Page 1

P-2086-WE

SM304-gb-08/04

Electro-Magnetic Single Disc

Clutches SFM and Brakes PBM

Service Manual

Page 2

We, WARNER ELECTRIC EUROPE, 7, rue Champfleur, B.P. 20095, F-49182 St Barthélemy d’Anjou Cedex

declare that the clutches and brakes made in our factories from St Barthélemy d’Anjou,

and hereafter designated : SFM and PBM

are exclusively designed for incorporation into a machine and to be assembled with other equipments to create a machine. The operation of

the product is submitted to the conformity of the complete equipment, following the provisions of the machinery directive 89/392/EEC and if

electric to the EMC directive 89/336 /EEC.

The conformity of the electric units to the Low Voltage directive 72/23 is supported by the full respect of the following standards : NFC 79300

and VDE 05808/8.65.

Drawn up in St Barthélemy d’Anjou, July 2002

E. PRAT, General Managing Director

CONTENTS

1 Technical specifications 2

2 Precautions and restrictions on use 2

2.1 Restrictions on use 2

2.2 Precautions 2

and safety measures

3 Installation 3

3.1 Transport - storage 3

3.2 Handling 3

1 Technical specifications

SFM Sizes 10 20 40 70 150 250 500

-1

Max. Speed min

Nominal airgap (0/+0,1) mm

Dimension M VAR00 mm

Weight VAR00 kg

Weight VAR01 kg

Weight VAR10 kg

Weight VAR11 kg

8000

0,2

24

0,5

0,59

0,7

0,79

PBM Sizes 10 20 40 70 150 250 500

-1

Max. Speed min

Nominal airgap (0/+0,1) mm

Weight VAR00 kg

Weight VAR01/VAR02 kg

8000

0,2

0,3

0,4

3.3 Installation 3

3.3.1 SFM VAR00 and VAR01 3

3.3.2 SFM VAR10 and VAR11 3-4

3.3.3 PBM VAR00, VAR01 and VAR02 4

4 Electrical connection 5

4.1 Important recommendations 5

4.2 Power supply 5

5 Appendices 6-7

6000

0,2

26,5

0,9

1,1

1,2

1,4

6000

0,2

0,5

0,7

5000

0,2

30

1,7

2,07

2,3

2,67

5000

0,2

0,95

1,32

4000

0,3

33,5

3

3,6

4

4,6

4000

0,3

1,7

2,32

3000

0,3

37,5

5,5

6,9

7,6

9

3000

0,3

3,3

4,8

2500

0,5

44

10

13,1

13

16,1

2500

0,5

5,9

9

2000

18,5

24,5

22,2

28,2

2000

11,5

17,6

0,5

51

0,5

Table 1

2 Precautions and restrictions on use

2.1 Restrictions on use

This equipment is designed for dry running.

Any oily material alters performance.

2.2 Precautions and safety measures

During the maintenance period make sure that the

moving parts of the machine are stationary and

that there is no risk of start-up.

Exceeding the maximum rotation speed

stated in the catalogue invalidates the

warranty.

Any modification made to the unit without

any express approval of a Warner Electric

representative will invalidate the guarantee and

This equipment is designed for a maximum

ambi ent temperature of 40°C (155°C casing

release Warner Electric from any liability regarding

conformity.

class).

2 Warner Electric Europe • +33 (0)2 41 21 24 24 P-2086-WE • 11/12

Page 3

Fig. 2

Airgap

Adjusting spacer

Symbol designating an action that

might damage the apparatus

Symbol designating an action that

might be dangerous to human safety

3 Installation

3.1 Transport / storage

These units are delivered in packaging that

guarantees a 6 months storage period whether

transported by land, by air, or by sea to any

destination excepting tropical countries.

3.2 Handling

Avoid any impacts on the equipment so as not to

alter their performance.

Never carry the equipment by the electrical supply

cable.

