Warmboard R User Manual

R

For assistance call

1.877.338.5493

1

05.18

Warmboard-R

installation guide

2

Table of Contents

Setup and preparation Hardwood and tile installation Carpet, other flooring, temperature

guide and R–values

10 important installation highlights Page 3

Approved tubing list Page 4

Necessary tools Page 5

Choosing the correct router Page 6

Custom routing Page 7

Panel types Page 8

Example of panel/tubing design Page 9

Installing over existing subfloor Page 10

Installing over concrete slab Page 11

Tubing installation Page 13

Installing solid wood flooring Page 16

Hardwood manufacturers Page 18

Installing traditional strip and Page 19

plank hardwood

Installing engineered, laminate, Page 21

and bamboo flooring

Installing tile Page 23

Tile resources Page 31

Installing carpet Page 32

Carpet and padding R-values Page 33

Installing cork flooring Page 34

Installing vinyl Page 35

Installing linoleum Page 36

Finish floor R-values Page 37

Required water temp chart Page 38

For assistance call

1.877.338.5493

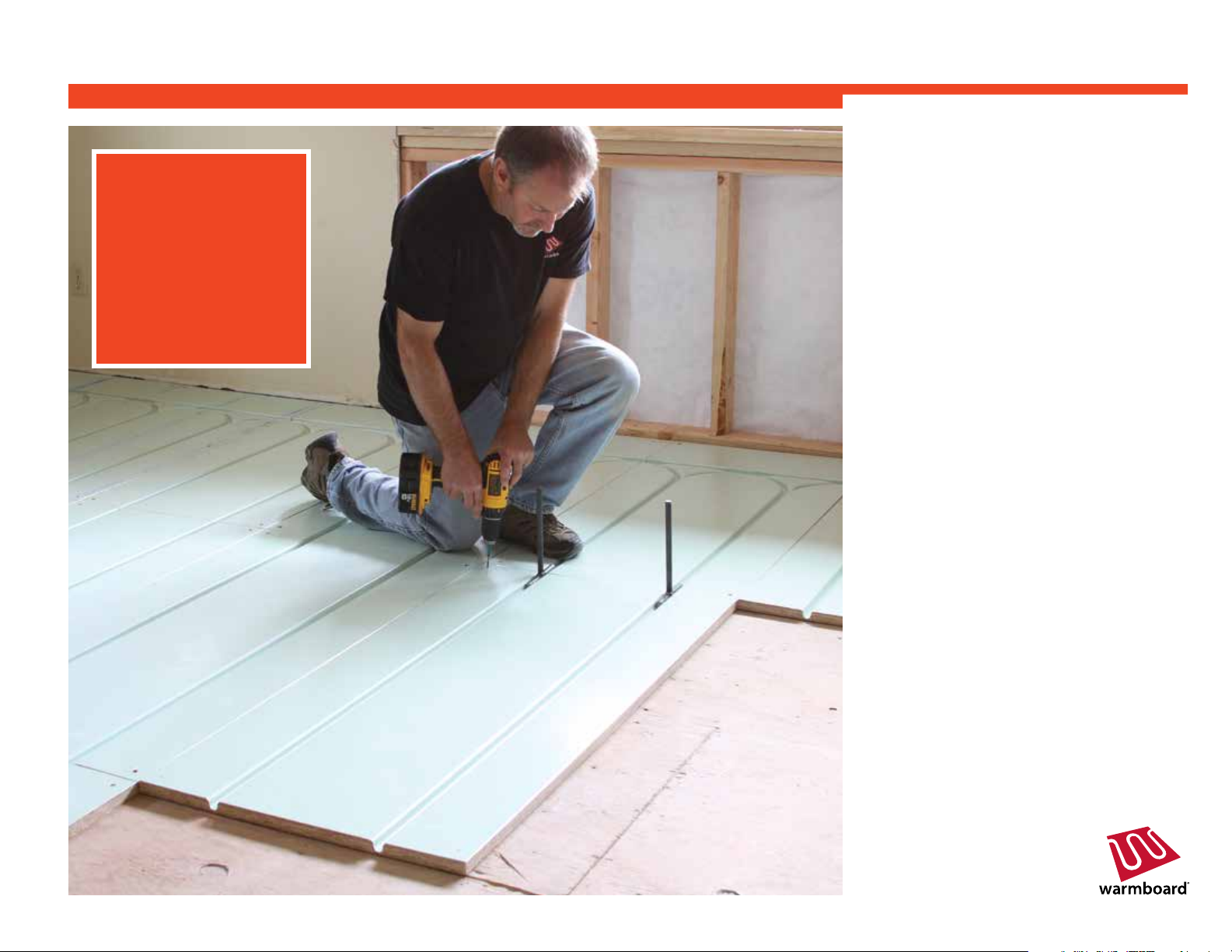

10 important installation

highlights

Read these highlights before proceeding. They will save you time and hassle in the long run.

3

1. We recommend the existing subfloor to

be reasonably smooth and flat prior to the

installation of Warmboard–R. Inspect for

squeaks and refasten to joists if necessary.

2. The existing subfloor needs to be dry prior to the

Warmboard–R installation. Warmboard–R cannot

be exposed to rain before or after installation.

