Page 1

Gen 2

Clutch/Electrically Released Brake UniModule

UM-50FBC, UM-100FBC, UM-180FBC

P-273-9

819-0530

Installation Instructions

Vented

Enclosed Version Optional

Page 2

Contents

Mounting to a C-Face Motor . . . . . . . .3

Mounting to a Reducer . . . . . . . . . . . . .4

Installing the Base Mount . . . . . . . . . . .4

Installing the Motor Mount Bracket . . .4

Mounting to other Power

Transmission Components . . . . . . . .5

Electrical Connections . . . . . . . . . . . . . .6

FB Brake Release Adjustment . . . . . . .6

Troubleshooting-Electrical . . . . . . . . . . .7

Troubleshooting-Mechanical . . . . . . . . .7

Enclosed UniModule Option . . . . . . . . .9

The 2030FBC UniModule is designed to mount

using a base mounting kit. This allows the

modules to be mounted as a separate drive unit

driven from the prime mover by V-belts, chain

and sprockets, couplings, timing belts and other

standard power transmission components.

(For UniModule sizes 210 and 215 please refer

to Warner Electric manual P-273-2)

For These UM FBC Combinations Use These

Installation Steps:

Failure to follow these

instructions may result in product damage,

equipment damage, and serious or fatal

injury to personnel.

The equipment covered by

this installation manual must be installed in

accordance with these instructions. Failure

to do so may damage the equipment and

void the warranty.

Warner Electric UniModules are designed to

National Electrical Manufacturers Association

(NEMA) standards. They can be mounted to

common NEMA C-Face motors and reducers as

well as common power transmission drive

components.

The 1020FBC UniModule is designed to mount

to the face of a C-Face motor as noted in

Table 1.

Corresponding

NEMA Frame Sizes

C-Face

UM Old New Shaft Pilot

Size NEMA NEMA Dia. Dia.

50 56 C 48 Y 5/8" 4-1/2"

100 56 C 48 Y 5/8” 4-1/2”

180 182 C 143 TC 7/8" 4-1/2"

