Page 1

Preassembled Clutch/Brake Module

P-273-1

819-0343

Installation Instructions

Page 2

2

Warner Electric • 800-825-9050 819-0343

Contents

Mounting to a Motor . . . . . . . . . . . . . . .3

Mounting to a Reducer . . . . . . . . . . . . .3

Installing the Base Mount . . . . . . . . . . .4

Installing the Motor Mount . . . . . . . . . . .4

Electrical Connections . . . . . . . . . . . . . .4

Start Up . . . . . . . . . . . . . . . . . . . . . . . . .5

Troubleshooting . . . . . . . . . . . . . . . . . . .5

Electrical Coil Data . . . . . . . . . . . . . . . .6

Mechanical Data . . . . . . . . . . . . . . . . . .6

Warranty . . . . . . . . . . . . . . . . .Back page

Failure to follow these

instructions may result in product damage,

equipment damage, and serious or fatal

injury to personnel.

Warner Electric’s UniModule has been designed

to NEMA standards and can be installed with all

standard power transmission drive systems.

Before installing the UniModule to a motor or

reducer, make certain that the UM UniModule

size and NEMA frame dimensions match according to the following chart.

Corresponding

NEMA Frame Sizes

C-Face

UM Old New Shaft Pilot

Size NEMA NEMA Dia. Dia.

50 56 C 48 Y 5/8 4 1/2

100 56 C 48 Y 5/8 4 1/2

180 182 C 143 TC 7/8 4 1/2

184 C 145 TC

210 213 C 182 TC 1-1/8 8 1/2

215 C 184 TC

215 213TC 1 3/8 8 1/2

215 TC 1 3/8 8 1/2

Install your specific modular combination according to the installation steps specified in the table.

Use only those steps indicated for each combination.

The 1020 and 1040 UniModules are furnished

with a special hardened key. It is strongly recommended that this key be used with the motor

shaft to avoid damage to the shaft and rotor hub.

The size 210 UniModules require an adapter ring

to be mounted to the motor prior to mounting the

1020 or 1040 UniModule. Adapter and mounting

hardware are provided with the UniModule

assembly.

Note: The equipment covered by this service

manual must be installed in accordance with

these instructions. Failure to do so may damage the equipment and void the warranty.

For These UM Combinations Use These

Installation Steps:

