Page 1

Safety Sentry

™

Electronic Breakaway Switch

P-616

819-0454

Installation Instructions

Page 2

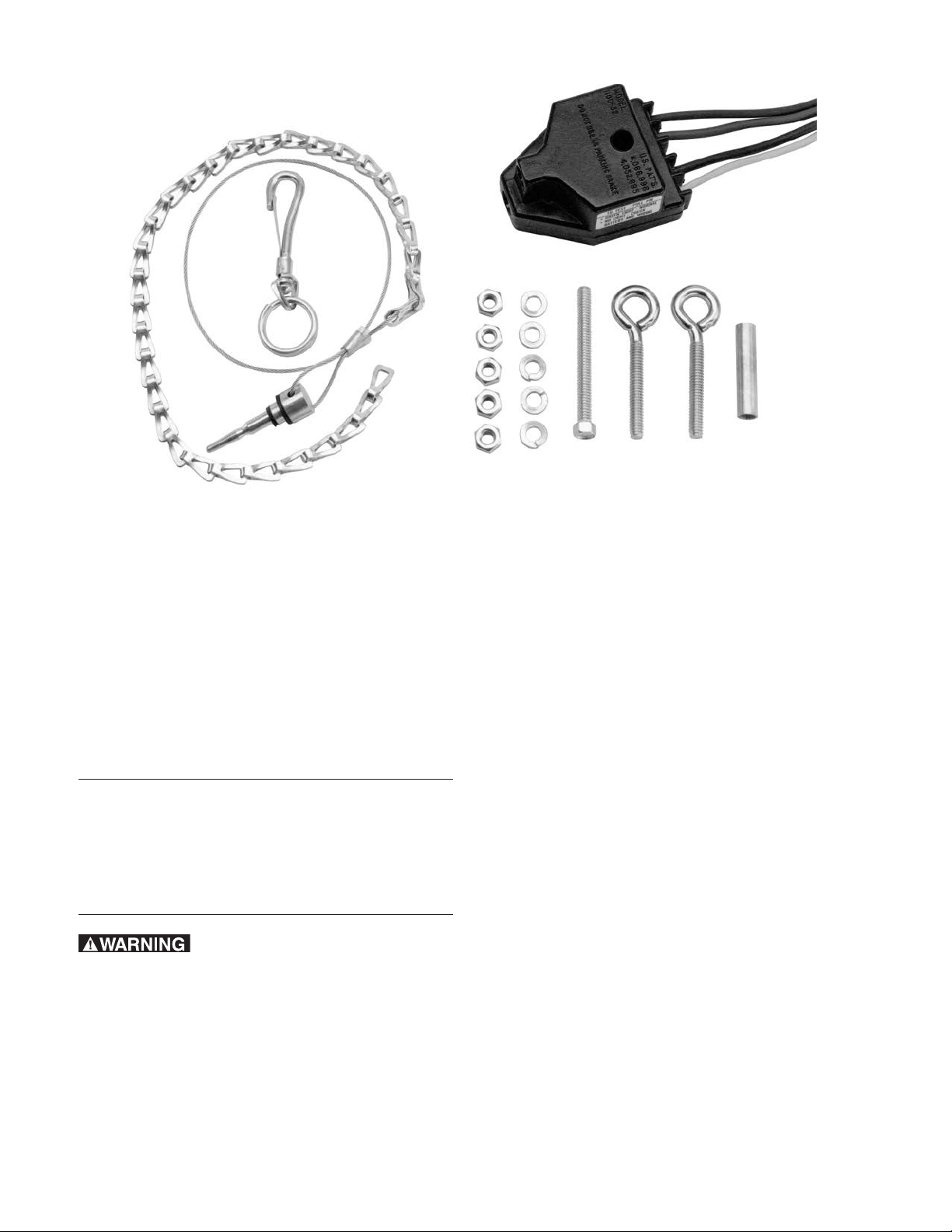

Parts List

Introduction

Mounting hardware included with the Safety Sentry

Breakaway Switch kit:

Qty Part

1 Chain/lanyard with snap hook

1 2-1/2" Bolt

1 1-5/8" Sleeve

2 Eyebolts

5 Lockwashers

5 Nuts

Failure to follow these

instructions may result in product damage,

equipment damage, and fatal injury to

personnel.

