Page 1

NEMA 4 UNIBRAKE

Warner Electric

®

Motor Brakes

P-1701-WE

Installation & Operating Instructions

Page 2

Contents

Operation

General Information. . . . . . . . . . . . . . . . . . . . . . . . 2

Brake Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Wear Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . 4

Torque Adjustments . . . . . . . . . . . . . . . . . . . . . . . 4

Disc Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 4

Coil Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 5

Service Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . Back Page

General Information

Unibrake Motor Brakes are not a

fail safe device. Where holding load represents

a risk of property damage, and/or personal

injury, an independent fail safe device must be

supplied independent of this brake. These

safety devices are neither provided nor are they

the responsibility of Warner Electric.

When properly connected, starting the motor

energizes the brake magnet coil, attracting the

armature to the coil, compressing the torque

springs, releasing pressure on the pressure

plates, permitting the brake discs to rotate

freely. When the motor and the brake magnet

coil de-energize, this decompresses the torque

springs, forcing the rotating disc(s) and

stationary pressure plates together, stopping

and holding the motor shaft and load.

When the motor is ‘off,’ to move the driven load

without energizing the motor, rotating the manual

release lever 90 degrees clockwise removes the

retarding torque from the motor shaft letting the

load be hand-moved. The lever returns to the

normal “set” position when the brake is

re-energized.

Brake Head

Warner Electric Unibrake motor brakes are spring

set, electro-magnetic release, direct acting, disc

brakes for the controlled stopping and holding of a

load. They have single phase electro-magnetic

coils in standard voltages and frequencies and are

factory set for rated retarding torque.

Construction

Motor brakes utilize one or more non-asbestos

friction discs mounted on a metal hub which is

fastened to a rotating shaft. The brake uses a two

ball pivot design for its armature plate. It also has

a self resetting manual release lever. Anti-rattle

clip between the rotating disc and hub help reduce

torsional vibration and pulsation noise. Unibrakes

housing is cast iron NEMA 4.

