Page 1

MTB II Modular Tension Brakes

P-259-1

819-0342

Installation Instructions

Page 2

Introduction

The instructions on this sheet cover installation

of all replacement components available for

modular tension brakes. These instructions are

divided into sections as designated by the

introductory headlines. Please check these

headings to locate the proper instruction for the

replacement components being installed.

Friction components, the most frequently

replaced items, are found near the end of these

instructions.

Failure to follow these

instructions may result in product damage,

equipment damage, and serious or fatal

injury to personnel.

Contents

Assembling Armature to Armature Carrier . . . . . . . .2

Installing the Armature Assembly . . . . . . . . . . . . . .3

Tapered Bushing Carrier . . . . . . . . . . . . . . . . . . . . .3

Straight Bore Carrier . . . . . . . . . . . . . . . . . . . . . . . .3

Mounting the Magnets . . . . . . . . . . . . . . . . . . . . . . .3

Adjusting the Armature Assembly . . . . . . . . . . . . . .4

Control Connection . . . . . . . . . . . . . . . . . . . . . . . . .5

Servicing Friction Surfaces . . . . . . . . . . . . . . . . . . .5

Rebuild Procedure . . . . . . . . . . . . . . . . . . . . . . . . . .5

Removal of the Armatures . . . . . . . . . . . . . . . . . . . .5

Replacement of Friction Pads . . . . . . . . . . . . . . . . .6

Assemble and Install the Armature Assembly . . . . .6

Wear-In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Modification of Straight Bore Armature Carriers . . .6

Bulk Head Mounting Brackets . . . . . . . . . . . . . . . . .7

Direct Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Universal Mounting . . . . . . . . . . . . . . . . . . . . . . . . .9