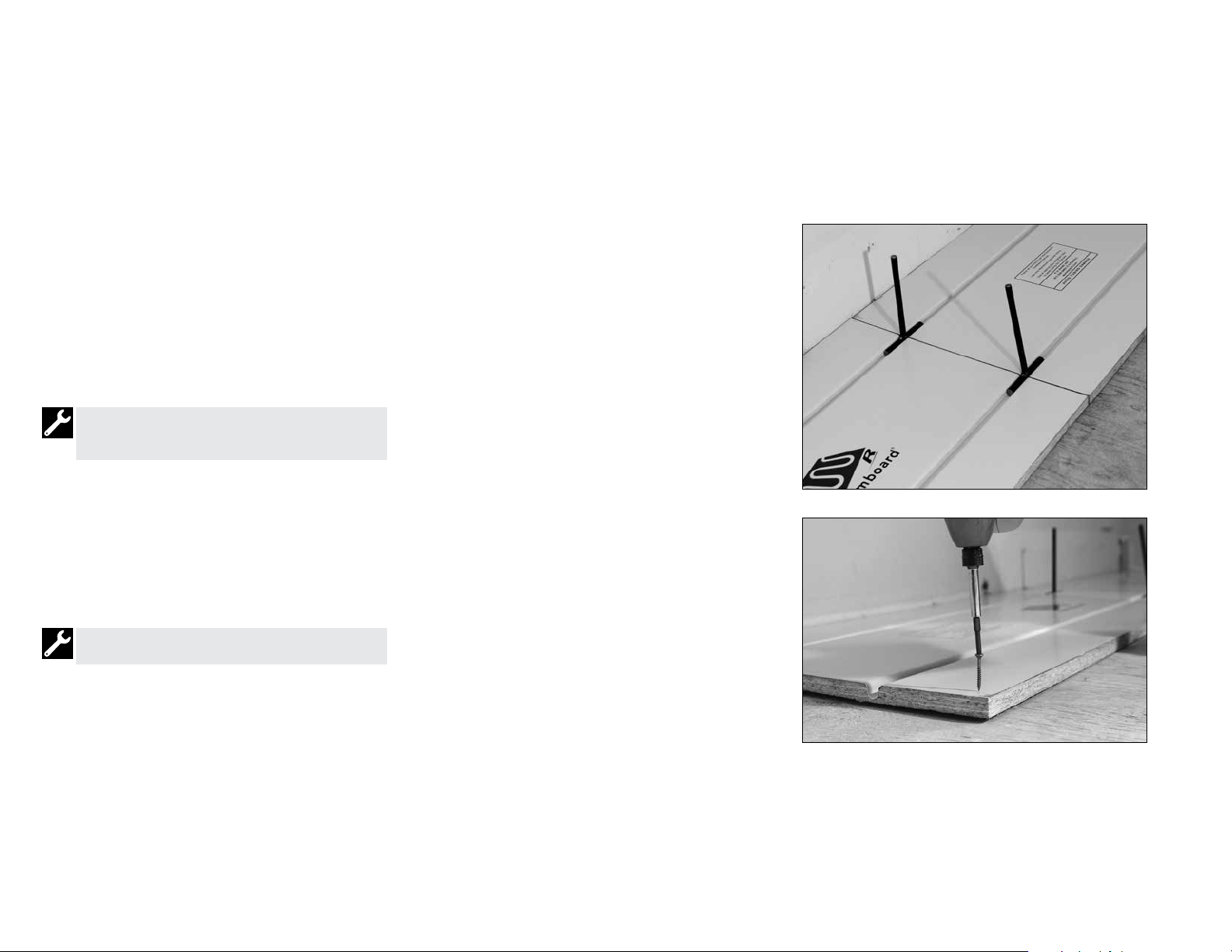

3. Use the provided alignment pins when fastening

the Warmboard–R panel.

4. ONLY use tubing approved by Warmboard, Inc.

Silicone or other types of adhesives should not

be used on tubing.

5. Tubing layouts for Warmboard–R can be quite

flexible. Make field revisions as needed. Do not

exceed 300 linear feet per loop.

6. Custom routes require a 1

router minimum. A Porter Cable router will

interface with the template guides provided by

Warmboard, Inc. Do not attempt a custom route

without the proper template guide attached to

the router (see page 6).

7. The Warmboard–R heating system (and the

entire radiant industry) requires the surface

temperature of the finished floors not to

exceed 85ºF.

8. When Warmboard–R is being installed over

a crawl space or existing subfloor, a minimum

of R-19 insulation is required underneath the

panels to prevent downward heat loss.

9. Review the installation manual before installing

finish floors

10. Call us if you have any questions:

1.877.338.5493

1

/

horsepower

2

CAUTION!

Warmboard–R panels must NOT be exposed

to water or excess moisture.

Approved tubing list

These are the tubing types/brands approved for use with Warmboard products.

Select ONLY from the tubing listed below. This will ensure a silent interface between the pex tubing and the aluminum groove. Installing other types of tubing

may create a ticking noise as the tubing expands during operation. This noise is created by the outer layer of the EVOH barrier rubbing against the aluminum.

Warmboard Inc. can also supply tubing and manifolds for your project. Ask your Project Manager for details.

4

PEX Aluminum PEX tubing, 1/2" ID

u

AIM: PEX-AL-PEX

u

Allied Pipe Systems: PEX-AL-PEX

u

Aqua Therm: PEX-AL-PEX

u

Bluefin: PEX-AL-PEX

u

ComfortPro: PEX-AL-PEX

u

EHT (Efficient Heating Technology):

u

Everhot: PEX-AL-PEX

u

Excel: PEX-AL-PEX

u

Henco: PEX-AL-PEX

u

Hydro-flex: PEX-AL-PEX

u

HYDRONX: PEX-AL-PEX

u

Inferno: PEX-AL-PEX

u

Infloor Heating Systems: PEX-AL-PEX

u

Mr. Pex: PEX-AL-PEX

u

RHT: PEX-AL-PE X

u

Rifeng: PEX-AL-PEX

u

Roth: PEX-AL-PEX

PEX-AL-PEX

u

Uponor: Multi-Layer composite tubing (MLC)

