Page 1

AT Brake–Major Service Repair

Instructions for Sizes 25, 55, 115

P-1405

819-0325

Repair Instructions

Page 2

Contents

Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warranty . . . . . . . . . . . . . . . . . . . . . . Back Page

Failure to follow these

instructions may result in product

damage, equipment damage, and

serious or fatal injury to personnel.

A major rebuild of an AT brake can be

accomplished by following these instructions to

replace the parts furnished in the appropriate

Warner Electric brake rebuild kit. Proceed

as follows:

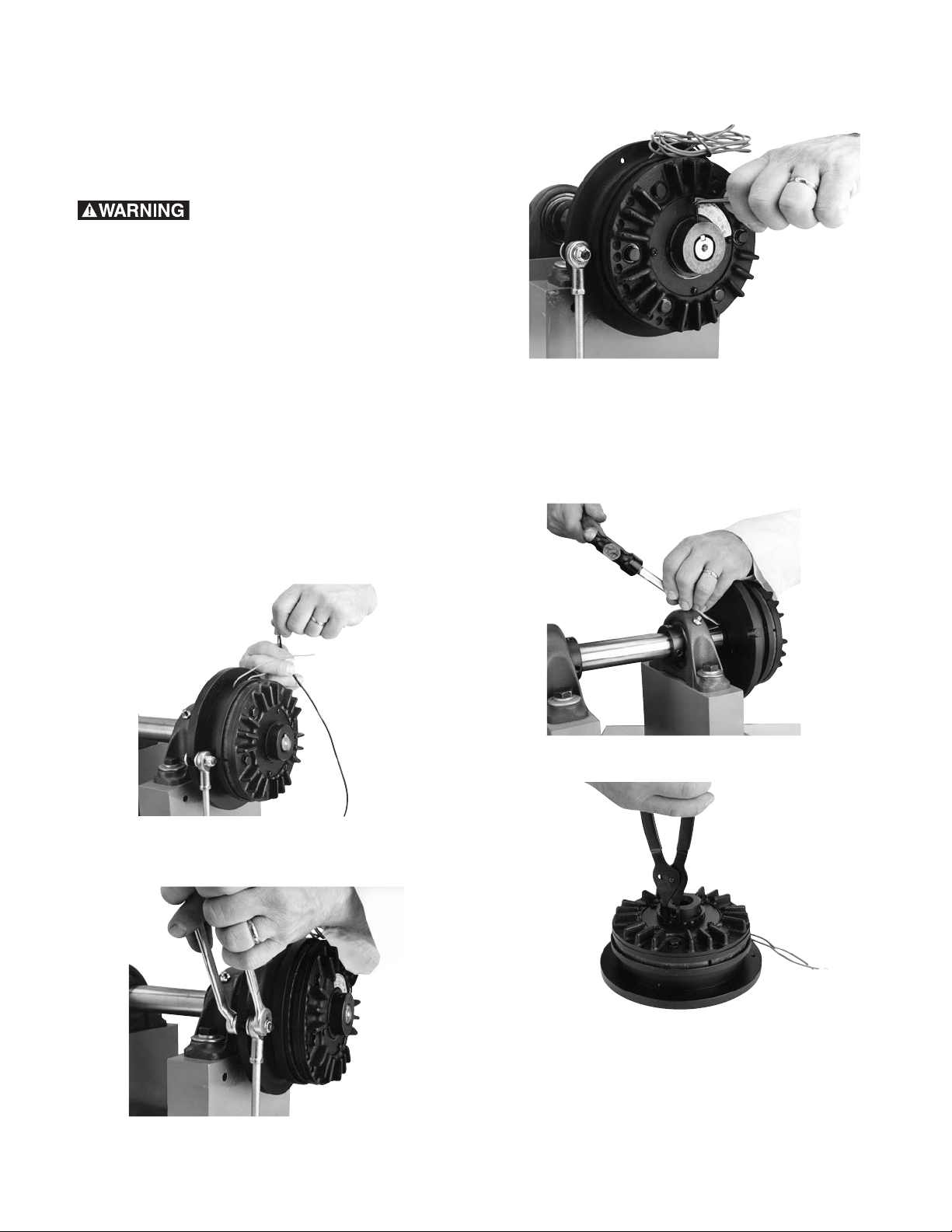

1. Turn off all power to machine and brake using

appropriate electrical lockout procedures.

