Page 1

CBC-1000 Series Loop Unidirectional

Clutch/Brake Control System

P-275

819-0496

Installation & Operating Instructions

Page 2

Contents

Introduction

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Selection Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Control Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Diagnostics Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back Page

Ordering Information

Model Number Part Number

CBC-1000 . . . . . . . . . . . . . . . . . . . . . . . . . 6060-448-001

Encoder Cable (Accessory) . . . . . . . . . . . . 6060-101-001

100 Pulse Per Revolution Encoder

w/10’ Cable. . . . . . . . . . . . . . . . . . . . . . . . 6060-101-010

250 Pulse Per Revolution Encoder

w/10’ Cable. . . . . . . . . . . . . . . . . . . . . . . . 6060-101-025

600 Pulse Per Revolution Encoder

w/10’ Cable. . . . . . . . . . . . . . . . . . . . . . . . 6060-101-060

1200 Pulse Per Revolution encoder

w/10’ Cable. . . . . . . . . . . . . . . . . . . . . . . . 6060-101-120

RS-232 to RS-422/485

Converter (Accessory. . . . . . . . . . . . . . . . . 6060-101-232

Warner Electric’s CBC-1000 is a closed-loop

positioning control with error compensation designed

for industrial clutch/brake applications. The position

loop is closed through encoder

feedback which generates pulses proportional to load

motion. The CBC-1000 uses this feedback to

determine the optimum brake actuation point. The

control can be programmed to operate in one of two

distinct modes: absolute or incremental. The CBC1000 includes eight solid state control outputs, a

batch counter and a serial communications interface.

The CBC-1000 system consists of four key

elements: the CBC-1000, a clutch/brake, a

clutch/brake control, and an encoder. Nearly any

electric clutch/brake size and configuration can be

used. These products are described in Warner

Electric’s Clutch/Brake Catalog, P-1234. The

Clutch/ Brake control, also found in Warner Electric’s

Clutch/Brake Catalog, should have solid-state

compatibility. Simple on-off, soft start/stop, and

overexcitation controls may all be utilized based on

the desired velocity profile. Warner Electric also offers

industrial grade encoders of various resolutions.

Failure to follow these instructions

may result in product damage, equipment damage,

and serious or fatal injury to personnel.

2

Warner Electric • 800-825-9050 P-275 • 819-0496

Page 3

Addendum Sheet

Warner Electric LLC

31 Industrial Park Road

New Hartford, CT 06057

tel 815-389-3771

fax: 815-389-2582

An Altra Industrial

Motion Company

CBC-1000AH

Service and Installation Instructions Additions to P-275

The CBC-1000AH Closed Loop Unidirectional Clutch/Brake Control System has had a feature addition and

the current manual number P-275 does not reflect this addition. The added feature is the auto home

capability (CBC-1000AH) which requires a marker input from the encoder to find its user defined home

position which might be lost during a power loss condition. There are a few simple steps that should be

followed to set up the CBC-1000AH properly.

1. Connect all the necessary components making sure the sig z wire (the marker pulse input) from the

encoder goes to control input 11 (sig z/marker) on the CBC-1000AH. This input was previously labeled

Continuous/Single.

2. After the encoder and the controls are installed and turned on, position the machine at home and reset

the counter.

3. Rotate the machine until the ‘ref’ light to the left/bottom of the display lights up.

4. Record the number displayed on the counter when the ‘ref’ light is lit.

5. Enter the programming mode by pressing the RUN/PGM key on the front panel of the control and

typing 1000. The number that you recorded should be put in programming line 1 (h, the home

reference number). Subsequently, all the programming line numbers in the P-275 manual will be

incremented by 1.

6. Every cycle when the CBC-1000AH sees the marker pulse the home reference number that was

recorded will be loaded into the counter value on the front panel display. It is important that this value is

as close as possible to what it should be. If more than ten cycles have occurred and your error is greater

than +/- 15, you should decrease/increase respectively the home reference number.

7. After cycling approximately ten times observe your actual braking distance number (BRK DIS, key 8 on

the front keypad) enter the programming mode and record this number in line 2 (bd, initial braking

distance). Subtract the home reference number recorded in line 1 from the move preset (MOV PST, key 2

on the front keypad). This number must be greater than the actual braking distance number. If the

braking distance number is larger, then the encoder needs to be rotated without the machine being

rotated to change where the marker pulse occurs. Otherwise, the marker pulse will occur after the brake

has come on and will not be detected.

8. Before exiting the program mode you will need to turn Count Retention off (CrEt, programming line 8). If

count retention is left on and a power failure occurs while the system is in its braking mode when power

is reapplied, it will take three cycles to find home.

The auto home feature will be very helpful when a power failure occurs and the encoder/control are unable to

track position. When power is reapplied a remote start can be applied and the machine will rotate until the

marker pulse is detected then the home reference number that was loaded in will be downloaded to the counter and CBC-1000AH will know its position and perform an accurate stop. The machine may miss its first home

position if the power up position is past where the marker pulse occurs.

The CBC-1000AH is programmed to not allow any outputs to fire until a home reference number is entered.

Also, depending on the speed of your system a lower resolution encoder may be needed to increase the length

of the marker pulse so it can be properly detected. The encoder that has been sent is a 600ppr

encoder. Therefore, your MOVE PRESET (key 2 on the front panel) needs to be changed to 600 if you are only

moving one revolution per cycle.

Page 4

Page 5

Selection Procedures

Select the Proper Clutch/Brake

Determine torque and inertia requirements.

Calculate heat dissipation for required cycle rate.

For best accuracy, mount clutch/brake directly on

nip or drive shaft. Avoid backlash.

Select Encoder (Quadrature)

Select encoder PPR for desired system resolution

(i.e., inches/pulse, degrees/pulse. Determine input

frequency; do not exceed 20 KHz (20,000 pulses/

sec). Mount encoder directly to nip or drive shaft for

best accuracy. Refer to Encoder Selection, page 7.

Select Clutch/Brake Power Supply

Use CBC-700 overexcitation control for best accuracy. Use CBC-500/550 for soft starting and/or

stopping. Note: Brake autogap may have to be

removed for best accuracy. Refer to clutch/brake

control, page 7.

Plan System Logic (Switching Requirements)

Use absolute mode for indexing applications such

as conveyors and turntables or cutoff applications

where close registration is required. Use

incremental mode for cutoff applications where

close registration is required. Use incremental mode

for cutoff applications. Refer to mode of operation,

page 8. Determine switching and relays required for

machine operation. Refer to pages 14-19 for

specific wiring options. Examples of incremental and

absolute wiring schematics are shown on pages 18

and 19.

Calculate Scaling Factor

Reference display scaling, page 8, to scale the

display to read inches, meters, degrees, rotations,

etc.

Determine Program Steps

Select absolute or incremental mode, output delays

and other options. Refer to Programming Section,

page 12.

Serial Communications

For data collection or remote operation, refer to

Serial Interface on pages 20-23.

Warner Electric • 800-825-9050 P-275 • 819-0496

3

Page 6

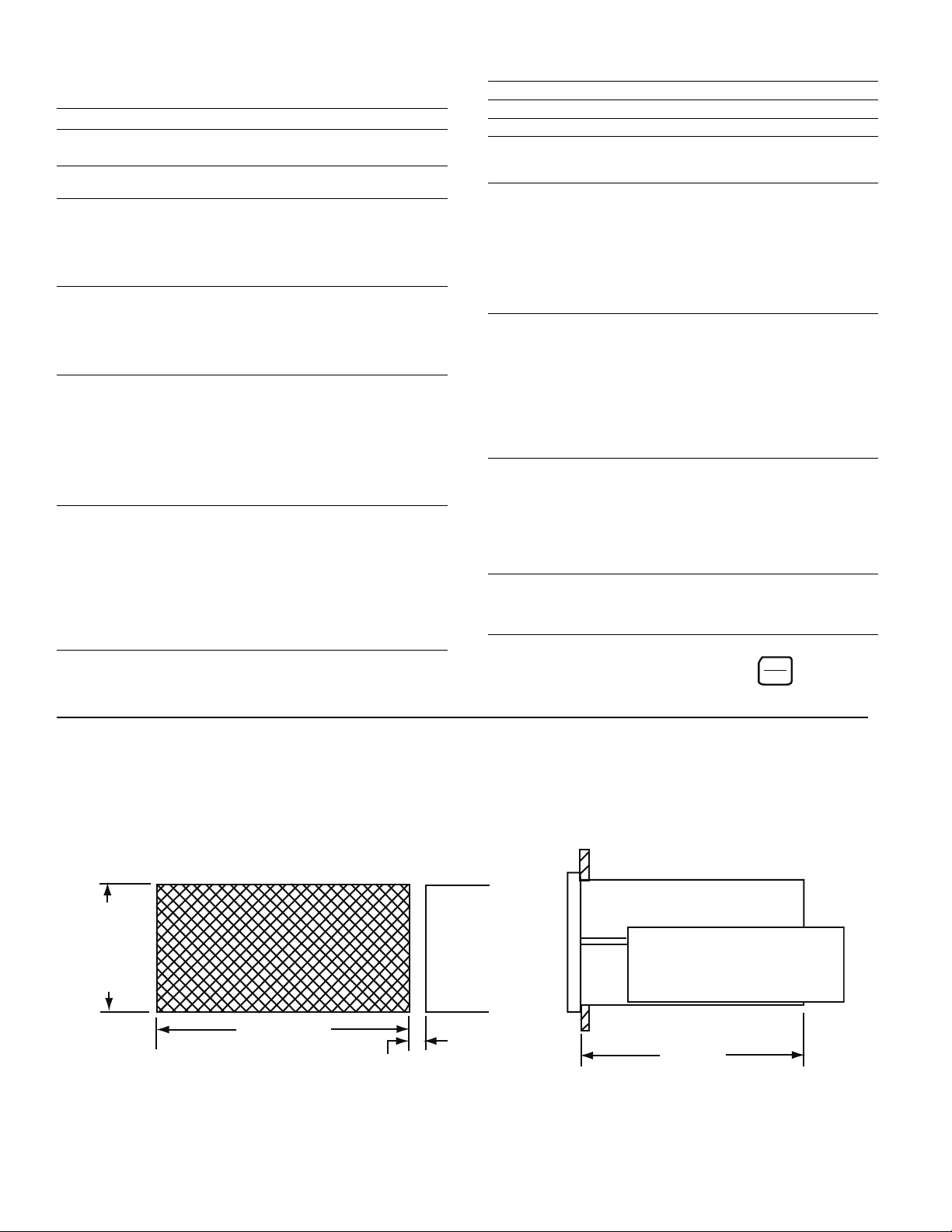

Specifications

RESET

CLEAR

Press

to clear error code

Make panel cutout. Affix adhesive gasket (if required) to panel. Remove

panel straps and slide unit thru cutout. Slide panel straps into enclosure

guides. Thread 5/8” long hex washer head screws into guides using a

3/16” hex driver and tighten securely.