PEX-AL-PEX

u

Warmboard PEX: PEX-AL-PEX

u

Watts: PEX-AL-PEX

u

Weil-McLain: PEX-AL-PEX

u

WSD (Willow Springs Distributing) PEX-AL-PEX

u

Zurn Alumicor: PEX-AL-PEX

Standard Barrier tubing, 1/2" ID

u

M r. Pex

u

Rehau Raupex Oxygen Barrier

(manufactured after 3/8/11)

u

ThermaPEX (LK PEX)

u

Uponor Helio PEX

u

Uponor Wirsbo hePEX

u

ViegaPEX Barrier

u

Watts RadiantPEX+

PERT tubing, 1/2" ID

u

Infloor Heating Systems: InfloorPERT

u

Oil Creek Plastics: HEATFLEX pipe

u

Roth: X-PERT S5, 5 layer

u

Watts: RadiantPERT

u

Zurn: hy-PE-RTube

Viega Fostapex is not approved, the diameter is too

large for the Warmboard groove.

CAUTION!

DO NOT USE silicone or other adhesives in the

tubing channels.

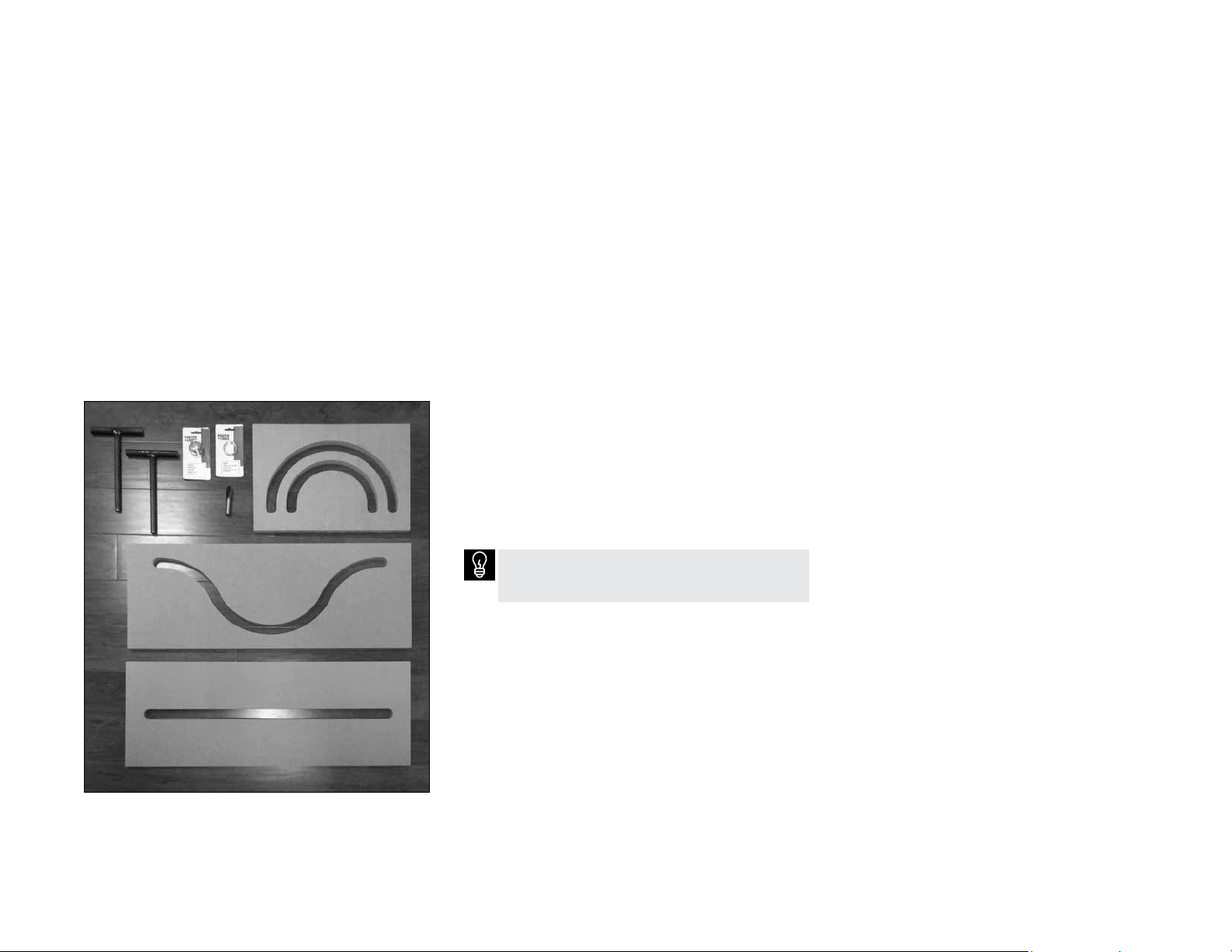

Necessary tools

For assistance call

1.877.338.5493

5

Installation kit includes

(supplied with each order)

u

3 Custom routing templates/guides (wood)

5

u

1 Router bit,

u

2 Alignment pins

u

1 Porter Cable template guide

u

1 Porter Cable guide lock nut

/

"

8

Additional materials and tools

(for on-site use)

u

Circular saw, carbide blade

1

u

Porter Cable router, 1

u

Electrician nailing plates

u

Heavy roller (typically a linoleum roller)

u

Warmboard approved tubing

u

Shop vacuum

u

Drill motor with a 1

u

PEX tubing cutter

u

Felt tip marking pen

u

Warmboard panel and tubing plans

u

Tubing un-coiler

u

4" grinder or dremel

Warmboard, Inc. can supply tubing and manifolds

at very competitive prices. Ask your Project Manager

for details.

