Page 1

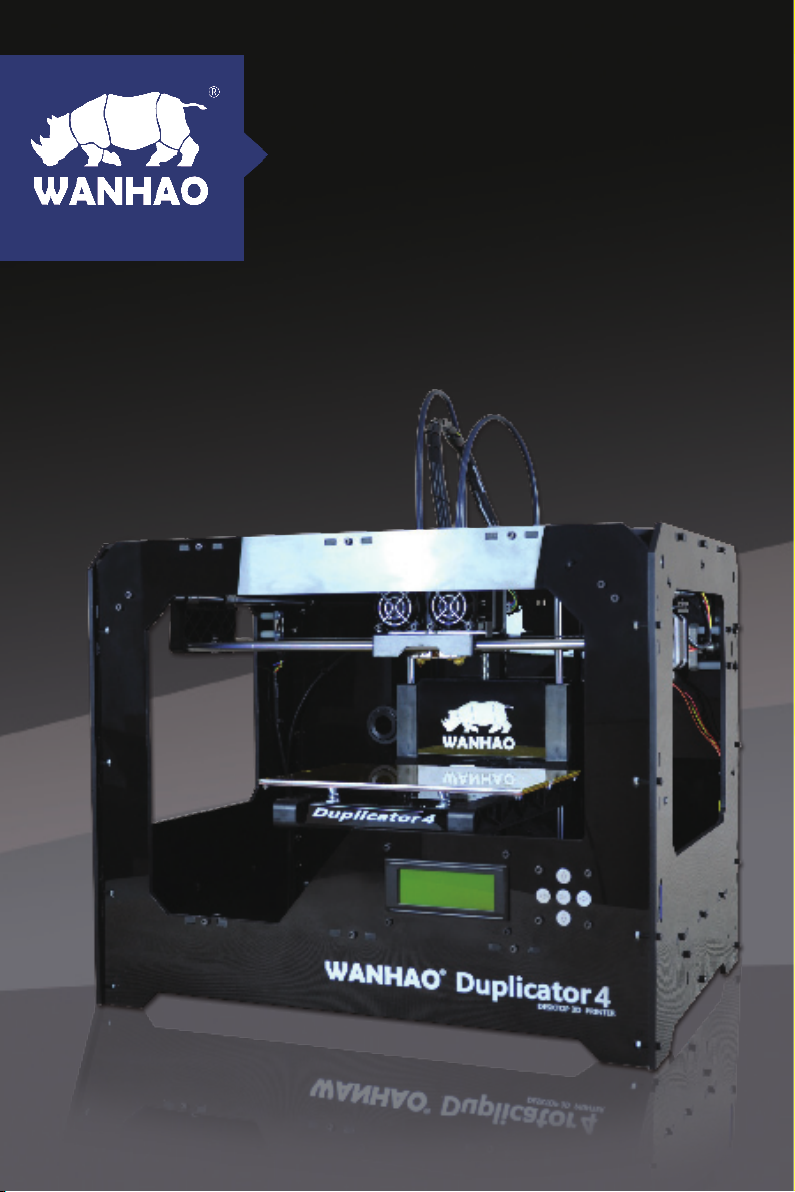

Duplicator

Desktop 3D Printer

4/4x

---------------------------

USER MANUAL

---------------------------

Page 2

Page 3

TABLE OF CONTENTS

------------------------------------------------------------------------------------------------------------------------------------------

A.

WELCOME LET'S GET STARTED

Specifications

How does it work

B.

SETTING UP YOUR WANHAO DUPLICATOR 4/4x DESKTOP

3D PRINTER

What's in the box

---------------------------------------------------------------------------------------

---------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------

--------------------------------------------------------------------------------

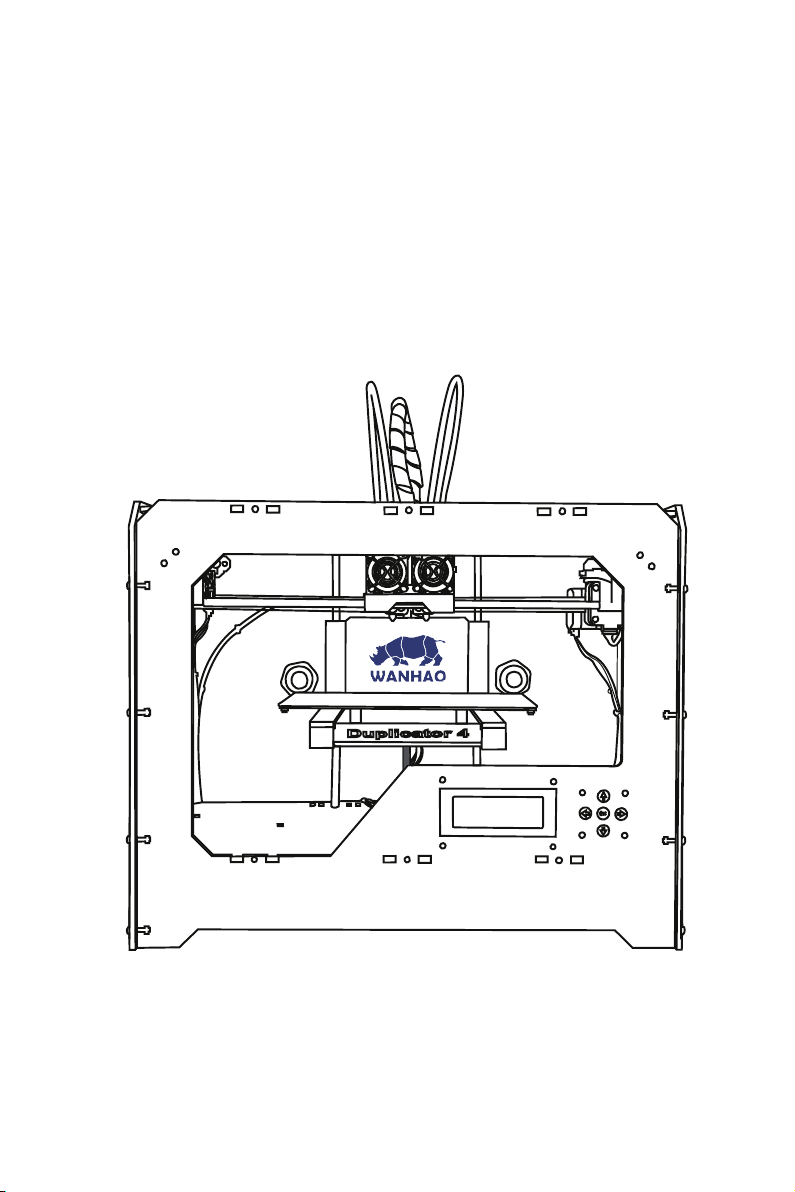

WANHAO Duplicator 4 Diagram

Unpacking your Wanhao Duplicator

Installing Building Plate

----------------------------------------------------------------------

Installing Filament Guide Tube and Spool Holder

Mounting Filament Spool and Atttaching USB cable

Attaching Power Cable and Powering On

C.

