Page 1

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 1 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Assembly Instructions

Spray Valve SMS-02

Article Number: S02-….

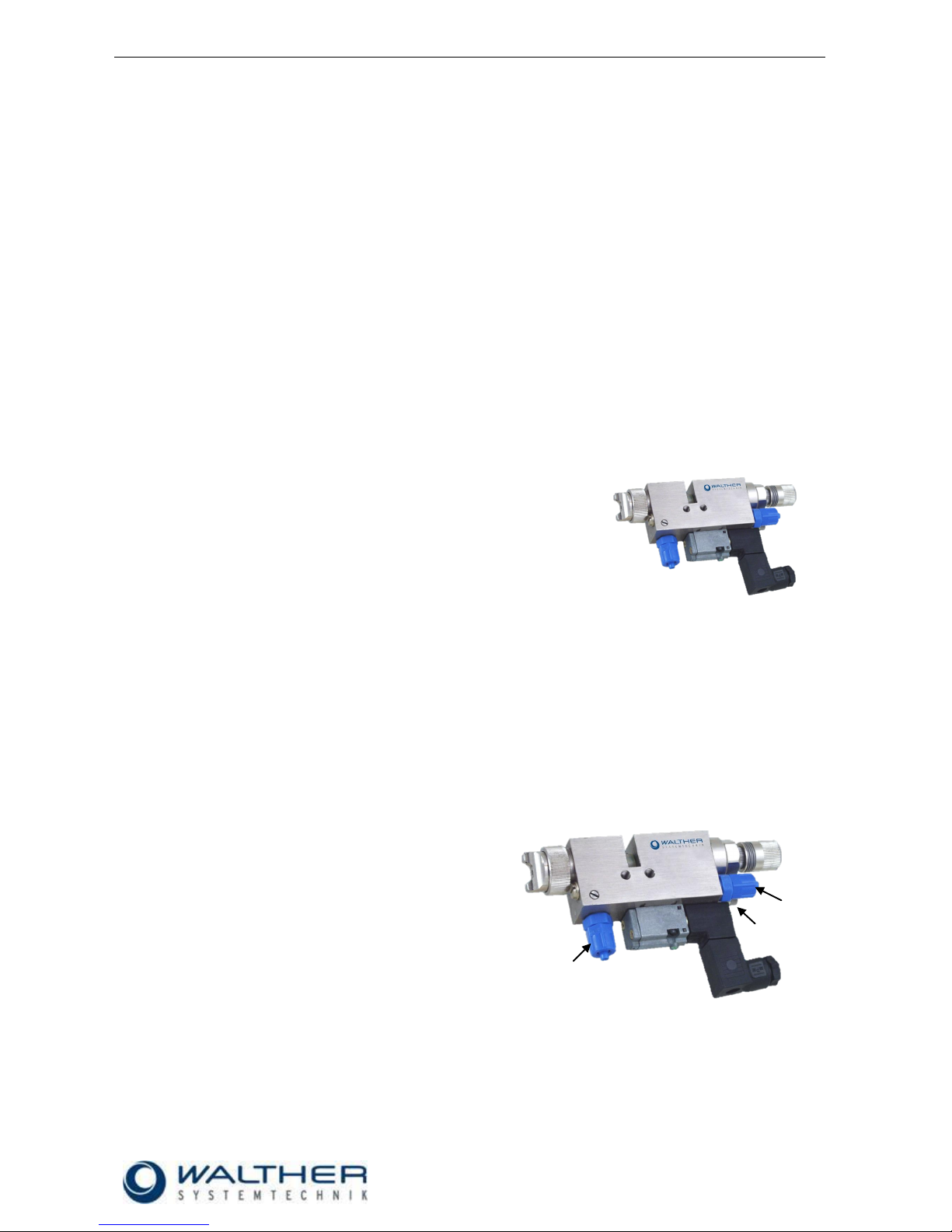

Picture: Spray Valve SMS-02 with flat air cap and raster-needle lock

NOTE

Please read the Assembly Instructions carefully before first using the incomplete device and

strictly adhere to the instructions!

The incomplete device may only be worked with and worked on by persons who are familiar

with the assembly instructions and the current regulations for industrial safety and accident

prevention.

Always keep this translated version of the “Original Assembly Instructions“ at the incomplete

device! The instructions have to be available anytime!

Page 2

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 2 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Table of Contents

Page

EC DECLARATION OF INCORPORATION ....................................................................................................................... 4

1 INTRODUCTION ................................................................................................................................................. 5

1.1 TARGET GROUP OF THE ASSEMBLY INSTRUCTIONS ............................................................................................................ 5

1.2 LIST OF SIGNS AND SYMBOLS ....................................................................................................................................... 5

2 SAFETY............................................................................................................................................................... 5

2.1 GENERAL INFORMATION ............................................................................................................................................. 5

2.2 DANGERS FROM RESIDUAL ENERGY ............................................................................................................................... 5

2.3 WARRANTY AND LIABILITY ........................................................................................................................................... 5

2.4 CORRECT USE ........................................................................................................................................................... 6

2.5 INCORRECT USE ........................................................................................................................................................ 6

2.6 QUALIFICATION OF PERSONNEL .................................................................................................................................... 6

3 TRANSPORT ....................................................................................................................................................... 7

3.1 PACKAGING .............................................................................................................................................................. 7

3.2 TASKS BEFORE TRANSPORT .......................................................................................................................................... 7

4 DESCRIPTION OF FUNCTION .............................................................................................................................. 7

4.1 PURPOSE OF THE DEVICE ............................................................................................................................................. 7

4.2 TECHNICAL DATA ....................................................................................................................................................... 8

4.3 TYPE LABEL .............................................................................................................................................................. 8

5 INSTALLATION AND START-UP ............................................................................................................................ 8

5.1 HOSE MOUNTING...................................................................................................................................................... 8

5.2 TOTAL VIEW / DESCRIPTION ......................................................................................................................................... 9

5.3 ADJUSTING THE DEVICE .............................................................................................................................................. 9

5.4 SMS-02 WITH RASTER-NEEDLE DETECTION ................................................................................................................. 10

5.4.1 Terminal Assignment for Needle Query..................................................................................................... 10

5.4.2 Terminal Assignment for Magnetic Valve.................................................................................................. 10

5.5 INSTALLATION DIAGRAM FOR COLOR-MARKING SYSTEMS ................................................................................................ 11

6 OPERATION ..................................................................................................................................................... 11

6.1 GENERAL INFORMATION ........................................................................................................................................... 11

6.2 OPERATION INFORMATION / OPERATING CONDITIONS .................................................................................................... 11

6.3 OPERATING ELEMENTS ............................................................................................................................................. 12