/

horsepower minimum required

2

1

/

" drill bit

4

Choosing the correct router

NOTE

Not all Porter Cable sub-bases interface

properly with the Warmboard supplied

Porter Cable metal template guides.

1

A minimum 1

size of the metal template guide is 1" OD, designed

for Porter Cable routers and accessories only.

/

horsepower router is required. The

2

6

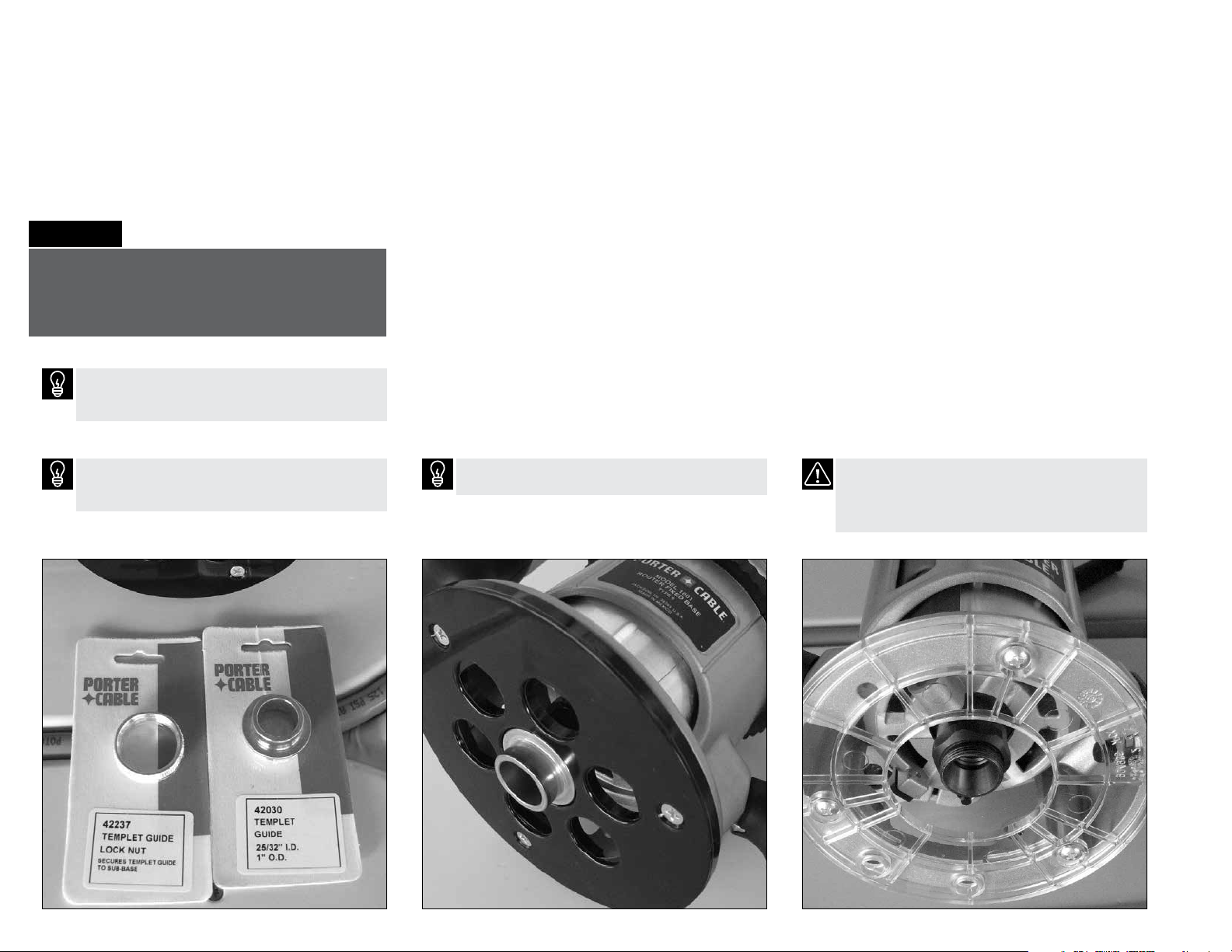

This photo shows the correct templet guides to use

with the Porter Cable router. These templet guides

are supplied by Warmboard.

This photo shows the correct sub-base and the

supplied metal templet guides installed.

CAUTION!

This Porter Cable router DOES NOT interface with

our supplied template guide and will not work to

create custom routes.