The main purpose of any trailer breakaway switch is

to automatically engage the electric trailer brakes

should the trailer become detached from the towing

vehicle. In addition to this basic function, your Safety

Sentry Breakaway Switch will:

1. Test the battery under load for approximately 10

volts minimum.

2. Illuminate its green light to indicate that the trailer

battery and breakaway switch are

operating properly.

Warner Electric • 800-825-9050 P-616 • 819-0454

2

Page 3

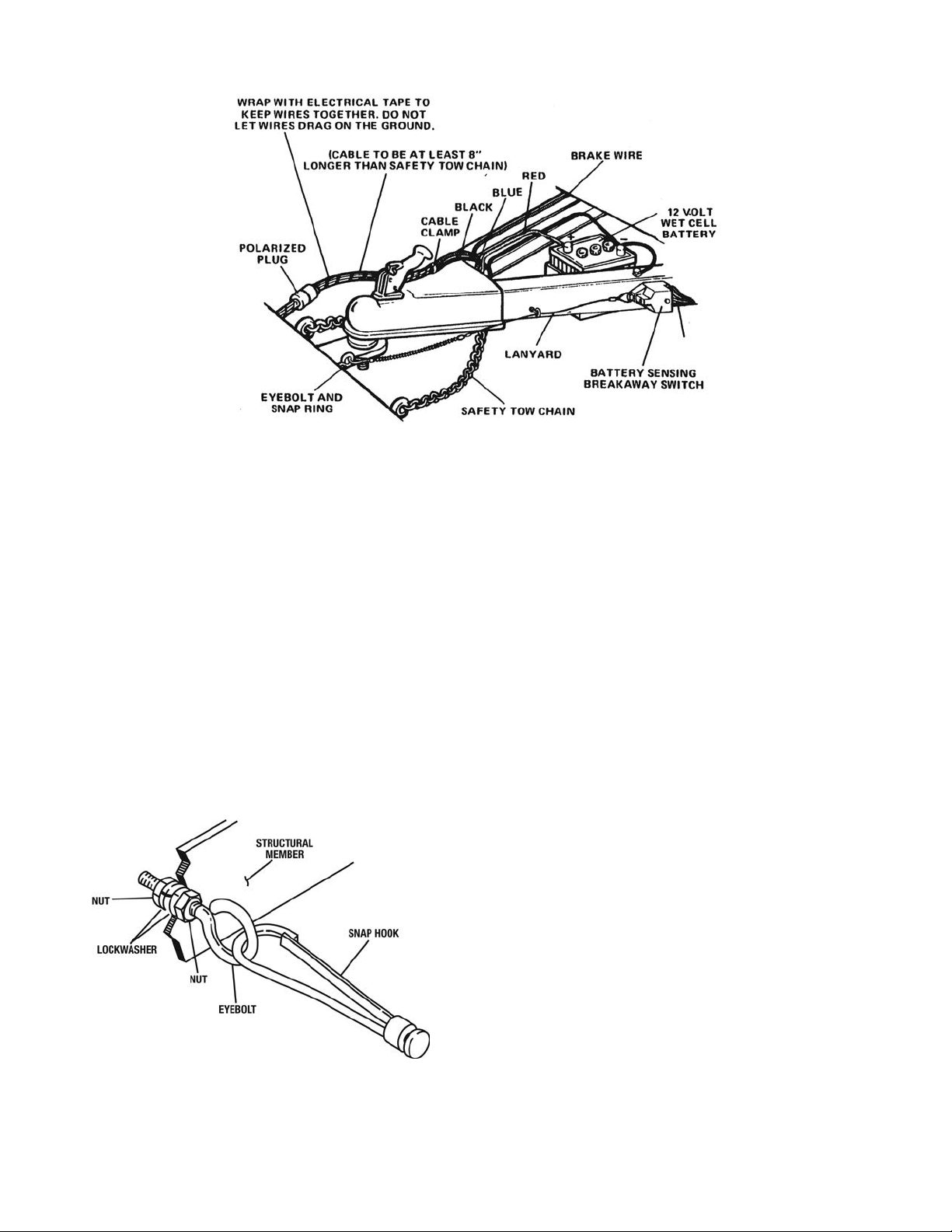

Mounting

Figure 1 - Typical Layout

Note the general layout in Figure 1 as you proceed

through the mounting instructions. Refer to the

parts list, page 2.

1. Drill a 9/32-inch hole for an eyebolt in a

convenient structural member on your towing

vehicle chassis near the hitch (not on the hitch

assembly).

Mount the eyebolt, with the eyebolt pointing

toward the breakaway switch, using two

1/4-inch nuts with lockwashers. Tighten

securely. See Figure 2.

2. Position the breakaway switch on a horizontal

or vertical surface of the trailer tongue or Aframe. The pin in the switch must point

towards the towing vehicle.

The switch must be positioned far enough

forward so the lanyard will reach the towing

vehicle.

It must also be set back far enough to allow an

eyebolt to be mounted to the tongue in front of

the switch.

3. Drill a 9/32-inch hole through the tongue for

mounting the switch.

Insert the furnished metal sleeve into the

mounting hole in the switch. The sleeve allows

the switch to pivot so the lanyard stays aligned

with the towing vehicle.

Bolt the switch to the tongue using the bolt,

nut, and lockwasher provided.

Figure 2

Towing Vehicle Eyebolt Mounting

Warner Electric • 800-825-9050 P-616 • 819-0454

3

Page 4

Figure 3 - Trailer Tongue Eyebolt Mounting

4. Refer to Figure 3 for correct location for

mounting the second eyebolt.

Drill a 9/32-inch hole for the eyebolt. Secure