5.43 ± 040

(138 + 1, -0 mm)

allow 0.32” (8mm) each

side between cutouts

2.68 ± .030

(68 + 1, -0 mm)

5.68

(144 mm)

Part No. 6060-448-001

Input Power 100 to 130 VAC, 50/60 Hz, 20VA

(200 to 260 VAC selectable)

Auxiliary Supply 12 VDC @ 175 mA

Used for powering encoder, etc.

Main Counter

Range 6 Decade

Reset Input 2 Individual with 6 decade range

Operation Quadrature

Reset Input External and front panel

Count Rate (20 kHz external input frequency)

Batch Counter

Range 6 Decade

Presets 1 with 6 Decade range

Operation Count UP by detecting Zero Speed

Reset Through front panel only

Output Latched, fixed to output terminal 21

Signal A and B Inputs

Input Frequency DC, 20 kHz quadrature max.

Input Type Single ended, Current Source

Input Logic Times 2

Input High Level 3.25 VDC min.

Input Low Level 1.75 VDC max.

Input Impedance 1.0Ω to common

Input current 3.25 mA steady state

Input Response 10 µs. min high and low time

Control Inputs

Input Frequency DC to 20 Hz max. each input

Input Type Single ended, current sinking

Input Logic Both Edge and Level sensitive

as defined by input use

Input High Level 10 VDC min. to 20 VDC max.

Input Low Level 0 VDC min. to 2 VDC max.

Input Impedance 4.7Ω pullup to +12 VDC

Input Current 2.5 mA steady state

Input Response 25 ms. make and break time

Display

Decade 7 Decade, 0.6" red LED

Decimal Point User programmable

Range: xxx.xxx to xxxxxx

Keyboard Sealed tactile feel, 18 positions

Program Security Program LOCK of lines 1 - 34

Control Outputs

Type 8 Solid State, 100 mA sink max.,

24 VDC max.

Serial Interface

Type RS-422A/485 compatible

Baud Rate Selectable: 300, 600, 1200, 2400

Parity Selectable: None, Odd, Even

Data ASCII

Format Start bit, 7 bit ASCII data, Parity bit,

Stop bit

I.D. Number Programmable 0 to 98: Allows

multidrop systems

Diagnostics

Test 0 Keyboard Test

Test 1 Non-Volatile RAM Test

Test 2 Input Test

Test 3 Output Test

Test 4 Display Test

Test 5 Program Memory Test

Test 6 Date Code Test

Test 7 Serial I/O Test

Test 8 Return to Factory Programming

Mechanical

Enclosure Aluminum extrusion with molded

VALOX bezel. 2.91” high x 5.67” wide x

6.03” deep overall

Weight 2.5 lbs.

Cutout 5.43” ± 0.04” x 2.68” ± 0.03”

Panel Thickness 1/16” to 1/4”

Panel Depth 5.68” minimum

Environmental

Operating Temp. 0° to +50°C (32° to 122°F)

Storage Temp. -18° to 85°C (0° to 186°F)

Ambient Humidity 90% and noncondensing

Controller Error Codes

Error 2: Low AC Line Voltage

Error 3: Input Frequency too fast

Error 4: Processor time fully utilized

Dimensions For Panel Mounting

4

Warner Electric • 800-825-9050 P-275 • 819-0496

Page 7

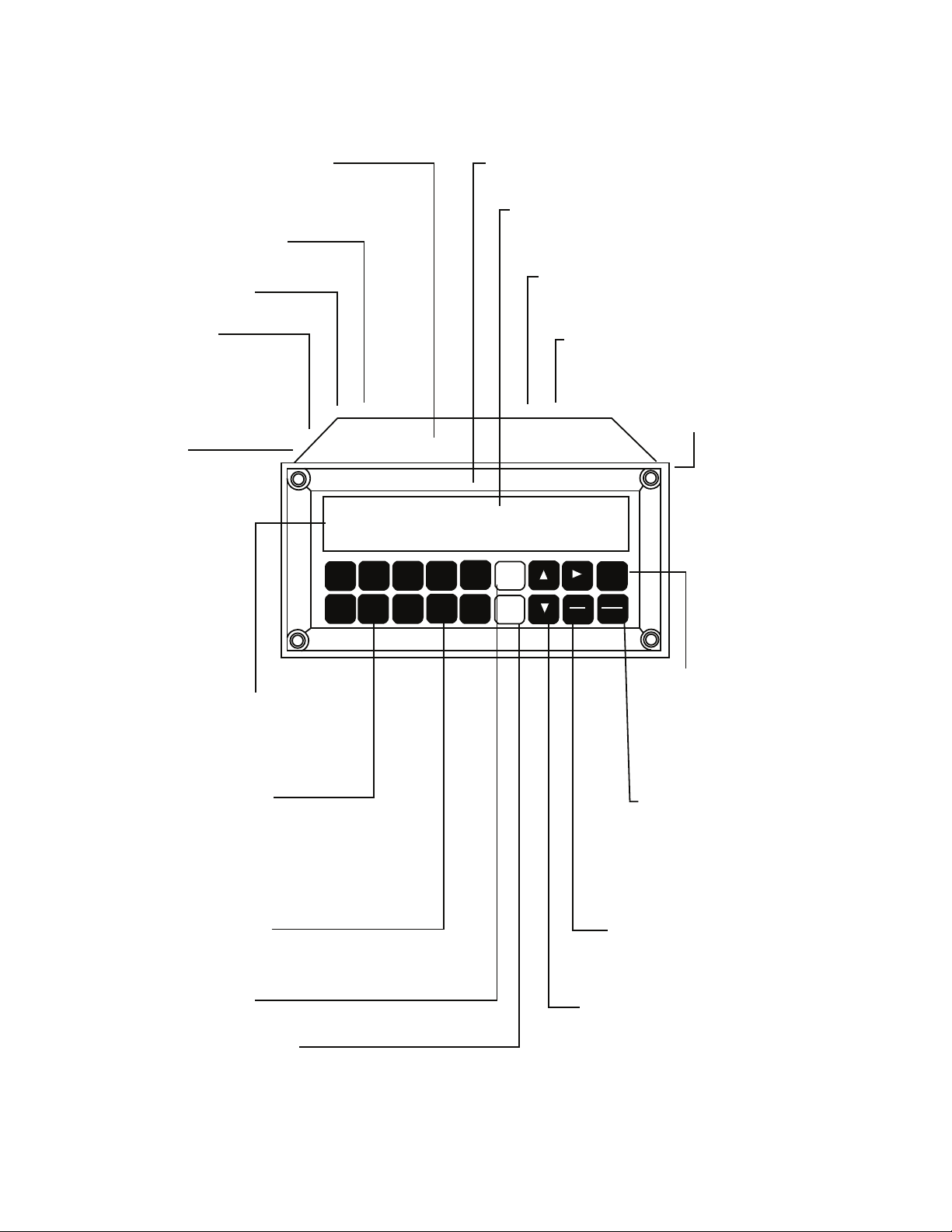

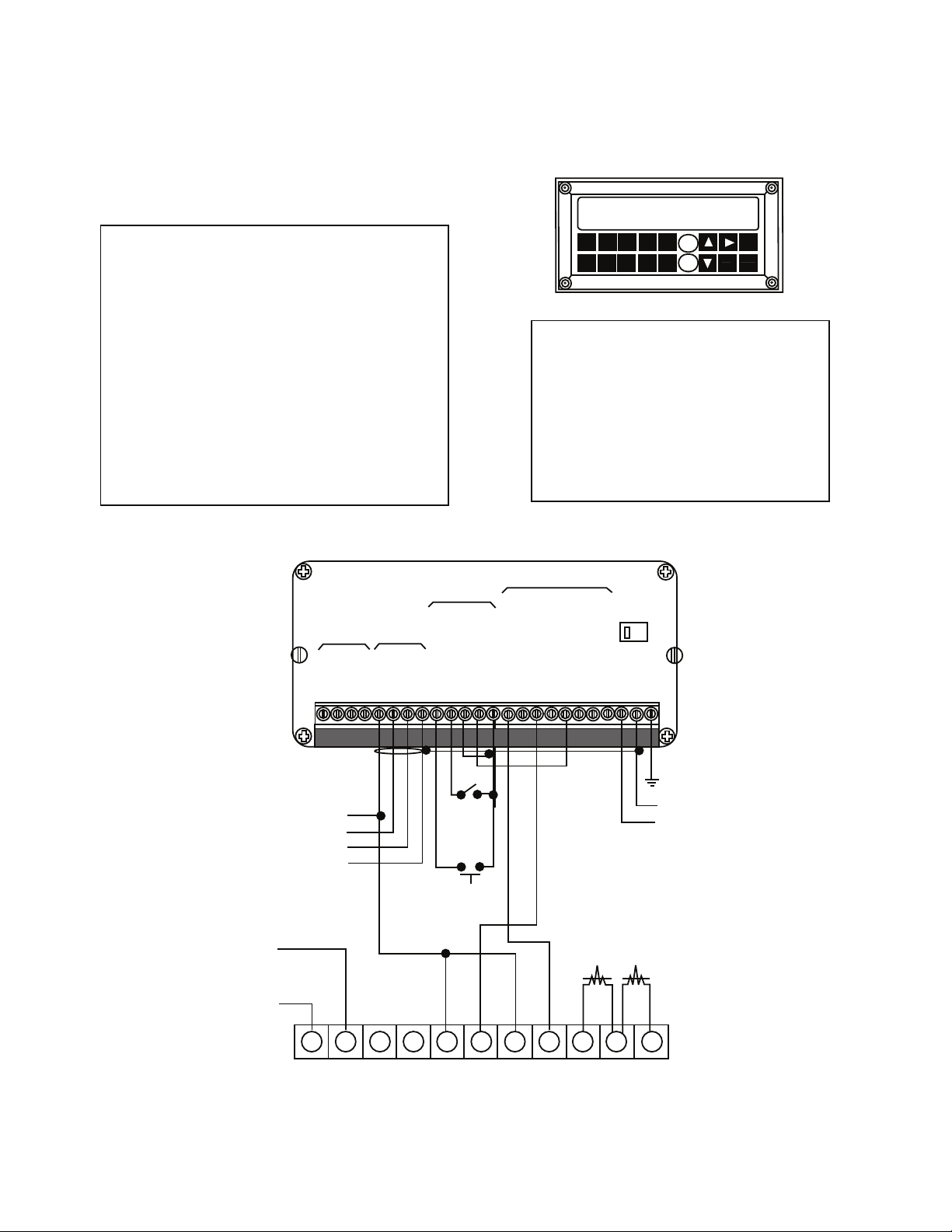

144.0001

CBC-1000WARNER ELECTRIC

E.W. PGM

CNT EDIT

BRK BCH

MOV PST

1

COUNT

2

MOV PST

3

E.W.