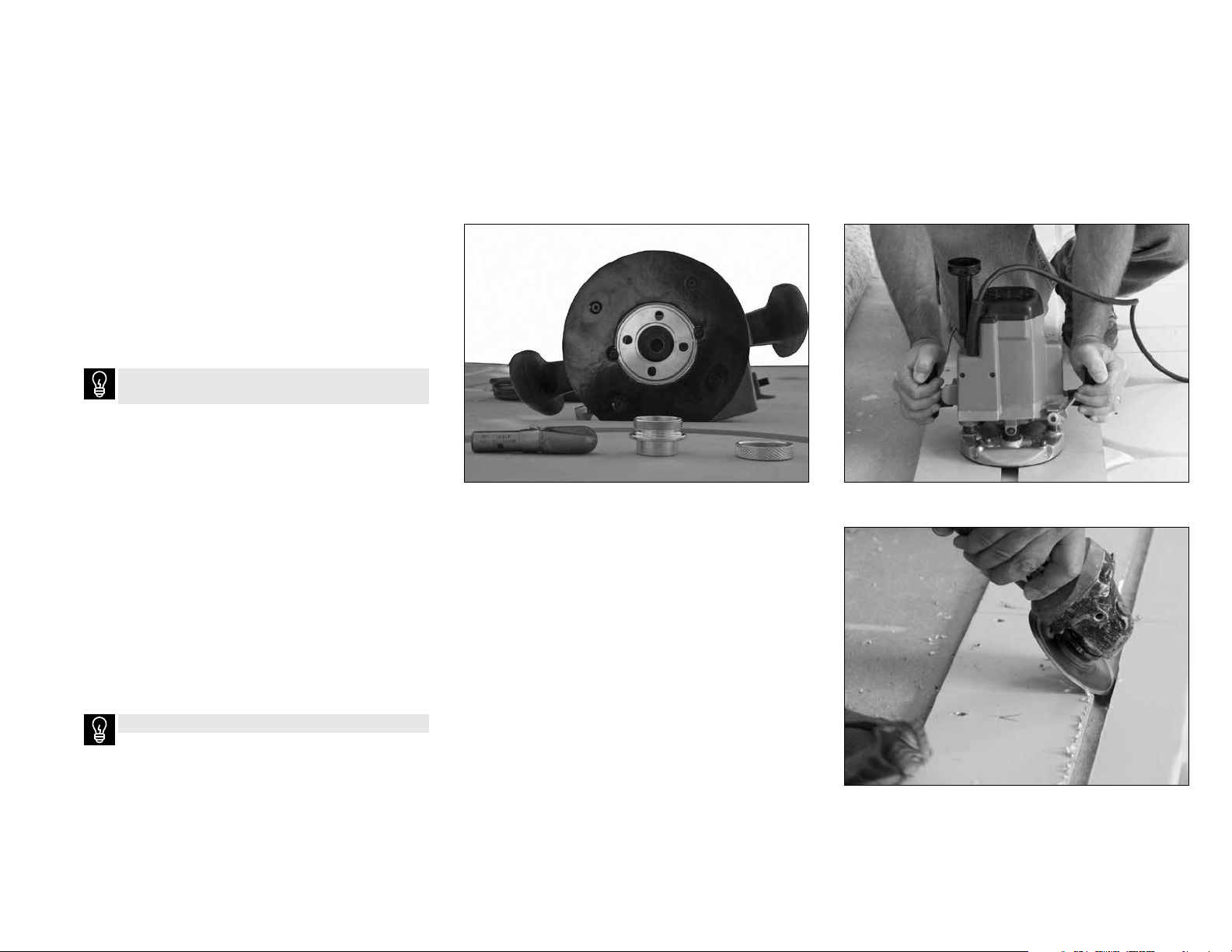

Custom routing

Check list

u

Review all the tubing layout plans. Using a felt tip marker

and the provided wood templates, mark all areas on the

Warmboard–R panel that will require custom routing.

u

Prepare router with router bit, template guide and

template guide lock nut.

The Porter Cable router is not provided. A minimum

1

/

1

horsepower is required.

2

Procedure

For assistance call

1.877.338.5493

7

u

Place the appropriate custom routing template over the

area to be routed

u

Fasten with 3 screws to secure the wooden template

in position

u

Ensure that the router bit and metal template guide are

properly installed, then proceed with the router

u

When the route is complete, remove the template guide

and use 4" grinder or deburring tool to remove aluminum

burrs to ensure that entire area is smooth in preparation

for tubing installation

Visit warmboard.com/videos for further instructions.

