Page 1

SF-120, SF-170, SF-250, SF-400 Bearing Mounted,

Flange Mounted, SFC-120, SFC-170, SFC-250,

SFC-400 Bearing Mounted, Flange Mounted

P-200

819-0481

Installation Instructions

Page 2

Contents

Mounting Examples and Options . . . . . . . . . . . . . . . . .3

Installation Instructions

SF-120, SF-170, SF-250, SF-400 . . . . . . . . . . . . .4

SFC-120, SFC-170, SFC-250, SFC-400 . . . . . . . .7

Electrical Coil Data . . . . . . . . . . . . . . . . . . . . . . . . . .11

Burnishing and Maintenance . . . . . . . . . . . . . . . . . . .12

Illustration Drawings

SF-120, SF-170 Flange Mounted . . . . . . . . .14-19

SF-120, SF-170 Bearing Mounted . . . . . . . . .18-21

SF-250, SF-400 Flange Mounted . . . . . . . . .22-25

SF-250, SF-400 Bearing Mounted . . . . . . . . .26-29

SFC-120, SFC-170 Flange Mounted . . . . . . .30-33

SFC-120, SFC-170 Bearing Mounted . . . . . .34-37

SFC-250, SFC-400 Flange Mounted . . . . . . .38-41

SFC-250, SFC-400 Bearing Mounted . . . . . .42-45

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . .Back Cover

Follow the installation instructions in this manual

carefully to ensure safe, reliable operation. All

stated or implied manufacturer warranties are

voided if this product is not installed in

accordance with these instructions.

Failure to follow these instructions

may result in product damage, equipment damage,

and serious or fatal injury to personnel.

SF-120

SF-250

Warner Electric • 800-825-9050 P-200 • 819-0481

2

SF-170

SF-400

Page 3

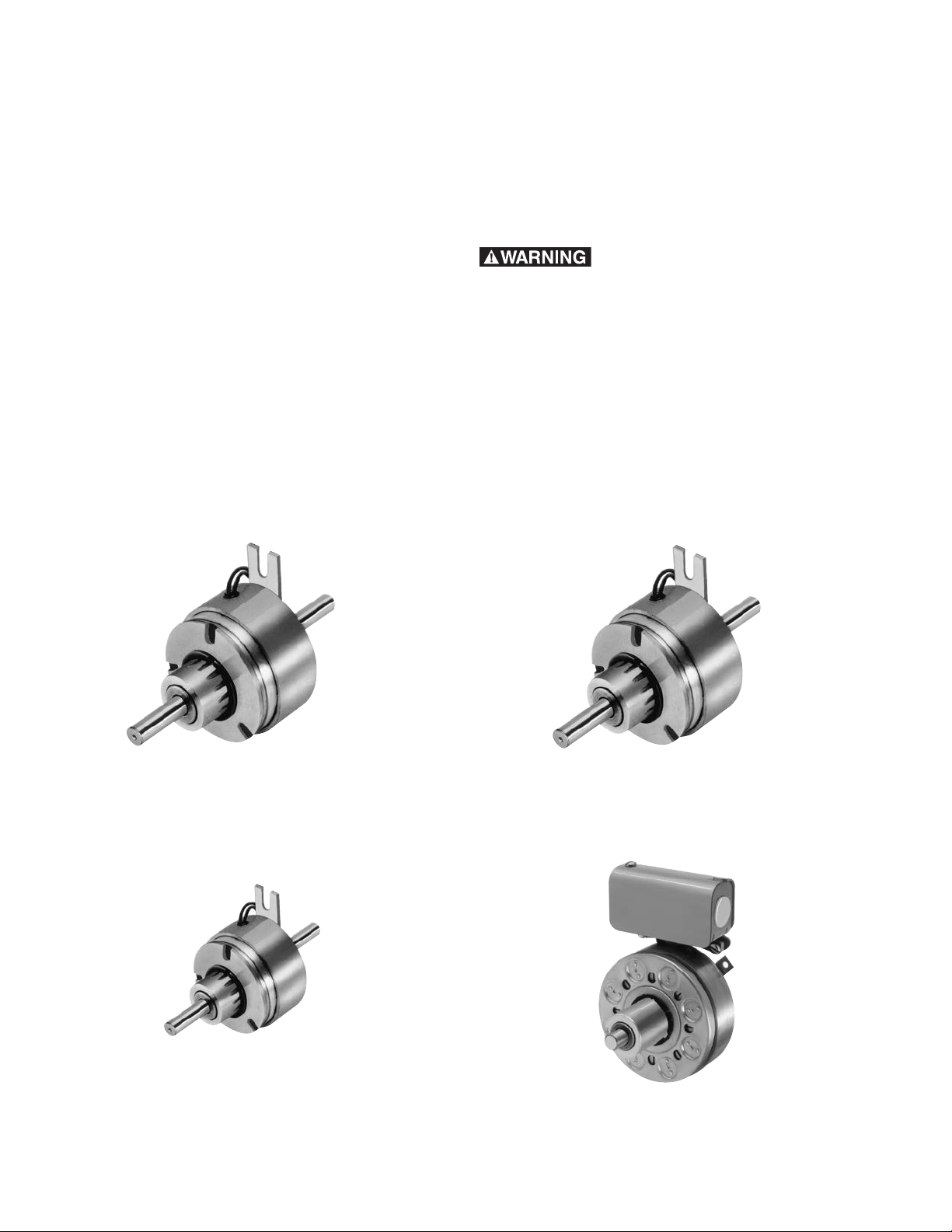

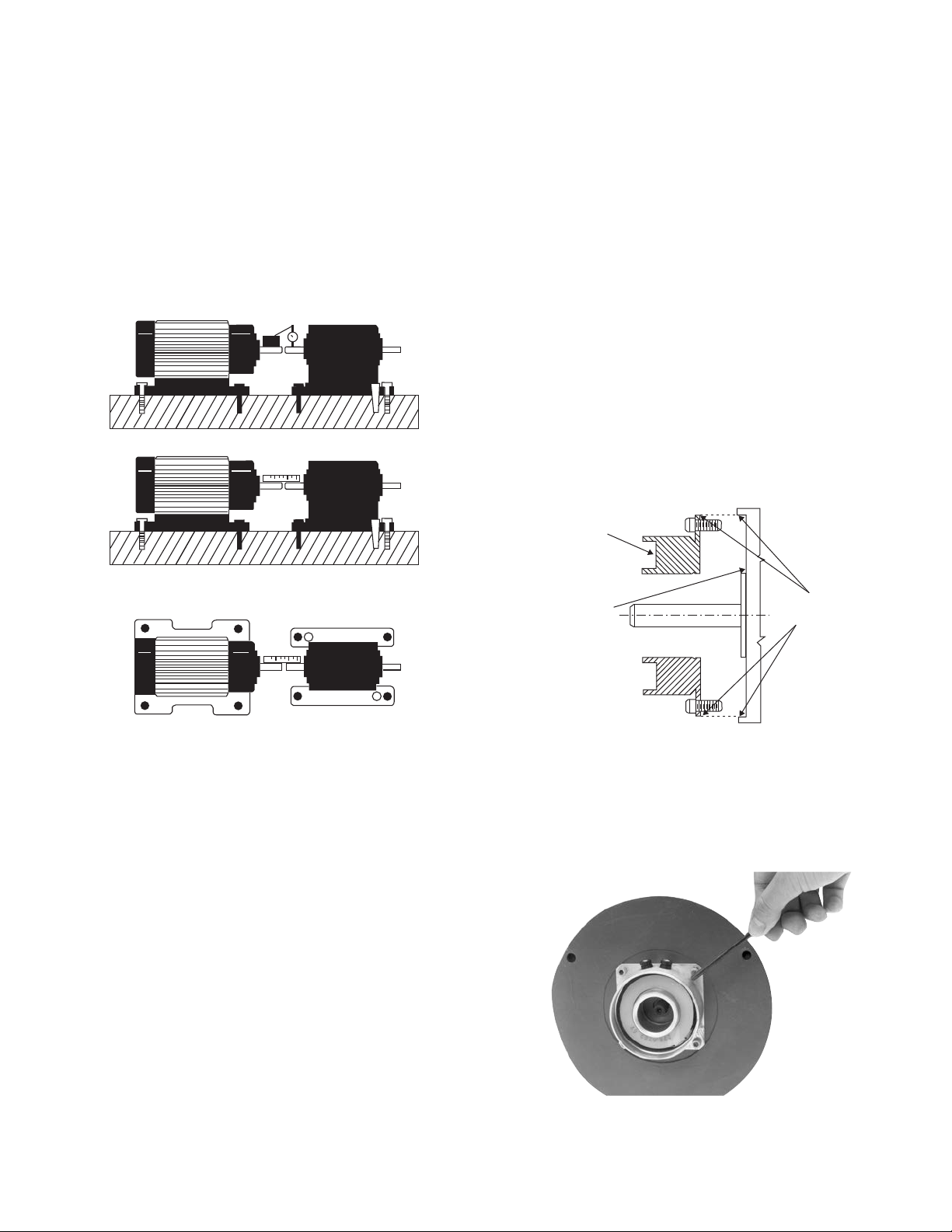

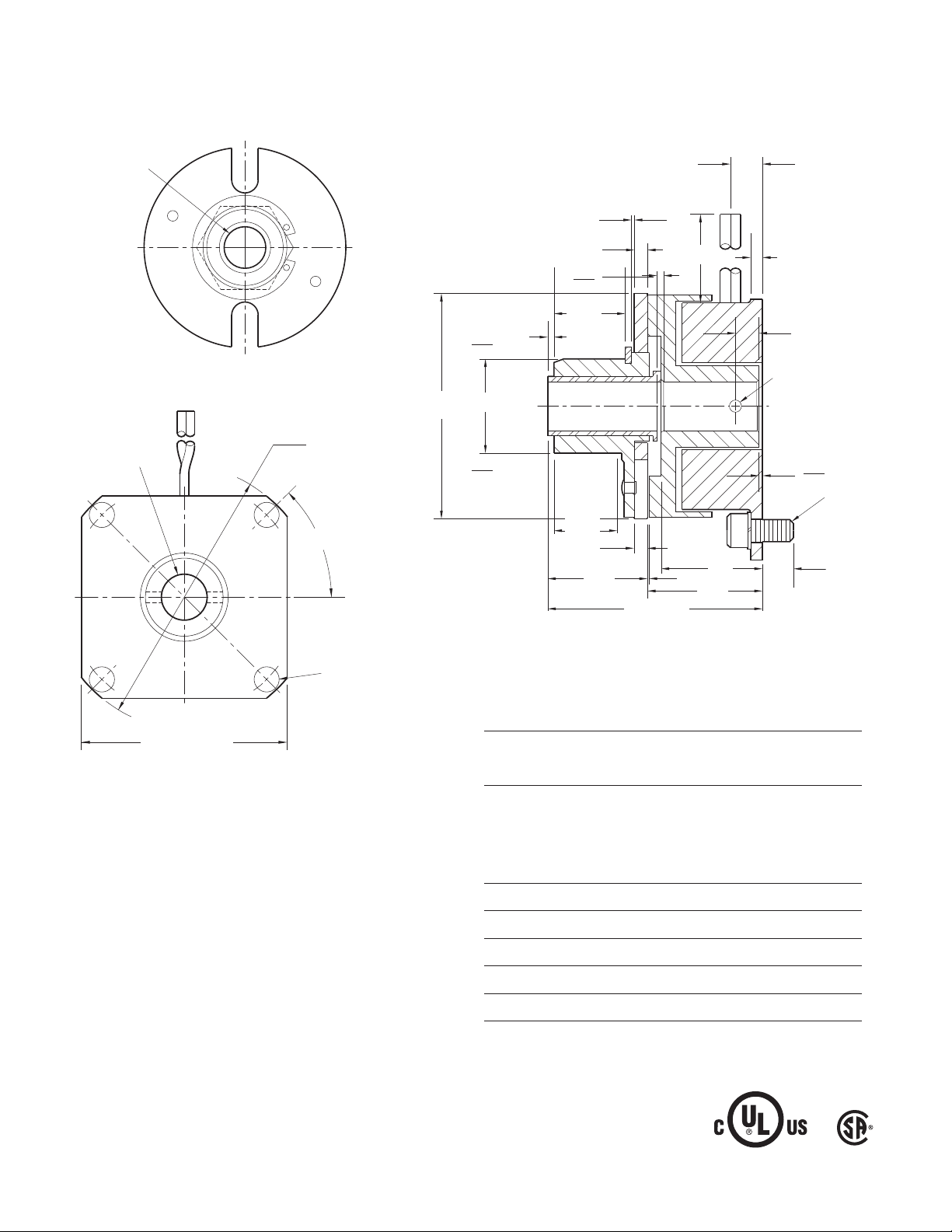

Mounting Examples and Options

Warner Electric clutches are simple to

install. They consist of components

which must be assembled on the

shaft and properly attached to the

machine frame.