STARTUP PORCESS: LEVELING, LOADING, TESTING

Leveling the Build Plate

-----------------------------------------------------------------------

Loading Duplicator ABS and PLA filament

Unloading Duplicator ABS and PLA filament

Making a Test Object from the SD Card

D.

MAKING AN OBJECT WITH WANHAO REPLICATOR G

Download and Install WanHao Replicator G

Download an Object From WanHao Thingshares

Open WanHao Replicator G

E.

TROUBLESHOOTING, DIAGNOTSTICS, AND MAINTANCE

Troubleshooting

Diagnostics

----------------------------------------------------------------------------------

------------------------------------------------------------------------------------------

LCD Panel/ Top-level Menu

LCD Panel/ Utility Menu

----------------------------------------------------------------------

LCD Panel/ Info and Setting Menu

Maintenance

----------------------------------------------------------------------------------------

---------------------------------------------------------

--------------------------------------------------------

--------------------------------------------------

-----------------------------

------------------------

------------------------------------------

---------------------

-----------------------------------------

-------------------------------------

---------------------------------------------

--------------------------------------

.

-------------------------------

---------------------------------------------------------------

----------------------------------------------------------------

-----------------------------------------------------

Lubricating the threaded Rod and the X-Axis Idler Pulley

Cleaning the Drive Gear

Glossary of Terms

Contact

------------------------------------------------------------------------------------------------

----------------------------------------------------------------------

--------------------------------------------------------------------------------

----------------

------------

-----------------

3-6

5

6

7-16

9

10

11-12

13

14

15

16

17-29

18-23

23-28

28

29

30-37

31-32

33

34-37

38-46

39

40

41

41

42

42

42

43

44-45

46

-----------------------------------------------------------------------------------------------------------------------------------------

TABLE OF CONTENTS

02

--------

Page 4

WANHAO

WELCOME

Let's get started

Page 5

This User Guide is designed to start your journey with the

WANHAO Duplicator 4/4x Desktop 3D Printer in the right direction.

Even if you are familiar with earlier WANHAO machines. it is

essential that you read through this guide, as there are several

important and exciting updates with the WANHAO Duplicator 4/4x.

In chapter A and B, you will learn the basics of the WANHAO

Duplicator 4/4x, how to unbox safely,and how to get set up.

Chapters C~E will take you though leveling, printing, maintenance,

and troubleshooting,

WANHAO is excited to welcome you to the world of the WANHO

Duplicator 4/4x. Following this guide will help ensure that you are

getting the most out of your machine, and that you continue to

make amazing things,

WARNING: The WANHAO Duplicator 4/4x generates high temperatures and

includes moving parts that can cause injury. Never reach inside the WANHAO

Duplicator 4/4x while it is in operation. Always allow the WANHAO Duplicator 4/4x

to cool down before reaching inside.

WARNNING: Do not leave the WANHAO Duplicator 4/4x unattended during

operation.

CAUTION: If opening the WANHAO Duplicator 4/4x for service, ensure that the

power supply is turned off and the cord is disconnected.

------------------------------------------------------------------------------------------------------------------------------------------

A WELCOME, LET'S STARTED

04

--------

Page 6

SPECIFICATIONS

--------------------------------------------------------------------------------------------------------------------------------------------

PRINTING

Print Technology:

The Max Printing Size:

Layer Resolution:

Positioning Precision:

Filament Diameter:

Nozzle Diameter:

TEMPERATURE

Ambient Operating

Temperature:

Storage Temperature:

FDM Technology

22.5*14.5*15cm

High 100 microns {0.0039 in}

Medium 270 microns {0.0106 in}

Low 340 microns {0.0133 in}

XY : 11 microns {0.0004 in}

Z:2.5 microns {0.0001 in}

1.75mm {0.069 in}

0.4mm {0.015 in}

15° – 32° C [60° – 90° F]

0° – 32° C [32° – 90° F]

MECHANICAL

Chassis:

Body:

Build Platform:

XYZ Bearings:

Stepper Motors:

ELECTRICAL

AC Input: 100 – 240 V, ~2 amps, 50 – 60 Hz

Power Requirements: 24 V DC @ 6.25 amps

Connectivity: USB, SD card [FAT 16, max. 2GB]

PHYSICAL DIMENSIONS

Without Spool:

With Spool:

Shipping Box:

Net Weight:

Shipping Weight:

47*32*38 cm

47*32*38 cm

59*43*54 cm

11.5kg /19kg

15kg/ 21kg

Stainless steel

DPP Panels

Aluminium Heating

plate/ Silicon Glass

Wear-resistant,

oil-infused bronze

1.8° step angle with

1/16 micro-stepping

Software

Software Bundle : WANHAO Replicator G Sailfish WanHao Edition

File Types: .stl, .Gcode

Supports: Windows (XP / 7/8 )

Linux (Ubuntu 10.04+)

Mac OS X (10.7 / 10.8 )

-------------------------------------------------------------------------------------------------------------------------------------------

05

WELCOME, LET'S GET STARTED

--------

Page 7

HOW DOES IT WORK

--------------------------------------------------------------------------------------------------------------------------------------------

The WANHAO Duplicator 4/4x makes solid, three-dimensional objects out of melted

WANHAO PLA/ABS Filament. Your 3D design files are translated into instructions for

the WANHAO Duplicator 4/4X and sent to the machine via USB cable or SD Card.

Then the WANHAO Duplicator 4/4X heats the WANHAO PLA Filament and squeezes

it out through a nozzle to make a solid object layer by layer. This method is called

Fused Filament Fabrication [FFF].

-----------------------------------------------------------------------------------------------------------------------------------------