Brake Assemblies and Part Numbers . . . . . . . . . .10

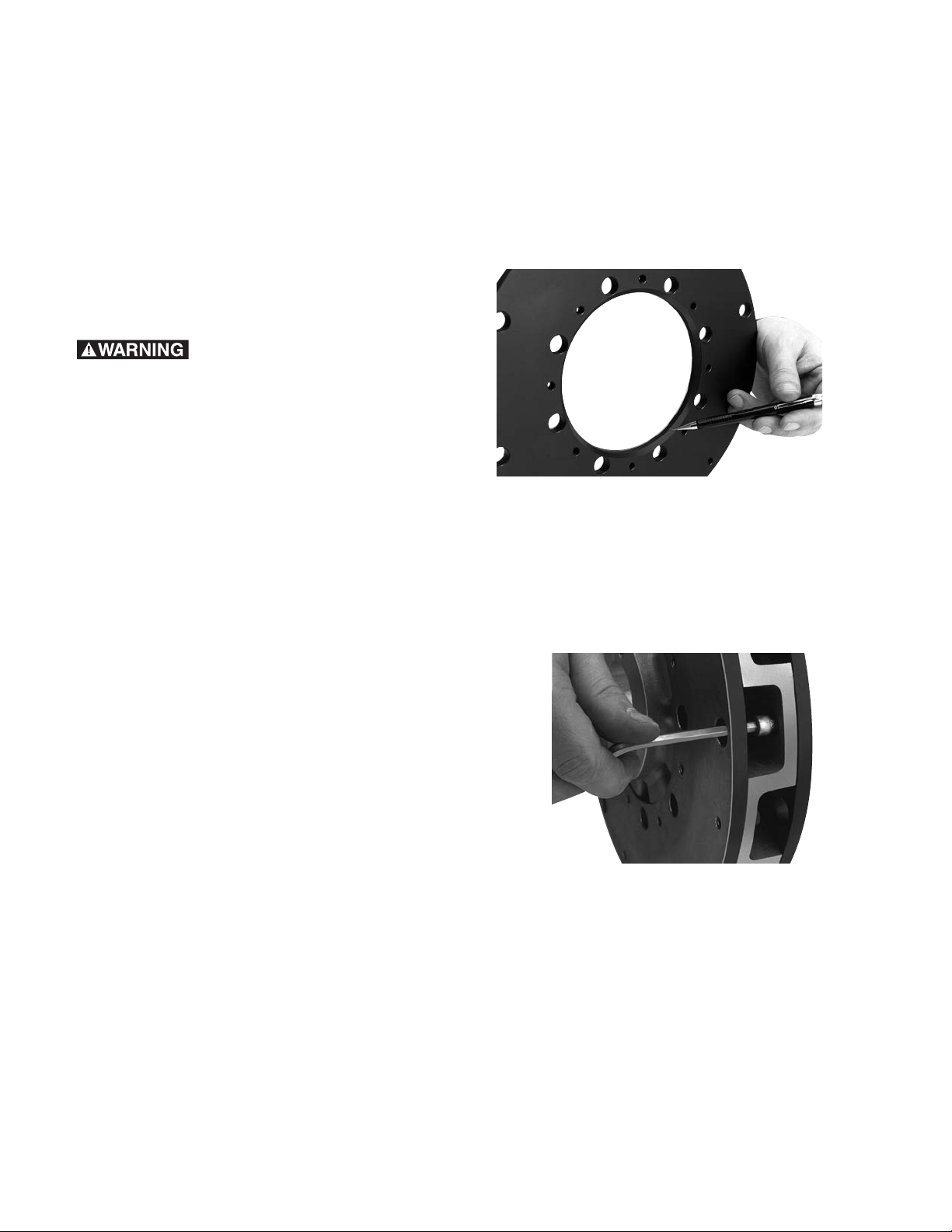

Assembling the Armature to the Armature

Carrier

The beveled edge on the inside diameter of the

armature is to be assembled facing the armature

carrier. Tighten all screws to 7-9 ft. lbs. torque.

(Figure 1)

Figure 1

Using the screws and lockwashers provided

with the armature(s), mount the armature(s) to

the armature carrier. If a single armature is used,

mount it on the appropriate side of the hub. Be

sure to allow easy access to the tapered

bushing. (Figure 3)

Figure 2

Warner Electric • 800-825-9050 819-0342

2

Page 3

Installing the Armature Assembly

Straight Bore Carrier

Insert the tapered bushing loosely into the

armature assembly and start the capscrews with

their lockwashers. (Figure 3)

Figure 3

Tapered Bushing Carrier

Install the key in the machine shaft keyway.

(Figure 4)

The armature carrier may be ordered with a

range of standard straight bores suitable for

various standard mounting products. Custom

bores are also available to adapt to special

devices. Consult the factory for information on

modifications.

Mounting the Magnets

If mounting brackets are used, mount the

brackets to the machine frame using the holes

prepared earlier. (Figure 6)

Figure 4

Slide the armature carrier assembly onto the

shaft to the approximate position required for

operation. Do not tighten the bushing yet

since final positioning will be required later.

(Figure 5)

Figure 6

If a Warner magnet carrier is used, place the

carrier on a horizontal surface with the pins

facing up. (Figure 7)

Figure 7

Figure 5

Warner Electric • 800-825-9050 819-0342

3

Page 4

If the magnets are to be free mounted, mount

the pins as required according to the free mount

layout. Place the magnets on the pins with the

lead wires outboard. (Figure 8)

Figure 8

Bolt the magnet carriers directly to the

mounting bracket with furnished capscrews

and lockwashers. (Figure 9)

Figure 9

Adjusting the Armature Assembly

For an armature assembly with a single

armature face, position the armature assembly

so the space between the back of the magnet

and the magnet carrier assembly is

approximately 1/4’’. (Figure 11)

Figure 11

For a dual armature assembly, position armature

assembly for approximately equal space behind

the magnets on each side. (Figure 12)

Note: If the universal mounting bracket is used

AND the armature assembly has 2 armatures,

the furnished spacers must be installed between

Figure 12

the magnet carriers and bracket. Tighten all magnet carrier mounting bolts securely. (Figure 10)

Tighten the armature assembly to the shaft. The

maximum axial runout on either face is to be

less than .015 T.I.R. (Figure 13)

Figure 10

Figure 13

Warner Electric • 800-825-9050 819-0342

4

Page 5

If the bore on the aluminum carrier has been

modified, the radial runout of the aluminum

carrier is not to exceed .008 inches. (Figure 14)

Figure 14

Servicing Modular Tension Brake Friction

Surfaces Magnet Inspection

Each magnet is supplied with visual wear

indicators. When the magnet is worn to these

indicators, pad replacement is required. (Figure

16)

If the magnet is supplied with an electronic wear

indicator, a signal will be sent to the control to

indicate replacement is required.