with two 1/4-inch nuts and two lockwashers.

This eyebolt is necessary so that the pin will be

pulled straight out from the breakaway switch

if the trailer should become disconnected.

5. Insert the breakaway switch disengagement

pin into the breakaway switch.

6. Disconnect the snap hook (it is not

permanently attached) from the chain end of

the lanyard assembly. Save the hook and its

attachment clip.

7. Thread the lanyard, chain end first, through the

eyebolt mounted on the trailer tongue.

8. Determine the correct length for the lanyard.

The lanyard is the correct length if the following

conditions are satisfied:

Condition 1: If trailer should become

disconnected, the lanyard must become

taut and pull the pin out of the breakaway

switch before the trailer safety chains

become taut.

Condition 2: If the trailer should become

disconnected, the lanyard must become taut

and pull the pin out of the breakaway switch

before the towing vehicle-to-trailer electrical

wiring becomes taut. Making the electrical

wires longer than the safety chains is a

convenient way to accomplish this.

Condition 3: During normal towing operation,

the lanyard must NOT become taut enough to

pull the pin out of the breakaway switch when

turning a corner.

Condition 4: During normal towing operation,

either straight or while turning corners, no

chains or wiring should be allowed to drag on

the ground.

Adjust the lanyard to the right length by

removing the individual chain links.

The lanyard, if installed correctly, now extends

from the switch, with the pin inserted into the

switch, through the eyebolt on the trailer

tongue, and attaches to the eyebolt on the

towing vehicle.

9. Leaving the lanyard threaded through the

eyebolt on the trailer tongue, secure the snap

hook to the end chain link. Use pliers to close

the snap hook attachment clip completely

around the end of the snap hook.