5

/

" Router Bit

8

Temp l ate Guide GuideLock Nut

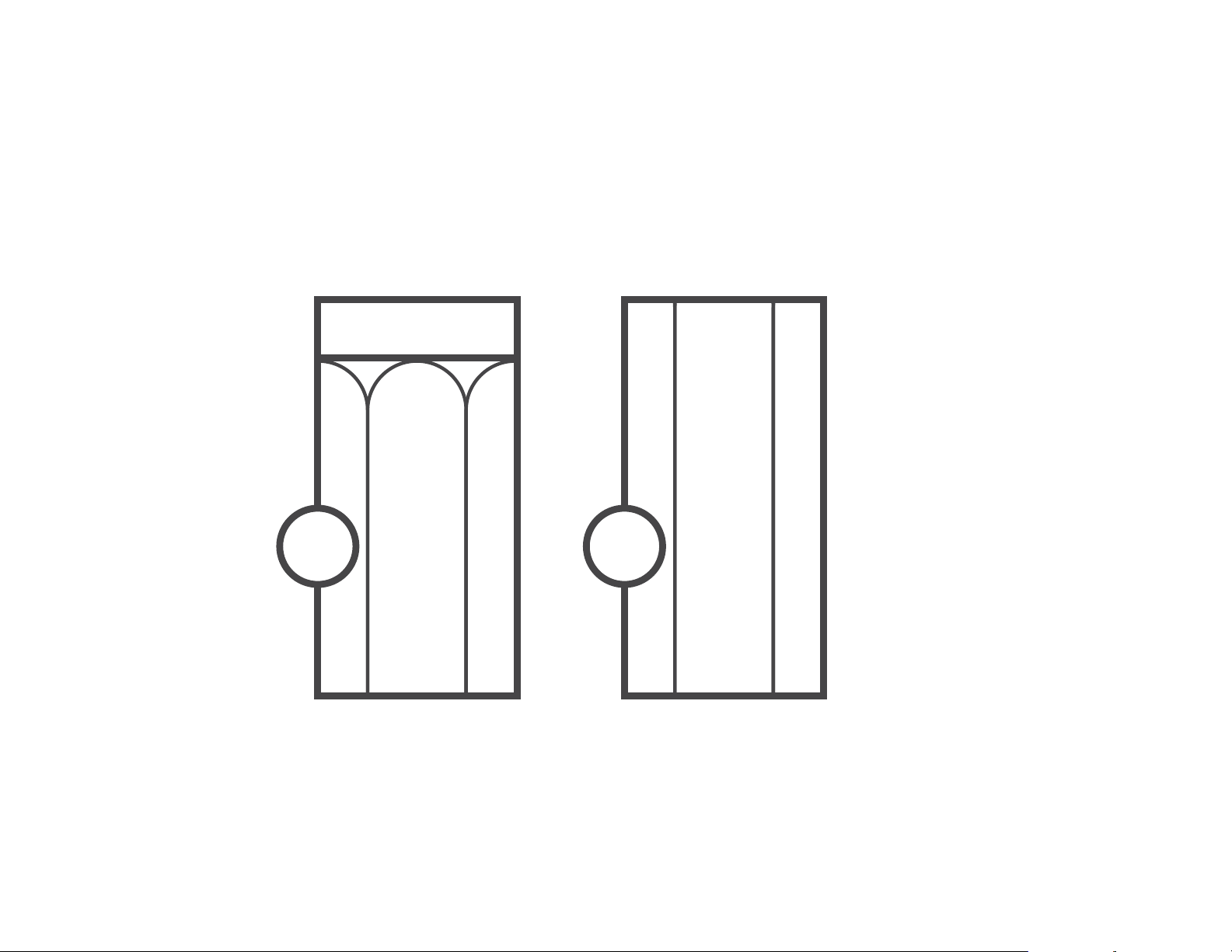

Panel types

8

7

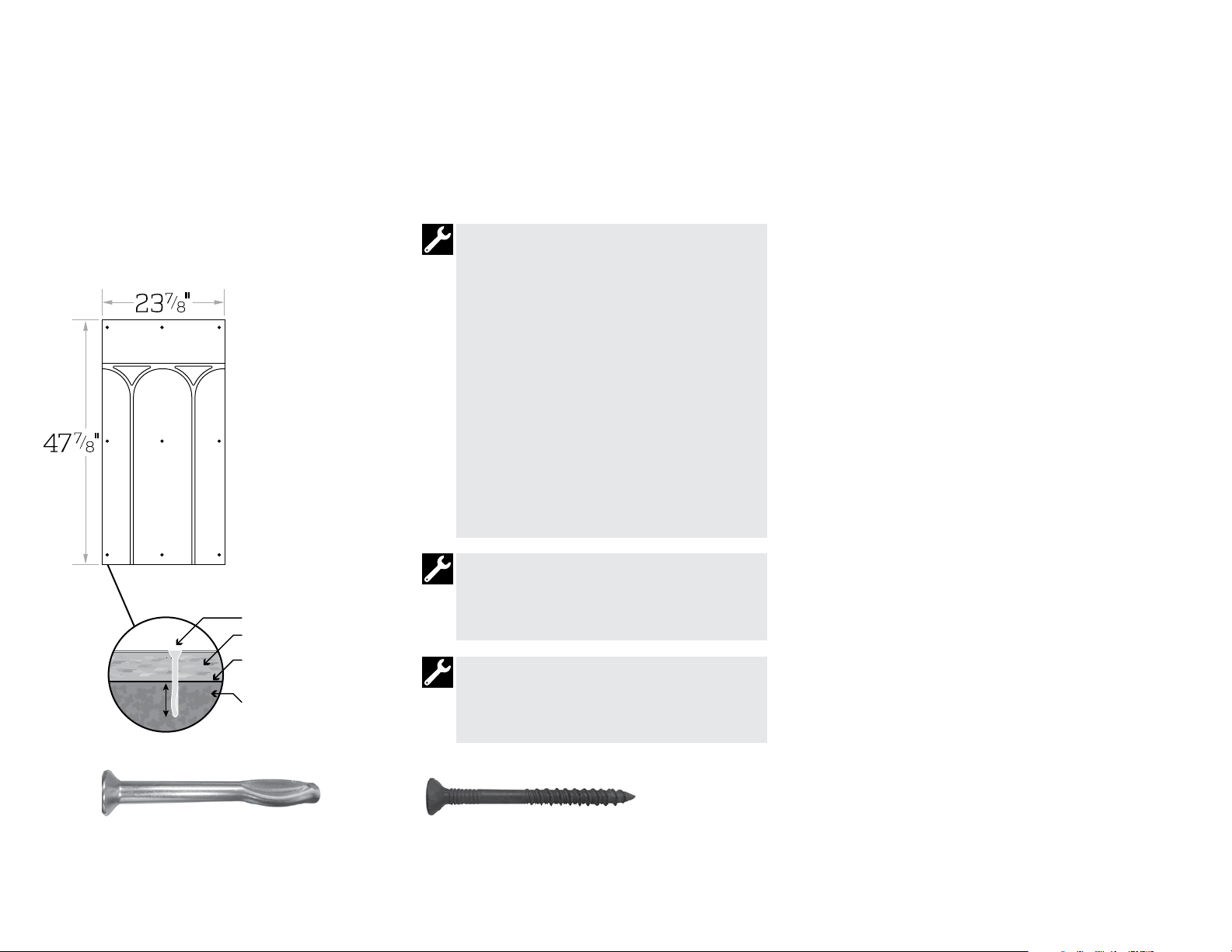

There 2 panel types of Warmboard–R panels. Each panel measures 23

Panels are made from OSB and are square-edged. Filler panels are also available.

/

" W x 47

8

RT RS

7

/

" L x

8

13

/

" H.

16

Turn Panel Straight Panel

NOTE Read all instructions before beginning the installation process.

Review supplied working drawings including floor plan dimensions, before installation.