Various customer furnished drive

components must be assembled with

the clutch. Pulleys, sprockets and

bearings/pillow blocks for shafting

may be essential elements of a

complete drive system. Squareness

and concentricity tolerances are

specified where critical to proper

clutch/brake functioning.

The illustrations show SF, and SFC

Flange Mounted and Bearing

Mounted units mounted with

customer supplied bearing mounted

pulley. In each illustration the drive pin

for a normal duty clutch is shown. In

this manner the pulley will support

the armature.

SF Clutches and SFC Clutch Couplings

Flange Mounting

Concentricity tolerances, held by customer,

are critical. Pilot surface required on

machine member. Eliminates bearings.

Good design for high speed applications.

SF Clutch

Typical Installation

SFC Clutch Coupling

Typical Installation

Bearing Mounting

Bearing supports field and holds close tolerances

required between rotor and field. Easy to install

and priced about the same as the flange

mounted design.

SF Clutch

Typical Installation

SFC Clutch Coupling

Typical Installation

Warner Electric • 800-825-9050 P-200 • 819-0481

3

Page 4

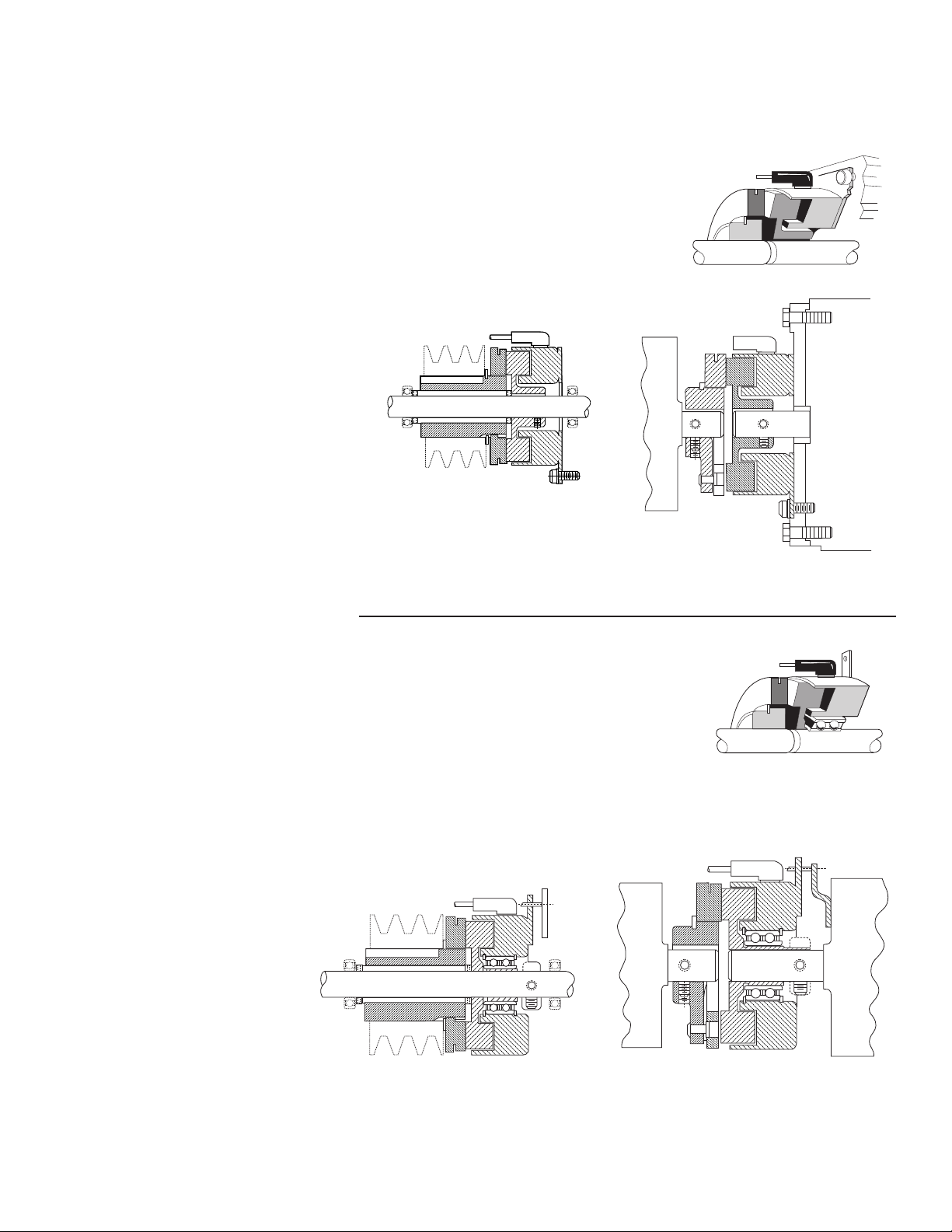

Clutch SF-120, SF-170, SF-250, SF-400

Field

Mounting

Surface

Pilot

Diameters

Installation Instructions

A. Installing the Conduit Box

To install the conduit box on the size 400 units, refer

to the instructions supplied with conduit box.

B. Mounting the Field-and-Rotor Assembly

Flange-Mounted Units

The fields and rotors are shipped separately for

flange-mounted units. On some applications it may

be necessary to mount the rotor first, and then bring

the field into position. In other instances the field

may be mounted first, and then the rotor (mounted

on a shaft) will be inserted into place.

Figure 2

7. Secure the assembly in this position by

alternately tightening the two setscrews.

1. Care must be taken in selecting the location for

mounting the field assembly. Pilot diameters are

machined on the field mounting flange to aid in

holding the field in the proper position.

2. An appropriate pilot diameter must be provided

on the mounting surface as well. (Figure 1)

Figure 1

3. The field assembly is then fastened in place with

capscrews and lockwashers. (Figure 2)

4. After the unit is in place, the mounting face and

pilot must be square and concentric with the

shaft in accordance with the tolerances listed on

the drawings.

5. Insert a key into the shaft keyway.

6. Slide the rotor assembly onto the shaft over

the key.

8. Position the field and rotor in accordance with

the overall axial dimension shown on the

illustration drawings for correct size unit. Holding

this dimension will assure the proper clearance

between the field and rotor.

Bearing-Mounted Units

In bearing-mounted units, the field and rotor are

shipped as an assembly. Either this assembly or the

armature and hub assembly can be mounted on the

shaft first, depending on the characteristics on each

application.

1. Insert the key into the shaft keyway.

2. Slide the rotor assembly over the key and on to

the shaft.

3. Secure the field-and-rotor assembly in place by

alternately tightening the two set screws.

Note: The field-and-rotor assemblies for 120

units and 250 units, 1/2 inch bore,

are held in place by set screws

inserted into a set collar on the end of

the rotor hub extension. Secure these

assemblies in place by alternately

tightening the screws.

4. A tab or torque arm on the field is used to

prevent rotation of the field caused by normal

bearing drag. Insert either a pin in the U-slot or

a fork around the torque arm to prevent this

rotation. Under no circumstances, however,

should the field be so tightly restrained as to

preload the bearing.