Both the visual and electronic wear indicators

are preset to indicate replacement at 85 percent

wear out, allowing 15 percent more life for

planned maintenance.

Control Connection

Contact with live wires can

cause injury or death. Be sure all power is

turned off before starting the connection

process.

Wire the magnets to the control in accordance

with the instructions included with the control.

Warner Electric offers several different systems

ranging from a simple manual control through a

roll follower system to several types of closed

loop systems. For more information, ask for

catalog P-771. (Figure 15)

A used armature should not be resurfaced

nor turned over to be used on the other side.

Figure 16

Rebuild Procedure

Note: When disconnecting and reconnecting

leads to the magnet, the input power must be

shut off to the control system.

Removal of the Armatures

If required, remove the armature assembly from

the shaft.

Figure 15

Remove the brackets and magnet carriers to

gain access to the armature(s). Remove the

armature face(s) with the armature in place, if

possible. If machine framework or components

prevent face(s) removal, the entire armature

assembly may have to be separated from the

brake hub and removed from the machine to

access the face(s).

Warner Electric • 800-825-9050 819-0342

5

Page 6

Since the armature and magnet faces are the

only tension brake components which sustain

wear, replaceable faces are offered for both, to

maximize brake life. The following instructions

deal with wear assessment and friction face

replacement.

Assemble and Install

the Armature Assembly

Follow the previous instructions for assembly

and installation of the armature assembly.

Wear-In

Replacement of Friction Pads

Remove the old pads from the magnets.

(Figure 17)

Figure 17

If the magnets are supplied with electronic wear

indicators, replace the hexagon brass contacts

(Warner Electric part no. 274-1029) on each

magnet. Tighten to 6-8 in. lb. torque. Attach the

new pads to the magnets. Tighten each screw

to 7-9 ft. lbs. torque. (Figure 18)

Replacement of the friction faces will require a

new wear-in period as the pads seat themselves

on the armature.

With a closed-loop control system, such as

dancer or load cell control, no changes in torque

will be apparent during wear-in. The control

system will compensate for any variations.

With a manual control system, however, an

unburnished brake will produce only about 75%

of its fully burnished torque. If full torque is

required at start-up, the brake should have a

preburnish period to fully seat the magnets on

the armature to provide full torque. If this is not

possible, several torque adjustment settings will

be required during the initial hours of on line

operation. Burnishing is the process of mating

the friction surfaces of a brake that is mounted

and ready for service.

Modification of Straight Bore

Armature Carriers

The straight bore armature carrier may be

modified to accept a variety of mountings.

If a modification to the armature is required, the

modified assembly must meet the following

requirements. With the armature assembly fully

installed on the shaft:

1. Maximum radial runout of the aluminum

carrier is .008”

2. Maximum axial runout on either face is .015”

Figure 18

Warner Electric • 800-825-9050 819-0342

6

T.I.R.

Page 7

Dimensions

7.250 (184.2) MAX. 7.250 (184.2) MAX.

3/4-10 UNC-2A

THREAD (2)

.200

(5.08)

SET-UP

1.644

(41.8)

EE

F

A

1.070

(27.2)

MIN.

MOUNTING

SPACER

3.440

(87.4)

3.125

(79.4)

.200

(5.08)

SET-UP

8.750 .003

(222.2 .762)

4.375 .015

(111.1 .381)

B

RADIUS

D

DIA.

C

BORE

G

DEG.

1.322

(33.58)

Modular Tension Brake

Bulk Head Mounting Brackets

Dual Armature Single Armature

inch (metric)

All Dimensions Nominal unless specified

Armature AB C BORE DEFG

Size Max. Stock* Bushing Max. Max. Max. Degree

10" 5.260 ± .020 7.750 1.750 .500–1.750 10.020 .479 3.55 180

(133.6 ± 0.5) (196.9) (44.45) (14.0–42.0) (254.5) (12.2) (88.9)

13" 6.822 ± .020 9.300 3.375 1.125–3.750 13.520 1.219 5.687 108 &

(173.3 ± 0.5) (236.2) (85.73) (28.0–95.0) (343.4) (31.0) (144.4) 144

15" 7.760 ± .020 10.230 3.375 1.125–3.750 15.325 1.219 6.875 120

(197.1 ± 0.5) (259.9) (85.73) (28.0–95.0) (389.3) (31.0) (174.6)

20" 10.250 ± .020 12.500 — 2.375–5.500 20.020 2.720 4.380 —

(260.4 ± 0.5) (317.5) ——(508.5) (69.1) (111.3)

* Stock bore is straight bore for use with Trantorque bushing.