4

5

9

0

6

BATCH

7

BCH PST8BRK DIS

EDIT

RUN

PGM

RESET

CLEAR

START

STOP

Metal Enclosure

• Improves Noise Immunity

• Eliminates RFI Emissions

• High Strength for Industrial Environment

Auxiliary Supply

Encoder Inputs

Control Inputs

Control Outputs

Display and Mode Annunciators

Display Function Keys

Numeric Keys 0-9

Start Key

Stop Key

CURSORS

RUN/PGM

RESET/CLEAR

EDIT

Neoprene Gasket Seal

AC Power Input

Serial Data I/O

Large LED Display

Sealed Front Panel

• NEMA 4 Rated

• 7 Decades

• High Intensity, High Contrast

• RS-422A/485

• Up to 32 units may be bussed together

• 115/230 VAC Selectable

• Built-in Line Filter

• Non-volatile Memory

• Used to enter the EDIT mode

to alter presets. Press again to

exit the EDIT mode

• Enabled by Programming Line

6 in the “off” position

• Resets the controller during operation

if Programming Line 5 is “on”

• Resets the Batch Counter if it

is being displayed

• Acts to clear the display in the

EDIT and PGM modes

• Used to switch between the RUN and

PGM modes

• UP: moves display toward top of program list in PGM mode

• RIGHT: moves display on same line in PGM mode

• DOWN: moves display thru programming steps in PGM

mode

• Used to initiate brake

• Used to initiate clutch

• Used to enter numeric

data in the EDIT and PGM modes

• COUNT: displays encoder input in engineering units

• MOV PST: displays desired length

• E.W.: displays desired duration of Early Warning

• BATCH: displays current batch count

• BCH PST: displays batch preset

• BRK DIS: displays stopping distance

• Displays the operation of the controller

(CNT, PGM, EDIT)

• Indicates what is being shown on the display

(MOV PST, E.W., BCH, BCH PST, BRK DIS)

• Start

• Early Warning

• Brake On (Stop)

• Zero Speed

• Zero Speed + Delay Time 1

• Zero Speed + Delay Time 2

• Auxiliary Start

• Batch Complete

• Start

• Stop

• Continuous/Single

• Reset

• Quadrature

• 12 VDC @ 175mA

Control Overview

Warner Electric • 800-825-9050 P-275 • 819-0496

5

Page 8

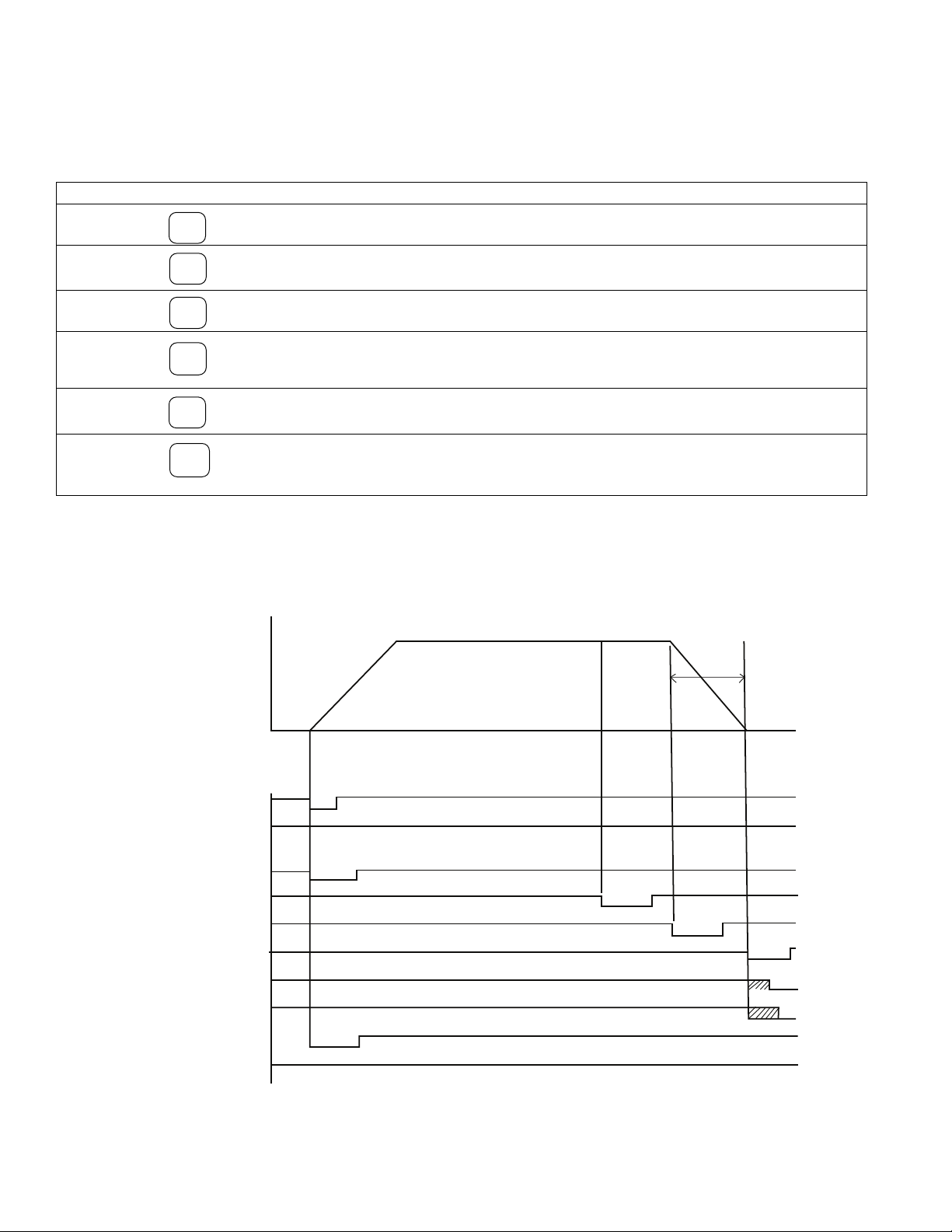

Operation

Velocity

(Speed)

Inputs:

(Active Low)

Outputs:

(Momentary)

(Edge Triggered)

Start

Start

Stop

Early Warning

Brake On

Zero Speed

Zero Speed & Delay Time 1

Zero Speed & Delay Time 2

Auxiliary Start

Batch Complete

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

Delay Time 1

Delay Time 2

Time

(count)

Braking

Distance

Brake On

Point

Early Warning

Point

Start

Point

Successful operation will require knowledge of the following definitions and their relationships to the

timing diagram.

Function Key Definitions

Count The actual move distance, in pulses or scaled into engineering units (inches, feet, rotations, degrees, etc.) displayed

Move Preset The desired move distance in pulses or scaled into engineering units. This is the value the operator enters to select a

Early Warning A distance prior to Move Preset at which the early warning output is activated. Expressed as pulses or engineering

1

COUNT

2

MOV

PST

3

E.W.

dynamically.

new move distance.It can also be locked during the RUN mode by simply programming line 6 to “off”.

units, this output can be used to accomplish a soft brake (slow down), energize valves, etc.

Batch A cumulative batch counter that can be dynamically displayed to show the number of operations, cycles, etc. When

6

BATCH

this counter reaches the value programmed by the Batch Preset (key 7) the Batch Complete Output (pin 21 on

CBC-1000) is activated. The batch counter can be manually or automatically reset.

Batch Preset A programmable batch counter activates the batch complete output when the value programmed has been reached

Braking Distance The actual distance required to stop. This value is dynamically updated to determine the brake actuation point.

7

BCH

PST

8

BRK DIS

by the batch (key 6).

Factory default is 25 pulses or engineering units which is only used for the first cycle after power-up. After the first

cycle the CBC-1000 will tune to the braking distance required.

Timing Diagram

6

Warner Electric • 800-825-9050 P-275 • 819-0496

Page 9

Operation

Speed Speed

Speed

On - Off

CBC-400

Time

Soft Start/Stop

Time

CBC-500

Note: Remove the brake autogap for

best

accuracy when soft stopping.

Overexcitation

Time

CBC-700

CBC-750

The CBC-1000 system cycle to cycle accuracy will

usually be plus or minus several encoder counts.

Various factors can affect positional

accuracy, the most significant of which are

discussed below:

d. System Resolution - Can also be increased

by mechanical means. For example,

decreasing the diameter of a nip roll

connected to the encoder will increase

system resolution.

The maximum encoder resolution at any operation

speed is:

Encoder Selection

a. Type - Only quadrature type encoders may be

used.

b. Location - The encoder should be mounted

as close as possible to the location where

accuracy is desired, minimizing the effects of

backlash and slippage. Direct mounting is

preferred to indirect mounting.

c. Resolution - Encoder resolution should be

maximized so the inherent plus or minus

several count tolerance equates to the

minimum linear or rotational inaccuracy. The

product of encoder counts and rotational

speed must be less than the input speed of

20,000 pulses per second (20kHz). The

adjacent table simplifies selection:

Clutch/Brake Control

1

x 20,000 x 60 = Max. PPR

RPM

Encoder Speed Encoder Resolution

(RPM) (pulses/rev.)

12,000 - 4,801 100

4,800 - 2,001 250

2,000 - 1,001 600

1,000 - 0 1200

480 - 0 2500

240 - 0 5000

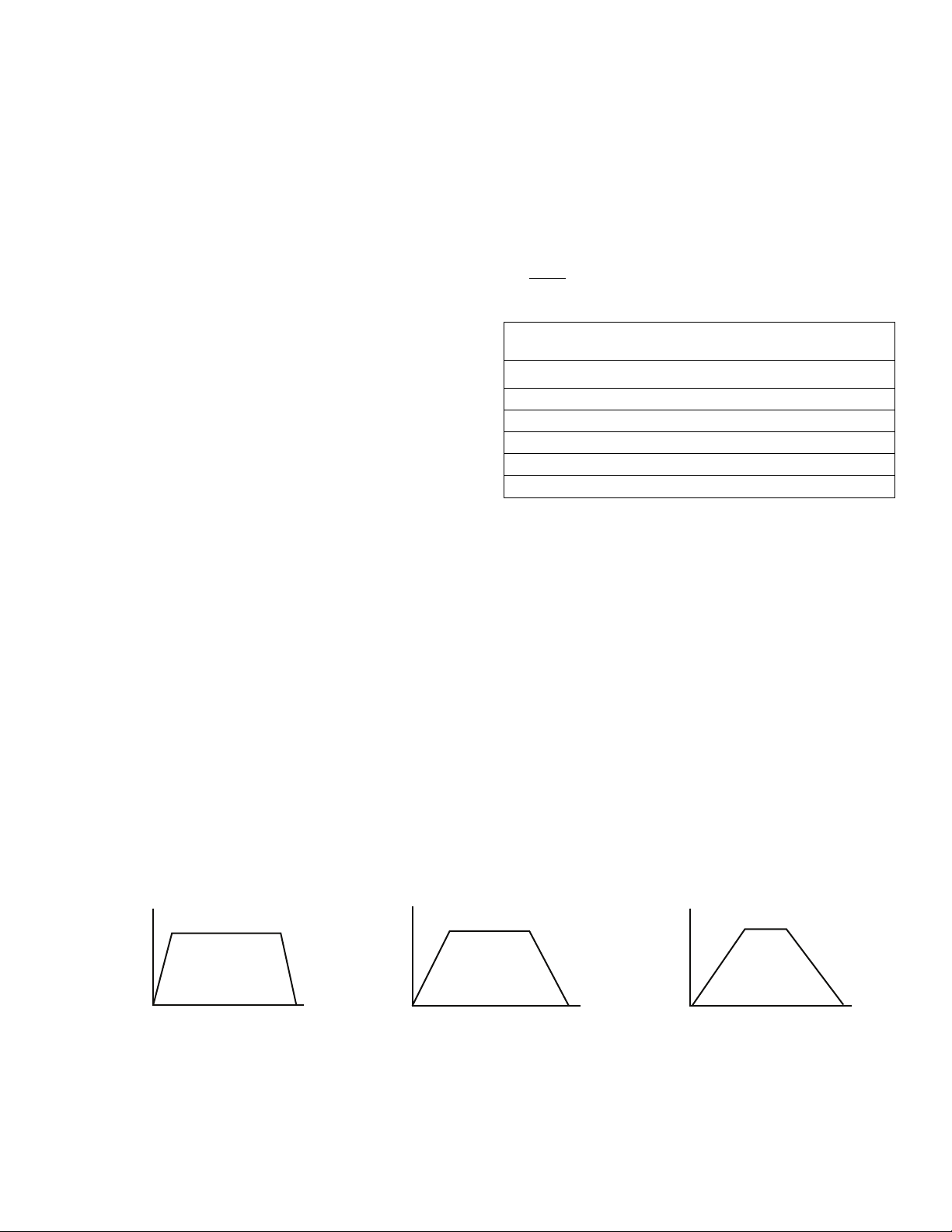

Various velocity profiles may be achieved by properly selecting the clutch/brake control. These can

generally be classified as overexcitation, on-off, and soft start/stop as depicted by the profiles below.