Warner Electric • 800-825-9050 P-200 • 819-0481

4

Page 5

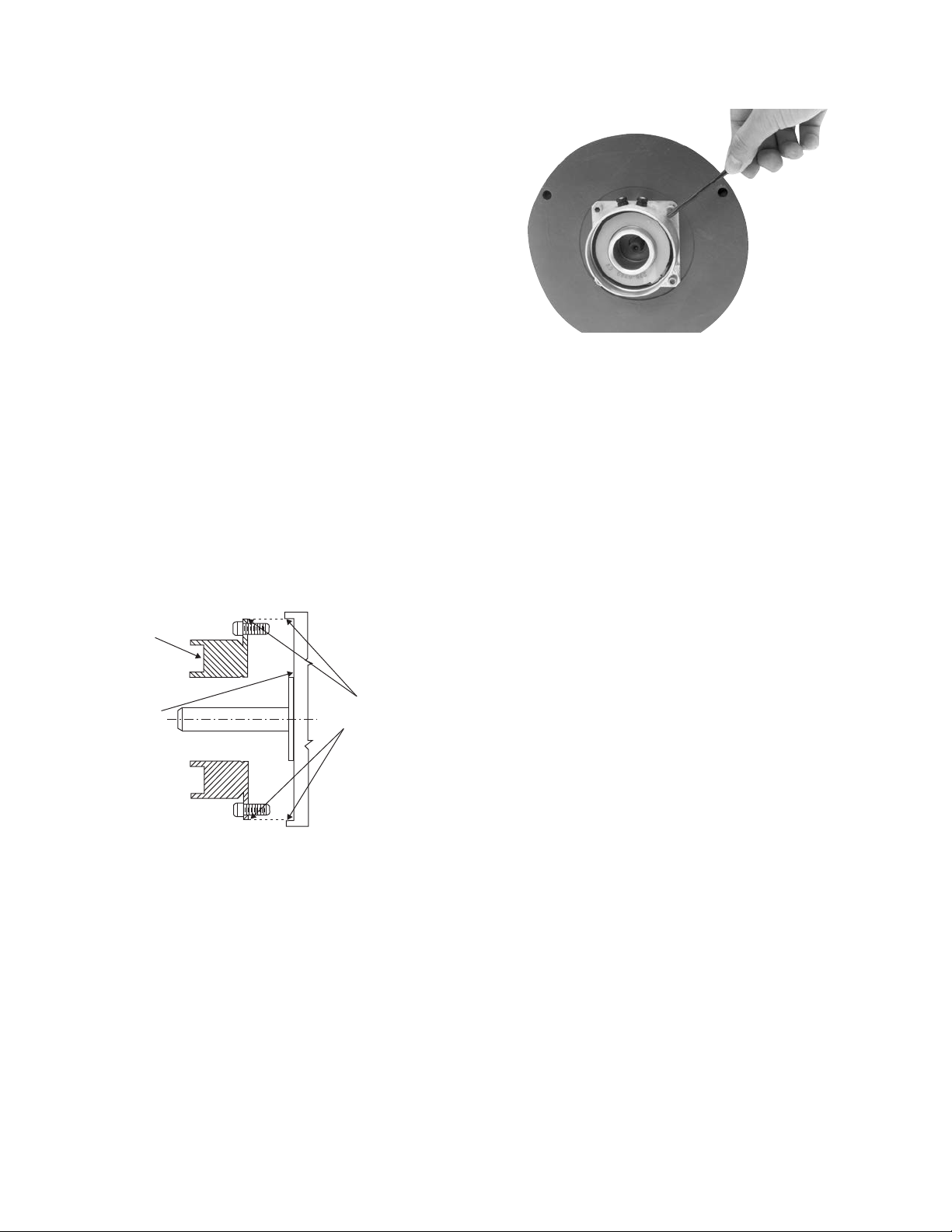

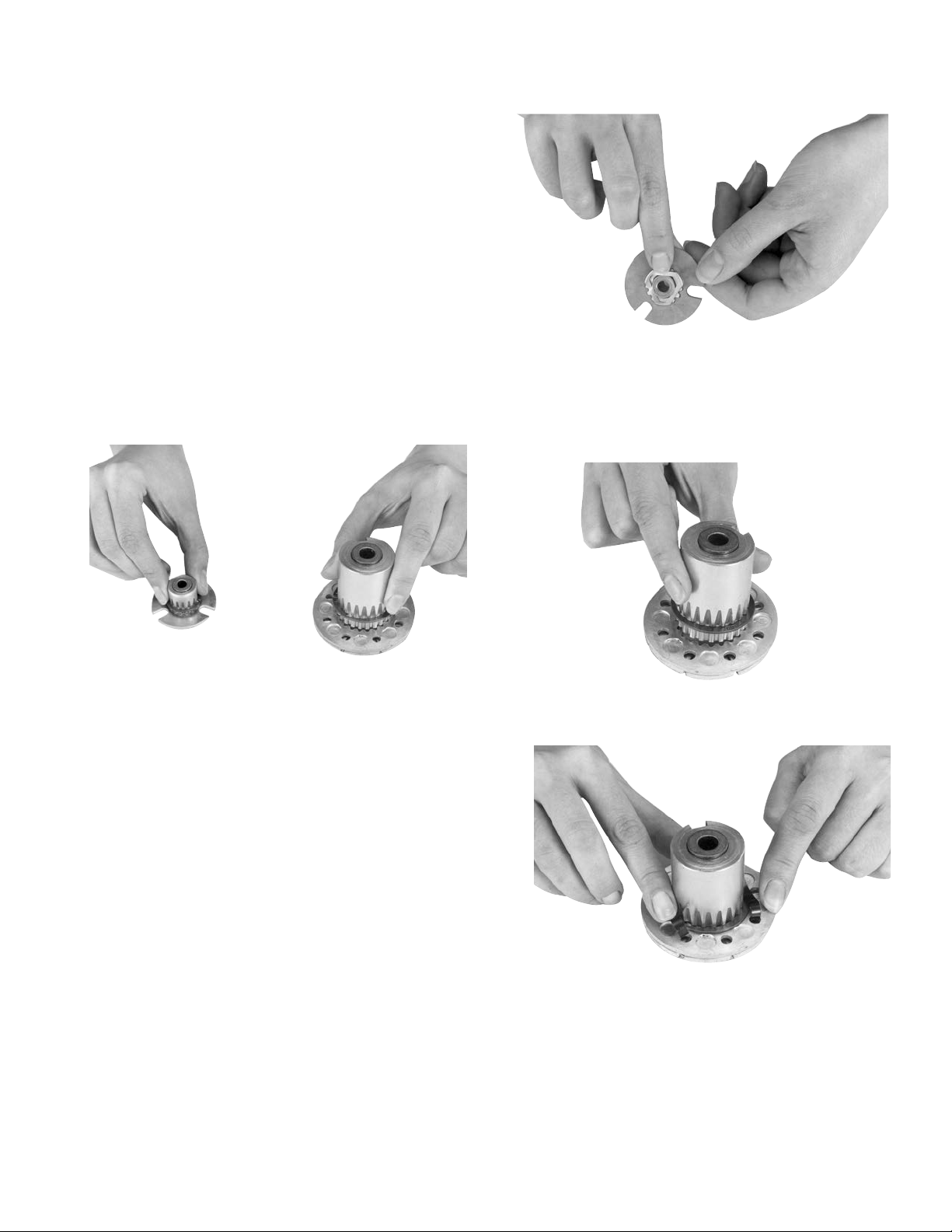

C. Assembling the Armature and Hub

The clutch units contain an extended armature hub

mounted on sleeve bearings. These hubs may be

adapted to a customer-supplied sheave, sprocket,

or gear for transmitting power to a parallel shaft.

1. The antibacklash armatures are shipped

assembled and ready to be installed. See

Section D.

2. The standard armature and hub must be

assembled before it can be installed. Assemble

the armatures so that the shiny surfaces size

(120 and 170) or backing plate sides size (250

and 400) are against the hub retainer ring

(Figure 3).

Figure 4

Insert both release springs into the holes of the

backing plate. Bow the springs as necessary to

insert them into the armature. (See Figure 6)

Figure 3

3. An optional release spring may be used with the

standard armatures and hubs. The release

spring forces the armature back against the hub

retainer ring when the magnet coil is

de-energized.

Follow these instructions to assemble the

armature and hub when the optional release

springs are being used.

SF-170

Assemble the splined armature to the hub. The

shiny side of the armature should be against the

hub retainer ring.

Assemble the release spring into the groove in

the hub spline. The curved portion of the spring

should be against the armature (Figure 4).

SF-250

Insert the hub, with snap ring intact, into the

armature from the backing plate side. (See

Figure 5)

Figure 5

Figure 6

Warner Electric • 800-825-9050 P-200 • 819-0481

5

Page 6

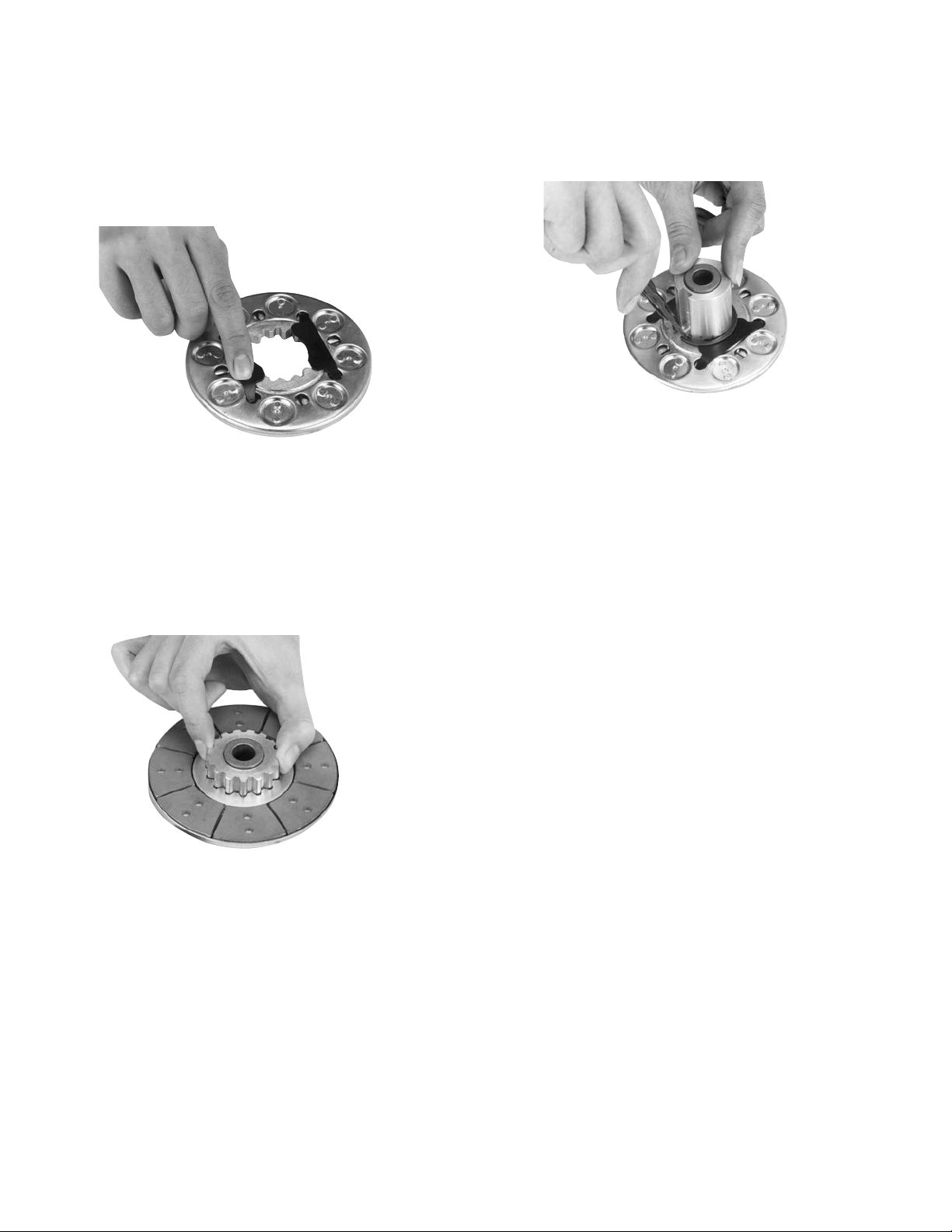

SF-400

Insert the release springs into the backing plate

holes of the armature. Bow the springs as necessary to insert them into the armature. (See

Figure 7)

Assemble the snap ring into the groove in the

hub, clamping the release spring against the

end of the spline. (See Figure 9)

Figure 9

Figure 7

Remove the snap ring from the hub.

Insert the hub, with the setscrew end first, into

the armature from the segmented side. Slide

the hub into the armature until the release

springs engage the snap ring groove. (See

Figure 8)

Figure 8

D. Mounting the Armature Assembly

1. Slide the armature assembly onto the shaft.

Position the assembly in accordance with the

overall axial dimensions given on the illustration

drawings.

2. The armature-hub assembly can be held in this

position with retainer rings, a set collar, a

shoulder on the shaft, or any combination of

these. The hub may need to be repositioned as

wear occurs with time.

Warner Electric • 800-825-9050 P-200 • 819-0481

6

Page 7

Clutch-Coupling SFC-120, SFC-170,

Field

Mounting

Surface

Pilot

Diameters

SFC-250, SFC-400

Installation Instructions

A. Aligning the Shafts

In order for the clutch-coupling unit to operate

properly, the mounting shafts of the motor and

reducer or other hardware must be aligned with

respect to each other before the unit is installed.

The two shafts should be concentric with each

other within .004 T.I.R., and angular alignment

should be within 1/2 degree.

B. Installing the Conduit Box

To install the conduit box on the size 400 units, refer

to the instructions supplied with conduit box.

C. Mounting the Field-and-Rotor Assembly

Flange-Mounted Units

The fields and rotors are shipped separately for

flange-mounted units. On some applications it will

be necessary to mount the rotor first, and then

bring the field into position. In other instances the

field will be mounted first, and then the rotor

(mounted on a shaft) will be inserted into place.

1. Care must be taken in selecting the location for

mounting the field assembly. Pilot diameters are

machined on the field mounting flange to aid in

holding the field in the proper position. (Figure

1)

1. Use a straight-edge to check if the shafts are

aligned with each other. For a more precise

indication of alignment, use a dial indicator.

(Figure 10)

2. Adjust the position of the motor, reducer, or

other hardware as required to achieve the

2. An appropriate pilot diameter must be provided

on the mounting surface as well.

3. The field assembly is then fastened in place

with capscrews and lockwashers. (Figure 2)

Figure 1

correct alignment.

3. To be sure the shafts stay in alignment, drill

holes for tapered dowel pins through the

mounting bases of the motor, reducer, or other

hardware and into the mounting surfaces. This

procedure will ensure that, after the clutchcoupling has been installed, the shafts can

easily be placed in proper alignment again by

lining up the holes and secured by inserting the

dowel pins.

Warner Electric • 800-825-9050 P-200 • 819-0481

Figure 2

7

Page 8

4. After the unit is in place, the mounting face and

pilot diameter must be square and concentric

with the shaft in accordance with the tolerances

listed on the drawings.

5. Insert a key into the shaft keyway.

6. Slide the rotor assembly onto the shaft over the

key.

7. Secure the assembly in this position by

alternately tightening the two setscrews.

8. Position the field and rotor in accordance with

the overall axial dimension shown on the

illustration drawings. Holding this dimension will

assure the proper clearance between the field

and rotor.

Bearing-Mounted Units

In bearing-mounted units, the field and rotor are

shipped as an assembly. Either this assembly or the

armature and hub assembly can be mounted on the

shaft first, depending on the characteristics of each

application.

1. Insert the key into the shaft keyway.

2. Slide the rotor assembly over the key and on to

the shaft.

C. Assembling the Armature and Hub

1. The antibacklash armatures are shipped

assembled and ready to be installed. See

Section D.

2. The standard armature and hub must be

assembled before it can be installed. Assemble

the armatures so that the shiny surfaces size

(120 and 170) or backing plate sides size (250

and 400) are against the hub retainer ring

(Figure 3).

Figure 3

3. An optional release spring may be used with the

standard armatures and hubs. The release

spring forces the armature back against the hub

retainer ring when the magnet coil is

de-energized.

3. Secure the field-and-rotor assembly in place by

alternately tightening the two set screws.

Note: The field-and-rotor assemblies for 120

units and 250 units, 1/2 inch bore,

are held in place by set screws

inserted into a set collar on the end of

the rotor hub extension. Secure the

assembly in place by alternately

tightening the screws.

4. A tab or torque arm on the field is used to

prevent rotation of the field caused by normal

bearing drag. Insert either a pin in the U-slot or

a fork around the torque arm to prevent this

rotation. Under no circumstances, however,

should the field be so tightly restrained as to

preload the bearing.