2. Disconnect the brake coil wires from the

incoming control unit wires, and remove

optional conduit box from brake if used.

4. Loosen the hub set screws holding brake on

shaft.

5. Remove the brake from its shaft by pulling

and/or gently tapping the hub with a hammer

and drift. Note: Do not hit the outer portion

of the brake outboard of the hub as this may

severely damage it.

6. Remove retaining ring.

3. Disconnect the anti-rotation torque arm from

the magnet.

Warner Electric • 800-825-9050 P-1405 • 819-0325

2

Page 3

When installing or removing

this or other retaining rings, be sure to

hold the ring with one hand so it will not

spring away, endangering personnel and

property, should the pliers lose their grip

on the ring. Safety glasses should always

be worn when installing or removing

retaining rings.

Remove plate retaining screws and plate.

7. Remove the armature retaining screws and

washers.

Remove the armature segments.

Remove wave spring and detent ring from

armature hub.

Lift the armature hub away from magnet

assembly.

8. Clean the removed hardware and apply one

®

drop of Loctite

grade AA or equivalent to each

capscrew thread before installation.

Warner Electric • 800-825-9050 P-1405 • 819-0325

3

Page 4

Install new armature segments onto the

Plate

Wave Spring

Detent Ring

Armature Hub

Wave Spring

Spring ends

placed up

Detent Ring

Slot in Detent

180º apart from

slot in Wave Spring

armature hub and fasten with capscrews and

washers.

Tighten the capscrews to the appropriate

torque specifications for your size unit:

Size Torque

25 29-35 in.-lbs.

55, 115 60-84 in.-lbs.

9. Install detent ring. The raised lip is to face the

hub armature fins.

Install the wave spring plate and screws.

Note: Install the wave spring with its split

180° from the split in the detent ring.

Warner Electric • 800-825-9050 P-1405 • 819-0325

4

Page 5

10. Remove the friction material segment

retaining screws and lift out the friction

material segments.

Press the hub with its bearing, out of the

magnet assembly. BE CAREFUL TO

AVOID DAMAGING THE EPOXY WHICH

COVERS THE COIL.

12. Remove the bearing from the hub by

pressing it off.

11. Turn the magnet assembly over and remove

screws.

Remove backplate and shim.

Remove retaining ring to expose the bearing.

13. Press the new bearing into the magnet

assembly. Be careful to press only the

outer race of the bearing.

Warner Electric • 800-825-9050 P-1405 • 819-0325

5

Page 6

14. Install shim and backplate.

Press

Hub

Magnet

Assembly

Support

Clean the removed hardware and apply one

drop of Loctite grade AA or equivalent to each

screw thread before threading into holes.

Tighten the screws to the appropriate torque

for your size unit:

15. Install the hub into the bearing by supporting

on the inner race of the bearing and pressing on the outer end of the hub. Press until the

inner race of the bearing is flush with the

shoulder on the hub. (See Figure 1)

Install the retaining ring on the hub adjacent to

Size Torque

the bearing.

25 16-20 in.lbs.

55, 115 30-35 in.lbs.

16. Clean all foreign material from the magnet

mounting surface. Install new friction

material segments from the kit.

Figure 1

Warner Electric • 800-825-9050 P-1405 • 819-0325

6

Page 7

The recessed holes should be facing away

Press Evenly

Approximately

1/16 Airgap

All Ground

Support

Support

Armature

Assembly

from the magnet body.

Clean the supplied hardware and apply one

drop of Loctite grade AA or equivalent should

be applied to each thread before installation.

Do not allow Loctite to get on friction material

surface.

17. Place the brake mounting flange down and

place the armature assembly on the hub. First

engage the spine teeth, then uniformly apply

force by hand, pushing the detent ring over

the spline outside diameter. Now apply force

to the Armature Assembly until the armature

contacts the friction disc. (See Figures 2 and

2A)

Rotate the hub and armature assembly by

hand. There should be no interference.

Install the retaining ring on the hub adjacent to

the armature.

Fasten with new screws. Note: Use only the

screws furnished with the kit as others may

damage the brake.