06A WELCOME, LET'S STARTED

--------

Page 8

W A N H A O

S e t t i n g U P Y o u r

WANHAO Duplicator

Desktop 3D P r i n t e r

4/4x

Page 9

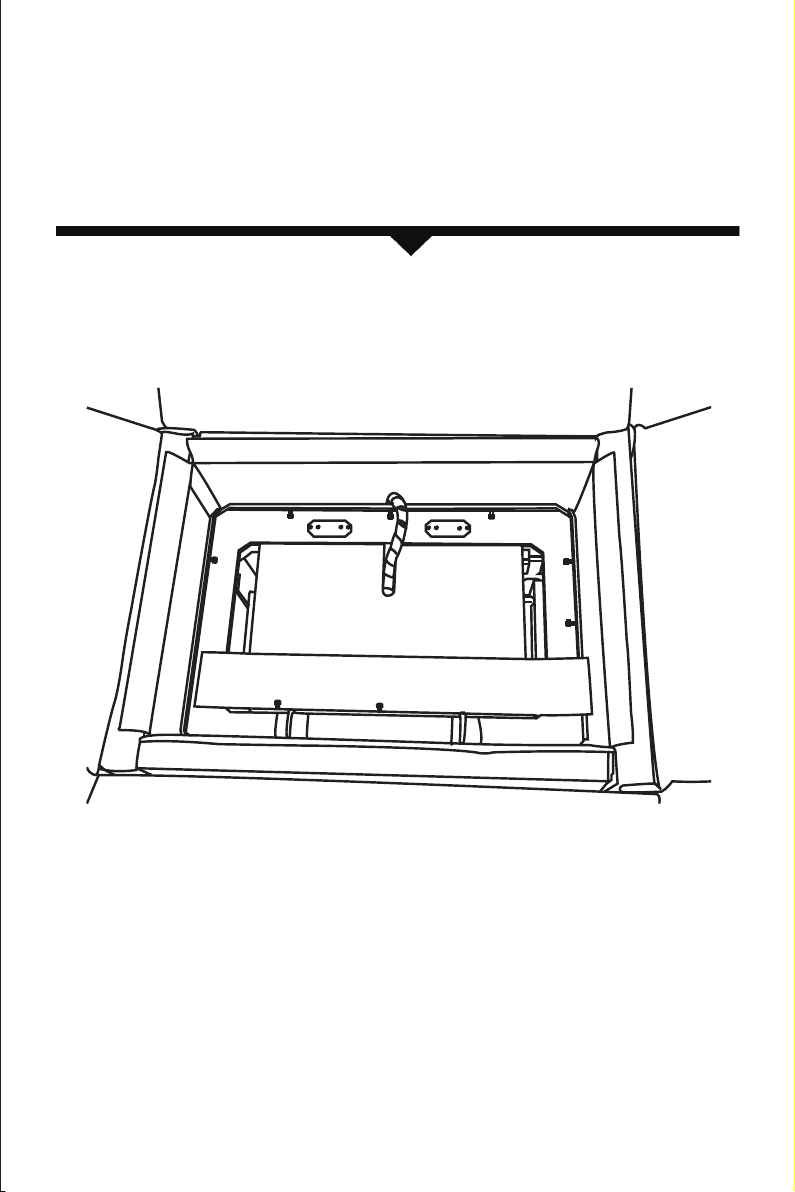

When you set up your WANHAO Duplicator 4/4X Desktop 3D Printer,

remember that it was build and packaged very carefully at the

WANHAO factory. We hope you’ll take your time and be just

as careful unpacking it and getting it set up.

NOTE: Do not force or tear anything during unpacking

and set up.This may damage the WANHAO Duplicator 4/4X

Desktop 3D Printer.SETTING UP YOUR WANHAO

DUPLICATOR 4/4X DESKTOP 3D PRINTER

------------------------------------------------------------------------------------------------------------------------------------------

A WELCOME, LET'S STARTED

08

--------

Page 10

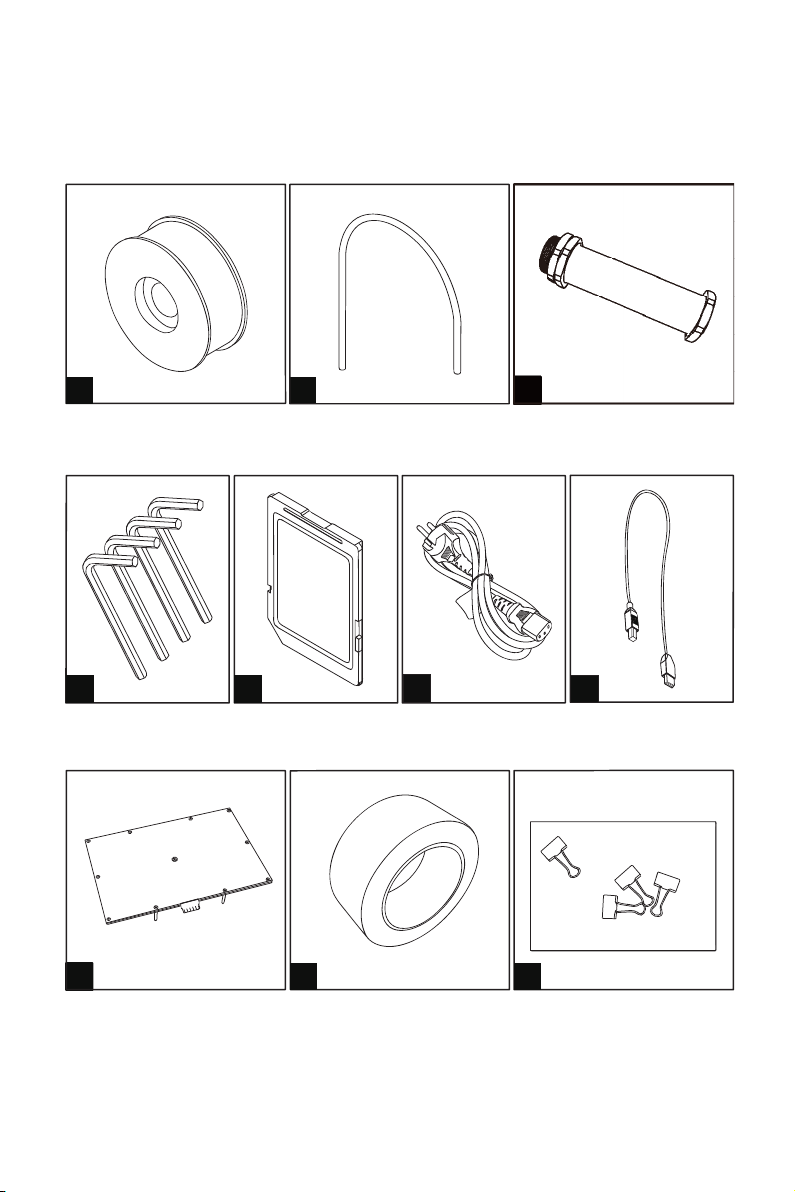

WHAT’S IN THE BOX

-----------------------------------------------------------------------------------------------------------------------------------------------

WANHAO ABS PLA

Filaments (2KG)

Hex wrenches

2pc Filament guide tube

1pc SD card

2pc Spool holder

P ower cord USB cable

Build plate 1 PC 3M tape 1 PC glass with clips

--------------------------------------------------------------------------------------------------------------------------------------