Follow these instructions to assemble the

armature and hub when the optional release

springs are being used.

Warner Electric • 800-825-9050 P-200 • 819-0481

8

Page 9

SFC-170

Assemble the splined armature to the hub. The

shiny side of the armature should be against the

hub retainer ring.

SFC-400

Insert the release springs into the backing plate

holes of the armature. Bow the springs as

necessary to insert them into the armature. (See

Figure 7)

Assemble the release spring into the groove in the

hub spline. The curved portion of the spring should

be against the armature (Figure 4).

Figure 4

SFC-250

Insert the hub, with snap ring intact, into the

armature from the backing plate side. (See Figure 5)

Remove the snap ring from the hub.

Figure 7

Insert the hub, with the setscrew end first, into the

armature from the segmented side. Slide the hub

into the armature until the release springs engage

the snap ring groove. (See Figure 8.)

Figure 5

Insert both release springs into the holes of the

backing plate. Bow the springs as necessary to

insert them into the armature. (See Figure 6)

Figure 6

Warner Electric • 800-825-9050 P-200 • 819-0481

Assemble the snap ring into the groove in the hub,

clamping the release spring against the end of the

spline. (See Figure 9.)

Figure 8

Figure 9

9

Page 10

D. Mounting the Armature Assembly

1. SFC 250 and 400 size units.

Insert a key in the keyslot of the shaft and slide the

armature assembly onto the shaft.

2. (SFC120 do not use keyway)

Position the assembly to allow a gap of about 1/64

inch between the faces of the armature and magnet.

The overall axial dimension should be in accordance

with the dimensions specified on the illustration

drawings.

3. Secure the assembly in this position by alternately

tightening the two setscrews in the hub.

4. The hub may need to be repositioned as wear

occurs with time.

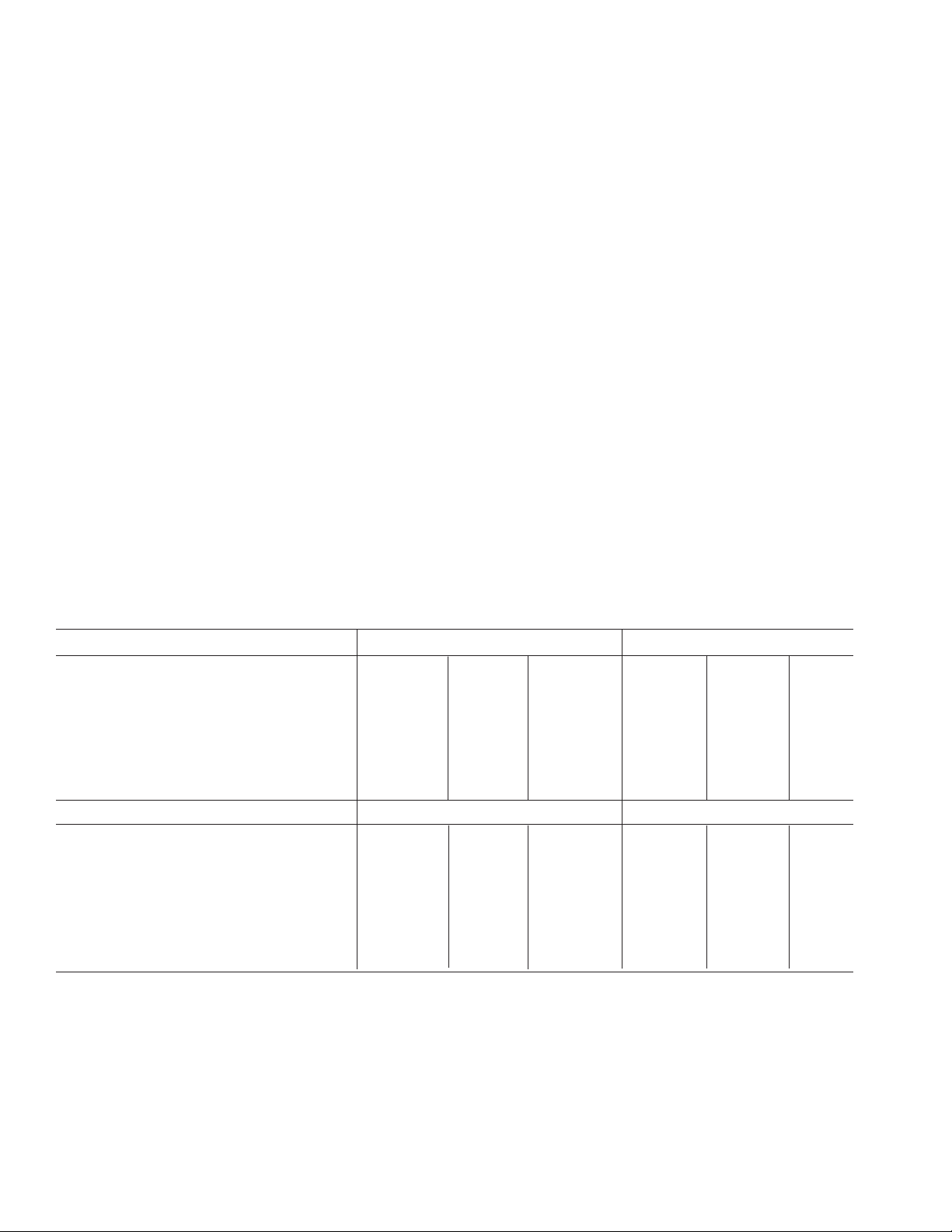

Electrical Coil Data

Unit Size SF/SFC 120 SF/SFC 170

Voltage – DC 6 24 90 6 24 90

Resistance @ 20°C — Ohms 6.32 104 1386 6.96 111.2 1506

Current — Amperes .949 .230 .065 .861 .215 .060

Watts 5.69 5.52 5.85 5.85 5.16 5.37

Coil Build-up — Milliseconds 12 12 11 17 17 16

Coil Decay — Milliseconds 8 878 76

Unit Size SF/SFC 250 SF/SFC 400

Voltage – DC 6 24 90 6 24 90

Resistance @ 20°C — Ohms 5 76.4 1079 4.88 73 1087

Current — Amperes 1.2 .314 .084 1.23 .322 .083

Watts 7.2 7.5 7.51 7.39 7.96 7.45

Coil Build-up — Milliseconds 48 48 44 154 154 154

Coil Decay — Milliseconds 15 15 13 62 60 55

Notes: Build-up time equals current to approximately 90% of steady state value and flux to 90%.

Decay time equals current to approximately 10% of steady state value and flux to 10%.

Approximately because current leads or lags flux by a small amount.

Warner Electric • 800-825-9050 P-200 • 819-0481

10

Page 11

Burnishing and Maintenance

Burnishing

Intimate metal to metal contact is essential between the

armature and the metal rings (poles) of the magnet or

rotor. Warner Electric clutches and brakes leave the

factory with the friction material slightly undercut to assure

good initial contact.

Normally, the desired wearing-in process occurs naturally

as the surfaces slip upon engagement. The time for

wear-in, which is necessary to obtain the ultimate torque

of the unit, will vary depending on speed, load, or cycle

duty.

If maximum torque is required immediately after

installation, the unit should be burnished by slipping the

friction surfaces together at reduced voltage. It is

recommended that the burnishings be done right on the

application, if at all possible.

Burnishing at high speed will result in a smoother wear-in

pattern and reduce the time for burnishing. The voltage

should be set at approximately 30% or 40% of the rated

value.

The unit should be cycled on and off to allow sufficient

time between slip cycles to prevent overheating.

When a Warner Electric brake or clutch is properly

assembled and installed, no further servicing, lubrication,

or maintenance should be required throughout the life of

the unit.

Maintenance

Wear Pattern: Wear grooves appear on the armature and

magnet surfaces. This is a normal wear condition, and

does not impair functioning of the unit. Normally, the

magnet and armature, as a mating pair, will wear at the

same rate. It is the usual recommendation that both components be replaced at the same time.

Heat: Excessive heat and high operating temperatures

are causes of rapid wear. Units, therefore, should be

ventilated as efficiently as possible, especially if the

application requires fast, repetitive cycle operation.

Foreign Materials: If units are used on machinery

where fine, abrasive dust, chips or grit are dispelled into

the atmosphere, shielding of the brake may be

necessary if maximum life is to be obtained.

Where units are used near gear boxes or transmissions

requiring frequent lubrication, means should be provided

to protect the friction surfaces from oil and grease to

prevent serious loss of torque.

Oil and grease accidentally reaching the friction surfaces

may be removed by wiping with a rag dampened with a

suitable cleaner, which leaves no residue. In performing

this operation, do not drench the friction material.

If the friction materials have been saturated with oil or

grease, no amount of cleaning will be completely

effective. Once such a unit has been placed back in

service, heat will cause the oil to boil to the surface,

resulting in further torque loss.

Torque Loss: If a brake or clutch slips or loses torque

completely, the initial check should be the input voltage

to the magnet as follows:

90-Volt Series: Connect a DC voltmeter with a range of

0-100 or more directly across the magnet terminals.

With the power on and the potentiometer turned up, a

normal reading is 90 volts, although 85 to 95 is

satisfactory. The reading should drop as the

potentiometer control is adjusted counterclockwise.

24-Volt Series: Use a DC voltmeter with a range of 030 volts or more. A normal reading is approximately 2226 volts.

Remachining the face of a worn armature is not

recommended. If a replacement armature is to be used

with a used magnet, it is necessary to remachine the worn

magnet face. In refacing a magnet: (1) machine only

enough material to clean up the complete face of the

magnet; (2) hold the face within .005" of parallel with the

mounting plate; and (3) undercut the molded facing

material .001" - .003" below the metal poles.

Warner Electric • 800-825-9050 P-200 • 819-0481

6-Volt Series: Use a DC voltmeter of approximately 015 volt range. A normal reading is from 5.5 to 6.5 volts.

The above checks normally are sufficient. Further

checks may be made as follows: a low range ammeter,

when connected in series with one magnet lead, will

normally indicate approximately .40 amperes for the 90

volt units, 1.0 ampere for the 24 volt, and 3.5 amperes

for the 6 volt series. These readings are with the power

on and the potentiometer control in the maximum

position.

11

Page 12

Ohmmeter checks should be made with the power off

and the circuit open (to be certain, disconnect one lead

to the magnet). Average resistance for the 90 volt series

is 220 ohms; for the 24 volt, 20 ohms; and for the 6 volt

series, 1.5 ohms. A very high or infinite resistance

reading would indicate an open coil.

If the above checks indicate that the proper voltage and

current is being supplied to the magnet, mechanical

parts should be checked to assure that they are in good

operating condition and properly installed.

Warner Electric • 800-825-9050 P-200 • 819-0481

12

Page 13

Warner Electric • 800-825-9050 P-200 • 819-0481

13

Page 14

SF-120 Clutch Flange Mounted

For Bore sizes see

chart below.

Std. Arm.

Antibacklash Arm.

Armature View

For Bore sizes see

chart below.

1.499/1.497

Pilot Dia.

45°

.130/.123 dia.

4 holes equally

spaced on 1.312

dia. B.C.*

1.234

Max. Dia.

.035/.004 (Std.)

.020/.008 (Anti.)

When New

.072 (Std.)

.072 (Anti.)

.020

.000

.375

(Std.)

.502

.031

.500

.515

.511

* Mounting holes are within .006 of true position relative to pilot diameter.

.375

(Anti.)

Std. Arm

Antibacklash Arm

.375

(Std.)

.375

(Anti.)

.528

1.171 Max.

12

*

.072 (Std.)

.072 (Anti.)

.625

.062

.065/.062 dia.

2 holes equally

spaced

.546

Bore Dimensions

.156

.109

.019

.000

#4-40

UNC-3A

.187

Max.

Rotor Armature

Field View

Bore Dia. Bore Dia.

.188/.187 .195/.190

.251/.250 .257/.252

.313/.312 —

Customer Shall Maintain:

1. Squareness of field mounting face with shaft with

.003 T.I.R. measured at pilot diameter.

2. Concentricity of field mounting pilot diameter with

rotor mounting shaft within .003 T.I.R.

Armature Shaft .187 – .250

Rotor Shaft .187 – .312

Static Torque 5 lb. in.

Maximum Speed 3,600 rpm

Standard Voltage D.C. 6, 24, 90

All dimensions are nominal unless otherwise noted.

