Page 1

Residential, TG-2000, and

Commercial MagStop

P-1177

819-0457

Installation & Operation

®

Clutch/Brake

Page 2

Contents

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

®

MagStop

Mounting Requirements. . . . . . . . . . . . . . . . . 6-7

Anti-Rotation Examples . . . . . . . . . . . . . . . . 8-14

Troubleshooting Checklist . . . . . . . . . . . . . 15-16

Electrical Evaluation . . . . . . . . . . . . . . . . . . . . 17

Components . . . . . . . . . . . . . . . . . . 5

This guide applies to Warner Electric MagStop

®

clutches and clutch/brakes used on power

quipment.

e

Residential, TG-2000, and Commercial MagStops

are available in a range of torque capacities. The

®

MagStop

name comes from the permanent

magnet brake (magnetic stopping) rather than

conventional spring activated mechanical brakes.

In addition to these general procedures, any

applicable OEM general and safety procedures

must also be followed.

Failure to follow these

instructions may result in product damage,

equipment damage, and serious or fatal

injury to personnel.

Warner Electric • 800-825-9050 P-1177 • 819-0457

2

Page 3

MagStop®Bearing Mounted Electric Clutch and Clutch/Brake Assemblies and Operation

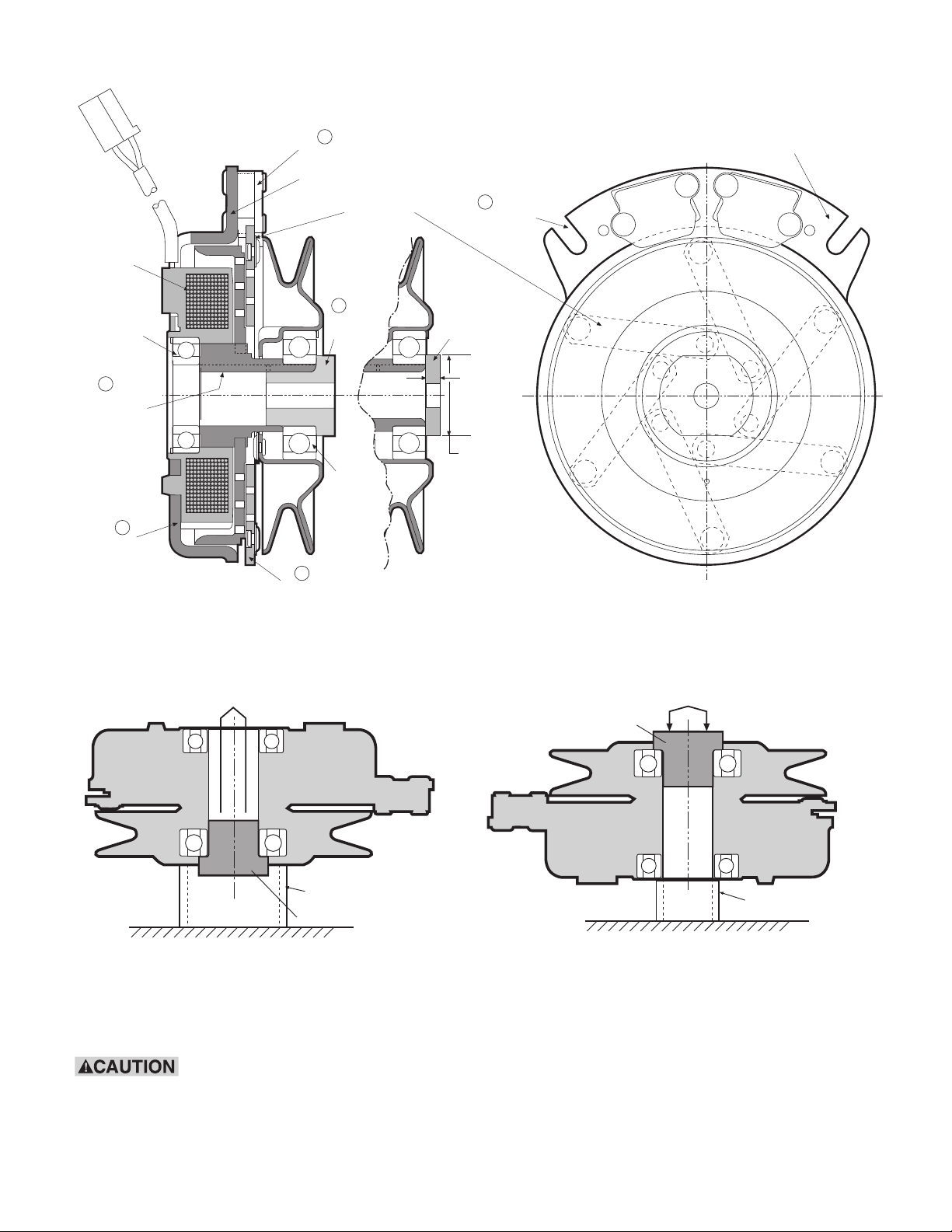

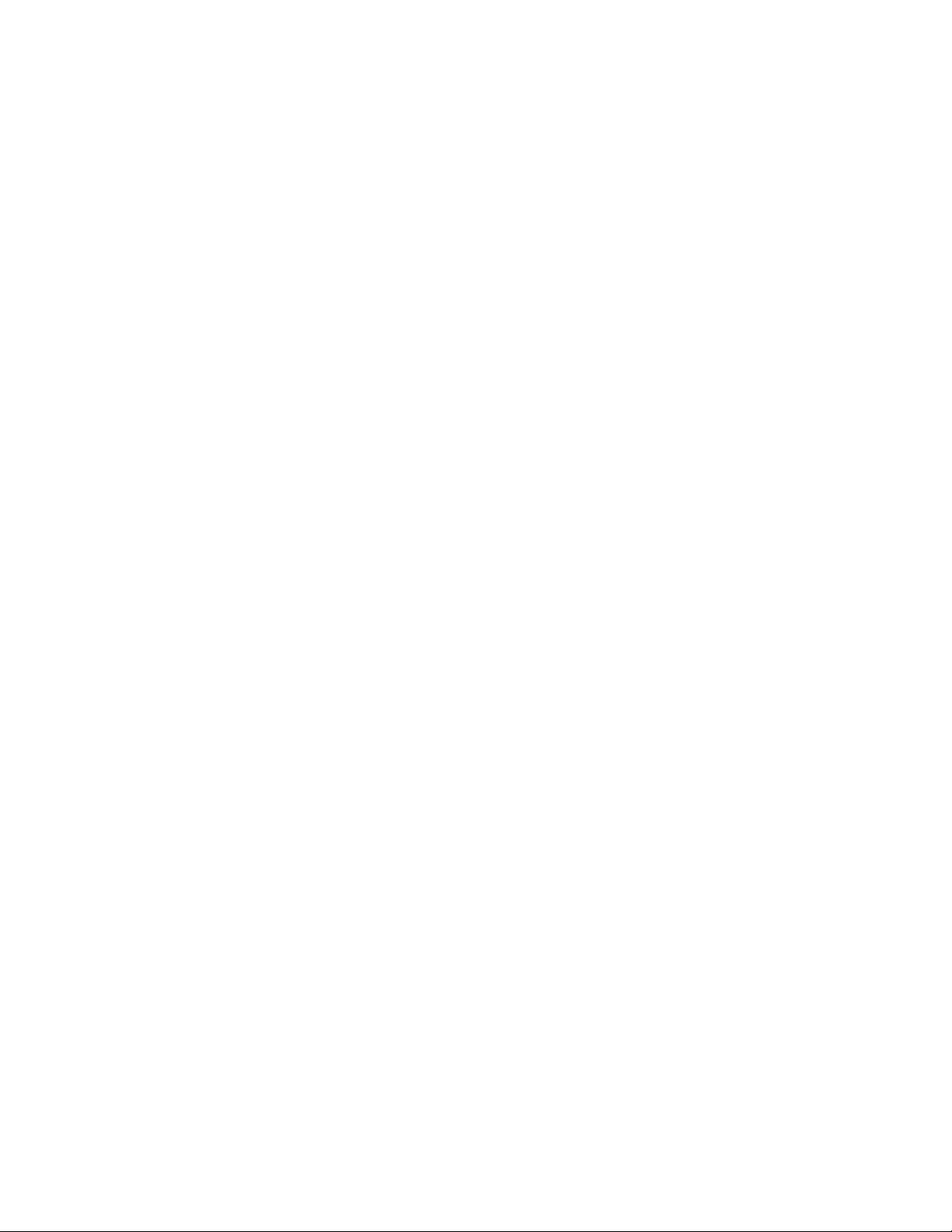

Components: (See Figure 1 on page 5.)