184 C 145 TC

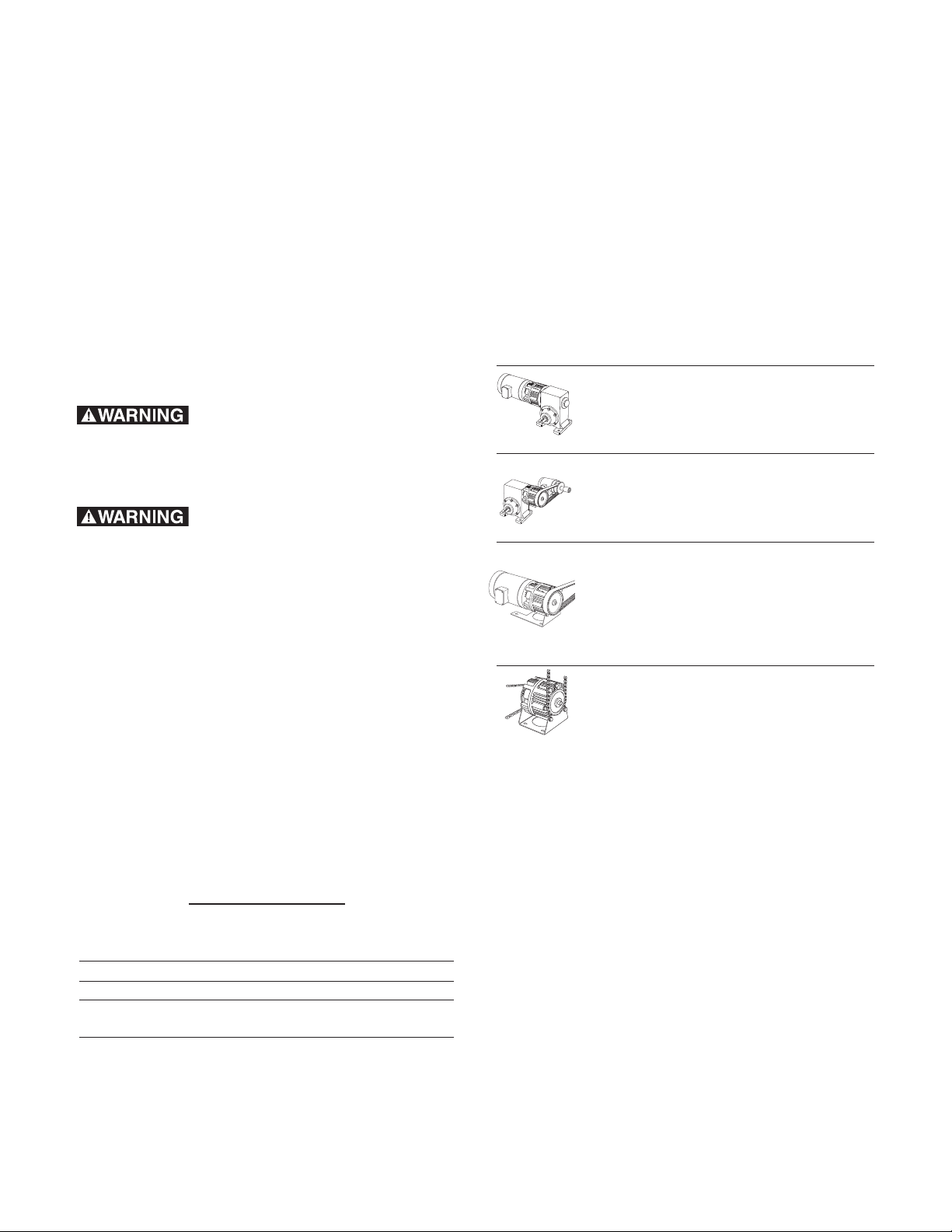

UniModule Clutch/Brake between

C-Face Motor and Reducer

1020FBC

UniModule Clutch/Brake

2030FBC

Motor Mount Module Clutch/Brake

on a C-Face Motor

1020FBC-M

Base Mounted

UniModule Clutch/Brake

2030FBC-B

Mounting to a Motor

Mounting to a Reducer

Electrical Connections

Brake Release Adjustment

Mounting to other

Power Transmission

Components

Electrical Connections

Brake Release Adjustment

Mounting to a Motor

Installing the Motor

Mount Bracket

Mounting to other

Power Transmission

Components

Electrical Connections

Brake Release Adjustment

Installing the Base Mount

Mounting to other

Power Transmission

Components

Electrical Connections

Brake Release Adjustment

Install your specific FBC UniModule

combination according to the installation steps

specified in the table. Use only those steps

indicated for each combination.

Table 1

Warner Electric • 800-825-9050 P-273-9 • 819-0530

2

Page 3

Mounting to a C-Face Motor

1. A hardened key is provided with the

mounting hardware for FBC UniModules.

Insert this key onto the motor shaft

(staking the key is necessary).

2. Align the keyway in the bore of the

UniModule to the key in the motor shaft

and slide the unit onto the motor shaft.

The normal alignment of the module to the

motor will be with the wire exit/conduit

box in the upright (12 o’clock) position as

shown in Figure 2.

alternately to ensure even alignment of the

module. Tighten them to 30-35 foot

pounds.

4. Next secure the clutch rotor and fan

assembly to the motor shaft by tightening

the two (2) setscrew as follows:

a. There are two (2) access slots on

either side of the UniModule. A long

Allen wrench can be used to tighten

the two setscrews (90° apart) which

secure the clutch rotor and fan

assembly to the motor shaft.

Do not hammer or force

the module into position. To do so may

damage bearings or cause the friction

faces to shift out of alignment.