These are shown in order of decreasing system accuracy. Accompanying each diagram are the

recommended clutch/brake controls per given classification. The control should have solid-state

switching. This will reduce unnecessary time delays inherent in electromechanical or mechanical

switching devices. In addition, the system will not require external components such as relays, etc.

Warner Electric • 800-825-9050 P-275 • 819-0496

7

Page 10

Mode Of Operation (Program Line 8)

The CBC-1000 is programmable to operate in either the absolute or incremental mode of operation.

Absolute mode is used in systems that tend to accumulate error. A common example is an indexing

conveyor or table. When used in this mode, the CBC-1000 maintains its position in an absolute sense and

compensates for any slight errors made on the prior move.

The incremental mode of operation is used for systems that will not accumulate error, such as a cut to length

paper sheeter or an auger filler. In such systems, each consecutive move is independent of the previous one.

In the incremental mode a reset signal to terminal 12 is required from one of the zero speed outputs or an

external source (Ref. page 18 for wiring diagram). The key to mode selection is programming line 8, Auto

Reset (on/off):

Absolute mode of operation - Auto Reset “On”

Incremental mode of operation - Auto Reset “Off”

Display Scaling (Program Line 3)

• Changing the CC & decimal point will affect presets

• CC should not exceed 1.0

• CC of .5 displays encoder pulses

The display can be easily scaled to display engineering units (inches, meters, degrees, rotations, etc). Line 3

of the programming (correction constant) prompts input of a factor (five decades) that will be multiplied by

the incoming pulse train to display the desired engineering units. Remember that the CBC-1000 includes a

times 2 internal multiplier effectively doubling the resolution of a given encoder. Thus, if one wishes to view

encoder pulses, a multiplier (correction constant) of ‘0.5’ should be entered on Line 3 in the programming

mode. The resolution of the encoder should be chosen to take advantage of the best instantaneous

accuracy of the calibrator. The best instantaneous accuracy is obtained with a correction constant setting not

exceeding 1.0000. The scaled units are also used to measure stop and move distances. Consequently, the

scaled units selected affect the system resolution. For example, with the correction constant set the display

at 1.0 inches, this is the smallest measurable increment. Remember, the decimal point must be programmed

(programming line 4) to display the desired display resolution. This resolution is also used in the denominator

of the correction constant equation. The general form of the equation for the correction constant is given

below.

CC (Correction Constant) = Distance traveled in engineering units per one revolution of the encoder

Display Resolution Desired X Encoder Resolution X 2

(0.001, 0.01, 1.0)

Example: Web measurement - Display in inches, display resolution in tenths of an inch

Encoder Resolution - 600 PPR

Mounting - Direct, via 4” diameter wheel

Calculation:

8

Warner Electric • 800-825-9050 P-275 • 819-0496

cc =

π0 = π x 4 = 12.5664

0.1 X 600 pulses/revolution X 2

= 0.1047

Page 11

t 0: Keyboard Test: Tests the function of the front panel keys.

Press to begin test. RUN: will be displayed. Press each front panel key except to

test key. The display will indicate if the key is functional.

t 1: Non-Volatile RAM Test: Tests CBC-1000 RAM.

Press to begin test. The test will return PASS or FAIL. Press to continue.

t 2: Input Test: Tests whether CBC-1000 is accepting inputs.

Press to begin test. Activate inputs to control.

If the input is received, a character will be displayed. “Ab” - Encoder

input, “1” - Start, “2” - Stop, “3” Continuous mode, “4” Reset. Press to continue.

t 3: Output Test: Used to determine whether CBC-1000 outputs are functional.

Press to begin test. Press keys 1-6 on the front panel. The corresponding output will

turn on and latch. Use a VOM to check for a high level state on terminal strip of CBC-1000.

Press to exit test.

t 4: Display Test: Tests function of each LED on front panel.

Press to begin test. Each digit of front panel display will automatically be turned on.

Check for faulty LEDs. Press to continue.

t 5: Program Memory Test: Tests program memory capability.

Press to begin test. PASS or FAIL will be returned. Press to continue.

t 6: Date Code Test: Displays software date code.

Press to display date code. Press to exit. Continue.

t 7: Serial Test: Tests connections with serial data interface module.

Press to begin test. PASS or FAIL will be displayed. Press to continue.

t 8: Factory Default Settings: Returns CBC-1000 to factory settings.

Press to return all program steps to factory default settings.

RUN

PGM

CBC-1000 Diagnostics Tests

Warner Electric • 800-825-9050 P-275 • 819-0496

9

Page 12

Programming

Press

Press

Press

Press

Press

Press

to display the current length or position (up to six digits).

to display the move preset (up to six digits).

to display the early warning preset (up to four digits).

to display the batch counter (up to six digits).

to display the batch counter preset (up to six digits).

to display the average braking distance (up to four digits).

1

COUNT

2

3

6

7

8

MOV PST

E.W.

BATCH

BCH PST

BRK DIS

Move

Preset

2

MOV PST

2

MOV PST

EDIT

EDIT

EDIT

EDIT

EDIT

EDIT

EDIT

EDIT

3

E.W.

7

BCH PST

1

6

COUNT

RESET

CLEAR

RESET

CLEAR

RESET

CLEAR

RESET

CLEAR

BATCH

RESET

CLEAR

Early

Warning

Batch

Preset

Batch

Counter

Reset

System

Home

To home the system: Press then press .

Press , then press , and press , now enter a new value using the numeric keys, then press .

Press

Press

Press

, then press

, then press

, then press

, and press

, and press

, and press

enter a new value using the numeric keys, then press .

enter a new value using the numeric keys, then press .

or to change the value incrementally. Then press .

, now

To manually reset the batch counter. , then press .Press

Or

View Presets and Values

The six function keys may all be viewed during the RUN mode. To view their values, press the desired function key and the value is displayed with the corresponding display annunciator. The controller process continues without interruption.

Entering Presets

The three presets (MOV PST, E.W., and BCH PST) may also be changed during the RUN mode provided that

programming line 6 (panel lock) is programmed “off”. To edit, press the desired preset function key, next

press the EDIT key followed by the CLEAR key. Enter the new value using the numeric keys, then press the

EDIT key to exit the edit mode and to replace the existing value in memory. The CBC-1000 will use the new

number entered after the edit mode is exited.

10

Warner Electric • 800-825-9050 P-275 • 819-0496

Page 13

Program Mode

Press

, then press

, then press

Move down one program line

or press

, then press line number, and press

Move up one program line

Select Options.

To exit the program: Press .

1

000

EDIT

RUN

PGM

RUN

PGM

COUNT

..

.

to jump to the line changing.

To enter the program mode to access the 34 features shown on pages 12 and 13, press the program key

and enter the 4-digit password (1000) followed by the down cursor. NOTE: Before entering the program

mode, the stop key or stop input should be activated. The CBC-1000 automatically activates the brake

upon entry into the program mode.

To enter the program mode:

Latching Outputs

To latch the outputs or keep the outputs activated until a certain position is reached during the cycle, all

zeros must be entered on programming lines 9-14 (shown on page 12). These latched outputs must be

turned off at a predetermined function (programming lines 19-22) by a drop command. Outputs may be

dropped at the Start command, Move Preset, Early Warning or Reset command. Press the front panel

buttons (1-6) and a “d” will be displayed for the output to be dropped.

Example: Program Line 19 ----.----.----.----. d

Releases zero speed + delay 2 output at start command

Latching the batch counter reset, which is programming line 15, requires the operator to manually reset

the batch counter (key 6) when it reaches the value programmed in the batch preset (key 7). By setting the

batch counter reset to momentary (00.01 to 99.99 seconds), the CBC-1000 will automatically reset the

batch counter and it will hold the batch complete output (pin 21) active for the time programmed.

Warner Electric • 800-825-9050 P-275 • 819-0496

11

Page 14

RESET

CLEAR

Programming

LINE DISPLAY DESCRIPTION OPTIONS DEFAULT

1 b d . Initial Braking Distance - - - - 2 5 The first brake distance used by the

CBC-1000 at power-up.

2 b d . Au E . # of Cycles Averaged 1 - 9 3 The number of cycles used for the running

average of brake distance.

3 c c . Correction Constant - . - - - - 0 . 5000 The scaling factor for the front panel display

(0.5000 for display in pulses).

4 d P . Decimal Point off, .0, .00, .000 oFF Number of decimal places displayed. Affects

all distance values in other registers.

5 F r S t. Front Panel Reset on - off on Enables or disables front reset in the RUN

Mode.

6 P L o c . Front Panel Lock on - off oFF “On” enables and “Off” disables changing

MOV PST, E.W., and BCH PST while running.

7 C r E t . Count Retention on - off on Retains system position during power off.

8 A r S t . AUTO Reset on - off oFF Select Absolute (ON) or Incremental (OFF)

mode of operation.

9 o 1 . Start Output 00.00 to 99.99 00 . 10 The duration (momentary or latched) of the

Start Output in seconds. For latched input,

enter all zeros or press .

10 o 2 . Early Warning Output 00.00 to 99.99 00 . 10 The duration (momentary or latched) of the

Early Warning output in seconds.

11 o 3 . Brake on Output 00.00 to 99.99 00 . 10 The duration (momentary or latched) of the

Brake On output in seconds.

12 o 4 . Zero Speed Output 00.00 to 99.99 00 . 10 The duration (momentary or latched) of the

Zero Speed output in seconds.

13 o 5 . Zero Speed + Delay 1 00.00 to 99.99 00 . 10 The duration (momentary or latched) of the

Zero Speed + Delay 1 output in seconds.