1. Rotor Assembly

Generally, the input of the clutch. Includes

a keyed hub which mates with the keyway in

the crank shaft. The rotor transmits the torque

from the crankshaft (driving shaft) to the

armature assembly (output).

2. Armature Assembly

Generally, the output of the clutch. Consists of

a disk, springs and pulley (or output flange).

With power applied the armature transmits

torque from the rotor to the driven load. Power

from the armature disk is transmitted to the

pulley or flange by means of the leaf springs.

3. Field Assembly

The clutch “power” source contains the coil

which generates magnetic attractive force.

4. Brake Poles

The two permanent magnets and plates

affixed to the field shell provide the brake

torque when the clutch is disengaged.

Brake poles are not present if the assembly

is a clutch only.

Optional Washer

A single .250 inch (6.35 mm) minimum thick steel

washer must be used between the clutch and the

crank shaft retaining bolt if the D-drive spacer is

not used.

A washer less than .250 inch

(6.35 mm) thick will deform and allow the

clamping load to be lost, resulting in damage

to the clutch and/or the crankshaft and

possible personal injury due to clutch

separating from the shaft. Multiple thinner

washers are not acceptable.

5. D-drive Spacer

A hub that is inserted into either armature

or field bearing (see Figure 2). The head

has flats that can be held with a wrench to

prevent rotation of the crankshaft when

tightening the mounting bolt (see Figure 5).

This hub also takes the place of the standard

retaining washer.

6. Anti-rotation Slot

Anti-rotation Slot (used with OEM’s

anti-rotation device) prevents MagStop from

rotation with crankshaft. If the field is bolted

rigidly or if its axial movement is restricted

the bearing in the field assembly will be

improperly loaded and may fail. Use OEM

supplied anti-rotation.

Warner Electric • 800-825-9050 P-1177 • 819-0457

3

Page 4

MagStop® Components

Wash er

Diameter

Must Not

Exceed OD

of Bearing

Inner Race.

Optional

Wash er

.250 Inch

(6.35 mm)

Minimum

Wash er

Thickness.

Coil

One piece

Field Assembly

D-drive

Spacer

Armature

Assembly

F

ield

Bearing

Armature

Bearing

Brake Pole s

Rotor

A

ssembly

Armature Leaf

Springs

2

Anti-

Rotation

Slot

Top View

One Piece Field Assembly with

Integral Anti-Rotation Slots

Field

A

ssembly

Support bearing

inner race

D-drive Spacer

Press

Support bearing outer race

D-drive Spacer

Press

Figure 1

D-drive Spacer Removal/Installation

D-drive Spacer removal

D-drive spacer may be installed on either end of clutch by OEM.

D-drive spacer must be removed or installed using an arbor press or equivalent.

On installation, opposite bearing INNER race must be supported or bearing damage may occur.

On removal, adjacent bearing OUTER race must be supported or bearing damage may occur.

Figure 2

D-drive Spacer installation

Warner Electric • 800-825-9050 P-1177 • 819-0457

4

Page 5

REQUIREMENTS

for a Successful Clutch

Application/Installation

Critical Requirements

The two most important requirements for a

successful clutch application or installation

are:

1. Antirotation device must allow both axial

and radial free-play!

Failure to allow this free-play will result

in field bearing failure. The greater the

restriction the faster the bearing will

fail!

2. Mounting bolt torque to be

minimum of:

• 3/8 -24 UNF use Grade 8 bolt torqued

to 40-45 lb.-ft.

(Grade 5 bolt is unacceptable)

• 7/16-20 UNF Grade 5 or 8 bolt torqued

to 50-55 lb.-ft.

(Grade 5 or 8 bolt is

acceptable)

• M 10 X 1.50 Class 10.9 torqued to

55-60 N-m

Note: All values are for dry (unlubricated)

plated bolts, please consult fastener

manufacturer if any type of locking element

(thread lock compound, patch etc.) is to

be used.

Failure to adhere to these requirements

will result in the failure of the clutch!

