Page 1

12

Wheel-Brakes

1

⁄4 x 51⁄2, 15 x 3, 161⁄2 x 5-6-7 (Std)

1

16 x 2

⁄2, 171⁄4 x 3-4-5

AA-110

819-0514

Installation & Operating Instructions

Page 2

Contents

Section l. Description And Operation . . . . . . . . . . . . . 4

Description and Operation. . . . . . . . . . . . . . . . . . . . 4

How to Break in Trailer Brakes . . . . . . . . . . . . . . . . 5

How to Apply Brakes . . . . . . . . . . . . . . . . . . . . . . . . 5

Section ll. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Prepare for Installation . . . . . . . . . . . . . . . . . . . . . . . 6

Install and Check Drum . . . . . . . . . . . . . . . . . . . . . . 6

Install Flanges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Install Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Install Armature in Drum . . . . . . . . . . . . . . . . . . . . . 8

Check Armature Depression . . . . . . . . . . . . . . . . . . 9

Adjust Armature Depression . . . . . . . . . . . . . . . . . 11

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . 11

Section lll. Maintenance. . . . . . . . . . . . . . . . . . . . . . . 12

Check Current Available . . . . . . . . . . . . . . . . . . . . . . . 12

Table I. Magnet Current Rating . . . . . . . . . . . . . . . 13

Check Amperage at Each Brake . . . . . . . . . . . . . . 14

Check for Lining Wear . . . . . . . . . . . . . . . . . . . . . . 14

Table II. Lining Wear. . . . . . . . . . . . . . . . . . . . . . . . 14

Check for Loose Wheel Bearings . . . . . . . . . . . . . 15

Inspect Drums . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Drum and Lining Clearance . . . . . . . . . . . . . . . . . . 16

Relining Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table III. Drum Rebore and Brake

Reline Tolerances . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Check Magnet and Armature. . . . . . . . . . . . . . . . . 17

Replacement of Magnets and Armatures . . . . . . . 18

Table IV. Magnet and Armature Wear . . . . . . . . . . 19

Testing Magnet. . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Replacing Magnet Leads . . . . . . . . . . . . . . . . . . . . 21

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back Page

Warner Electric • 800-825-9050 819-0514

2

Page 3

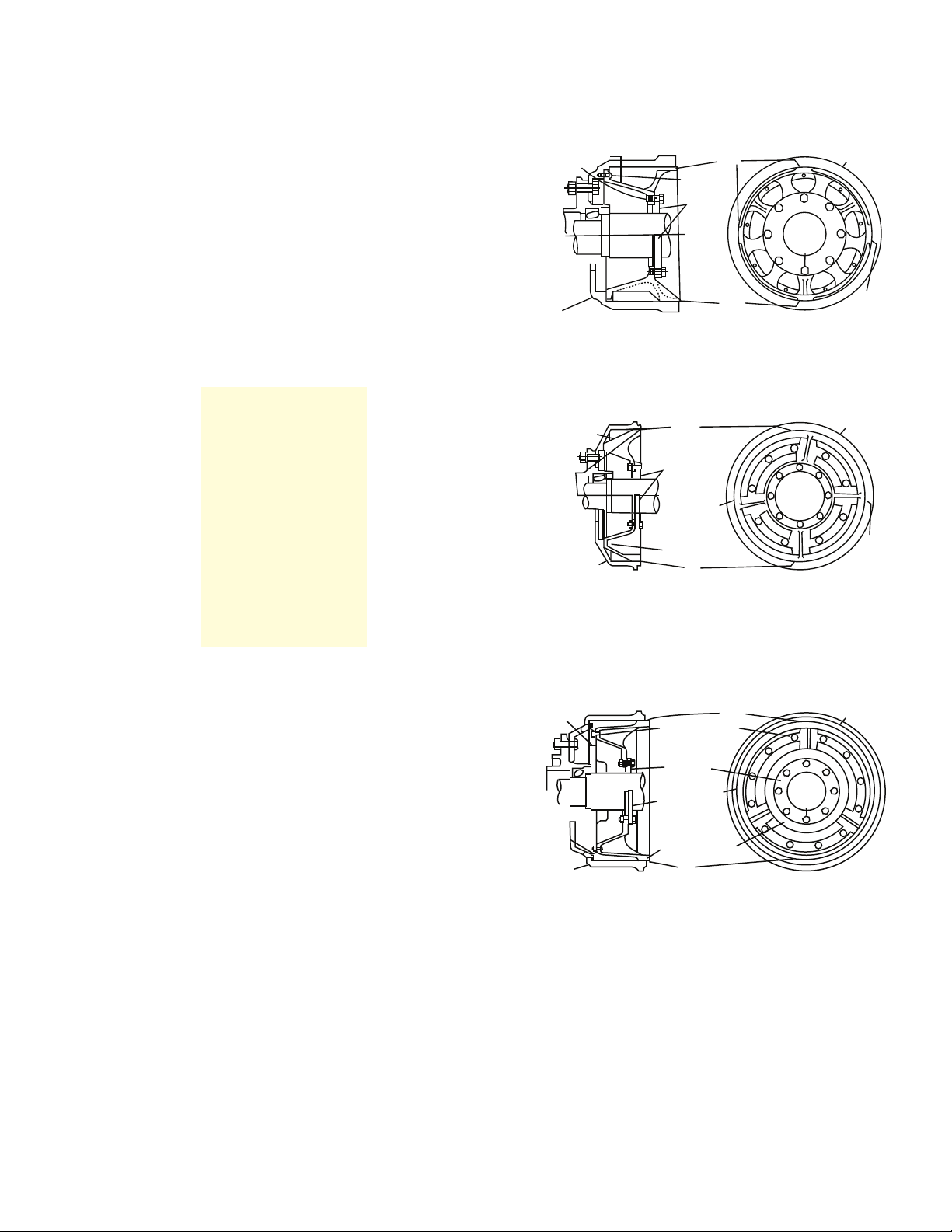

Brake Band

Magnet

Cam Lever

Trunnion

Armature

Drum

Spider

Brake Band

Dust Cover

Magnet

Cam Lever

Armature

Spider

Trunnion

Dust Cover

Brake Shoe

2-1/4 x 5-1/2 Brakes

Armature

Magnet

Cam Lever

Amature Adapter

Drum

Trunnion

Armature

Brake Band

Magnet

15 x 3 Brakes

Backing Plate

Drum

Trunnion

Cam Lever

16-1/2 x 5-6-7 Brakes

Warner Electric • 800-825-9050 819-0514

16 x 2-1/2 and 17-1/4 x 3-4-5 Brakes

3

Page 4

Failure to follow these instructions

may result in product damage, equipment damage,

and serious or fatal injury to personnel.

