Page 1

ATT Tension Brakes

P-221

819-0338

Installation Instructions

Page 2

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Wear Indication . . . . . . . . . . . . . . . . . . . . . . . . . .5

Brake Repair on the Shaft . . . . . . . . . . . . . . . . . .6

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . .8

Dimensions and Specifications . . . . . . . . . . . . . .9

Exploded View and Parts Lists . . . . . . . . . . . . .10

Warranty . . . . . . . . . . . . . . . . . . . . . . . .back cover

Failure to follow these

instructions may result in product damage,

equipment damage, and serious or fatal injury

to personnel.

Introduction

The Warner Electric AT Tension (ATT) brake you

have purchased has been designed to provide

long and trouble free service. It is a rugged and

durable unit which is rebuildable with friction face

replacement kits discussed in this service manual.

The friction face replacement kit renews the friction

surfaces.

This service manual includes instructions required

for installation, repair on the shaft, and

troubleshooting information, specifications,

dimensions, an exploded view and parts lists.

Please refer to the Table of Contents for section

page numbers.

All installation and repair involving ATT brakes must

be carried out in accordance with the procedures

specified in the service manual. All stated or

implied manufacturer warranties are voided if this

product is not installed and serviced in accordance

with these instructions.

Warner Electric • 800-825-9050 P-221 • 819-0338

2

Page 3

Other Tensioning Products

Warner Electric offers many tension control

products in addition to the ATT line. Basic tension

brakes and high performance modular tension

brakes are available, as well as a complete line of

electronic tension controls. These include a basic

manual control, a load cell control, a closed loop

dancer control, and splicer controls. For more

information on these and other products, please

call or write:

Warner Electric

31 Industrial Park Road

New Hartford, CT 06057

Phone (815) 389-3771

Modular control systems for

tension brakes are either manual

adjust or closed loop types.

Simple tension control

requires only a tension

brake and this manual

control.

Splicer control offers dual functions for

two roll systems requiring simultaneous

tensioning and holding.

Load cell control system

automatically adjusts

tension from load cell

amplifier input.

Modular tension brakes are

available in 10", 13", 15", and

20" diameters with single or

dual friction discs and two to

twelve magnets.

Warner Electric • 800-825-9050 P-221 • 819-0338

3

Page 4

Brake Installation

1. Remove your ATT brake from its shipping

carton and inspect it thoroughly to ensure

that is has arrived in good condition.

An accessory kit included with your brake

contains a coil wire retainer and mounting

hardware.

2. If used, install the Warner Electric conduit box

in accordance with its furnished instructions.

3. Mount the magnet to the machine frame

using the hardware in the accessory kit so

that the magnet face is square with the

armature shaft within .006 T.I.R. and the

magnet mounting pilot diameter is concentric

with the armature shaft within .010 T.I.R.

This is important to assure proper

function and unit life.

5. Slide the armature over the input hub.

6. Slide the hub onto the shaft and provide a

1/16" gap between the friction faces.

4. Tighten the mounting screws to the machine

frame to the appropriate torque for your size

brake.

Size Torque

25 12.5 ft.-lbs.

55 25 ft.-lbs.

115 25 ft.-lbs.

7. Tighten the set screws located in the hub to

the appropriate torque for your size unit:

Size Torque

25 80 in.-lbs.

55 160 in.-lbs.

115 275 in.-lbs.

Warner Electric • 800-825-9050 P-221 • 819-0338

4

Page 5

8. When using a Warner Electric tension control,

follow the connection diagram supplied with

the control.

If a Warner Electric TCS-210, -220, -310, or

320 control is used, add a 68 ohm resistor

across the sense circuit. Although the TCS

series controls are recommended, a MCS

control can be used with normal hook-up.

Wear Indication

Your ATT brake should be visually inspected on a

periodic basis to determine if the wearing surfaces

warrant replacement. The friction face and

armature should be replaced when the armature

reaches the wear indicator on the magnet shell. If

replacement is not made at this time, further use

will wear into the screw heads making removal and

replacement of the friction facing difficult.

The drawing below illustrates the area to be

inspected.

9. Your ATT brake is now ready for its static test.

Apply DC voltage to the coil through the

brake control. The armature should pull

against the friction material face.

10. Run the brake under its operating load.

11. Your ATT brake may not achieve its full torque

until after a short “break-in” period. To break

in the brake, cycle it on and off under full load

at operating speed a minimum of ten times in

quick succession.

Your ATT brake is now ready to run.

When the friction surfaces are worn to this point,

replace with the appropriate friction face

replacement kit. All of the components needed to

refurbish the wearing surfaces of your brake are

provided in the replacement kit.