09

SETTING UP YOUR WANHAO DUPLICATOR 4/4X DESKTOP 3D PRINTER

--------

Page 11

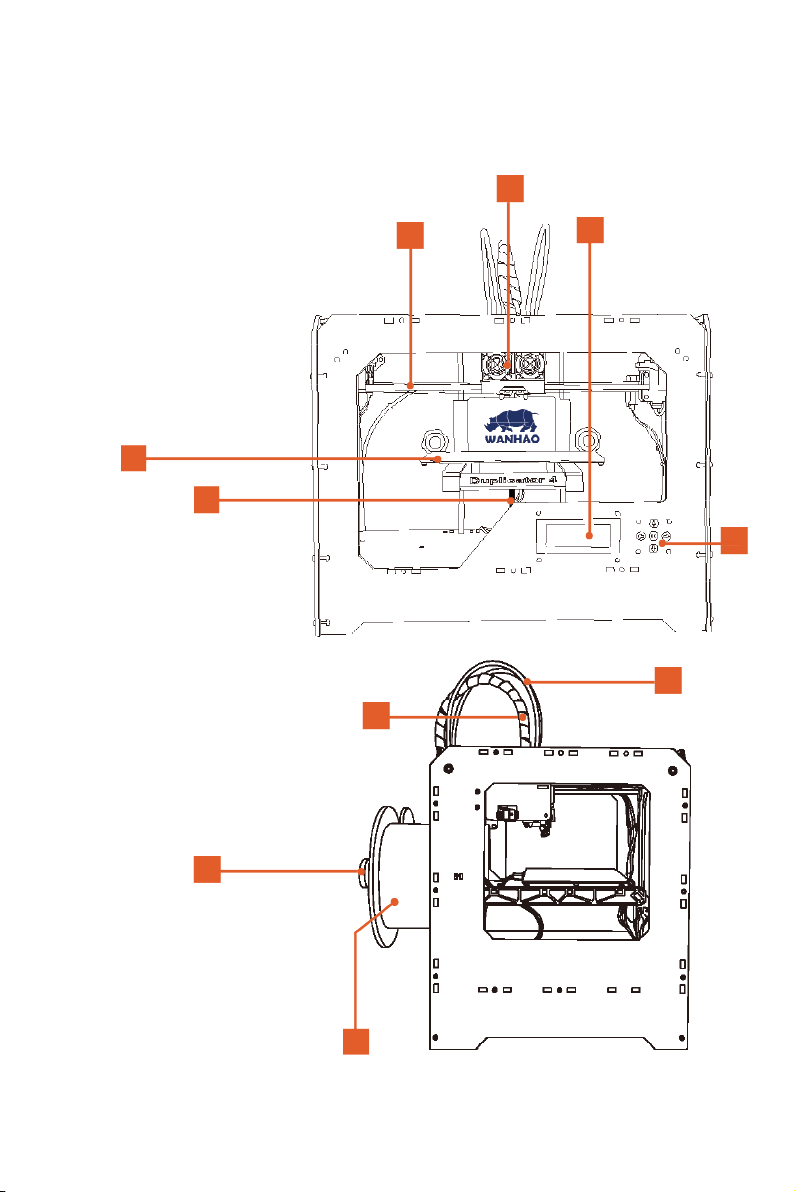

SPECIFICATIONS

----------------------------------------------------------------------------------------------------------------------------------------------

[1]

GANTRY SYSTEM

[2] LCD PANEL

[3] KEY PAD

[4] THE EADED Z-AXIS ROD

[5] BUILD PLATFORM

[6] FILAMENT GUIDE TUBE

[7] EXTRUDER CABLE

[8] EXTRUDER

[9] FILAMENT SPOOL

[10] SPOOL HOLDER

5

4

1

8

2

6

3

7

10

9

------------------------------------------------------------------------------------------------------------------------------------------

SETTING UP YOUR WANHAO DUPLICATOR 4/4X DESKTOP 3D PRINTER

10

--------

Page 12

UNPACKING YOUR WANHAO DUPLICATOR

4/4x

-------------------------------------------------------------------------------------------------------------------------------------------

1. Opening the Box

Place the WANHAO Duplicator 4/4X

A.

box on the ground. Open the

box and remove the top

cardboard sheet.

Remove the WANHAO Duplicator 4/

B.

4X User Manual.We recommend that

you use the manual to guide you

though the setup process and

keep it at hand as you unpack the

contents of the box. If you find

that anything described in the

manual is missing, email us

at support@wanhao3dprinter com.

Remove the layer of foam and the

C.

sheet of cardboard underneath.

Remove the two protective bumper

D.

box pieces form the side of the

Duplicator 4/4X.

---------------------------------------------------------------------------------------------------------------------------------------

11

SETTING UP YOUR WANHAO DUPLICATOR 4/4X DESKTOP 3D PRINTER

--------

Page 13

UNPACKING YOUR WANHAO DUPLICATOR

4/4x

--------------------------------------------------------------------------------------------------------------------------------------------

2. Removing the WANHAO Duplicator 4/4x from the Box

Open the plastic covering and

A.

firmly grasp the frame of the

WANHAO Duplicator 4/4x from

the outside. Lift it out of the

box and place it on a stable

surface.

NOTE: The black cable is not a

handle. Do not pull or twist the

black cable at any time.

3. Removing the Accessory Box

Remove the two remaining

A.

protective foam pieces

from the bottom of the

Duplicator 4/4x’s box.

Pull out the accessory box.

B.

This box contain the

remaining items from the

“What’s in the Box”section.

NOTE: Your WANHAO Duplicator 4/4x should now be fully unpacked.

We recommend that you keep the box and foam inserts in case you

need to transport your WANHAO Duplicator 4 in the future.

-----------------------------------------------------------------------------------------------------------------------------------------

SETTING UP YOUR WANHAO DUPLICATOR 4/4x DESKTOP 3D PRINTER

12

--------

Page 14

INSTALLING BUILD PLATE

--------------------------------------------------------------------------------------------------------------------------------------------

4. Installing the Build Plate

Never tear off the yellow kapton

tape on the aluminium plate. You

can either put the silicon glass onto

the platform to make the build plate

perfect flat or without silicon glass

plate(for freshman recommended).

Please adjust the 4 knobs under HBP

to re-level the heating plate if you are

adding the silicon glass plate. Wanhao

masking tape is used for both ABS and

PLA printing which can make filament

stick to the platform easier.

5. Freeing the Extruder

A. Use strong scissors or a wire cutter

to cut the zip ties holding the gantry

system in place. Discard the zip ties

and the plastic pieces holding them

in place.

NOTE: Operate scissors with care.

B. A small plastic piece attached to the

X-axis belt and gantry rods prevents

the extruder form moving. Carefully

snap the piece off of the rods and

tilt it to slide if off of the belt.

---------------------------------------------------------------------------------------------------------------------------------------

13

SETTING UP YOUR WANHAO DUPLICATOR 4/4x DESKTOP 3D PRINTER

--------

Page 15

INSTALLING FILAMENT GUIDE TUBE AND SPOOL HOLDER

---------------------------------------------------------------------------------------------------------------------------------------------

6. Installing the Filament Guide Tube

Locate the filament guide tube.

A.

Insert one end into the hole at

the top of the extruder and push

the tube in as far as it will go.

Insert the other end of the

B.

filament guide tube into the left

guide tube holder (when viewed

from the back) on the back of the

WANHAO Duplicator 4/4x. Make sure

that the end of the filament guide

tube is flush with the bottom of

the guide tube holder. The filament

guide tube should not hang down

past the bottom of the guide tube

holder.

7. Installing the Spool Holder

A. Locate the spool holder. Tilt the spool

holder and insert the round end

into the left side opening on the back

of the WANHAO Duplicator 4/4x (when

viewed from the back).