Section l

Description and Operation

The Warner Electric Brake is basically a mechanical

friction brake which uses a simple principle of

electricity for its actuation. The small amount of

electrical current required is obtained from the storage

battery and/or generator with which every towing

vehicle is equipped.

Unlike the ignition system of the engine, the Warner

Electric Brake does not require the use of high tension

current; therefore, no harmful shock is possible.

The main components of the Warner Electric Brake

are the backing plate or brake spider, magnet,

armature, brake band or brake shoes, cams and brake

drum; the nomenclature of the brake components

being dependent on method of fabrication, design,

and to some extent on brake size. With the

electro-mechanical actuating components (magnet

and armature) removed, (Figure 1-1), the brake consists

of a brake spider, which is mounted on the axle flange

and supports the brake shoes and cams. These

components are similar to, and functionally the same

as, those components found in all other mechanical

friction brakes.

The electro-mechanical actuating components

comprise a “friction clutch” and serve to generate the

force which multiplied by the cams, presses the brake

shoes into the brake drum. One plate of this “clutch” is

the armature, (Figure 1-2) which is bolted to the drum

and rotates with the wheel. The other plate of this

“clutch” is the magnet, (Figure 1-3) which is mounted

on the brake spider and is free to rotate a limited number of degrees in either direction. When the “clutch” is

engaged (upon application of an electric current to the

magnet) any movement of the trailer wheel (forward or

backward) causes the magnet to rotate and braking

results.

Figure 1-2

Armature Assembly

Brake Shoe

Cams

Figure 1-1

Electric Brake—Magnet Removed

Brake Spider

Dust Cover

Figure 1-3

Magnet Assembly

Warner Electric • 800-825-9050 819-0514

4

Page 5

Operation

How to Break in Trailer Brakes

When the magnet rotates, a trunnion, located on the

back of the magnet, moves the cam. The cam, bearing

on the brake shoe end, moves the brake shoe into

contact with the brake drum. After the toe end of the

brake shoe is forced against the brake drum, the shoe

(being free to float on its support and somewhat flexible in structure) will tend to follow the drum until the

complete brake shoe assembly is making contact with

the drum. The brake shoe is limited in its travel, however, since the heel end is forced against an anchor,

which is part of the brake spider assembly.

As the amount of current applied to the magnet is

increased, the attractive force between the magnet and

armature becomes greater. With an increase in attractive force between magnet and armature, more torque

is developed by the “clutch” and the pressure exerted

by the magnet trunnion upon the brake shoe (through

the cam) increases; and the shoe is pressed tighter into

the drum.

Until the vehicle is brought to a stop, slippage between

the magnet and armature occurs. However, if during a

stop sufficient pressure is built up, slippage between

the magnet and armature ceases and the entire unit

(magnet, armature, brake shoe, and brake drum) will

lock and slide the tire, providing the brake is of proper

capacity for the wheel load.

No brake adjustment is necessary. The magnet movement is sufficient to wear the brake lining down to the

rivet heads if the proper brake shoe to drum clearance

is maintained when new lining is present. When the lining has worn out, the cams come against a positive

stop (preventing further magnet rotation) preventing the

rivet heads from scoring the drum. Improper clearance

between brake shoe and drum initially will cause the

magnet to reach full travel before completely wearing

out the lining. In either case, as full magnet travel is

reached, a gradual loss of brake power will result.

Thus from the foregoing description, it is readily seen

that the Warner Electric Brake is a simple power-brake.

The amount of power developed being controlled by

the amount of current metered to the magnet by the

brake controls. Maximum power being achieved by an

amount of current approximately equal to that used by

a tail-lite.

When the armatures and magnets are new, to prevent

possible damage and to increase their efficiency, the

following steps should be followed during the initial

braking applications:

1. Attain a minimum vehicle speed of thirty miles

per hour and apply trailer brakes only until the

vehicle speed is retarded to approximately fifteen miles per hour, then release the brakes

allowing the vehicle to regain speed. DO NOT

LOCK THE WHEELS.

2. Next, drive for about one-half mile without

applying the trailer brakes. Repeat Step No. 1.

3. It will be necessary to follow Steps No. 1 and

2 until you have traveled approximately six

miles.

4. Allow the brakes to run free during the next

four miles. Then apply the brakes to check

their efficiency.

This procedure is also recommended whenever a

wheel has been pulled for maintenance of any kind or

when the trailer has set idle for any extended period of

time.

How to Apply Brakes

A brake is designed for a fixed capacity based upon

wheel load and tire size, and it is mounted in a minimum of space in order to clear springs and frames.

Considering this, it should not be required to handle

more than its own wheel load.

To obtain satisfactory trailer brake performance, the

towing vehicle’s brakes must handle their own load,

and therefore, must be applied simultaneously with the

trailer brakes. Consequently, the towing vehicle’s

brakes and the tractor trailer brake control system

must be kept in good repair to obtain maximum results

from the trailer brakes.

Overloading or using only the trailer brakes to stop the

complete tractor-trailer unit, will cause the heat absorption capacity of the brake to be exceeded. Hotter

brakes, longer stops, and shorter lining life will result.

Warner Electric • 800-825-9050 819-0514

5

Page 6

Section ll. Installation

Prepare Brake and Axle for Installation

The performance of an electric brake depends entirely

upon an accurate installation. Follow instructions, for

accuracy is definitely demanded and a brake properly

installed assures long life and dependable performance.