10. Fasten snap hook to the towing vehicle

eyebolt.

Warner Electric • 800-825-9050 P-616 • 819-0454

4

Page 5

Electrical Connection

Recommended Parts List for Customer Wiring:

Item Qty Description

1. 6' No. 12 AWG insulated wire (stranded) blue

2. 6' No. 12 AWG insulated wire (stranded) black

3. 6' No. 12 AWG insulated wire (stranded) white

4. 6' No. 12 AWG insulated wire (stranded) red

5. 2 1/4-inch bolts, length suitable for the type of trailer tongue used

6. 2 1/4-inch nuts

7. 4 washers for 1/4-inch bolt

8. 2 lockwashers for 1/4-inch bolt

9. 1 roll of electrical tape

10. 3 wire nuts or insulated line connectors (binding screw type) for three No. 12 AWG wires

11. 1 socket and plug connector with a minimum of three poles capable of accepting

No. 12 AWG wire

12. 1 12 volt wet cell battery (100 amp-hour max.)

Figure 4 - Wiring Diagram

Refer to the wiring diagram shown in Figure 4 as

you follow the electrical connection instructions

wet cell storage battery with a maximum rated

capacity of 100 amp-hours.

below. Plan ahead by starting with long wires. All

wires must be a least No. 12 AWG and insulated.

The final length of the wires from the trailer,

including the connector, should be longer than

the safety chains.

Solder connections are preferable for attaching

two wires together. If crimp-type connectors are

used, make sure they are crimped tightly. All such

connections should be taped with electrical tape

to prevent corrosion and short circuiting.

(Note: Refer to Mounting, Item 8, Condition 2).

The trailer battery must be 12 volts and have

adequate capacity to meet all legal requirements of

the state in which the trailer will be towed. Use a

Warner Electric • 800-825-9050 P-616 • 819-0454

5

Page 6

Your breakaway switch has four wires: white, blue,

black, and red. They should be connected as

follows:

1. Ground – White Wire

Attach the white wire to the trailer frame

adjacent to the switch using a 1/4-inch bolt,

nut, two washers, and one lockwasher. Be

sure the frame area is bare metal and free of

rust. (See Figure 5)

Figure 5 - Ground Connections

2. Brakes – Blue Wire

Connect the blue wire to the positive (+) wire

running to the trailer brakes. Be careful not to

connect to the ground (-) wire leading from the

brakes.

3. Trailer Battery Charging – Black Wire

Warner Electric recommends that a charging

circuit be used to maintain the trailer battery in

a fully-charged condition.

a. If a charging circuit is used, it must be

connected through the Safety Sentry switch

using the black wire as shown in Figure 4.

Connect the black wire from the switch,

through the polarized connector, to the output

side of the battery isolator. If a battery isolator

is not used, connect the wire directly to the

towing vehicle battery (+) terminal.

The wire must be long enough for the switch

to swivel freely after the connection to the

trailer frame has been made. Make sure the

final connection is tight.

Connect the trailer battery ground (-) to the

trailer frame, also using 1/4-inch bolt, nut, two

washers, and one lockwasher as shown in

Figure 5.

Make sure the final connection is tight. (Note:

The white wire from the switch and the battery

ground terminal may be connected to one

common ground on the trailer frame if

convenient.)

A ground wire should be run from the towing

vehicle battery (-) to the socket at the rear of

the vehicle. From the socket, the ground wire

should be connected to the trailer frame.

(There should now be a total of 3 ground

connections: the breakaway switch white wire

to the trailer frame; the ground side of the

trailer battery to the trailer frame; the ground

side of the towing vehicle battery, through the

socket at the rear of the vehicle, to the trailer

frame.)

Failure to connect the

charging circuit through the switch will

result in incorrect operation of the switch.

b. If a charging circuit is not used, cut off the

black wire from the Safety Sentry close to the

switch's plastic housing. Insulate the exposed

end of the wire with a recognized electrical

insulating tape or equivalent. This will prevent

the exposed lead from grounding.