7 MAINTENANCE AND REPAIR ............................................................................................................................ 13

7.1 GENERAL INFORMATION ........................................................................................................................................... 13

7.2 CLEANING .............................................................................................................................................................. 13

7.3 EXCHANGING THE AIR VALVE (11.0.0) ........................................................................................................................ 13

7.4 EXCHANGING THE RETURN CHECK VALVE, COMPLETE (10.0.0)......................................................................................... 13

7.5 REPLACING THE NEEDLE (7.0.0) AND THE NOZZLE (2.1.0) .............................................................................................. 13

7.6 EXCHANGING THE SEALING BUSH (6.0.0) .................................................................................................................... 14

7.7 INSERTING GASKETS AND O-RINGS: ............................................................................................................................ 14

7.8 MAINTENANCE FOR OPERATION IN COLOR-MARKING SYSTEMS (NORMAL OPERATION) ........................................................ 14

7.9 SPARE PARTS .......................................................................................................................................................... 15

7.10 CUSTOMER SERVICE / SUPPORT ............................................................................................................................. 15

8 TROUBLESHOOTING ........................................................................................................................................ 16

8.1 GENERAL INFORMATION ........................................................................................................................................... 16

8.2 FAILURES: .............................................................................................................................................................. 16

8.3 SPRAY IMAGE/ TYPE OF DEFECT .................................................................................................................................. 17

9 TAKING OUT OF SERVICE ................................................................................................................................. 18

9.1 SHORT INTERRUPTION .............................................................................................................................................. 18

9.2 LONG-TERM INTERRUPTION ....................................................................................................................................... 18

Page 3

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 3 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

9.3 FINAL SHUTDOWN OF DEVICE .................................................................................................................................... 18

10 APPENDIX ........................................................................................................................................................ 19

10.1 DIMENSIONED DRAWING (FLAT JET) ....................................................................................................................... 19

10.2 DIMENSIONED DRAWING (ROUND JET) ................................................................................................................... 19

10.3 SPARE PARTS DRAWING SMS-02 (STANDARD) ......................................................................................................... 20

10.3.1 Spare Part List for SMS-02 (Standard) .................................................................................................. 21

10.4 SPARE PART DRAWINGS SMS-02 (RASTER-NEEDLE DETECTION) ................................................................................. 22

10.4.1 Spare Part List for SMS-02 (Raster-Needle Detection) .......................................................................... 23

10.5 ARTICLE NUMBERS FOR AIR CAPS .......................................................................................................................... 24

10.6 ARTICLE NUMBERS FOR NOZZLES ........................................................................................................................... 25

10.7 ARTICLE NUMBERS FOR NOZZLE NEEDLES ................................................................................................................ 27

10.8 ARTICLE NUMBERS FOR VALVES ............................................................................................................................. 28

10.9 ARTICLE NUMBERS FOR THREADED JOINTS ............................................................................................................... 28

10.10 ARTICLE NUMBERS FOR OTHER PARTS ..................................................................................................................... 29

10.11 WEAR-AND-TEAR PARTS ...................................................................................................................................... 30

10.12 ACCESSORIES ..................................................................................................................................................... 31

10.13 DESCRIPTION PNEUMATIC NEEDLE-STROKE ADJUSTMENT 97800037 .......................................................................... 33

Page 4

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 4 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

EC Declaration of Incorporation

in accordance with EU Machinery Directive 2006/42/EU, dated 17 May 2006, Appendix II B

We herewith confirm that the below mentioned incomplete device meets the basic requirements for safety

and health as stated in EU Machinery Directive 2006/42/EU for its design and construction as well as for the

configuration released by us on the market. This machine component will not be operated before it has been

determined that the incomplete system where the machine component will be installed also meets the

requirements of the Directive (2006/42/EG).

Manufacturer

Walther Systemtechnik GmbH

Hockenheimer Straße 3

D- 76726 Germersheim

Description

Spray Valve SMS-02, Article-No. S02-…

We also declare the conformity with other, product-relevant directives/guidelines:

Mach. Direct. 2006/42/EU App. I, Clause: 1.1.2, 1.1.3, 1.1.5, 1.1.6, 1.3.2, 1.3.3,

1.3.4, 1.5.1, 1.5.8, 1.5.9

EMC- Directive 2014/30/EU, dated 26. February 2014

Applied harmonized standards, in particular:

DIN EN ISO 12100 Safety of Machinery – General Design Principles –

Risk Assessment and Risk Reduction (ISO

12100:2010)

In addition, we also confirm that the special documentation according to Appendix VII Part B has

been prepared.

The manufacturer, respectively his authorized representative obligates himself to submit this documentation

to the market surveillance authorities, if requested.

This EC Declaration of Incorporation becomes invalid if the incomplete device will be altered or changed

without consent of Walther Systemtechnik GmbH.

Authorized representative for Technical Documentation:

Stefan Hirl, Hockenheimer Straße 3, D- 76726 Germersheim

Germersheim, 04 April 2017

(Place, Date) (Stefan Hirl, Management)

Page 5

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 5 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

1 Introduction

1.1 Target Group of the Assembly Instructions

Operating Personnel

Maintenance Personnel

1.2 List of Signs and Symbols

The assembly instructions warn users of operations which may put their health at risk.

The warnings are indicated by combinations of text and symbols as follows:

DANGER

Describes a potentially dangerous situation.

Death, grievous bodily harm or severe material damage WILL occur if the respective

measures of precaution have not been taken

WARNING

Describes a potentially dangerous situation.

Death, grievous bodily harm or severe material damage MAY occur if the respective measures

of precaution have not been taken.

CAUTION

Describes a potentially dangerous situation.

Slight injuries CAN occur if the respective measures of precaution have not been taken. This

signal word is also used to describe possible property damages.

IMPORTANT

Indicates tips for usage and other particularly useful information.

No dangerous situation.

2 Safety

2.1 General Information

The construction of this device is according to the latest technology and is absolutely reliable. The individual

components as well as the complete device are continuously checked by our quality management.

2.2 Dangers from Residual Energy

Please instruct the operating personnel on the respective measures to be taken against the occurrence of

mechanical, hydraulic, pneumatic and electric / electronic residual energies.

2.3 Warranty and Liability

According to the conditions laid down by the German Engineering Association (VDMA), Walther Systemtechnik GmbH has a guarantee of 12 months under normal European operating conditions on its own

parts (spare parts are excluded); or according to the conditions of the manufacturer.

This guarantee can only be granted by Walther Systemtechnik GmbH, if:

the user has thorough knowledge of the content of the assembly instructions;

the user follows the instructions and notes contained in the assembly instructions;

the user does not rebuild or make changes on parts of the device without prior consent of WST Sys-

temtechnik GmbH.