In preparing for installation, make certain that the hub

drum pilot (A, Figure 2-1) is at a perfect right angle with

the drum mounting surface (B), and that the drum pilot

(A) runs concentric with the axle spindle within .010”

total indicator reading. This may be checked on the

axle with a dial indicator or by removing the hub and

placing it in a lathe, using its own bearings on the

arbor for centering. If drum pilot bore and mounting

holes are not already present, bore drum pilot, allowing

a maximum of .004” clearance; and drill bolt holes,

using the hub as a template.

A

Axle

Figure 2-2

Checking Drum on Lathe

Install Flanges

If axle is equipped with brake mounting flanges suitable for installing electric brakes, clean flanges to

insure proper fit between flange and brake spider. If

axle is not equipped with flanges or old flanges are not

suitable for installing electric brakes, new flanges properly located - must be welded in position on the

axle. Cut off old flanges with a cutting torch leaving

axle clean and smooth.

Hub

B

Figure 2-1

Installing Drum on Axle

Install and Check Drum

Mount drum on hub and tighten securely. Check drum

for concentricity making certain that drum bore is concentric with axle spindle with .010” total indicator reading. Rotate drum on hub for best results. If drum is not

within concentricity limits, place hub and drum assembly in drum lathe (Figure 2-2) and remove the very minimum of stock which will permit drum to run within

concentricity limits. If it becomes necessary to remove

more than 1/32” from drum bore (diameter), remove

1/16” stock from drum and use oversized lining of

1/32” shim stock under lining to maintain proper drum

to lining clearance.

Select the correct brake mounting flange for the size of

brake to be installed.

#4604 for 15 x 3” brake

#40039 for 121⁄4 x 51⁄2” brake

#40039 for 161⁄2 x 5, 6, 7” brake

Mark the inside of the flange 1/16” larger than the actual size of the axle, (Figure 2-3). Cut the opening with a

cutting torch or turn out on a lathe. If opening in flange

is not large enough to permit assembly over axle collar,

cut flange in half with a hacksaw. Do not use a cutting

torch!

Mark 1/16”

larger than Axle

Saw Here

Figure 2-3

Installing New Mounting Flanges

Warner Electric • 800-825-9050 819-0514

6

Page 7

Kit 7494 Consists of:

Welding Fixture EQ-793

Mtg Accessory 111526

Shim

Axle

Flange

Welding Fixture

Bolted to Drum

Drum

Shim

Drum

Shim

Axle

Flange

Bolted To

Welding

Fixture

Kit 7494 Consists of:

Welding Fixture EQ-793

Mtg Accessory 111526

Shim

Axle

Flange

Axle

Flange

Welding Fixture

Bolted to Drum

Welding Fixture

Bolted to Drum

Drum

Shim

Drum

Drum

Drum

Shim

Shim

Shim

Shim

Shim

Axle

Flange

Bolted To

Welding

Fixture

Kit 7504 Consists Of:

Welding Fixture EQ-730

Mounting Acc. 11603

Kit 7494 Consists of:

Welding Fixture EQ-793

Mtg Accessory 111526

Shim

Axle

Flange

Axle

Flange

Welding Fixture

Bolted to Drum

Welding Fixture

Bolted to Drum

Drum

Shim

Drum

Drum

Drum

Drum

Drum

Shim

Shim

Shim

Shim

Shim

Shim

Shim

Shim

Axle

Flange

Bolted To

Welding

Fixture

Axle

Flange

Bolted To

Welding

Fixture

Kit 7504 Consists Of:

Welding Fixture EQ-730

Mounting Acc. 11603

Welding Fixture Bolted

To Armature Adapter

Axle Flange

Weld

Armature

Adapter

Welding Fixture No.

EQ-615-A

Armature Adapter

Indentification

16½ x 5 - 21⁄64”

16½ x 6 - 53⁄64”

16½ x 7 - 1-21⁄64”

Bevel edges of hacksaw cut to provide surface for

good weld.

If a 16-1⁄2 x 5, 6, or 7” brake is to be installed, bolt

armature adapter to the drum, (Figure 2-4).

Adapter #3979 for 16-1⁄2 x 5” brake

Adapter #3993 for 16-1⁄2 x 6” brake

Adapter #3942 for 16-1⁄2 x 7” brake

It is important that a thin coating of “Permatex” or

other suitable sealer be used between armature

adapter and brake drum to prevent grease from leaking

under adapter and getting into brake assembly.

Figure 2-4

Bolting Armature Adapter to Drum

Figure 2-5

Location of Welding Fixture Inside of Drum

(12-1/4 x 5-1/2” Brake)

Figure 2-6

Location of Welding Fixture Inside of Drum

(15 x 3” Brake)

Bolt the welding fixture inside of drum as illustrated in

Figures 2-5, -6, -7.

Figure 2-7

Location of Welding Fixture Inside of Drum

(16-1/2 x 5, 6, 7” Brake)

Bolt axle flange to welding fixture and install hub,

Fixture #EQ-615A (Figure 2-7) for 16-1⁄2 x 5, 6, 7” brake.

Fixture #EQ-793 (Figure 2-5) for 12-1⁄4 x 5-1⁄2” brake.

Fixture #EQ-730 (Figure 2-6) for 15 x 3” brake. If clearance between drum and fixture is present, center the

fixture in drum by using shims between fixture and

drum in four locations as shown.

drum, and welding fixture assembly in place on axle.

Pull wheel bearing lock nut tight. If flange has been cut

in half, insert shims (Figure 2-8) in hacksaw cut before

welding to prevent shrinkage. If grease seal is used as

Warner Electric • 800-825-9050 819-0514

a bearing spacer and is too large for flange or welding

fixture to pass over, put welding fixture and flange on

axle and assemble to drum after hub and drum assembly are placed on axle. Center welding fixture in drum

by using shims as illustrated in Figures 2-5, -6, -7.