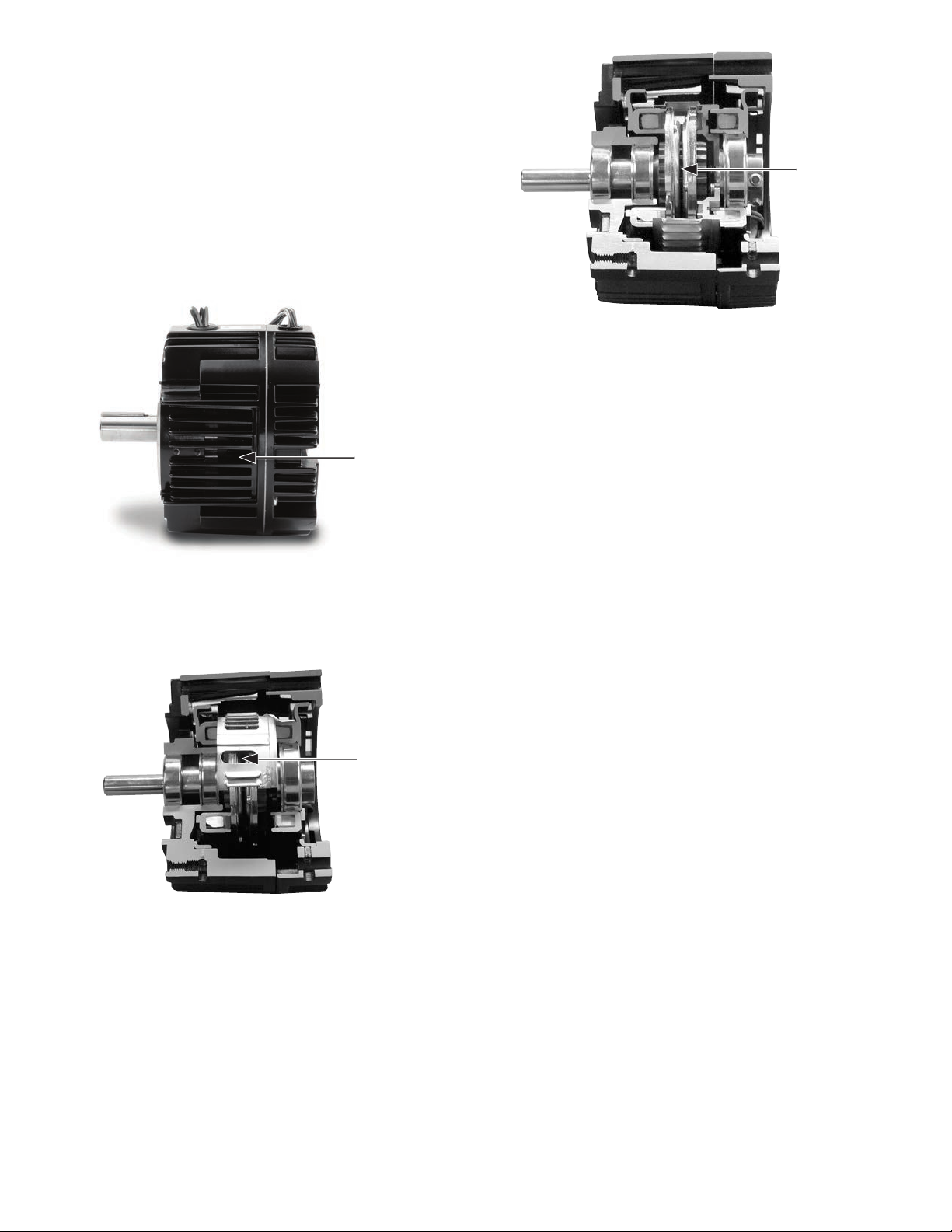

Figure 2

b. Alternately align each setscrew with

one of the access slots by rotating the

clutch rotor and fan assembly through

one of the side vents with a small

screw driver taking care not to damage

the fan. (Figure 3a)