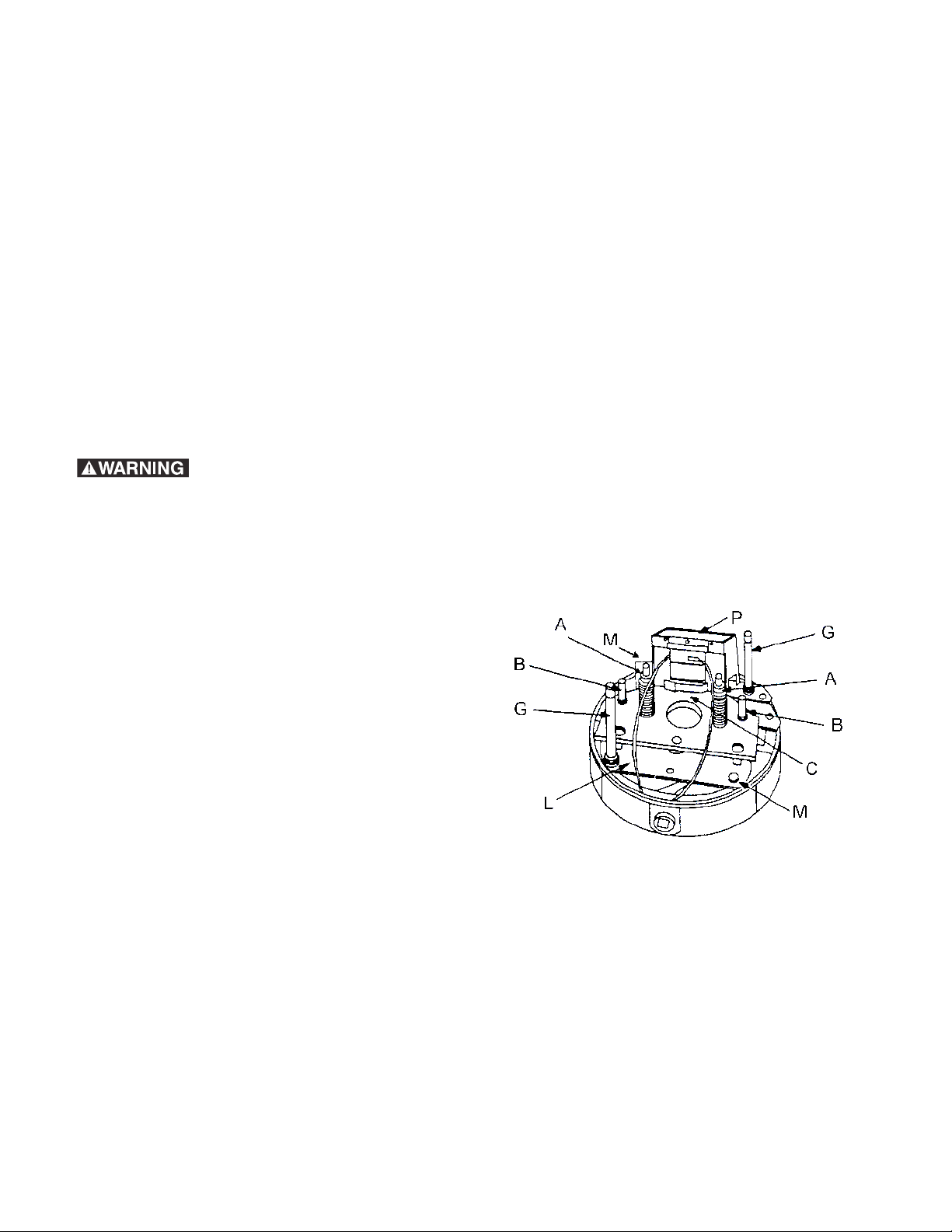

A = Torque Adjust Nuts and Springs

B = Wear Adjustment Screws

C = Armature Plate

G = Cover Mounting Studs

L = Lead Wires

M = Mounting Holes (2)

P = Solenoid (coil)

Warner Electric • 800-825-9050 P-1701-WE

2

Page 3

Any mechanism or load held in

position by the brake should be checked to

avoid possible damage or injury to personnel

before brake is released manually.

Installation

This brake is assembled and tested prior to

shipment. It must be disassembled to mount to

your motor and maintain seals to your motor. Do

not make any adjustments to the (2) Wear

Adjustment Screws “B” or (2) Torque Adjust Nuts

“A” during installation to your motor.

• Replace pressure plate(s) and friction disc(s)

into housing keeping them in their original

order.

• Remove hand tightened caps screws from head

casting. Replace brake mechanism with coil

into housing and tighten with (2) cap screws,

lock washers and (2) cover hex studs.

• Rotate release lever one or two times to verify

release and assembly of brake is correct.

• Cover will be assembled after brake is wired.

Leads should be twisted and inserted into the

insulation sleeve and routed to conduit port or

openings through back of motor after wiring.

Wiring

Brake disassembly

• Place brake on bench or work surface; remove

cover from brake.

• Remove the two cover hex mounting studs and

brake mechanism with coil. Do not make any

adjustments to the brake mechanism.

• Remove pressure plate(s) and friction disc(s)

keeping them in the original order.

• Remove brake hub. Be careful not to

damage housing seal.

Brake assembly to your motor

• Position brake head casting onto motor

mounting face and secure by hand tightening

(2) 3/8 inch socket head cap screws.

• Attach hub to shaft using key and set screws

provided with Unibrake. Position hub 5/16 inch

below head surface. Do not damage housing

seal when sliding hub through seal. Tighten

(2) set screws to motor shaft with 55-100 in. lbs.

of torque. Set screws can be accessed through

conduit opening.

Disconnect power before

touching any internal part.

Unibrake magnet coils (AC) are single phase and

dual voltage. These can be wired internal to the

motor. Direct current brake coils must be

separately operated; switch contacts to control the

brake must be different from those used to control

the motor. Normally, motor and brake

contacts must be interlocked.

Determine the voltage of the brake and use the

appropriate wiring instructions below.

Remove cover, turn both screws “B” equal

amounts in a clockwise direction until air gap (Gap

“G”) from above chart is obtained.

Warner Electric • 800-825-9050 P-1701-WE

3

Page 4

Determine the voltage of the brake and use the

appropriate wiring instructions below.

Remove cover, turn both screws “B” equal

amounts in a clockwise direction until air gap (Gap

“G”) from above chart is obtained.

Motor Voltage

3 Phase AC Low Voltage B1 & B3 to T1 & T7 B2 & B4 to T2 & T8

High Voltage B1 to T1 B2 to B3 B4 to T2

1 Phase AC Low Voltage B1 & B3 to T1 & T3 B2 & B4 to T2 & T4

High Voltage B1 to T1 B2 to B3 B4 to T4

Separately AC

Separately DC 24 or 90 VDC

Low Voltage 115 VAC B1 & B3 to Line 1 (L1) B2 & B4 to Line 2 (L2)

High Voltage 230 VAC B1 to Line 1 (L1) B2 to B3 B4 to Line 2 (L2)

Brake Leads (B) to Motor Leads (T)

or Separate Power Supply

B1 to DC + B2 to DC -

Coils are not polarity sensitive

connections can be reversed.

Wear Adjustments

1) Disconnect power brake

before touching any internal part. 2) Any loads

that are held in position by this brake must be

supported before performing any adjustments

or maintenance.

Motor brake discs require periodic adjustment due

to expected wear. On rapid cycling applications

regular inspections should take place, i.e. after

20,000 to 50,000 cycles for the first inspection

and then every 150,000 to 200,000 cycles.

Adjustments should be made to the air gap

between the armature and magnet for continued

brake effectiveness. If an increase in stopping

time is noted adjust brake as follows:

Gap Chart

Measurement of air gap should be made at

approximate center of magnet with pressure

applied to armature plate “C” to assure plate is

seated on pivot balls. Failure to adjust for wear

will result in eventual loss of braking torque.