UniModule Clutch/Brake Between Mounting to a Motor

C-Face Motor and Reducer - 1020 Mounting to a Reducer

UniModule Clutch between Electrical Connections

Motor and Reducer - 1040 Start Up

UniModule Clutch/Brake - 2030 Chain or pulley Drive to

a Reducer

Electrical Connection

UniModule Clutch - 3040 Start Up

Motor Mount Module Clutch-Brake Mounting to a Motor

on a C-Face Motor - 1020-M Installing the Motor Mount

Motor Mount UniModule Clutch Electrical Connection

on a C-Face Motor - 1040-M Start Up

Base Mounted Installing the Base Mount

UniModule Clutch-Brake - 2030-B Electrical Connection

UniModule Clutch - 3040-B Start Up

Page 3

3

Warner Electric • 800-825-9050 819-0343

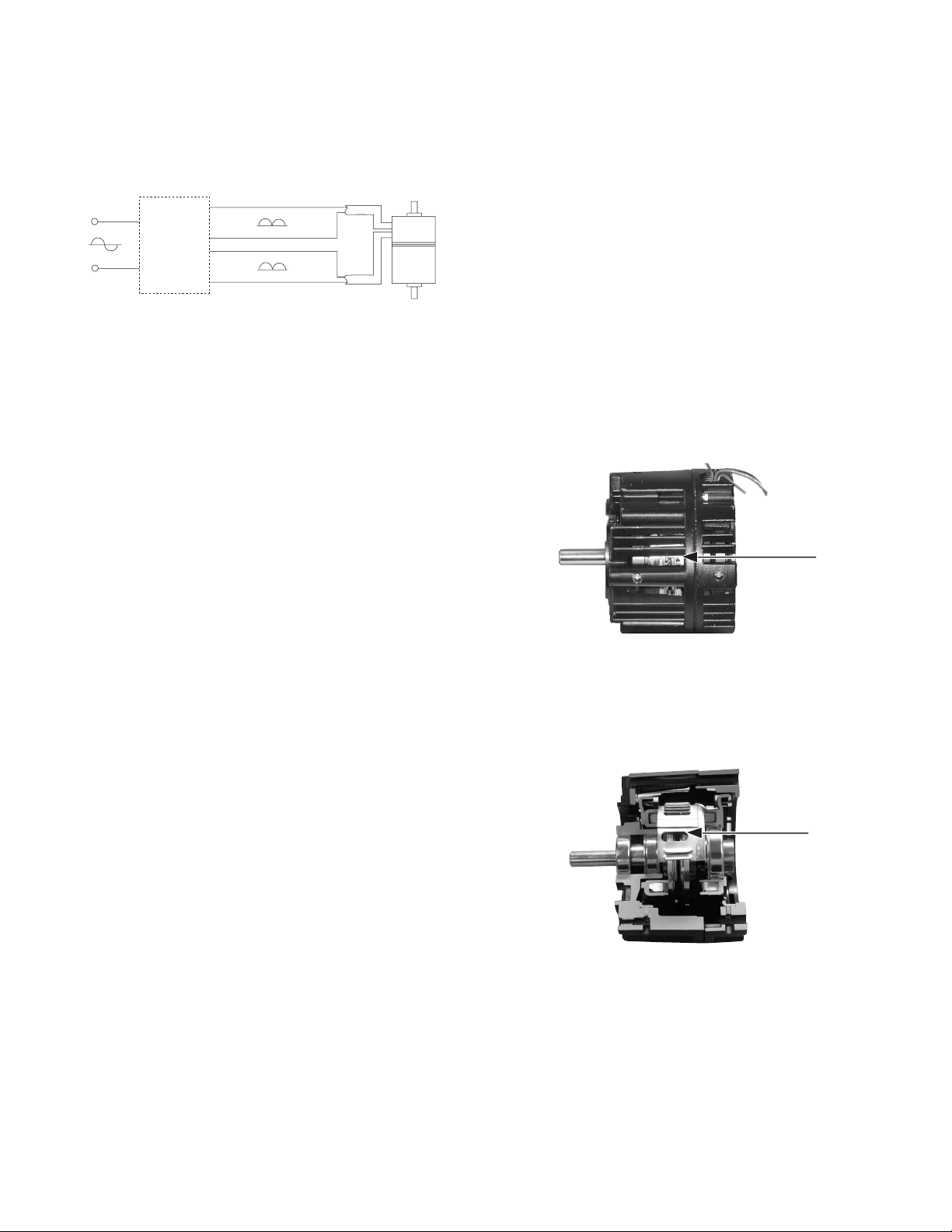

3. The access hole for the Allen wrench to tighten the rotor setscrews is shown in Figure 3.

Rotate the clutch rotor as necessary to insert

the wrench into the setscrews. Tighten both

screws alternately and securely. Failure to

properly tighten the setscrews may result in

damage to the motor shaft and rotor hub and

will void warranty. (40 to 45 in. lbs. for 180

size, 80 to 85 in. lbs. for 50 and 210 sizes.)

Figure 3

Mounting to a Reducer

The output side of a UniModule may be

mounted directly to a reducer.

A. Align the output shaft and key of the

UniModule with the corresponding shaft hole

and keyway of the reducer. Slide assembly

together, matching pilot diameter on the

UniModule with pilot diameter on the reducer.

B. Bolt the UniModule to the reducer flange. The

four (4) bolts required (3/8 - 16 UNC-2A) are

normally furnished with the reducer. (18 to 22

ft. lbs. for 50 and 180 sizes, 40 to 45 lbs. for

210 size.)

Figure 4

Mounting to a Motor:

1. Replace the existing motor shaft key with the

hardened key provided with the unit. If necessary, prick punch the keyway of the motor

shaft to keep the key from moving in the keyway. Slide the module assembly onto the

motor shaft. (See Figure 1) Align the key in

the motor shaft with the keyway in the rotor

hub.

Do not use force. If the UniModule does

not slide on freely, polish the motor shaft

sufficiently to achieve a slip fit.

Figure 1

2. The housing is provided with vent holes which

are normally placed in the down position.