7

Page 8

Shims

Figure 2-8

Location of Shims for Welding Flange

With an electric arc, tack both outer edges of hacksaw

cut, if cut is present. T

ack flange (Figure 2-9) to axle in

approximately four places. Complete weld by welding

hacksaw cut first - outer edge to axle - then make

continuous weld between flange and axle. Remove

bolts that hold flange to welding fixture and remove

hub, drum, and welding fixture from axle. Complete

weld on opposite side of flange. Remove welding

fixture from drum and clean all weld splatter from drum

or spindle surfaces.

Install Brakes

The desired position for mounting brakes on the axle is

indicated in Figure 2-10. Whenever possible they

should be mounted so that the brake spider anchor is

down and 45° to the rear as determined by forward

vehicle travel. Mounting brakes in this position affords

the best wheel bearing loading during application of

brakes. If the brakes are marked right and left hand

because of the type and location of lining segments in

brake shoes, the woven lining (with arrow indicating

drum rotation for forward vehicle travel) must always

be on the toe end of the shoe ring. Left and right hand

are determined by facing in the direction of forward

vehicle travel. In the event it is not possible to locate

the brake spider anchor as shown, the anchors must

be in the same relative location for all wheels.

For Brakes

Direction

of Travel

Marked Right

and Left Hand

Locate Woven

Lining on

Toe End

Tack Weld

Figure 2-9

Weld Points on Flange

NOTE: Do not use same hub and drum assembly as

template for all wheels. Use hub and drum

designated for each wheel location.

Brake

Spider

Anchor

45°

Figure 2-10

Brake Mounted in Correct Position

Install Armature in Drum

Bolt armature inside of drum (Figure 2-11). Armature

bolts directly to armature adapter for 16-1⁄2” series

brakes. On 12-1⁄4 x 5-1⁄2” and 15 x 3” brakes, grease

guard is placed between armature and drum when

armature is bolted in place. A thin coating of

“Permatex” or other suitable sealer must be used

between grease guard and drum at this time.

Warner Electric • 800-825-9050 819-0514

8

Page 9

Figure 2-11

Bolt Armature Inside of Drum

NOTE: Armatures are marked right and left hand,

and they must be installed accordingly.

Face in direction of forward vehicle travel to

establish right and left hand relationship.

Outside Legs

Middle

Movable

Frame

Thumb

Screw

Leg

Collar

Check Armature Depression

Before closing up the brake assembly by mounting

the wheel on the axle, check the armature depression.

Since the armature and magnet must run in light

contact at all times (the armature is spring mounted to

compensate for armature and magnet wear), it is

absolutely necessary that the proper magnet and

armature relationship, termed armature depression, is

maintained at all times. Because this relationship

between armature and magnet constitutes a blind

assembly, an armature depression gauge (Figure 2-12)

is used.

Gauge #40252 for 12-1/4 x 5-1/2” brake

Gauge #40252 for 15 x 3” brake

Gauge #4812 for 16-1/2 x 5, 6, or 7” brake

Step 1 To determine the amount of depression,

place the outside legs of the gauge against

the magnet facing with both thumb screws

loose and with collar on middle leg on the

outside of gauge crossbar (Figure 2-13).

Push the middle, movable leg into contact

with the bearing shoulder. Make certain that

the gauge is held perpendicular to the

magnet and that the magnet is flush against

the brake spider.

Magnet

Face

Bearing

Shoulder

Collar

Go-No-Go

Gauge

Thumb

Screw

Figure 2-12

Armature Depression Gauge

Figure 2-13

Using Depression Gauge—Step 1

Warner Electric • 800-825-9050 819-0514

9

Page 10

Figure 2-14

Using Depression Gauge—Step 2

Step 2 Next, tighten the frame thumb screw,

positioning the movable leg (Figure 2-14).

Move the collar up against the frame and

tighten the collar thumb screw fixing the

collar securely upon the movable leg.

Armature

Face

Bearing

Figure 2-16

Using Depression Gauge—Step 3

Step 4 Reverse the gauge so collar on center leg is

below gauge crossbar

, and place the outside

legs against the armature face (Figure 2-16).

Make certain gauge legs are on armature

face and not between segments or in

welding projection holes. Loosen the thumb

screw on the gauge frame only, and push the

movable leg against the bearing. Tighten the

gauge frame thumb screw fixing the movable

leg in this new position. Check this position

of the three legs in three points, 120˚ apart,

to insure correct reading.

Figure 2-15

Positioning Armature Disc

Step 3 With the wheel assembly lying down so that

the armature is horizontal, place the inner

bearing in the hub and rotate under light

Measuring Armature Depression

Figure 2-17

pressure to make certain bearing is fully

seated. Have someone hold the armature

disc (Figure 2-15) up against the stops or

place three wedges equally spaced under

the disc to hold it against the stops. Using

Step 5 The distance between the gauge frame and

the collar on the movable leg is the armature

depression (Figure 2-17). It should be

between 1/8” and 3/16”.

wedges is the more accurate method.

Warner Electric • 800-825-9050 819-0514

10

Page 11

Figure 2-18

Using GO-NO-GO Gauge

Adjust Armature Depression

If the depression is less than 1/8”, the difference must

be made up by placing shims (Figure 2-19) under the

armature retaining ring. If the depression is more than

3/16”, place a hardened bearing spacer between the

inner bearing and the bearing shoulder on the axle.

Warner Electric does not supply bearing spacers.

If wedges have been used under the armature to check

depression, be sure to remove them.

Cleaning

Step 6 The armature gauge is provided with a Go-

No-Go gauge (Figure 2-18) pr

esenting an

easy manner of checking for correct depression. The small end of the pin is 1/8” in diameter and should slip between the gauge

frame and the collar. The large end of the pin

is 3/16” in diameter and should not slip

between the gauge frame and collar.

Spacer No. 3516 1/16” thick For use with 12-1/4” x 5-1/2”

Spacer No. 3516A 1/32” thick and 15” x 3” Brakes

Spacer No. 3313 1/16” thick For use with 16” x 2-1/2”,

Spacer No. 3313A 1/32” thick 17-1/4” x 3”, 4”, 5”, and

16-1/2” x 5”, 6” and 7” Brakes

Clean all grease and oil from the brake drum surface,

armature face, magnet face, and brake lining with

carbon tetrachloride before mounting wheels. Pack

wheel bearings with a good grade of bearing grease.