Warner Electric • 800-825-9050 P-1177 • 819-0457

5

Page 6

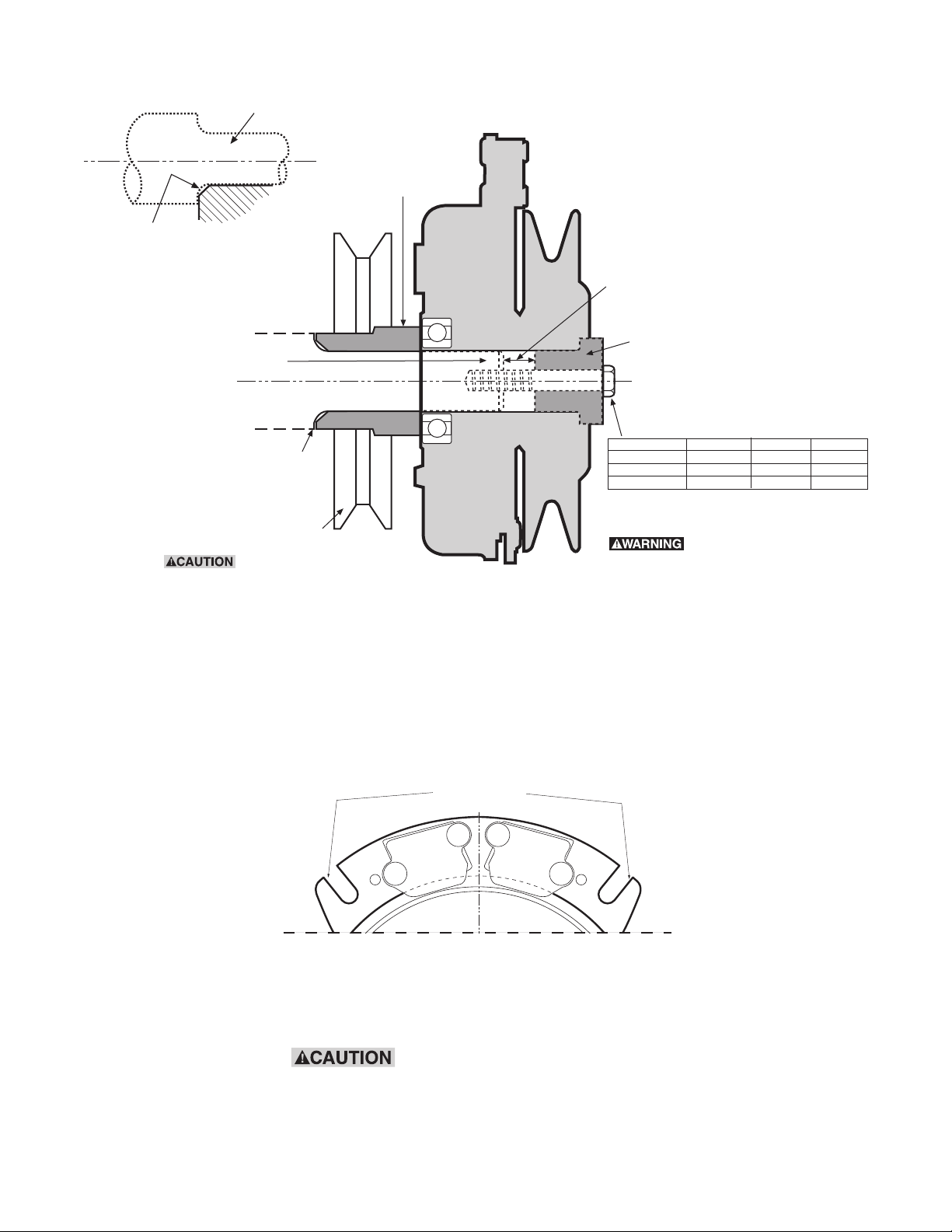

S

haft

S

houlder

G

round

D

rive

Pulley

Shaft end and

D-drive

spacer must

not touch

D

-drive Spacer

E

ngine Shaft

Failure to torque bolt

to requirements will

degrade clamping and

can allow the clutch to

separate from the

shaft, causing risk of

personal injury.

Thread size Torque ft.lb. Torque N-m

3/8-24" UNF 40-45 ft.lb. 54-61 N-m

7

/16-20" UNF 50-55 ft.lb. 67-75 N-m

M 10 X 1.50 40-45 ft.lb. 54-61 N-m

Ground drive pulley or spacer

must be chamfered to clear this

radius on the engine shaft

shoulder.

Shaft

G

round Drive Spacer

(

or spacer if no ground

r

ound

drive used)

Always bottom the clutch against a

flat surface; never against radius.

N

ote:

Must have faces parallel to each other

(within .003") and be perpendicular

t

o the bore.

