Page 1

WANHAO Duplicator i3

User Manual V1.2

© Wanhao USA 2015

www.wanhaousa.com

Page 2

Safety

WARNING: The components on the Duplicator i3 generate high temperatures and move

extremely fast. Reaching inside of the Duplicator i3 while it is in operation may cause injury.

Stay clear of the printer frame perimeter while the machine is in operation. Always control the

Duplicator i3 from the rotary dial on the front of the printer or via the computer software. Never

push or pull any of the components by hand. After a print, make sure your printer is off and that

your nozzle is no longer hot before removing a model from the printer.

WARNING: The Duplicator i3 is a heavy machine and extra caution is advised when

lifting/moving the printer. Failure to properly lift/move the printer can result in injury.

CAUTION:

turned

result in electrical shock.

CAUTION:

When

and the power cord is disconnected from the wall socket. Failure to do so can

off

Only use the stock power supply provided with your Duplicator i3.

opening the Duplicator i3 for service, ensure that the power supply is

Page 3

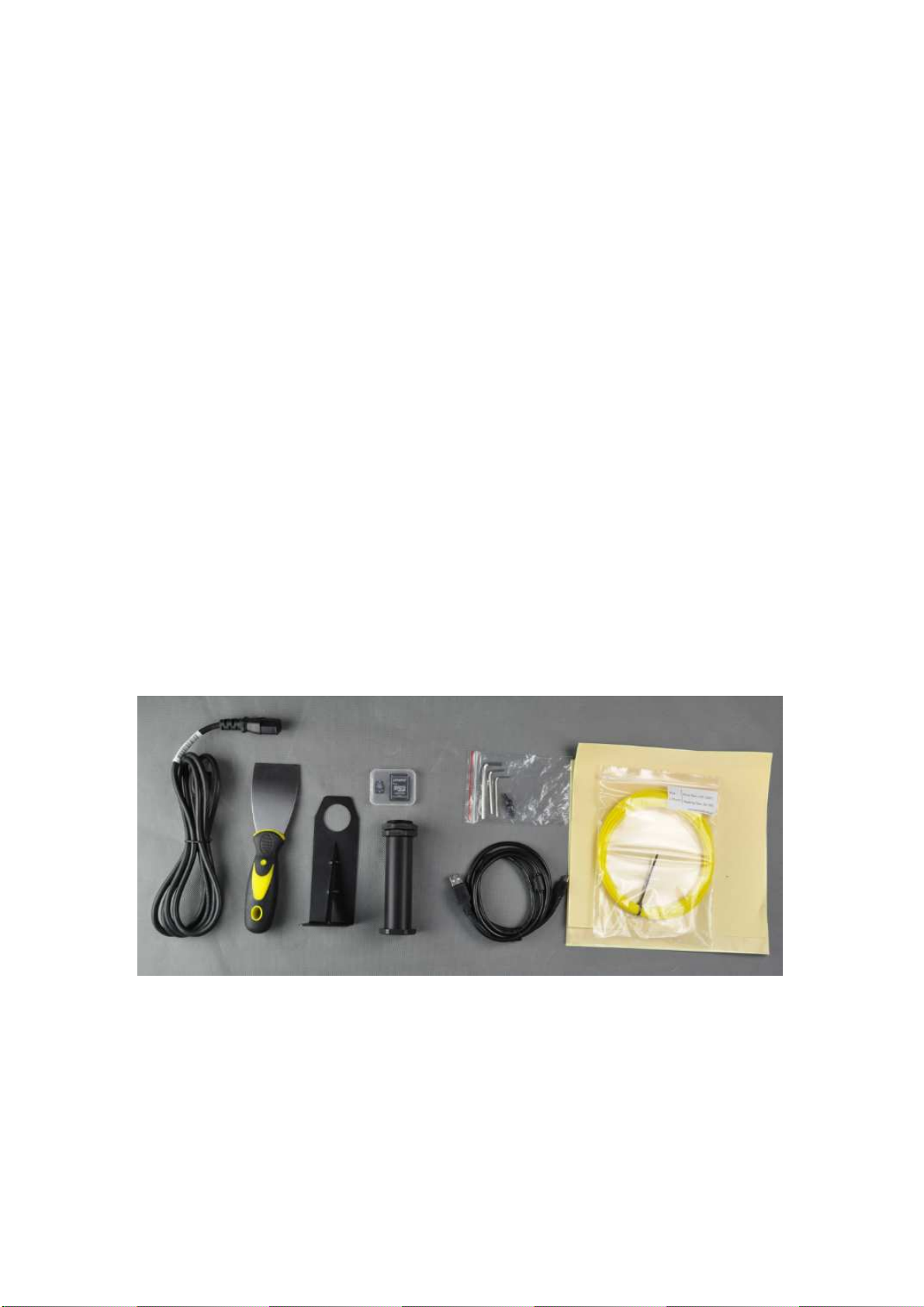

What's In The Box

Duplicator i3 3D Printer

Control Box

Model Removal Tool

Hex Screws & Key Kit

Filament Spool Holder

Spool Holder Stand

10M (~30FT) PLA Filament Pack

USB Cable

SD Card Kit

Platform Tape Sheets

Power Supply Cable

Page 4

Unboxing &

Hardware Setup #1

Your printer was packed securely to ensure safe shipment and storage. Make sure

to remove shipping ribbons, foam inserts, and packaging carefully to

damage. Make sure to begin the unboxing by laying the outer printer box on a dry,

clean, and stable work surface (table or floor).

prevent

1. Cut off shipping ribbons & open

the outer printer box.

3. Remove the top-layer foam insert.

2. Remove the cardboard

accessories box.

4. You should now see your printer

base and control box

NOTE: Never lift your printer by any electronics cables! We also recommend that you

keep your printer box for future transport and long-term storage.

Page 5

5. Remove the printer base from the foam packaging and place onto a

flat surface.

6. Remove and place the control box next to the printer base. Remove

the second-layer foam insert revealing the square tower frame & the

extruder assembly.

7. Cut the white ribbon that secures

the extruder assembly to the tower

frame.

8. Remove the tower frame and stand

it up vertically on the flat surface.

Page 6

9. Insert the printer base into the tower frame and match the screw

slots where the two frames meet.