14 o 6 . Zero Speed + Delay 2 00.00 to 99.99 00 . 10 The duration (momentary or latched) of the

Zero Speed + Delay 2 output in seconds.

15 o 8 . Batch Counter Reset 00.00 to 99.99 LATCH Momentary for automatic (internal) reset or

latched for manual (operator) reset.

16 d 1 . Delay Time 1 00.00 to 99.99 0 . 50 The delay time for Zero Speed + Delay 1

output in seconds.

17 d 2 . Delay Time 2 00.00 to 99.99 1 . 00 The delay time for Zero Speed + Delay 2

output in seconds.

18 0 5 P . Zero Speed Window 01, .05,.10, .25 sec. 10 The time window in seconds to determine

Zero Speed, Zero Speed equals no pulses

received within window.

19 5 Start Command 1-6 - - - - - - Releases latched outputs at the start

Release Outputs command. Press 1-6 on the front panel to

release or drop output.

20 L Move Preset Release 1-6 - - - - - - Releases latched outputs at the move preset.

Outputs Press 1-6 on the front panel to release output

or drop output.

12

Warner Electric • 800-825-9050 P-275 • 819-0496

Page 15

Programming

LINE DISPLAY DESCRIPTION OPTIONS DEFAULT

21 E Early Warning 1-6 - - - - - - Releases latched outputs at the

Release Outputs Warning signal.

Press 1-6 on the front panel to

release output or drop output.

22 r Reset Command 1-6 - - - - - - Releases latched outputs at reset.

Release Outputs Press 1-6 on the front panel to

release output or drop output.

23 b r . Baud Rate off, 300, 600, 900 oFF See Serial Interface Section.

1200, 2400

24 P A r Parity nonE, odd, EuEn nonE See Serial Interface Section.

25 i d . n o . Identification Number 0 - 99 0 Control identification number. See

Serial Interface Section. See

Troubleshooting Section on page

25 for further information on

diagnostic tests listed below.

26 t 0 . Keyboard Test rdy y Front panel keyboard test.

27 t 1 . Non-Volatile RAM test Press y Non-Volatile RAM test.

28 t 2 Input Test Ab - encoder inputs Control input test.

1 - start

2 - stop

3 - cont. 4 reset

29 t 3 Output Test 1 - E y Control output test.

30 t 4 Display Test Press y Front panel display test.

31 t 5 Program Memory Test Press y Control program memory test.

32 t 6 Date Code Test Press y Displays Date Code of CBC-1000

33 t 7 Serial Test Press y Control serial test.

34 t 8 Factory Default Press y Returns control to factory default

Settings settings.

y

Refer to

Diagnostics

Test, Page 9

software.

Warner Electric • 800-825-9050 P-275 • 819-0496

13

Page 16

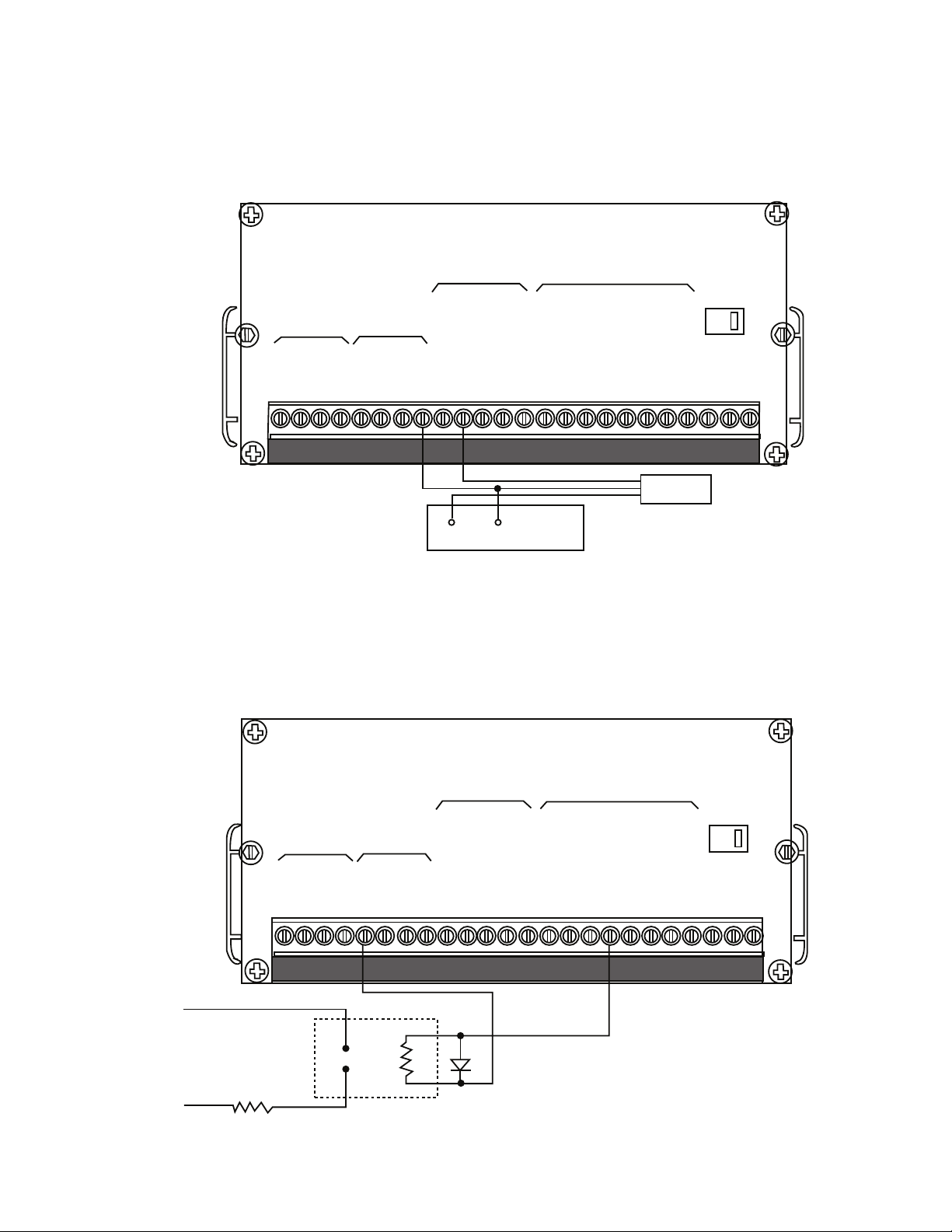

Installation

Note:

1) Set Selector switch for correct input voltage.

2) Unit is not fused. Wire through .25 AMP Slow

Blow fuse.

3) The case shield should not be used when the

encoder is mounted on a grounded surface.

Note: the Start Input is enabled by connecting

terminal 11 to terminal 13 (see below).

In the single cycle mode, the external start

input is ignored. The front panel start key must

be pressed to initiate the clutch.

In the continuous mode, both the front panel

start key and the external start input can be

used to initiate the clutch.

Closed: Continuous cycle mode

Open: Single cycle mode

Start

Reset

Serial

Date

Serial

Date

Serial

Date

Signal

Inputs

Signal

Inputs

Signal

Inputs

Control

Inputs

Control

Inputs

Control

Inputs

Control

Outputs

Control

Outputs

Control

Outputs

VAC

1 2 3 5 6 74 8 9 10 11 12 13 14 15 16 17 1819 20 21 22 23 24

1 2 3 5 6 74 8 9 10 11 12 13 14 15 16 17 1819 20 21 22 23 24

1 2 3 5 6 74 8 9 10 11 12 13 14 15 16 17 1819 20 21 22 23 24

VAC

VAC

+VDC

Sig A

Sig B

Common

(WHT)

(RED)

(BLUE)

(BLK)

Case

(Shield)

(BLK Heat Shrink)

Hot

Neut

115 VAC

0r

230 VAC

Bld. Gnd

Neutral

Hot

Batch Complete

Aux. Start

Zero Speed + Delay 2

Zero Speed + Delay 1

Zero Speed

Early Warning

Start

COM

Reset

Continuous/Single

Stop

Start

Brake On

COM

Sig B

Sig A

+12V

TXD +

TXD -

RXD +

RXD -

Bld. Gnd

Neutral

Hot

Batch Complete

Aux. Start

Zero Speed + Delay 2

Zero Speed + Delay 1

Zero Speed

Early Warning

Start

COM

Reset

Continuous/Single

Stop

Start

Brake On

COM

Sig B

Sig A

+12V

TXD +

TXD -

RXD +

RXD -

Bld. Gnd

Neutral

Hot

Batch Complete

Aux. Start

Zero Speed + Delay 2

Zero Speed + Delay 1

Zero Speed

Early Warning

Start

COM

Reset

Continuous/Single

Stop

Start

Brake On

COM

Sig B

Sig A

+12V

TXD +

TXD -

RXD +

RXD -

115

115115

Connection Diagrams

AC Input and Quadrature Encoder Input Wiring

Start and Reset Input Wiring

Continuous/Single Input Wiring

14

Warner Electric • 800-825-9050 P-275 • 819-0496

Page 17

Installation

Serial

Data

Signal

Inputs

Control

Inputs

Control

Outputs

VAC

Serial

Data

Signal

Inputs

Control

Inputs

Control

Outputs

VAC

Closed: Brake On Output (terminal 16) activated

Open: Normal Operation

Note: A start input can not be executed when the switch is closed.

Stop

(E-Stop)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

RXD -

RXD +

TXD -

TXD +

+ 12V

Sig A

Sig B

COM

Start

Stop

Continuous/Single

Reset

COM

Start

Early Warning

Brake On

Zero Speed

Zero Speed + Delay 1

Zero Speed + Delay 2

Aux. Start

Batch Complete

Hot

Neutral

Bld. Gnd

RXD -

RXD +

TXD -

TXD +

+ 12V

Sig A

Sig B

COM

Start

Stop

Continuous/Single

Reset

COM

Start

Early Warning

Brake On

Zero Speed

Zero Speed + Delay 1

Zero Speed + Delay 2

Aux. Start

Batch Complete

Hot

Neutral

Bld. Gnd

CBC-1000 Open Collector Outputs:

COM

(Terminal 13)

Output

(Terminals 14 thru 21)

100 mA. sink @ 24 VDC

115

Typical

of each

output

30V

- Connect to brake Input terminal of the clutch/brake control (i.e. Terminal 6 on the CBC-700)

- Connect to clutch Input terminal of the clutch/brake control (i.e. Terminal 8 on the CBC-700)

- Connect to clutch and brake Input terminals of the clutch/brake control (i.e. Terminals 5 & 7 on the CBC-700)

Connection Diagrams

Stop Wiring (E-Stop)

Control Output (Outputs 1-8, Terminals 14-21) Wiring

Duration of output signal controlled by programming lines 10-17.

Warner Electric • 800-825-9050 P-275 • 819-0496

15

Page 18

Delay Timers 1 or 2 may be used to initiate an

external start input signal and function like a cycle

timer. The delay times are programmed on lines

16 and 17 of the program mode. In the diagram,

Delay Time 1 is used to initiate the external start

input signal to begin the next operation.