Set Screws

Side Vent

Access Slots

Figure 3a

c. Using a torque wrench and long Allen

If anti-fretting lubricant is

used on the motor shaft for future ease of

removal, ensure that any excess is wiped

off before unit assembly to avoid lubricant

contaminating the clutch or brake friction

faces.

socket, tighten the two (2) setscrews

to: (Figure 3b)

• Size 50: 80-85 inch pounds

(Requires 5/32 inch Allen wrench)

• Size 100 or 180: 40-45 inch pounds

(Requires 1/8 inch Allen wrench)

3. Secure the FBC UniModule to the motor

with the four (4) long mounting tie-bolts

provided. Tighten the four (4) bolts

Warner Electric • 800-825-9050 P-273-9 • 819-0530

3

Page 4

Figure 3b

Mounting to a Reducer

1. Warner Electric UniModules are furnished

with a hardened key pre-mounted on the

output shaft.

2. Align the output shaft and key of the

module with the corresponding bore and

keyway of the reducer. Slide the assembly

together as shown in Figure 4.

Installing the Base Mount

Model 2030FBC UniModule is designed to be

base mounted as shown in Figure 5.

Optional Base Mount Kit,

Warner Electric part numbers:

UM-50/100...........................5370-101-004

UM-180................................5370-101-002

Figure 5

Figure 4

3. Bolt the module to the reducer flange.

The four (4) bolts that are required

(3/8-16UNC2A) are typically provided with

the reducer. Tighten to 18-22 foot pounds

of torque.

1. The pilot diameters on each end of the

UniModule will mate with the pilot

diameters on the base.

2. Secure the base to the UniModule with the

four (4) bolts provided. Tighten to 18 to 22

foot pounds.

Installing the Motor Mount Bracket

A Motor Mount Bracket can be installed on

the output end of a 1020FBC UniModule to

provide a foot mounting for the complete

assembly of a UniModule and C-face motor.

Optional Motor Mount Kit,

Warner Electric part numbers:

UM-50/100............................5370-101-078

UM-180.................................5370-101-079

Warner Electric • 800-825-9050 P-273-9 • 819-0530

4

Page 5

1. Mount the bracket to the face of the

UniModule underneath the UniModule

and motor as shown in Figure 6. A pilot

diameter on the UniModule mates with

a pilot diameter on the bracket.

Figure 6

Overhung Load Data

(Shaft Side Load)

Overhung load data is provided in this manual

for the design engineer concerned with a

specific problem in this area. The maximum

A

2. Secure the motor bracket in place with

four (4) short bolts and washers provided.

Tighten to 18 to 22 foot pounds.

Mounting to other Power

Transmission Components

Couplings, pulleys, sprockets or

similar power transmission components can be mounted to the input and output shafts of a UniModule.

When mounting a pulley or

sprocket, ensure that the key is fully

engaged within the device hub or bushing.

Confirm that the belt or chain tightness

meets the maximum side load capability of

the UniModule shown in

Table 2.

R

allowable overhung load which can be applied

to the shaft of an UniModule may be

determined by the use of the accompanying

chart.

UniModule Housing Face Load Rating

UM-50 1" (Center of Shaft) 177

UM-100 1” (Center of Shaft) 192

UM-180 1" (Center of Shaft) 192

Distance Load is

Applied from Maximum

"A" Inches "R" Lbs.

2" (End of Shaft) 123

3" 95

2” (End of Shaft) 134

3” 104

2" (End of Shaft) 134

3" 104

Table 2

Warner Electric • 800-825-9050 P-273-9 • 819-0530

5

Page 6

Electrical Connections

To avoid injury (or even death), always

make certain all power is off before

attempting to install or service this device

or any electrical equipment.

The conduit connection hole in the

UniModules are threaded for standard ½

inch conduit connection. UniModule FBC

clutches and brakes operate on DC voltage.

Warner Electric offers a complete line of

electronic controls to meet the needs of

almost any clutch/brake application. Each

Warner Electric control will show the proper

wiring connections for its use.