ATT-25 5161-101-008

ATT-55 5162-101-008

ATT-115 5163-101-008

Warner Electric • 800-825-9050 P-221 • 819-0338

5

Page 6

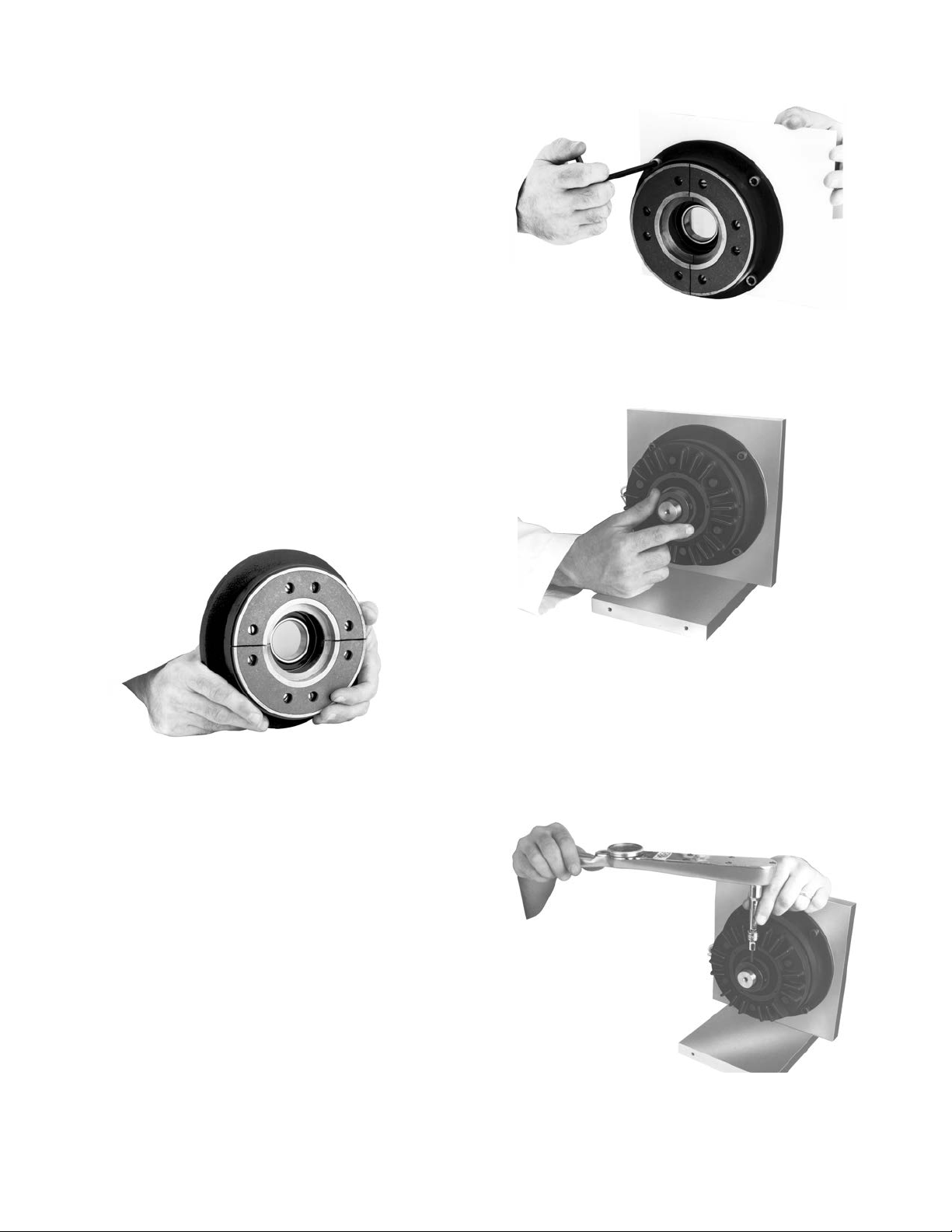

Complete Brake Repair–On The Shaft

The new ATT design incorporates a rugged, durable

design for long life and maximum heat dissipation.

Easy-to-replace friction surfaces extend the design

life for continued like-new performance. The ATT

offers complete repair-on the shaft following ten

easy steps. The repair can be completed utilizing

the parts in the friction face replacement kit.

1. Move the brake armature away from the

magnet for disassembly and reassembly.

2. Remove the hex head cap screws, washers

and lockwashers to loosen the armature

segments from the cast iron carrier.

6. Insert two new friction material segments.

The recessed holes should be facing away

from the magnet body.

3. Lift out the two worn armature segments.

4. Remove the screws which attach the friction

material segments to the brake magnet

through the appropriate access holes.