Note: the CBC-1000 must be configured in the

continuous mode as shown.

Output 4, 5 or 6 (Terminals 17, 18, 19) may be

used to reset the counter in the incremental

mode. Remember, in the incremental mode

(programming line 8, auto Reset -”off”) it is

necessary to externally reset the counter at the

completion of the previous operation. In the

diagram, Delay Time 1 (programming line 16) is

used to reset the counter, Delay Time 2 to start.

The Batch Complete Output may be used to stop

operations after a preset batch count (programmed

via function key 7, see page 10). Once this batch

preset has been reached, it is necessary to reset

the batch counter (function key 6, see page 10) to

continue another batch. The batch counter can be

reset manually or automatically by programming

line 15 (refer to page 12).

12345678910 11 12 13 14 1516 17 18 19 20 21 22 23 24

12345678910 11 12 13 14 1516 17 18 19 20 21 22 23 24

1 2345 678 910 11 12 13 14 15 16 1718 19 20 21 22 23 24

RXD -

RXD +

+12V

Sig A

Sig B

TXD -

TXD +

COM

Start

Stop

Continuous/Single

Reset

COM

Start

Early Warning

Brake On

Zero Speed

Zero Speed + Delay 1

Zero Speed + Delay 2

Aux. Start

Batch Complete

Hot

Neutral

Bld. GND

RXD -

RXD +

+12V

Sig A

Sig B

TXD -

TXD +

COM

Start

Stop

Continuous/Single

Reset

COM

Start

Early Warning

Brake On

Zero Speed

Zero Speed + Delay 1

Zero Speed + Delay 2

Aux. Start

Batch Complete

Hot

Neutral

Bld. GND

RXD -

RXD +

+12V

Sig A

Sig B

TXD -

TXD +

COM

Start

Stop

Continuous/Single

Reset

COM

Start

Early Warning

Brake On

Zero Speed

Zero Speed + Delay 1

Zero Speed + Delay 2

Aux. Start

Batch Complete

Hot

Neutral

Bld. GND

Serial

Data

Signal

Inputs

Serial

Data

Signal

Inputs

Serial

Data

Signal

Inputs

Control

Inputs

Control

Outputs

Control

Inputs

Control

Outputs

Control

Inputs

Control

Outputs

VAC

VAC

VAC

115

115

115

Installation

Connection Diagrams

Delay Timer Used as a Cycle Timer

Delay Timer Used to Reset the Count in the Incremental Mode of Operation

Batch Complete Configured to Stop Operation after Batch Preset has been Reached

16

Warner Electric • 800-825-9050 P-275 • 819-0496

Page 19

Installation

14

+12V

COM

Auxiliary

Power

Supply

Sensor

Note: Use shielded

wire on sensor

when far away

from control to

minimize noise.

-12V

+12V

Relay

115 VAC

Load

H

N

115 VAC

Serial

Data

Signal

Inputs

Control

Inputs

Control

Outputs

Power

Serial

Data

Signal

Inputs

Control

Inputs

Control

Outputs

Power

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

RXD -

RXD +

TXD -

TXD +

+12V

Sig A

Sig B

COM

Start

Early Warning

Continuous/Single

Reset

COM

Start

Brake On

Zero Speed

Zero Speed + Delay 1

Aux. Start

Batch Complete

Hot

Neutral

Bld. GND

Zero Speed + Delay 2

Early Warning

RXD -

RXD +

TXD -

TXD +

+12V

Sig A

Sig B

COM

Start

Early Warning

Continuous/Single

Reset

COM

Start

Brake On

Zero Speed

Zero Speed + Delay 1

Aux. Start

Batch Complete

Hot

Neutral

Bld. GND

Zero Speed + Delay 2

Early Warning

230

230

With Auxiliary Power Supply (Rear View)

Typical Sensor Wiring

Typical Relay Wiring

Warner Electric • 800-825-9050 P-275 • 819-0496

17

Page 20

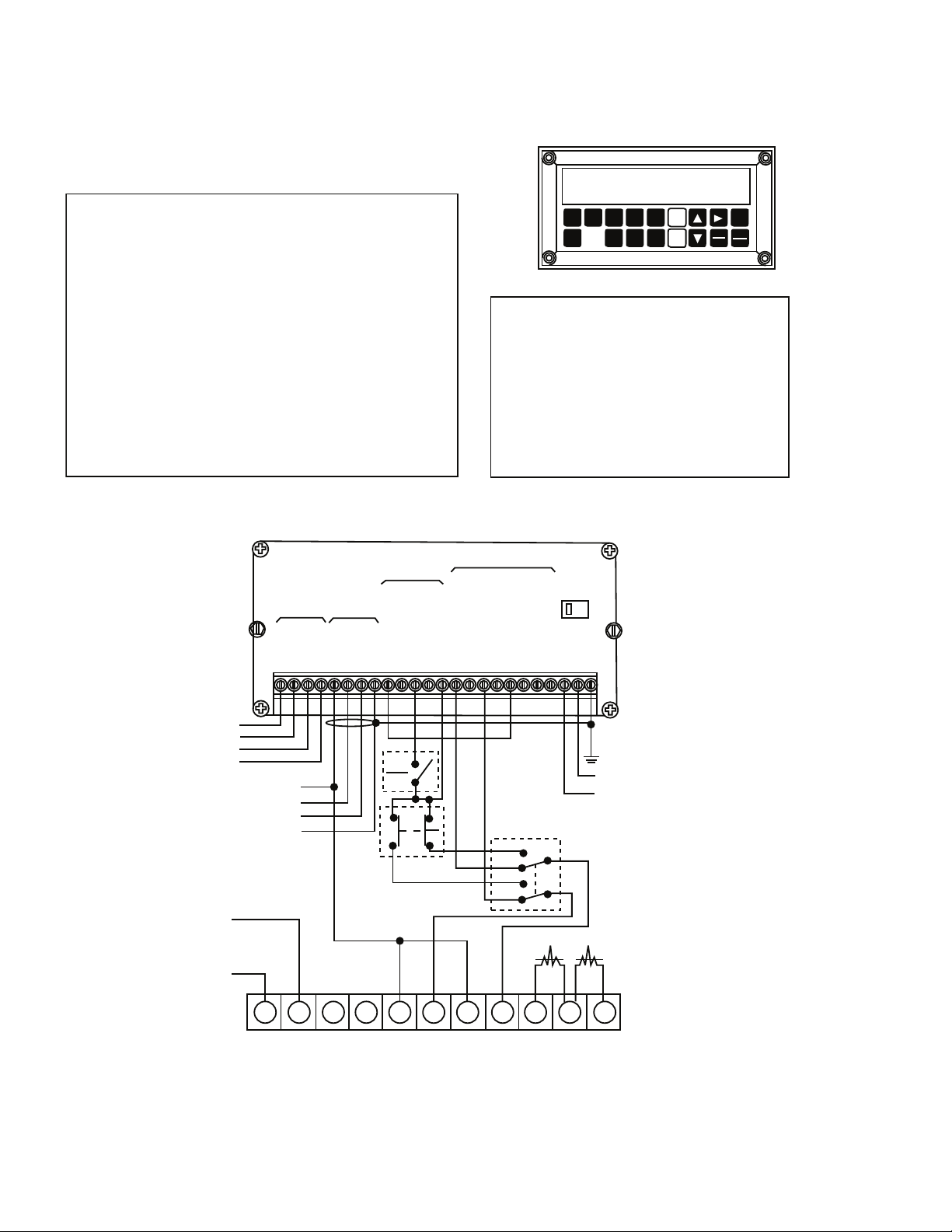

Applications

E.W. PGM

CNT EDIT

BRK BCH

MOV PST

START

STOP

144.0001

CBC-1000WARNER ELECTRIC

1 2 3

4 5

678

9 0

EDIT

RUN

PGM

RESET

CLEAR

Programming Table

Line 8 Auto Reset ON

Line 16 Delay Time 1.200

NOTES:

1. Absolute mode requires Line 8 be “on” and that

reset be used only to “home”.

2. Continuous/Single switch used to stop machine at

end of cycle when in open position. Closed

position enables Start input, terminal 9

which will restart the machine.

Serial

Data

Signal

Inputs

Control

Inputs

Control

Outputs

VAC

From RS-422/485

Interface:

TXD —

TXD +

RXD —

RXD +

+ VDC

SIG A

SIG B

COMMON

CBC-700-90: 120 VAC

CBC-700-24: 24 VAC

Brake Input Clutch Input

+ +

—

—

Aux.

Supply

(12 VDC)

+

—

Brake Clutch

CBC-700:

(WHT)

(RED)

(BLUE)

(BLK)

Cont.

Single

CL

JOG

RUN

JOG

RUN

JOG

RUN

12345678910 11

Note:

Counter must be reset after

Jogging to a new home position.

Note:

Case shield should not be

used when the encoder is

mounted on a grounded

surface.

HOT

NEUT

115 VAC

CASE

(Shield)

RXD —

RXD +

TXD —

TXD +

+ 12V

Sig A

Sig B

COM

Start

Stop

Continuous/Single

Reset

COM

Start

Early Warning

Brake On

Zero Speed

Zero Speed + Delay 1

Zero Speed + Delay 2

Aux. Start

Batch Complete

Hot

Neutral

Bld. GND

115

12345678910 11 12 13 14 15 16 17 18 19 2120 22 23 24

COUNT

MOV PST

E.W.

BATCH

BCH PST

BRK DIS

Absolute Mode of Operation

18

Warner Electric • 800-825-9050 P-275 • 819-0496

Page 21

Applications

NOTES:

1. Incremental mode requires Reset before restarting.

This may be achieved using outputs 5 or 6.

CAUTION: Machine may restart following key pad

STOP. Continuous/Single Jumper enables esternal start input generated through Output 6, terminal 19. Keep single continuous switch open to

disable the external start signal.

Programming Table

Line 8 Auto Reset OFF

Line 16 Delay Time 1.70

Line 17 Delay Time 21.0

144.0001

CBC-1000

WARNER ELECTRIC

E.W POM

CNT EDIT

BRK BCH

MOV PST

1 2

3

4

5

6 78

9

0

COUNT MOV PST

E.W.

BATCH

BCH PST BRKDIS

STOP

START

EDIT

RESET

CLEAR

RUN

PGM

+VDC

SIG A

SIG B

COMMON

(WHT)

(RED)

(BLUE)

(BLK)

STOP

START

CBC-700:

Aux.

Supply

(12 VDC)

+

Brake Input

Clutch Input

+

+

_

_

_

Brake

Clutch

(Shield)

NEUT

HOT

115 VAC

Note:

Case shield should not be

used when the encoder is

mounted on a grounded

surface.