-----------------------------------------------------------------------------------------------------------------------------------------

SETTING UP YOUR WANHAO DUPLICATOR 4/4x DESKTOP 3D PRINTER

14

--------

Page 16

INSTALLING BUILD PLATE

------------------------------------------------------------------------------------------------------------------------------------------------

8. Mounting the Filament Spool

A. Open the box containing the

ABS and PLA Filament. Remove the

spool from its bag.

B. Fit the spool onto the spool holder.

Ensure that the WANHAO ABS and

PLA filament unwinds

counterclockwise(when viewed form

the back).Squeeze the spool holder

and push the spool on until it locks.

WANHAO

9. Attaching the USB Cable

Locate the USB-A to USB-B cable.

A.

Insert the USB cable into the USB-B

Port on the back of the WANHAO

Duplicator 4/4x. Do not attach the other

end of the USB cable to anything yet.

Do not plug the AC power cord into

an electrical outlet until step 11 of this

chapter.

Spool

Holder

USB cable

---------------------------------------------------------------------------------------------------------------------------------------

15

SETTING UP YOUR WANHAO DUPLICATOR 4/4x DESKTOP 3D PRINTER

--------

Page 17

ATTACHING POWER SUPPLY AND POWERING ON

--------------------------------------------------------------------------------------------------------------------------------------------

10. Attaching the Power Supply

A. Locate the power supply cable.

Attach the cable to the power supply.

B. Ensure that the power switch on the

WANHAO Duplicator 4/4x is set to

the OFF position.

C. Insert the power supply connector

into the power input on the back

of the Duplicator 4/4x.

Ensure that the flat side of the

connector faces down.

Power Supply

11. Powering On the WANHAO Duplicator 4/4x

Plug the AC power cord into an

A.

electrical outlet.

Set the power switch to the ON

B.

position.

The WANHAO Duplicator 4/4x will

C.

display The Duplicator text on the LCD

panel. This is the beginning of

the startup script that will guide

you through initial calibration

and your first build.

NOTE: The socket-outlet shall be installed

near the equipment and shall be easily

accessible.

------------------------------------------------------------------------------------------------------------------------------------------

16SETTING UP YOUR WANHAO DUPLICATOR 4/4x DESKTOP 3D PRINTER

--------

Page 18

S t a r t u p P r o c e s s :

L e v e l i n g ,

Loading,

Testing

Page 19

After you power on the WANHAO DUPLICATOR Desktop 3D Printer, the

LCD panel will light up and display text. The LCD panel will now run the

Startup Script. The Startup Script will guide you through leveling the

build plate, loading WANHAO PLA Filament, and creating your first build.

THE LCD KEYPAD

Four arrow buttons surround a central

•

OK button. Use the arrows to navigate

through the LCD menus and make

selections.

The left arrow usually allows you to

•

go back or cancel an action.

OK button means the Printer is working.

•

NOTE: Use the up and down arrow buttons to scroll through the top-level menu

on the LCD panel, and use the OK button to select Utlities. You can use the left

arrow to return to the Startup at any time. We also have vedios for you about

this item. If you have problems or questions, refer to the troubleshooting chapter

in this manual or contact WANHAO Support at support@wanhao3dprinter.com.

------------------------------------------------------------------------------------------------------------------------------------------

Startup process: leveling, loading , testing

C

18

--------

Page 20

INSTALLING BUILD PLATE

--------------------------------------------------------------------------------------------------------------------------------------------

After the initial welcome message, the LCD will display the fillowings:

1. Start printer the LCD display the items

for operating.

2. Navigate to Utility and press OK.

3. Choose this item to start platform leveling.

Why Leveling Is Important

!

•

If the build platform is too far from the extruder nozzle, or if one part of

the plate is farther away from the nozzle than another part, your builds

might not stick to the build plate.

•

If the build platform is too close to the extruder nozzle, the build plate

can block the Printer PLA Filament from extruding from the nozzle.

This can also scratch the build plate.

•

Leveling your build plate often will help ensure that objects adhere well

to the plate.

* How to Level the Build Plate

To level the build plate, you must adjust the four knobs which under the build

platform. These four knobs lower and raise the build plate.

• Tightening the knobs [turning them to the right] moves the build plate away

from the extruder nozzle.

• Loosening the knobs [turning them to the left] moves the build plate closer to

the extruder nozzle.

• The distance between the extruder nozzle and the build plate should be about

the thickness of the A4 paper.

---------------------------------------------------------------------------------------------------------------------------------------

Startup process: leveling, loading , testing

C

19

--------

Page 21

LEVELING THE BUILD PLATE

------------------------------------------------------------------------------------------------------------------------------------------------

1.Make Some Room Between the Build Plate and the Nozzle

When directed by the LCD screen,

tighten each of the four knobs under

the build platform about four turns.

Support

Card

Leveling

Knobs

------------------------------------------------------------------------------------------------------------------------------------------

Startup process: leveling, loading , testing

C

20

--------

Page 22

LEVELING THE BUILD PLATE

--------------------------------------------------------------------------------------------------------------------------------------------

2. Adjust the Knobs as Directed

The script will prompt you to adjust the

knobs individually. As you adjust each

knob, make sure the A4 Paper just slides

between the nozzle and build plate.

You should feel some friction on the A4

Paper but still be able to easily pass the

Paper between the plate and the extruder

nozzle without tearing or damaging the

paper.

3. Adjust Each Knob Again

The script will prompt you to adjust each

knob again. This allows for fine tuning.

This time, the A4 Paper should slide between

the build plate and nozzle with more friction.

4. Confirm your Adjustment

After the second set of adjustments, the

nozzle will move to the center of the build

plate. Confirm that the the A4 Paper slides

between the nozzle and plate with a moderate

amount of friction.

---------------------------------------------------------------------------------------------------------------------------------------

Startup process: leveling, loading , testing

21

C

--------

Page 23

LEVELING THE BUILD PLATE

----------------------------------------------------------------------------------------------------------------------------------------------

Compare your printed raft with the following Nozzle height checking diagram to

5.

ensure you have the correct nozzle height and filament width.

---------------------------------------------------------------------------------------------------------------------------------------

Startup process: leveling, loading , testing

C

22

--------

Page 24

LEVELING THE BUILD PLATE

--------------------------------------------------------------------------------------------------------------------------------------------

NOTE: If you have problems, or if you need to level your build plate again, you

can use the up and down arrows to scroll through the top-level menu on the

LCD panel and use the OK button to select Utilities. Scroll to Level Build Plate and

select it. You can use these menus to return to the leveling script at any time.

------------------------------------------------------------------------------------------------------------------------------------------

Startup process: leveling, loading , testing23

C

--------

Page 25

Loading PLA Filament

--------------------------------------------------------------------------------------------------------------------------------------------

When you have completed the initial leveling tasks, the LCD menu will display the

following text: “I am Ready”. Before building, youmust load the PLA Filament

into the extruder. The extruder will heat the PLA Filament and use the melted

material to build things.

What You Will Do

*

• Remove the end of the

filament guide tube

from the hole in the top

of the extruder.

• Feed the free end of the

PLA Filament from the

spool into the end of

the filament guide tube

where it attaches to the

back of the Printer

• Push the PLA Filament

all the way through the

filament guide tube.