5. Lift the worn friction material segments.

7. Attach the new friction material segments

to the brake with the screws through the

appropriate access holes. Apply one drop of

Loctite (grade 290 or equivalent) to each

screw.

Warner Electric • 800-825-9050 P-221 • 819-0338

6

Page 7

Note: Use only the screws included with

the repair kit since any other screws may

damage the unit. Tighten to 18 to 22 lb. in.

torque.

8. Insert the two new armature segments.

9. Attach the new armature segments to the

cast iron carrier with hex cap screws,

lockwashers and washers. Apply one drop of

Loctite (grade 290 or equivalent) to each

screw. Tighten to the appropriate torque for

your size unit.

Size Torque

ATT 25 29-35 in.-lbs.

ATT 55 60-84 in.-lbs.

ATT 115 60-84 in.-lbs.

10. Ensure there is a 1/16" gap between the

friction faces.

11. Your ATT brake is now ready for its static

test. Apply DC voltage to the coil through

the brake control. The armature should

pull against the friction material face with

an audible “click”.

12. Run the brake under its operating load.

13. Your ATT brake may not achieve its full torque

until after a short “break-in” period. To break

in the brake, cycle it on and off under full load

at operating speed a minimum of ten times in

quick succession.

Your ATT brake is now ready to run.

Warner Electric • 800-825-9050 P-221 • 819-0338

7

Page 8

ATT Brake Troubleshooting Guide

In performance problems are present after carefully following the instructions in this manual, use the following

check list.

Symptom Check

Brake armature will not move or • Coil Resistance

engage when power is applied Coil may be open. See Chart 1.

to the coil. • Power Supply

Assure proper DC voltage is being delivered to the brake.

• Airgap

If greater than 3/32" gap around entire periphery, reset.

Vibration • Runout

Assure that shaft on which the clutch is mounted doesn’t have excessive runout.

• Shaft Engagement

Assure adequate shaft length and diameter engagement in the hub.

Low Tension • Power Supply

Assure proper DC voltage is being delivered to the brake.

• Adequate Burnishing

Unit must be run and cycled a few times to achieve full rated torque.

• Friction Surfaces

Replacement may be required.

• Installation of replacement friction material or armature segments may be

incorrect and not allow full contact.

Clutch/Brake Coil Approx. Coil

Size Voltage Resistance (Ohms)

25 24 20.6

25 90 290

55 24 19.6

55 90 230

115 24 16.5

115 90 182

Chart 1

Warner Electric • 800-825-9050 P-221 • 819-0338

8

Page 9

Electric Brakes and Clutches

ATT Series – Advanced Technology Brakes and Clutches

D

Customer shall maintain:

1. Squareness of brake mounting face with

armature hub shaft within .006 T.I.R.

Shaft Bore and

Keyway Dimensions

Model Unit Bore Key

ATTB-25

ATTB-25

ATTB-25 .7525 19.11

ATTB-55 .7505 19.06

ATTB-25 .8775 22.29

ATTB-55 .8755 22.24

( ) denotes millimeters

Model Max. Nom. Max. Dia. Dia. Nom. Max. Nom. Max.

ATTB-25

ATTB-55

ATTB-115

.5025 12.76

.5005 12.71

.6275 15.94

.6255 15.89

( )

( )

( )

( )

DE F G H J L M P

1.347 4.748 3.767 5.250 5.625/5.623 1.544 .225 3.586 2.080

(34.21) (120.60) (95.68) (133.35) (142.87/142.82) (39.22) (5.71) (91.08) (52.83)

1.770 5.37 3.767 6.875 7.373/7.375 1.544 .491 4.208 3.105

(44.96) (136.40) (95.68) (174.62) (187.27/187.33) (39.22) (12.47) (106.88) (78.87)

2.152 6.278 3.767 8.500 9.000/8.998 1.544 .463 5.116 3.105

(54.66) (159.46) (95.68) (215.90) (228.60/228.55) (39.22) (11.76) (129.95) (78.87)

1/8 Sq.

3/16 Sq.

3/16 Sq.

3/16 Sq.

Model Unit Bore Key

ATTB-55 1.0025 25.46 1/4 Sq.

1.0005 25.41

ATTB-55 1.1275 28.64 1/4 Sq.

ATTB-115 1.1255 28.59

ATTB-115 1.2525 31.81 1/4 Sq.

1.2505 31.76

ATTB-115 1.7775 34.99 5/16 Sq.

1.3755 34.94

ATTB-115 1.5025 38.16 3/8 Sq.

1.5005 38.11

2. Concentricity of brake mounting pilot diameter

with armature hub shaft within .010 T.I.R.

ABC

Max. Min.

Model Dia. Max. Dia.