Warner Electric • 800-825-9050 P-200 • 819-0481

14

Page 15

1B

1A-1

1A-2

1A

2

4

3

SF-120 Clutch Flange Mounted – Outside Mounted Drawing I-25508

Item Description Part Number Qty.

1A Armature and Hub

1A-1 Armature Hub 1

3/16" Bore 5602-541-009

1/4" Bore 5602-541-008

1A-2 Armature 110-0110 1

1B Antibacklash Armature 1

3/16" Bore 5602-111-002

1/4" Bore 5602-111-003

5/16" Bore 5602-111-007

2 Rotor 1

3/16" Bore 5602-751-004

1/4" Bore 5602-751-002

5/16" Bore 5602-751-003

3 Mounting Accessory 5101-101-001 1

4 Field 1

6 Volt 5602-451-003

24 Volt 5602-451-005

90 Volt 5602-451-007

How to Order:

1. Specify Type of Armature Desired.

2. Specify Bore Size for Item 1A-1 or 1B and Item 2.

3. Specify Voltage for Item 4.

Example:

SF-120 Clutch per I-25508 - 90 Volt

Standard Armature

1/4" Armature Hub Bore

1/4" Rotor Bore

These units meet standards set forth in UL508 and are

listed under guide card #NMTR2, file #59164.

These units are CSA certified under file #LR11543.

Warner Electric • 800-825-9050 P-200 • 819-0481

15

Page 16

SF-170 Clutch Flange Mounted

Std. Arm.

Antibacklash

Arm.

For Bore sizes & Keyway

sizes see chart below.

Armature View

For Bore sizes

see chart below.

2.437

2.435

45°

Pilot

Dia.

1.718

Max. Dia.

.484 (Std.)

.390 (Anti.)

When New

.035/.004 (Std.)

.021/.009 (Anti.)

.031

.751

.750

.633

.629

.086 (Std.)

.094 (Anti.)

.484

(Std.)

.390

(Anti.)

Std. Arm

Anti. Arm

.086

(Std.)

.094

(Anti.)

.632

.040

.000

*

1.703 Max.

12

.035/.004

.021/.009

.187

.750

.375

.062

.751/.750

pilot dia.

backing plate

only

#8-32

UNC-3A

.437

Max.

1

.160

.150

.204/.187 dia. 4 holes

equally spaced on

2.125 diameter.

Mounting holes are

1.812

within .010 of true position relative to pilot

diameter.

Field View

Customer Shall Maintain:

1. Squareness of field mounting face with shaft with

.003 T.I.R. measured at pilot diameter.

2. Concentricity of field mounting pilot diameter with

rotor mounting shaft within .003 T.I.R.

*Diameter over knurl.

Rotor Bore Dimensions

Rotor Keyway Armature

Bore Dia. Bore Dia.

.251/.250 .062/.031 .2522/.2507

.313/.312 .062/.031 .3145/.3130

.376/.375 .093/.047 .3773/.3755

Armature Shaft .250 – .375

Rotor Shaft .250 – .375

Static Torque 15 lb.in.

Maximum Speed 5,000 rpm

Standard Voltage D.C. 6, 24, 90

All dimensions are nominal unless otherwise noted.

Warner Electric • 800-825-9050 P-200 • 819-0481

16

Page 17

1A

1A-1

1A-2

1A-3

2

4

3

1B

SF-170 Clutch Flange Mounted – Outside Mounted Drawing I-25754

Item Description Part Number Qty.

1A Armature and Hub

1A-1 Armature Hub 1

1/4" Bore 5123-541-002

5/16" Bore 5123-541-003

3/8" Bore 5123-541-004

1A-2 Armature 110-0111 1

1A-3 Release Spring 808-0019 1

1B Antibacklash Armature 1

1/4" Bore 5603-111-033

5/16" Bore 5603-111-034

3/8" Bore 5603-111-035

2 Rotor 1

1/4" Bore 5603-751-028

5/16" Bore 5603-751-029

3/8" Bore 5603-751-030

3 Mounting Accessory 5102-101-001 1

4 Field 1

6 Volt 5603-451-047

24 Volt 5603-451-049

90 Volt 5603-451-051

How to Order:

1. Specify Type of Armature Desired.

2. Specify Bore Size for Item 1A-1 or 1B and Item 2.

3. Specify Voltage for Item 4.

Example:

SF-170 Clutch per I-25754 - 90 Volt

Antibacklash Armature

1/4" Armature Hub Bore

1/4" Rotor Bore

These units meet standards set forth in UL508 and are

listed under guide card #NMTR2, file #59164.

These units are CSA certified under file #LR11543.

Warner Electric • 800-825-9050 P-200 • 819-0481

17

Page 18

SF-120 Clutch Bearing Mounted

.156

Std. Arm.

Antibacklash

Arm.

For Bore sizes

see chart below.

.562

Armature View

.562

For Bore sizes

see chart below.

.125

45°

1.234

Max. Dia.

.502

.500

.515

.511

.031

.035/.004 (Std.)

When New

*Customer shall maintain dimension as noted.

.020/.008 (Anti.)

.072 (Std.)

.072 (Anti.)

.375

(Std.)

.375

(Anti.)

Std. Arm

Antibacklash Arm

.375

(Std.)

.375

(Anti.)

.072 (Std.)

.072 (Anti.)

.528

Max.

.020

12

.000

*

.035/.004 (Std.)

.020/.008 (Anti.)

1.406 Max.

.781

.859

.062

.218

.687

.093

Field View

.578

Bore Dimensions

.703

Rotor Armature

Bore Dia. Bore Dia.

.188/.187 .195/.190

.251/.250 .257/.252

.313/.312 —

Armature Shaft .187 – .250

Rotor Shaft .187 – .250

Static Torque 5 lb.in.

Maximum Speed 3,600 rpm

Standard Voltage D.C. 6, 24, 90

All dimensions are nominal unless otherwise noted.

Warner Electric • 800-825-9050 P-200 • 819-0481

18

Page 19

1B

1A-1

1A-2

2

3

4

1A

SF-120 Clutch Bearing Mounted Drawing I-25509

Item Description Part Number Qty.

1A Armature and Hub

1A-1 Armature Hub 1

3/16" Bore 5602-541-009

1/4" Bore 5602-541-008

1A-2 Armature 110-0110 1

1B Antibacklash Armature 1

3/16" Bore 5602-111-002

1/4" Bore 5602-111-003

5/16" Bore 5602-111-007

2 Rotor 1

3/16" Bore 5602-751-008

1/4" Bore 5602-751-006

5/16" Bore 5602-751-007

3 Field 1

4 Set Collar 5602-266-001 1

6 Volt 5602-451-021

24 Volt 5602-451-023

90 Volt 5602-451-025

How to Order:

1. Specify Type of Armature Desired.

2. Specify Bore Size for Item 1A-1 or 1B and Item 2.

3. Specify Voltage for Item 3.

Example:

SF-120 Clutch per I-25509 - 90 Volt

Standard Armature

1/4" Armature Hub Bore

These units meet standards set forth in UL508 and are

listed under guide card #NMTR2, file #59164.

These units are CSA certified under file #LR11543.

Warner Electric • 800-825-9050 P-200 • 819-0481

19

Page 20

SF-170 Clutch Bearing Mounted

Std. Arm.

Antibacklash

Arm.

For Bore sizes see

chart below.

Armature View

.187

.500

For Bore sizes

see chart below.

1.718

Max.

Dia.

.035/.004 (Std.)

.021/.009 (Anti.)

When New

.031

.751

.750

.633

†

.629

.086 (Std.)

.094 (Anti.)

.040/.000

.484

(Std.)

.390

(Anti.)

Std. Arm.

Anti. Arm.

.484

(Std.)

.390

(Anti.)

.632

Max.

1.203

12

.37

5

.062

*

.093

.625

.086 (Std.)

.094 (Anti.)

1.093

.250

1.062

1.750 Max. Dia.

Field View

Customer Shall Maintain:

*Customer shall maintain dimension as noted.

1.906 Max.

1.375

Bore Dimensions

Rotor Armature

Bore Dia. Bore Dia.

.251/.250 .2522/.2507

.313/.312 .3145/.3130

.376/.375 .3773/.3755

Armature Shaft .187 – .250

Rotor Shaft .250 – .375

Static Torque 15 lb.in.

Maximum Speed 5,000 rpm

Standard Voltage D.C. 6, 24, 90

† over knurl

Warner Electric • 800-825-9050 P-200 • 819-0481

20

All dimensions are nominal unless otherwise noted.

Page 21

1A

1A-1

1A-2

1A-3

2

3

4

1B

SF-170 Clutch Bearing Mounted Drawing I-25755

Item Description Part Number Qty.

1A Armature and Hub

1A-1 Armature Hub 1

1/4" Bore 5123-541-002

5/16" Bore 5123-541-003

3/8" Bore 5123-541-004

1A-2 Armature 110-0111 1

1A-3 Release Spring `808-0019 1

1B Antibacklash Armature 1

1/4" Bore 5603-111-033

5/16" Bore 5603-111-034

3/8" Bore 5603-111-035

2 Rotor 1

1/4" Bore 5603-751-019

5/16" Bore 5603-751-021

3/8" Bore 5603-751-020

3 Field 1

6 Volt 5603-451-039

24 Volt 5603-451-041

90 Volt 5603-451-043

4 Retainer Ring 748-0024 1

How to Order:

1. Specify Type of Armature Desired.

2. Specify Bore Size for Item 1A-1 or 1B and Item 2.

3. Specify Voltage for Item 3.

Example:

SF-170 Clutch per I-25755 - 90 Volt

Antibacklash Armature

1/4" Armature Hub Bore

These units meet standards set forth in UL508 and are

listed under guide card #NMTR2, file #59164.

These units are CSA certified under file #LR11543.

Warner Electric • 800-825-9050 P-200 • 819-0481

21

Page 22

SF-250 Clutch Flange Mounted

For Bore & Keyway sizes

see chart below.

For Bore & Keyway

sizes see chart

below.

.437

Armature View

24°

12°

.437

2.625

Max. Dia.

1.376

1.375

Dia.

.062

.750

Dia.

.135

.095

.750

1.250

1.125

*

.343 Max.

.015 When New

1.453 Min.

2

3.281 Max.

*Customer shall maintain dimension as noted.

.171

.468

.380/.370

.062

1.063

1.061

Pilot

Dia.

8-32 UNC-

3A

.437

Max.

45°

3.500

3.498

Pilot Dia.

*Mounting holes are within .010 of true position relative to pilot diameter.

Field View

.204/.187 dia. (4) holes

equally spaced on 3.125

dia.*

Customer Shall Maintain:

1. Squareness of field mounting face with shaft within

.003 T.I.R. measured at pilot diameter.

2. Concentricity of field mounting pilot diameter with

rotor mounting shaft within .003 T.I.R.

Bore and Keyway Dimensions

2.625 Sq.

Armature Keyway Rotor Keyway

Bore Dia. Bore Dia.

.3750/.3745 .376/.375 .093 x .046

.5000/.4995 .312 x .156 *.438/.437 .125 x .031

*.5625/.5620 x 1.250 .501/.500 .125 x .031

.6250/.6245

*Available on special order only.

Armature Shaft .375 – .625

Rotor Shaft .375 – .500

Static Torque 70 lb.in.

Maximum Speed 7,500 rpm

Standard Voltage D.C. 6, 24, 90

All dimensions are nominal unless otherwise noted.

Warner Electric • 800-825-9050 P-200 • 819-0481

22

Page 23

1

3

2

4

5

5-1

6

SF-250 Clutch Flange Mounted – Outside Mounted Drawing I-25520

Item Description Part Number Qty.

1 Armature Hub 1

3/8" Bore 5124-541-002

1/2" Bore 5124-541-003

5/8" Bore 5124-541-005

2 Armature 5124-111-001 1

3 Release Spring 5103-101-003 1

4 Rotor 1

3/8" Bore 5103-751-008

1/2" Bore 5103-751-010

5 Field 1

6 Volt 5103-451-002

24 Volt 5103-451-004

90 Volt 5103-451-007

5-1 Terminal Accessory 5103-101-002 1

6 Mounting Accessory 5102-101-001 1

How to Order:

1. Specify Bore Size for Item 1 and Item 4.

2. Specify Voltage for Item 5.

Example:

SF-250 Clutch per I-25520 - 90 Volt

3/8" Armature Hub Bore

3/8" Rotor Bore

These units meet standards set forth in UL508 and are

listed under guide card #NMTR2, file #59164.