Note: All values are for dry (unlubricated) plated bolts,

please consult fastener manufacturer if any type of locking

e

lement (thread lock compound, patch etc.) is to be used.

Grade Class

Grade 8

G

rade 5 or 8

Grade 10.9

Anti-rotation Slots

Mounting

Figure 3

Typical Engine Installation with Ground Drive Pulley

Anti-Rotation

Figure 4

See Anti-Roatation Examples on pages 8-14

or if its axial movement is restricted, the

If the field is bolted rigidly

bearing in the field assembly will be

Warner Electric • 800-825-9050 P-1177 • 819-0457

6

improperly loaded and may fail. Use only

factory installed anti-rotation device.

Page 7

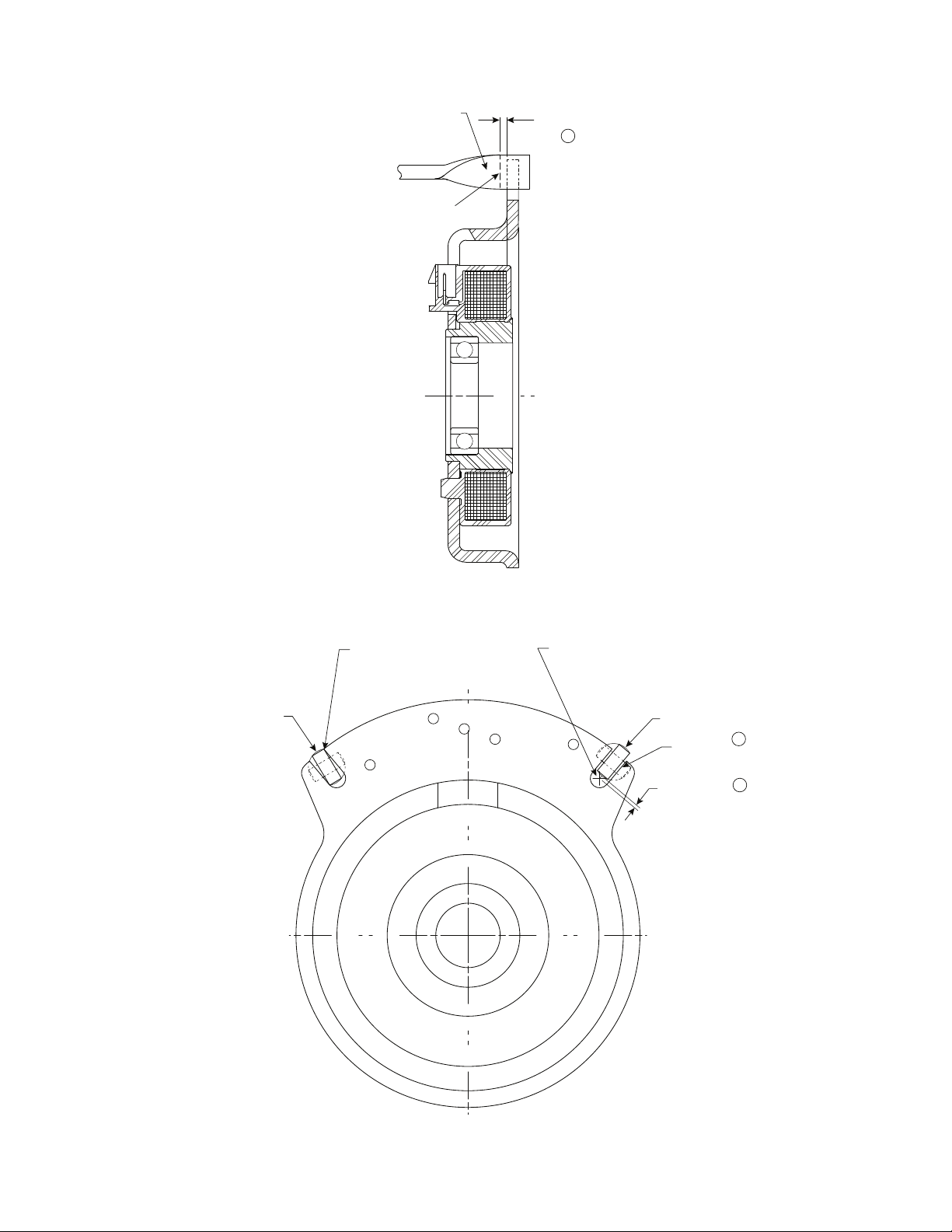

Attached To Frame

Incorrect

Do Not Orient So That

Bracket Will Bind In Slot

Do Not Bottom In Slot

Correct

.030 Min.

