Page 1

P-2081-WE

SM302gb - rev 02/09

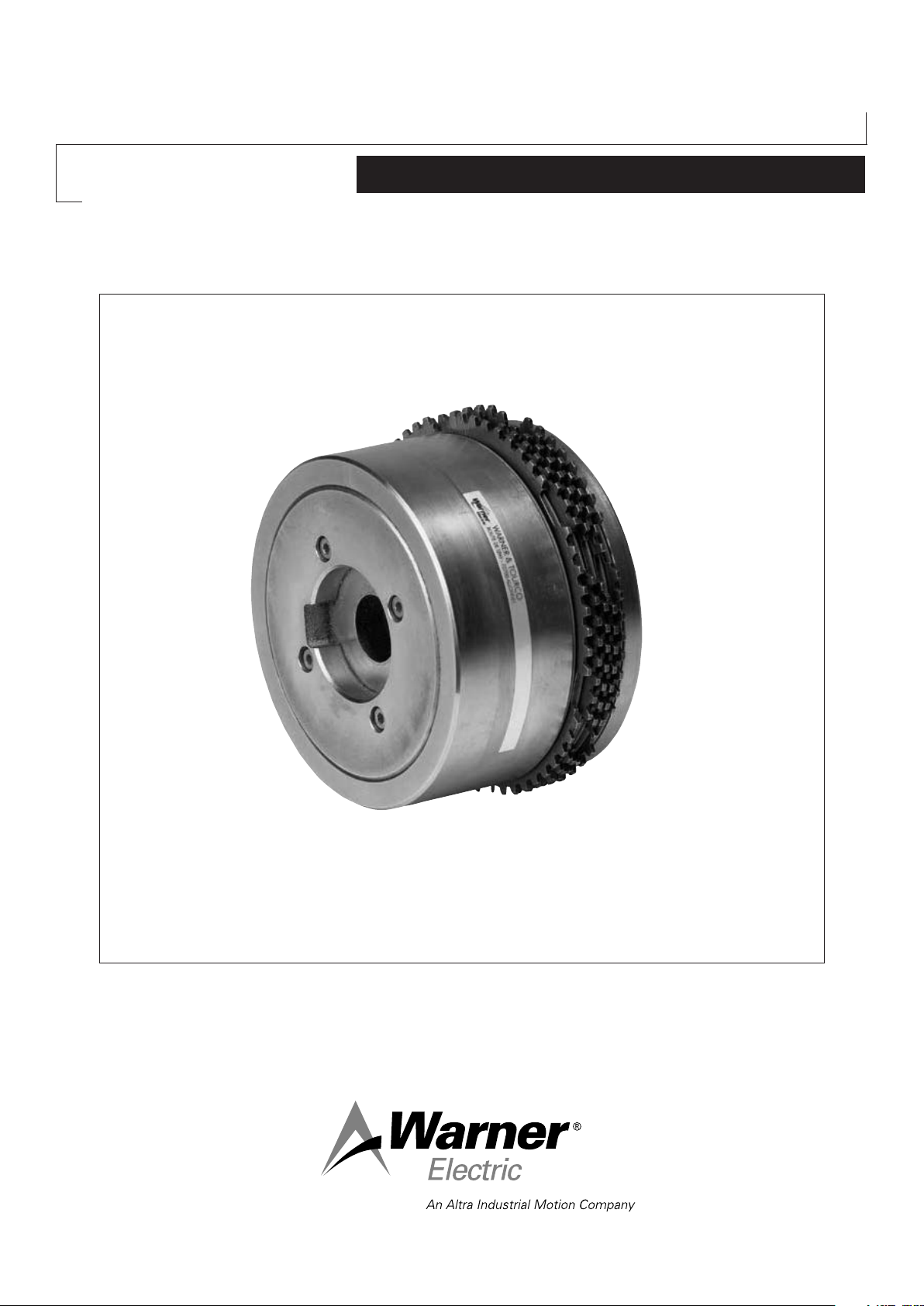

Pneumatic Multidisc Clutch

P 130 VAR00 / VAR02

Service Manual

Page 2

We, WARNER ELECTRIC EUROPE, 7, rue Champfleur, B.P. 20095, F-49182 St Barthélemy d’Anjou Cedex

declare that clutches made in our factory from St Barthélemy d’Anjou,

and hereafter designated : P 130 VAR00/VAR02

are designed to be incorporated into an

installation or assembled with other equipment

in order to form a machine that is covered by

directive 98/37/EC.