Page 6

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 6 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

2.4 Correct Use

This device is a needle valve and will be used for processing materials which can be sprayed in continuous

or intermitting operation. Under no circumstances shall aggressive media such as acids, alkaline solutions,

detergents, chemicals or others be sprayed. If you are not sure, please contact the manufacturer if a certain

spray medium is suitable for this device.

2.5 Incorrect Use

Operating the incomplete device with insufficient knowledge about the operation, maintenance and care

of the device.

Making changes, extensions or alterations on the incomplete device that may hamper its safety without

the prior consent of Walther Systemtechnik GmbH.

Operating the incomplete device with defective safety installations or not properly attached or malfunc-

tioning safety devices.

Using unsuitable materials.

Handling the incomplete device while energized.

2.6 Qualification of Personnel

Only trained and instructed personnel may conduct work on the equipment.

The responsibilities of the personnel for assembly work, operation, repair work or maintenance work must be

clearly assigned to individuals!

Persons in training may work with the equipment only under supervision of an experienced person.

Personnel

Task

Instructed

Personnel

Personnel with Technical

Qualification

Specialist

Supervisor

Packaging, Transport

X

-

-

-

Commissioning

X

X

-

Operation

X

-

Troubleshooting, general

X

X

-

Troubleshooting

mechanical

-

X

-

-

Troubleshooting electrical

-

-

X

-

Setting up

-

X

-

-

Maintenance

-

X

-

-

Repair

-

X

X

-

Taking out of service,

Storage

-

X

X

-

Page 7

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 7 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

3 Transport

3.1 Packaging

The type of packaging depends on the individual mode of shipping. If not separately contracted, the

packaging is in accordance with the rules and regulations of Walther Systemtechnik GmbH. This rule is in

accordance with the Federal Association for Packaging HPE.

3.2 Tasks before Transport

The following has to be done before transport:

Disconnect all power lines.

The actual transport of the incomplete device and its individual parts requires special care in order to prevent

damages from external forceful impact or careless on- and off-loading. Depending on the mode of

transportation, suitable transport and load securing has to be selected. The incomplete device will be aligned

and leveled by appropriate fastening elements.

4 Description of Function

The spray valves of SMS-02 series are suitable for the application of liquid up to viscous media, such as

grease, oil, separating agents, colors or glues. One of the major characteristics of SMS-02 series is the

integrated spray air valve with which you can adjust the post-spray duration for cleaning the nozzles.

Depending on the individual air cap, a round or flat jet is produced. And depending on the viscosity of the

applicable medium, the application image can be adjusted individually via the nozzle size or the atomized air

pressure or also the material pressure. Three different hoses are supplying atomized air, control air and

medium.

4.1 Purpose of the Device

CAUTION

The use of other media can cause functional failures, damages or even the destruction of the

device.

Spray valve SMS-02 is a pneumatically controlled application device for processing sprayable materials,

such as glues, grease, colors etc. The control air lines were kept short due to a directly flanged 5/2-way

magnetic valve (17.0.0) and they produce fast and very precise open/close movements of the needle (7.0.0).

The working piston is firmly connected to the needle (7.0.0) and receives air pressure from the 5/2-way

magnetic valve for the larger piston surface. This results in the opening movement of the needle. As soon as

the air pressure on the larger surface of the working piston is turned off, the control air on the smaller surface

of the working piston will initiate the closing movement.

During the operation, the closing spring (9.6.3) is disabled. This happens through the control air which is

permanently pending on the smaller working surface and which also simultaneously compresses the closing

spring (9.6.3) above the closing piston (9.8.3). Thereby the closing spring cannot hamper the fast switching

times of the needle. The closing spring will only be operational in case of failure or turn-off of the compressed

air supply. This will guarantee that no sprayable medium will be released during a defect in the air supply.

The device uses pre-supply/after-supply air (Setting-up of System, see also 6.3) for cleaning the nozzle

(2.1.0).

The device is used for spraying applications. The material pressure has to correspond with the desired spray

image and also with the atomizing air pressure. Spraying can be intermitting as well as continuous. The

control air pulses will be transferred via the 5/2-way magnetic valve (17.0.0) to the working piston.

Depending on the individual case of operation, it is important to adapt the control air pressure to the

switching frequency. For 5 intermissions already, this pressure has to be set to 5 bar.

Page 8

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 8 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

4.2 Technical Data

General Data

Size with flat-jet air cap [mm]

130 x 80 x 22

Size with round-jet air cap [mm]

127 x 80 x 22

Weight [g]

ca. 525

Air consumption [l/min]

ca. 150 (at 3 bar; nozzle- 1.0 mm and flat-jet)

Switching time [ms]

ca. 100 (for color marking systems ca. 200)

Energy Supply

Control air pressure [bar]

4.5-6

Atomizer air pressure [bar]

0.5 – 5 (at least 0.5 bar lower than control pressure)

Material pressure [bar]

max. 35

Voltage [VDC]

24

Power consumption [W]

1,8

4.3 Type Label

The type label was etched into the casing. The serial number is

hammered into this label.

5 Installation and Start-up

The valves can be installed in any position. The distance to the application area depends on the desired

application width. An intermitting operation of the device will cause natural oscillations; therefore a solid

installation is most important. Try to avoid excessive natural oscillations (transmission from device to valve).

5.1 Hose Mounting

There are three functional hoses which will be connected as follows:

1 Material to G 1/8-connection (matching screw

connections can be ordered as accessories!)

2 Control air SL to screw connection for 6mm-

hose (21.0.0)

3 Atomizer air ZL to screw connection for 6mm-

hose (21.1.0)

1 3 2

Page 9

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 9 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

5.2 Total View / Description

1

Basic casing

2

Nozzle with air cap and retainer ring

3

Raster needle lock

4

5/2-way magnetic valve

5

Material connection

6

Connection for atomizer air

7

Connection for control air

8

2x Fastening thread M5

5.3 Adjusting the Device

The stroke adjustment of the needle (Pos. 7.0) will be used for setting the material quantity. A left turn of the

raster-needle locking screw will increase the material quantity. A finely ascending precision thread results in

a needle stroke which changes 0.5mm with one turn of the raster head.

IMPORTANT

The maximum turn of the raster-needle locking screw anti-clockwise should not exceed the

noticeable raster steps. This will already exceed the maximum needle stroke adjustment.

If you continue turning, the raster-needle locking screw will be dislocated!

IMPORTANT

Nozzle and nozzle needle can be damaged by wrong treatment. Only reduce the material flow

with emerging material (right turn of adjusting screw). Do not turn adjusting screw further to

the right after closing of the nozzle!