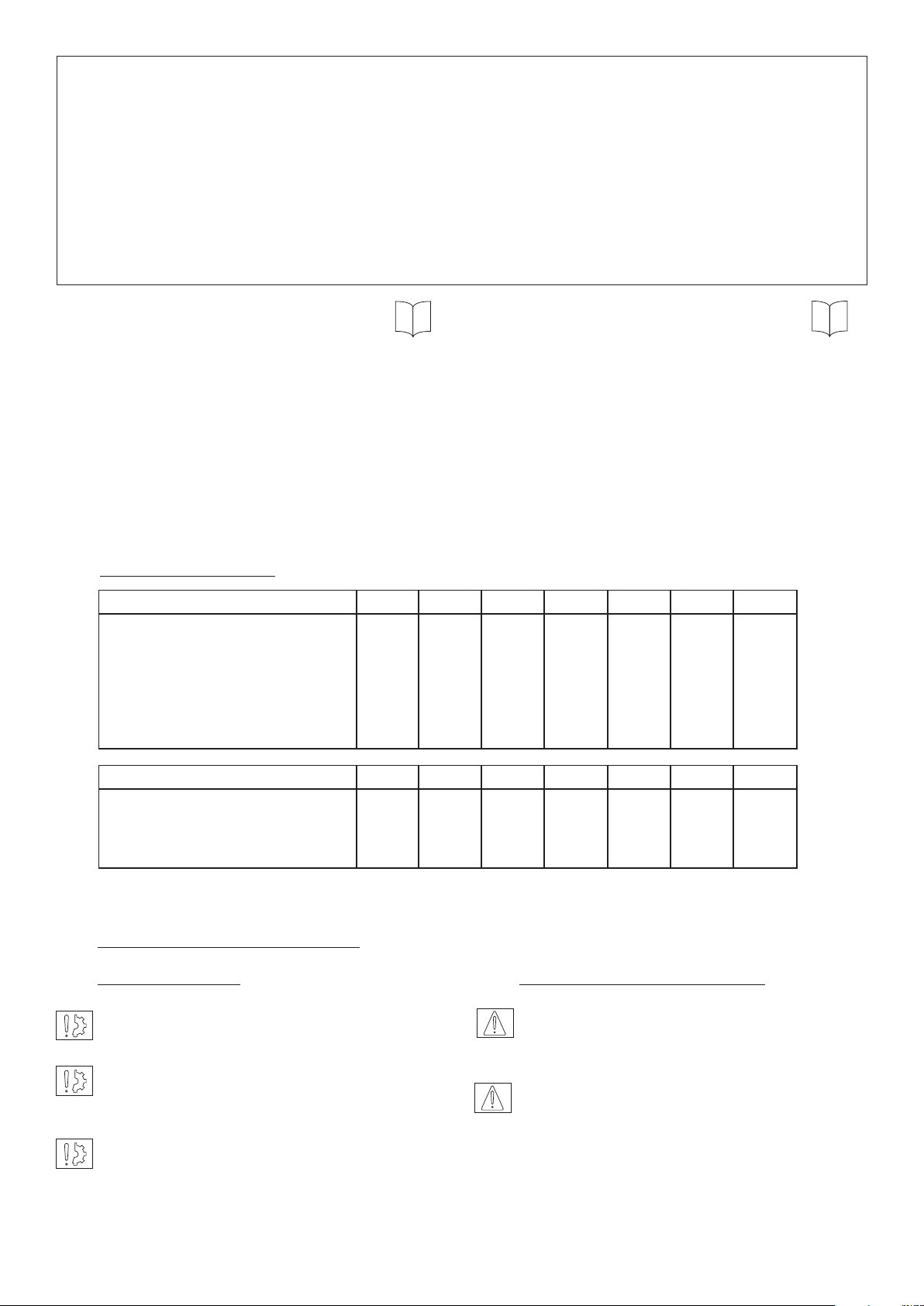

3.3 Installation 3.3.1SFM (VAR00 and VAR01)

Inductor (104) should be fixed to the frame of the

machine, centred by the collar (see figure 1) or

directly centred on a bearing forming a support

(see figure 2). In this case, a circlip fitted in the

groove provided for the purpose holds it central to

the bearing.