Loose Fit

.060 Min.,

Worst Case Stackup

Must Not Allow

Bottoming In Slot

A1

A1

Incorrect

Do Not Orient So That

Bracket Will Bind In Slot

Do Not Bottom In Slot

Correct

.030 Min.

Loose Fit

.060 Min.,

Worst Case Stackup

Must Not Allow

Bottoming In Slot

A1

A1

Anti-Rotation Example

Warner Electric • 800-825-9050 P-1177 • 819-0457

7

Page 8

Incorrect

A

1

Make Sure That This

Area Does Not Contact

Field Shell

.125 Min.

Do Not Orient So That

Bracket Will Bind In Slot

Do Not Bottom In Slot

Correct

.

030 Min.

Loose Fit

.060 Min.,

Worst Case Stackup

Must Not Allow

B

ottoming In Slot

A1

A1

Incorrect

Do Not Orient So That

Bracket Will Bind In Slot

Do Not Bottom In Slot

Correct

.030 Min.

Loose Fit

.060 Min.,

Worst Case Stackup

Must Not Allow

Bottoming In Slot

A1

A1

Anti-Rotation Example

Warner Electric • 800-825-9050 P-1177 • 819-0457

8

Page 9

Make Sure That

Twisted Area Does

Not Contact

Field Shell

D

o Not Orient So That

Bracket Will Bind In Slot

.030 Min.

Loose Fit

.060 min.,

Worst Case Stackup

Must Not Allow

B

ottoming In Slot

.125 Min.

C

orrect

Do Not Bottom In Slot

Incorrect

A

1

A

1

A1

Beginning of Flat

Do Not Orient So That

Bracket Will Bind In Slot

.030 Min.

Loose Fit

.060 min.,

Worst Case Stackup

Must Not Allow

Bottoming In Slot

Correct

Do Not Bottom In Slot

Incorrect

A1

A1

Anti-Rotation Example

Warner Electric • 800-825-9050 P-1177 • 819-0457

9

Page 10

.030 Min.

Loose Fit

A

1

Screw Must Be

Free To Move

Anti-Rotation Example

10

Warner Electric • 800-825-9050 P-1177 • 819-0457

Page 11

A

ircraft Cable,

.030 Min. Slack

A1

Aircraft Cable,

.030 Min. Slack

A1

Anti-Rotation Example

Warner Electric • 800-825-9050 P-1177 • 819-0457

11

Page 12

.

030 Min.

C

ombined

Loose Fit

A1

.030 Min.

Combined

Loose Fit

A

1

Anti-Rotation Example

Warner Electric • 800-825-9050 P-1177 • 819-0457

12

Page 13

.030 Min.

Loose Fit

A

1

A1

.060 Min.,

W

orst Case Stackup

Must Not Allow

Bottoming In Slot

.030 Min.

Loose Fit

A1

A1

.060 Min.,

Worst Case Stackup

Must Not Allow

Bottoming In Slot

Anti-Rotation Example

Warner Electric • 800-825-9050 P-1177 • 819-0457

13

Page 14

Troubleshooting Checklist

. Symptom: Clutch will not engage

A

Problem Possible Causes Solution

Blown fuse • Low coil resistance • Replace with new MagStop unit

• Defective battery • Replace

• Faulty charging system • Repair or replace

• Bad wiring or connections, PTO switch • Repair or replace

Low voltage supply • Defective battery • Replace

(Less than 12 VDC at clutch) • Faulty charging system • Repair or replace

• Bad wiring or connectors, PTO switch • Repair or replace

Incorrect coil resistance • Damaged coil • Replace with new MagStop unit

(see Step 1, page 17)

Inadequate current supply • Broken clutch lead wire • Repair

• Faulty electrical system • Measure clutch coil resistance and

supply voltage at the clutch. If both

are correct, electrical system

is faulty. Repair or replace.