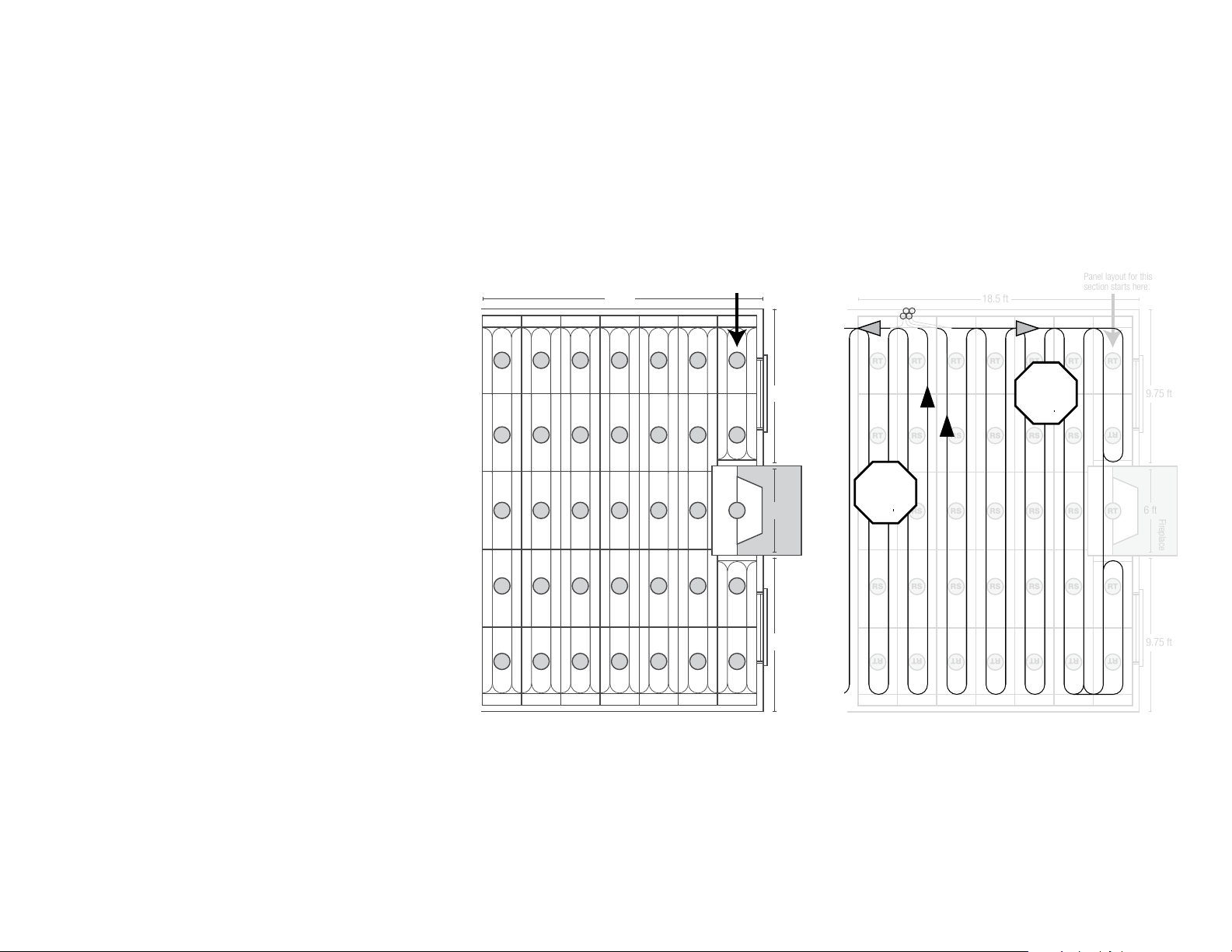

Example of panel and

tubing design

For assistance call

1.877.338.5493

9

Warmboard does encourage confident contractors

and homeowners to draw their own panel and tubing

shop drawings. We recommend loop lengths of 300

foot maximum, from supply to return manifold.

The modular design of the Warmboard–R panel

allows opportunity for little or no custom routing.

If the finish floor is a nail down hardwood,

Warmboard–R panel should install perpendicular

to the hardwood planks.

If this is not an endeavor you want to take on,

Warmboard, Inc. can provide the shop drawings.

Panel layout example Tubing layout example

Panel layout for this

18.5 ft

RT RT RT RT RT RT RT

RT RS RS RS RS RS

RS RS RS RS RS RS RT

RS RS RS RS RS RS RT

RTRTRTRTRTRTRT

section starts here.

RT

9.75 ft

6 ft

9.75 ft

Fireplace

18.5 ft

RT RT RT RT RT RT RT

RT RS RS RS RS RS

1.2

ZONE 1

RS RS RS RS RS RS RT

170

RS RS RS RS RS RS RT

RTRTRTRTRTRTRT

1.1

ZONE 1

210

Panel layout for this

section starts here.

RT

9.75 ft

6 ft

9.75 ft

Fireplace

Installing over existing subfloor

10

It is essential that the existing subfloor is both

flat and smooth before the installation of

Warmboard–R. Inspect the subfloor for evenness

along the joists and flatness between the joists.

If necessary, sand the subfloor, install extra

blocking below the subfloor, and refasten the

subfloor to even areas. Also, inspect for squeaks

and refasten with decking screws as necessary.

The subfloor and Warmboard– R need to be dry. The

Warmboard–R cannot be exposed to any rain before

or after installation.

Cutting and installing Warmboard–R is very

straightforward. The panels can be trimmed with

a standard skill or table saw and will rip just like

ordinary OSB. It is best to cut the panels with the

aluminum side down. We recommend two different

options for attaching the panels to the subfloor.