Control Requirements for (FB) Fail

Safe Brakes

for standard ½ inch conduit connectors.

FB Brake Release

Adjustment

Instructions for setting the optimum release

voltage of permanent magnet applied/

electrically released brakes.

The following procedure will result in the

brake releasing and allowing the load to be

free to move. Be sure the load is in a safe

condition before proceeding with

this process.

In a permanent magnet applied/electrically

released brake, the attractive force between

the brake surfaces is created by permanent

magnets. The brake is electrically released by

applying DC power to the electro-magnetic

coil in the brake that opposes the permanent

magnets.

Electrically Released Permanent Magnet

Brakes must use one of Warner Electric’s

adjustable power supplies. See the Service

Installation sheet included with the power

supply for connection information.

Note: All Electrically Released Permanent

Magnet Modules are polarity sensitive.

Therefore, the (+) red wire must be connected

to the positive terminal and the (-) black wire

to the negative terminal. Potentiometer control

will then provide adjustment for the proper

brake release point.

When switching a 1020FBC or 2030FBC

power must be applied to both the clutch and

FB brake simultaneously to engage the clutch

and at the same time release the brake.

If a Conduit Box is desired, Warner Electric

Conduit Box Kit, part number 5370-101-042,

can be purchased separately. The Conduit

Box provides two conduit connection holes

Warner Electric • 800-825-9050 P-273-9 • 819-0530

6

Electrically released brakes are polarity

sensitive: the positive lead of the power

supply must be connected to the positive

(red) lead of the brake and the negative lead

of the power supply must be connected to

the negative (black) lead of the brake.

The power supply applied to the brake must

also be adjustable so that the optimum

release voltage for each individual brake

can be determined and set.

The following procedure describes how to set

the adjustable power supply to the optimum

release point of the brake. A volt-meter is

required to perform the procedure.

No power is applied to motor during this

procedure. Power normally supplied by

motor to brake control should be supplied

by alternate method.

1. With power off, connect the positive lead

Page 7

of the power supply to the positive (red)

lead of the brake and the negative lead of

the power supply to the negative (black)

lead of the brake.

2. Connect a volt-meter to measure the

voltage applied across the brake.

3. Adjust the power supply to its lowest

possible output, and then energize the

power supply to apply power to the brake

only.

requires DC power to function. If power is not

reaching the clutch or brake, the clutch will

not engage and the brake will not disengage.

A good practice to follow is to check for

power at the lead wires to the clutch or brake

using a voltmeter.

• If power is present in the proper voltage

and current, then skip ahead to the

Mechanical Troubleshooting section.

• If power is not present, inspect the lead

wires for breaks or cuts.

4. Starting from the low voltage point, slowly

increase the applied voltage while visually

watching the brake armature through one

of the vent slots and fan slot on either side

of the module until the brake armature

disengages from the brake magnet. Note

and record this voltage reading.

5. Add twenty (20) volts for a 90 volt brake

and ve (5) volts for a 24 volt brake to this

reading and set the supply to this level.

This will be the proper release voltage for

your setup.

6. With the brake energized, spin the output

shaft by hand to insure that it turns freely.

If a scraping sound is noted when the

output shaft is spun, it means an

armature is dragging slightly. This needs to

be corrected by repeating brake release

adjustment steps 1-5 above and/or

performing armature airgap adjustment as

described in the Troubleshooting –

Mechanical section of this instruction.

• If the wires are intact, the problem may

be with the power supply or the switch.

• Using a voltmeter, check to see that

voltage is leaving the power supply and

that the switch is sending power to the

Electrical Coil Data

Clutch Brake Clutch Brake

Voltage–D.C. 90 90 24 24

Resistance UM-50 452 429 31.8 28.8

(OHMS) UM-100/180 392 308 26.7 21.7

Current UM-50 .20 .21 .76 .83

(Ampheres) UM-100/180 .23 .29 .90 1.1

Power UM-50 18 19 19 20

(WATTS) UM-100/180 21 27 22 27

Coil Build Up UM-50 52 40 52 40

clutch or brake.