NOTE

The duration of the after-supply air will be individually set from the outside at the spray valve.

The adjusting screw (10.4.0) is flush-mounted at the side and will be turned (in spray direction:

to the right) with a screwdriver in order to adjust the duration of the after-supply air as follows.

right turn = longer after-supply air duration

left turn = shorter after-supply air duration

Basic setting = screw flush-mounted with basic body; then one turn to the

right

3 8 6 7 4 2 5

1

Page 10

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 10 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

5.4 SMS-02 with Raster-Needle Detection

Optionally, you can use a raster-needle lock with a pre-installed, inductive proximity switch. It will release a

signal when the needle piston with the needle is open. This will help you in digitally monitoring the status

„nozzle open“.

5.4.1 Terminal Assignment for Needle Query

5.4.2 Terminal Assignment for Magnetic Valve

+

-

Standard plug 24V valve (left [+] and right [-])

Raster-Needle Detection

Page 11

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 11 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

5.5 Installation Diagram for Color-Marking Systems

6 Operation

6.1 General Information

This device may only be operated if the safety-related equipment is permanently effective and not suspended during operation or altered in its intended effectiveness.

6.2 Operation Information / Operating Conditions

CAUTION

Never point the jet at people. The wearing of eye protection is strongly recommended. The

spraying process can create noise depending on the air and fluid pressures used. Ear protection should be worn, if required.

WARNING

Danger caused by flammable, harmful fluid. Always follow the safety instructions on the container or the safety data sheet for the fluid.

Spray valves of the SMS-02 series generally operates with a control pressure of 5 - 6 bar. The atomizer

pressure has to be lower than the material pressure in order to avoid a repulse of the material. Atomized air

pressure and material pressure should be closely correlated.

IMPORTANT

Accident prevention directions will be strictly followed when applying high material

pressures. Please strictly follow the following instructions when planning and constructing

application systems!

Each spraying valve must be equipped with its own pressure regulator for atomizing air.

In case several spraying valves are supplied by one and the same material pressure tank, these

valves must not spray simultaneously.

The supply route for the material between material pressure tank and spraying valve must not exceed

2 m.

Connection ZL

Connection SL

ca. 5-6 bar

Raster-needle lock for

spray medium adjustment

Connection M

max. 35 bar

Page 12

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 12 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

If the pause time is a multiple of the spray time, the valve must be sprayed free in a separate location

or the spray valve should be operated several times to optimize the application.

After standstills of 15 min. and more, the valve must be sprayed free by pressing the switch 3 to 5

times.

The application can be controlled as intermitting or continuous. Depending on the individual use, the control

pressure has to be adjusted to the set switching frequency on the one hand and to the higher or lower

material pressures on the other. Under appropriate operating conditions (material pressure, control pressure,

needle stroke, and short supply lines) a total of 50 strokes per second can be reached.

IMPORTANT

A device-specific set-up is required for an optimum adjustment of the application image.

Basic results from lab tests can be used. Of course, these may have to be adjusted for the

individual device. The parameters nozzle size, opening time, opening stroke, material pressure and if required, also temperature have to be combined.

For longer standstills, the material can remain in the valve, if it remains under pressure (no contact to outside

air).

6.3 Operating Elements

1

Manual release at magnetic valve (green button)

2

Adjusting screw for adjusting the after-supply air

3

Adjusting button for the raster-needle adjustment

1 2 3

Page 13

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 13 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

7 Maintenance and Repair

7.1 General Information

The spray valves of the SMS-02 series are high-quality precision devices which will not fail if treated

correctly and will operate almost maintenance-free. All mobile parts should be regularly oiled and also the

threads should be greased when the nozzles are cleaned or exchanged. Always keep clean and observe

minimum instructions to maintain a long life of the valve. Always use clean and filtered material only. The

control air must also be clean, if necessary. Maintenance also depends on the individual operating conditions

and the type of media used.

CAUTION

Before starting any maintenance or repair work, ensure that all air-operated tools are

depressurized and disconnected from the air supply.

Before opening the spray valve it must be disconnected from the air and fluid supply.

Otherwise, ejected components can cause injuries.

7.2 Cleaning

IMPORTANT

Only use soft brushes for outside cleaning of the nozzle tips. Never use metal tools with

sharp edges.

Wash equipment thoroughly after use to remove residues and dirt, especially if needle (Pos.7.0.70), or

sealing sleeve (6.1.0) or material nozzle (Pos.2.1.0) have to be exchanged.

7.3 Exchanging the Air Valve (11.0.0)

Unscrew locking screw (11.1.0)

Remove spring (11.3.0)

Pull out locking piston (11.2.0)

Exchange O-rings (11.1.1 + 11.2.1) if necessary

Slightly grease and re-assemble in reverse sequence.

7.4 Exchanging the Return Check Valve, complete (10.0.0)

Unscrew locking screw (10.4.0)

Unscrew fastening thread pin (10.6.0)

Use a screw (M3) of sufficient length and screw it in instead of adjusting screw (10.4.0) in order to

carefully pull out the basic casing (10.1.0)

If necessary, also exchange the reversing sleeve (10.5.0) and the O-ring (10.2.0) as well as the O-ring

(10.3.0) on the unscrewed adjusting screw (10.4.0).

Slightly grease and re-assemble in reverse sequence.

7.5 Replacing the Needle (7.0.0) and the Nozzle (2.1.0)

Completely unscrew raster-needle lock (9.0.3)

Remove air cap (1.1.0) with retainer ring (3.1.0)

Unscrew nozzle (2.1.0)

Carefully push needle (7.0.0) from the nozzle side to the back

Re-assemble new, slightly greased parts in reverse order.

IMPORTANT

Nozzle set = Nozzle needle, nozzle and air cap (should always replaced at the same time)!

We do not recommend employing used needles. Leakages are caused by pricking needles

which are not completely clean through the shaped sealing (5.1.0).

Page 14

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 14 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

7.6 Exchanging the Sealing Bush (6.0.0)

Unscrew raster-needle lock completely (9.0.3)

Remove air cap (1.1.0) with retainer ring (3.1.0)

Unscrew nozzle (2.1.0)

Carefully push needle (7.0.0) from the nozzle side to the back

Then use a screwdriver to unscrew sealing bush (6.0.0) from the thread.

IMPORTANT

Due to the outside O-ring (5.3.0), the sealing sleeve cannot easily fall through the fastening

thread of the main body (4.1.0). Therefore an additional small strip of sheet metal (0.5 – 1.0

mm) will be slid between the body gap and flat towards the front end of the sealing sleeve.

Then you can carefully push the sealing sleeve together with the O-ring (5.3.0) to the back of

the thread. Now the sealing sleeve can be easily removed from the casing.