10. Locate the screws (4 PCS) in your cardboard accessories

box

and use them to screw the tower frame to the printer base. Start

by screwing in one screw from the outside of the frame towards the

inside of the frame.

11. Lastly, turn your printer on it's side and insert a screw from

the inside of the frame towards the outside of the frame. This will lock

in your frames and prevent shifting of during operation.

Page 7

Once your tower is locked in placed you will need to make sure that your X-Axis (the

2 parallel rods running left-to-right) is perfectly level to your printing platform. You

can raise each side of the X-Axis by turning the couplers at the bottom of the Z-Axis

threaded rods.

12. Raise/lower the right side of

the X-Axis by turning the

cylindrical coupler at the bottom

of the

Z-Axis threaded rod.

13. Do the same for the coupler

on the left side. You need to

make sure that your X-Axis (the 2

parallel rods running left-to-right)

is perfectly level.

Page 8

Hardware Setup #2

Find the Spool Holder Stand

position on top of the Control Box by aligning the two screw slots so

that they are at the rear of the stand. Insert 2 screws and secure the

stand to the Control Box.

and the Control Box. Place the stand into

Find

the Filament Spool Holder and unscrew 1 of the end nuts on the

side with 2 end nuts. Place the holder through the hole in the stand and

secure the previously removed end nut back into place.

Page 9

Hardware Setup #3

To protect your printer against damage during shipping we have disconnected the

Z-Axis and X-Axis stepper motor cable connectors. You will need to insert each

connector into their corresponding sockets before using your printer. The longest

cable is for X-Axis.

The other 2 cables near the sides of your printer are for the Z-Axis stepper motors.

To insert the connector simply line up the terminals and give a slight push.

Right side Z-Axis stepper

motor.

Left side Z-Axis stepper

motor.

Page 10

Hardware Setup #4

Find your build platform (it’s the aluminum plate towards the front of

your printer on which you will be building your models). Tear off one

masking

possible. You will be printing on this sheet. You can also use painter's tape as a

substitute.

tape sheet and cover the platform with the sheet being as smooth as

Note: Your printer is able to operate

using 2 voltage options: 110V and

220V. Make sure you set the switch to

the correct voltage

country's power supply voltage (USA

uses 110V). Before connecting

anything, make sure that the

Duplicator i3 power switch is in the

OFF position.