St Barthélemy d’Anjou, July 2002

Eric Prat, General Managing Director

CONTENTS

1 Technical specifications 2

2 Precautions and restrictions on use 2

2.1 Restrictions on use 2

2.2 Precautions 3

and safety measures

3 Installation 3

3.1 Transport - storage 3

3.2 Handling 3

3.3 Setting up 3

4 Maintenance 3

1 Technical Specifications

4.2 Spare Parts 4

4.3 Dismantling / Reassembling 4

5 Pneumatic connection 4

5.1 Important recommendations 4

5.2 Connection diagrams 5

6 Appendix 5

6. 1 Drawings / Description 5

7. Troubleshooting 5

Symbol designating

an action that might

damage the brake

Symbol designating an

action that might be

dan gerous to human safety

Symbol designating an

elec trical action that might be

dangerous to human safety

2 Precautions and restrictions on use

2.1 Restrictions on use

These clutches are designed solely to run

These clutches are designed to run dry. Any oily

material alters their performance.

on a horizontal shaft. Ask our technical

department about other positions.

Exceeding the maximum rotation speed given in

the catalogue invalidates the warranty.

2 Warner Electric Europe • +33 (0)2 41 21 24 24 P-2081-WE • 2/13

Page 3

2.2 Precautions and safety measures

During the maintenance period make sure

that the moving parts of the machine are

stationary and that there is no risk of start-up.

All intervention have to be made by qualified

personnel, owning this manual.

In cases where two coaxial shafts are fitted, the

maximum authorised setover is 0,05 mm. The

angular misalignment should not exceed 0,1

mm over a length of 100 mm. If these values

cannot be attained, we recommend that an

elastic coupling is fitted between the drive and

receiving parts.

Any modification made to the brake without

the express authorisation of a representative of

Warner Electric, in the same way than any use

out of the contrac tual specifications accepted

by “Warner Electric”, will result in the warranty

being invalidated and Warner Electric will

no longer be liable in any way with regard to

conformity.

3 Installation

3.1 Transport / storage

These units are supplied as standard in

packaging guaranteeing protection for a period

of 6 months by land or air transport, or after

transport by ship to neighbouring continents

(without crossing the tropics).

3.2 Handling

The clutch is supplied pre-assembled with the

driving flange not fixed.

Avoid any impact on the units so not to alter

their performance.

3.3 Mise en place

The hub (515) is normally supplied at tolerances

H7 for the bote and P9 for the width of the

keyway (In accordance with NF E 22-175/DIN

6885/BS 4235/ISO R773).

Do not forget to secure the bolts fixing the

driving flange (529) with Loctite 243 or an

equivalent type of product and tighten them to

torque.

Never directly strike the cylinder (401), closing

flange (408), or hub (515), use a soft alloy block

or drift between these parts and the fitting

device provided.

It is essential to comply with the length

dimension “ L ± 0,5 “ (see table 1) in order to

prevent any risk of contact between the drive

flange (529) and the hub (515).

4 Maintenance

4.1 Maintenance

P130, VAR00/02 series clutches only require low

maintenance because wear in the disc set is

automatically compensated for by movement in

the piston, within the limits of its travel.

It is however necessary to:

• Regularly check the seal of the pressure

chamber and in the event of leakage, or after 5

years use, change the seals (701, 702)

• Check the wear on the disc set, by measuring

the travel of the piston (402), using table 2,

below and the diagrams on annex

The drive flange (529) is generally supplied at a

bore H7 but without fixing holes.