Warner Electric • 800-825-9050 819-0342

7

Page 8

Modular Tension Brake–Direct Mounting

C

BORE

D

DIA.

G

DEG.

1.795

(45.6)

1.644

(41.8)

E

1.830

(46.6)

.865

(22.0)

MAX.

.350

(8.9)

MAX.

BULK

HEAD

.200

(5.08)

SET-UP

F

E

3.500 .002

(88.9 .051)

1.750 .015

(44.5 .381)

MAGNET

ASSEMBLY

A

1.322

(33.58)

7.080 (179.8) MAX.

5.330 .020

(135.4 .508)

.350

(8.9)

MAX.

BULK

HEAD

.200

(5.08)

SET-UP

Dual Armature Single Armature

inch (metric)

All Dimensions Nominal unless specified

Armature AB C BORE DE FG

Size Max. Stock* Bushing Max. Max. Max. Degree

10" 3.350 ± .020 N/A 1.750 .500–1.750 10.020 .479 3.550 120

13" 5.215 ± .020 N/A 3.375 1.125–3.750 13.520 1.219 5.687 72

(85.1 ± 0.5) (N/A) (44.45) (14.0–42.0) (254.5) (12.2) (88.9)

(132.5 ± 0.5) (N/A) (85.73) (28.0–95.0) (343.4) (31.0) (144.4)

15" 5.850 ± .020 N/A 3.375 1.125–3.750 15.325 1.219 6.875 60

(148.6 ± 0.5) (N/A) (85.73) (28.0–95.0) (389.3) (31.0) (174.6)

20" 8.125 ± .040 N/A — 2.375–5.500 20.020 2.720 ——

(206.4 ± 1.0) (N/A) ——(508.5) (69.1) —

* Stock bore is straight bore for use with Trantorque bushing.

Warner Electric • 800-825-9050 819-0342

8

Page 9

Modular Tension Brake–Universal Mounting Brackets

.404

.395

10.26

10.03

3.500 .003

(88.9 .762)

1/2-14 NPT

B

Radius

3.300

(83.8)

2.400

(61.0)

.500

(12.7)

.200

(5.08)

SET-UP

.200

(5.08)

SET-UP

1.644

(41.8)

E

E

F

1.500

(38.1)

5.085 (129.2) MAX.

1.835

(46.6)

.500

(12.7)

1/2-14 NPT

(Shown with

Dust Plug)

HOLES

1.750

(44.5)

1.210 (30.7)

.630

(16.0)

MIN.

A

C

BORE

D

DIA.

G

DEG.

(

)

1.322

(33.58)

7.125 (181.0) MAX.

inch (metric)

All Dimensions Nominal unless specified

Armature AB C BORE DE FG

* Stock bore is straight bore for use with Trantorque bushing.

Dual Armature Single Armature

Size Max. Stock* Bushing Max. Max. Max. Degree

10" 8.625 ± .020 9.500 1.750 .500–1.750 10.020 .479 3.550 180

(219.0 ± 0.5) (241.3) (44.45) (14.0–42.0) (254.5) (12.2) (88.9)

13" 10.187 ± .020 11.000 3.375 1.125–3.750 13.520 1.219 5.687 108 &

(258.7 ± 0.5) (279.4) (85.73) (28.0–95.0) (343.4) (31.0) (144.4) 144

15" 11.125 ± .020 12.000 3.375 1.125–3.750 15.325 1.219 6.875 120

(282.6 ± 0.5) (304.8) (85.73) (28.0–95.0) (389.3) (31.0) (174.6)

20" 13.470 ± .020 14.250 — 2.375–5.500 20.020 2.720 4.380 —

(340.4 ± 0.5) (362.0) ——(508.5) (69.1) (111.3)