7.7 Inserting Gaskets and O-Rings:

If you do not have a complete sealing sleeve (6.0.0) with integrated material sealing kit (5.0.0) available as

replacement, you have to remove the old gaskets and replace them by new ones.

For this purpose, you have to clean the sealing sleeve so that no residues from sprayed medium will hamper

the installation of the new gaskets. Slightly grease the O-ring holders with a lubricant (technical petrolatum).

First insert the O-ring (6.2.0) into the back boring to the bottom of the sealing sleeve.

Then insert the O-ring (5.3.0) into the outer groove.

Insert the shaped sealing (5.1.0) into the front holder. This shaped sealing is not symmetrical. Make

sure that the side with the larger boring points to the front when inserting it; it has to point towards the

nozzle after the installation of the complete sealing sleeve.

Slightly grease the complete sealing sleeve (6.0.0) and move it back into the main body (4.1.0); do not

turn when pushing it carefully through the fastening thread together with the outside O-ring (5.3.0), using a screwdriver.

After that screw the sealing sleeve into the thread (slightly tighten).

IMPORTANT

Do not use any metal or sharp-edged equipment or tools when inserting the O-rings and the

shaped sealing. The shaped sealing in particular is a very precise and sensitive part which has

outstanding sealing characteristics and should therefore not be hit or pressed.

7.8 Maintenance for Operation in Color-Marking Systems (Normal Operation)

The spray cap will be cleaned every other day with a special thinner and a soft cloth. Make sure that no cloth

fibers are left on the nozzle tip.

The material section of the spray valve should be cleaned with a special thinner every other week. Please

observe the following steps:

Needle lock (9.0.3) completely open (remember raster setting for later use!)

Remove air cap (1.1.0/x) and unscrew nozzle (2.1.0) with a SW 6 open wrench.

IMPORTANT

Hold spray valve downwards so that no medium can flow into the air channels. Discharged

medium will be collected in a container and disposed of later.

Clean with a soft (paint-)brush and a special thinner.

Re-assemble nozzle and air cap after cleaning.

Re-set the raster-needle setting.

A cleaning cycle will be initiated after standstills (e.g. breaks over night or on weekends). The nozzle will be

sprayed clean. This cleaning cycle will be activated through the system controls.

IMPORTANT

Use a dummy or a cloth during the cleaning cycle in order to avoid soiling!

Page 15

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 15 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

After longer system standstills (e.g. 2-3 weeks), the complete system will be cleaned before re-start. If

necessary, the material hoses and if applicable, also the inlays of the pressure tank have to be replaced.

The material pressure container will be opened every week and the color will be thoroughly stirred (if

no agitator is provided).

The material pressure container will be cleaned every 3-4 months; material lines and inlays will be

exchanged.

IMPORTANT

Clean the complete system every six months!

7.9 Spare Parts

IMPORTANT

Only use original spare parts from the manufacturer!

Wrong or defective spare parts from other manufacturers can damage the device. If other

than original spare parts of the manufacturer will be used, all obligations from the manufacturer or his sales partners, such as guarantees, service contracts etc will be forfeited without

further notice.

7.10 Customer Service / Support

Walther Systemtechnik GmbH

Hockenheimer Straße 3

D-76726 Germersheim

Germany

Phone ++49(0)7274-7022-0

Fax ++49(0)7274-7022-91

Email info@walther-2000.de

Internet www.walther-2000.de

Page 16

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 16 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

8 Troubleshooting

8.1 General Information

IMPORTANT

First check all supply lines for connection and serviceability.

In case of serious problems that cannot be resolved, please contact the Walther Systemtechnik GmbH

customer service.

8.2 Failures:

Fault

Possible Cause

Action

Nozzle needle does

not open.

No electrical current (slight clickingsound at the magnetic valve )

Check electrical power supply

Not enough control air pressure

Check control air pressure (make sure it

set to 5-6 bar)

Leakages

Check O-ring (6.2.0), O-ring (7.4.0) or

O-ring (7.5.0) and replace if necessary

Needle (7.0.0) is sticky within the needle

sealing screw (6.1.0)

Disassemble and clean

Needle stroke is set too low

Turn left at raster-needle setting for

proper setting

Pre-supply/After-supply

air is constantly

blowing

Adjusting screw (10.4.0) was screwed in

too deep

Move adjusting screw back to basic

setting (see 4.3)

Locking piston (11.2.0) not suitable for

atomizer air pressure

Replace air valve (11.0.0) completely

(see spare parts list)

O-ring (11.2.1) on locking piston

defective

Replace O-ring

Medium leaks at slot

(covered by plastic

protection sleeve 5.4.0)

Leakage of material sealing

Complete overhaul of spray valve

Page 17

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 17 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

8.3 Spray Image/ Type of defect

SPRAY IMAGE

PROBLEM

CAUSE

ACTION

Normal Spray Image (Flat jet)

Normal Spray Image (Round jet)

Spray image shaped

too much

upwards and

downwards

Soiled

air cap

Soiled

nozzle

Clean nozzles

Spray image too much

left-sided or right-sided

Soiled

air cap

Soiled

nozzle

Clean nozzles

Heavy application in the

middle of the spray image

Too much material

Material too thick

Reduce

material supply

Dilute material

Split

spray image

Too little material

Pressure flat jet too

high

Increase

material supply

Increase pressure

for round jet

Page 18

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 18 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

9 Taking out of Service

9.1 Short Interruption

A short interruption (15 min or more) has to be followed by a fine spraying.

IMPORTANT

Please follow the Operating Manual!

9.2 Long-term Interruption

The following has to be observed for a long-term interruption of the device/machine:

Depressurize material supply lines

Take off air cap (1.1) and clean nozzle (2.1) with a special thinner and a soft cloth. Make sure that no

cloth fibers are left on the nozzle tip.

IMPORTANT

Please follow the maintenance instructions!

9.3 Final Shutdown of Device

The following is important for a shutdown of the machine / device:

Clean spray valve with a special thinner.

IMPORTANT

Please follow the maintenance instructions!

Page 19

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 19 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10 Appendix

10.1 Dimensioned Drawing (Flat jet)

10.2 Dimensioned Drawing (Round jet)

Page 20

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 20 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.3 Spare Parts Drawing SMS-02 (Standard)

IMPORTANT

Air control valve and return check valve are available only as complete!

Page 21

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 21 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.3.1 Spare Part List for SMS-02 (Standard)

Pos.

Article-No.