Rotor/armature airgap too large • Rotor/armature wear; end of usable life • Replace with new MagStop unit

(greater than .125 inch/3.18mm)

B. Symptom: Brake will not engage

Problem Possible Causes Solution

Armature/brake poles wore out •End of usable life • Replace with new MagStop unit

Contaminated friction surfaces •Engine oil leak on brake •Repair leak

• Replace with new MagStop unit

C. Symptom: Clutch slip

Problem Possible Causes Solution

Low voltage supply • Defective battery • Replace

(less than 12 VDC at clutch) • Faulty charging system • Repair or replace

• Bad wiring or connectors, PTO switch • Repair

Inadequate current supply • Broken clutch lead wire • Repair

• Faulty electrical system •Measure clutch coil resistance and

supply voltage at the clutch. If both

are correct, electrical system is

faulty. Repair or replace.

Overloaded clutch • Clogged deck, back spindle, etc. • Remove excess grass

• Replace spindle

Contaminated friction surfaces • Engine oil leak on clutch • Repair leak

• Replace with new MagStop unit

Warner Electric • 800-825-9050 P-1177 • 819-0457

14

Page 15

Troubleshooting Checklist (Continued)

D. Symptom: Noisy clutch/Vibration

Problem Possible Causes Solution

Failed bearing •Loose mounting (bolt not torqued properly) • Replace (see Mounting Figure 3, page 7)

• Field assembly movement restricted • Confirm proper Anti-rotation

(see Anti-rotation, Figure 4, page 7)

Adapter plate rattles against • Some noise is normal • If noise is excessive, repair or replace

anti-rotation pin anti-rotation device. (Follow OEM’s

Specifications. See Anti-rotation,

Figure 4, page 7).

Clutch loose on shaft • Loose mounting (bolt not torqued properly) • Tighten mounting bolt to specification.

See Mounting, Figure 3. page 7.

• Mounting bolt too long and bottoms •Use correct length bolt (see

in engine shaft before clamping clutch Mounting page 7, Figure 3)

• Mounting washer too thin and deforms • See Figure 1 and Warning on page 5.

when bolt is tightened.

• Shaft bottoms on D-drive • Use proper spacer (see Mounting page 7)

Clutch not mounted square • Ground Drive Spacer mounting shoulder • Replace

not squared. See Mounting Figure 3.

• Clutch integral key hitting end of keyway • Space clutch away from radius in shaft

in engine shaft keyway.

• Incorrect or no chamfer on ground • Increase chamfer on ground drive spacer.

drive spacer. See Caution, Figure 3, page 7.

Broken Spring • Loose mounting • Replace clutch

A clutch with broken rivets or springs may separate from the shaft and cause personal injury.

Burnishing Procedure when installing a

®

new MagStop

This procedure should be performed with the load

attached (mowing deck, snowblower,

pump etc.)

Note: Do NOT add additional load

(e.g. cutting grass).

1. Run engine at full throttle and engage load

bringing load to full speed then disengage load.

2. Let load come to a full stop then engage again.

Clutch/Brake

3. Repeat these procedures (1 and 2) 10

times. After burnish procedure is complete,

to maximize deck drive train life, always

engage clutch at half throttle.

