Page 1

AT Clutch – Major Service

Sizes 25, 55, 115

P-1404

819-0324

Installation Instructions

Page 2

2

Warner Electric • 800-825-9050 819-0324

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warranty. . . . . . . . . . . . . . . . . . . . . . . back cover

Failure to follow these

instructions may result in product damage,

equipment damage, and serious or fatal

injury to personnel.

AT Clutch – Major Service

A major rebuild of an AT clutch can be accomplished by following these instructions to

replace the parts furnished in the appropriate

Warner Electric clutch rebuild kit. Part numbers

and component descriptions for these kits are

found on page 11 of this manual. Item numbers

in these instructions refer to clutch components

shown on page 10, exploded view. Proceed as

follows:

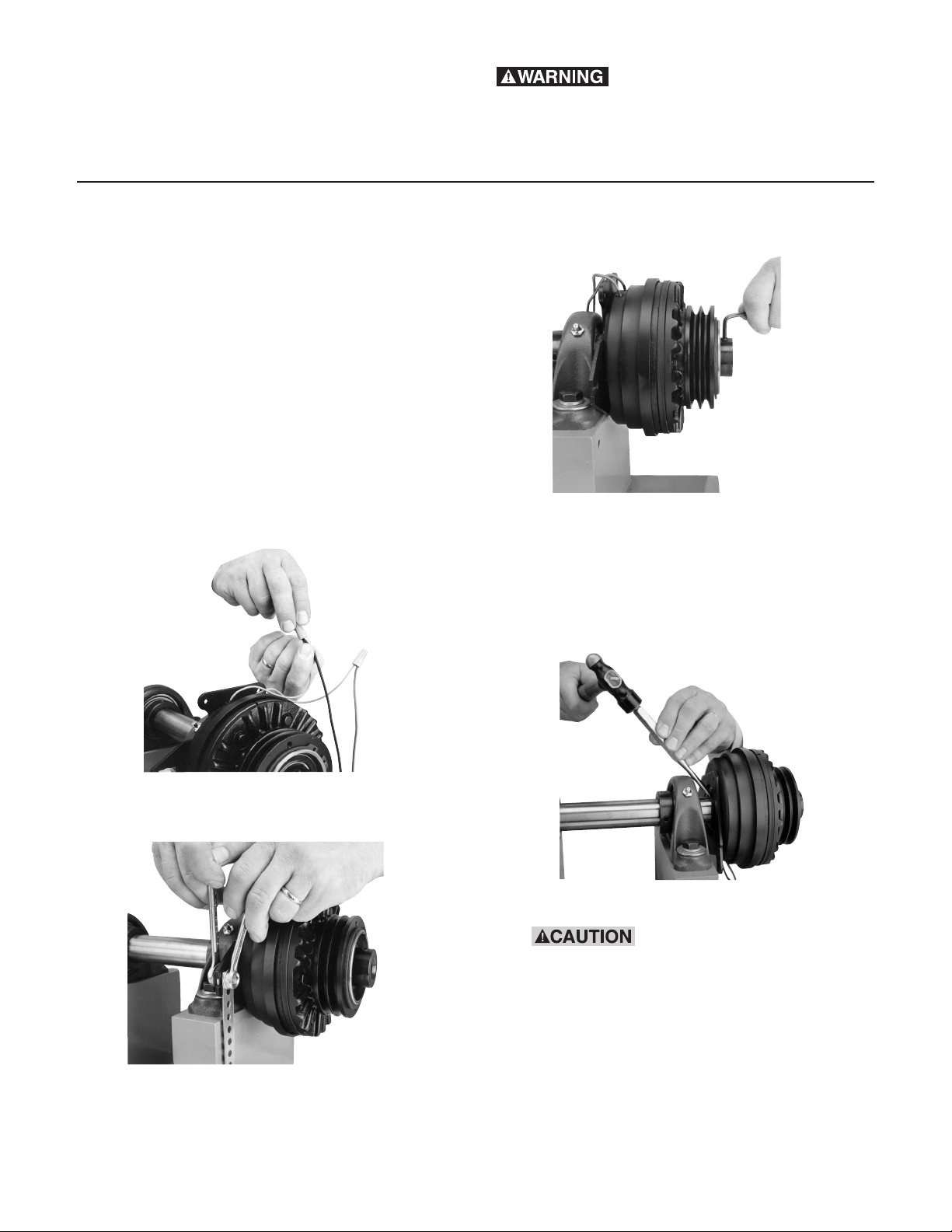

1. Turn off all power to the clutch.

2. Disconnect the coil wires from the incoming

control unit wires.