Qty

Description

VITON

EPDM

ISOLAST

1.1.0 * 1

Air cap

X X X

2.1.0 * 1

Nozzle

X X X

3.1.0

97410028

1

Retainer ring

X X X

4.1.0

97510030

1

Main body

X X X

5.0.0

979504.000

1

Material wear-and-tear set complete

X

5.0.0

979504.001

1

Material wear-and-tear set complete

X

5.0.0

979504.002

1

Material wear-and-tear set complete

X

6.0.0

97810014

1

Sealing screw complete (Pos. 6.1.0/6.2.0)

X

6.0.0

97810026

1

Sealing screw complete (Pos. 6.1.0/6.2.0)

X

6.0.0

97810028

1

Sealing screw complete (Pos. 6.1.0/6.2.0)

X

7.0.0

7.4.0

7.5.0

*

97640007

97640005

1

1

1

Nozzle needle complete

O-ring 14.00 x 1.78mm

O-ring 10.82 x 1.78

X

X

X

X

X

X

X

X

X

9.0.0

9.1.3

9.2.3

9.3.3

9.6.3

9.7.3

9.8.3

9.9.3

97900004

97610092

97220092

97930000

97820020

97640005

97710005

97640043

1

1

1

1

1

2

1

1

Raster-needle lock complete

Needle-stroke raster head

Raster locking screw

Pressure disk

Pressure spring

O-ring 10.82 x 1.78

Locking piston

O-ring 15 x 1

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

10.0.0

97800015

1

Return check valve complete

X X X

11.0.0 * 1

Air control valve complete

X X X

17.0.0 * 1

Magnetic valve 5/2-way

X X X

21.0.0 * 1

Threaded joint

X X X

21.1.0 * 1

Straight threaded joint G 1/8

X X X

21.2.0 * 1

Straight threaded joint G 1/8

X X X

* Please see the following pages for article numbers.

IMPORTANT

Always indicate the inscribed serial numbers when ordering spare parts!

Page 22

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 22 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.4 Spare Part Drawings SMS-02 (Raster-Needle Detection)

IMPORTANT

Air control valve and return check valve are available only as complete!

Page 23

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 23 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.4.1 Spare Part List for SMS-02 (Raster-Needle Detection)

Pos.

Article-No.

Qty

Description

VITON

EPDM

ISOLAST

1.1.0 * 1

Air cap

X X X

2.1.0 * 1

Nozzle

X X X

3.1.0

97410028

1

Retainer ring

X X X

4.1.0

97510590

1

Main body

X X X

5.0.0

979504.000

1

Material wear-and-tear set complete

X

5.0.0

979504.001

1

Material wear-and-tear set complete

X

5.0.0

979504.002

1

Material wear-and-tear set complete

X

6.0.0

97810014

1

Sealing screw complete (Pos. 6.1.0/6.2.0)

X

6.0.0

97810026

1

Sealing screw complete (Pos. 6.1.0/6.2.0)

X

6.0.0

97810028

1

Sealing screw complete (Pos. 6.1.0/6.2.0)

X

7.0.0

7.4.0

*

97640007

1

1

Nozzle needle complete

O-ring 14.00 x 1.78mm

X X X X X

X

8.0.0

97820090

1

Pressure spring

X X X

9.0.0

97900033

1

Raster-needle lock complete

X X X

10.0.0

97800015

1

Return check valve complete

X X X

11.0.0 * 1

Air control valve complete

X X X

17.0.0 * 1

Magnetic valve 5/2-way

X X X

21.0.0 * 1

Threaded joint

X X X

21.1.0 * 1

Straight threaded joint G 1/8

X X X

21.2.0 * 1

Straight threaded joint G 1/8

X X X

* Please see the following pages for article numbers.

IMPORTANT

Always indicate the inscribed serial numbers when ordering spare parts!

Page 24

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 24 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.5 Article Numbers for Air Caps

1.1.0

Air cap, Flat jet, Standard, 45° (Ø20x14.5mm)

Article-No.

Description

97310038

Air cap, Flat jet, 0.2-1.0mm

97310039

Air cap, Flat jet, 1.2-1.5mm

97310231

Air cap, Flat jet, 1.8-2.0mm

1.1.0

Air cap, Flat jet, Standard, 60° (Ø20x14.5mm)

Article-No.

Description

97310032

Air cap, Flat jet, 0.2-1.0mm

97310033

Air cap, Flat jet, 1.2-1.5mm

97310079

Air cap, Flat jet, 1.8-2.0mm

97310090

Air cap, Flat jet, 2.5mm

1.1.0

Air cap, Flat jet, Standard, 90° (Ø20x14.5mm)

Article-No.

Description

97310036

Air cap, Flat jet, 0.2-1.0mm

97310037

Air cap, Flat jet, 1.2-1.5mm

97310166

Air cap, Flat jet, 1.8-2.0mm

97310167

Air cap, Flat jet, 2.5mm

1.1.0

Air cap, Flat jet, KLS, 45° (Ø20x14.5mm)

Article-No.

Description

97310292

Air cap, Flat jet, KLS 0.2-1.0mm

97310546

Air cap, Flat jet, KLS 1.2-1.5mm

97310547

Air cap, Flat jet, KLS 1.8-2.0mm

1.1.0

Air cap, Flat jet, KLS, 60° (Ø20x14.5mm)

Article-No.

Description

97310081

Air cap, Flat jet, KLS 0.2-1.0mm

97310082

Air cap, Flat jet, KLS 1.2-1.5mm

97310083

Air cap, Flat jet, KLS 1.8-2.0mm

97310608

Air cap, Flat jet, KLS 2.5mm

1.1.0

Air cap, Flat jet, KLS, 90° (Ø20x14.5mm)

Article-No.

Description

97310108

Air cap, Flat jet, KLS 0.2-1.0mm

97310211

Air cap, Flat jet, KLS 1.2-1.5mm

97310545

Air cap, Flat jet, KLS 1.8-2.0mm

Page 25

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 25 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

1.1.0

Air cap, Round jet, Standard, 15° (Ø20x11mm)

Article-No.

Description

97310034

Air cap, Round jet, 0.2-1.0mm

97310035

Air cap, Round jet, 1.2-1.5mm

97310080

Air cap, Round jet, 1.8-2.0mm

97310091

Air cap, Round jet, 2.5mm

1.1.0

Air cap, Round jet, KLS, 15° (Ø20x11mm)

Article-No.

Description

97310084

Air cap, Round jet, KLS 0.2-1.0mm

97310085

Air cap, Round jet, KLS 1.2-1.5mm

97310086

Air cap, Round jet, KLS 1.8-2.0mm

97310250

Air cap, Round jet, KLS 2.5mm

1.1.0

Marking Air cap, Round jet 8° (Ø20x18mm)

Article-No.

Description

97310578

Marking air cap, 0.2-0.5mm

97310727

Marking air cap, 0.8-1.0mm

1.1.0

Special spin air cap, round jet

Article No.