Warner Electric • 800-825-9050 P-1177 • 819-0457

15

Page 16

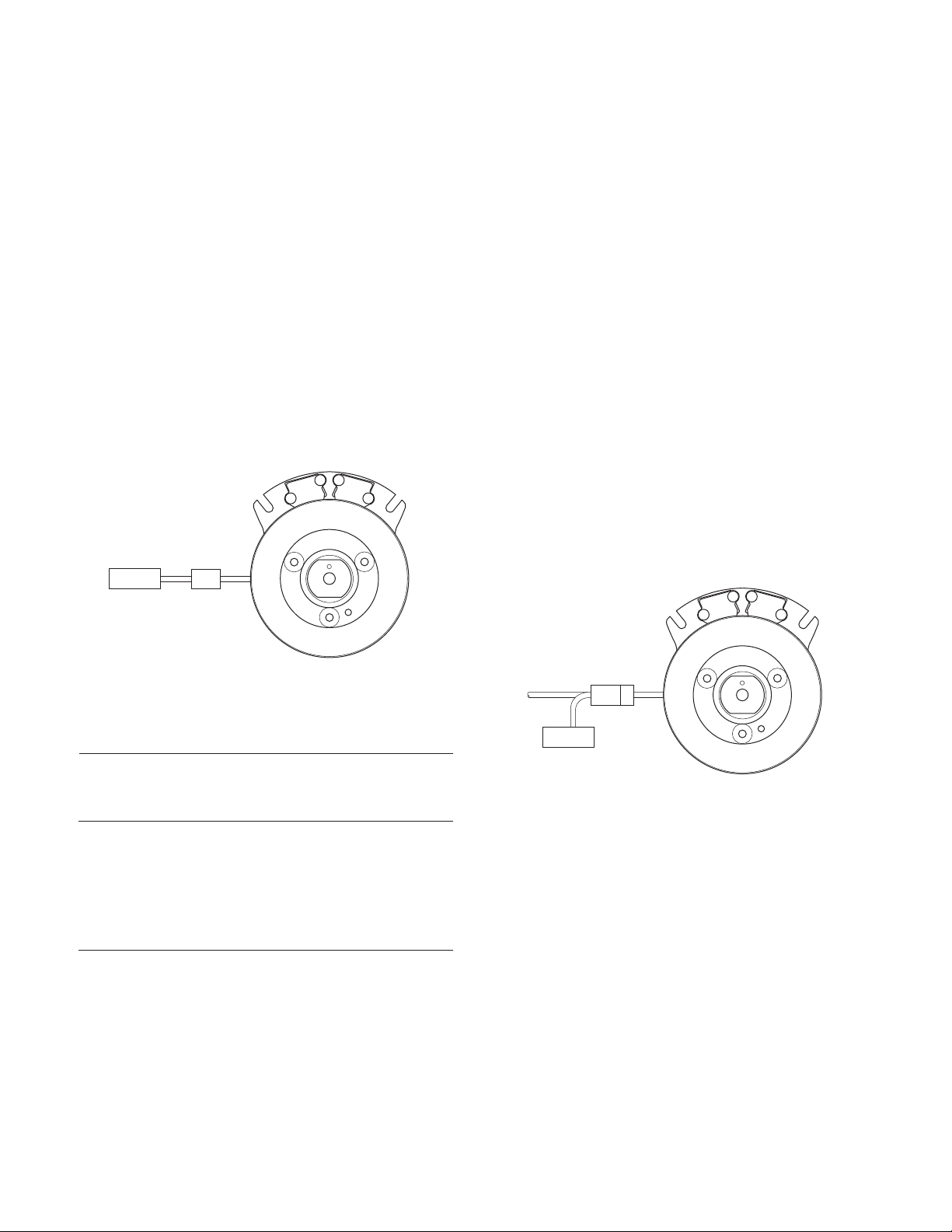

Electrical Evaluation

Meter

Meter

Step 1. How to Measure Clutch Coil resistance

See Figure 5)

(

1. Turn engine and PTO switch off.

2. Disconnect clutch at clutch connector.

3. Select meter setting for ohm reading.

4. Connect meter leads to clutch.

5. Check meter reading and refer to the chart

below for correct clutch resistance reading.

(values are @ 68°F.)

If reading falls in acceptable range proceed

to step 2, if not replace the clutch.

Step 2. Measure the supply voltage at the clutch

(See Figure 6)

1. Turn engine off.

2. Connect meter leads at the clutch connector.

3. Select meter setting for voltage reading.

4. Make sure wires will not become entangled

in rotating components of clutch.

5. Start engine and engage PTO switch.

6. Measure voltage across the leads at

the connectors.

7. Voltage should be 12-14 volts DC. If clutch

still fails to operate, replace clutch.

8. If voltage is not within 12-14 volt range

consult EOM’s service manual.

Figure 5

Resistance Measurement

Table 1

Resistance

Torque at 70˚ F

Model (ft.-lb.) Nom. Nm (ohms) ±5%

MS-60 60 81 7.18

MS-80 80 108 3.68

TG2K-125 125 169 2.84

CMS-150 150 203 2.47

CMS-175 175 237 2.30

CMS-200 200 271 1.84

Note: If bench tested with 12 volts applied,

armature may not pull away from brakepoles.

Rotational motion is required to engage clutch.

Figure 6

Voltage Measurement

Warner Electric • 800-825-9050 P-1177 • 819-0457

16

Page 17

Warner Electric • 800-825-9050 P-1177 • 819-0457

17

Page 18

Warner Electric LLC

31 Industrial Park Road • New Hartford, CT 06057

815-389-3771 • Fax: 815-389-2582

Manufacturing Facility

802 E. Short Street • Columbia City, IN 46725

260-244-6183 • Fax: 260-244-3928

www.warnerelectric.com

P-1177 • 819-0457 8/11 Printed in USA

Loading...

Loading...