Be sure wheel bearings are tight, as loose bearings

cause grabby, erratic brakes. Under no circumstances

should a grease gun be used; and if any grease fittings

are present, remove them and plug holes before

releasing the unit for service.

Electrical Connections

Make necessary electrical connections in accordance

with recommended wiring diagrams CWA-001 through

CWA-008 furnished separately.

Figure 2-19

Armature Retainer Ring Shims

Warner Electric • 800-825-9050 819-0514

11

Page 12

Section lll Maintenance

During preventive maintenance periods or when

attempting to diagnose brake troubles, three simple

checking procedures should be followed. Merely by

checking the current available for braking, the approximate amount of brake lining wear, and whether or not

the wheel bearings are tight; most brake troubles can

be pin pointed and the condition of the electric brake

system determined.

Check Current Available

Be sure that the electrical circuit of the towing vehicle

is connected to the electrical circuit of the trailer

(Figure 3-1). It is good practice to check and clean the

socket and plug contacts periodically to insure a clean,

tight connection.

Figure 3-2

Connecting Ammeter to Controller and Brake Wire

Make a light, fast application of the controller

(Figure 3-3) and observe the direction of movement

of the ammeter needle. If needle moves in wrong

direction, reverse the ammeter leads. Current of the

wrong polarity in excessive amounts can damage the

ammeter. When ammeter is correctly connected in the

brake circuit, make a full application of the controller,

noting the total current in the circuit as shown by the

ammeter. Move the load control from 100% to 0 and

observe movement of ammeter needle. There should

be a gradual reduction of current. Return load control

to 100% and note current reading. If same as previous

reading, load control is operating correctly.

Figure 3-1

Towing V

Remove either one of the brake circuit wires from a

controller terminal and connect a low reading DC

ammeter (15-25 amp. capacity) between the contr

terminal and the wire just removed (Figure 3-2). Make

certain load control is set at 100% (full on). Start

engine and idle fast enough to insure full battery

charge.

Warner Electric • 800-825-9050 819-0514

12

ehicle Electrical Connection

oller

Figure 3-3

Checking Circuit Curr

To determine whether proper current is available for

braking, refer to Table l- Magnet Current Rating.

ent

Page 13

Table l - (Magnet Current Rating)

Brake Size

Brake Size

6 Volt 12 Volt 6 Volt

12-1/4 x 5-1/2” 3.7-4.1 3.0-3.7 *16 x 2-1/2” 3.4-3.8

15 x 3” 3.7-4.1 3.0-3.7 *17-1/4 x 3 & 4 3.0-3.4

16-1/2 x 5*, 6*, 7” 3.4-3.8 2.6-3.2 *17-1/4 x 5 4.0-4.5

AMPS

* Not in production - service parts only.

When the towing vehicle has a 6-volt electrical system,

all brakes will be connected in parallel; therefore, the

total current in the brake circuit should be equal to the

number of brakes times the value given in Table l.

If the reading at the controller is higher than the maximum based on Table l, check for a short in the wiring,

cable, controller, or brake magnets (Figure 3-4). If the

reading at the controller is less than the minimum

based on Table l, check the complete electrical circuit

If the towing vehicle has a 12-volt electrical system, all

single axle trailers will be wired in parallel; and the total

current in the brake circuit, should again be equal to

the number of brakes times the value given in Table l.

However, if the trailer is a tandem axle trailer, all brakes

may be wired in parallel or the brakes on each axle

may be wired in series and the axles wired in parallel. If

for loose or dirty connections, broken wires, improper

wire size, and conformity of wiring arrangement with

Warner Wiring Diagrams. If towing vehicle has a 12-volt

electrical system, check to make certain proper external resistor is being used. All splices and terminals

should be soldered and ground connections made at

battery or welded to the frame.

all brakes on a tandem axle trailer are in parallel. the

total current in the brake circuit should be equal to the

number of brakes times the value given in Table l. If, on

a tandem axle trailer, the brakes on each axle are wired

in series and the axles are wired in parallel, the total

current in the brake circuit should be equal to that of a

single axle trailer wired in parallel.

AMPS

Figure 3-5

Checking Amperage at Brake Magnets

Figure 3-4

Checking Electrical Connections

Warner Electric • 800-825-9050 819-0514

13

Page 14

Check Amperage at Each Brake

“A”

“A” Measured

Here

Inside

Rim Dia. “D”

Check for Lining Wear

Amperage check at the controller should be followed

by an individual amperage check at each brake magnet

(Figure 3-5). When all brakes are connected in parallel,

connect the ammeter between either of the brake terminals and the wire removed from that terminal. Make

light, fast controller application to insure that meter is

properly connected into brake circuit with respect to

polarity. The reading at each brake should be the same

and equal to the value given in Table I. If brakes are

connected in series on a given axle (tandem axle trailer

and 12-volt tractor), current per axle is equal to one

magnet based on Table I. To check each individual

magnet when series is connected, disconnect both

leads from one brake and connect ammeter between

the two leads. The reading per magnet should be

double that given in Table I. If current reading for any

one brake is incorrect, inspect for broken wires, dirty

or loose connections and shorts. Failure to find fault

externally, when brake amperage is incorrect, will

necessitate removal of wheel for further inspection.

To check for lining wear, apply the tractor hand controller full on and back up the unit to set the trailer

brakes hard. Do not release the brake, but mark the rim

as indicated in Table II, page 15. Without releasing the

brake, move the unit forward to set the trailer brakes

hard, and again mark the rim as indicated in Table II.

Measure the dimension “A” on the curve of the rim.

Note: The differences in loading and method

of measuring give only approximate results

which should be close enough to determine

whether the magnet is approaching

maximum travel and/or the lining is worn out.

For greater accuracy, it may be necessary to

disconnect all brakes except one and check

each wheel individually. After setting brake

as above, ease clutch off so as to allow

deflection of trailer suspension, caused by

brake application, to release.