Description

97310197

Special spin 0.2-2.0mm

10.6 Article Numbers for Nozzles

2.1.0

Nozzle, Standard, stainless steel (Ø12x18mm)

Article-No.

Description

97210110

Nozzle, Standard, 0.2mm

97210111

Nozzle, Standard, 0.3mm

97210112

Nozzle, Standard, 0.5mm

97210113

Nozzle, Standard, 0.8mm

97210114

Nozzle, Standard, 1.0mm

97210115

Nozzle, Standard, 1.2mm

97210116

Nozzle, Standard, 1.5mm

97210117

Nozzle, Standard, 2.0mm

97210118

Nozzle, Standard, 2.5mm

Page 26

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 26 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

2.1.0

Nozzle, KLS, stainless steel (Ø12x17.2mm)

Article-No.

Description

97210119

Nozzle, KLS, 0.2mm

97210120

Nozzle, KLS, 0.3mm

97210121

Nozzle, KLS, 0.5mm

97210122

Nozzle, KLS, 0.8mm

97210123

Nozzle, KLS, 1.0mm

97210124

Nozzle, KLS, 1.2mm

97210125

Nozzle, KLS, 1.5mm

97210126

Nozzle, KLS, 2.0mm

97210564

Nozzle, KLS, 2.5mm

3.0

Nozzle, KLS, spin, stainl.-steel 30° (Ø12x17,3mm)

Article-No.

Description

97210805

Nozzle, KLS, 0.3mm

97210806

Nozzle, KLS, 0.5mm

97210807

Nozzle, KLS, 0.8mm

97210808

Nozzle, KLS, 1.0mm

97211391

Nozzle, KLS, 1.2mm

97210809

Nozzle, KLS, 1.5mm

97210810

Nozzle, KLS, 2.0mm

97211467

Nozzle, KLS, 2.5mm

2.1.0

Marking nozzle, stainless steel 8°(Ø8x18mm)

Article-No.

Description

97212056

Marking nozzle 0.2mm

97211875

Marking nozzle 0.3mm

97211461

Marking nozzle 0.5mm

97212146

Marking nozzle 0.8mm

2.1.0

Nozzle, special spin, stainless steel (Ø12x18mm)

Article No.

Description

97210483

Nozzle, special spin, 0.2mm

97210484

Nozzle, special spin, 0.3mm

97210482

Nozzle, special spin, 0.5mm

97210485

Nozzle, special spin, 0.8mm

97211030

Nozzle, special spin, 1.0mm

97212510

Nozzle, special spin, 1.5mm

97212397

Nozzle, special spin, 2.0mm

Page 27

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 27 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.7 Article Numbers for Nozzle Needles

7.0.0

Nozzle needle complete, Standard, Marking, Special

spin (Ø3x72.5mm)

Article-No.

Description

97112508

Nozzle needle, Standard, 0.2/0.3mm

97110471

Nozzle needle, Standard, 0.5mm

97111251

Nozzle needle, Standard, 0.8mm

97111079

Nozzle needle, Standard, 1.0mm

97112506

Nozzle needle, Standard, 1.2mm

97112388

Nozzle needle, Standard, 1.5mm

97111069

Nozzle needle, Standard, 1.8/2.0mm

97111171

Nozzle needle, Standard, 2.5mm

7.0.0

Nozzle needle complete, KLS, (Ø3x72.5mm)

Article-No.

Description

97110187

Nozzle needle, KLS, 0.2/0.3mm

97110188

Nozzle needle, KLS, 0.5mm

97110189

Nozzle needle, KLS, 0.8/1.0mm

97110190

Nozzle needle, KLS, 1.2mm

97110191

Nozzle needle, KLS, 1.5mm

97110192

Nozzle needle, KLS, 2.0mm

97111301

Nozzle needle, KLS, 2.5mm

7.0.0

Nozzle needle complete, Raster-needle query,

Standard, Marking, Special spin (Ø3x77.5mm)

Article-No.

Description

97111795

Nozzle needle, Standard, 0.2/0.3mm

97111330

Nozzle needle, Standard, 0.5mm

97112037

Nozzle needle, Standard, 0.8mm

97111338

Nozzle needle, Standard, 1.0mm

97113030

Nozzle needle, Standard, 1.2mm

97111999

Nozzle needle, Standard, 1.5mm

97111854

Nozzle needle, Standard, 2.0mm

97112930

Nozzle needle, Standard, 2.5mm

7.0.0

Nozzle needle complete, Raster-needle query, KLS,

(Ø3x77.5mm)

Article-No.

Description

97111431

Nozzle needle, KLS, 0.2/0.3mm

97111430

Nozzle needle, KLS, 0.5mm

97111243

Nozzle needle, KLS, 0.8/1.0mm

97111432

Nozzle needle, KLS, 1.2mm

97111433

Nozzle needle, KLS, 1.5mm

97111434

Nozzle needle, KLS, 2.0mm

97112931

Nozzle needle, KLS, 2.5mm

Page 28

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 28 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.8 Article Numbers for Valves

11.0.0

Air Control Valve

Article-No.

Description

97800016

Air control valve for atomizer air pressure > 1,8 bar

97800132

Air control valve for atomizer air pressure < 1,8 bar

17.0.0

5/2-way Magnetic Valve

Article-No.

Description

97150015

Magnetic valve 24V / DC / 1.8W with plug

97150023

Magnetic valve 24V / DC / 1.8W with LED plug

97150017

Magnetic valve 110V / 50Hz / 1.8W with plug

97150016

Magnetic valve 220V / 50Hz / 1.5W with plug

97640110

Seal Buna for 5/2-way solenoid valve

10.9 Article Numbers for Threaded Joints

21.0.0

Threaded joint for connection „Control air SL“

Article-No.

Description

QSM-M5-4-I

Threaded joint M5 (for hose 4mm)

QSM-M5-6-I

Threaded joint M5 (for hose 6mm)

97220089

Threaded joint complete (SW 8x19mm)

21.1.0

Threaded joint for connection „Atomizer air ZL“

Article-No.

Description

QSM-1/8-4-I

Threaded joint G1/8 (for hose 4mm)

QSM-1/8-6-I

Threaded joint G1/8 (for hose 6mm)

QSM-1/8-8-I

Threaded joint G1/8 (for hose 8mm)

97220022

Threaded joint (SW 13x28mm)

Page 29

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 29 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

21.2.0

Threaded joint for connection „Material M“

Article-No.

