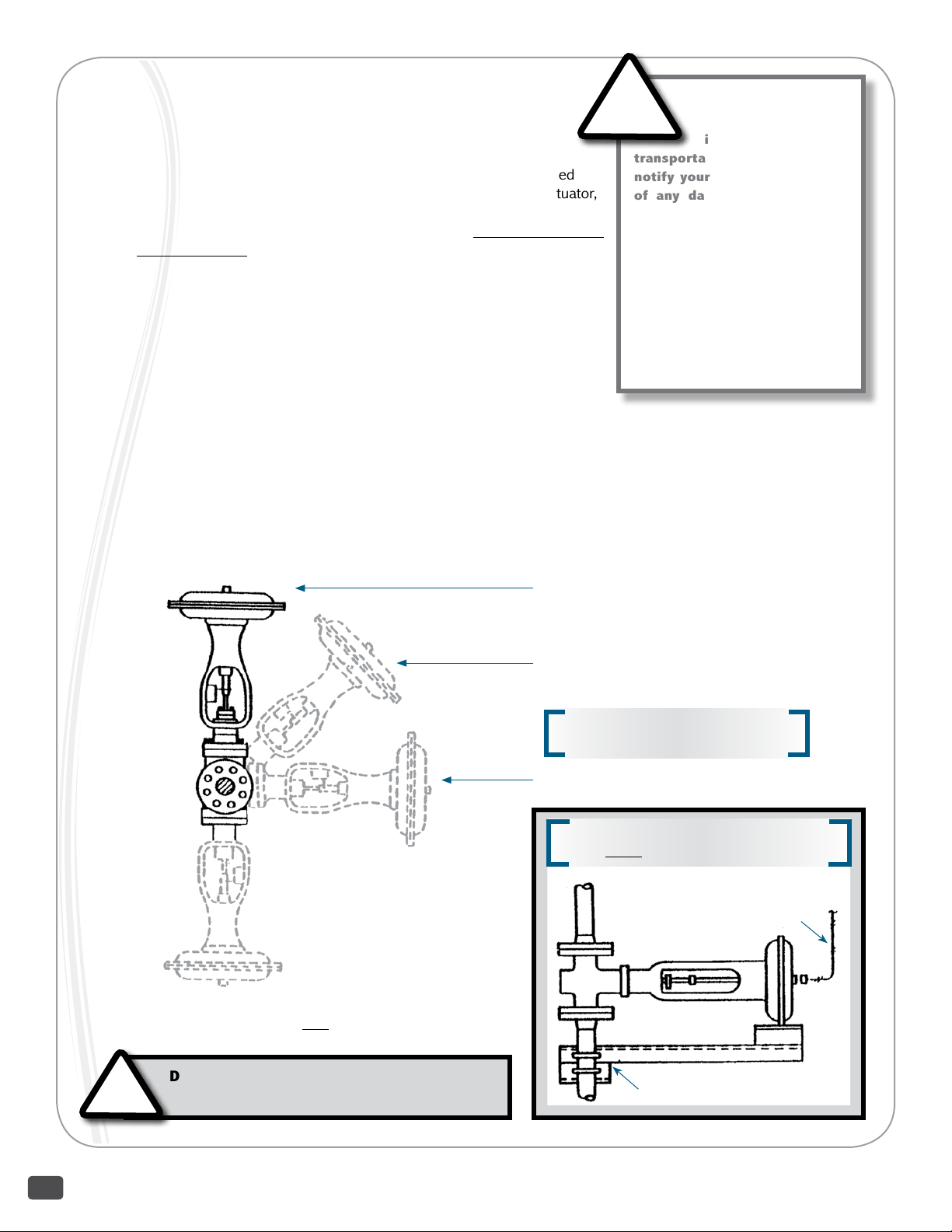

INSTALLATION

See also separate actuator and accessory

instructions for additional installation guidelines.

• Be sure that the flow medium, ambient temperature and the selected

location will not exceed the maximum temperature of the valve, actuator,

or accessories. Information can be found in the product specifications

and on the nameplate(s) regarding these limits (See Information Present

on Control Valves section for location of important information on valve).

• Follow good piping practices. Install a bypass around the valve. Install

stop valves in inlet and outlet piping to provide means to isolate valve.

• A straight run of pipe is recommended for 10 pipe diameters upstream

of the valve and 20 pipe diameters downstream of the valve.

• Protect valve and downstream equipment with a self-cleaning strainer.

•

Provide proper inlet and outlet drainage in steam service to prevent water hammer or possible erosion in equipment.

• Install gauges in inlet and outlet piping to provide means for checking adjustment and operation.

• For maximum efficiency and minimum wear install valve in vertical position with the stem pointing upward.

• Actuators mounted in any position other than vertical must be supported independent of the valve.

!

transportation. Immediately

notify your sales organization

of any damaged goods upon

receipt. Do not attempt to move

or disturb the valve further so

photos may be taken. If the

shipping container is noticeably

damaged refuse receipt, as

the shipping company should

be held liable until a shipping

representative is available to

take photos.

Check valve for any

damage due to

improper storage or

VERTICAL BELOW PIPING

Position is suitable for gases, but

NOT

for liquids or steam.

VERTICAL ABOVE PIPING IS

CORRECT MOUNTING POSITION.

All other positions reduce service life of equipment.

NEXT BEST POSITION

45º from vertical above piping on either side.

Valve must have an 8 Bolt Flange.

A non-vertical mounting position may be necessary

to protect actuator in high temperature applications,

but may reduce packing life.

WORST POSITION

DL84 Actuators mounted in any position other than

vertical

MUST

(Horizontal on either side).

be supported independent of the valve.

OPTION A:

Hanger Cable

DO NOT MOUNT DL115 ACTUATORS IN

!

2600 Emrick Blvd • Bethlehem, PA 18020 • USA •800-922-0085 • www.warrencontrols.com

8

THE HORIZONTAL POSITION

OPTION B: L’s with U-BOLTS

Loading...

Loading...