Tighten each screw to 18-22 in.lbs. of torque.

Figure 2

When installing or removing

this or other retaining rings, be sure to

hold the ring with one hand so it will not

spring away, endangering personnel and

property, should the pliers lose their grip

on the ring. Safety glasses should always

be worn when installing or removing

retaining rings.

18. Reinstall the brake on the shaft with the key in

its keyway.

Figure 2A

Warner Electric • 800-825-9050 P-1405 • 819-0325

7

Page 8

19. Tighten the hub set screws, on the shaft and

key per the following torque specifications:

Size Torque

25 80 in.lbs.

55 160 in.lbs.

115 275 in.lbs.

21. Reconnect the wires.

22. Your AT brake is now ready for its static test.

Apply DC voltage to the coil through the brake

control. The armature should pull against the

friction material face with an audible click.

20. Secure the torque arm to the brake. The

torque arm attachment must be flexible

enough to compensate normal shaft and

bearing runout without causing binding or side

loading to the brake.

23. Run the brake under its operating load.

24. Your AT brake might not achieve its full torque

until after a short “break-in” period. To break in

the brake, cycle it on and off under full load at

operating speed a minimum of ten times in

quick succession. (See note)

Your AT brake is now ready to run.

Note: Your application may require more

cycles to achieve full torque due to load and

RPM.

Warner Electric • 800-825-9050 P-1405 • 819-0325

8

Page 9

Warranty

Warner Electric LLC warrants that it will repair or replace (whichever it deems advisable) any

product manufactured and sold by it which proves to be defective in material or workmanship within a

period of one (1) year from the date of original purchase for consumer, commercial or industrial use.

This warranty extends only to the original purchaser and is not transferable or assignable without Warner

Electric LLC’s prior consent.

Warranty service can be obtained in the U.S.A. by returning any defective product, transportation charges

prepaid, to the appropriate Warner Electric LLC factory. Additional warranty information may be obtained by

writing the Customer Satisfaction Department, Warner Electric LLC, 449 Gardner Street, South Beloit, Illinois

61080, or by calling 815-389-3771.

A purchase receipt or other proof of original purchase will be required before warranty service is

rendered. If found defective under the terms of this warranty, repair or replacement will be made, without

charge, together with a refund for transportation costs. If found not to be defective, you will be notified and,

with your consent, the item will be repaired or replaced and returned to you at your expense.

This warranty covers normal use and does not cover damage or defect which results from

alteration, accident, neglect, or improper installation, operation, or maintenance.

Some states do not allow limitation on how long an implied warranty lasts, so the above limitation may not

apply to you.

Warner Electric LLC’s obligation under this warranty is limited to the repair or replacement of the

defective product and in no event shall Warner Electric LLC be liable for consequential, indirect,

or incidental damages of any kind incurred by reason of the manufacture, sale or use of any defective

product. Warner Electric LLC neither assumes nor authorizes any other person to give any other warranty or

to assume any other obligation or liability on its behalf.

WITH RESPECT TO CONSUMER USE OF THE PRODUCT, ANY IMPLIED WARRANTIES WHICH THE

CONSUMER MAY HAVE ARE LIMITED IN DURATION TO ONE YEAR FROM THE DATE OF ORIGINAL

CONSUMER PURCHASE. WITH RESPECT TO COMMERCIAL AND INDUSTRIAL USES OF THE

PRODUCT, THE FOREGOING WARRANTY IS IN LIEU OF AND EXCLUDES ALL OTHER WARRANTIES,

WHETHER EXPRESSED OR IMPLIED BY OPERATION OF LAW OR OTHERWISE, INCLUDING, BUT NOT

LIMITED TO, ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you. This warranty gives you specific legal rights and you may also

have other rights which vary from state to state.

Changes in Dimensions and Specifications

All dimensions and specifications shown in Warner Electric catalogs are subject to change without notice.

Weights do not include weight of boxing for shipment. Certified prints will be furnished without charge on request to Warner Electric.

Warner Electric

31 Industrial Park Road • New Hartford, CT 06057

815-389-3771 • Fax: 815-389-2582

www.warnerelectric.com

P-1405 • 819-0325 8/11 Printed in USA

Loading...

Loading...