• Wait for the PLA

Filament to heat and

extrude.

Filament

Guide Tube

extruder

Filament Spool

------------------------------------------------------------------------------------------------------------------------------------------

Startup process: leveling, loading , testing

C

24

--------

Page 26

Loading PLA Filament

--------------------------------------------------------------------------------------------------------------------------------------------

1. Detach the Filament Guide Tube

Pull here

Locate where the filament guide tube

attaches to the top of the extruder.

You must remove the filament guide

tube from the extruder. To remove the

tube, gently pull it out of the hole in

the top of the extruder.

2. Feed the Filament Through the Filament Guide Tube

Free the end of the PLA Filament

from the filament spool. With a pair

of scissors, cut a clean edge. Feed

the end of the PLA Filament into the

end of the guide tube where it

attaches to the back of the Printer.

Feed the PLA Filament through the

guide tube until it emerges from

the other end of the tube.

NOTE: To avoid filament jams,

ensure that the PLA Filament

feeds from the bottom of the

spool toward the top of the spool.

Put the right filament iinto the

left filament tube. Put the left

filament into the right filament

tube.

---------------------------------------------------------------------------------------------------------------------------------------

25

Startup process : leveling, loading , testing

C

--------

Page 27

LEVELING THE BUILD PLATE

--------------------------------------------------------------------------------------------------------------------------------------------

3. Press the OK to Begin Heating the Extruder

After you’ve fed the PLA Filament

all the way through the guide tube,

press the OK button on the LCD menu.

The Duplicator will start to heat your

extruder.

WARNING: Do not touch the extruder

while it is heating — it heats to 220° C.

Press the ok

4. Press the "OK" to Continue

After the extruder reaches 220° C, the

LCD panel will prompt you to load the

PLA Filament into the extruder. Click

through the message until your Printer

asks you to press the OK when you see

plastic extruding.

------------------------------------------------------------------------------------------------------------------------------------------

Startup process: leveling, loading , testing 26

C

--------

Page 28

LEVELING THE BUILD PLATE

--------------------------------------------------------------------------------------------------------------------------------------------

5. Push the Filament into the Extruder

To use one hand to push the loading

button down and Take the end of the PLA

Filament closest to the extruder and firmly

push it into the hole in the top of the

extruder.Ensure that the filament goes

into the center of the opening and doesn’t

get caught at the edge of the opening.

Maintain pressure on the filament and

continue pushing it into the opening.

After about five seconds, you should

begin to feel the motor pulling in the

filament. Maintain pressure for another

five seconds and then let go.

6. Stop Extrusion

Watch the extruder nozzle. After a few

moments, you should see a thin string of

the PLA Filament that you loaded come

out of the nozzle. Press the OK button to

stop extrusion.

NOTE: Don’t be surprised if the

filament that initially comes out of the

nozzle is not the color you expected.

There’s probably some filament inside

the extruder left over from our testing

process in factory. Wait until you see the

color that you loaded come out of the

nozzle before you press the OK button.

---------------------------------------------------------------------------------------------------------------------------------------

Startup process: leveling, loading , testing

27

C

--------

Page 29

LEVELING THE BUILD PLATE

---------------------------------------------------------------------------------------------------------------------------------------------

7. Return the Filament Guide Tube

Push the guide tube back into the opening

on the top of the extruder.

NOTE: If you have problems or need to load

the PLA Filament again, you can use the up

and down arrows to scroll through the

top-level menu on the LCD panel and use

the OK button to select Utilities. Scroll to

Change Filament and select it. Then select

Load. You can use these menus to return to

the load script at any time.

8. Remove the Extruded PLA

Wait a few minutes for the extruded PLA

to cool, then pull it off the nozzle. You can

discard this extra filament. Don’t touch

the nozzle; it may still be hot. Don’t leave

plastic clinging to the extruder nozzle. This

can cause newly extruded plastic to stick to

the nozzle instead of the build platform.

Unloading PLA Filament

*

If you need to unload the PLA Filament, the LCD menu will walk you through the

process. To run the script for unloading the filament, go to the LCD panel and

select Utilities >Filament Options > Unload.

------------------------------------------------------------------------------------------------------------------------------------------

Startup process: leveling, loading , testing

C

28

--------

Page 30

MAKING A TEST OBJECT FROM THE SD CARD

----------------------------------------------------------------------------------------------------------------------------------------------

1. Locate the SD Card

The WANHAO DUPLICATOR package

includes an SD card pre-loaded with

files for making test objects.

SD Card

2. Select a Project from the SD Card

After you have successfully leveled the build platform and loaded the PLA

Filament into the extruder, the LCD panel will say: “I am ready”

A:Use the up and down arrow buttons to navigate through the list of models on

the SD card.

B:To select a model, press OK.

C:The Printer will begin to build your object. You can use the LCD panel to monitor

the temperature of the extruder and the status and progress of your object.

more object availiable please download from our websiteShare

: WWW.THINGSHARES.com

---------------------------------------------------------------------------------------------------------------------------------------

Startup process: leveling, loading , testing

C

--------

29

Page 31

Making an Object with

WanHao ReplicatorG

Page 32

How to make an object using a computer and WanHao Replicator G

Making an object with WanHao Replicator G

-------------------------------------------------------------------------------------------------------------------------------------------

31

D Making an Object with Wanhao Replicator G

--------

Page 33

Using WanHao Replicator G

--------------------------------------------------------------------------------------------------------------------------------------------

Replicator G is software that prepares 3D models for building and sends them to

your WanHao Duplicator Desktop 3D Printer for building.

Download and Install WanHao Replicator G.

a. Go to the computer you plan to connect to your WanHao Duplicator and

open a

b. Enter the URL www.wanhao3dprinter.com and download the correct Replicator

installer for your operating system.

c. After downloading, open the installer and follow the directions to install the

software.

d. Use the supplied USB cable to connect your WanHao Duplicator to your

computer.

browser session.

NOTE: You can find a video of this tutorial at http://www.wanhao3dprinter.com

------------------------------------------------------------------------------------------------------------------------------------------

D Making an Object with Wanhao Replicator G

32

--------

Page 34

USING WANHAO REPLICATORG

--------------------------------------------------------------------------------------------------------------------------------------------

2. Download an Object From WanHao Thingshares

Thingshares is a website where WanHao users and others can share design files.

ThingShares

A. Open a browser session and go

to www.thingshares.com. Use

the search field at the upper

middle to search for

“what files you want” .

Your search results should

include that. Click on the link.

B. At the left of the page you will

see a button that says

“Download”Click this button

to open the Downloads window.

------------------------------------------------------------------------------------------------------------------------------------------

33

D Making an Object with Wanhao Replicator G

--------

Page 35

USING WANHAO REPLICATORG

--------------------------------------------------------------------------------------------------------------------------------------------

3. Open WanHao Replicator G

[1] Zoom in and out:

use the scroll wheel on your mouse

to zoom in and out.

[2] View:

go into View mode. In this mode,

click and drag with your mouse to

rotate the plate and the object.