If maximum travel based on Table II has been reached

and loss of brake power has been experienced, wheels

should be removed and the brakes relined.

Table II — Lining Wear

Nom.

Tire

Rim

Size

14

“D”

(in.)

15 14.7 7.8 8.15

16 15.7 7.3 8.7

18 17.6 6.5 9.75 8.6

20 19.6 5.85 10.8 9.6 6.0 11.3 9.1 12.3

22 21.6 5.3 10.5 6.6 12.45 10.0 13.5

24 23.7 4.87 11.6 7.25 13.65 10.9 14.8

Warner Electric • 800-825-9050 819-0514

C

“A” Maximum

12-1/4 x 5-1/2 15 x 3 16 x 2-1/2 16-1/2 x 5, 6, 7 17-1/4 x 3 17-1/4 x 4, 5

Page 15

Check For Loose Wheel Bearings

Inspect Drums

During brake inspection periods and before removing

wheels, jack up each wheel and check for loose wheel

bearings (Figure 3-6). If by using a bar under the tires,

the wheels can be moved up and down on the axle the

wheel bearings are loose or worn. This condition can

cause grabby or noisy brakes, a dragging brake which

creates undue heat and rapid lining wear, or a possible

wheel lockup. Bearings Must Be Kept Snug.

Figure 3-6

Checking for Loose Wheel Bearings

Before relining brakes or during regular maintenance

periods, the drum should be checked for an

out-of-round condition. This may be accomplished

by an inside micrometer or a dial indicator mounted

on a stub spindle (Figure 3-8). Drums should not be

out-of-round more than .010”, since such a condition

can cause erratic, grabby brakes and possible difficulty

in assembling the wheel onto the axle.

Whenever a wheel is removed, always check the drum

mounting bolts. They must be kept tight, since a loose

drum has the same effect as loose wheel bearings. A

loose drum may also cause the drum mounting bolts to

shear off during a brake application.

When wheels must be removed for maintenance or

, always check for worn or defective bearings and

repair

cups (Figure 3-7). Defective parts must be replaced.

Also check the hub for cracks and for proper fit of the

bearing cups in the hub.

Figure 3-7

Inspecting Wheel Bearings

Figure 3-8

Checking Drum with Inside Micrometer

and Dial Indicator

Warner Electric • 800-825-9050 819-0514

15

Page 16

Check drums for excessive heat checking and scoring.

Heat checking may be a sign of an undersized brake, a

dragging brake, or an unbalanced brake condition in

the tractor-trailer unit. Heat checking will also be

accompanied by excessive brake lining wear. If the

brake drum is scored, check for loose lining rivets or

foreign metal particles imbedded in the lining. Drums

which have excessive heat checking or scoring should

be turned.

Drum and Lining Clearance

Caution should be exercised when boring drums and

relining shoes as there is no definite yardstick to follow

as to how much a drum may be oversized. It is

generally recommended that a drum shall not be bored

oversize more than 1/4” on the diameter and that shim

stock thicker than 1/8” shall not be used with riveted

lining. In some operations, such as mountainous

terrain, it is recommended that drums be replaced

before this time. In order that peak brake efficiency be

obtained, use only factory approved and tested lining

as covered by Charts I-26011 and I-26012 in the

replacement parts section of this manual.

Since the electric brake cannot be adjusted to

compensate for drum and lining wear, clearance

between drum and lining is one of the most important

factors governing electric brake operation. This

clearance is best controlled at the initial installation,

during re-lines, and during drum replacement. If proper

clearance between drum and lining is maintained at

these times, the electric brake is so designed that the

lining will be completely worn out by the time the

maximum cam travel is reached. However, if too much

clearance is present initially, maximum cam travel will

be reached before the lining is completely worn out

and a gradual loss of brake power will result. Too little

clearance initially may cause a brake to drag with a

possible wheel lockup, or make it difficult to assemble

the wheel onto the axle. Considerable variation in drum

to lining clearance between brakes on a given unit

could cause unbalanced braking.

Relining Brakes

Brake shoe and lining assemblies as received from

the factory are ground to give a drum to lining

clearance of approximately .020” (.040” on the

diameter) with respect to the nominal brake diameter.

When relining or replacing a drum, the drum bore and

overall lining diameter (Figure 3-9), should be matched

to obtain approximately .020” clearance. Table III will

serve as a guide for obtaining proper clearance.

Do not weld metal to band ends to compensate for

drum wear, excessive drum to lining clearance, or wear

of brake components.

Always check the brake shoe assembly for worn loose

or greasy lining. If any of these conditions exists,

replace with Warner recommended lining. The high

radial pressures developed by the brakes will cause too

soft a lining to wear rapidly, often causing damage to

the drum and the brakes to fade under heat. Where

greasy lining is encountered, inspect and replace

grease seals. If enough grease is present, it may be

necessary to remove the grease guard or armature

adapter and clean grease from wheel and drum. When

replacing the grease guard or armature adapter, a thin

coating of “Permatex” or other suitable sealer must be

used between adapter and drum. Surface grease on

lining, drum braking surface, magnet, and armature can

be removed with carbon tetrachloride or other suitable

solvent. However, if grease has penetrated lining or

magnet facing, they must be replaced since grease will

seep to the surface under heat causing weak brakes.

Figure 3-9

Measuring Band Size with Outside Micrometers

Warner Electric • 800-825-9050 819-0514

16

Page 17

Table III - Drum Rebore and Brake Reline Tolerances

Brake Size Brake Shoe Dia.

12-1/4 x 5-1/2”

15 x 3

16 x 2-1/2

16-1/2 x 5, 6, 7

17-1/4 x 3, 4, 5

11.442 0.385 —

11.450 0.400 —

14.300 0.325 —

14.310 0.330 —

15.4370 0.265 —

15.4375 0.275 —

15.682 0.390 —

15.692 0.400 —

16.370 0.385 —

16.375 0.405 —

When brakes are relined, but the drum is not turned;

the ridge left on the bell end of the drum, due to drum

wear on the drum braking surface, should be removed.