VAC

Control

Outputs

Control

Inputs

Signal

Inputs

Serial

Data

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

RXD –

RXD +

TXD –

TXD +

+12V

Sig A

Sig B

COM

Start

Stop

Continuous/Single

Reset

COM

Start

Early Warning

Brake On

Zero speed + Delay 1

Zero speed + Delay 2

Aux. Start

Batch Complete

Hot

Neutral

Bld. GND

Zero Speed

115

CBC-700-90: 120 VAC

CBC-700-24: 24 VAC

1 2 3 4 5 6 7 8 9 10 11

Incremental Mode Of Operation

Warner Electric • 800-825-9050 P-275 • 819-0496

19

Page 22

Serial Interface

RS-232 to

RS-422/485

converter

RS-232 to

RS-422/485

converter

RXD

RXD

RXD

RXD

COM

COM

COM

COM

TXD

TXD

TXD

TXD

—

—

—

—

+

+

+

+

RXD —

RXD +

TXD —

TXD +

COM

1234 8

CBC-1000

CBC-1000

CBC-1000

RXD —

RXD +

TXD —

TXD +

COM

BLDG

GND

RXD —

RXD +

TXD —

TXD +

COM

BLDG

GND

Bldg Gnd

Bldg Gnd

COMPUTER

TXD +

from

CBC-1000

TXD —

COM

To

Receiver

+5V

(2)

10 kΩ max. to

100 Ω min.

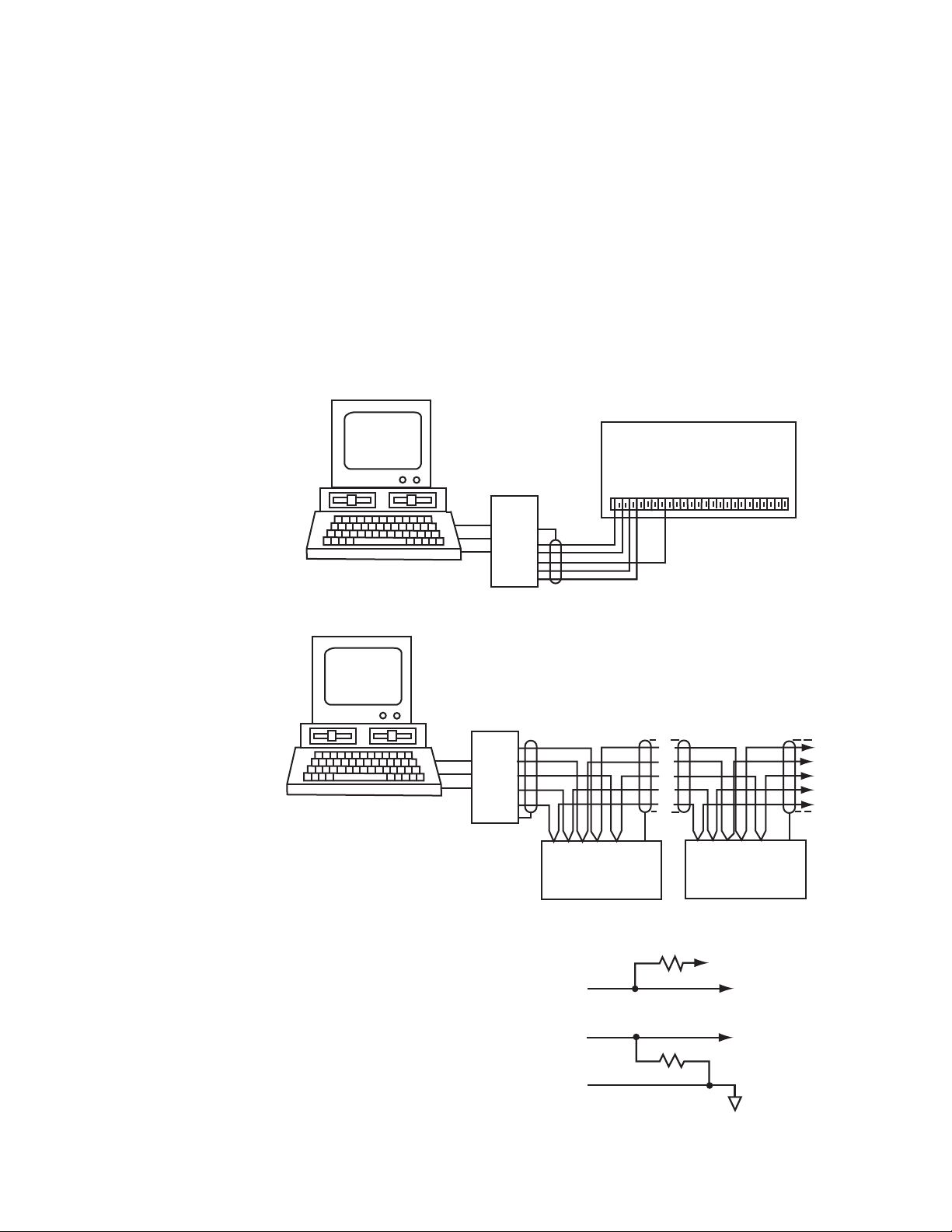

Overview

The CBC-1000 is equipped with an RS-422A/485 Serial Interface for remote data collection,

programming and networking applications. Front panel keyboard and some external control inputs

are supported. Additionally, facilities are provided for individual (local) and group (global) control of

single and multiple unit configurations respectively in a bus oriented system. Knowledge of serial

communications and the ASCII data format is required by the user who wishes to use the remote

capabilities or to integrate the control into a larger system.

Two applications will be discussed. The first consists of a single CBC-1000 and a display terminal. It

explains the use of the serial commands that mimic the keyboard operation and some control

inputs. An application of multiple units under the control of a host computer will also be discussed.

Single Unit Wiring

20

Multiple Unit Wiring

Termination

The RS-422A/485 receivers require termination to

minimize the effects of noise while the bus is not

being driven. The CBC-1000 incorporates the

terminations internally (as shown). When

connection is made to an RS-422/485 device other

than the CBC-1000, the receiver should be

terminated as shown.

Warner Electric • 800-825-9050 P-275 • 819-0496

Page 23

Serial Interface

Cable Selection

The CBC-1000 serial interface uses a simple

interconnect scheme and low cost wiring making it

superior to parallel data transfer schemes. Through

three wire pairs, remote operation at distances up to

5,000 feet can be implemented. The following

general guidelines should be observed:

1. Use #24 AWG Twisted pair, overall

shielded cable.

2. Use a “daisy chained” connection scheme for bus

systems.

In the RUN mode the numbers 1, 2, 3, 6, 7, & 8

cause new lines to be transmitted.

We have seen how the CBC-1000 control works for

remote viewing; we will now see how

programming may be done from a remote

location.

You may program only one CBC-1000 control at a

time. If the unit is in program mode via the front

panel keyboard, then it will not respond to the serial

input. To enter the PROGRAM mode, first send the

RUN/PGM (‘P’) character. The control will “answer”

by transmitting the LOC entry line as shown below.

3. if a “multidrop” system is used, keep the drop

length at 10% of the main line.

4. Tie the cable shield to Building Ground at the

CBC-1000 end of the cable.

Single Unit Operation

The operator can monitor the control locally via the

front panel keyboard and display. The serial

interface extends these monitoring activities to a

remote location. The connection of a remote display

terminal is straightforward. The baud rate and parity

for both devices must be the same. The ID number

should be set to ‘0’ (line 25 in the program table).

When power is applied to the CBC-1000 control, it

will start a continuous serial transmission of the

count:

CBC-1000 Display R: CNT. 123.456

when in the RUN mode.

The function keys (1, 2, 3, 6, 7, & 8) are set to scroll

down through the eight RUN modes lines.

For example:

Host Mode CBC-100 Display

1 R: CNT 123.456

2 R: MOV PST 11.50

3 R: E.W. 0.25

6 R: BCH 1500

7 R: BCH PST 2500

8 R: BRK DIS 0.25

Host Mode CBC-1000 Display

P R: LOC. 1

The control remains active (in the RUN mode) until

the proper lock combination is entered. Each

numeric entry is entered from right to left “calculator

style”. The character sequence 1-0-0-0 would

produce the following display on the terminal:

Host Mode CBC-1000 Display

1 R: LOC. 1

0 R: LOC. 10

0 R: LOC. 100

0 R: LOC. 1000

When this combination is correctly entered with a

down cursor from the CBC-1000 keyboard or “D”

from Host Terminal, the control exits the RUN mode

and enters the PROGRAM mode and returns with

the following:

Host Mode CBC-1000 Display

D P: bd. 25

Note that the PROGRAM (‘P’) prompt is now

shown. You are at the top of the PROGRAM table

(line 1) as shown on page 12. Once the PROGRAM

mode has been entered it is possible to program

any line in the table. Refer to the COMMAND

CHARACTER table for the keyboard equivalent

serial characters. A programming example is shown

on page 23.

Warner Electric • 800-825-9050 P-275 • 819-0496

21

Page 24

Serial Interface

Host Mode CBC-1000 Display

C P: MOV PST .000

4 P: MOV PST .004

5 P: MOV PST .045

6 P: MOV PST .456

7 P: MOV PST 4.567

8 P: MOV PST 45.678

9 P: MOV PST 456.789

The first serial entry (‘C’) clears the data field for the

current line. As can be seen in the COMMAND

CHARACTER table, this character mimics the

RESET/CLEAR key. Numeric data entry is self

explanatory.

Multiple Unit Operation

For multiple unit systems (up to 32 units) a special

addressing scheme is implemented so no conflicts

arise on the serial bus. Each unit is given a unique

serial address (ID number entered on line 25). Such

a system application is shown on page 20. All units

are programmed with the same baud rate and

parity. It is advised that the initial ID number

programming be done before the units are

bussed together.

To control one CBC-1000 in a bus oriented system

the host must first address it by sending an

ADDRESS COMMAND SEQUENCE. This is shown

below.

host: (ESC) A nn (where nn is unit number 1 to 99)

This escape code sequence will suspend the

transmission from all units including the one that is

addressed. The addressed unit will respond to all

subsequent commands while the other units just

“listen” on their receive input and turn their transmit

output off.

In some cases the host may want to send many

commands to a CBC-1000 control without waiting

for responses. This may be done by first

suspending transmission (CTRL S) then by

requesting a single UPDATE.

host: (ESC) U

Setup Mode Operation

The SETUP mode may be entered directly from the

RUN mode by cursoring to the desired SETUP line

(4-8) using the ‘D’ command character then sending

the ‘L’ command character which mimics the KEY

keyboard key. This action will place the control in

the SETUP mode allowing the user to change the

data in lines 3 through 8 in the program table. Serial

entry into the SETUP mode has the same

operational requirements and restrictions as if it

were entered via the front panel keyboard. Refer to

pages 6-8 for a complete operational description.

Preset setpoints are changed using the numeric

RST/CLR and DOWN cursor keys. The SETUP

mode is exited by sending another ‘L’ command

character at which time the controls revert back to

the RUN mode.

Remote Operation

Some of the unit’s CONTROL inputs are

effectively duplicated by serial commands, so it is

possible to implement a single or multiple unit

system with remote capability. Such a system can

be used for multiple machine, multiple axis or

multiple section applications. Keep in mind the

addressing requirements for multiple unit systems

previously discussed.

To receive data from an addressed unit the host

sends it a command to resume transmission using

the RESUME control character, (CTRL Q).

If you wish to suspend data data transmission you

may do so by using the SUSPEND control

character, (CTRL S).