These units are CSA certified under file #LR11543.

Warner Electric • 800-825-9050 P-200 • 819-0481

23

Page 24

SF-400 Clutch Flange Mounted

For Bore & Keyway

sizes see chart below.

Removable plug

in ends for 1/2"

conduit.

For Bore &

Keyway

sizes see

chart

below.

Armature View

3.750

4.687 Max.

4.234

Max. Dia.

1.376

1.375

Dia.

.062

.015 When New

.875

Dia.

.328 Max.

1.468

Min.

2.125

3.546 Max.

1.546

.082

.042

1.125

1.312

.192/.182

1.500

*

.937

3.562

.250

1.875

1.873

Pilot Dia.

1/4-20 UNC-

3A

.093

.609 Max.

5.625

5.623

Pilot

Dia.

.296/.280 dia. (4) holes equally spaced on

5.000 dia. Mounting holes are within .010 of

true position relative to pilot diameter.

45°

Field View

Customer Shall Maintain:

1. Squareness of field mounting face with shaft within

.003 T.I.R. measured at pilot diameter.

2. Concentricity of field mounting pilot diameter with

rotor mounting shaft within .003 T.I.R.

*3. Customer shall maintain dimension as noted.

4.250

Sq.

Bore and Keyway Dimensions

Armature Keyway Rotor Keyway

Bore Dia. Bore Dia.

.5000/.4995 .312 x .156 .501/.500 .125 x.062

.6250/.6245 x 1.25 .626/.625

.7500/.7495 .751/.750 .187 x .093

Armature Shaft .500 – .750

Rotor Shaft .500 – 1

Static Torque 270 lb.in.

Maximum Speed 4,500 rpm

Standard Voltage D.C. 6, 24, 90

All dimensions are nominal unless otherwise noted.

Warner Electric • 800-825-9050 P-200 • 819-0481

24

Page 25

1

3

2

4

5

5-1

6

7

SF-400 Clutch Flange Mounted – Outside Mounted Drawing I-25695

Item Description Part Number Qty.

1 Armature Hub 1

1/2" Bore 5125-541-002

5/8" Bore 5125-541-003

3/4" Bore 5125-541-004

2 Armature 5125-111-001 1

3 Release Spring 5104-101-003 1

4 Rotor 1

1/2" Bore 5104-751-033

5/8" Bore 5104-751-034

3/4" Bore 5104-751-035

7/8" Bore 5104-751-036

1" Bore 5104-751-037

5 Field 1

6 Volt 5104-451-032

24 Volt 5104-451-033

90 Volt 5104-451-034

5-1 Terminal Accessory 5103-101-002 1

6 Conduit Box 5200-101-010 1

7 Mounting Accessory 5104-101-002 1

How to Order:

1. Specify Bore Size for Items 1 and 4.

2. Specify Voltage for Item 5.

Example:

SF-400 Clutch per I-25695 - 90 Volt

3/4" Armature Hub Bore

3/4" Rotor Bore

These units, when used in conjunction with the correct

Warner Electric conduit box, meet the standards set of

UL508 and are listed under guide card #NMTR2, file

#59164.

These units are CSA certified under file #LR11543

Warner Electric • 800-825-9050 P-200 • 819-0481

25

Page 26

SF-250 Clutch Bearing Mounted

For Bore & Keyway sizes

see chart below.

Armature View

2.625

Max. Dia.

1.376

1.375

Dia.

.062

.343 Max.

.015 When New

.750

Dia.

1.453 Min.

2

3.468 Max.

*Customer shall maintain dimension as noted.

.125

.085

1.437

1.125

*

1.312

.468

.171 + .062

- 0

.062

.609

Dia.

.171

.187

.187

.937

For Bore & Keyway

sizes see chart

below.

45°

.500

.437

1.562

Rad.

Field View

24°

12°

1.750

Max.

Bore and Keyway Dimensions

Armature Keyway Rotor Keyway

Bore Dia. Bore Dia.

.3750/.3745 .376/.375 .093 x .046

.5000/.4995 .312 x .156 .438/.437* .125 x .062

.5625/.5620* x 1.25 .501/.500 .125 x .062

.6250/.6245

* Available on special order only.

Armature Shaft .375 – .625

Rotor Shaft .375 – .500

Static Torque 70 lb.in.

Maximum Speed 7,500 rpm

Standard Voltage D.C. 6, 24, 90

All dimensions are nominal unless otherwise noted.

Warner Electric • 800-825-9050 P-200 • 819-0481

26

Page 27

1

2

3

4

(Shipped Assembled)

4-1

4-2

4-3

4-2

4-4

4-4-1

4-5

SF-250 Clutch Bearing Mounted Drawing I-25521

Item Description Part Number Qty.

1 Armature Hub 1

3/8" Bore 5124-541-002

1/2" Bore 5124-541-003

5/8" Bore 5124-541-005

2 Release Spring 5103-101-003 1

3 Armature 5124-111-001 1

4 Field and Rotor Assembly 1

6 Volt – 3/8" Bore 5103-452-002

24 Volt – 3/8" Bore 5103-452-004

90 Volt – 3/8" Bore 5103-452-007

6 Volt – 1/2" Bore 5103-452-016

24 Volt – 1/2" Bore 5103-452-018

90 Volt – 1/2" Bore 5103-452-021

4-1 Rotor 1

3/8" Bore 5103-751-014

1/2" Bore 5103-751-016

4-2 Retainer Ring 748-0371 2

4-3 Ball Bearing 166-0108 1

4-4 Field 1

6 Volt 5103-451-018

24 Volt 5103-451-020

90 Volt 5103-451-023

4-4-1 Terminal Accessory 5103-101-002 1

4-5* Set Collar 266-0005 1

*Used with 1/2" Bore only.

How to Order:

1. Specify Bore Size for Item 1 and Item 4.

2. Specify Voltage for Item 4.

Example:

SF-250 Clutch per I-25521 - 90 Volt

1/2" Armature Hub Bore

1/2" Rotor Bore

These units meet standards set forth in UL508 and are

listed under guide card #NMTR2, file #59164.

These units are CSA certified under file #LR11543.

Warner Electric • 800-825-9050 P-200 • 819-0481

27

Page 28

SF-400 Clutch Bearing Mounted

For Bore & Keyway

sizes see chart below.

45°

.500

.187

Dia.

.187

.859

Armature View

3.750

2.312 Rad.

Removable plug

in ends for 1/2"

conduit.

4.687

Max.

1.546

1.218

.015 When New

4.234

1.376

1.375

Dia.

.062

.875

Dia.

1.468

Min.

.328 Max.

2.125

3.859 Max.

.090

.050

1.281

1.812

1.625

*

Max.

Dia.

For Bore &

Keyway sizes

see chart

below.

Bore and Keyway Dimensions

Armature Keyway Rotor Keyway

Bore Dia. Bore Dia.

.501/.500 .125 x.062

.5000/.4995 .312 x .156 .626/.625

.6250/.6245 x 1.25 .751/.750 .187 x .093

.7500/.7495 .876/.875

1.001/1.000

.062

3.562

1.375

Dia.

.203

.328

Armature .500 – .750

Field View

*Customer shall maintain dimension as noted.

Rotor Shaft .500 – 1

Static Torque 270 lb.in.

Maximum Speed 4,500 rpm

Standard Voltage D.C. 6, 24, 90

All dimensions are nominal unless otherwise

noted.

Warner Electric • 800-825-9050 P-200 • 819-0481

28

Page 29

1

2

3

4-1

4-3

4-4

4-4-1

4-2

5

4

(Shipped Assembled)

SF-400 Clutch Bearing Mounted Drawing I-25696

Item Description Part Number Qty.

1 Armature Hub 1

1/2" Bore 5125-541-002

5/8" Bore 5125-541-003

3/4" Bore 5125-541-004

2 Release Spring 5104-101-003 1

3 Armature 5125-111-001 1

4 Field and Rotor Assembly 1

6 Volt – 1/2" Bore 5104-452-052

24 Volt – 1/2" Bore 5104-452-053

90 Volt – 1/2" Bore 5104-452-054

6 Volt – 5/8" Bore 5104-452-055

24 Volt – 5/8" Bore 5104-452-056

90 Volt – 5/8" Bore 5104-452-057

6 Volt – 3/4" Bore 5104-452-058

24 Volt – 3/4" Bore 5104-452-059

90 Volt – 3/4" Bore 5104-452-060

4-1 Rotor 1

1/2" Bore 5104-751-043

5/8" Bore 5104-751-044

3/4" Bore 5104-751-045

4-2 Retainer Ring 748-0018 1

4-3 Ball Bearing 166-0150 1

4-4 Field 1

4-4-1 Terminal Accessory 5103-101-002 1

5 Conduit Box 5200-101-010 1

6 Volt 5104-451-038

24 Volt 5104-451-039

90 Volt 5104-451-040

How to Order:

1. Specify Bore Size for Items 1 and 4.

2. Specify Voltage for Item 4.

Example:

SF-400 Clutch per I-25696 - 90 Volt

3/4" Armature Hub Bore

3/4" Rotor Bore

These units, when used in conjunction with the correct

Warner Electric conduit box, meet standards set forth in

UL508 and are listed under guide card #NMTR2, file

#59164.

These units are CSA certified under file #LR11543

Warner Electric • 800-825-9050 P-200 • 819-0481

29

Page 30

SFC-120 Clutch Coupling Flange Mounted

Std. Arm.

Antibacklash

Arm.

For Bore sizes

see chart below.

Armature View

For Bore sizes

see chart below.

1.499/1.497

Pilot Dia.

1.234

Max.

Dia.

.015 When New

.072 (Std.)

.072 (Anti.)

.109 (Std.)

.140 (Anti.)

.500

Std. Arm

Antibacklash Arm.

.562

.072

(Std.)

.072

(Anti.)

.015

.343

12 Min.

.968 (Std.)

.968 (Anti.)

.546

.625

.156

.062

.109

.063/.062 dia.

(2) holes

equally

spaced.

.019

.000

#4-40 UNC-

.187

Max.

3A

45°

.130/.123 dia. (4)

holes equally

spaced on 1.312

dia. Mounting

holes are within

.006 of true position relative to pilot

diameter.

1.140 Max. Sq.

Field View

Customer Shall Maintain:

1. Squareness of field mounting face with rotor

shaft within .003 T.I.R. measured at pilot diameter.

2. Concentricity of field mounting pilot diameter

with rotor mounting shaft within .003 T.I.R.

3. Rotor and armature shafts in line within .003 T.I.R.

Bore Dimensions

Rotor Armature

Bore Dia. Bore Dia.

.188/.187 .188/.187

.251/.250 .251/.250

.313/.312 (.313/.312)*

*(Antibacklash Armatures)

Armature Shaft .187 – .250

Rotor Shaft .187 – .312

Static Torque 5 lb. in.

Maximum Speed 3,600 rpm

Standard Voltage D.C. 6, 24, 90

All dimensions are nominal unless otherwise noted.

Warner Electric • 800-825-9050 P-200 • 819-0481

30

Page 31

1B

1A-1

1A-2

2

4

1A

3

SFC-120 Clutch Coupling Flange Mounted – Outside Mounted Drawing I-25503

Item Description Part Number Qty.

1A Armature and Hub

1A-1 Armature Hub 1

1A-2 Armature 110-0110 1

1B Antibacklash Armature 1

2 Rotor 1

3 Mounting Accessory 5101-101-001 1

4 Field 1

3/16" Bore 5622-541-009

1/4" Bore 5622-541-008

3/16" Bore 5622-111-004

1/4" Bore 5622-111-002

5/16" Bore 5622-111-003

3/16" Bore 5602-751-004

1/4" Bore 5602-751-002

5/16" Bore 5602-751-003

6 Volt 5602-451-003

24 Volt 5602-451-005

90 Volt 5602-451-007

How to Order:

1. Specify Type of Armature Desired.

2. Specify Bore Size for Item 1A-1 or 1B and Item 2.

3. Specify Voltage for Item 4.

Example:

SFC-120 Clutch per I-25503 - 90 Volt

Standard Armature

1/4" Armature Hub Bore

1/4" Rotor Bore

These units meet standards set forth in UL508 and are

listed under guide card #NMTR2, file #59164.