This may be accomplished by turning or by using a

hand grinder (Figure 3-10) with a flexible disc.

Replacement Lining Thickness Tolerances

Standard Oversize

Check Magnet And Armature

Make certain that proper magnet and armature

relationship is being maintained. That is, the magnet

poles should always be in contact with the armature

(metal to metal). This is initially accomplished by

undercutting the magnet facing .005 to .007” below

the magnet poles (Figure 3-11) at the factory. This

insures that the magnet poles will be fully seated in

their armature tracks before the magnet facing comes

into contact with the armature. Normally the magnet

pole tracks in the armature should be only slightly

wider than the magnet poles. If excessively wide tracks

are present on the armature, a loose drum or loose

wheel bearings are usually at fault.

Magnet Poles

Magnet Facing

Armature

Undercut .005” to .007”

Figure 3-10

Removing Ridge on Drum

Magnet Shell

Figure 3-11

Cross Section of Magnet and Armature

Warner Electric • 800-825-9050 819-0514

17

Page 18

During normal operation, the face of the armature and

New

Slightly Scored

(Normal)

Badly Scored

(Needs Replacement)

magnet will become scored or grooved to some extent

(Figure 3-12). This condition is not detrimental and

does not show excessive wear or defective parts. In

the case of some magnets, termed “air gap” and

distinguished by an expansion groove in the magnet

facing, a ridge will appear on the armature opposite

this groove after considerable wear. It is recommended

that the ridge be partially ground off, so that at

maximum wear, it cannot cut through the magnet

facing and short out the magnet coil.

Figure 3-12

Typical Wear Patterns

Often times, when there is a complaint of weak brakes

and all other things appear normal, a glazed magnet

facing is at fault or a condition exists whereby the

magnet facing prevents the magnet poles from coming

into direct contact with the armature. This condition

may be remedied by placing the magnet in a lathe

(Figure 3-13) and undercutting the magnet facing

(Do Not machine the magnet poles) with a carbon

tipped tool or by using a small piece of sandpaper

(Do Not use emery cloth) on the finger tips or on a

small block of wood. Whenever possible, use only

sandpaper; undercutting the magnet facing in a lathe

reduces magnet wear life.

Figure 3-13

Undercutting the Magnet Facing

Replacement of Magnets and Armatures

Note: All single wire magnets are replaceable

with 2 wire magnets by grounding one wire

to the brake.

Table IV is a guide to determine when magnet and

armature should no longer be refaced. As indicated

magnets and armatures may be used even when

dimensions “A” and “B” are below the minimum;

but they should never be refaced when below this

minimum. If a magnet needs to be replaced, a new or

refaced armature must be used. However, an armature

may be replaced without replacing the magnet. In this

case, merely make certain the magnet facing is below

the magnet poles to insure proper pole contact initially.

Warner Electric • 800-825-9050 819-0514

18

Page 19

Magnets

“A”

“A”

Air Gap

Non-Air

Gap

Armatures

Air Gap Type

(AG)

“B”

“B”

Non-Air Gap Type

(NAG)

Do Not Reface Armature if Min.

Thickness is Less Than Dim. “B”

Do Not Reface Magnet if Min.

Thickness is Less Than Dim. “A”

Table IV — Magnet and Armature Wear

Magnet and Armature can be used if dimensions “A” and “B” are below minimum given, but they should not be refaced after

minimum dimensions are reached.

Brake Size

Magnet

AG=Air Gap

NAG=Non Air

Gap

Dim.

A

Armature

AG=Air Gap

NAG=Non Air

Gap

Dim.

B

No. Type No. Type

12-1/4 x 5-1/2 40122 2 wire AG 1-15/64 4998A, 9A NAG 27/64

15 x 3 40110 2 wire AG 1-7/32 4998A, 9A NAG 27/64

16 x 2-1/2

16-1/2 x 5, 6, 7

17-1/4 x 3, 4

17-1/4 x 5

4696

4752

4752A

40040

40092

4653

4750

40031

40093

4653

4708

40091

40013

40090

1 wire NAG

2 wire NAG

2 wire AG

2 wire AG

2 wire AG

1 wore NAG

2 wire NAG

2 wire AG

2 wire AG

1 wire NAG

2 wire NAG

2 wire AG

1-9/32

1-9/32

1-9/32

1-13/32

1-13/32

1-9/32

1-9/32

1-9/32

1-9/32

1-9/32

1-9/32

1-9/32

4655C, 6C

4655C, 6C

40045-6

40047-8

40047-8

4597A, 8A

4597A, 8A

40019-20

40019-20

4597A, 8A

4597A, 8A

40019-20

AG

AG

NAG

NAG

NAG

AG

AG

NAG

NAG

AG

AG

NAG

3/16

3/16

3/8

27/64

27/64

3/16

3/16

25/64

25/64

3/16

3/16

25/64

NOTE: All single wire magnets are replaceable with 2 wire

Warner Electric • 800-825-9050 819-0514

magnets by grounding one wire to the brake.

19

Page 20

Non-Air Gap Magnet

Air Gap Magnet

Air Gap Armature

Figure 3-14,

Types of Magnets and Armatures

It is important that magnets and armatures be used

in pairs (Figure 3-14), both from a wear pattern

standpoint and for proper electrical characteristics.

Therefore, during repair and maintenance periods,

never interchange magnets and armatures. When

new magnets and armatures are to be replaced,

either individually or in pairs, make certain that proper

electrical characteristics will be obtained. Thus, either

the magnet or armature must have an air gap in order

to insure proper brake release. If both magnet and

armature have an air gap, weak brakes will result.

Always order replacement parts by the number

stamped on the armature retainer ring or the magnet

nameplate.

Check the magnet bushing for damage or excessive

wear. A new bushing is approximately 1/16” thick and

should not be used when worn below 1/32”. Worn

bushings may be removed by driving a “prick punch”

between magnet and bushing. Install new bushing by

placing the magnet face down on a clean, smooth

surface and pressing the bushing into the magnet 1/4”

below the level of the magnet surface facing you.

Remove any rough edges with a bearing scraper.