Note: Unequal adjustment of screws “B” will result

in unequal pivot action on balls that will increase

noise and shorten brake life.

Torque Adjustments

Most applications do not require torque

adjustments. Motor brakes are factory set for

rated torque which is maximum torque. To

increase stopping time or reduce torque on 3, 6,

and 10 ft. lb., turn 2 lock nuts “A” an equal amount

counterclockwise to increase spring length. For

the 6, 10, and 15 ft. lb. brakes, one full turn will

reduce torque by about 12-1/2%. The 3 ft. lb.

brake will be reduced in torque by about 8%.

Torque should not be reduced by less than 1/2 of

the rated torque.

If torque is adjusted measure air gap (see wear

adjustment) and verify it is within dimensions from

Gap Chart.

No. of Discs Gap “G”

1 .075 inch

2 or 3 .090 inch

before touching any internal part. 2) Any loads

that are held in position by this brake must be

1) Disconnect power brake

supported before performing any adjustments

or maintenance.

Warner Electric • 800-825-9050 P-1701-WE

4

Page 5

Friction Disc Replacement

Hubs

Remove cover, (2) cover support studs “G”, and (2)

3/8-16 mounting cap screws at “M”.

Lift off brake mechanism assembly. Remove

pressure plate(s) and brake disc(s). Replace with

new pressure plate(s) and disc(s). Reassemble

brake mechanism assembly. Multiple disc units,

the domed pressure plate is positioned furthest

away from the motor or brake head; the (B) wear

adjustment screws are in contact with this plate.

Note: Cast Iron Head uses casting surface for last

pressure plate. Set air gap as for wear

adjustment.

Magnetic Coil Replacement

Remove cover, (1) cover stud “G”, (1) 3/8-16

mounting cap screw “M” and (2) slotted screws

“E”.

Lift off complete coil assembly “P” and replace

with new coil assembly of proper electrical rating.

Position leads so as to avoid contact with rotating

parts. Set air gap as for Wear Adjustment.

Disc/Pressure Plate Kits

Number Kit Kit

Discs Number Contents

Cast Iron Heads

1 327212-4 1FD and 1DPP

2 327212-5 2FD, 1DPP and 1FPP

3 327212-6 3FD, 1DPP and 2FPP

FD = Friction Disc, DPP = Domed Plate FPP = Flat Plate

CI Head

Bore Hub Number

5/8 58D29

3/4 58D30

7/8 58D31

Cast Iron Head Hub

Coil Assembly (Solenoids)

Unibrake magnet coils (AC) are single phase.

Coil Voltage Coil Part No. DC Resistance*

60/115/230 VAC 79137-18-K

50/115/230 VAC 79137-18-N

50/220/440 VAC 79137-18-P

60/230/460 VAC 79137-18-J

60/200/400 VAC 79137-18-L

60/287/575 VAC 79137-18-G

50/208/416 VAC 79137-18-M

24 VDC 327208 Leads B1 to B2 = 26.4 Ohms

90 VDC 327209 Leads B1 to B2 = 390 Ohms

*Resistance values plus or minus 10% at 25°C.

Leads B1 to B2 or

B3 to B4 = 8.7 Ohms

Leads B1 to B2 or

B3 to B4 = 11.5 Ohms

Leads B1 to B2 or

B3 to B4 = 43.5 Ohms

Leads B1 to B2 or

B3 to B4 = 34.5 Ohms

Leads B1 to B2 or

B3 to B4 = 24.3 Ohms

Leads B1 to B2 or

B3 to B4 = 54.5 Ohms

Leads B1 to B2 or

B3 to B4 =35.6 Ohms

Friction Disc Only

1 327213 Disc with Anti-Rattle Clip

Coil Assembly

Friction Disc (FD)

5 inch diameter

Warner Electric • 800-825-9050 P-1701-WE

Pressure Plates

Domed (DPP) / Flat (FPP)

5

Page 6

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship

within a period of one (1) year from the date of original purchase for consumer, commercial or

industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without

Warner Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation

charges prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information

may be obtained by writing the Customer Satisfaction Department, Warner Electric LLC, 449

Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made,

without charge, together with a refund for transportation costs. If found not to be defective, you will

be notified and, with your consent, the item will be repaired or replaced and returned to you at

your expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation

may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any

defective product. Warner Electric LLC neither assumes nor authorizes any other person to give

any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH

THE CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF

ORIGINAL CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL

USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. This warranty gives you specific legal rights and

you may also have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without

notice. Weights do not include weight of boxing for shipment. Certified prints will be furnished

without charge on request to Warner Electric.

Warner Electric LLC

31 Industrial Park Road • New Hartford, CT 06057

815-389-3771 • Fax: 815-389-2582

www.warnerelectric.com

An Altra Industrial Motion Company

P-1701-WE 06/11 Printed in USA

Loading...

Loading...