Description

975165100656

Threaded joint G1/8 (for hose 6mm)

11.118-6

Threaded joint G1/8 (for hose 6mm)

11.118-8

Threaded joint G1/8 (for hose 8mm)

97220022

Threaded joint (SW 13x28mm)

RV08GE1/8LR/KÖ/ED

Threaded joint G1/8 (for hose NW6)

RV10GE1/8LR/KÖ/ED

Threaded joint G1/8 (for hose NW8)

RV12GE1/8LR/KÖ/ED

Threaded joint G1/8 (for hose NW10)

10.10 Article Numbers for Other Parts

Article-No.

Description

97150131

Plug with LED

97820168

Stronger pressure spring Raster-needle query

Page 30

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 30 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.11 Wear-and-Tear Parts

Material wear-and-tear set complete for SMS-02 (Standard and Needle query)1

Consisting of:

# Pos. 5.1.0 (Variseal)

# Pos. 5.3.0 (O-ring)

# Pos. 5.4.0 (protection sleeve)

# Pos. 6.2.0 (O-ring)

Article-No.

Description

979504.000

Material wear-and-tear set for SMS-02 (Standard), VITON

979504.001

Material wear-and-tear set for SMS-02 (Standard), EPDM

979504.002

Material wear-and-tear set for SMS-02 (Standard), ISOLAST

1

This material wear-and-tear set is recommended when nozzle needle and nozzle are replaced.

Wear-and-tear set complete for SMS-02 (Standard) 2

Consisting of:

# Pos. 5.0.0 (Material sealing set complete)

# Pos. 6.2.0 (O-ring)

# Pos. 7.4.0 (O-ring)

# Pos. 7.5.0 (O-ring)

# Pos. 9.6.3 (pressure spring)

# Pos. 9.7.3 (O-ring)

# Pos. 9.9.3 (O-ring)

# Pos. 10.0.0 (return check valve complete)

# Pos. 11.0.0 (air control valve complete)

Article-No.

Description

979504.003

Wear-and-tear kit for SMS-02 (Standard), VITON

979504.004

Wear-and-tear kit for SMS-02 (Standard), EPDM

979504.005

Wear-and-tear kit for SMS-02 (Standard), ISOLAST

Wear-and-tear set complete for SMS-02 (Raster-needle query) 2

Consisting of:

# Pos. 5.0.0 (Material sealing set complete)

# Pos. 6.2.0 (O-ring)

# Pos. 7.4.0 (O-ring)

# Pos. 8.0.0 (pressure spring)

# Pos. 10.0.0 (return check valve complete)

# Pos. 11.0.0 (air control valve complete)

Article-No.

Description

979504.006

Wear-and-tear kit for SMS-02 (Raster-needle query), VITON

979504.007

Wear-and-tear kit for SMS-02 (Raster-needle query), EPDM

979504.008

Wear-and-tear kit for SMS-02 (Raster-needle query), ISOLAST

2

This wear-and tear kit is recommended for a complete overhaul of the device.

Page 31

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 31 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.12 Accessories

Figure

Article Number

Description

97xxxxxx

Nozzle Extension

(see also Product Catalog ACCESSORIES)

97410042

Retainer ring hexagonal

97410059

Retainer ring stainless steel

979565.001

Hot Plate

(see also Product Catalog ACCESSORIES)

97PA21G-XX

Pressure Sensor

(see also Product Catalog „Checking/Prüfen“)

97947xxx

Counter

978000037

Pneumatic Needle-Stroke Adjustment

979444

Cleaning set

(see also Product catalog ACCESSORIES)

Page 32

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 32 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Needle Detection

The mounting of the needle setection will be made factory-side. It will be integrated in the raster needle lock

(Pos. 9.0 Spare Part List). If ordered as spare part, please note that a complete raster needle lock will be

delivered as the initiator has to be set at the factory and also glued in.

Pos.

Description

1

Raster needle detection

Pressure Sensor

The installation of the pressure sensor will be made factory-side. Its actual position can be either at the side

right or on top. Please refer to the assembly instructions „Pressure Sensors 97PA-21x-xxx“ for additional

information.

Pos.

Description

2

Pressure sensor mounted on top of the spray valve

3

Pressure sensor mounted at the right side of the spray valve

Heating Plate

The heating plate (4) will be mounted factory-side. Its actual position will be at the side (left / right). Please

see the description „Heating and Accessories“ for additional information.

3

2 1 4

4

Page 33

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 33 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

10.13 Description Pneumatic Needle-Stroke Adjustment 97800037

Description of Function

The pneumatic Needle Stroke Adjustment (PNA) is used for a remote-controlled change between two needle-stroke settings.

The front regulating screw (1; see pic.) determines the minimum needle stroke of the spraying device for a

PNA with applied pressure. The back regulating screw (2; see pic.) determines the additional (maximum)

needle stroke for a PNA without applied pressure.

Setting

For a pre-setting, the front regulating screw (1; see pic.) will be turned back (left turn) until no more raster

steps are possible. After that the back regulating screw (2; see pic.) will be turned to the front until stop (right

turn). Strictly follow this procedure to ensure a correct setting of both needle positions.

The spray application has to be activated/released in order to adjust both needle positions. The discharged

medium will be set to the desired minimum quantity (low needle stroke) through the front regulating screw (1;

see pic.). Then the desired maximum quantity (large stroke) will be set by turning back (left turn) of the back

regulating screw.

Important!

The PNA has to permit an opening of the needle in both positions (large and small stroke). In no case will it

be used to close the needle.

This is exclusively performed by the controls of the spray valve!

When a pressure of 6 bar will be applied to the PNA at the hose nipple (3; see pic.), the small needle stroke

has been set; the large stroke is set without pressure.

Operation

You can switch between the stroke settings during operation via the hose nipple (3):

- Air pressure = 6 bar

- With applied air = low stroke

- With air turned off = large stroke

Page 34

Rev. 1.2

Assembly Instructions - Spray Valve SMS-02

Page 34 of 34

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Pos.

Article No.

Qty

Description

1.0

97610172

1

Raster head

1.1

97610170

1

Regulating hollow spindle

1.2

97820000

1

Pressure spring

1.3

97320022

1

Cylinder pin DIN 6325

1.4

97320196

1

Regulating button

3.0

97710021

1

Piston complete

3.1

97320145

1

Piston rod

3.2

97710020

1

Piston

3.3

97640007

1

O-Ring Viton®

4.0

97320198

1

Air cylinder, complete

4.1

97610031

3

Threaded pin DIN 914

4.2

97320193

1

Air cylinder with knurl

4.3

97320144

1

Raster hollow screw

4.4

97640027

1

O-Ring Viton®

5.0

97610173

1

Raster head

5.1

97610171

1

Regulating hollow spindle

5.2

97820000

1

Pressure spring

5.3

97320022

1

Cylinder pin DIN 6325

5.4

97320197

1

Regulating button

Loading...

Loading...