3. Disconnect the field anti-rotation pin or field

restraining arm (Item 16).

4. Loosen the setscrews (Item 6) which hold

the clutch to its shaft.

5. Remove the clutch from its shaft by pulling

and/or gently tapping the hub with a hammer and drift.

Note: Do not hit the outer portion of the

clutch outboard of the hub as this may

severely damage it.

6. Remove the retainer ring (Item 11).

When removing this or

other retaining rings, be sure to hold the

retaining ring with one hand so it will not

spring away and endanger personnel and

property should the pliers lose their grip

on the ring. Safety glasses should always

be worn when installing or removing

retaining rings.

Page 3

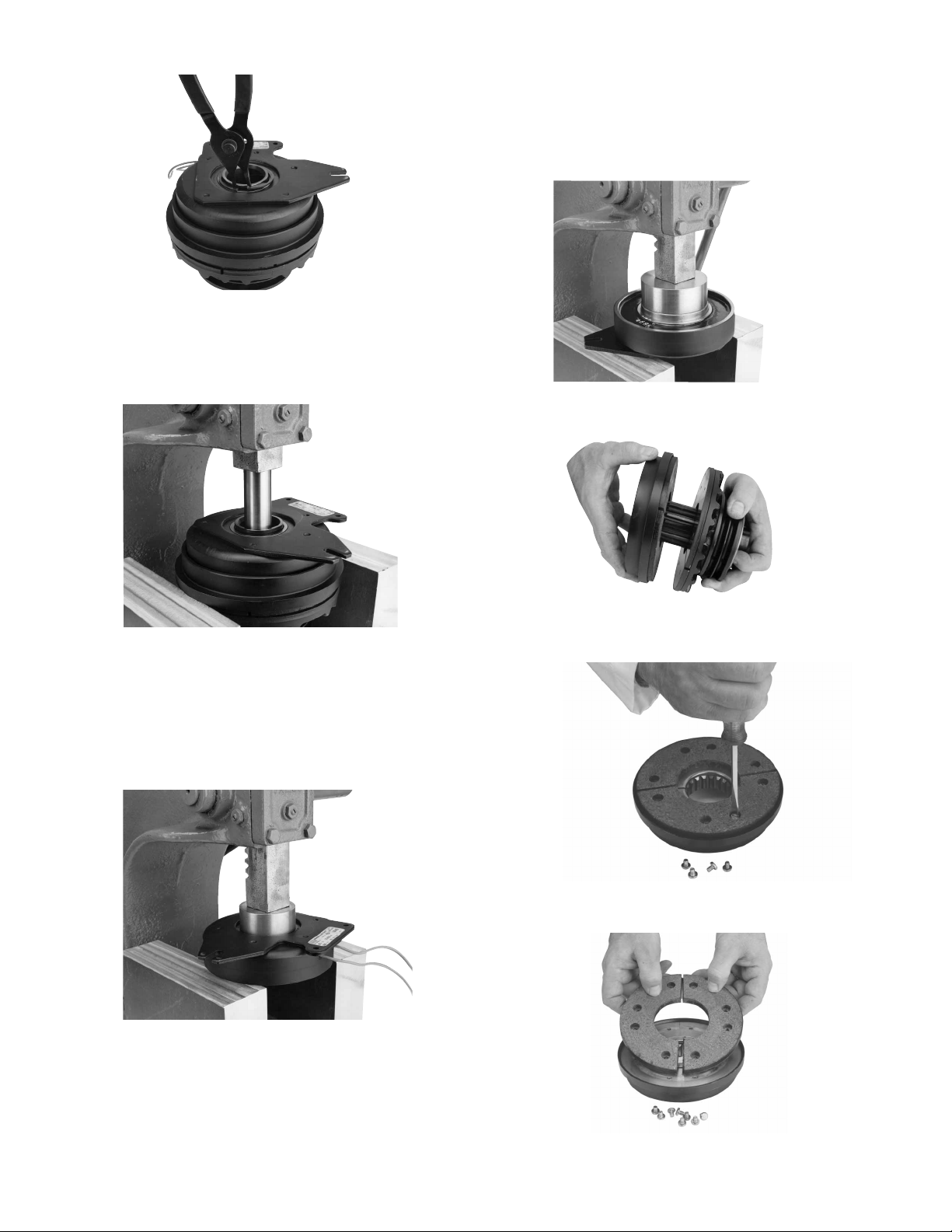

9. Press the new bearing (Item 9) into the field

assembly by pressing on the bearing outer

race. Do not press on the bearing inner

race or damage to the bearing will result,

making it unusable.