[3] Move :

go into Move mode. In this mode,

click and drag with your mouse to

to move an object around the plate.

[4] Rotate:

to go into Turn mode. In this mode,

click and drag with your mouse to

rotate the object in all directions.

[5] Mirror:

to go into Mirror mode. In this

mode, click the buttons at the upper

side of the right to reflect the object

in X, Y, Z respectively.

Click the View button to

Click the Move button to

Click the Rotate button

Click the Mirror button

You can also

[6] Scale :

go into Scale mode. In this mode,

click and drag with your mouse to

to enlarge or shrink your object. Use

the bottons at the upper side of the

Scale button to open the Change

Dimensions submenu and scale

by a percentage or to a specific

measurement.

[7] Generate GCode:

button to open the Generate GCode

dialog, where you can specify print

resolution and other options and

click Generate GCode for building.

[8]

Status Bars and adjust the HBP

printing temperature based on

your printing material (see FAQ on

www.wanhao3dprinter.com). After

adjustment, choose printing. ABS

HBP printing temperature: 110 ℃ ;

PLA HBP printing temperature:

60℃

Click the Scale button to

Click this

Click the "gcode" at the forth

------------------------------------------------------------------------------------------------------------------------------------------

D Making an Object with Wanhao Replicator G

34

--------

Page 36

USING WANHAO REPLICATORG

--------------------------------------------------------------------------------------------------------------------------------------------

3. Open WanHao Replicator G | Continued

8

5

4

3

2

7

6

---------------------------------------------------------------------------------------------------------------------------------------

D Making an Object with Wanhao Replicator G

35

--------

Page 37

USING WANHAO REPLICATORG

---------------------------------------------------------------------------------------------------------------------------------------------

4. Open the .stl files in WANHAO REPLICATORG

a. Click on the File button.Navigate to the location of the file .stl and select it.

The file will open at the center of the build plate.

b. Use the buttons on the left side to adjust the object's size, location, etc. Then

generate Gcode. You will see the Generate GCode dialogue:

[1] Slicing Profile:

slicing default, if not already selected.

[2] Extruder:

you are going to use.

[3] Raft:

object built on a raft. Rafts provide

a base for supports and help your

object stick to the build plate.

[4] Support :

your object include easily removable

support structures under overhanging

parts of the object.

[5] Object infill:

your object infill rate. It's better to

make 10%

[6] Layer Height:

change your printing layer height to

specify your printing quality.

[7] Number of shells:

specify you shell numbers, suggested

data: 1

[8] Feedrate(mm/s):

change your printing speed: 3080mm/s

[9] Travel Feedrate:

change your travel speed:70

Select this to have your

Select Replicator

Choose the extruder

Select this to have

Select this to make

Select this to

Select this to

Select this to

Select this to

[10] Print temperature:

to change your extruder printing

temperature: 220

Select this

------------------------------------------------------------------------------------------------------------------------------------------

D Making an Object with Wanhao Replicator G

36

--------

Page 38

USING WANHAO REPLICATORG

--------------------------------------------------------------------------------------------------------------------------------------------

4. Build from SD Card

4a. Press the third button in the

green bar to "Build to File

for use with SD card" And

save the file as .x3g format

to your SD card. Specify a

name for the file.

4b. Put the SD card to the card

slot and choose the saved

file to print.

5. Build with Computer

4c. Choose your machine type in

replicator G , then connection

serial port in Machine button.

Then press connect button.

After connection, press print.

SD Card printing

-----------------------------------------------------------------------------------------------------------------------------------------

D Making an Object with Wanhao Replicator G

37

--------

Page 39

Troubleshooting,

Diagnostics, and

Maintenance

Page 40

This chapter describes basic troubleshooting and maintenance tasks

for your WANHAO Duplicator4 Desktop 3D Printer. For details on

more advanced troubleshooting and m aintenance tasks, go to

wanhao3dprinter.com/FAQ.

--------------------------------------------------------------------------------------------------------------------------------------------

39

E Troubleshooting , Diagnostics , and Maintenance

--------

Page 41

USING WANHAO REPLICATORG

-------------------------------------------------------------------------------------------------------------------------------------------

PROBLEM

--------------------------------------------------------------------------------

1. Can't load WanHao

Filament into the

extruder

SOLUTION

Make a fresh cut at the end of the Filament.

Cut the Filament at an angle—a narrow tip

will help with loading.

Use more force when pushing the Filament into

the extruder. Grasp the filament firmly and push it

into the middle of the hole on top of the extruder.

Ensure that you insert the Filament straight down

into the extruder, not diagonally.

After you feel the motor grab the filament,

continue to maintain pressure on the filament for

another five seconds.

--------------------------------------------------------------------------------

2. Object is stuck to

build plate

Wait for the object to cool down. Objects will

detach more easily after they have cooled.

If the object is still stuck, take a thin metal craft

spatula and carefully work the blade under the

edge of the object. When the blade is most of the

way under the object, twist the handle slightly. The

object should come free.

--------------------------------------------------------------------------------

3. Can't remove the

Filament from extruder

Run the filament load script in the onboard Utilities

menu and let the filament advance for about five

seconds. Then run the unload script again.

----------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------------------------

E Troubleshooting , Diagnostics , and Maintenance

40

--------

Page 42

DIAGNOSTICS LCD PANEL

| TOP-LEVEL MENU

---------------------------------------------------------------------------------------------------------------------------------------------

Build from SD Displays the list of models on the SD card. Select one

to start a build

--------------------------------------------------------------------------------

Preheat

Allows you to preheat the extruder.

--------------------------------------------------------------------------------

Utilities Tools that allow you to configure and maintain your

Duplicator 4.

--------------------------------------------------------------------------------

----------------------------

DIAGNOSTICS LCD PANEL

| UTILITIES MENU

------------------------------------------------------------------------------------------------------------------------------------------

UTILITIES

--------------------------------------------------------------------------------

----------------

----------------

Monitor Mode

Change Filament

Displays the current temperature of the extruder.

When making an object, displays the percent

completed.

Scripts that walk you through tasks associated with

the Filament.

LOAD(Left / Right):

the process of loading the Filament.

Script that walks you through

Script that walks you

Level Build Plate

UNLOAD(Left / Right):

through the process of unloading the Filament.

Script that walks you through the process of leveling

the build plate.

-----------------------------------------------------------------------------------------------------------------------------------------

41

E Troubleshooting , Diagnostics , and Maintenance

--------

Page 43

LCD PANEL | INFO AND SETTINGS MENU

-------------------------------------------------------------------------------------------------------------------------------------------

Bot Statistics:

lifetime of your duplicator 4 and the duration in hours and minutes of the last

build.

General Settings:

1,Sound:

2,Heat hold:

a 3D print is canceled

Preheat Settings:

Before you print,you can set the temperature when you generate G code.

Displays the estimated total hours and minutes of building in the

Optional settings and information

Turns the duplicator 4/4X’s indicator sounds on or off.

Specifies a time period for your extruder to continue heating when

Allows you to change the temperature setting for the extruder.