Non-Air Gap Armature

If, during the amperage check at each wheel a

defective magnet was indicated, the magnet leads,

backing plate terminals, and backing plate terminal

block should be inspected. Defective parts should be

replaced and all connections cleaned and tightened. If

the trouble is not readily apparent, remove the magnet

for further checking.

Testing Magnet

Figure 3-15

Testing Amperage Capacity of Magnet

Warner Electric • 800-825-9050 819-0514

20

Page 21

Copper Clips

Test the magnet for amperage capacity by using an

ammeter and a 6-volt battery (Figure 3-15). The

ammeter should indicate the amperage value given

on the magnet nameplate, plus or minus 10%. The

magnet amperage is rated at 70°F; therefore, a hot

magnet will indicate slightly lower and a cold magnet

will indicate slightly higher. If amperage reading is

incorrect, the magnet should be replaced, after first

making certain that the magnet leads are not defective

and that the magnet leads are making a good positive

connection with the magnet coil.

To test the magnet for a ground, connect an ammeter

and a 6-volt battery to the magnet (Figure 3-16). If any

amperage is indicated, a grounded condition exists.

The ground may be in either the leads or within the

magnet itself; therefore, check the leads thoroughly

before replacing magnet. Old style magnets having a

single magnet lead have one coil lead grounded to the

magnet shell; and therefore, will indicate proper

amperage when tested in this manner if not defective.

Coil Leads

Steel Clips

Figure 3-17

Installing Magnet Lead Wires

Straighten coil leads. Remove the old magnet lead

assembly and replace with new. Bend steel clips tight

against the fiber insulator and magnet leads. Fit the

magnet coil leads into the copper clips, secure coil

leads in clips, and solder (Figure 3-18). Use caution in

soldering to prevent excess solder from grounding coil

leads to magnet shell.

Figure 3-16

Testing Magnet for Ground

Replacing Magnet Leads

When magnet leads are found to be defective, they

can readily be replaced in the field. Refer to the repair

parts section for correct magnet lead to be used, or

order leads by magnet number and brake size.

Where magnet lead wires are soldered to the magnet

coil, it will be necessary to replace the complete

magnet lead assembly whenever one of the leads is

found to be defective. Pry up the two steel clips which

hold the magnet leads to the magnet shell, just enough

to slide wire out (Figure 3-17). Use a soldering iron to

melt solder on terminals and open copper clips holding

magnet coil leads.

If magnet lead wire is mechanically connected, pry up

steel clip holding lead to magnet shell, remove screw

fasteners, and remove defective lead. Clean magnet

coil lead and all contact surfaces.

Figure 3-18

Soldering Magnet Lead Wires

Warner Electric • 800-825-9050 819-0514

21

Page 22

Steel Clip

Ceramic

Terminal

Block

Figure 3-19

Removing Leads from Ceramic Block

Replace with new lead and bend steel clip to clamp

lead to magnet. Cover connection with Glyptal or other

suitable sealer.

On magnets having a ceramic terminal block for

magnet lead connections, minor repairs to the terminal

block may be made by using a suitable ceramic filler. If

the ceramic block is damaged extensively, use a hack

saw, and cut through the steel clip holding the block in

place. Remove screws, and other attaching parts

holding magnet leads in place and straighten magnet

coil leads. Use extreme caution and bend steel clip up

(Figure 3-19) and slightly to the rear to permit removal

of remainder of terminal block. Clean magnet coil leads

and all contact surfaces of screw, and other attaching

parts, before inserting new terminal block. Bend steel

clip back in place to clamp terminal block to magnet,

and re-assemble magnet leads (Figure 3-20). If steel

clip is damaged during repair, it may be replaced by

welding new clip in place if extreme care is used to

prevent damage to magnet coil and coil insulation from

over-heating. Do not allow weld splatter to get on

magnet poles. Test magnet for short or ground after

any attempt at welding.

Figure 3-20

Installing Leads in Ceramic Block

While wheel is removed, blow out brake assembly with

air hose, making certain that all wheel bearings and

bearing surfaces are pr

otected. Check the magnet and

brake cams for movement; removing and cleaning

thoroughly if necessary. Check magnet and band return

springs for damage or loss of tension. Springs will lose

tension after considerable use due to heat; therefore, it

is recommended that at each reline all springs be

replaced. Never use diagonal cutters to remove or

replace springs.

Before replacing the wheel, always check the armature

depression. Follow the procedure outlined in the brake

installation section beginning with Figure 2-12. While

checking depression, check to make certain armature

face is parallel with the armature mounting ring. To do

so, measure the highest extended height of the

armature face at each armature stop. Pry up armature

stops, which are low if necessary.

Clean all grease and oil from the brake drum surface,

armature face, magnet facing and poles, and brake

lining with carbon tetrachloride. Pack wheel bearings

with a good grade of bearing grease and mount wheel

and drum assembly on axle. Draw up wheel bearing

lock nut tight enough to avoid loose wheel bearings.

Warner Electric • 800-825-9050 819-0514

22

Page 23

Warner Electric • 800-825-9050 819-0514

23

Page 24

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship

within a period of one (1) year from the date of original purchase for consumer, commercial or

industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without

Warner Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation

charges prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information

may be obtained by writing the Customer Satisfaction Department, Warner Electric LLC, 449

Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made,

without charge, together with a refund for transportation costs. If found not to be defective, you

will be notied and, with your consent, the item will be repaired or replaced and returned to you

at your expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation

may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any

defective product. Warner Electric LLC neither assumes nor authorizes any other person to give

any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH

THE CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF

ORIGINAL CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL

USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you. This warranty gives you specic legal

rights and you may also have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specications shown in Warner Electric catalogs are subject to change without

notice. Weights do not include weight of boxing for shipment. Certied prints will be furnished

without charge on request to Warner Electric.

Warner Electric LLC

31 Industrial Park Road • New Hartford, CT 06057

815-389-3771 • Fax: 815-389-2582

www.warnerelectric.com

AA-110 819-0514 4/06 Printed in USA

Loading...

Loading...