We recommend a tolerance h6 for the shaft and

an adjustment H7/f7 for he drive flange (529).

• Centre the flange (529) on the recieving part,

then fix it with bolts and lock them

• Slide the hub (515) onto the shaft (after

adjusting the keyways) by positioning the teeth

of the outer discs (302) or (305), opposite of the

hollows of the driving flange (529).

Warner Electric Europe • +33 (0)2 41 21 24 24 P-2081-WE • 2/13 3

Page 4

4.2 Spare Parts

5 Pneumatic Connections

All orders for spare parts must state the size

of the unit with its code number, the reference

number of the part (see appendice 1), and the

quantity of each component wanted.

4.3 Dismantling / Reassembling

During maintenance work, ensure that the

mechanism to be driven by the clutch is at

rest and that there is no risk of it being started

accidentally. Also ensure that the compressed

air is turned off.

Dismantling:

• Remove the fixing screws from the cylinder

(401) or closing flange (408)

• Remove the cylinder (401) or closing flange

(408)

• Take out the piston (402)

• Remove the worn disc set

• Fit a new disc set

Start with an outer disc (302 or 305), then an

inner disc (308), and then alternate, ending of

necessity with an outer disc.

• Change the seals (701, 702)

• Refit the piston (402)

• Refit the cylinder (401) or closing flange (408)

Take care not to damage the seals while

reassembling

• Replace the cylinder (401) or closing flange

(408 fixing screws, tighten them to the torque

shown in table 3, below and secure them with

Loctite 243 or an equivalent type of product

5.1 Important Recommendations

Ensure that working pressures are complied

with, to get the nominal performance from the

equipment.

Do not exceed the maximum pressures

(see table 1).

These clutches should be supplied with filtered,

oiled air.

5.1 Connection Diagram

The diagrams are only given as an indication.

Fig 1: Basic circuit for circuit under pressure

a: source of pressure

b: air treatment unit

c: distributor

d: flexi pipe and rotating seal

e: clutch engagement by application of pressure

4 Warner Electric Europe • +33 (0)2 41 21 24 24 P-2081-WE • 2/13

Page 5

6 Appendix

6.1 Drawings / Description

7 Troubleshooting

Warner Electric Europe • +33 (0)2 41 21 24 24 P-2081-WE • 2/13 5

Page 6

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any product manufactured and

sold by it which proves to be defective in material or workmanship within a period of one (1) year from the date of original

purchase for consumer, commercial or industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without Warner Electric LLC’s

prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation charges prepaid, to

the appropriate Warner Electric LLC factory. Additional warranty information may be obtained by writing the Customer

Satisfaction Department, Warner Electric LLC, 449 Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-

3771.

A purchase receipt or other proof of original purchase will be required before warranty service is rendered. If found

defective under the terms of this warranty, repair or replacement will be made, without charge, together with a refund for

transportation costs. If found not to be defective, you will be notified and, with your consent, the item will be repaired or

replaced and returned to you at your expense.

This warranty covers normal use and does not cover damage or defect which results from alteration, accident, neglect, or

improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the defective product and

in no event shall Warner Electric LLC be liable for consequential, indirect, or incidental damages of any kind incurred by

reason of the manufacture, sale or use of any defective product. Warner Electric LLC neither assumes nor authorizes any

other person to give any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH THE CONSUMER MAY

HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL CONSUMER PURCHASE. WITH

RESPECT TO COMMERCIAL AND INDUSTRIAL USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU

OF AND EXCLUDES ALL OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you. This warranty gives you specific legal rights and you may also have other rights which

vary from state to state.

Changes in Dimensions and Specications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without notice. Weights do not

include weight of boxing for shipment. Certified prints will be furnished without charge on request to Warner Electric.

Warner Electric Europe

7 rue Champfleur, B.P. 20095, St Barthelemy d’Anjou - France

+33 (0)2 41 21 24 24 • Fax: +33 (0)2 41 21 24 70

www.warnerelectric.com

Printed in USAP-2081-WE • 2/13

Loading...

Loading...