Find your Power Cable in the

cardboard accessories box and plug

it into the power supply socket on

your Control Box (the socket is

located next to the power switch).

according to your

Your Hardware Setup is now

complete.

Page 11

Powering On Your Printer

Once you have prepared your printer

for operation press the power switch

on the back of your control box. The

power switch is located next to the

power cable socket.

If you are not able to turn your printer

on please re-check all of your power

cable connections.

Upon turning on your printer you should see the WANHAO logo while your printer's

firmware boots up and then ultimately the status monitor screen. While your printer is

in operation the status monitor screen will show you real-time information pertinent to

your printer.

Use the rotary dial on the front of your

control box to browse through the LCD

menu.

When you wish to make a selection on

the LCD menu push-click the rotary dial.

Page 12

Leveling Your Build Platform

Properly leveling your build platform is crucial to the quality of your print. The term

"leveling your build platform" refers to the manipulation of the four corners of your

build platform in order to properly space the distance in between your extruder

nozzle and the build surface...this is what will ultimately determine the resolution,

strength, and accuracy or your prints. The image below will show you the correct

and incorrect height at which your nozzle should be in relation to the build

platform:

SIDE VIEW END VIEW COMMENTS

Nozzle Too High:

Insufficient contact

area resulting in

poor adhesion and

extrusion skipping.

OK:

Filament pushed

into the build

surface slightly to

maximize surface

area contact while

still allowing good

extrusion flow.

Nozzle Too Low:

Not enough

clearance for the

filament to be

extruded...this will

result in damage to

the extruder and/or

build surface.

Page 13

Before you start leveling the build plate

make sure that you have placed your

build surface (Tape Sheet, Glass Plate,

or Custom Surface) onto your build

plate so that you can account for the

added height of your chosen surface

during leveling.

To begin leveling your build plate push-click the rotary dial so that you are within

the LCD's Main Menu. Scroll down to QUICK SETTINGS and push-click the

rotary dial once more.

Next, scroll down to HOME ALL and your stepper motors will begin to operate in

sequence to leave your nozzle resting right above the left-front of your build

surface.

The image to the right shows where

your

after selecting HOME ALL.

extruder assembly should rest

At this point go ahead and turn your

printer OFF via the power switch on the

back of your control box.

Page 14

Once you have turned your printer OFF

there will no longer be power to your

stepper motors and you will be able to

move the platform (Forward/Back along

the Y-Axis) and also the extruder

assembly (Left/Right along the X-Axis).

This will allow you to MANUALLY move

the platform & extruder assembly so

that you can check nozzle heights at all

four corners of the build platform.

Because your prints will normally start at the very center of your build plate you

should check your nozzle height about 2 in. (50mm) from each corner towards

the center. The image below shows blue X's at the recommended spot to check

your nozzle height. Checking your nozzle height at these X's will allow a more

accurate leveling for smaller prints that would normally not extend far out into

the corner of your build plate.

Page 15

Manually move your platform & extruder

assembly to nozzle height check

position #1 and take a look at the space

between the brass nozzle tip

underneath the extruder assembly and

the build surface. Turn the wingnut

underneath the closest corner of the

build platform either clockwise or

counter-clockwise to raise or lower that

particular corner.

By raising the corner height you are bringing that part of the platform closer to

the nozzle.

By lowering the corner height you are moving that part of the platform further

away form the nozzle.

The space between the brass nozzle tip

and the build surface should be roughly

the thickness of 1 sheet of copy paper.

To be accurate, slide a sheet of copy

paper back and forth between the two

components and keep adjusting the

height until you can barely feel the

nozzle dragging down the movement of

the copy paper.

You will do this for ALL four corners. If you want to be totally accurate you can

also do this same nozzle height check procedure for the very center of the

build plate.

*Note that once you adjust the height for one of the positions then your other

previously adjusted positions may become affected and need re-adjustment.

Although tedious, the best prints are always started by having a perfectly

leveled build platform.

Your build platform leveling is now complete.

Loading...

Loading...