These units are CSA certified under file #LR11543.

Warner Electric • 800-825-9050 P-200 • 819-0481

31

Page 32

SFC-170 Clutch Coupling Flange Mounted

.375

.015 When New

Std. Arm.

Antibacklash

Arm.

For Bore & Keyway sizes

see chart below.

Armature View

For Bore sizes

see chart

below.

2.437

2.435

Dia.

45°

1.718

Max.

Dia.

.125 (Std.)

.109 (Anti.)

.625

(Std.)

(Anti.)

.086 (Std.)

.094 (Anti.)

.086 (Std.)

.094 (Anti.)

.843

.515

Max.

12

.015

1.375 (Std.)

1.359 (Anti.)

.187

.750

.062

.752

.750

Pilot Dia.

Backing Plate Only

#8-32

UNC-3A

.437

Max.

.160/.150

.204/.187 dia.

(4) holes

equally spaced

on 2.125 dia.

Mounting holes

are within .010

of true position

relative to pilot

diameter.

1.812 Max. Sq.

Field View

Customer Shall Maintain:

1. Squareness of field mounting face with

rotor shaft within .003 T.I.R. measured at pilot

diameter.

2. Concentricity of field mounting pilot diameter

with rotor mounting shaft within .003 T.I.R.

3. Rotor and armature shafts in line within .003 T.I.R.

Bore Dimensions

Rotor Armature

Bore Dia. Keyway Bore Dia.

.251/.250 .062 x .031 .251/.250

.313/.312 .062 x .031 .313/.312

.376/.375 .093 x .046 .376/.375

Armature Shaft .250 – .375

Rotor Shaft .250 – .375

Static Torque 15 lb. in.

Maximum Speed 5,000 rpm

Standard Voltage D.C. 6, 24, 90

All dimensions are nominal unless otherwise noted.

Warner Electric • 800-825-9050 P-200 • 819-0481

32

Page 33

1A-1

1A

1A-2

1A-3

1B

3

2

4

SFC-170 Clutch Coupling Flange Mounted – Outside Mounted Drawing I-25756

Item Description Part Number Qty.

1A Armature and Hub

1A-1 Armature Hub 1

1/4" Bore 5102-541-002

5/16" Bore 5102-541-003

3/8" Bore 5102-541-004

1A-2 Armature 110-0111 1

1A-3 Release Spring 808-0019 1

1B Antibacklash Armature 1

1/4" Bore 5623-111-008

5/16" Bore 5623-111-009

3/8" Bore 5623-111-010

2 Rotor 1

1/4" Bore 5603-751-028

5/16" Bore 5603-751-029

3/8" Bore 5603-751-030

3 Mounting Accessory 5102-101-001 1

4 Field 1

6 Volt 5603-451-047

24 Volt 5603-451-049

90 Volt 5603-451-051

How to Order:

1. Specify Type of Armature Desired.

2. Specify Bore Size for Item 1A-1 or 1B and Item 2.

3. Specify Voltage for Item 4.

Example:

SFC-170 Clutch per I-25756 - 90 Volt

Antibacklash Armature

1/4" Armature Hub Bore

1/4" Rotor Bore

These units meet standards set forth in UL508 and are

listed under guide card #NMTR2, file #59164.

These units are CSA certified under file #LR11543.

Warner Electric • 800-825-9050 P-200 • 819-0481

33

Page 34

SFC-120 Clutch Coupling Bearing Mounted

.015 When New

.072 (Std.)

.072 (Anti.)

.156

.062

12

.218

Std. Arm.

Antibacklash

Arm.

For Bore sizes

see chart below.

Armature View

.562

For Bore

sizes

see chart

below.

.125

45°

.109 (Std.)

.140 (Anti.)

.500

(Std.)

1.234

Max.

Dia.

.562

(Anti.)

.072 (Std.)

.072 (Anti.)

.015

Bore Dimensions

Rotor Armature

Bore Dia. Bore Dia.

.188/.187 .188/.187

.251/.250 .251/.250

.313/.312 (.313/.312)*

.781

.859

1.203 Max.

.093

.687

Dia.

*(Antibacklash Armatures)

.578

.703

Armature Shaft .187 – .250

Field View

Rotor Shaft .187 – .312

Static Torque 5 lb. in.

Maximum Speed 3,600 rpm

Customer Shall Maintain:

1. Alignment between rotor and armature shafts to be

.003 T.I.R.

Warner Electric • 800-825-9050 P-200 • 819-0481

34

Standard Voltage D.C. 6, 24, 90

All dimensions are nominal unless otherwise noted.

Page 35

1B

1A-1

2

1A-2

1A

3

4

SFC-120 Clutch Coupling Bearing Mounted Drawing I-25504

Item Description Part Number Qty.

1A Armature and Hub

1A-1 Armature Hub 1

3/16" Bore 5622-541-009

1/4" Bore 5622-541-008

1A-2 Armature 110-0110 1

1B Antibacklash Armature 1

2 Rotor 1

3 Field 1

4 Set Collar 5602-266-001 1

3/16" Bore 5622-111-004

1/4" Bore 5622-111-002

5/16" Bore 5622-111-003

3/16" Bore 5602-751-008

1/4" Bore 5602-751-006

5/16" Bore 5602-751-007

6 Volt 5602-451-021

24 Volt 5602-451-023

90 Volt 5602-451-025

How to Order:

1. Specify Type of Armature Desired.

2. Specify Bore Size for Item 1A-1 or 1B and Item 2.

3. Specify Voltage for Item 3.

Example:

SFC-120 Clutch per I-25504 - 90 Volt

Standard Armature

1/4" Armature Hub Bore

These units meet standards set forth in UL508 and are

listed under guide card #NMTR2, file #59164.

These units are CSA certified under file #LR11543.

Warner Electric • 800-825-9050 P-200 • 819-0481

35

Page 36

SFC-170 Clutch Coupling Bearing Mounted

.375

Std. Arm.

Antibacklash

Arm.

Armature View

1.87

.500

For Bore sizes

see chart below.

1.718

Max.

Dia.

.086 (Std.)

.094 (Anti.)

.015 When New

.125 (Std.)

.109 (Anti.)

.625

(Std.)

.843

(Anti.)

12

.015

.086 (Std.)

.094 (Anti.)

1.562 Max.

1.093

1.203

.062

.093

.625

Dia.

.250

For Bore sizes

see chart below.

1.375

1.062

1.750 Max. Dia.

Field View

Customer Shall Maintain:

1. Alignment between rotor and armature shafts to be

.003 T.I.R.

Bore Dimensions

Rotor Armature

Bore Dia. Bore Dia.

.251/.250 .251/.250

.313/.312 .313/.312

.376/.375 .376/.375

Armature Shaft .250 – .375

Rotor Shaft .250 – .375

Static Torque 15 lb. in.

Maximum Speed 5,000 rpm

Standard Voltage D.C. 6, 24, 90

All dimensions are nominal unless otherwise noted.

Warner Electric • 800-825-9050 P-200 • 819-0481

36

Page 37

1A

1A-1

1A-2

1B

1A-3

2

3

4

SFC-170 Clutch Coupling Bearing Mounted Drawing I-25757

Item Description Part Number Qty.

1A Armature and Hub

1A-1 Armature Hub 1

1/4" Bore 5102-541-002

5/16" Bore 5102-541-003

3/8" Bore 5102-541-004

1A-2 Armature 110-0111 1

1A-3 Release Spring 808-0019 1

1B Antibacklash Armature 1

1/4" Bore 5623-111-008

5/16" Bore 5623-111-009

3/8" Bore 5623-111-010

2 Rotor 1

1/4" Bore 5603-751-019

5/16" Bore 5603-751-021

3/8" Bore 5603-751-020

3 Field 1

6 Volt 5603-451-039

24 Volt 5603-451-041

90 Volt 5603-451-043

4 Retainer Ring 748-0024 1

How to Order:

1. Specify Type of Armature Desired.

2. Specify Bore Size for Item 1A-1 or 1B and Item 2.

3. Specify Voltage for Item 3.

Example:

SFC-170 Clutch per I-25757 - 90 Volt

Antibacklash Armature

1/4" Armature Hub Bore

These units meet standards set forth in UL508 and are

listed under guide card #NMTR2, file #59164.

These units are CSA certified under file #LR11543.

Warner Electric • 800-825-9050 P-200 • 819-0481

37

Page 38

SFC-250 Clutch Coupling Flange Mounted

For Bore & Keyway sizes

see chart below.

Std. Arm.

Antibacklash

Arm.

For Bore & Key-

way sizes see

chart below.

.437 Max.

Armature View

24°

12°

.437 Max.

2.625

Max.

Dia.

.015 When New

.171 (Std.)

.562 (Anti.)

1.187

(Std.)

1.390

(Anti.)

.171

Max.

.015

.687

.546

.343

Max.

.171

.750

1.968 (Std.)

1.984 (Anti.)

1.125

1.250

.468

.062

.380/.370

1.063

1.061

Pilot Dia.

Backing Plate

Only

8-32 UNC3A

.437

Max.

45°

3.500/3.498

Pilot Dia.

.204/.187 dia. (4) holes equally spaced on

3.125 dia. Mounting holes are within .010 of

true position relative to pilot diameter.

Field View

Customer Shall Maintain:

1. Squareness of field mounting face with rotor shaft

within .003 T.I.R. measured at pilot diameter.

2. Concentricity of field mounting pilot diameter with

rotor mounting shaft within .003 T.I.R.

3. Rotor and armature shafts in line within .003 T.I.R.

Bore and Keyway Dimensions

2.625 Sq.

Armature Keyway Rotor Keyway

Bore Dia. Bore Dia.

.376/.375 .093 x .046

*.438/.437 .376/.375 .093 x .046

.501/.500 .125 x .062 *.438/.437 .125x .062

*.563/.562 .501/.500

.626/.625

*.688/.687 .187 x .093

.751/.750

* Available on special order only.

Armature Shaft .375 – .750

Rotor Shaft .375 – .500

Static Torque 70 lb. in.

Maximum Speed 7,500 rpm

Standard Voltage D.C. 6, 24, 90

All dimensions are nominal unless otherwise noted.

Warner Electric • 800-825-9050 P-200 • 819-0481

38

Page 39

1A-1

1A-3

1A

1A-2

2

4

3

3-1

1B

SFC-250 Clutch Coupling Flange Mounted Outside Mounted Drawing I-25522

Item Description Part Number Qty.

1A Armature and Hub

1A-1 Armature Hub 1

3/8" Bore 5103-541-002

1/2" Bore 5103-541-004

5/8" Bore 5103-541-006

3/4" Bore 5103-541-008

1A-2 Armature 5124-111-001 1

1A-3 Release Spring 5103-101-003 1

1B Antibacklash Armature 1

2 Rotor 1

3 Field 1

3-1 Terminal Accessory 5103-101-002 1

4 Mounting Accessory 5102-101-001 1

3/8" Bore 5365-111-003

1/2" Bore 5365-111-005

5/8" Bore 5365-111-007

3/4" Bore 5365-111-009

3/8" Bore 5103-751-008

1/2" Bore 5103-751-010

6 Volt 5103-451-002

24 Volt 5103-451-004

90 Volt 5103-451-007

How to Order:

1. Specify Type of Armature Desired.

2. Specify Bore Size for Item 1A-1 or 1-B and Item 2.

3. Specify Voltage for Item 3.

Example:

SFC-250 Clutch Coupling per I-25522 - 90 Volt

Standard Armature

1/2" Armature Hub Bore

1/2" Rotor Bore

These units meet standards set forth in UL508 and are

listed under guide card #NMTR2, file #59164.

These units are CSA certified under file #LR11543.

Warner Electric • 800-825-9050 P-200 • 819-0481

39

Page 40

SFC-400 Clutch Coupling Flange Mounted

For Bore & Keyway sizes

see chart below.

Std. Arm.

Antibacklash

Arm.

Removabl

e plug in

ends for

1/2"

conduit.

For Bore

& Keyway

sizes see

chart

below.

Armature View

3.750

4.687

.015 When New

.187 (Std.)

.218 (Anti.)

1.250

4.234

Max.

Dia.

1.640

.187 (Std.)

.218 (Anti.)