Failure to cut off and

insulate the black wire when no charging

circuit is used could cause an electrical

short circuit. This may deplete the trailer

battery and destroy the Safety Sentry,

completely immobilizing the breakaway

system.

4. Trailer Battery – Red Wire

Connect the red wire directly to the trailer

battery (+) terminal using an appropriate

battery connector.

Warner Electric • 800-825-9050 P-616 • 819-0454

6

Page 7

Operation

Your Safety Sentry Breakaway Switch should now

be ready for use. Always test the system before

using it to assure that it is in proper working

condition.

Use the following procedure to test the brake

system:

1. Put the towing vehicle in “Park”. Set the

emergency brake if the vehicle has manual

transmission.

2. Couple the plug and socket together.

The battery will be charged directly from the

towing vehicle while the engine is running. To

accomplish this the pin must be inserted in the

switch.

If the battery does not charge to 10 volts, it

must be replaced.

The green light should now illuminate, or the

trailer brakes must be checked.

c. Check the trailer brake wiring. All brake

magnets should be connected with good

quality connectors and taped to avoid a

possible short circuit.

3. Pull the disengagement pin from the switch.

The green light on the switch will illuminate for

at least 10 seconds if the system is connected

and the battery is functioning properly.

4. If the green light does not illuminate, use the

following procedure to check the system and

locate the cause of the problem:

a. Check your wiring to ensure all connections

have been made properly. Refer to Figure 4.

Check all connections to be sure they are

tight. Check ground connections to be sure

they are attached to rust-free areas of the

trailer frame. They must be connected to bare

metal surfaces.

Correct any errors which have been made. If

the green light does not illuminate, proceed

with the next step.

b. Use a voltmeter to check the trailer battery for

proper output. The battery must supply at

least 10 volts, with the switch pin pulled (trailer

brakes on), for the green light to illuminate.

d. The green light should now illuminate, or the

Safety Sentry should be replaced.

e. As a final check, pull the disengagement pin

on the Safety Sentry and try to pull the trailer

forward with the towing vehicle. If the trailer

brakes are engaged, it will be difficult for the

towing vehicle to move the trailer.

If the trailer and towing vehicle

are connected while parked, prolonged use

of the trailer battery for lights or other

purposes will also drain the towing vehicle

battery. The problem can be avoided by

disconnecting the plug from the socket.

DO NOT USE AS A PARKING BRAKE (pin

removed). Prolonged activation will discharge

the battery and cause the brakes to release.

If the voltage is low, the battery should be

charged to a minimum of 10 volts and

checked again with the pin pulled before the

trailer is towed.

Warner Electric • 800-825-9050 P-616 • 819-0454

7

Page 8

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship within

a period of one (1) year from the date of original purchase for consumer, commercial or industrial

use.

This warranty extends only to the original purchaser and is not transferable or assignable without

Warner Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation

charges prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information may

be obtained by writing the Customer Satisfaction Department, Warner Electric LLC, 449 Gardner

Street, South Beloit, Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made,

without charge, together with a refund for transportation costs. If found not to be defective, you will

be notified and, with your consent, the item will be repaired or replaced and returned to you at your

expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation

may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any

defective product. Warner Electric LLC neither assumes nor authorizes any other person to give

any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH

THE CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF

ORIGINAL CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL

USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. This warranty gives you specific legal rights and

you may also have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without

notice. Weights do not include weight of boxing for shipment. Certified prints will be furnished

without charge on request to Warner Electric.

Warner Electric LLC

31 Industrial Park Road • New Hartford, CT 06057

815-389-3771 • Fax: 815-389-2582

www.warnerelectric.com

P-616 • 819-0454 8/11 Printed in USA

An Altra Industrial Motion C ompany

Loading...

Loading...