Page 1

Pump Clutch Installation

P-1423

819-0388

Installation Instructions

Page 2

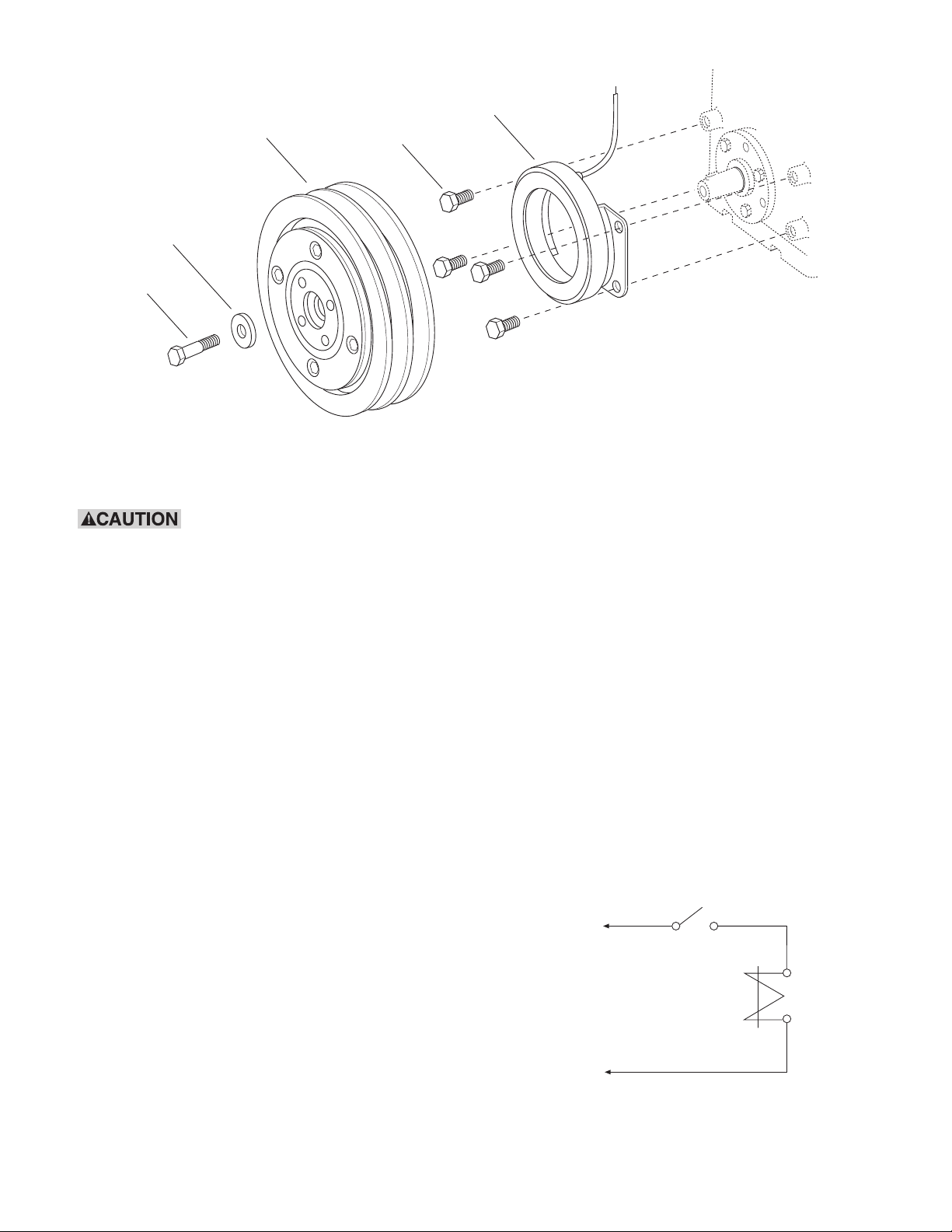

Washer (4)

Rotor-Pulley

Assembly (3)

Capscrews &

Lockwashers (2)

Field Assembly (1)

Cap Screw (5)

Rotor-Pulley

Assembly

Failure to follow these

instructions may result in product damage,

equipment damage, and serious or fatal

injury to personnel.

General

This pump clutch has been developed specifically

for use in pump applications. Properly installed, it

will provide maintenance-free service. The clutch

uses a stationary field that does not require slip

rings or brushes.