Warner Electric • 800-825-9050 819-0342

9

Page 10

Brake Assemblies and Part Numbers

6

6

5

9

2

2

2a

1

3

9a

9b

4

4a

8

7

MTB II

Part Numbers

Item Description 10" Armature 13" Armature 15" Armature 20" Armature

1 Armature Carrier (Bushing Enters from Flush

Side of Carrier as Shown) 295-0021 295-0023 295-0019 –

Armature Carrier Reverse Taper (Bushing

Enters from Extended Side of Carrier 295-0031 295-0030 295-0029 –

Armature Carrier (Straight Bore) 295-0026 295-0027 295-0028 –

2 Armature (Replaceable Face) 5216-101-025 5216-101-026 5216-101-024 –

2a Armature Mounting Accessory (included with Armature 5216-101-023 5216-101-023 5216-101-023 –

3 Bushing (Customer Supplied) Taper Bore Browning P1 Browning R1 Browning R1 _

Straight Bore Use Trantorque. Consult Warner Electric

4 Female Pin Kit (includes 2 Pins) 5216-101-030 5216-101-030 5216-101-030 5216-101-030

4a Male Pin Kit (includes 32 Pins with Nuts and Lockwashers) 5216-101-029 5216-101-029 5216-101-029 5216-101-029

Magnet Carriers

5 Single Magnet Carrier Assembly 5216-295-004 5216-295-004 5216-295-004 5216-295-004

6 Dual Magnet Carrier Assembly 5216-295-005 5216-295-006 5216-295-007 5216-295-007

Carrier Brackets

7 Universal Mounting Bracket, Series 10-0, 13-0, & 20-0 (2) 5216-101-020 5216-101-020 5216-101-020 5216-101-020

Universal Mounting Bracket, Series 10-10, 13-13, & 20-20 (2) 5216-101-021 5216-101-021 5216-101-021 5216-101-021

8 Bulk Head Mounting Bracket (3) 5216-101-022 5216-101-022 5216-101-022 5216-101-022

Magnets

9 Magnet Assembly, Standard 5216-631-010 5216-631-010 5216-631-010 5216-631-010

Magnet Assembly, HICO 5216-631-013 5216-631-013 5216-631-013 5216-631-013

9a Friction Pad, Standard (Replacement Part Only) 5216-101-028 5216-101-028 5216-101-028 5216-101-028

Friction Pad, HICO 5216-631-031 5216-631-031 5216-631-031 5216-631-031

9b Preload Spring (1) (Included with Magnets) 808-0008 808-0008 808-0008 808-0008

10 Magnet Assembly with Wear Indicator 5216-631-009 5216-631-009 5216-631-009 5216-631-009

10a Friction Pad with Wear Indicator (Replacement Part Only) 5216-101-027 5216-101-027 5216-101-027 5216-101-027

(1) Two of each required for each brake magnet.

(2) Includes magnet carrier (4 & 5) mounting hardware.

(3) Includes magnet mounting hardware, bracket mounting bolts and spacers.

Browning is a registered trademark of Emerson Electric Co., Trantorque is a registered trademark of Trantorque Corporation.

Warner Electric • 800-825-9050 819-0342

10

Page 11

Warner Electric • 800-825-9050 819-0342

11

Page 12

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship

within a period of one (1) year from the date of original purchase for consumer, commercial or

industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without

Warner Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation

charges prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information

may be obtained by writing the Customer Satisfaction Department, Warner Electric LLC, 449

Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made,

without charge, together with a refund for transportation costs. If found not to be defective, you

will be notified and, with your consent, the item will be repaired or replaced and returned to you

at your expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation

may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any

defective product. Warner Electric LLC neither assumes nor authorizes any other person to give

any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH

THE CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF

ORIGINAL CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL

USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you. This warranty gives you specific legal

rights and you may also have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without

notice. Weights do not include weight of boxing for shipment. Certified prints will be furnished

without charge on request to Warner Electric.

Warner Electric LLC

31 Industrial Park Road • New Hartford, CT 06057

815-389-3771 • Fax 815-389-2582

www.warnerelectric.com

P-259-1 819-0342 12/11 Printed in USA

An Altra Industrial Motion Company

Loading...

Loading...