• Finally, if there is no power leaving the

switch or power supply, check the

incoming AC power to ensure that it is

reaching the power supply.

Troubleshooting - Electrical

If a UniModule is not functioning properly it is

best to check for these problems before

replacing it.

Troubleshooting - Mechanical

Both clutch and FB brake armatures are

equipped with an AutogapTMassembly that

maintains the proper airgap between friction

faces through the life of the product. Each

A standard UniModule FBC clutch/brake

Warner Electric • 800-825-9050 P-273-9 • 819-0530

UniModule is airgap adjusted and pre-

7

Page 8

burnished at the factory, but the airgaps

can shift as a result of rough handling during

shipping and installation.

An airgap that is too large can prevent the

armature from engaging. An airgap that is

too small can cause the armature to rub

continuously, causing higher running

temperatures and decreased wear life.

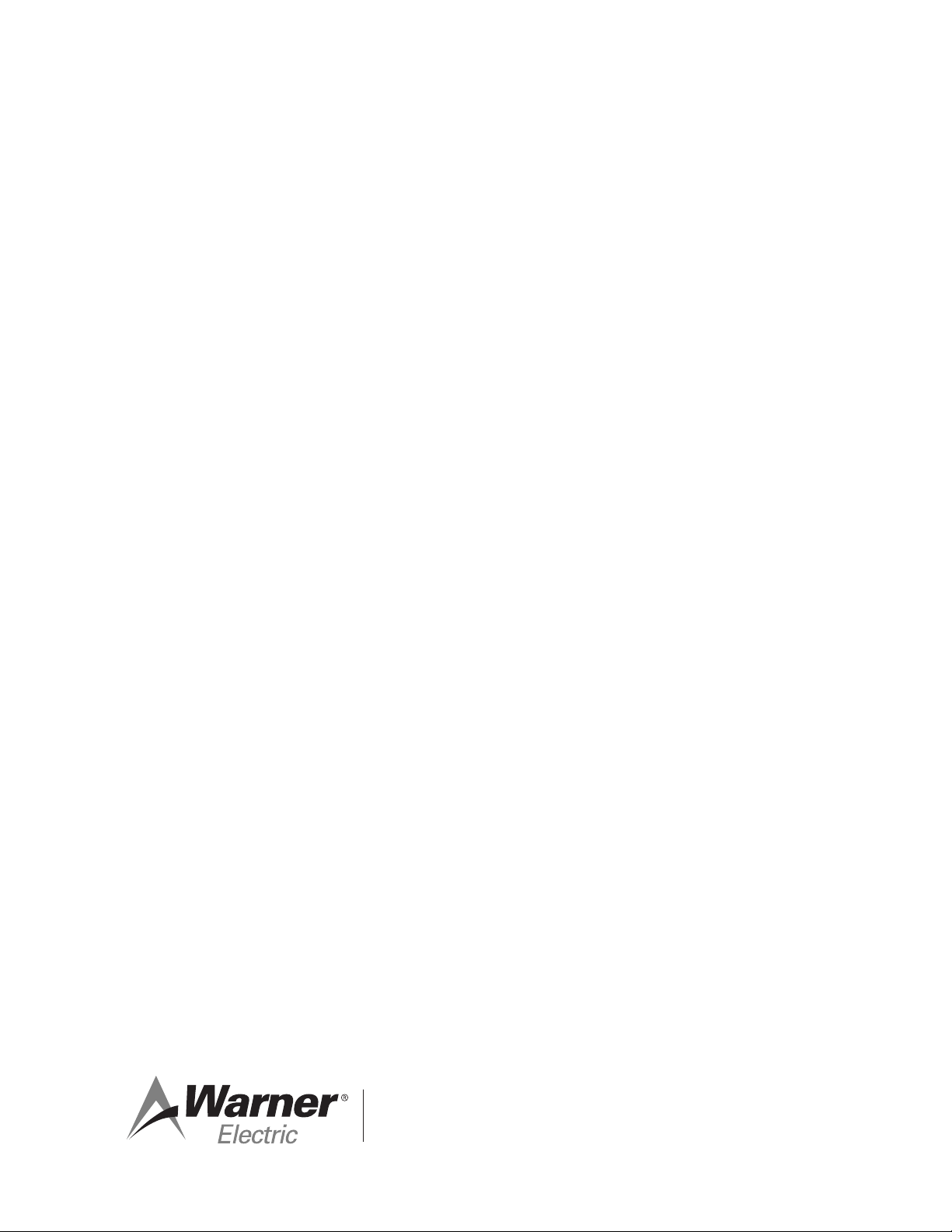

To reset the airgaps, you will need to access

Figure 9

Figure 7

the armatures.

Looking

through the vents on either side of the housing, you will see the fan on the clutch rotor.

Figure 8

Rotate the fan

(input) until you

see the 1/2 x 1 inch window on the outer

periphery of the fan. Through this window,

you will be looking between the two armatures of the clutch and brake. (Figures 7

& 8)

If either armature is too far away from its

mating friction suface, it is possible to move it

back into adjustment using a flat blade

screwdriver. (Figure 9)

Note: When resetting the clutch or FB brake

armature airgap, both the clutch and brake

must be released (the brake energized, and

the clutch not energized).

This is a three step process.

1. Simply slide the screwdriver through

the window. By twisting the screwdriver, it

works as a wedge to apply pressure on

the back of the armature pushing it

toward its mating friction surface.

Warner Electric • 800-825-9050 P-273-9 • 819-0530

8

Page 9

Mechanical Data

UM-50FBC UM-100/180FBC

Static Torque - lb. ft. 16 30

Maximum Speed - rpm 3600 3600

Average Weight-lbs.

1020 15.6 18.7

2030 18.4 21.7

Inertia - WR - lb.ft.

Configuration 50 100/180

1020 input .021 .047

1020 output .0195 .050

2030 input .021 .048

2030 output .0195 .050

2

Enclosed UniModule Option

If an Enclosed UniModule is required, an

optional Cover Kit, Warner Electric part

number 5370-101-076, can be purchased