In the case of collar centring, we specify an H9

tolerance.

Airgap

Adjusting spacer

Fig. 2

On VAR01 the armature is mounted on a hub

(332), sup plied reamed to tolerance H7 and

splined to tolerance P9.

The assembled hub / armature assembly

should be secured centrally so as to respecter

the nominal airgap.

It is essential when assembling to respect the

nominal airgap (see chapter 1) and dimension

M (See table 1).

The setover between the housing and shaft should

not exceed 0.05 mm.

On VAR00, the armature (331) is fixed by means

of CHC “profile head” screws (DIN 7984) locked

by means of a LOCTITE 270 type thermoplastic

liquid.

Airgap

Adjusting

spacer

Fig. 1

In the case where two co-axial shafts are fitted,

the recommended setover is 0.05 mm maximum.

The angular misalignment should not be greater

than 0,1 mm over a length of 100 mm.

When assembling or dismantling the moving

armature, never hit or pull it, this action could

generate permanent distortion of the

membrane-spring and malfunction.

3.3.2 SFM (VAR10 and VAR11)

The inductor (109) is stopped from rotating by

means of a stop foot. This should be fitted so

as to get a minimum play of 0,25 mm between

the sides of the notch to avoid any strain on the

inductor and internal bearing.

In case of vibrations, it is strongly recommended

to insert a damping elastic slot between the

anti-rotation device and the anti-rotation slot

and to fix the coil’s cable the nearest of it to

avoid whipping.

On VAR10, the armature is fixed (331) by means

of CHC “profile head” screws (DIN 7984) locked

by means of a LOCTITE 270 type thermoplastic

liquid.

Warner Electric Europe • +33 (0)2 41 21 24 24 P-2086-WE • 11/12 3

Page 4

The device supporting the moving armature

Airgap

Adjusting

spacer

Airgap

Adjusting spacer

Locking nger

Airgap

Adjusting

spacer

Airgap

Airgap

Adjusting

spacer

should be secured centrally so as to respecter

the nominal airgap.

Airgap

In the case of collar centring, we specify an H9

tolerance.

The setover between the housing and shaft

should not exceed 0,2 mm.

Airgap

Adjusting spacer

Locking nger

Fig. 3

On VAR11, the hub / moving armature assembly

(332) is supplied reamed to tolerance H7 or H8

and splined to tol erance P9.

Airgap

Adjusting spacer

Locking nger

Fig. 4

Adjusting

spacer

Fig. 5

On VAR00, the armature is fixed by means of

CHC “pro file head” screws (DIN 7984) locked

by means of a LOC TITE 270 type thermoplastic

liquid.

On VAR01 and VAR02 the armature is mounted

on a hub (332) or (333), supplied reamed to

tolerance H7 or H8 and splined to tolerance P9.

The assembled hub / armature assembly should

be secured centrally so as to respect the nominal

airgap.

The angular misalignment of the shaft should

not be greater than 0,1 mm over a length of 100

mm.

Airgap

When assembling or dismantling the moving

armature, never hit or pull it, this action

could generate permanent distortion of the

In the case where two co-axial shafts are

membrane-spring and malfunction.

fitted, the recommended setover is 0,05 mm

maximum. The angular misalignment should

not be greater than 0,1 mm over a length of

100 mm.

Adjusting spacer

It is essential when assembling to respect the

nom- inal airgap (see chapter 1).

3.3.3 PBM VAR00, VAR01 and VAR02

When assembling or dismantling the moving

Fig. 6

armature, never hit or pull it, this action could

The inductor (104) should be rigidly fixed to

the frame of the machine, centred by the collar

generate permanent distortion of the membrane

spring and malfunction.

(see figure 5) or directly centred on a bearing

forming a support (see figure 6). In this case, a

circlip fitted in the groove provided for the pur-

It is essential when assembling to respect the

nominal airgap (see chapter 1).

pose holds it central to the bearing.