Rotate the assembly to where the vent holes

are toward the bottom and insert the four long

capscrews (provided) through the mounting

holes in the housing and into the motor face.

Tighten alternately and securely. (30 to 35 ft.

lbs.)

Figure 2

Page 4

4

Warner Electric • 800-825-9050 819-0343

Size 210

A. Mount the UniModule on the Motor Mount so

that the base of the Motor Mount is underneath the UniModule and motor (Figure 6). A

pilot diameter on the UniModule mates with a

pilot diameter on the Motor Mount.

B. Secure the Motor Mount to the UniModule

with three (3) bolts provided. (40 to 45 ft. lbs.)

Figure 6

Electrical Connections

To avoid injury (or even

death), always make certain all power is off

before attempting to install or service this

control or any electrical equipment.

The UniModule is provided with one conduit connection hole, threaded for standard 1/2" conduit

connectors. Both the clutch and the brake lead

wires are brought out through this opening. The

conduit box accessory kit, P/N 5370-101-042,

provides two conduit connection holes for standard 1/2" conduit connectors.

The clutch and brake coils operate on DC voltage. Warner Electric offers a full line of AC voltage powered controls to meet the needs of

almost every clutch/brake application. The service and installation instructions included with

each Warner Electric control show the proper

electrical connections.

Installing the Base Mount

UniModules 2030 and 3040 can be basemounted. (Figure 5)

Figure 5

A. Mount each UniModule so that the base is

located below the ventilation holes. A pilot

diameter on the end of each UniModule

mates with pilot diameters on the base.

B. Secure the base to the UniModule with the

four (4) bolts provided. (18 to 22 ft. lbs. for 50

and 180 sizes, 40 to 45 ft. lbs. for 210 size.)

Installing the Motor Mount (M)

A. Motor Mount (M) can be installed to the out-

put end of the UniModule to provide a foot

mounting for the complete assembly of

UniModule and motor.

Size 50, 100, and 180

A. Remove the two (2) long hex head bolts from

the side of the UniModule toward the ventilation holes.

B. Mount the UniModule on the Motor Mount so

that the base of the Motor Mount is underneath the UniModule and motor (Figure 6). A

pilot diameter on the UniModule mates with a

pilot diameter on the Motor Mount.

C. Secure the Motor Mount in place with two (2)

longer mounting bolts (30 to 35 ft lbs.) and

the two shorter bolts (18 to 22 ft. lbs.) all provided in the kit.

Page 5

5

Warner Electric • 800-825-9050 819-0343

Trouble Shooting - Mechanical

A likely mechanical cause for a clutch or brake

not engaging when DC power is applied is that

the airgap between the friction faces is too

large. When power is applied to an Electro-magnetic clutch/brake, the unit magnetically clamps

the friction faces together.

An airgap that is too large can keep the unit

from clamping together. Sometimes this airgap,

when set at the factory can shift during shipment or installation.

To r eset the airgap, you will need to access the

armatures. There are gaps between the fins on

the housing on 1/3 of the unit circumference.

Figure 7

When looking through one of these gaps, you

will see the fan on the clutch rotor. In that fan,

there is a 1/2" x 1" window.

Figure 8

It is possible to look inside the unit and see the

armatures by looking through this window.

When looking into the window, you will be looking between the two armatures of a clutch/brake

unit.

Clutch/Brake

Control

AC

Clutch

Brake

White

Black

Red

Red

Black

Black

DC

DC

Vol ta ge

Voltage

Voltage

Start-Up

With the motor at rest, check the following:

A. Spin the output shaft by hand to ensure that

it turns freely. The bearings should be quiet

and the armatures should not drag.

B. With full voltage applied to the clutch or

brake, switch back and forth between the

clutch and brake and observe the armatures

(plates) through the vent holes and opening in

the fan. They should move back and forth

approximately 1/32" when switched. Turn

the output shaft as you check to be sure that

the armatures fully engage 360 degrees.

Trouble Shooting - Electrical

If a clutch or brake or clutch/brake will not

engage, review wiring, switching, and connections.

1. Using a multimeter, confirm that DC voltage is

reaching the lead wires when it should be

and that the coil resistance is correct. (See

Electrical Coil Data)

2. Visually inspect to ensure that the lead wires

are not split or cut.

