Page 1

you can

Duplicator 9

MARK

I

WANHAO

PRODUCT BROCHURE

Page 2

DUPLICATOR 9 MARK I

Page 3

DUPLICATOR 9 MARK I

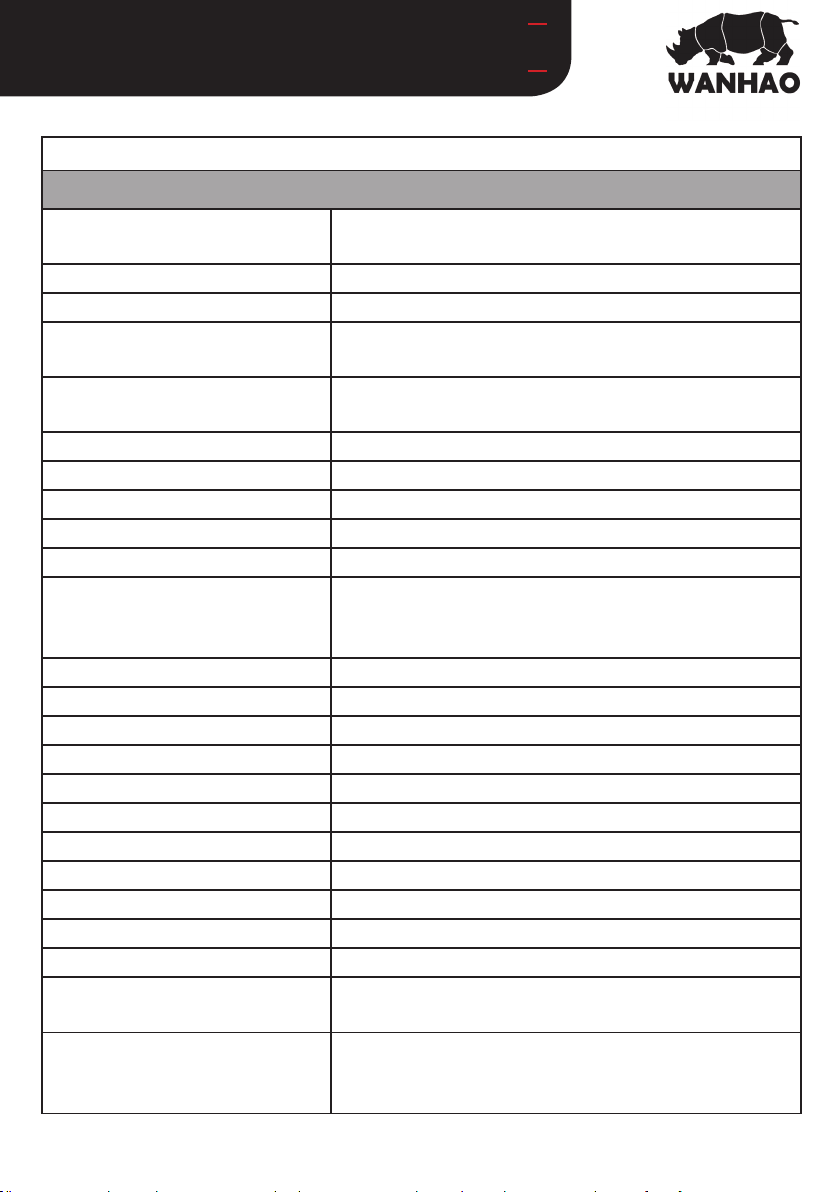

Technical Specifi cations

Primary attributes

of the technology

Software CURA, host by Repitator, Simplify 3D

Extruder system MK10 extruder with full metal hot end

Material support PLA, PVA, PEVA, PLA, Nylon,

Max printable area 300*300*400mm/ 400*400*400mm

Filament diameter/light 1.75mm

Max printing speed 70mm/s

Case Material Aluminum Case

With Insulate cover or not Insulate Tent Available

Extruder Quantity 1

Accuracy X 0.012mm

Net Weight(kg) 20kg

Gross Weight(kg) 22kg

Material cost USD12-34

Bed leveling 4 Points leveling

Packing size(cm) 60*50*35cm

Plateform Holder Steel frame holder

Rail locking system Steel bolt locking frame

Layer Thickness 100 micron- 400 micron

Plateform Aluminium plateform W/ heating,

Resume printing

LCD display English/Chinese/ customrized any language

Power supply unit Inside 110 AND 250V(optional), 50/60Hz, 4.0A

Typical application •A perfect printer for educators who intend to

PLA printer, entrance level printer.

Full assembled. Developped from Prusa i3.

Any material melting<=300’C

/ 500*500*500mm

Y 0.012mm

Z 0.004mm

Can resume printing after power break

(input), and takes standard IEC cable

use the printers in technical educatioin.

•Great printer for DIY hobbist.

Page 4

DUPLICATOR 9 MARK I

THERE'S NO MORE FUNCTION THAN PRINTING.

One click to start printing Loading different material so simple

One time monitoring your printing You can preheat before your prints

All steps are visual Resume printing when there's power

break

Page 5

DUPLICATOR 9 MARK I

1. Single extruder cable.

2. Near End wire feeding system

3. Full metal hot end

4. Heating bed

5. Anti-backlash rolling system

6. MK10 full metal extruder

7. Locking System

8. Touching screen

1

2

5

3

4

9. Anti-backlash rolling system

10. Z axis lead screw

6

7

8

9

11. Super precise Nozzle

10

12. Cable Chain

13

13.Y axis bearing

11

12

Page 6

9 IMPROVEMENTS

We have encounter Issue for big printer

Remote feeding system has providing

lot of strings.

D9 Advantages

Near End feeding system reduce the

strings to a reasonable scale.

Metal Sheet amount is easy to

deformed in shipping.

2 bolt bushing could be loose in shipping

Machining Motor amount providing

better dimentional size and strength

4 bolt locking thick bushing enable better

linear track.

Page 7

9 IMPROVEMENTS

Fixed rolling stand would be loose

after shipping and long time working

Hand soldering components is not so

reliable as SMT components.

Self-adjusting tension bearing would

always keep it tight.

Profestional motherbaord design, better

wiring ensure safety usage.

Twist and push control is classic, but

not so good for children and newbee.

Touching Screen, Visual guidance, more

user friendly.

Page 8

9 IMPROVEMENTS

Power break would lead to printing again.

Especially headache for some big project.

Without insulate cover, it's big challenge

to print something big.

Resume printing when power break would

save you lot of time in big project.

Insulate tent can provide more consistent

temperature to keep prints with less

deformation

Less support make your issue not

easy to resolve.

Profestional support worldwide make

your way easy

Page 9

Loading...

Loading...