The clutch consists of two major components;

a stationary magnetic field assembly and a

rotor-pulley assembly. The field assembly is

mounted on the pump face. The rotor-pulley is

mounted to the pump shaft and driven by v-belts.

Electricity energizes the clutch field to couple the

clutch magnetically, thus driving the pump

mechanism. De-energizing the field releases

the clutch and uncouples the pump.

Pump

(Not Included)

Field

Assembly

Wiring

The coil in the field assembly has a single leadwire

(hot) and is grounded through the field shell. It will

only be necessary to connect this leadwire to the

electrical system as the pump should already be

negatively grounded. Figure 1 shows an example

of a typical system.

Service

The clutch automatically compensates for wear

requiring no adjustments throughout the life of the

clutch. Do not lubricate the unit. If the clutch

should fail to operate, check the electrical circuit to

be sure the proper voltage is being supplied to the

clutch. Do not attempt to make any mechanical

adjustments to the clutch.

Clutch Switch

Positive

Clutch

Negative

Figure 1

Warner Electric • 800-825-9050 P-1423 • 819-0388

2

Page 3

Installation

Diagnose Clutch Failure

Most clutch failures are a direct result of a system

problem or failure. Before installing a new clutch,

determine what caused the old clutch to fail and

fix the system problem. By simply replacing the

clutch without fixing the cause of the clutch

failure, the new clutch may fail in the same

manner as the old clutch.

Step 1

Position the field assembly (1) against the face of

the pump and align the field mounting holes with

those in the pump. Insert four capscrews into the

bolt holes. Tighten the capscrews to a wrench

torque of 7-10 lb.ft. (85-120 lb.in.).

Use care not to strip the

threads in the pump body.

Step 2

The pump shaft must be clean and free of burrs.

Check the shaft key for proper position and

seating.

Step 3

Slide the rotor-pulley assembly (3) onto the

tapered shaft (aligning the key and the keyway).

Secure the rotor-pulley assembly using the

washer (4) and self-locking capscrew (5) provided

with the clutch. Tighten the capscrew to a wrench

torque of 15-20 lb.ft. (180-240 lb.in.)

Step 5 (If Required)

To remove the rotor-pulley from the pump shaft,

remove the self-locking capscrew (5) and washer

(4). Then, insert a 5/8-11 UNC capscrew (not

provided) into the center hole of the rotor. Rotate

the screw against the pump shaft until the rotor

breaks loose from the shaft.

Do not use a wheel puller on

theouter diameter of the pulley as this can

damage the clutch bearing. Warranty will be

voided if clutch is removed without using the

5/8-11 UNC threaded hole provided in the hub

center.

Step 6

Clutch Burnish Procedure

Install drive belts as required by pump design. Run

the pump at normal operating speed and cycle the

clutch on and off at a rate of 10 to 15 times per

minute for 50 cycles minimum. This procedure will

help bring the clutch up to operating torque

capacity.

Note: To prevent electrical system damage,

use the pump clutch control to cycle the

clutch.

Step 4

Rotate the rotor-pulley manually to ensure there

is no interference between the field and the

rotor-pulley. If any interference occurs, a

rubbing/scrapping noise will be heard as the

pulley rotates. If rubbing or some other

mechanical interference does occur, disassemble

the clutch (per step 5) and repeat assembly

of the field assembly to the pump.

Warner Electric • 800-825-9050 P-1423 • 819-0388

3

Page 4

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship within a

period of one (1) year from the date of original purchase for consumer, commercial or industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without Warner

Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation

charges prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information may be

obtained by writing the Customer Satisfaction Department, Warner Electric LLC, 449 Gardner Street,

South Beloit, Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made, without

charge, together with a refund for transportation costs. If found not to be defective, you will be notified

and, with your consent, the item will be repaired or replaced and returned to you at your expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation may

not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any defective

product. Warner Electric LLC neither assumes nor authorizes any other person to give any other

warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH THE

CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL

CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL USES OF THE

PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES,

WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR OTHERWISE, INCLUDING, BUT

NOT LIMITED TO, ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. This warranty gives you specific legal rights and you

may also have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without

notice. Weights do not include weight of boxing for shipment. Certified prints will be furnished without

charge on request to Warner Electric.

Warner Electric LLC

31 Industrial Park Road • New Hartford, CT 06057

815-389-3771 • Fax: 815-389-2582

www.warnerelectric.com

P-1423 • 819-0388 8/11 Printed in USA

An Altra Industrial Motion C ompany

Loading...

Loading...