It is crucial to use the provided alignment pins to line

up the channels from panel to panel.

Screw fasteners methods

1

Use a 8 x 1

R4 screw with a top

at Home Depot). Using an equivalent product is

acceptable. Fasten with in a pattern of 3 rows of 4.

u

No pre-drilling required

u

Self counter sinking

u

No adhesive needed

/

" “GRK Uber Grade” multi-purpose

2

1

/

" smooth shank (available

2

Nail and glue method

Using a construction adhesive designed for bonding

OSB and plywood, such as “Loctite PL Wood” is an

excellent choice. The use of an equal product is also

acceptable. Follow all directions as specified by the

adhesive manufacture.

For nailing, use a ring shank or a screw nail.

To determine the appropriate length of the nail to

use, evaluate existing thickness of subfloor and add

13

/

". This will be the minimum length required.

16

Fasten nails with a pattern of 3 rows of 4.

Installing over concrete slab

For assistance call

1.877.338.5493

11

Benefits

Installing Warmboard–R over an existing concrete

slab can retrofit a basement or home remodel with a

state of the art radiant floor heating system. Finish

floor options include the broad range available with

a Warmboard system such as hardwood, tile, carpet,

vinyl and linoleum.

Concrete slab requirements

The existing slab must be level and flat. A newly

poured slab needs to be well cured which requires

a minimum of 30 days. A moisture test should be

conducted prior to installation to ensure the slab

is properly cured. The slab must have sufficient

drainage from rain and snow on a year round

basis. If the Warmboard–R panels are exposed

to any standing water or any moisture intrusion,

the wood will rot. Do not use Warmboard–R if

these environmental conditions are possible.

When Warmboard–R is being installed over an

existing slab, it is crucial for the panels never to

be exposed to weather. After installation, if the

Warmboard panels are exposed to rain or snow,

the moisture will be trapped in the panel and

wood rot will take place.

Testing for moisture

There are several possible methods by which to test

the moisture content of a newly poured slab, the

simplest being “The Plastic Sheet Method” (ASTM

D 4263-83). For this method, seal an 18" x 18"

square of clear plastic sheet to the slab with tape

on all 4 sides. If, after 16 hours, any condensation

is found on the underside of the plastic or if the

surface of the concrete is darkened, the concrete

is considered too wet for coating application.

Do not allow the sheet to come in contact with

direct sunlight or excessive heat.

It is possible for this particular method to yield a

false result, giving the impression that the slab is

fully cured, when in fact it still contains moisture.

For example, in cooler conditions, the concrete

may retain its moisture and fail to condense on

the plastic. However, an obvious appearance of

moisture in this method almost always indicates

excessive moisture.

With the Plastic Sheet Method, the best way to

ensure a reliable result is to make sure that the

surface temperatures and ambient conditions during

the test are very similar to those present after the

Warmboard panels are installed.

If no moisture test is conducted, we recommend

giving a newly poured slab 90 days to cure fully.

Installation method 1

Install a vapor retarder directly to the slab.

We recommend either a 6 or 10-mil polyethylene

overlapped two feet (2') at the seams. Continue with

Warmboard–R panel installation with the use of

Tapcon concrete fasteners or Split Drive Anchors.

We recommend a maximum of 9 fasteners for

each panel.

Installation method 2

Install a 6- or 10-mil polyethylene vapor retarder

directly to the slab, overlapping two feet (2') at the

seams. Next, install the

or Homasote 440 Soundbarrier over the entire slab

(adding a R-value of 1.2). Gap all Homasote panels

3

/

" from all adjoining panels and

16

Use fasteners to attach the entire assemble to slab.

We recommend 9 fasteners per panel. Review the

installation instructions of the Homasote Comfort

Base or the 440 Soundbarrier at homasote.com

Before installation of a Tapcon fastener, drill a pilot

1

/

hole

" deeper than the Tapcon will reach. Draw the

2

bit in and out of the pilot hole repeatedly to loosen

excess material. Then remove the excess using a

shop vacuum.

1

/

" Homasote Comfort Base

2

3

/

" from walls.

8

12

Fastening pattern for

Warmboard–R over concrete

Split drive anchor OR

Tapcon concrete screw

13

/

" Warmboard–R

16

6-mil polyethylene

vapor barrier

1" min

Concrete slab

We highly recommend flat head split drive anchors.

They will save many hours, or days, of labor by

comparison.

Concrete drilling should be done with panels in

place. Predrilling the panels prior to installation is

not recommended.

Concrete drilling should be done with a heavy duty

1

roto hammer drill and a high quality

/

" masonry

4

drill bit. Use a 3 lb. sledge hammer to drive the split

drive anchor through the predrilled panel and into the

concrete.

1

1

/

Use a

/

" x 2

" flat head split drive anchor.

4

2

Split drive anchors can be difficult to find in common

retail stores. We suggest visiting confast.com

or calling 888-498-5747.

Before installation of a Tapcon fastener, drill a pilot

hole 1/2" deeper than the Tapcon will reach. Draw

the bit in and out of the pilot hole repeatedly to

loosen excess material. Remove the excess using

a shop vacuum.

Predrill with Warmboard–R in place using a high-quality

1

masonr y bit. Drilling depth should be

/

" deeper than

2

the required specication without drilling through the

slab. All concrete drilling should be done with a heavy

duty rotary hammer drill.

Preferred method

1

1

/

/

2

" x

"Flat Head Split Drive Anchor

2

4

1

/

Use

" high-quality masonr y bit

4

1

1

/

/

" x

" Flat Head Tapcon Concrete Screw

2

4

4

3

/

Use

" high-quality masonr y bit

16

Loading...

Loading...