4 Warner Electric Europe • +33 (0)2 41 21 24 24 P-2086-WE • 11/12

Page 5

4 Electrical connection

SFM and PBM equipment should be supplied

with Direct Current and has factory fitted wires

of length 400 mm. Polarity has no effect on

operation.

4.1 Important recommendations

Ensure that the nominal supply voltage is

complied with (a lower voltage causes a reduction

in the starting distance and transmissible torque).

The connecting wires should be of sufficient

diameter to prevent power loss between source

and the equipment to be supplied.

I (A) / L (m) 0 to 10 m from 10 to 20 m

0 to 2 (A)

3 to 6 (A)

1,5 mm

1,5 mm

2

2

1,5 mm

2,5 mm

2

2

Tolerance for the supply to the clutch or brake

terminals +5% / -10% (NF C 79-300)

4.2 Power supply

For the control of these clutches and brakes we

advise the use of Warner Electric CBC 140-4,

CBC 140-6, CBC 400, CBC 450, CBC 500, CBC

550, and CBC 700 supply units.

Warner Electric supply units provide protection

for the coils and circuits. In the case where a

brake or clutch is used without our supply units,

with switch on the DC circuit, it is essential

to protect the coil against power spikes by a

varistor fitted in parallel.

Warner Electric Europe • +33 (0)2 41 21 24 24 P-2086-WE • 11/12 5

Page 6

SFM VAR00

5 Appendices

5.1 Appendix 1

202

104

SFM VAR01

202 104

331

Rep Designation

104

202

331

Magnet

Rotor + friction material

Assembled moving armature

332

M

Rep Designation

104

202

332

Magnet

Rotor + friction material

Moving armature ext. Hub

SFM VAR10

331

Rep Designation

109

331

Magnet

Assembled moving armature

109

SFM VAR11

332

Rep Designation

109

332

Magnet

Moving armature ext. Hub

109

6 Warner Electric Europe • +33 (0)2 41 21 24 24 P-2086-WE • 11/12

Page 7

PBM VAR00

5.2 Appendix 2

331

PBM VAR01

332 104

104

Rep Designation

104

331

Magnet

Assembled moving armature

PBM VAR02

333 104

Rep Designation

104

332

Magnet

Moving armature ext. Hub

Rep Designation

104

333

Warner Electric Europe • +33 (0)2 41 21 24 24 P-2086-WE • 11/12 7

Magnet

Moving armature ext. Hub

Page 8

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any product manufactured and

sold by it which proves to be defective in material or workmanship within a period of one (1) year from the date of original

purchase for consumer, commercial or industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without Warner Electric LLC’s

prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation charges prepaid, to

the appropriate Warner Electric LLC factory. Additional warranty information may be obtained by writing the Customer

Satisfaction Department, Warner Electric LLC, 449 Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-

3771.

A purchase receipt or other proof of original purchase will be required before warranty service is rendered. If found

defective under the terms of this warranty, repair or replacement will be made, without charge, together with a refund for

transportation costs. If found not to be defective, you will be notified and, with your consent, the item will be repaired or

replaced and returned to you at your expense.

This warranty covers normal use and does not cover damage or defect which results from alteration, accident, neglect, or

improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the defective product and

in no event shall Warner Electric LLC be liable for consequential, indirect, or incidental damages of any kind incurred by

reason of the manufacture, sale or use of any defective product. Warner Electric LLC neither assumes nor authorizes any

other person to give any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH THE CONSUMER MAY

HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL CONSUMER PURCHASE. WITH

RESPECT TO COMMERCIAL AND INDUSTRIAL USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU

OF AND EXCLUDES ALL OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you. This warranty gives you specific legal rights and you may also have other rights which

vary from state to state.

Changes in Dimensions and Specications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without notice. Weights do not

include weight of boxing for shipment. Certified prints will be furnished without charge on request to Warner Electric.

Warner Electric Europe

7 rue Champfleur, B.P. 20095, St Barthelemy d’Anjou - France

+33 (0)2 41 21 24 24 • Fax: +33 (0)2 41 21 24 70

www.warnerelectric.com

Printed in USAP-2086-WE • 11/12

Loading...

Loading...