10. Remove the rotor assembly (Item 8) from

the hub (Item 6).

11. Remove the screws (item 8-5) which retain

the friction disc segments (item 8-1).

12. Lift the friction disc segments (item 8-1) off

the rotor, exposing the Autogap assembly.

7. Remove the field assembly (Item 10) and

bearing (Item 9) by locating and supporting

on the rotor outer diameter (Item 8) and

pressing on the hub (Item 6).

8. Remove the bearing (Item 9) from the field

assembly (Item 10) by pressing on the inner

race while supporting the field assembly on

its face.

Note: Use caution to avoid damaging the

epoxy covering the coil.

3

Warner Electric • 800-825-9050 819-0324

Page 4

4

Warner Electric • 800-825-9050 819-0324

13. Install replacement Autogap components as

follows: Remove plate (item 8-2-size 115

only), and detent ring (item 8-3) to expose

wave spring (item 8-4). Remove and replace

wave spring (item 8-4). Reinstall the detent

ring and plate (items 8-3 and 8-2). Note:

The detent ring lip must point away from

the friction disc. Install the wave spring

with its split 180° from the split in the

detent ring.

14. Clean all foreign matter from rotor mounting

surface. Install the new friction disc segments (Item 8-1) with new screws (Item 8-5)

included with the kit. Note: Use only the

screws included with the kit as any others

may damage the clutch.

Apply a drop of Loctite grade AA or equivalent to each screw prior to installation.

Tighten each screw to 18-22 in. lb. torque.

15. Remove the snap ring (Item 3) from the

armature hub assembly.

When installing or removing this or other retaining rings, be sure

to hold the ring with one hand so it will

not spring away, endangering personnel

and property should the pliers lose their

grip on the ring. Safety glasses should

always be worn when installing or

removing retaining rings.

Remove the pulley, sheave, or sprocket if it

interferes with removing the cap screws

(Item 7-2).

16. Disassemble the armature hub assembly by

removing cap screws (Item 7-2), lock washers (Item 7-3) and armature segment (Item

7-1).

Page 5

5

Warner Electric • 800-825-9050 819-0324

Remove the set screws.

Remove the external and internal retaining

rings (Items 2 and 3) from the splined hub

(Item 6) and the armature hub (Item 1).

17. Locate and support on the sheave end of

the assembly near the fins and press on the

field end of the splined hub (Item 6).

To remove the hub and bearing assembly,

remove the bearings (Item 4) and spacer

(Item 5) from the hub (Item 6) by pressing

them off.

Proceed with reassembly per the following

instructions:

Note: It is imperative that all bearings be

installed exactly as instructed to avoid

damage to the bearings.

Apply one drop of Loctite grade AA or

equivalent to each cap screw thread prior to

installation.

Install the new armature segments (Item 7-

1) supplied in the kit onto the armature hub,

(Item 1) using cap screws and washers

(Items 7-2, 7-3 and 7-4).

Page 6

20. Install the spacer (Item 5) as shown in

Figure 3.

Figure 3

21. Press the outer bearing (Item 4) into place

by applying force evenly against the bearing

outer and inner races simultaneously while

supporting the armature face. Continue

pressing until the outer race firmly locates

against the spacer. See Figure 4.

Figure 4

22. Install the external and internal retaining

rings (Items 2 and 3) adjacent to the outer

bearing. (See Figure 5)

Figure 5

6

Warner Electric • 800-825-9050 819-0324

Tighten the cap screws to the appropriate

torque for your size unit:

Size Torque

25 29-35 in.-lbs.

55-115 60-84 in.-lbs.

18. Install the inner adapter bearing (Item 4)

onto the hub, (Item 6) by pressing on the

inner race of the bearing. With the end of

the hub supported as shown in Figure 1,

press the bearing until its inner race locates

against the hub shoulder.

Figure 1

19. Press the hub and bearing into the Adapter

Assembly until the outer race of the bearing

locates against the shoulder of the adapter

hub. Note that the force is to be exerted

on the outer race. Support the armature

face as shown in Figure 2.