MAINTENANCE

-------------------------------------------------------------------------------------------------------------------------------------------

Lubricating the Threaded Rod and the X-Axis Idler Pulley

1. Find the tube of PTFE-based grease,

included with your wanhao 3d printer.

2. Grasp both sides of the build platform

and push it gently to the bottom of

duplicator 4/4X,Use a clean, lint-free rag

[or your finger],to spread the PTFE-based

grease onto the top section of the

threaded rod.Grasp both sides of the build

platform and move it to the top of the

duplicator 4/4X,Use a clean, lint-free rag

[or your finger] to spread the PTFE-based

grease onto the bottom section of the

threaded rod. Make sure you get the

grease inside of the threads themselves

3. Locate the X-axis idler pulley. If you are,facing the front of duplicator 4/4X, the

idler pulley is at the top left side. The idler pulley is one of the pulleys that allow

the rubber belt to move the extruder from left to right, or along the X-axis.The

pulley at the other side of the gantry is called the timing pulley and does not

require lubrication.

------------------------------------------------------------------------------------------------------------------------------------------

E Troubleshooting , Diagnostics , and Maintenance

42

--------

Page 44

Cleaning the Drive Gear

-------------------------------------------------------------------------------------------------------------------------------------------

The drive gear is the part of the extruder that pushes filament through the

extruder. When you make things with your wanhao 3d printer , small pieces of

hardened PLA/ABS can stick to the drive gear. If you are having problems with

your extruder, cleaning the drive gear might help.

Unload the wanhao PLA/ABS Filament from the extruder. To start the script for

1.

unloading the wanhao PLA/ABS Filament, go to the LCD panel and select Utilities

> Filament Options > Unload.

Unscrew the two bolts at the lower corners of the fan guard using the 2.5 mm

2.

hex key included with your duplicator 4/4X .As one piece, remove the fan guard,

the fan, the heat sink, and spacers. Keep these pieces together and set them aside.

Unclip the motor wires.

3.

4. Pull the motor assembly out.

Find the drive gear on the motor shaft.Using a small instrument like a makeup

5.

brush, toothbrush or toothpick, remove all the pieces of filament stuck to the

drive gear.

Reseat the motor assembly.

6.

Plug in the motor wires

7.

Add the fan guard, the fan, the heat sink, and spacers to the front of the

8.

extruder and bolt them on.

Reload the wanhao PLA/ABS Filament. To do this, go to the LCD panel and

9.

select Utilities > Filament Options > Load.

------------------------------------------------------------------------------------------------------------------------------------------

43

E Troubleshooting , Diagnostics , and Maintenance

--------

Page 45

Glossary Of Terms

-------------------------------------------------------------------------------------------------------------------------------------------

24V fan :

Yellow Tape:

printed with wanhao Filament. You can find yellow tape at any hardware store.

Build plate :

Drive gear:

Extruder:

pushes it through the nozzle onto the build plate.

Filament guide tube:

filament spool to the extruder.

FIRMWARE:

GANTRY :

the X and Y axes.

GCode:

printer will use to build an object. GCode is converted to .x3g before being sent

to your machine.

LCD control panel :

duplicator 4/4X. This control panel provides status information about the wanhao

duplicator 4/4X and includes control menus and diagnostics。

Wanhao ABS/PLA Filament:

PLA Filament is the source material from which you make objects on the wanhao

duplicator 4/4X.

The fan that cools the wanhao Filament as it extrudes.

Yellow masking tape that makes a great build surface for objects

The acrylic surface on which the Duplicator 4/4X builds an object.

The gear that drives the Wanhao Filament into the heater

The assembly that draws the filament from the spool, melts it , and

The plastic tube that guides the wanhao Filament from the

The software that runs on your wanhao 3d printer

The metal rods that allows the duplicator 4/4X’s extruder to move on

The computer language used to describe the toolpath your wanhao 3d

The display at the front lower right corner of the wanhao

ABS/ PLA is a renewable bioplastic. Wanhao ABS/

Replicator G:

scale and move 3D models and send them to the wanhao duplicator 4/4X for

building.

Motor assembly:

the extruder.

Free software created by wanhao that allows you to load, rotate,

The stepper motor and the drive block that push filament into

---------------------------------------------------------------------------------------------------------------------------------------

E Troubleshooting , Diagnostics , and Maintenance

44

--------

Page 46

Motor wires :

Nozzle:

Filament emerges to be spread onto the build plate。

Plunger:

Filament against the drive gear.

The bundle of electrical wires that provide power to the motor.

The opening on the end of the extruder from which heated wanhao

A part of the extruder assembly. The MK9 plunger pushes the wanhao

Power supply:

block and two plugs.

SD Card:

duplicator 4/4X and has a maximum capacity of 2GB.

Spacers:

place.

Spool holder:

4/4X and holds the spool of wanhao Filament. The spool holder ensures that the

Filament is fed evenly to the extruder.

Thingshares:

with the wanhao duplicator 4/4X.

Threaded rod:

entire length. This rod allows the build platform to move up and down, or along

the Z-axis.

A widely used file format for 3D models.

.stl :

USB cable :

with a computer using the USB interface on the computer.

A compact format for describing the toolpath your wanhao duplicator 4/4X

.X3G:

will use to build an object.

The power supply for the wanhao duplicator 4/4X. It includes a

Secure Digital memory card that can store digital data and be read by

The plastic pieces that keep the extruder fan and heat sink secure and in

The plastic piece that attaches to the back of wanhao duplicator

A website for uploading and downloading 3D model files for use

The long rod behind the build platform that is threaded along its

The cable that allows the wanhao duplicator 4/4X to communicate

--------------------------------------------------------------------------------------------------------------------------------------

45

E Troubleshooting , Diagnostics , and Maintenance

--------

Page 47

CONTACT US

-------------------------------------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------

SUPPORT

---------------------------------------------------------------------

SALES

---------------------------------------------------------------------

FORUM

www.wanhao3dprinter.com

Our website has extensive documentation and

troubleshooting information about your wanhao

duplicator 4/4X Desktop 3D Printer. It’s a great

resource when you want to try to solve issues quickly

on your own.

support@wanhao3dprinter.com

If you ever need help resolving an issue with your

wanhao 3d printer, send an email to the address

above to open a ticket with the wanhao Support

Team. To help us understand your problem from the

start, it is very helpful to include pictures or a video

as attachments with your email

sales@wanhao3dprinter.com

To learn about other wanhao products, including

wanhao Filament, please email the address above,

or call our Sales Team at +86-579-82346658

Wanhao has create one google forum to help customer

to improve their printing skills and share their

FORUM:https://groups.google.com/forum/#!forum/

wanhao-printer-3d

experience.

---------------------------------------------------------------------------------------------------------------------------------------

E Troubleshooting , Diagnostics , and Maintenance

46

--------

Page 48

WANHAO

®

Made in China

sales@WanHao3DPrinter.com

+86-579-82346658

www.wanhao3Dprinter.com

Loading...

Loading...