.328 Max.

(Std.)

(Anti.)

.328

.875

.671

.828

.015

1.546

2.328/2.359

1.125

1.312

1.500

1.50

.937

3.562

.093

.250

1.875

1.873

Pilot Dia.

1/4-20

UNC-3A

.192/.182

.609 Max.

5.626

5.623

Pilot Dia.

.296/.280 dia. (4) holes equally spaced on 5.000 dia.*

Field View

Customer Shall Maintain:

1. Squareness of field mounting face with rotor shaft

within .003 T.I.R. measured at pilot

diameter.

2. Concentricity of field mounting pilot diameter with

rotor mounting shaft within .003 T.I.R.

3. Rotor and armature shafts in line within .003 T.I.R.

4.250 Sq.

45°

*Mounting holes are within .010 of true position relative to pilot diame-

ter.

Bore and Keyway Dimensions

Armature Keyway Rotor Keyway

Bore Dia. Bore Dia.

.501/.500 .125 x .062 .501/.500 .125 x.062

*.563/.562

.626/.625 .626/.625

*.688/.687 .187 x .093 .751/.750 .187 x .093

.751/.750 .876/.875

.876/.875 1.001/1.000

*Available on special order only

Armature Shaft .500 – .875

Rotor Shaft .500 – 1

Static Torque 270 lb. in.

Maximum Speed 4,500 rpm

Standard Voltage D.C. 6, 24, 90

All dimensions are nominal unless otherwise noted.

Warner Electric • 800-825-9050 P-200 • 819-0481

40

Page 41

1A-1

1A-3

1A

1A-2

2

3

5

3-1

4

1B

SFC-400 Clutch Coupling Flange Mounted – Outside Mounted Drawing I-25697

Item Description Part Number Qty.

1A Armature and Hub

1A-1 Armature Hub 1

1/2" Bore 5104-541-002

5/8" Bore 5104-541-004

3/4" Bore 5104-541-006

7/8" Bore 5104-541-007

1A-2 Armature 5125-111-001 1

1A-3 Release Spring 5104-101-003 1

1B Antibacklash Armature 1

1/2" Bore 5367-111-003

5/8" Bore 5367-111-005

3/4" Bore 5367-111-007

7/8" Bore 5367-111-008

2 Rotor 1

1/2" Bore 5104-751-033

5/8" Bore 5104-751-034

3/4" Bore 5104-751-035

7/8" Bore 5104-751-036

1" Bore 5104-751-037

3 Field 1

6 Volt 5104-451-032

24 Volt 5104-451-033

90 Volt 5104-451-034

3-1 Terminal Accessory 5103-101-002 1

4 Conduit Box 5200-101-010 1

5 Mounting Accessory 5104-101-002 1

How to Order:

1. Specify Type of Armature Desired.

2. Specify Bore Size for Item 1A-1 or 1B and Item 2.

3. Specify Voltage for Item 3.

Example:

SFC-400 Clutch Coupling per I-25697 - 90 Volt

3/4" Armature Hub Bore

3/4" Rotor Bore

These units, when used in conjunction with the correct

Warner Electric conduit box, meet standards set forth in

UL508 and are listed under guide card #NMTR2, file

#59164.

These units are CSA certified under file #LR11543.

Warner Electric • 800-825-9050 P-200 • 819-0481

41

Page 42

SFC-250 Clutch Coupling Bearing Mounted

For Bore & Keyway sizes

see chart below.

Std. Arm.

Antibacklash

Arm.

.187 Dia.

.187

Armature View

45°

.500 12°

.437

Max.

1.562 Rad.

24°

1.750 Max.

2.625

Max.

Dia.

.687 (Std.)

.718 (Anti.)

1.187

(Std.)

1.390

(Anti.)

.171 (Std.)

.187 (Anti.)

.343 Max.

.015 (Std.)

.015 (Anti.)

when new

.687

(Std.)

.718

(Anti.)

2.156 (Std.)

2.171 (Anti.)

1.437

1.125

.015 (Std.)

.015 (Anti.)

1.312

Bore and Keyway Dimensions

.468

.062 -0

.062

.609

Dia.

.171 +

.171

.937

For Bore & Keyway sizes

see chart below.

Field View

Customer Shall Maintain:

1. Armature shaft to be concentric with rotor shaft

within .003 T.I.R.

Armature Keyway Rotor Keyway

Bore Dia. Bore Dia.

.375/.376 .093 x .046 .376/.375 .093 x .046

*.438/.437

.501/.500 .125 x .062 *.438/.437 .125 x .062

*.563/.562 .501/.500

.626/.625

*.688/.687 .187 x .093

.751/.750

* Available on special order only.

Armature Shaft .375 – .750

Rotor Shaft .375 – .500

Static Torque 70 lb. in.

Maximum Speed 7,500 rpm

Standard Voltage D.C. 6, 24, 90

All dimensions are nominal unless otherwise noted.

Warner Electric • 800-825-9050 P-200 • 819-0481

42

Page 43

1B

1A-1

1A

1A-3

1A-2

2-1

2-2

2-3

2

(Shipped Assembled)

2-2

2-4

2-5

2-4-1

SFC-250 Clutch Coupling Bearing Mounted Drawing I-25523

Item Description Part Number Qty.

1A Armature and Hub

1A-1 Armature Hub 1

3/8" Bore 5103-541-002

1/2" Bore 5103-541-004

5/8" Bore 5103-541-006

3/4" Bore 5103-541-008

1A-2 Armature 5124-111-001 1

1A-3 Release Spring 5103-101-003 1

1B Antibacklash Armature 1

3/8" Bore 5365-111-003

1/2" Bore 5365-111-005

5/8" Bore 5365-111-007

3/4" Bore 5365-111-009

2 Field and Rotor Assembly 1

6 Volt – 3/8" Bore 5103-452-002

24 Volt – 3/8" Bore 5103-452-004

90 Volt – 3/8" Bore 5103-452-007

6 Volt – 1/2" Bore 5103-452-016

24 Volt – 1/2" Bore 5103-452-018

90 Volt – 1/2" Bore 5103-452-021

2-1 Rotor 1

2-2 Retainer Ring 748-0371 2

2-3 Ball Bearing 166-0108 1

2-4 Field 1

3/8" Bore 5103-751-014

1/2" Bore 5103-751-016

Item Description Part Number Qty.

6 Volt 5103-451-018

24 Volt 5103-451-020

90 Volt 5103-451-023

2-4-1 Terminal Accessory 5103-101-002 1

2-5 Set Collar* 266-0005 1

*Used with 1/2" Bore only.

How to Order:

1. Specify Type of Armature Desired.

2. Specify Bore Size for Item 1A-1 or 1B and Item 2.

3. Specify Voltage for Item 2.

Example:

SFC-250 Clutch Coupling per I-25523 - 90 Volt

Standard Armature

1/2" Armature Hub Bore

1/2" Rotor Bore

These units meet standards set forth in UL508 and are

listed under guide card #NMTR2, file #59164. These

units are CSA certified under file #LR11543.

Warner Electric • 800-825-9050 P-200 • 819-0481

43

Page 44

SFC-400 Clutch Coupling Bearing Mounted

For Bore & Keyway sizes

see chart below.

Std. Arm.

Antibacklash

Arm.

45°

Armature View

3.750

4.687

Remov-

able

plug in

ends for

1/2"

conduit.

.015 (Std.)

.015 (Anti.) when

new

.328 Max.

.875 (Std.)

.843 (Anti.)

1.250

4.234

(Std.)

Max.

Dia.

1.640

(Anti.)

.187 (Std.)

.218 (Anti.)

.875 (Std.)

.843 (Anti.)

.015

1.546

1.281

(Std.)

1.812

1.625

2.640 (Std.)

2.734 (Anti.)

1.218

3.562

1.375

Dia.

.062 (Std.)

.203 (Anti.)

.328 (Anti.)

.500

.187

.187

2.312

.859

For Bore & Keyway

sizes see chart

below.

Field View

Customer Shall Maintain:

1. Armature shaft to be concentric with rotor

shaft within .003 T.I.R.

Bore and Keyway Dimensions

Armature Keyway Rotor Keyway

Bore Dia. Bore Dia.

.501/.500 .125 x .062 .501/.500 .125 x.062

*.563/.562

.626/.625 .626/.625

*.688/.687 .187 x .093 .751/.750 .187 x .093

.751/.750 .876/.875

.876/.875 1.001/1.000

* Available on special order only.

Armature Shaft .500 – .875

Rotor Shaft .500 – 1

Static Torque 270 lb. in.

Maximum Speed 4,500 rpm

Standard Voltage D.C. 6, 24, 90

All dimensions are nominal unless otherwise noted.

Warner Electric • 800-825-9050 P-200 • 819-0481

44

Page 45

1B

1A-1

1A-3

1A-2

2-1

1-A

2

(Shipped Assembled)

2-3

2-4

2-4-1

2-2

3

SFC-400 Clutch Coupling Bearing Mounted Drawing I-25698

Item Description Part Number Qty.

1A Armature and Hub

1A-1 Armature Hub 1

1/2" Bore 5104-541-002

5/8" Bore 5104-541-004

3/4" Bore 5104-541-006

7/8" Bore 5104-541-007

1A-2 Armature 5125-111-001 1

1A-3 Release Spring 5104-101-003 1

1B Antibacklash Armature 1

1/2" Bore 5367-111-003

5/8" Bore 5367-111-005

3/4" Bore 5367-111-007

7/8" Bore 5367-111-008

2 Field and Rotor Assembly 1

6 Volt – 1/2" Bore 5104-452-052

24 Volt – 1/2" Bore 5104-452-053

90 Volt – 1/2" Bore 5104-452-054

6 Volt – 5/8" Bore 5104-452-055

24 Volt – 5/8" Bore 5104-452-056

90 Volt – 5/8" Bore 5104-452-057

6 Volt – 3/4" Bore 5104-452-058

24 Volt – 3/4" Bore 5104-452-059

90 Volt – 3/4" Bore 5104-452-060

6 Volt – 7/8" Bore 5104-452-061

24 Volt – 7/8" Bore 5104-452-062

90 Volt – 7/8" Bore 5104-452-063

6 Volt – 1" Bore 5104-452-064

24 Volt – 1" Bore 5104-452-065

90 Volt – 1" Bore 5104-452-066

2-1 Rotor 1

1/2" Bore 5104-751-043

Item Description Part Number Qty.

5/8" Bore 5104-751-044

3/4" Bore 5104-751-045

7/8" Bore 5104-751-046

1" Bore 5104-751-047

2-2 Retainer Ring 748-0018 1

2-3 Ball Bearing 166-0150 1

2-4 Field 1

6 Volt 5104-451-038

24 Volt 5104-451-039

90 Volt 5104-451-040

2-4-1 Terminal Accessory 5103-101-002 1

3 Conduit Box 5200-101-010 1

How to Order:

1. Specify Type of Armature Desired.

2 Specify Bore Size for Item 1A-1 or 1-B and

Item 2.

3. Specify Voltage for Item 2.

Example:

SFC-400 Clutch Coupling per I-25698 - 90 Volt

Antibacklash Armature

3/4" Armature Hub Bore

3/4" Rotor Bore

These units meet standards set forth in UL508 and are

listed under guide card #NMTR2, file #59164. These units

are CSA certified under file #LR11543.

Warner Electric • 800-825-9050 P-200 • 819-0481

45

Page 46

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship

within a period of one (1) year from the date of original purchase for consumer, commercial or

industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without

Warner Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation

charges prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information

may be obtained by writing the Customer Satisfaction Department, Warner Electric LLC, 449

Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made,

without charge, together with a refund for transportation costs. If found not to be defective, you

will be notified and, with your consent, the item will be repaired or replaced and returned to you

at your expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation

may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any

defective product. Warner Electric LLC neither assumes nor authorizes any other person

to give any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH

THE CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF

ORIGINAL CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL

USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you. This warranty gives you specific legal rights

and you may also have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without

notice. Weights do not include weight of boxing for shipment. Certified prints will be furnished

without charge on request to Warner Electric.

Warner Electric LLC

31 Industrial Park Road

815-389-3771

www.warnerelectric.com

An Altra Industrial Motion Company

P-200 819-0482 06/11 Printed in USA

• Fax: 815-389-2582

• New Hartford, CT 06057

Loading...

Loading...