ATTB-25

ATTB-55

ATTB-115

Pilot

4.822 2.730 .264

(122.48) (69.34) (6.70)

6.271 3.010 .330

(159.28) (77.97) (8.38)

7.906 3.625 .330

(200.81) (12.07) (8.38)

For replacement parts list and exploded view drawing, see page 10.

Warner Electric • 800-825-9050 P-221 • 819-0338

9

Page 10

Brake Assemblies and Part Numbers

ATT Series – Advanced Technology Brakes

ATTB-25, ATTB-55, ATTB-115

Brake Assemblies

Unit Size Voltage Part No.

ATTB-25-1/2 24 5191-6

ATTB-25-1/2 90 5191-10

ATTB-25-5/8 24 5191-7

ATTB-25-5/8 90 5191-11

ATTB-25-3/4 24 5191-8

ATTB-25-3/4 90 5191-12

ATTB-25-7/8 24 5191-9

ATTB-25-7/8 90 5191-13

ATTB-55-3/4 24 5192-6

ATTB-55-3/4 90 5192-10

ATTB-55-7/8 24 5192-7

ATTB-55-7/8 90 5192-11

Warner Electric • 800-825-9050 P-221 • 819-0338

10

Unit Size Voltage Part No.

ATTB-55-1 24 5192-8

ATTB-55-1 90 5192-12

ATTB-55-1-1/8 24 5192-9

ATTB-55-1-1/8 90 5192-13

ATTB-115-1-1/8 24 5193-6

ATTB-115-1-1/8 90 5193-10

ATTB-115-1-1/4 24 5193-7

ATTB-115-1-1/4 90 5193-11

ATTB-115-1-3/8 24 5193-8

ATTB-115-1-3/8 90 5193-12

ATTB-115-1-1/2 24 5193-9

ATTB-115-1-1/2 90 5193-13

Page 11

Part Numbers

Item ATTB-25 ATTB-55 ATTB-115

No. Description Qty. Part No. Qty. Part No. Qty. Part No.

1 Armature Hub 1 540-0908 1 540-0851 1 540-0864

2-1 Armature 1 110-0220 1 110-0218 1 110-0223

2-2 Facing Assem. 1 5191-445-003 1 5192-445-003 1 5193-445-003

2-3 Screw 6 797-1389 8 797-1389 8 797-1389

2-4 Screw 4 797-1020 6 797-1387 6 797-1174

2-5 Lockwasher –– 6 950-0355 6 950-0355

2-6 Flatwasher –– 2 950-0023 2 950-0023

3 Magnet Assem. 1– 1 – 1–

24 Volts D.C. – 5191-631-007 – 5192-631-007 – 5193-631-014

90 Volts D.C. – 5191-631-008 – 5192-631-008 – 5193-631-015

4 Splined Hub 1– 1 – 1 –

1/2" Bore – 5191-541-002 –– ––

5/8" Bore – 5191-541-003 –– ––

3/4" Bore – 5191-541-004 – 5192-541-002 ––

7/8" Bore – 5191-541-005 – 5192-541-003 ––

1" Bore –– – 5192-541-004 ––

1-1/8" Bore –– – 5192-541-005 – 5193-541-002

1-1/4" Bore –– – – –5193-541-003

1-3/8" Bore –– – –5193-541-004

1-1/2" Bore –– – – –5193-541-005

5 Mtg. Acc’y. 1 5191-101-007 1 5192-101-007 1 5192-101-007

Optional Accessory Items

6 Conduit Box 1 5162-101-002 1 5162-101-002 1 5162-101-002

Kit Items

7 Friction Face

Replacement Kit 1 5161-101-008 1 5162-101-008 1 5163-101-008

(includes items 2-1, 2-2, 2-3, 2-4, 2-5, 2-6)

Warner Electric • 800-825-9050 P-221 • 819-0338

11

Page 12

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship

within a period of one (1) year from the date of original purchase for consumer, commercial or

industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without

Warner Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation

charges prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information

may be obtained by writing the Customer Satisfaction Department, Warner Electric LLC, 449

Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made,

without charge, together with a refund for transportation costs. If found not to be defective, you

will be notified and, with your consent, the item will be repaired or replaced and returned to you

at your expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation

may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any

defective product. Warner Electric LLC neither assumes nor authorizes any other person to give

any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH

THE CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF

ORIGINAL CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL

USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you. This warranty gives you specific legal

rights and you may also have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specifications shown in Warner Electric catalogs are subject to change

without notice. Weights do not include weight of boxing for shipment. Certified prints will be

furnished without charge on request to Warner Electric.

Warner Electric

31 Industrial Park Road • New Hartford, CT 06057

815-389-3771 • Fax: 815-389-2582

www.warnerelectric.com

P-221 • 819-0338 8/11 Printed in USA

Loading...

Loading...