Figure 2

Support

Support

Press

Force

Bearing

Hub

Shoulder

Hub

Press

Force

Armature

Assembly

Support

Support

Adapter

Shoulder

Press Force

Press Force

Armature

Assembly

Support

Adapter

Shoulder

Support

Spacer

Spacer

Support

Press Force

Evenly Applied

Press Force

Evenly Applied

Support

Page 7

7

Warner Electric • 800-825-9050 819-0324

Note: The Armature Assembly must rotate

freely on the hub. Inspect to insure that

the inner bearing is still firmly located

against the hub shoulder as previously

shown in (Figure 1). When inspecting,

place unit firmly on flat surface with

exposed hub end up.

Figure 1

23. Install the rotor assembly onto the hub (Item

6) making sure that the spline teeth are

aligned. When the Autogap detent ring (item

8-3) contacts the spline outside diameter,

press by hand evenly on the rotor until the

friction disc contacts the armature. Release

pressure. Support as shown. The rotor will

spring back approximately .050”. The

Autogap is now set. When the hub is rotated by hand, the armature and the friction

disc must not touch. (See Figure 6)

Figure 6

24. Press the field assembly onto the hub by

pushing the inner race of the bearing

while supporting on the hub. Apply force

until the inner race of the bearing is located

flush against the shoulder adjacent to the

spline. (See Figure 7)

Figure 7

Install the retaining ring (Item 11) on the hub

with snap ring pliers.

Rotate the hub. No interference between

the shell and rotor is allowable.

When installing or removing this or other retaining rings, be sure

to hold the ring with one hand so it will

not spring away, endangering personnel

and property, should the pliers lose their

grip on the ring. Safety glasses should

always be worn when installing or

removing retaining rings.

Support

Support

Press

Force

Bearing

Hub

Shoulder

Hub

Press

Force

SUPPORT

MAXIMUM

.050 AIRGAP

ALL AROUND

PUSH

PUSH

SPLINE

DETENT

RING

SUPPORT

SUPPORT

PRESS

FORCE

SHELL

ASSEMBLY

PRESS

FORCE

SUPPORT

UNTIL FLUSH

Page 8

8

Warner Electric • 800-825-9050 819-0324

25. Reinstall the sheave, pulley, or sprocket,

and key.

Reinstall the sheave retainer ring and conduit box, if used. Refer to the conduit box

installation instructions.

26. Reinstall the clutch assembly on the shaft,

placing the key in its keyway.

27. Tighten the hub set screws onto the key to

the appropriate torque for your size unit:

Size Torque

25 80 in.-lbs.

55 160 in.-lbs.

115 275 in.-lbs

205 275 in.-lbs.

305 670 in.-lbs.

Assure proper alignment of driving and driven sheave, pulley, or sprocket before tightening set screws.

28. Secure the field by its pin or restraining arm

accessory to avoid rotation.

29. Reconnect the wires.

30. Your AT clutch is now ready for its static

test. Apply DC voltage to the clutch coil

through the clutch control. The armature

should pull against the friction material face

with an audible “click”.

Page 9

9

Warner Electric • 800-825-9050 819-0324

31. Install the drive belt or chain.

32. Run the clutch under its operating load.

33. Your AT clutch may not achieve its full

torque until after a short “break-in” period.

To break in the clutch, cycle it on and off

under full load at operating speed a minimum of ten times in quick succession.

Your AT clutch is now ready to run.

Page 10

10

Warner Electric • 800-825-9050 819-0324

2

3

9

12

14

15

13

11

16

7-1

6

10

8-1

8

Optional

Optional

5

4

7-3

7-2

7-2

7-3

7-4

1

8-2

8-4

8-3

8-5

Page 11

Component Parts

ATC-25 ATC-55 ATC-115

Item Description Part No. Qty. Part No. Qty. Part No. Qty.