22

Warner Electric • 800-825-9050 P-275 • 819-0496

Page 25

Serial Interface

HIGH

LOW

S D0 D1 D2 D3 D4 D5 D6 P S

ʻ

(sp)(sp) (sp) (cr)(cr) R : Co . 12 3 . 45 6

Two types of commands are available, LOCAL and

GLOBAL. LOCAL commands affect only the unit

that is currently addressed. GLOBAL commands on

the other hand affect all units regardless of address.

In this way it is possible to command many units to

begin control at the same point in time. The table

below lists the LOCAL and GLOBAL commands

that are supported.

LOCAL and GLOBAL COMMANDS

Control

Command

Output

Control Control Input

Batch

Reset to Zero

Counter

Reset to Zero

LOCAL GLOBAL Comments

(ESC) LO (ESC) GO

(ESC) LB (ESC) GB

(ESC) LR (ESC) GR

Simulates Output

Resets Batch

Reset Counter

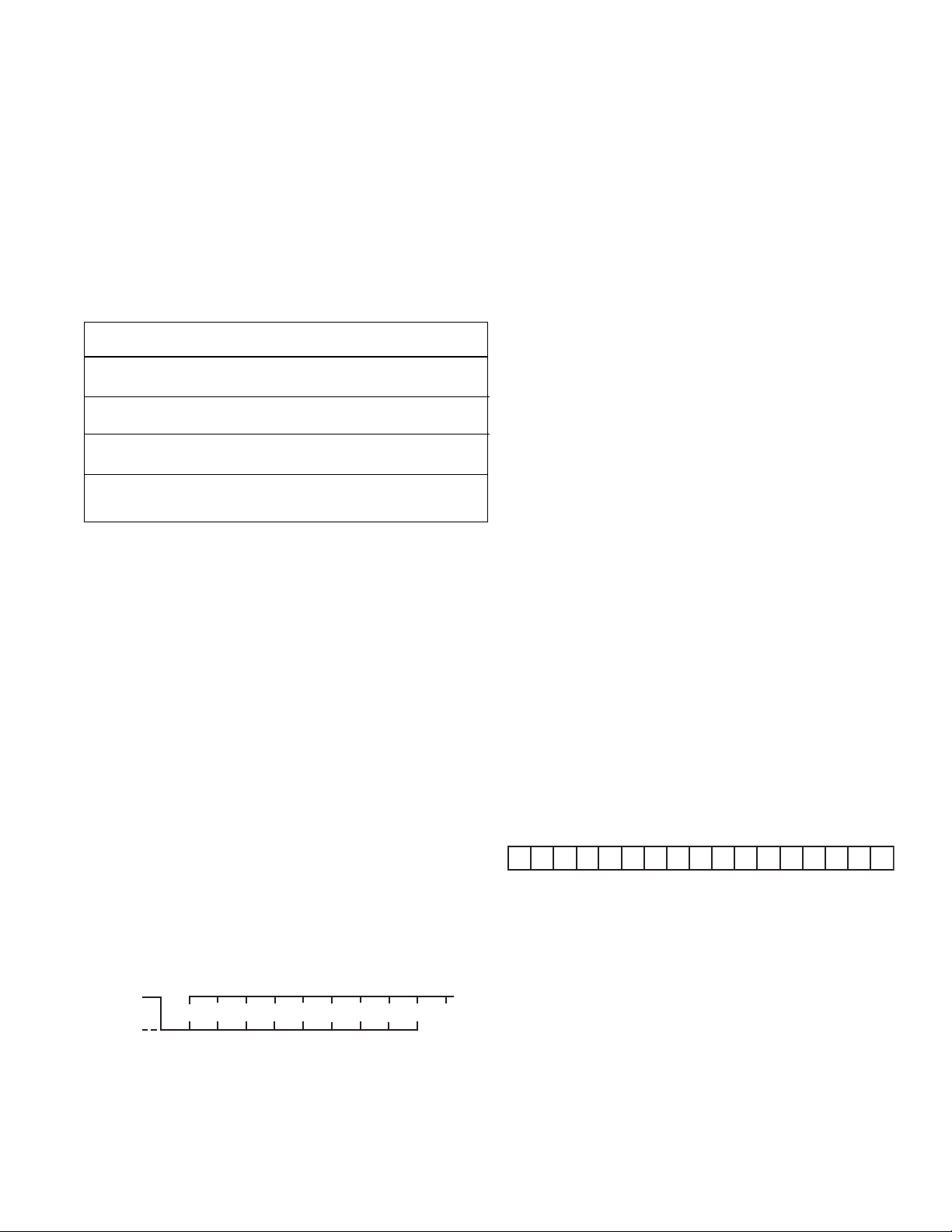

Formats and Protocol

Character Format

The serial interface sends and receives information

by characters consisting of 10 bits. The

RS-422A/485 interface requires a 0.2V minimum

differential across + and - terminals. A logic high

(mark) is a positive differential and a logic low

(space) is a negative differential. ( Connection to

EIA-422/485 equipment that uses the opposite

polarity requires swapping the + and - connections

at the other equipment.)

Parity Bit (see note)

The parity bit is programmable as “Odd”, “Even”, or

“No” parity. Odd and Even parity force the total

number of data bits to be even or odd for data that

is transmitted by the CBC-1000 control. Incoming

parity is always compared to the calculated parity.

Characters with parity errors are discarded. If No

parity is selected incoming parity is ignored.

Characters are transmitted with Odd or Even parity

as selected on line 24 of the program table. If No

parity is selected then “high” bit is added as an

extra Stop bit.

Baud Rate (see note)

Select the baud rate to match the device

communicating with the control. You may select:

300, 600, 1200, or 2400 baud on line 23 of the

program table. Gaud rate is common to both

transmitter and receiver.

Line Format

The CBC-1000 control transmits only complete

lines. The driver is turned off when not transmitting

causing the bus to enter a “float” state. Ignore data

on the bus during this “float” time. Unless otherwise

commanded, the CBC-1000 control continuously

transmits the Count Value. The line format is as

follows:

• a carriage return at the beginning of a line

• a prefix indicating RUN, SETUP, or

PROGRAM

• a unique line mnemonic

• a five digit data field with decimal point

• a carriage return at the end of the line

The character format is as follows:

• Start bit (“low”) logic level)

• ASCII data (7 bits), least to most significant

• Parity bit (programmable)

• Stop bit (“high” logic level”)

Note: To make changes in Parity or Baud Rate

power must first be removed then reapplied after

program changes to either are made. Both Parity

and Baud Rate are initialized when the control

“powers up”.

Warner Electric • 800-825-9050 P-275 • 819-0496

23

Page 26

Command Characters

ʻSʼ

“U”

ʻCʼ

“Q”

ʻDʼ

thru

ʻEʼ

ʻRʼ

ʻPʼ

ʻ0ʼ THRU ʻ9ʼ

RUN

PGM

EDITSTOP

0

STAR T

RESET

CLEAR

(

Command Characters mimic the operation of the front

panel keyboard. Below is a list of the serial equivalents of

the front panel keys.

Control Characters

Two control characters are used to start and stop

the transmission from the CBC-1000 control. They

are shown below:

(CTRL) S Suspends transmission following the

completion of a line being sent. The

driver will then be turned Off.

(CTRL) Q Resumes transmission from a unit that

had been turned Off. The RUN mode line

currently selected will be

continuously updated.

Protocol

The CBC-1000 will “buffer” up to 16 Command and

Control Characters (but not Escape Code

Sequences) listed above, sent in “burst mode”.

Those characters are read, in order, every 20 msec.

The protocol should be careful not to overflow the

receive buffer. Additionally, Escape Code Sequences

should not be sent until the buffer has emptied and

all characters have been processed.

Escape Code Sequences

Escape code sequences are a group of special

commands used for bus oriented systems. Every

CBC-1000 control recognizes these commands.

The two listed below are in addition to those listed

in the table of LOCAL and GLOBAL commands.

(ESC) A nn The Address command is used to

select a single control within a

system. Only that unit whose serial

I.D. number matches the two digit

serial address (nn) will be selected.

Only that unit will respond to

subsequent serial commands. All

units, even the addressed one,

suspend transmission.

(ESC) U The Update command instructs the

currently addressed unit to transmit a

single line only.

24

Warner Electric • 800-825-9050 P-275 • 819-0496

Page 27

RESET

CLEAR

RESET

CLEAR

RESET

CLEAR

RESET

CLEAR

Troubleshooting

Problem Solution

Machine starts but does not stop

Establish a move Preset

Ensure brake functions properly using output test.

Display counts backwards Reverse encoder A, B, wiring.

Control may be responding to a start command. Check for

Machine stops but then restarts

transient signals. Use a Single/Continous switch which

disables the external start command.

System works well except for first cycle after power

down

Control appears to function perfectly but the but the

actual error is greater than the display indicates.

System accumulates error.

Control accumulates too many counts. Home zero position is drifting.

Monitor “Braking Distance” during successful operation, then

program this value into “Initial Braking Distance” Line 1.

Check for slippage between the encoder and the manual

items.

Change to Absolute Mode by programming Auto Reset (line

8) “on”. DO NOT use external reset except to home.

Check Display Scaling, page 8, and check for electrical

noise, such as ground loops. Eliminate noise.

Control appears to work but proper motion is not occuring.

System does not operate and fails diagnostic tests 1, 4,

5, or 7. Reference page 9.

System stops, but does not fire outputs.

Review Clutch Brake and Control Service Manuals. Use

Output Test (line 29) to verify performance.

Return unit for repair, call an Authorized Warner Electric

Distributor.

Lower zero speed window (line 18) to minimize effects of

encoder ”bounce” caused by vibrations.

Error Codes

If an error message appears

Error Code 2 - Low Line Voltage. Correct line voltage. Press to clear error code.

Error Code 3 - Feedback too fast.

Disconnect power to CBC-1000 momentarily and error

should clear. Press to clear error code.

Reduce encoder resolution and/or speed to keep encoder

feedback less than 20,000 PPS. Press

to clear error code.

Error Code 4 - Process Time fully utilized

Warner Electric • 800-825-9050 P-275 • 819-0496

Reduce encoder resolution or consult factory.

Press to clear error code.

25

Page 28

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship

within a period of one (1) year from the date of original purchase for consumer, commercial or

industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without

Warner Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation

charges prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information

may be obtained by writing the Customer Satisfaction Department, Warner Electric LLC, 449

Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made,

without charge, together with a refund for transportation costs. If found not to be defective, you

will be notified and, with your consent, the item will be repaired or replaced and returned to you

at your expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation

may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any

defective product. Warner Electric LLC neither assumes nor authorizes any other person

to give any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH

THE CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF

ORIGINAL CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL

USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you. This warranty gives you specific legal rights

and you may also have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without

notice. Weights do not include weight of boxing for shipment. Certified prints will be furnished

without charge on request to Warner Electric.

Warner Electric LLC

431 Industrial Park Road

815-389-3771

www.warnerelectric.com

An Altra Industrial Motion Company

P-275 819-0496 06/11 Printed in USA

• Fax: 815-389-2582

• New Hartford, CT 06057

Loading...

Loading...