separately to enclose the open vents in the

housing.

Each Cover Kit includes two (2) vent covers

and four (4) screws needed to convert a

vented UniModule to an enclosed design

(non-washdown) as shown in Figure 10.

Figure 10

Note: When using this Cover Kit to enclose

the module the vent covers should be

assembled as the final step.

Notes:

Visit Warner Electric’s website at

www.warnerelectric.com for dimensional

drawings, weights, inertias, and a complete

offering of our products including clutches,

brakes and clutch/brake controls and

service parts.

In addition, Warner Electric module

products, controls, and service parts

information can be found in our catalog

P-1234-WE. Call 815-389-3771 to request any

of our catalogs.

Warner Electric • 800-825-9050 P-273-9 • 819-0530

9

Page 10

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship

within a period of one (1) year from the date of original purchase for consumer, commercial or

industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without

Warner Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation

charges prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information

may be obtained by writing the Customer Satisfaction Department, Warner Electric LLC, 449

Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made,

without charge, together with a refund for transportation costs. If found not to be defective, you

will be notified and, with your consent, the item will be repaired or replaced and returned to you at

your expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation

may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any

defective product. Warner Electric LLC neither assumes nor authorizes any other person to give

any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH

THE CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF

ORIGINAL CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL

USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you. This warranty gives you specific legal

rights and you may also have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without

notice. Weights do not include weight of boxing for shipment. Certified prints will be furnished

without charge on request to Warner Electric.

Warner Electric LLC

31 Industrial Park Road • New Hartford, CT 06057

815-389-3771

www.warnerelectric.com

P-273-9 • 819-0530 6/12 Printed in USA

• Fax: 815-389-2582

Loading...

Loading...