1Armature Hub 540-0907 1 540-0852 1 540-0863 1

2 Retaining Ring 748-0732 1 748-0726 1 748-0737 1

3 Retaining Ring 748-0731 1 748-0728 1 748-0736 1

4Bearing 166-0278 2 166-0277 2 166-0279 2

5 Spacer 807-0119 1 807-1061 1 807-1063 1

6 Splined Hub 1 1 1

1/2" Bore 540-0910

5/8" Bore 540-0911

3/4" Bore 540-0912 540-1501

7/8" Bore 540-0913 540-1502

1" Bore 540-1503

1-1/8" Bore 540-1504 540-0857

1-1/4" Bore 540-0858

1-3/8" Bore 540-0859

1-1/2" Bore 540-0860

*7-1 Armature 110-0220 1 110-0218 1 110-0223 1

*7-2 Screw 797-1519 4 797-1462 6 797-1463 6

*7-3 Lockwasher 950-0436 4 950-0355 6 950-0355 6

*7-4 Flatwasher 950-0023 2 950-0023 2

*8 Rotor 5161-751-001 1 5162-751-001 1 5163-751-001 1

8-1 Facing Assembly 5161-445-003 1 5162-445-003 1 5163-445-003 1

8-2 Retainer Plate 686-0108 1

8-3 Detent Ring 748-2031 1 748-2038 1 748-2020 1

8-4 Wave Spring 808-0404 1 808-0401 1 808-0384 2

8-5 Machine Screw 797-1389 8 797-1389 8 797-1389 8

*9 Bearing 166-0283 1 166-0284 1 166-0279 1

10 Field Assembly 1 1 1

6 volts DC 5161-451-002 5162-451-002 5163-451-002

90 volts DC 5161-451-003 5162-451-003 5163-451-003

24 volts DC 5161-451-004 5162-451-004 5163-451-004

*11 Retainer Ring 748-0018 1 748-0727 1 748-0737 1

12 Adapter 104-0300 2

13 Screw 797-1396 4

14 Lockwasher 950-0102 4

Optional Accessory Items

15 Conduit box 100-1 5162-101-002 1 5162-101-002 1 5162-101-002 1

16 Restraining Arm Assembly 5162-101-004 1 5162-101-004 1 5163-101-004 1

Kit Items

* Clutch Rebuild Kit 5161-101-011 1 5162-101-011 1 5163-101-011 1

(includes items 7-1, 7-2, 7-3, 7-4, 8, 9, 11)

Note: In some versions of this product, item 8 consists of a one (1) piece rotor.

Friction Face Replacement Kit 5161-101-007 5162-101-007 5163-101-007

For Clutches with Replaceable Friction Face Only

Mounting Accessory Kits (not shown)

1 1/2” Bore - 3/4” Bore 5161-101-001

1-1 Ring Retainer Ext. 748-0734 1

1-2 Wire Retainer 742-0027 1

1-3 Key 590-0104 1

1-4 Setscrew 797-1393 2

1 7/8’ Bore 5161-101-002

1-1 Ring Retainer Ext. 748-0734 1

1-2 Wire Retainer 742-0027 1

1-3 Key 590-0104 1

1-4 Collar and Setscrew 266-0031 1

1 3/4’ Bore - 1” Bore 5162-101-001

1-1 Ring Retainer Ext. 748-0725 1

1-2 Wire Retainer 742-0026 1

1-3 Key 590-0103 1

1-4 Setscrew 797-1386 2

1 1-1/8’ Bore 5162-101-010

1-1 Ring Retainer Ext. 748-0725 1

1-2 Wire Retainer 742-0026 1

1-3 Key 590-0103 1

1-4 Setscrew 797-1077 2

1-5 Collar 266-0032 1

1 All bore sizes 5163-101-001

1-1 Ring Retainer Ext. 748-0738 1

1-2 Wire Retainer 742-0026 1

1-3 Key 590-0105 1

1-4 Setscrew 797-1395

11

Warner Electric • 800-825-9050 819-0324

Page 12

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship

within a period of one (1) year from the date of original purchase for consumer, commercial or

industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without

Warner Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation

charges prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information

may be obtained by writing the Customer Satisfaction Department, Warner Electric LLC, 449

Gardner Street, South Beloit, Illinois 61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made,

without charge, together with a refund for transportation costs. If found not to be defective, you

will be notied and, with your consent, the item will be repaired or replaced and returned to you

at your expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation

may not apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the

repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any

defective product. Warner Electric LLC neither assumes nor authorizes any other person to give

any other warranty or to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH

THE CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF

ORIGINAL CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL

USES OF THE PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL

OTHER WARRANTIES, WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR

OTHERWISE, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitation or exclusion may not apply to you. This warranty gives you specic legal

rights and you may also have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specications shown in Warner Electric catalogs are subject to change without

notice. Weights do not include weight of boxing for shipment. Certied prints will be furnished

without charge on request to Warner Electric.

Warner Electric LLC

31 Industrial Park Road • New Hartford, CT 06057

815-389-3771 • Fax: 815-389-2582

www.warnerelectric.com

P-1404 819-0324 6/05 Printed in USA

Loading...

Loading...