Please refer to the following figure for the proper

UniModule electrical connections. Clutch leads

are identified with a white insulator sleeve.

Brake leads have a black insulator sleeve.

Page 6

6

Warner Electric • 800-825-9050 819-0343

Figure 9

If the armature for either the clutch or the

brake is too far away from its mating friction

surface, it is possible to move this back into

adjustment using a flat head screwdriver.

This is a three-step process.

1. Simply slide the screwdriver through the

window and press the armature toward its

mating friction surface.

2. Rotate the output of the unit. The rotor

and window should stay in place when you

do this. Only the armatures will move.

Rotating the rotor will move the window.

3. Repeat steps 1 & 2 to ensure that the airgap between the armature and its mating

friction surface is about 1/32" and that the

armature is kept square. (If the armature is

cocked, it may engage on one rim, giving

the appearance of engagement but failing

to provide full torque.)

If a scraping sound is noted when the output

shaft is spun, it means an armature is dragging. Insert a screwdriver through the vent

holes and slot in the fan and pry the dragging

armature (clutch or brake as observed) away

from the mating surface evenly all the way

around. Re-check the engagement as

described in step B of the Start-Up instructions.

Electrical Coil Data

Clutch Brake Clutch Brake Clutch Brake

Voltage–D.C. 90 90 24 24 6 6

Resistance UM-50 452 452 31.8 31.8 1.86 1.86

(OHMS) UM-100/180 392 392 26.7 26.7 1.81 1.81

UM-210/215 248 248 17.9 17.9 1.22 1.22

Amperes UM-50 .199 .201 .755 .755 3.23 3.23

UM-100/180 .230 .230 .896 .896 3.31 3.31

UM-210/215 .363 .363 1.34 1.34 4.9 4.9

WATTS (17.9) UM-50 18 18 18.1 18.1 19.4 19.4

UM-100/180 20.7 20.7 21.5 21.5 20.0 20.0

UM-210/215 32.7 32.7 32 32 29.6 29.6

Build Up UM-50 52 53 52 53 52 53

(Milliseconds) UM-100/180 72 75 72 75 72 70

UM-210/215 120 100 120 100 110 100

Decay UM-50 6.2 5.0 6.2 5.0 6.5 5.0

(Milliseconds) UM-100/180 12 10 12 10 12 10

UM-210/215 20 10 20 10 20 10

Mechanical Data

UM-50 UM-100/180 UM-210/215

Static Torque - lb. ft. 16 30 95

Maximum Speed - rpm 3600 3600 3600

Average Weight-lbs.

1020 10 13.2 30.6/31

1040 8.3 10.3 24.3/25

2030 13 16.5 41.3/42

3040 11.3 13.6 35/35.5

Inertia - WR - lb.ft.

Configuration 50 100/180 210 215

1020 input .021 .047 .190 .190

1020 output .0195 .050 .193 .195

1040 input .021 .047 .190 .190

1040 output .0105 .027 .112 .114

2030 input .021 .048 .198 .200

2030 output .0195 .050 .193 .195

3040 input .021 .048 .198 .200

3040 output .0105 .027 .112 .114

Page 7

7

Warner Electric • 800-825-9050 819-0343

Page 8

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship

within a period of one (1) year from the date of original purchase for consumer, commercial or

industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without

Warner Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation

charges prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information

may be obtained by writing the Customer Satisfaction Department, Warner Electric LLC, 449

Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made,

without charge, together with a refund for transportation costs. If found not to be defective, you

will be notified and, with your consent, the item will be repaired or replaced and returned to you

at your expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation

may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any

defective product. Warner Electric LLC neither assumes nor authorizes any other person to give

any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH

THE CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF

ORIGINAL CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL

USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you. This warranty gives you specific legal

rights and you may also have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without

notice. Weights do not include weight of boxing for shipment. Certified prints will be furnished

without charge on request to Warner Electric.

Warner Electric LLC

449 Gardner Street

• South Beloit, IL 61080

815-389-3771

• Fax: 815-389-2582

www.warnerelectric.com

P-273-1 819-0343 6/05 Printed in USA

Loading...

Loading...